Sandblaster Parts Diagram: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for sandblaster parts diagram

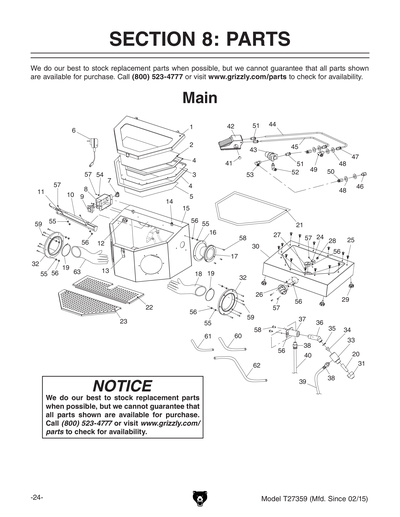

Navigating the complex landscape of sourcing sandblaster parts diagrams can present significant challenges for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the intricate components of sandblasting equipment is crucial not only for ensuring operational efficiency but also for minimizing downtime and repair costs. This comprehensive guide delves into the various types of sandblaster parts, their applications across different industries, and offers insights on how to effectively vet suppliers to secure quality components.

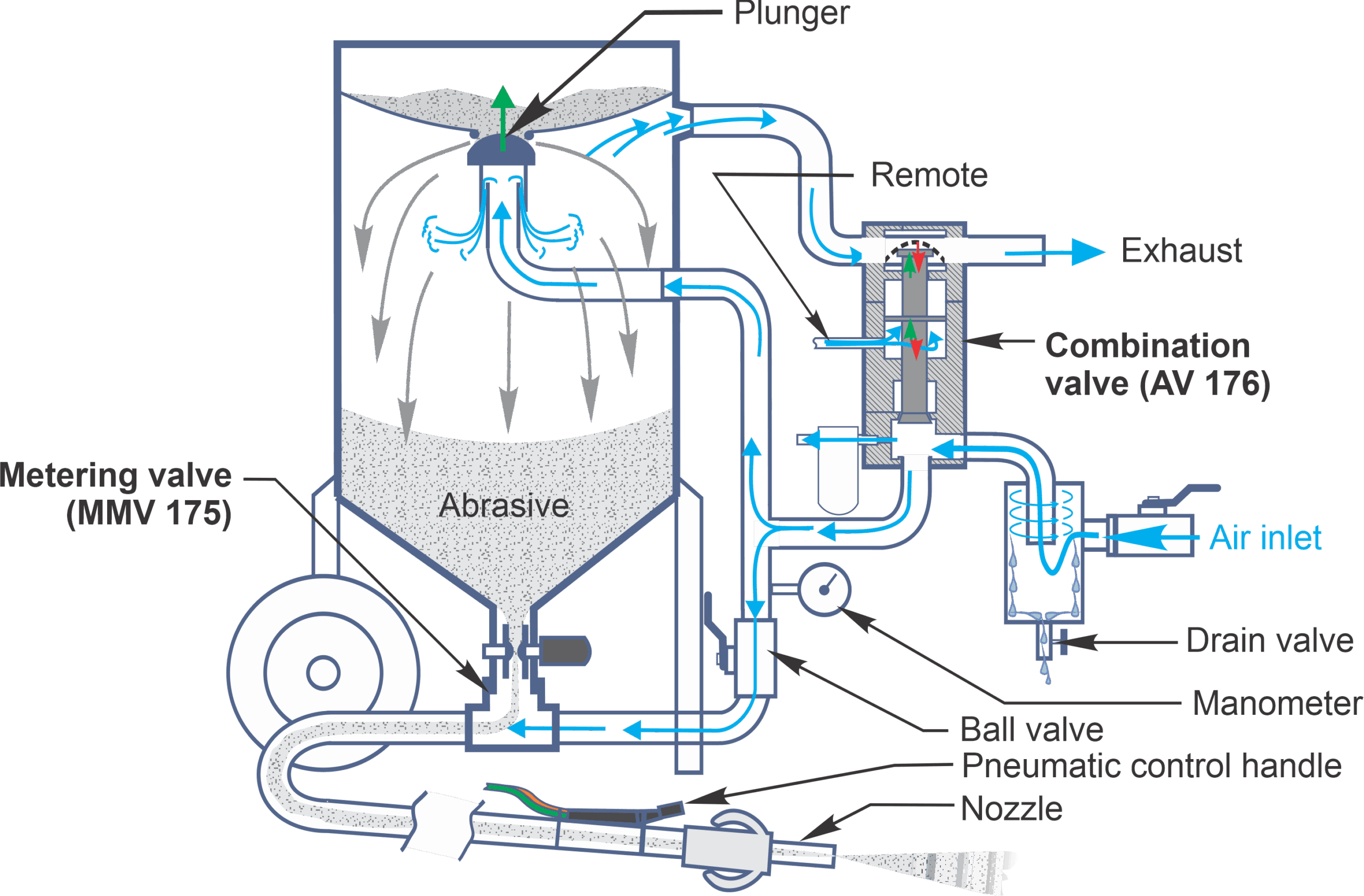

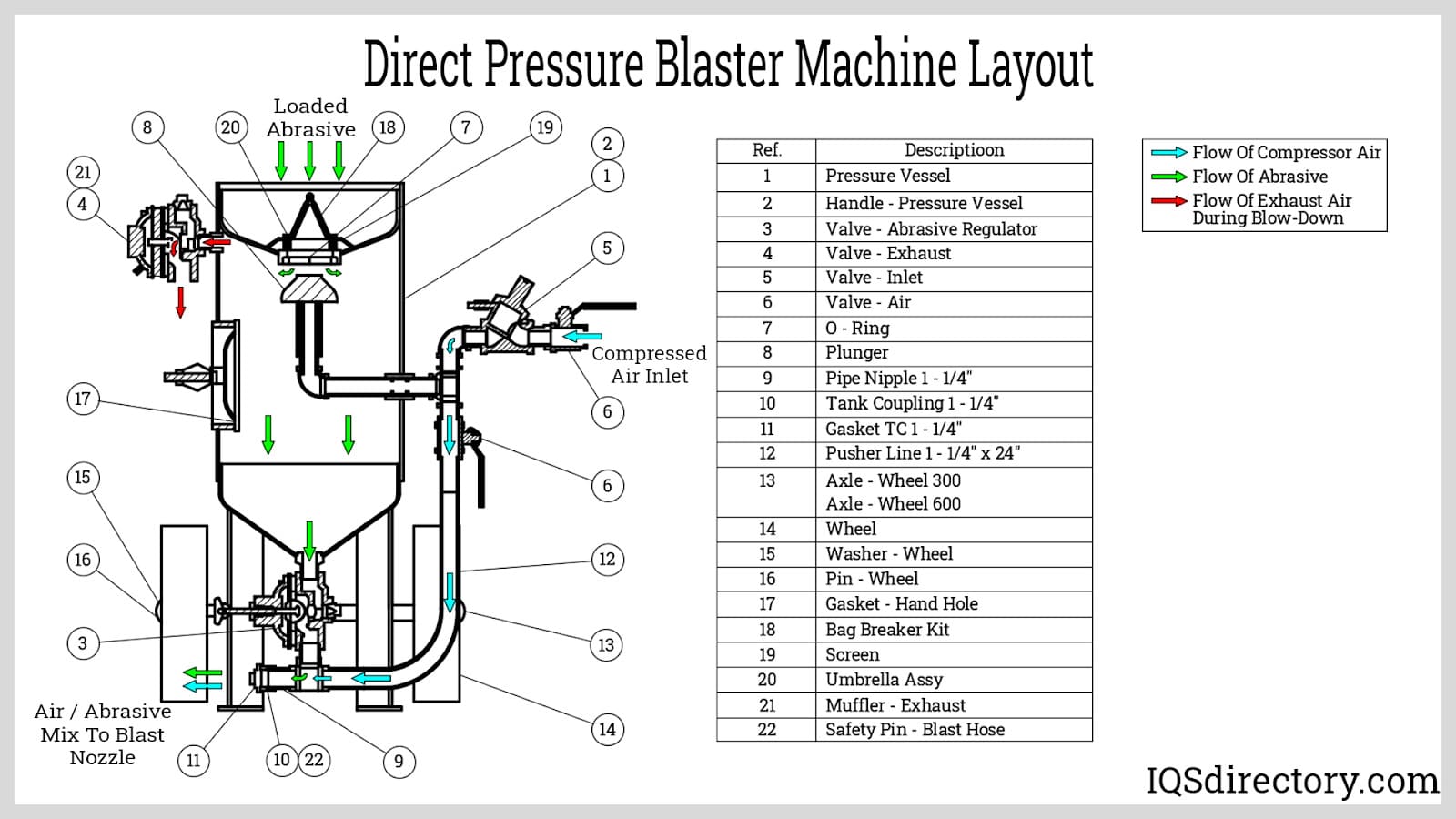

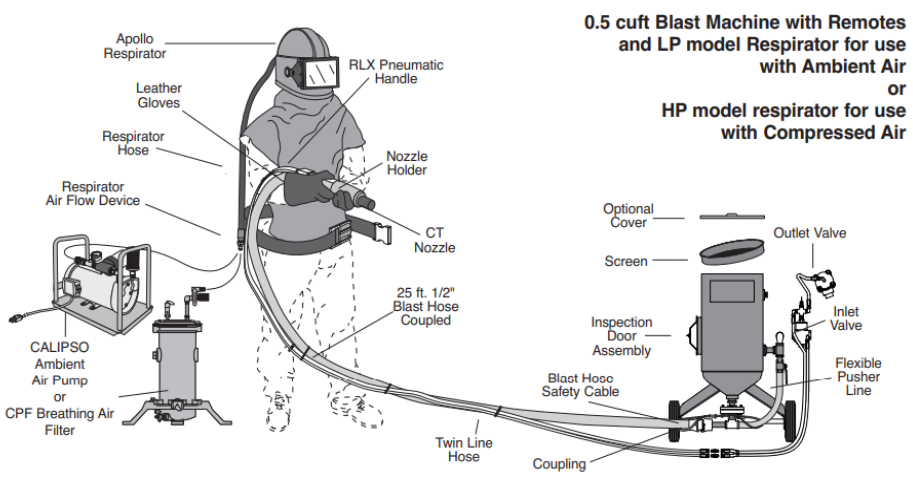

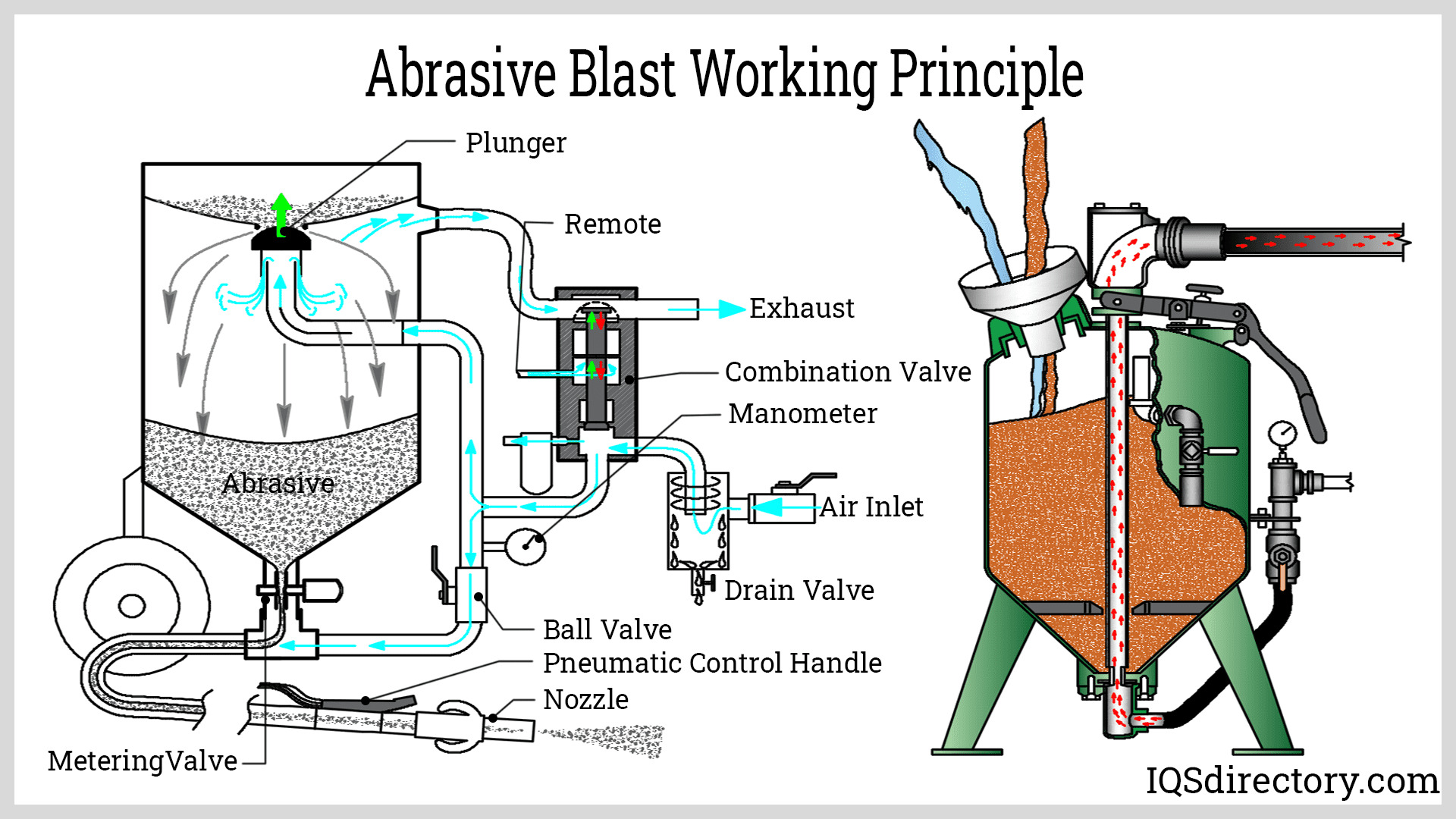

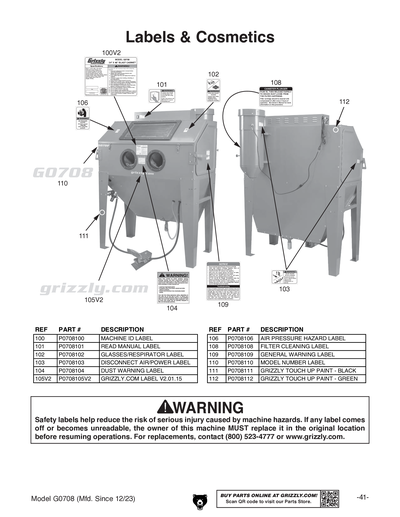

In this guide, you will discover detailed information about essential parts such as compressors, blasting pots, hoses, and nozzles, along with their respective diagrams for easier identification. We also address critical factors that influence purchasing decisions, including cost considerations, compatibility, and maintenance practices. By equipping B2B buyers with the knowledge they need to make informed choices, this guide aims to streamline the procurement process, ensuring that you not only find the right parts but also optimize your sandblasting operations.

Whether you are a seasoned industry professional or new to the sandblasting sector, this resource is designed to empower you with actionable insights, enabling you to navigate the global market effectively. With a focus on maximizing performance and minimizing costs, you will be better positioned to meet your operational goals and drive business success in your region.

Understanding sandblaster parts diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Sandblaster | Compact, mobile, often powered by air compressors | Automotive, DIY, small workshops | Pros: Versatile, easy to transport; Cons: Limited capacity for large projects. |

| Bulk Sandblaster | Larger capacity, designed for high-volume tasks | Industrial manufacturing, construction | Pros: High efficiency, suitable for large jobs; Cons: Requires more space and investment. |

| Dustless Blasting System | Uses water to minimize dust, environmentally friendly | Restoration, delicate surfaces | Pros: Cleaner operation, less health risk; Cons: Higher initial setup cost. |

| Automated Sandblasting System | Robotic or semi-automated, programmable | Mass production, automotive assembly | Pros: Consistent results, reduced labor; Cons: High initial investment, maintenance complexity. |

| Specialty Blasters | Tailored for specific materials or applications | Aerospace, medical devices | Pros: Precision and effectiveness; Cons: Limited versatility, often costly. |

What are the Characteristics of Portable Sandblasters?

Portable sandblasters are designed for mobility and ease of use, making them ideal for smaller projects or jobs that require flexibility. They typically operate on air compressors and have a compact design, allowing them to be transported easily between job sites. Common applications include automotive restoration, DIY projects, and small workshops. While they offer versatility and convenience, buyers should consider their limited capacity for larger projects, which may necessitate multiple refills or setups.

Illustrative image related to sandblaster parts diagram

Why Choose Bulk Sandblasters for Industrial Applications?

Bulk sandblasters are engineered for high-volume tasks, featuring larger capacities that enable them to handle extensive jobs efficiently. These systems are commonly used in industrial manufacturing and construction settings where speed and productivity are paramount. Their ability to deliver consistent abrasive flow makes them suitable for heavy-duty applications. However, buyers should be aware of the need for significant investment and adequate space to accommodate these larger units.

How Do Dustless Blasting Systems Benefit Users?

Dustless blasting systems incorporate water into the blasting process to minimize airborne dust, making them an environmentally friendly option. This type of equipment is particularly beneficial for restoration work and on surfaces that require careful treatment, such as delicate materials or historical structures. While they provide a cleaner working environment and reduce health risks associated with dust inhalation, the initial setup cost can be higher compared to traditional sandblasting systems.

What Advantages Do Automated Sandblasting Systems Offer?

Automated sandblasting systems leverage robotics or programmable technology to enhance productivity and precision in blasting operations. They are especially valuable in mass production scenarios, such as automotive assembly lines, where consistent results are crucial. While these systems can significantly reduce labor costs and improve efficiency, potential buyers should consider the high upfront investment and the complexity of maintenance that may accompany such advanced technology.

What Makes Specialty Blasters Unique?

Specialty blasters are designed for specific materials or applications, such as aerospace components or medical devices, where precision and effectiveness are critical. These systems often come with tailored features that cater to unique blasting requirements. While they can deliver exceptional results for niche markets, buyers must consider their limited versatility and the potential higher costs associated with purchasing specialized equipment.

Key Industrial Applications of sandblaster parts diagram

| Industry/Sector | Specific Application of sandblaster parts diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Surface preparation for painting and coating parts | Ensures high-quality finishes and reduces rework costs | Need for durable parts that withstand high usage rates |

| Construction | Restoration of concrete surfaces and structures | Enhances aesthetic appeal and prolongs lifespan of structures | Availability of parts for various blasting techniques |

| Oil & Gas | Cleaning of equipment and pipelines | Increases operational efficiency and safety | Compliance with industry standards and regulations |

| Shipbuilding | Hull cleaning and surface preparation | Reduces maintenance costs and improves performance | Need for specialized nozzles and protective gear |

| Metal Fabrication | Removal of rust and contaminants from metal surfaces | Ensures product quality and reduces production time | Sourcing of high-quality abrasives and nozzles |

How is the Sandblaster Parts Diagram Used in Automotive Manufacturing?

In automotive manufacturing, the sandblaster parts diagram is crucial for understanding the components involved in surface preparation before painting and coating. This process ensures that surfaces are clean and free from contaminants, which is vital for achieving a high-quality finish. For B2B buyers, sourcing durable parts that can withstand the high usage rates in production environments is essential to minimize downtime and reduce rework costs, ultimately enhancing overall productivity.

What Role Does Sandblaster Parts Diagram Play in Construction?

In the construction sector, the sandblaster parts diagram aids in the restoration of concrete surfaces, ensuring they are properly prepared for treatments and finishes. This application not only enhances the aesthetic appeal of structures but also prolongs their lifespan by effectively removing old coatings and contaminants. International buyers need to consider the availability of parts suitable for various blasting techniques to accommodate different project requirements and ensure compliance with local regulations.

How is the Sandblaster Parts Diagram Applied in Oil & Gas Industries?

The oil and gas industry utilizes sandblaster parts diagrams for the cleaning of equipment and pipelines, which is essential for maintaining operational efficiency and safety. Regular maintenance through effective blasting reduces the risk of corrosion and buildup, which can lead to costly downtime. Buyers in this sector should prioritize sourcing components that comply with stringent industry standards and regulations, ensuring that their equipment operates safely and efficiently in demanding environments.

Why is the Sandblaster Parts Diagram Important for Shipbuilding?

In shipbuilding, the sandblaster parts diagram is used for hull cleaning and surface preparation, which are critical for maintaining vessel performance and reducing maintenance costs. Proper surface treatment prevents corrosion and ensures that coatings adhere effectively. Buyers in this industry must consider the need for specialized nozzles and protective gear to ensure worker safety and equipment longevity, particularly in marine environments where conditions can be harsh.

How Does the Sandblaster Parts Diagram Benefit Metal Fabrication?

In metal fabrication, the sandblaster parts diagram is instrumental in the removal of rust and contaminants from metal surfaces. This process is vital for ensuring product quality and reducing production time, as clean surfaces allow for better adhesion of paints and coatings. B2B buyers should focus on sourcing high-quality abrasives and nozzles that meet specific project needs, helping to streamline operations and enhance the overall efficiency of their production processes.

3 Common User Pain Points for ‘sandblaster parts diagram’ & Their Solutions

Scenario 1: Difficulty Identifying the Right Parts for Replacement

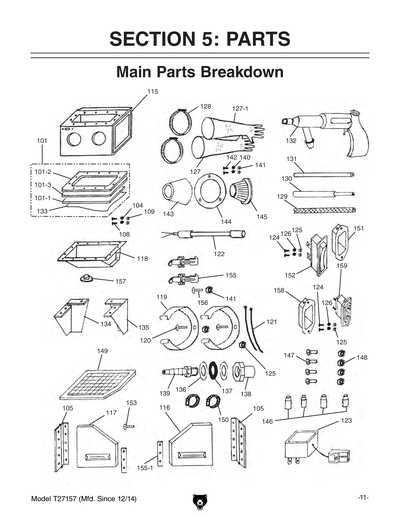

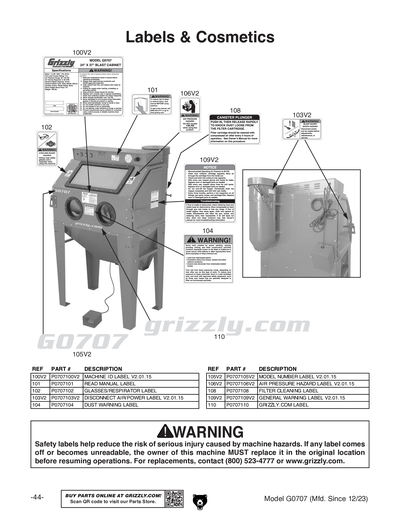

The Problem: One of the most significant challenges faced by B2B buyers of sandblasting equipment is accurately identifying and sourcing the correct replacement parts. This issue often arises when users are unfamiliar with the specific components of their sandblaster or when they lack access to clear, detailed diagrams. For instance, a company may have an older model of a sandblaster, and the existing parts may have different specifications than newer models. This can lead to incorrect orders, extended downtime, and increased costs due to the need for expedited shipping of the right parts.

The Solution: To overcome this challenge, B2B buyers should utilize detailed parts diagrams specific to their sandblaster model. These diagrams typically break down the components into labeled parts, making it easier to identify what needs to be replaced. Buyers should first consult the manufacturer’s website or contact their support team for access to these diagrams. Additionally, they should take the time to compare the components visually with their existing equipment. When ordering parts, providing the model number and any other relevant specifications ensures that the correct items are sourced. Establishing a relationship with a reliable supplier who understands the intricacies of sandblasting equipment can also streamline the process, as they can offer personalized advice based on the buyer’s specific needs.

Scenario 2: Misunderstanding the Functionality of Components

The Problem: Another common pain point is the misunderstanding of how various components within a sandblaster work together. Many buyers may know that certain parts are essential but lack a comprehensive understanding of their roles, which can lead to operational inefficiencies. For instance, if a buyer replaces a compressor without understanding its relationship with the blasting pot and nozzle, they may not achieve the desired blasting pressure, resulting in suboptimal performance and increased wear on the equipment.

The Solution: To mitigate this issue, B2B buyers should invest time in learning about the functionality of each part as depicted in the sandblaster parts diagram. A thorough understanding of how each component interacts with others is crucial for effective operation and maintenance. Manufacturers often provide resources, including manuals and instructional videos, that explain the components’ functions and their relationships. Buyers can also benefit from participating in training sessions or webinars offered by equipment suppliers. These resources help users not only understand their equipment better but also make informed decisions regarding maintenance, upgrades, and replacements.

Scenario 3: Inadequate Maintenance Leading to Frequent Breakdowns

The Problem: Frequent breakdowns due to inadequate maintenance is a significant pain point for companies relying on sandblasting equipment. Without a proper understanding of the parts and their maintenance needs, buyers may overlook essential upkeep tasks, such as cleaning filters or checking seals. This neglect can lead to costly repairs and project delays, which can significantly impact productivity and revenue.

The Solution: To address maintenance challenges, B2B buyers should refer to the maintenance sections of their sandblaster parts diagrams. These often include recommended maintenance schedules for each component, indicating when specific tasks should be performed. Establishing a routine maintenance plan based on these guidelines ensures that all parts function optimally and can extend the lifespan of the equipment. Additionally, buyers should maintain a checklist of maintenance tasks to be performed regularly, and consider setting reminders for critical checks. Investing in training for staff on the importance of maintenance and how to execute it effectively can further enhance equipment reliability and reduce the incidence of breakdowns.

Strategic Material Selection Guide for sandblaster parts diagram

What Are the Key Materials Used in Sandblaster Parts?

When selecting materials for sandblaster parts, it is essential to consider their properties, advantages, disadvantages, and how they align with international standards. Below, we analyze four common materials used in sandblaster parts, focusing on their relevance to B2B buyers.

1. Steel

Key Properties: Steel is renowned for its high tensile strength and durability, making it suitable for components exposed to high pressure and abrasive materials. It typically has a temperature rating of up to 500°F (260°C) and excellent corrosion resistance when treated with coatings.

Pros & Cons: The primary advantage of steel is its robustness, which ensures a long lifespan under heavy use. However, it can be prone to rust if not properly coated, which may lead to increased maintenance costs. Manufacturing complexity can vary based on the specific steel grade and treatment processes.

Illustrative image related to sandblaster parts diagram

Impact on Application: Steel parts are compatible with various abrasive media, including garnet and aluminum oxide, making them versatile for different blasting applications.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards for steel grades and coatings. In regions like Europe, adherence to DIN standards is crucial, while buyers in South America and Africa may prioritize cost-effectiveness.

2. Aluminum

Key Properties: Aluminum is lightweight and resistant to corrosion, with a melting point of around 1,220°F (660°C). It also possesses good thermal conductivity, which can be beneficial in dissipating heat during operations.

Illustrative image related to sandblaster parts diagram

Pros & Cons: The lightweight nature of aluminum allows for easier handling and transportation of sandblaster parts. However, it is generally less durable than steel and may not withstand extreme pressures as effectively, making it less suitable for heavy-duty applications.

Impact on Application: Aluminum is ideal for components that require a balance of weight and corrosion resistance, such as nozzles and housings. However, it may not be compatible with all abrasive materials, particularly those that are highly abrasive.

Considerations for International Buyers: Compliance with JIS standards for aluminum alloys is important, especially in Japan and parts of Europe. Buyers should also consider local availability and pricing fluctuations.

3. Rubber

Key Properties: Rubber is flexible and has excellent impact resistance, making it suitable for seals and gaskets in sandblasting equipment. It can withstand temperatures up to 250°F (121°C) and is resistant to various chemicals.

Pros & Cons: The flexibility of rubber allows for effective sealing, preventing leaks and maintaining pressure. However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures, leading to increased replacement costs.

Illustrative image related to sandblaster parts diagram

Impact on Application: Rubber parts are essential for maintaining the integrity of the blasting system, particularly in areas where pressure and abrasive materials are present. They are compatible with most blasting media but may require frequent replacement.

Considerations for International Buyers: Buyers should ensure that rubber components meet local safety and environmental regulations. Compliance with ASTM and ISO standards is often necessary for international shipments.

4. Composite Materials

Key Properties: Composite materials, often a combination of plastics and fibers, offer excellent strength-to-weight ratios and corrosion resistance. They can withstand temperatures up to 300°F (149°C) and are often designed to be non-conductive.

Pros & Cons: Composites are lightweight and resistant to corrosion, making them ideal for various applications. However, they can be more expensive to manufacture and may not be as widely available as traditional materials.

Impact on Application: Composite materials are particularly useful in applications requiring non-conductivity and lightweight properties, such as certain nozzle designs. They can handle a variety of abrasive media but may not be suitable for high-pressure applications.

Considerations for International Buyers: Buyers should verify that composite materials meet relevant international standards, such as ASTM and ISO, especially when sourcing from different regions.

Summary Table of Material Selection for Sandblaster Parts

| Material | Typical Use Case for sandblaster parts diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Blasting pots, valves, and hoses | High durability and strength | Prone to rust without proper treatment | Medium |

| Aluminum | Nozzles and lightweight components | Lightweight and corrosion-resistant | Less durable under extreme pressure | Medium |

| Rubber | Seals and gaskets | Effective sealing and impact resistance | Degrades over time with exposure | Low |

| Composite Materials | Specialized nozzles and housings | Excellent strength-to-weight ratio | Higher manufacturing cost | High |

This strategic material selection guide serves as a foundational resource for B2B buyers, helping them make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for sandblaster parts diagram

What Are the Key Stages in the Manufacturing Process of Sandblaster Parts?

The manufacturing process of sandblaster parts involves several critical stages, each designed to ensure the durability, efficiency, and safety of the final product. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Sandblaster Parts?

The initial stage of manufacturing begins with material selection and preparation. Common materials for sandblaster components include high-grade steel, aluminum, and specialized alloys, chosen for their strength and resistance to wear. The materials undergo rigorous quality checks to verify they meet specific standards for hardness and corrosion resistance.

Illustrative image related to sandblaster parts diagram

Once selected, the materials are cut and shaped according to precise specifications. Advanced techniques such as laser cutting or water jet cutting are often employed to achieve high accuracy, ensuring that each component will fit seamlessly into the overall assembly.

What Forming Techniques Are Used in Sandblaster Parts Manufacturing?

After preparation, the next step is forming the components. This process can involve various techniques, including:

- Casting: Liquid metal is poured into molds to create complex shapes, often used for parts like blasting pots and valves.

- Machining: Processes like turning, milling, and drilling are utilized to achieve the necessary dimensions and tolerances. CNC (Computer Numerical Control) machines are prevalent in this stage for precision.

- Stamping: Sheet metal is shaped through a stamping process to produce flat components, such as brackets or covers.

These techniques are critical in ensuring that each part meets the design specifications and functional requirements of sandblasting equipment.

How Are Sandblaster Parts Assembled?

Once the individual components are manufactured, they are assembled into the final product. This stage often involves the following:

- Sub-assembly: Smaller components are first assembled into sub-units, such as valves or hoses.

- Main assembly: The sub-units are then combined to form the complete sandblaster system. This process is typically performed in a clean environment to avoid contamination.

- Testing during assembly: Quality control checks are integrated into the assembly line, ensuring that each component is functioning correctly before moving to the next stage.

What Quality Assurance Measures Are Implemented in Sandblaster Parts Manufacturing?

Quality assurance is vital in the manufacturing of sandblaster parts to ensure safety, reliability, and compliance with international standards. Manufacturers often adhere to frameworks such as ISO 9001, which outlines requirements for a quality management system.

Which International Standards Should B2B Buyers Be Aware Of?

For international B2B buyers, understanding the relevant standards is crucial. Key certifications include:

- ISO 9001: Focuses on consistent quality management practices.

- CE Marking: Indicates compliance with EU safety and environmental requirements.

- API Standards: Relevant for parts used in oil and gas applications, ensuring they meet industry-specific safety and performance standards.

These certifications can serve as benchmarks for evaluating potential suppliers, ensuring that their products meet global quality standards.

What Are the QC Checkpoints in Sandblaster Parts Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process, categorized into three main types:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Checks are conducted at various stages of production to monitor the manufacturing process. This can include dimensional checks and functional tests to ensure components are being produced correctly.

- Final Quality Control (FQC): At this stage, the finished products undergo thorough testing, including functional tests and performance evaluations, to verify they meet all specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers looking to source sandblaster parts, verifying supplier quality control practices is essential for ensuring product reliability. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and quality management systems.

- Request Quality Reports: Ask for documentation that outlines testing results and compliance with international standards. This can include certificates of compliance and detailed quality reports.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures, ensuring that they adhere to industry standards.

What Are the Common Testing Methods Used for Sandblaster Parts?

Various testing methods are employed to ensure that sandblaster parts meet quality and safety standards:

- Pressure Testing: This method assesses the integrity of pressure vessels and pipes, ensuring they can withstand operational conditions without failure.

- Performance Testing: Components like nozzles and valves are evaluated under operational conditions to ensure they perform as expected.

- Fatigue Testing: Parts are subjected to cyclic loads to determine their durability and resistance to wear over time.

What Nuances Should International B2B Buyers Consider Regarding Quality Control and Certification?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regulatory Differences: Different countries may have varying regulations regarding safety and environmental standards. It is essential to understand these differences and ensure that suppliers comply.

- Language Barriers: Documentation and communication may be challenging due to language differences. Ensuring that all quality reports and certifications are available in a language understood by both parties can help mitigate misunderstandings.

- Local Standards: In addition to international certifications, some regions may have local standards that need to be met. Familiarizing oneself with these can aid in supplier selection.

By understanding the manufacturing processes and quality assurance measures specific to sandblaster parts, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sandblaster parts diagram’

When sourcing sandblaster parts, having a clear and organized approach can save time, reduce costs, and ensure that you acquire the right components for your operations. This guide provides a step-by-step checklist to help B2B buyers efficiently navigate the procurement process for sandblaster parts diagrams.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical specifications required for your sandblasting equipment. Consider factors such as the type of abrasive materials you will use, the size of the sandblasting pot, and the pressure ratings needed for your specific applications. Having these specifications documented will help you communicate effectively with suppliers and ensure compatibility with existing equipment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in sandblasting parts and accessories. Look for companies with a strong reputation in the industry and positive reviews from other B2B buyers. Pay attention to their product range, focusing on those that offer detailed parts diagrams and comprehensive catalogs.

- Tip: Utilize online forums and industry-specific platforms to gather insights about suppliers and their reliability.

Step 3: Evaluate Supplier Credentials

Before making a commitment, verify the credentials of your shortlisted suppliers. Check for certifications relevant to quality management (like ISO) and compliance with international safety standards. This step is crucial to ensure that the products you receive meet industry requirements and minimize risks associated with substandard parts.

- Sub-bullet: Request documentation of past projects or partnerships that demonstrate their capability and reliability.

Step 4: Request Detailed Parts Diagrams

Once you’ve identified potential suppliers, request detailed sandblaster parts diagrams for the specific models you need. These diagrams should clearly illustrate the components and their functions, allowing you to verify that the parts will meet your operational needs. A good parts diagram can simplify assembly, maintenance, and repairs.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers and compare their pricing structures. Consider not only the upfront costs but also payment terms, shipping fees, and warranties offered. Understanding the total cost of ownership will help you make an informed decision that aligns with your budget.

- Tip: Look for suppliers that provide volume discounts or flexible payment options, especially if you anticipate placing large orders.

Step 6: Assess After-Sales Support and Service

Evaluate the level of after-sales support provided by each supplier. Reliable suppliers should offer technical assistance, maintenance guidance, and easy access to replacement parts. Understanding their support structure will help ensure that you can efficiently resolve any issues that may arise post-purchase.

Step 7: Finalize Your Order and Confirm Delivery Details

Once you have selected a supplier, finalize your order by confirming all details, including part numbers, quantities, and delivery timelines. Ensure that you have a clear understanding of the shipping method and any tracking options available. This final step is crucial to prevent delays and ensure that you receive your parts on time for your projects.

Illustrative image related to sandblaster parts diagram

By following this checklist, B2B buyers can streamline the sourcing process for sandblaster parts diagrams, ensuring they acquire the right components efficiently and effectively.

Comprehensive Cost and Pricing Analysis for sandblaster parts diagram Sourcing

What Are the Key Cost Components in Sourcing Sandblaster Parts Diagrams?

When sourcing sandblaster parts diagrams, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing sandblaster parts significantly impact pricing. High-grade materials, such as stainless steel or specialized alloys, will naturally incur higher costs but can offer better durability and performance.

-

Labor: Labor costs can vary based on the region and the skill level required for assembly and maintenance. Skilled labor in manufacturing hubs may command higher wages, which can be reflected in the final pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Effective overhead management can lead to lower prices for buyers.

-

Tooling: Custom tooling for specific parts or configurations can drive up initial costs. Buyers should consider whether standard parts can meet their needs to avoid unnecessary expenses.

-

Quality Control (QC): Rigorous QC processes ensure that parts meet safety and performance standards, which can add to the overall cost. However, investing in quality control often results in lower long-term costs due to reduced failure rates.

-

Logistics: Shipping and handling costs vary widely based on the origin and destination of the parts. International buyers should be aware of potential tariffs and duties that can affect overall pricing.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can fluctuate based on market conditions and demand.

How Do Price Influencers Affect Sandblaster Parts Diagram Costs?

Several factors influence the pricing of sandblaster parts diagrams, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often result in lower unit costs. Negotiating higher order quantities can yield significant savings, especially for international buyers who plan long-term projects.

-

Specifications and Customization: Customized parts or specific specifications can lead to higher prices due to additional tooling and labor costs. Buyers should weigh the necessity of customization against potential savings from off-the-shelf solutions.

-

Material Quality and Certifications: Parts that meet international safety and quality certifications, such as ISO or CE marking, may come at a premium. However, these certifications can mitigate risks associated with equipment failure.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their proven track record, while lesser-known suppliers might offer lower prices at the risk of quality issues.

-

Incoterms: Understanding shipping terms and responsibilities outlined in Incoterms is critical for international transactions. These terms dictate who pays for shipping, insurance, and tariffs, influencing the total cost of ownership.

What Negotiation Strategies Can B2B Buyers Employ for Cost-Efficiency?

To maximize cost-efficiency in sourcing sandblaster parts diagrams, buyers should consider the following strategies:

Illustrative image related to sandblaster parts diagram

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers often have room for flexibility, especially on larger orders.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider maintenance, operational costs, and potential downtime when evaluating suppliers. A higher upfront cost may be justified by lower operational expenses.

-

Research Market Prices: Familiarize yourself with market rates for various parts to avoid overpaying. Utilize multiple suppliers to gauge competitive pricing.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers can reduce shipping costs and lead times, enhancing supply chain efficiency.

-

Leverage Relationships: Establishing long-term relationships with suppliers can lead to better pricing and priority service, as suppliers may be more willing to offer favorable terms to repeat customers.

Conclusion: How Can International B2B Buyers Navigate Pricing Nuances?

International buyers must navigate various pricing nuances when sourcing sandblaster parts diagrams. Factors such as currency fluctuations, import regulations, and regional market conditions can all affect final pricing. It is crucial to conduct thorough market research, establish clear communication with suppliers, and leverage negotiation strategies to achieve the best possible outcomes.

Disclaimer: Prices may vary widely based on market conditions, specific requirements, and supplier capabilities. Always request quotes and validate terms before finalizing purchases.

Alternatives Analysis: Comparing sandblaster parts diagram With Other Solutions

Introduction to Alternative Solutions in Sandblasting

When evaluating the effectiveness of sandblaster parts diagrams, it’s essential to consider alternative solutions that may offer similar functionalities or benefits. Understanding these alternatives can empower B2B buyers to make informed decisions tailored to their specific operational needs. This analysis compares the traditional sandblaster parts diagram with two viable alternatives: digital sandblasting simulations and automated sandblasting systems.

Comparison Table

| Comparison Aspect | Sandblaster Parts Diagram | Digital Sandblasting Simulation | Automated Sandblasting System |

|---|---|---|---|

| Performance | High accuracy in identifying parts | Good for training and planning | Consistent, high-efficiency output |

| Cost | Typically low, mainly for diagrams | Moderate, software licensing fees | High initial investment, but low operational costs |

| Ease of Implementation | Easy to understand and use | Requires training for effective use | Complex setup, requires skilled personnel |

| Maintenance | Minimal, mainly for physical diagrams | Software updates needed | Regular maintenance required for machines |

| Best Use Case | DIY repairs and maintenance | Training and planning scenarios | Large-scale, continuous operations |

Detailed Breakdown of Alternatives

Digital Sandblasting Simulation

Digital simulations offer an innovative approach to understanding and planning sandblasting projects. They provide visual representations of how different equipment and techniques will perform on specific materials. The primary advantage of this method is its ability to allow users to experiment with various parameters without the need for physical resources. However, the drawback lies in the requirement for software training, which may not be feasible for all users. While these simulations can be a valuable training tool, they may lack the tactile feedback necessary for real-world applications.

Automated Sandblasting System

Automated systems represent a significant leap in sandblasting technology, delivering consistent results with minimal human intervention. These systems are designed for high-volume operations and can significantly reduce labor costs over time. The primary benefits include speed and efficiency, making them ideal for large-scale projects. On the downside, the initial investment is substantial, and operational complexity requires skilled personnel for setup and maintenance. B2B buyers must weigh the upfront costs against long-term savings to determine if an automated system aligns with their operational goals.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate solution for your sandblasting needs hinges on various factors, including project scale, budget constraints, and operational capacity. Sandblaster parts diagrams are excellent for straightforward maintenance and DIY repairs, while digital simulations can enhance training and project planning. For businesses focused on high-volume operations, investing in an automated sandblasting system could yield significant efficiency gains. By carefully evaluating these alternatives against your specific requirements, you can make a strategic decision that optimizes both performance and cost-effectiveness in your sandblasting operations.

Essential Technical Properties and Trade Terminology for sandblaster parts diagram

Understanding the technical specifications and terminology associated with sandblaster parts is crucial for B2B buyers, particularly in the context of international procurement. Here’s a breakdown of essential properties and commonly used terms that will aid in making informed purchasing decisions.

What Are the Key Technical Properties of Sandblaster Parts?

-

Material Grade

Material grade refers to the quality and specifications of the materials used in sandblaster components, such as stainless steel or aluminum. High-grade materials ensure durability and resistance to corrosion, which is vital for maintaining performance in demanding environments. For B2B buyers, selecting parts with the appropriate material grade can lead to reduced maintenance costs and prolonged equipment life. -

Tolerance

Tolerance indicates the allowable variation in dimensions of a part. In sandblasting equipment, precise tolerances are critical for ensuring that components fit together correctly and function as intended. Poor tolerances can lead to inefficiencies and increased wear. For businesses, understanding tolerance specifications can help avoid costly errors and ensure compatibility with existing equipment. -

Pressure Rating

The pressure rating is the maximum pressure that a component, such as a nozzle or blasting pot, can withstand. This specification is crucial for safety and operational efficiency. Selecting parts with the appropriate pressure rating for specific applications ensures that the equipment operates safely and effectively, reducing the risk of accidents and equipment failure. -

Flow Rate

Flow rate measures the volume of air or abrasive material that can pass through a component within a specific time frame. This property affects the efficiency and speed of the sandblasting process. Buyers should consider the flow rate to ensure that their equipment can meet the demands of their projects without compromising performance. -

Compatibility

Compatibility refers to how well different parts and accessories can work together within the sandblasting system. This is particularly important when upgrading or replacing components. Understanding compatibility can prevent issues related to performance and safety, ensuring that all parts function cohesively within the system.

What Are Common Trade Terms in the Sandblasting Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the sandblasting industry, OEM parts are often preferred for their guaranteed compatibility and reliability. B2B buyers should look for OEM parts to ensure that they are receiving high-quality components specifically designed for their equipment. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can influence purchasing decisions and inventory management. Understanding MOQ can help businesses optimize their supply chain and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In the context of sandblaster parts, issuing an RFQ can facilitate competitive pricing and help businesses make cost-effective purchasing decisions. Properly structured RFQs can also streamline the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms is essential for B2B buyers engaged in international transactions, as it helps clarify shipping costs, insurance, and risk management associated with the procurement of sandblaster parts. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for B2B buyers to effectively plan their projects and manage inventory levels. Delays in lead time can disrupt operations and lead to increased costs, making it a vital consideration in procurement strategies.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and project outcomes in the sandblasting industry.

Navigating Market Dynamics and Sourcing Trends in the sandblaster parts diagram Sector

What Are the Key Market Dynamics and Trends Impacting Sandblaster Parts Diagrams?

The global sandblaster parts market is witnessing significant transformation driven by various factors including technological advancements, evolving customer needs, and the growing emphasis on efficiency and safety. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that offer comprehensive parts diagrams, enabling them to streamline maintenance and repairs. A notable trend is the shift towards online platforms where buyers can access detailed parts diagrams, enhancing their ability to identify and source specific components quickly. This digital transformation facilitates improved inventory management and reduces downtime, which is critical for operational efficiency.

Emerging technologies such as 3D printing and IoT (Internet of Things) are reshaping the landscape by allowing for on-demand production of parts and real-time monitoring of equipment performance. These innovations not only reduce lead times but also help buyers manage their supply chains more effectively. Furthermore, as companies seek to optimize costs, sourcing partnerships that offer bulk purchasing discounts or just-in-time delivery services are becoming increasingly popular.

How Does Sustainability and Ethical Sourcing Affect the Sandblaster Parts Industry?

Sustainability is becoming a pivotal aspect of the sandblaster parts market, with buyers increasingly concerned about the environmental impact of their procurement choices. The production of sandblaster components can involve significant energy consumption and waste generation, prompting the need for suppliers to adopt greener practices. Ethical sourcing has emerged as a critical consideration, with businesses seeking suppliers that adhere to sustainable manufacturing processes and labor practices.

Certifications such as ISO 14001 for environmental management and adherence to REACH regulations for chemical safety are becoming essential for suppliers aiming to attract international clients. Additionally, the use of eco-friendly materials in manufacturing parts, such as recyclable metals and non-toxic coatings, is gaining traction. Buyers who prioritize suppliers with green certifications not only contribute to environmental preservation but also enhance their brand reputation in a market that increasingly values corporate social responsibility.

What Is the Historical Context of the Sandblaster Parts Diagram Market?

The sandblasting industry has evolved significantly since its inception in the late 19th century. Originally, sandblasting was primarily used for cleaning and surface preparation in industrial applications. Over the decades, advancements in technology have led to the development of more sophisticated equipment and components, resulting in the need for detailed parts diagrams to facilitate maintenance and repairs. The introduction of portable sandblasters in the mid-20th century further diversified the market, catering to various sectors including automotive, construction, and restoration.

Today, the availability of parts diagrams not only reflects the complexity of modern sandblasting equipment but also serves as a critical resource for international B2B buyers. Understanding the historical context helps buyers appreciate the advancements in technology and the ongoing trends that shape the current market landscape. As the industry continues to innovate, the focus on efficiency, safety, and sustainability will likely remain at the forefront of sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of sandblaster parts diagram

-

1. How do I solve compatibility issues with sandblaster parts?

To resolve compatibility issues with sandblaster parts, start by consulting the specific parts diagram for your sandblasting equipment. This diagram will detail each component and its corresponding part number, ensuring you order the correct items. If you’re unsure, reach out to your supplier for assistance; they can provide insights based on your equipment model. Additionally, consider the type of blasting you intend to perform, as different applications may require specific parts for optimal performance. -

2. What is the best way to identify the right sandblaster parts for my machine?

The best way to identify the right sandblaster parts is by referencing the machine’s parts diagram. This diagram typically includes all components and their respective part numbers. If you cannot locate the diagram, contact the manufacturer or a trusted supplier for guidance. They can assist you in finding the correct parts based on your machine’s specifications and intended use. Always ensure that you match the part number to avoid compatibility issues. -

3. What are the minimum order quantities (MOQs) for sandblaster parts?

Minimum order quantities (MOQs) for sandblaster parts can vary significantly depending on the supplier and the type of parts you require. Some suppliers may have a low MOQ for standard parts, while specialized components might have higher MOQs due to their unique nature. It’s advisable to discuss your specific needs with suppliers to negotiate terms that suit your purchasing strategy, particularly if you’re sourcing for large-scale projects or ongoing maintenance. -

4. How can I vet suppliers when sourcing sandblaster parts internationally?

Vetting suppliers is crucial when sourcing sandblaster parts internationally. Start by researching the supplier’s reputation through customer reviews, industry certifications, and their history of compliance with international standards. Request references from previous clients and inquire about their experience with product quality and delivery timelines. Additionally, consider visiting the supplier’s facility if possible or utilizing third-party inspection services to ensure they meet your quality expectations. -

5. What payment terms should I expect when purchasing sandblaster parts?

Payment terms can vary widely among suppliers in the sandblaster parts industry. Common terms include upfront payment, net 30 or net 60 days, and payment upon delivery. It is essential to clarify these terms before finalizing your order to avoid misunderstandings. For larger orders, you may have room to negotiate favorable terms, especially if you have a strong purchasing history or plan to establish a long-term partnership with the supplier. -

6. What quality assurance measures should I look for in sandblaster parts?

When sourcing sandblaster parts, look for suppliers that implement strict quality assurance measures. This includes adherence to international quality standards, such as ISO certifications, and thorough inspection processes for each part before shipment. Request documentation of quality control procedures and any certifications that confirm the parts meet industry specifications. A reliable supplier should also offer warranties or guarantees on their products to ensure confidence in their quality. -

7. How do logistics and shipping impact the sourcing of sandblaster parts?

Logistics and shipping play a critical role in the sourcing process for sandblaster parts, particularly for international buyers. Consider the shipping methods available, estimated delivery times, and customs regulations that may affect your order. Collaborate with suppliers who have experience in international shipping and can provide transparent tracking information. Additionally, factor in shipping costs when budgeting for your purchase, as these can significantly influence the overall project cost. -

8. Can I customize sandblaster parts to fit specific applications?

Yes, many suppliers offer customization options for sandblaster parts to meet specific application requirements. Customization may include alterations in size, material, or design to enhance performance for particular blasting tasks. When considering customization, discuss your specific needs with the supplier and inquire about their capabilities and lead times for custom orders. Providing detailed specifications will help ensure that the customized parts meet your operational standards effectively.

Top 4 Sandblaster Parts Diagram Manufacturers & Suppliers List

1. Norton – Sandblasting Equipment

Domain: nortonsandblasting.com

Registered: 1998 (27 years)

Introduction: Norton Sandblasting Equipment supplies parts and accessories for the 1.5, 3.5, 6.5, 10 and 20 cu.ft. Schmidt portable sand blasters. Parts include various valves and controls such as Combo-Micro Valve Pneumatic, Combo-Micro Valve Electric, Thompson Valve Pneumatic, Thompson Valve Electric, and several Micro Valves (MV, MV2, MV3). The company stocks many parts in their warehouse, with select parts …

2. Pinterest – Home-made Sand Blaster Machine Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Home-made Sand Blaster Machine Diagram, parts diagram, tools needed, assembly instructions, woodworking projects.

3. Mere Blasting – Key Components of a Sandblasting System

Domain: meremblasting.com

Registered: 2022 (3 years)

Introduction: Key Components of a Sandblasting System: 1. Compressor: Provides high-pressure air to propel abrasive materials. 2. Blasting Pot: Stores and mixes abrasive material with air, regulating flow for even distribution. 3. Hoses and Fittings: Durable hoses connect the compressor to the blasting pot, preventing leaks and maintaining pressure. 4. Nozzle: Directs the flow of abrasive material onto the surf…

4. Stockcake – Empire Sandblaster Parts Diagram

Domain: stockcake.com

Registered: 2017 (8 years)

Introduction: Free Sandblaster Parts Diagram Image, detailed technical diagram of an Empire sandblaster, color-coded components, directional indicators, exploded view arrangement, critical components highlighted in industrial blue and safety yellow, detailed labels for each piece, professional isometric layout, suitable for maintenance technicians and equipment operators, grid lines and metallic surface details…

Strategic Sourcing Conclusion and Outlook for sandblaster parts diagram

In the evolving landscape of industrial sandblasting, a thorough understanding of sandblaster parts diagrams is crucial for international B2B buyers. By identifying and sourcing the right components—from compressors to nozzles—companies can optimize their operations, enhance safety, and reduce costs. Strategic sourcing of these parts not only ensures consistent equipment performance but also mitigates downtime and maintenance expenses, which are critical for businesses operating across diverse markets such as Africa, South America, the Middle East, and Europe.

As you navigate the complexities of sourcing, leverage local suppliers who understand regional requirements and can provide tailored solutions. This approach not only fosters strong partnerships but also enhances your supply chain resilience. Investing in quality parts and maintaining an updated parts diagram will empower your organization to achieve superior blasting results, leading to higher customer satisfaction and repeat business.

Looking ahead, the demand for efficient and environmentally friendly blasting solutions will continue to grow. Engage with reputable suppliers and industry experts to stay ahead of market trends and technological advancements. Take proactive steps now to secure your competitive edge in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to sandblaster parts diagram