Sachet Packing Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Sachet Packing Machines

In an era where convenience drives consumer demand, sachet packaging has emerged as a powerhouse solution for industries like food, pharmaceuticals, and consumer goods. These compact, single-serve formats—think powders, liquids, and granules sealed in three- or four-side pouches—not only enhance portability but also extend shelf life and reduce waste. For B2B buyers in the USA and Europe, investing in the right sachet packing machine can boost production efficiency, with outputs ranging from 40 to 1,000 sachets per minute across 1 to 20 lanes. Yet, the global market’s rapid evolution, fueled by automation and sustainability trends, presents a compelling opportunity: streamline operations and capture market share in a sector projected to grow at 5-7% annually through 2030.

The challenge? Navigating this crowded landscape. Buyers often grapple with mismatched machine capabilities—such as varying web widths (up to 32 inches) or cycle rates (up to 50 per minute)—against specific needs like regulatory compliance in FDA or EU standards, scalability for low-to-high volume runs, and integration with existing lines. Overlooking these can lead to downtime, inflated costs, or suboptimal output, eroding competitive edges in price-sensitive markets.

This comprehensive B2B guide demystifies the process, equipping procurement teams and operations managers with actionable insights. We’ll cover:

- Market Overview: Key trends, suppliers, and regional considerations for USA and European buyers.

- Machine Types and Features: Breakdown of vertical form fill seal (VFFS) models, from single-lane to multilane systems, including specs like maximum sachet dimensions (up to 8″ width, 12″ length).

- Selection Criteria: Evaluating factors such as throughput, maintenance, and customization options like tear notches.

- Implementation Strategies: Best practices for integration, ROI calculation, and vendor evaluation.

Armed with this knowledge, you’ll make informed decisions to optimize your packaging line and drive business growth.

(Word count: 312)

Top 10 Sachet Packing Machine Manufacturers & Suppliers List

1. 5 Best Small Sachet Packaging Machines | Save Costs & Scale

Domain: spackmachine.com

Registered: 2016 (9 years)

Introduction: Find flexible small sachet packaging machines for SMEs. SpackMachine’s FDA-compliant models with quick-change tooling reduce costs and scale ……

2. Top 10 Packing Machine Manufacturers in the world – Landpack

Domain: landpack.com

Registered: 2009 (16 years)

Introduction: 1. Landpack-China · 2. Tetra Pak- Switzerland · 3. Krones-Germany · 4. KHS GmbH-Germany · 5. Sidel-France · 6. Syntegon-Germany · 7. MULTIVAC-Germany….

Understanding sachet packing machine Types and Variations

Understanding Sachet Packing Machine Types and Variations

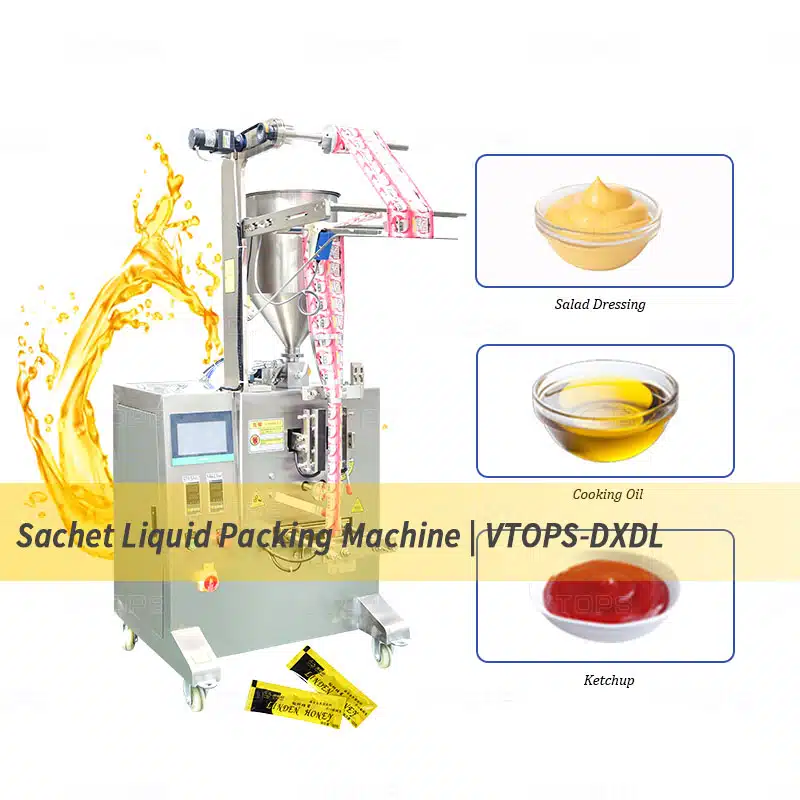

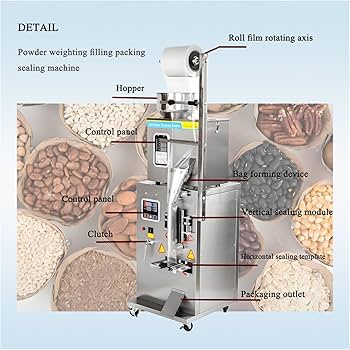

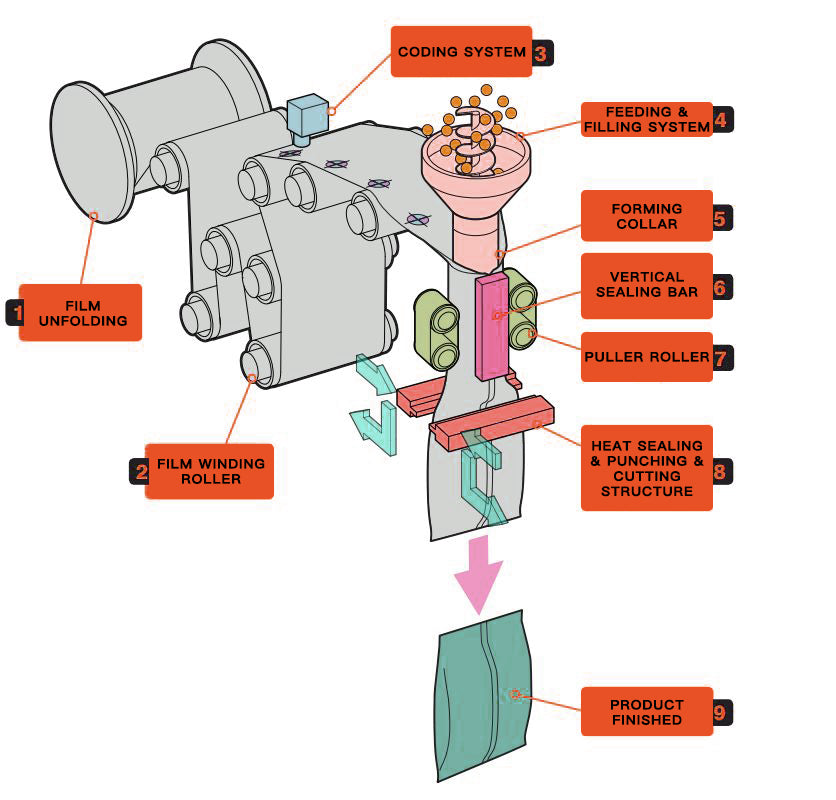

Sachet packing machines are essential for producing compact, sealed packages for powders, liquids, granules, and other products. Based on design, output, and lane configuration, we identify four key types: Single-Lane VFFS Machines, Low-Output Multi-Lane Machines, Medium-Output Multi-Lane Machines, and High-Output Multi-Lane Machines. These variations support three-side or four-side seal sachets and cater to diverse production needs in food, pharmaceutical, and related industries.

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Single-Lane VFFS Machines | Modular vertical form fill seal (VFFS) design; 1 lane; output up to 40 sachets/min; max web width 32″; sachet sizes up to 8.5″ width and 11.5″ length; options for tear notches and seal patterns. | Packaging small batches of powders, liquids, or granules in food, pharma, and cosmetics; suitable for startups or low-volume runs. | Pros: Compact footprint, easy maintenance, cost-effective for entry-level operations. Cons: Lower output limits scalability for high-volume production. |

| Low-Output Multi-Lane Machines | VFFS with 4-10 lanes; output up to 500 sachets/min; max sachet width 4″; length up to 12″; handles liquids, powders, granules. | Medium production of sachets for condiments, supplements, or single-serve items in food and pharma sectors. | Pros: Increased efficiency over single-lane; versatile for various products. Cons: Moderate speed may not suit bulk runs; requires more space than single-lane models. |

| Medium-Output Multi-Lane Machines | VFFS with 8-12 lanes; output up to 600 sachets/min; max sachet width 5″; length up to 12″; robust construction for continuous operation. | Medium to high-volume packaging of powders, liquids, or granules in food processing, pharmaceuticals, and nutraceuticals. | Pros: Higher throughput for growing operations; reliable for diverse materials. Cons: Higher initial cost; maintenance needs increase with lane count. |

| High-Output Multi-Lane Machines | VFFS with 12-20 lanes; output up to 1000 sachets/min at 50 cycles/min; max sachet width 8″; compact footprint despite high capacity. | Large-scale production of sachets for bulk items like seasonings, medications, or samples in industrial food and pharma environments. | Pros: Maximizes productivity without compromising seal quality; ideal for high-demand lines. Cons: Significant upfront investment; complex setup for optimal performance. |

Single-Lane VFFS Machines

These machines, such as the AP-140 and AP-180 models, operate on a single packaging lane using vertical form fill seal technology. They form sachets from a film web, fill them with product, and seal them in one continuous process. Key specifications include a maximum output of 40 sachets per minute, with sachet dimensions ranging from 4.5″ x 7.5″ to 8.5″ x 11.5″. They support three-side or four-side seals and can include features like tear notches for user convenience. Ideal for businesses in the USA and Europe starting with sachet packaging, these machines offer smooth operation and minimal maintenance, making them suitable for low-volume production of food items, pharmaceuticals, or samples.

Illustrative Image (Source: Google Search)

Low-Output Multi-Lane Machines

Exemplified by the MSB 406mm model, these machines feature 4-10 lanes for parallel packaging, achieving up to 500 sachets per minute. They handle a variety of products including liquids, powders, and granules, with maximum sachet sizes of 4″ width and 12″ length. The VFFS design ensures consistent sealing across lanes, with options for customized seal patterns. In B2B contexts across the USA and Europe, they are used for low to medium production runs, such as packaging single-serve condiments or supplements, providing a step up in efficiency from single-lane systems while maintaining a manageable footprint.

Medium-Output Multi-Lane Machines

Models like the MSB 508mm offer 8-12 lanes and deliver up to 600 sachets per minute, supporting sachet widths up to 5″ and lengths up to 12″. Built for durability, these VFFS machines process powders, liquids, and granules with high reliability. They are designed for medium production environments, enhancing output without excessive complexity. For USA and European manufacturers in food and pharma, these machines facilitate scaling operations, such as producing nutraceutical packets or sauce sachets, balancing cost and performance effectively.

High-Output Multi-Lane Machines

The MSB 813mm represents this type, with 12-20 lanes and capabilities up to 1000 sachets per minute at 50 cycles per minute. Despite a compact design, it accommodates sachets up to 8″ wide and maintains seal integrity at high speeds. These VFFS machines are optimized for bulk runs of diverse products like granules or liquids. In high-volume B2B settings in the USA and Europe, they support large-scale operations in industries such as food processing or pharmaceuticals, enabling efficient production of items like seasoning packets or medical samples.

Key Industrial Applications of sachet packing machine

Key Industrial Applications of Sachet Packing Machines

Sachet packing machines, such as Unified Flex’s vertical form fill seal (VFFS) models, support efficient packaging of powders, liquids, granules, and other products into three- or four-side seal sachets. These machines offer 1-20 lanes, outputs of 40-1000 sachets per minute, and features like tear notches and custom seal patterns. Below is a summary of key industries, specific applications, and associated benefits.

Illustrative Image (Source: Google Search)

| Industry | Applications | Detailed Benefits |

|---|---|---|

| Food and Beverage | Packaging of condiments (e.g., ketchup, mayonnaise), instant mixes (e.g., coffee, sugar packets), spices, and nutritional powders. | Enables portion-controlled, hygienic packaging that extends shelf life and reduces waste; high-speed multi-lane operations (up to 1000 sachets/min) boost production efficiency for medium to high-volume runs; compact sachets enhance portability for on-the-go consumption, supporting retail and foodservice distribution. |

| Pharmaceuticals | Single-dose medications, powdered supplements, and liquid formulations like oral rehydration solutions. | Ensures precise dosing and tamper-evident seals for compliance with FDA and EU regulations; modular designs facilitate easy maintenance and quick changeovers, minimizing downtime in regulated environments; supports sterile packaging of sensitive products, improving patient safety and supply chain integrity. |

| Cosmetics and Personal Care | Sample packets of creams, lotions, shampoos, and gels for promotional or travel-sized use. | Provides customizable sachet sizes (up to 8″ width) with tear notches for user convenience; high-output capabilities (e.g., 600 sachets/min on 12 lanes) enable cost-effective mass production of samples, aiding marketing efforts; flexible film handling ensures leak-proof seals, preserving product quality during transport. |

| Nutraceuticals and Supplements | Vitamin powders, protein mixes, and herbal granules in single-serve formats. | Facilitates accurate filling for consistent dosing, supporting health and wellness branding; small footprint machines suit space-constrained facilities, while variable lane options scale from low (40 sachets/min) to high production; enhances product freshness with barrier films, meeting consumer demands for convenience in USA and European markets. |

| Chemicals and Household Products | Small packets of detergents, fertilizers, seeds, or adhesives. | Offers robust construction for handling abrasive or viscous materials without compromising seal integrity; multi-lane efficiency streamlines packaging for industrial bulk runs, reducing labor costs; customizable features like seal patterns ensure safe, spill-proof containment, complying with safety standards in diverse applications. |

3 Common User Pain Points for ‘sachet packing machine’ & Their Solutions

3 Common User Pain Points for Sachet Packing Machines & Their Solutions

Pain Point 1: Inadequate Production Speed for High-Volume Runs

- Scenario: A food manufacturer needs to scale up output for single-serve condiment packets to meet seasonal demand spikes in the US market.

- Problem: Single-lane machines limit throughput to 40 sachets per minute, causing bottlenecks, increased labor costs, and missed delivery deadlines.

- Solution: Unified Flex’s Multilane Sachet Baggers (e.g., MSB 813mm) support up to 20 lanes and deliver 1000 sachets per minute at 50 cycles per minute, enabling seamless high-volume production without compromising seal quality.

Pain Point 2: Limited Flexibility for Diverse Product Types and Sizes

- Scenario: A pharmaceutical company in Europe packages varying products like powders and liquids into sachets of different dimensions for clinical trials.

- Problem: Inflexible machines require frequent reconfiguration or multiple units, leading to downtime, higher setup costs, and inconsistent packaging quality across product lines.

- Solution: Unified Flex’s modular VFFS machines, such as the AP-180 Sachet (up to 8.5″ width and 11.5″ length) or MSB 508mm (handling liquids, powders, and granules across 12 lanes), offer customizable options like tear notches and seal patterns for efficient adaptation to various sachet sizes and product types.

Pain Point 3: Excessive Downtime Due to Maintenance and Operation Complexity

- Scenario: A B2B supplier in the USA experiences frequent breakdowns on aging sachet equipment during peak production for granular supplements.

- Problem: Complex designs result in prolonged maintenance, operational disruptions, and elevated repair expenses, reducing overall equipment efficiency.

- Solution: Unified Flex’s user-friendly machines, like the AP-140 Sachet with its sleek, modular design, ensure smooth operation and minimal maintenance, supporting up to 40 sachets per minute while streamlining efficiencies for low to medium production runs.

Strategic Material Selection Guide for sachet packing machine

Strategic Material Selection Guide for Sachet Packing Machines

Selecting the right packaging materials is critical for sachet packing machines to ensure product integrity, regulatory compliance, and operational efficiency. Materials must be compatible with vertical form fill seal (VFFS) systems, such as those from Unified Flex, which support web widths up to 32 inches (81.28 cm) and handle products like granules, liquids, and powders in 3-side or 4-side seal sachets. Key considerations include barrier properties, sealability, machinability, cost, and sustainability, aligned with USA (FDA) and European (EU) standards for food and pharmaceutical applications.

Key Factors in Material Selection

- Barrier Properties: Materials should protect against moisture, oxygen, light, and contaminants to extend shelf life, especially for sensitive products like pharmaceuticals or perishable foods.

- Sealability and Machinability: Films must form reliable seals at machine speeds of 40-1000 sachets per minute and be compatible with 1-20 lanes, ensuring minimal downtime.

- Regulatory Compliance: Must meet FDA 21 CFR or EU Regulation (EC) No 1935/2004 for food contact; pharma-grade materials require USP Class VI certification.

- Sustainability: Opt for recyclable or biodegradable options to meet growing demands in USA and Europe.

- Product Compatibility: Liquids require high-barrier laminates; powders need anti-static properties; granules benefit from puncture-resistant films.

- Machine-Specific Constraints: Select films within max sachet dimensions (e.g., up to 8″ width and 12″ length on MSB models) and web widths to avoid waste.

Common Materials and Analysis

The following materials are widely used in sachet packaging. Selection depends on product type, machine model (e.g., AP-140 for smaller runs or MSB-813mm for high-output), and market requirements.

-

Polyethylene (PE) Films: Low-cost, flexible option for non-barrier needs. Ideal for dry granules or powders in food applications. Offers good sealability but limited moisture/oxygen protection. Machinable on all Unified Flex models; suitable for low to medium production (up to 500 sachets/min).

-

Polypropylene (PP) Films: Provides moderate barrier against moisture and is heat-sealable. Commonly used for pharma powders or liquid sachets requiring sterilization. Compatible with multi-lane setups (e.g., MSB-508mm); eco-variants available for European markets.

Illustrative Image (Source: Google Search)

-

Polyethylene Terephthalate (PET) Laminates: High-strength, transparent films with excellent oxygen barriers when laminated. Suited for light-sensitive products like vitamins or condiments. Runs efficiently on high-speed machines (up to 1000 sachets/min on MSB-813mm); complies with FDA/EU regs.

-

Aluminum Foil Laminates: Superior barrier for moisture, light, and gases; essential for pharma liquids or oxygen-sensitive foods. Puncture-resistant and sealable at various patterns (e.g., with tear notches). Best for bulk runs but requires precise machine calibration to avoid tearing.

-

Paper-Based or Biodegradable Films: Emerging for sustainable packaging, often laminated with PE/PP for sealability. Suitable for eco-focused brands in Europe; offers moderate barriers for dry products. Compatible with lower-speed models like AP-180 but may reduce output due to handling needs.

For optimal performance, test materials on-site with Unified Flex machines to verify seal quality and cycle rates (up to 50 cycles/min).

Illustrative Image (Source: Google Search)

Material Comparison Table

| Material | Barrier Properties | Sealability | Cost (Relative) | Sustainability | Suitability for Products | Machine Compatibility |

|---|---|---|---|---|---|---|

| Polyethylene (PE) | Low (moisture/oxygen) | High | Low | Moderate (recyclable) | Granules, powders | All models; up to 1000 sachets/min |

| Polypropylene (PP) | Moderate (moisture) | High | Medium | High (biodegradable options) | Liquids, powders | Multi-lane (e.g., MSB series) |

| PET Laminates | High (oxygen/light) | High | Medium | Moderate (recyclable) | Sensitive foods/pharma | High-output (e.g., MSB-813mm) |

| Aluminum Foil Laminates | Excellent (all barriers) | High | High | Low (non-biodegradable) | Liquids, oxygen-sensitive | All models; precise calibration needed |

| Paper-Based/Biodegradable | Moderate (with lamination) | Medium | Medium-High | High (compostable) | Dry, eco-products | Lower-speed (e.g., AP-140/180) |

In-depth Look: Manufacturing Processes and Quality Assurance for sachet packing machine

In-depth Look: Manufacturing Processes and Quality Assurance for Sachet Packing Machines

Sachet packing machines, such as Unified Flex’s vertical form fill seal (VFFS) models like the AP-140, AP-180, and Multilane Sachet Baggers (MSB series), are engineered for high-efficiency packaging of powders, liquids, and granules into three- or four-side seal sachets. Below, we outline the key manufacturing processes involved in producing these machines, followed by quality assurance protocols. These steps ensure reliability, scalability (1-20 lanes, 40-1000 sachets/min), and compliance for B2B applications in food, pharma, and related sectors.

Manufacturing Processes

Manufacturing sachet packing machines involves precision engineering to handle diverse outputs and web widths up to 32 inches (81.28 cm). The process is divided into preparation, forming, assembly, and quality control stages.

Preparation

- Material Sourcing and Inspection: High-grade stainless steel, alloys, and electronic components are sourced from certified suppliers. Materials undergo initial inspections for durability, corrosion resistance, and compatibility with food/pharma standards (e.g., FDA-compliant for USA markets).

- Design and Prototyping: CAD models are developed based on specifications like maximum sachet dimensions (e.g., 8.5″ width for AP-180) and cycle rates (up to 50/min). Prototypes are tested for modular features, such as easy maintenance in the AP series.

- Component Fabrication Planning: Blueprints detail lane configurations (1-20) and output capabilities, ensuring scalability for models like the MSB 813mm (up to 1000 sachets/min).

Forming

- Metal Forming and Machining: Sheets are cut, bent, and machined using CNC equipment to create frames, forming tubes, and sealing jaws. Precision forming ensures tight tolerances for sachet sizes (e.g., up to 12″ length in MSB models).

- Component Shaping: Electrical panels, motors, and pneumatic systems are formed to support high-speed operations (40-1000 sachets/min). Heat-sealing elements are calibrated for consistent seal patterns and tear notches.

- Surface Treatment: Parts receive coatings for hygiene and longevity, such as powder coating or anodizing, tailored for cleanroom environments in pharma applications.

Assembly

- Sub-Assembly Integration: Modular components (e.g., film unwinders, fillers, and cutters) are assembled into subsections. For multiline models like MSB 508mm (up to 600 sachets/min on 12 lanes), lanes are aligned for synchronized operation.

- System Integration: Electronics, sensors, and controls are installed for user-friendly interfaces and automation. Final wiring ensures compatibility with variable web widths (up to 32″) and product types (liquids, powders, granules).

- Functional Testing: Assembled units undergo dry runs to verify output rates and features like small footprints in high-output models (e.g., MSB 813mm).

Quality Control

- In-Process Inspections: Each stage includes dimensional checks, weld integrity tests, and component functionality verifications using tools like calipers and multimeters.

- Performance Validation: Machines are tested at full capacity (e.g., 500 sachets/min for MSB 406mm) to confirm seal quality, cycle consistency, and minimal downtime.

- Compliance Audits: Units are checked against regional regulations, including CE marking for Europe and UL certification for USA.

Quality Assurance Standards

Unified Flex adheres to ISO 9001 standards for quality management systems, ensuring consistent manufacturing processes and continuous improvement. This certification covers design, production, and service, guaranteeing traceability and defect minimization. For B2B clients in USA and Europe, additional alignments include ISO 22000 for food safety (relevant to packaging machines) and adherence to GMP guidelines in pharma sectors. Regular audits and supplier certifications maintain high standards, reducing risks in production runs and supporting warranties on models like the AP-140 and MSB series.

| Model | Max Lanes | Max Output (Sachets/Min) | Max Sachet Width | Key QA Feature |

|---|---|---|---|---|

| AP-140 | 1 | 40 | 4.5″ | Modular design for easy QC access |

| AP-180 | 1 | 40 | 8.5″ | Robust construction with seal integrity checks |

| MSB 406mm | 10 | 500 | 4″ | Multi-lane synchronization testing |

| MSB 508mm | 12 | 600 | 5″ | High-durability audits for medium runs |

| MSB 813mm | 20 | 1000 | 8″ | Bulk-run validation for seal quality |

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sachet packing machine’

Practical Sourcing Guide: A Step-by-Step Checklist for Sachet Packing Machine

This checklist provides a structured approach for B2B buyers in the USA and Europe to source sachet packing machines, focusing on vertical form fill seal (VFFS) models suitable for food, pharma, and other industries. Prioritize machines with 1-20 lanes, outputs of 40-1000 sachets per minute, and options for 3-side or 4-side seals.

Illustrative Image (Source: Google Search)

Step 1: Define Your Requirements

- Identify product type (e.g., granules, liquids, powders) and packaging needs (e.g., sachet size, seal type, tear notches).

- Determine production volume: Calculate required output (e.g., 40-1000 sachets/min) based on cycles per minute (up to 50) and lanes (1-20).

- Specify machine specs: Maximum web width (e.g., up to 32″), sachet dimensions (e.g., width 4-8″, length 7.5-12″), and compliance with USA (FDA) or EU (CE) regulations.

Step 2: Research Suppliers and Models

- Search for manufacturers like Unified Flex, focusing on VFFS machines such as AP-140 (max 40 sachets/min, 4.5″ width), AP-180 (max 40 sachets/min, 8.5″ width), or multilane models (e.g., MSB 406mm for 500 sachets/min on 10 lanes, MSB 508mm for 600 on 12 lanes, MSB 813mm for 1000 on 20 lanes).

- Compare features: Modular design, ease of maintenance, and output efficiency for low-to-high production runs.

- Review case studies or videos for real-world applications in food and pharma sectors.

Step 3: Evaluate Technical and Compliance Factors

- Assess machine footprint and integration: Ensure compatibility with existing lines (e.g., compact designs for small spaces).

- Verify certifications: Confirm FDA compliance for USA or CE marking for Europe, including hygienic designs for food/pharma.

- Check customization: Options for auto pouch bagging, seal patterns, and web widths up to 32″.

Step 4: Request Quotes and Consultations

- Contact suppliers for free consultations and quick quotes, providing your specs (e.g., lanes, output, product type).

- Request demos or videos to evaluate operation (e.g., smooth VFFS processes).

- Compare pricing: Factor in total cost of ownership, including maintenance and spare parts availability in USA/Europe.

Step 5: Finalize and Implement

- Negotiate terms: Include warranties, training, and after-sales support for installation and operation.

- Plan logistics: Account for shipping, customs (for EU/USA imports), and lead times.

- Test and validate: Schedule on-site trials to ensure output (e.g., 40-1000 sachets/min) meets your needs before full commitment.

| Key Consideration | USA Focus | Europe Focus |

|---|---|---|

| Regulatory Compliance | FDA standards for food/pharma | CE marking and EU hygiene regs |

| Supplier Support | Local service centers | EU-based distributors for faster response |

| Output Scalability | Models up to 1000 sachets/min for high-volume | Emphasis on energy-efficient, modular designs |

Comprehensive Cost and Pricing Analysis for sachet packing machine Sourcing

Comprehensive Cost and Pricing Analysis for Sachet Packing Machine Sourcing

Sourcing sachet packing machines involves evaluating total ownership costs beyond the initial purchase price. This analysis breaks down key cost components—materials, labor, and logistics—based on industry benchmarks for vertical form fill seal (VFFS) machines like those from Unified Flex (e.g., AP-140, AP-180, and multilane models MSB series). Prices vary by model complexity (1-20 lanes, 40-1000 sachets/min output), customization (e.g., tear notches, seal patterns), and supplier location. For USA and Europe buyers, expect base prices starting at $20,000 for entry-level single-lane models and exceeding $150,000 for high-output multilane systems. Always request quotes for precise figures.

Cost Breakdown

Materials

Materials costs encompass the machine itself, consumables, and spare parts. These form the bulk of upfront expenses and ongoing maintenance.

- Machine Acquisition: Entry-level VFFS machines (e.g., AP-140 or AP-180, single-lane, up to 40 sachets/min) range from $20,000-$50,000. Multilane models (e.g., MSB 813mm, up to 20 lanes and 1000 sachets/min) can cost $100,000-$300,000 or more, depending on web width (up to 32 inches) and features like modular designs for food, pharma, or granular products.

- Consumables and Parts: Packaging film, seals, and fillers add 10-20% to annual costs. For a medium-production setup (e.g., MSB 508mm, 600 sachets/min), expect $5,000-$15,000/year in film and maintenance parts.

- Factors Influencing Costs: Material quality (e.g., stainless steel for pharma compliance) and customizations (e.g., 3- or 4-side seal sachets) increase prices by 15-30%.

| Component | Estimated Cost Range (USD) | Notes |

|---|---|---|

| Base Machine (Single-Lane) | $20,000-$50,000 | Suitable for low-volume runs; e.g., AP-140 (4.5″ max width). |

| Base Machine (Multilane) | $100,000-$300,000+ | High-output; e.g., MSB 813mm (8″ max width, 1000 sachets/min). |

| Annual Consumables | $5,000-$20,000 | Depends on production volume and material type (powders, liquids). |

Labor

Labor costs include installation, operation, training, and maintenance, impacting long-term efficiency.

- Installation and Training: Professional setup for VFFS machines costs $5,000-$15,000, including on-site technician time (2-5 days). Training for operators adds $1,000-$3,000 per session.

- Operational Labor: For a multilane machine (e.g., 10-20 lanes), skilled operators earn $40,000-$60,000/year in the USA/Europe. Automation reduces headcount but requires periodic oversight.

- Maintenance: Annual servicing (e.g., for smooth operation in models like MSB 406mm) ranges from $2,000-$10,000, often covered under warranties (1-2 years standard).

| Component | Estimated Cost Range (USD) | Notes |

|---|---|---|

| Installation/Training | $5,000-$15,000 (one-time) | Essential for modular designs; minimizes downtime. |

| Annual Operator Salaries | $40,000-$60,000 per person | Scales with lanes/output; e.g., higher for 50 cycles/min models. |

| Maintenance Labor | $2,000-$10,000/year | Includes diagnostics for reliable performance. |

Logistics

Logistics cover shipping, import duties, and site preparation, which are critical for international sourcing (e.g., from North American suppliers like Unified Flex to Europe).

Illustrative Image (Source: Google Search)

- Shipping and Freight: Domestic USA shipping for a compact machine (e.g., AP-180 footprint) costs $1,000-$5,000. International to Europe adds $5,000-$20,000, including ocean freight and insurance.

- Duties and Taxes: EU imports may incur 5-10% tariffs plus VAT (20-27% varying by country). USA buyers face minimal duties for domestic sourcing.

- Site Preparation: Facility modifications (e.g., electrical setup for 1-20 lane machines) range from $2,000-$10,000.

| Component | Estimated Cost Range (USD) | Notes |

|---|---|---|

| Shipping (Domestic) | $1,000-$5,000 | For machines with small footprints. |

| Shipping (International) | $5,000-$20,000 | Includes customs clearance for Europe. |

| Duties/Taxes (Europe) | 5-10% of machine value + VAT | Varies by EU country; plan Anguilla for USA/Europe trade. |

Tips to Save Costs

- Source Locally or Regionally: Opt for USA-based suppliers (e.g., Unified Flex) to reduce logistics fees by 20-40% compared to Asian imports.

- Choose Modular Designs: Select flexible models like AP-140/AP-180 for easy upgrades, avoiding full replacements and saving 15-25% on future expansions.

- Bulk Purchasing: Negotiate discounts (5-15%) for consumables by committing to annual volumes, especially for high-output machines (e.g., MSB series).

- Energy-Efficient Models: Invest in machines with low cycles/min ratings but high efficiency to cut utility costs by 10-20% annually.

- Lease vs. Buy: Consider leasing for entry-level setups to spread costs over 3-5 years, reducing upfront capital by 50%.

- Maintenance Contracts: Secure extended warranties or service plans to cap repair costs at predictable rates, potentially saving 10-30% on unplanned downtime.

- Compare Quotes: Request free consultations from multiple suppliers to benchmark pricing and features, ensuring ROI for applications in food, pharma, or granules.

Alternatives Analysis: Comparing sachet packing machine With Other Solutions

Alternatives Analysis: Comparing Sachet Packing Machines With Other Solutions

This section compares sachet packing machines (e.g., Unified Flex models like AP-140, AP-180, and multilane baggers) with two common alternatives: stick pack machines and blister packaging machines. These alternatives are often considered for packaging powders, liquids, granules, and similar products in food, pharma, and related industries. The comparison focuses on key operational and application factors.

Comparison Table

| Feature | Sachet Packing Machines | Stick Pack Machines | Blister Packaging Machines |

|---|---|---|---|

| Primary Package Type | Flat, three- or four-side seal sachets (compact, single-serve) | Elongated, narrow tubes (stick-shaped sachets) | Rigid, cavity-based blisters with foil or plastic backing |

| Output Range | 40–1,000 sachets/min (1–20 lanes, up to 50 cycles/min) | 100–1,200 sticks/min (multi-lane configurations) | 200–600 blisters/min (depending on mold size and automation) |

| Product Suitability | Powders, liquids, granules; ideal for food, pharma, cosmetics | Powders, liquids, gels; common in supplements, condiments | Solids (tablets, capsules); primarily pharma and medical devices |

| Package Size Flexibility | Width: 4.5–8″; Length: 7.5–12″; customizable with tear notches | Width: 0.5–2″; Length: 2–10″; high length-to-width ratio | Fixed cavity sizes (custom molds required); less flexible for liquids |

| Machine Footprint | Compact (e.g., 32″ max web width); suitable for small to medium spaces | Slim design; efficient for high-volume, narrow packages | Larger footprint due to molding stations; requires more space |

| Initial Cost | Moderate ($50,000–$200,000 depending on lanes and features) | Moderate to high ($60,000–$250,000 for multi-lane) | High ($100,000–$500,000 due to tooling and precision) |

| Maintenance and Operation | Modular VFFS design; easy maintenance, smooth operation | Similar VFFS; minimal downtime with proper setup | Complex (thermoforming involved); higher maintenance for molds |

| Typical Applications | Single-dose condiments, supplements, samples (USA/Europe food/pharma regs compliant) | Energy gels, instant drinks, portion-controlled products | Pharmaceuticals, OTC meds; strong tamper-evidence |

Note: Costs are approximate based on industry averages for entry-level to advanced models; actual pricing varies by supplier and customization.

Analysis

Sachet packing machines excel in versatility and efficiency for compact, flexible packaging of diverse products like powders and liquids, with high output (up to 1,000 sachets/min) in a small footprint, making them ideal for medium to high-volume B2B operations in the USA and Europe. They outperform stick pack machines in package width flexibility and broader product compatibility but may yield lower speeds for ultra-high-volume narrow formats. Compared to blister packaging machines, sachets offer lower costs and easier adaptation for non-solid products, though blisters provide superior protection for tablets and regulatory compliance in pharma. Businesses should select based on product type, production scale, and compliance needs—e.g., sachets for cost-effective food sampling, sticks for portable supplements, or blisters for secure drug delivery. For custom consultations, evaluate throughput and integration with existing lines.

Essential Technical Properties and Trade Terminology for sachet packing machine

Essential Technical Properties and Trade Terminology for Sachet Packing Machines

Key Technical Properties

Sachet packing machines, often based on vertical form fill seal (VFFS) technology, are designed for efficient packaging of powders, liquids, granules, and other products into three-side or four-side seal sachets. Essential properties include scalability, output capacity, and compatibility with various materials. Below is a summary of core technical specifications, drawn from industry-standard models.

| Property | Description | Typical Range/Example |

|---|---|---|

| Number of Packaging Lanes | Determines parallel processing capability for higher throughput. | 1-20 lanes |

| Output Rate | Measures production speed, impacting efficiency for low to high-volume runs. | 40-1,000 sachets per minute |

| Maximum Web Width | Refers to the width of the film roll used for forming sachets; affects machine footprint and sachet size. | Up to 32″ (81.28 cm) |

| Maximum Cycles per Minute | Indicates operational speed per lane or cycle, crucial for seal quality and consistency. | Up to 50 cycles per minute |

| Sachet Dimensions | Defines the size of output sachets, customizable for product needs. | Width: 4-8″; Length: 7.5-12″ (varies by model) |

| Seal Types and Features | Includes seal configurations and add-ons for usability. | Three-side or four-side seals; options for tear notches and custom patterns |

These properties ensure machines like single-lane (e.g., AP-140 or AP-180) or multilane baggers (e.g., MSB series) suit applications in food, pharma, and other sectors, with modular designs for easy maintenance.

Trade Terminology

In B2B transactions for sachet packing machines, understanding key terms facilitates negotiations, procurement, and compliance. Below are essential terms with definitions relevant to USA and European markets.

- VFFS (Vertical Form Fill Seal): A packaging process where film is formed into sachets, filled with product, and sealed in a vertical orientation; standard for sachet machines.

- MOQ (Minimum Order Quantity): The smallest quantity of machines or parts a supplier will produce or sell in one order, often 1-5 units for custom equipment to cover setup costs.

- OEM (Original Equipment Manufacturer): A company that designs and manufactures machines under its own brand, which may be rebranded or customized by buyers (e.g., for private labeling).

- FOB (Free on Board): Shipping term indicating the point at which risk transfers from seller to buyer, typically at the port of origin; common in international trade from North America to Europe.

- CIF (Cost, Insurance, and Freight): Incoterm where the seller covers costs, insurance, and freight to the destination port; useful for European importers to minimize logistics risks.

- Lead Time: The duration from order placement to delivery, typically 8-12 weeks for sachet machines, depending on customization.

- Throughput: Overall production capacity, expressed in sachets per minute or hour, factoring in lanes and cycles.

These terms support informed decision-making, from quoting to installation, ensuring alignment with regulatory standards like FDA (USA) or CE marking (Europe).

Navigating Market Dynamics and Sourcing Trends in the sachet packing machine Sector

Navigating Market Dynamics and Sourcing Trends in the Sachet Packing Machine Sector

This section examines the historical evolution, current market trends, sustainability considerations, and sourcing strategies in the sachet packing machine industry. Focused on B2B applications in the USA and Europe, it provides actionable insights for procurement and operational decision-making in food, pharmaceutical, and related sectors.

Illustrative Image (Source: Google Search)

History of Sachet Packing Machines

Sachet packaging emerged in the 1950s as a response to demand for single-serve, portable products, initially driven by food and beverage industries. Early machines were manual or semi-automated, focusing on basic three- or four-side seal formats for powders and granules.

- 1960s-1980s: Introduction of vertical form fill seal (VFFS) technology automated processes, enabling higher outputs (up to 40 sachets per minute) and broader applications in pharmaceuticals for precise dosing.

- 1990s-2000s: Advancements in multilane systems increased efficiency, with machines supporting 1-10 lanes and outputs reaching 500 sachets per minute, aligning with globalization and just-in-time manufacturing.

- 2010s-Present: Integration of digital controls, modular designs, and high-speed capabilities (up to 1,000 sachets per minute) has positioned sachet machines as essential for scalable production, as seen in models like Unified Flex’s MSB series.

This evolution reflects a shift from labor-intensive methods to automated, high-precision systems, reducing costs and enhancing product safety.

Current Market Trends

The sachet packing machine market is projected to grow at a CAGR of 5-7% through 2030, driven by demand for convenient packaging in food, pharma, and cosmetics. Key trends include automation, customization, and scalability to meet diverse production needs.

- Automation and Efficiency: Adoption of VFFS machines with 1-20 lanes for outputs of 40-1,000 sachets per minute, optimizing for low- to high-volume runs. For instance, multilane baggers like the MSB 813mm handle bulk operations without compromising seal quality.

- Customization and Flexibility: Machines now support variable sachet sizes (up to 8″ width and 12″ length), tear notches, and seal patterns for liquids, powders, and granules, catering to niche markets.

- Regional Dynamics: In the USA, emphasis on FDA-compliant systems for pharma; in Europe, EU regulations drive demand for energy-efficient models. Supply chain disruptions have accelerated nearshoring, with North American manufacturers gaining traction.

| Machine Model | Max Lanes | Max Output (Sachets/Min) | Max Sachet Width | Key Applications |

|---|---|---|---|---|

| AP-140 Sachet | 1 | 40 | 4.5″ | Low-volume food/pharma |

| AP-180 Sachet | 1 | 40 | 8.5″ | Versatile powders/liquids |

| MSB 406mm | 10 | 500 | 4″ | Medium-run granules |

| MSB 508mm | 12 | 600 | 5″ | High-efficiency liquids |

| MSB 813mm | 20 | 1,000 | 8″ | Bulk production |

These trends underscore the need for machines that balance speed, reliability, and minimal downtime.

Illustrative Image (Source: Google Search)

Sustainability in Sachet Packaging

Sustainability is a core driver, with regulations like the EU’s Packaging and Packaging Waste Directive pushing for reduced environmental impact. B2B buyers prioritize machines that support eco-friendly materials and processes.

- Material Innovations: Shift to recyclable or biodegradable films, with machines compatible with mono-materials to minimize waste. Unified Flex models, for example, accommodate sustainable webs up to 32″ wide.

- Energy Efficiency: High-cycle machines (up to 50 cycles per minute) incorporate low-energy servos and modular designs for reduced power consumption, aligning with USA’s ENERGY STAR standards.

- Waste Reduction: Multilane systems optimize material use, cutting scrap rates by 10-20% compared to older models. Lifecycle assessments favor durable, low-maintenance equipment to extend operational life.

Procuring sustainable machines can yield cost savings through incentives like tax credits in Europe and compliance with corporate ESG goals.

Sourcing Strategies for USA and Europe

Effective sourcing involves evaluating global suppliers while prioritizing regional compliance and supply chain resilience.

- Supplier Evaluation: Focus on manufacturers offering modular VFFS systems with proven outputs (e.g., 40-1,000 sachets per minute). Unified Flex exemplifies North American reliability, with options for 1-20 lanes and quick consultations.

- Regional Considerations: In the USA, source FDA-certified machines; in Europe, ensure CE marking and adherence to REACH regulations. Post-pandemic, hybrid sourcing (e.g., North American assembly with Asian components) mitigates risks.

- Best Practices: Conduct ROI analyses on output vs. footprint; negotiate for customization like auto pouch baggers. Leverage digital platforms for quotes and videos to assess machine performance remotely.

By aligning sourcing with these trends, businesses can enhance competitiveness and adapt to market shifts.

Frequently Asked Questions (FAQs) for B2B Buyers of sachet packing machine

Frequently Asked Questions (FAQs) for B2B Buyers of Sachet Packing Machines

1. What types of products can be packaged using your sachet machines?

Our sachet machines are designed for granular products, liquids, powders, and more, making them suitable for industries like food, pharmaceuticals, and cosmetics. They support versatile applications without compromising on seal integrity.

2. What seal configurations and customization options are available?

Machines produce three-side and four-side seal sachets. Additional options include tear notches, custom seal patterns, and variable sizes to meet specific branding or functional needs.

3. What is the production capacity of these machines?

Output ranges from 40 to 1000 sachets per minute, depending on the model. Single-lane machines like the AP-140 and AP-180 achieve up to 40 sachets per minute, while multilane models (e.g., MSB 813mm) reach 1000 sachets per minute on a 20-lane setup.

4. How many packaging lanes do the machines support?

Configurations are available from 1 to 20 lanes, allowing scalability for low to high-volume production runs. This flexibility helps optimize throughput based on your operational demands.

Illustrative Image (Source: Google Search)

5. What are the maximum sachet dimensions possible?

Sachet widths range up to 8 inches (e.g., MSB 813mm), and lengths up to 12 inches (e.g., MSB 406mm and MSB 508mm). Maximum web width is 32 inches (81.28 cm), supporting efficient material use.

6. Are these machines suitable for food and pharmaceutical applications?

Yes, our vertical form fill seal (VFFS) machines comply with standards for food and pharma packaging. They ensure hygienic operation, precise filling, and reliable sealing for sensitive products.

7. What maintenance and operational features do the machines offer?

Models feature modular, user-friendly designs for smooth operation and minimal maintenance. They include easy-to-access components and run at up to 50 cycles per minute, reducing downtime in production environments.

8. How can we request a quote or consultation for integration into our production line?

Contact us for a free consultation or quick quote. We assess your needs, including integration with existing systems, to provide tailored recommendations on models like the AP series or multilane baggers.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for sachet packing machine

Strategic Sourcing Conclusion and Outlook for Sachet Packing Machines

In conclusion, strategic sourcing of sachet packing machines from reliable providers like Unified Flex delivers substantial value for B2B operations in the USA and Europe. These vertical form fill seal (VFFS) systems enable efficient packaging of granules, liquids, and powders into three- or four-side seal sachets, with customizable features such as tear notches and seal patterns. Key models, including the AP-140, AP-180, and multiline baggers (MSB series), support 1-20 lanes and outputs of 40-1000 sachets per minute, enhancing productivity, reducing downtime, and accommodating diverse production scales from low to high-volume runs.

Core Value Summary

- Efficiency Gains: Up to 50 cycles per minute with minimal maintenance, streamlining operations.

- Flexibility: Modular designs handle sachet widths up to 8″ and lengths up to 12″, ideal for food, pharma, and other sectors.

- Scalability: Options for 40-1000 sachets/min output, supporting business growth without quality compromise.

Looking ahead, the outlook is promising amid rising demand for sustainable, compact packaging. Trends include increased automation integration, eco-friendly materials, and AI-driven predictive maintenance, projected to grow the market by 5-7% annually in North America and Europe through 2028. Businesses should prioritize suppliers offering consultations and customization to future-proof investments and maintain competitive edges.

(Word count: 198)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.

Illustrative Image (Source: Google Search)