Rubber Tote Bag: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for rubber tote bag

In today’s competitive landscape, sourcing the right rubber tote bag can be a challenging endeavor for international B2B buyers. With varying needs across markets in Africa, South America, the Middle East, and Europe, businesses must navigate a complex environment filled with diverse styles, materials, and supplier capabilities. This comprehensive guide serves as a vital resource, addressing key considerations such as the types of rubber tote bags available, their applications in various industries, and effective strategies for vetting suppliers.

Understanding the nuances of the global market is crucial for making informed purchasing decisions. This guide empowers B2B buyers by offering actionable insights into cost structures, quality assessments, and the latest trends in rubber tote bags. By exploring the unique characteristics of products suited for different regions, buyers can better align their procurement strategies with market demands, ultimately enhancing their brand’s appeal and operational efficiency.

Whether you are looking to enhance your product offerings or simply seeking reliable suppliers, this guide equips you with the knowledge necessary to navigate the intricate landscape of rubber tote bags effectively. Dive in to discover how to optimize your sourcing processes, ensuring you choose the right products that resonate with your target audience while maintaining cost efficiency and quality standards.

Understanding rubber tote bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Beach Tote | Waterproof, spacious, often features vibrant colors and patterns | Retail for beachwear, promotional events | Pros: Durable and easy to clean; Cons: Limited to casual use. |

| Insulated Tote | Thermal insulation for food and beverages | Catering, outdoor events, food delivery | Pros: Keeps items cold/hot; Cons: Heavier than standard totes. |

| Eco-Friendly Rubber Tote | Made from recycled materials, often biodegradable | Sustainable product lines, eco-conscious brands | Pros: Appeals to eco-friendly consumers; Cons: May have a higher price point. |

| Fashion Tote | Trendy designs, often with designer branding | Fashion retail, event giveaways | Pros: High aesthetic appeal; Cons: May prioritize style over functionality. |

| Utility Tote | Multi-pocket design, rugged construction for heavy-duty use | Construction, logistics, outdoor activities | Pros: Versatile and functional; Cons: Bulkier and less stylish. |

What Are the Characteristics of Beach Totes?

Beach totes are typically designed for leisure activities, featuring waterproof materials that can withstand sand and water exposure. They are spacious, allowing for the storage of towels, sunscreen, and other essentials, and often come in vibrant colors and fun patterns. B2B buyers in retail or promotional sectors can leverage these bags for beachwear collections or as giveaways at summer events. When purchasing, consider the durability and ease of cleaning, as these factors significantly impact long-term usability.

How Do Insulated Totes Differ from Other Variants?

Insulated totes are uniquely designed to maintain the temperature of their contents, making them ideal for catering services, outdoor events, and food delivery businesses. The thermal insulation can keep food and beverages hot or cold for extended periods. B2B buyers should assess the weight and insulation efficiency when selecting insulated totes, as these factors can influence transportation and user experience. While they offer excellent functionality, their heavier weight may limit their appeal for casual use.

Why Choose Eco-Friendly Rubber Totes?

Eco-friendly rubber totes are crafted from recycled or biodegradable materials, catering to the growing demand for sustainable products. These bags are increasingly popular among brands focused on environmental responsibility. B2B buyers targeting eco-conscious consumers can benefit from incorporating these totes into their product lines. However, the initial price point may be higher than conventional options, so businesses should weigh the long-term brand loyalty and customer appeal against upfront costs.

What Makes Fashion Totes a Good Option for Retail?

Fashion totes blend style with functionality, often featuring trendy designs and branding that appeals to fashion-forward consumers. These bags are suitable for retail environments, particularly in high-traffic areas like shopping malls or during events. B2B buyers should consider the target demographic’s style preferences when selecting these totes. While they offer high aesthetic appeal, it’s essential to ensure that functionality, such as durability and storage capacity, is not compromised.

How Are Utility Totes Used in Various Industries?

Utility totes are characterized by their rugged construction and multi-pocket designs, making them ideal for heavy-duty applications in construction, logistics, and outdoor activities. Their versatility allows businesses to utilize these bags across different sectors, from carrying tools to organizing supplies. When sourcing utility totes, B2B buyers should evaluate the material strength and pocket configurations to meet specific industry needs. While they may lack the aesthetic appeal of fashion totes, their practicality is unmatched in demanding environments.

Key Industrial Applications of rubber tote bag

| Industry/Sector | Specific Application of Rubber Tote Bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Promotional giveaways for events and sales | Enhances brand visibility and customer engagement | Quality of materials, customization options, cost-efficiency |

| Hospitality | Guest amenities for beach resorts and hotels | Provides a practical and stylish accessory for guests | Durability, weather resistance, design aesthetics |

| Food & Beverage | Catering and food delivery services | Ensures safe transport of food items | Food safety compliance, size options, insulation features |

| Travel & Tourism | Travel bags for excursions and day trips | Offers convenience and functionality for travelers | Lightweight design, portability, ease of cleaning |

| Education | School and college merchandise | Promotes school spirit and community engagement | Customization for branding, durability for everyday use |

How are Rubber Tote Bags Used in Retail Promotions?

In the retail sector, rubber tote bags serve as effective promotional giveaways during events and sales campaigns. Businesses leverage these bags to enhance brand visibility, as they can be customized with logos and designs that resonate with their target audience. This not only increases customer engagement but also provides a practical item that consumers can use repeatedly, thereby extending the brand’s reach. For international buyers, especially in regions like Africa and South America, sourcing considerations should include the quality of materials to withstand various climates and cost-efficiency to ensure a good return on investment.

What Role Do Rubber Tote Bags Play in Hospitality?

In the hospitality industry, particularly in beach resorts and hotels, rubber tote bags are often provided as guest amenities. These bags serve multiple purposes, from carrying personal items to beach essentials, thereby enhancing the guest experience. They are favored for their durability and stylish appearance, which aligns with the branding of upscale establishments. For B2B buyers in the Middle East and Europe, key sourcing factors include the bags’ weather resistance and design aesthetics to ensure they meet guest expectations and complement the resort’s image.

How Do Rubber Tote Bags Benefit Food & Beverage Services?

Rubber tote bags find significant applications in the food and beverage industry, particularly for catering and food delivery services. These bags are designed to ensure the safe transport of food items, maintaining temperature and preventing spillage. For businesses in this sector, the value lies in reliability and compliance with food safety standards. International buyers, especially from regions with stringent regulations, must consider insulation features and size options to cater to various food types and delivery requirements.

Why are Rubber Tote Bags Essential for Travel & Tourism?

In the travel and tourism sector, rubber tote bags are ideal for excursions and day trips, providing travelers with a convenient way to carry essentials. Their lightweight design and portability make them a favorite among tourists seeking practicality without sacrificing style. For B2B buyers, particularly in Europe and South America, sourcing considerations should focus on ease of cleaning and the bag’s ability to endure rough handling during travel.

How Do Rubber Tote Bags Support Educational Institutions?

Educational institutions utilize rubber tote bags as merchandise to promote school spirit and community engagement. These bags can be customized with school logos and colors, making them popular among students and alumni alike. For international buyers in regions like Africa and Brazil, it is crucial to consider customization options for branding and the durability of the bags to withstand everyday use by students. This not only fosters a sense of belonging but also serves as a practical item for carrying books and supplies.

3 Common User Pain Points for ‘rubber tote bag’ & Their Solutions

Scenario 1: Limited Durability for Daily Use

The Problem: B2B buyers often face the challenge of sourcing rubber tote bags that can withstand the rigors of daily use, especially in industries like retail and logistics. Many suppliers offer bags that may seem appealing initially but quickly deteriorate under heavy loads or adverse weather conditions. This can lead to dissatisfaction among clients and increased costs due to frequent replacements, which negatively impacts profit margins and brand reputation.

The Solution: To overcome durability issues, B2B buyers should prioritize sourcing rubber tote bags made from high-quality, reinforced materials. Look for specifications that detail the thickness and tensile strength of the rubber, as these factors significantly influence longevity. Additionally, consider bags with reinforced seams and sturdy handles that can bear heavy weights without ripping. Engaging with manufacturers who provide samples or test bags before bulk purchases can also help ensure that the selected products meet durability expectations. Establishing long-term relationships with reliable suppliers who focus on quality control will further safeguard against future issues.

Scenario 2: Difficulty in Customization and Branding

The Problem: For businesses looking to enhance brand visibility, the inability to customize rubber tote bags can be a significant drawback. Many suppliers may offer limited color options or printing capabilities, making it challenging for buyers to find a product that aligns with their branding strategies. This can lead to missed marketing opportunities, especially in competitive markets where differentiation is crucial.

The Solution: Buyers should seek out suppliers who specialize in customizable rubber tote bags, offering a wide range of colors, sizes, and printing techniques. When evaluating suppliers, inquire about their capabilities for screen printing, heat transfer, or embossing logos on the bags. It’s also beneficial to request examples of previous custom orders to assess the quality of their work. Furthermore, consider suppliers that allow for smaller minimum order quantities for customized products, enabling businesses to test market reactions without committing to large inventories. This approach not only enhances brand visibility but also helps establish a unique identity in the marketplace.

Scenario 3: Eco-Consciousness and Sustainability Concerns

The Problem: With increasing awareness of environmental issues, B2B buyers are often concerned about the sustainability of the products they source, including rubber tote bags. Many traditional rubber products can be harmful to the environment, and companies that do not prioritize sustainability may face backlash from consumers and clients. This creates a dilemma for buyers who wish to maintain eco-friendly practices while still fulfilling their operational needs.

The Solution: To address these concerns, buyers should actively seek out suppliers that offer eco-friendly rubber tote bags made from recycled or sustainably sourced materials. Look for certifications that validate the environmental claims, such as Global Recycled Standard (GRS) or OEKO-TEX certification. Engaging with suppliers who are transparent about their manufacturing processes and material sourcing can also enhance credibility. Additionally, consider integrating sustainability messaging into marketing materials, highlighting the eco-friendly aspect of the products to appeal to environmentally conscious consumers. This not only aligns with corporate responsibility goals but also strengthens brand loyalty among eco-aware customers.

Strategic Material Selection Guide for rubber tote bag

When selecting materials for rubber tote bags, it’s essential to consider various factors that affect performance, durability, and overall suitability for specific applications. Below, we analyze four common materials used in the production of rubber tote bags, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of PVC for Rubber Tote Bags?

Polyvinyl Chloride (PVC) is a widely used synthetic plastic polymer known for its versatility. Key properties include excellent resistance to moisture and chemicals, making it suitable for outdoor and beach environments. PVC can withstand temperatures ranging from -15°C to 60°C, ensuring it performs well in various climates.

Pros: PVC is cost-effective and readily available, making it a popular choice for manufacturers. Its durability allows for long-lasting products, and it can be easily molded into various shapes and designs.

Cons: However, PVC is less environmentally friendly compared to other materials, as it can release harmful chemicals during production and disposal. Additionally, it may become brittle over time when exposed to UV light, reducing its lifespan.

How Does Neoprene Compare as a Material for Rubber Tote Bags?

Neoprene is a synthetic rubber that offers excellent elasticity and resistance to heat and chemicals. It typically performs well in temperatures from -40°C to 120°C, making it suitable for a range of applications.

Pros: Neoprene is highly durable and resistant to wear and tear, which is advantageous for tote bags that see frequent use. It also provides good insulation, making it suitable for carrying temperature-sensitive items.

Cons: The primary drawback of neoprene is its higher cost compared to PVC. Additionally, its manufacturing process can be more complex, leading to longer production times.

What Are the Benefits of Using Thermoplastic Elastomers (TPE) in Rubber Tote Bags?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, offering flexibility and durability. TPEs can withstand temperatures from -30°C to 80°C, making them versatile for various conditions.

Pros: TPE is highly elastic and resistant to UV light, which helps maintain its appearance over time. It is also recyclable, aligning with increasing global sustainability trends.

Cons: The main limitation of TPE is its cost, which is generally higher than traditional rubber materials. Additionally, TPEs may not provide the same level of chemical resistance as PVC or neoprene.

What Should International Buyers Consider When Choosing Rubber Tote Bag Materials?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, compliance with local and international standards is crucial. Common standards include ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Buyers should also consider the environmental impact of materials, as there is a growing demand for sustainable products.

Furthermore, regional preferences may influence material choice. For instance, buyers in Europe may prioritize eco-friendly materials, while those in the Middle East might focus on durability in extreme temperatures.

Summary Table of Material Selection for Rubber Tote Bags

| Material | Typical Use Case for rubber tote bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Beach and casual tote bags | Cost-effective and durable | Environmental concerns and UV brittleness | Low |

| Neoprene | Insulated and high-use tote bags | Excellent durability and insulation | Higher cost and complex manufacturing | High |

| Thermoplastic Elastomers | Versatile everyday tote bags | Elasticity and UV resistance | Higher cost and limited chemical resistance | Medium |

| Rubber | Heavy-duty and industrial tote bags | Strong and durable | Heavier and less flexible than alternatives | Medium |

By carefully considering these materials and their respective properties, advantages, and limitations, international B2B buyers can make informed decisions that align with their product requirements and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber tote bag

What are the Main Stages of Manufacturing Rubber Tote Bags?

The manufacturing process of rubber tote bags involves several key stages, each critical for ensuring the final product meets both quality and functional requirements.

1. Material Preparation

The first step in the production of rubber tote bags is material preparation. This typically involves sourcing high-quality rubber, which may be natural or synthetic, depending on the desired characteristics of the final product. Before production, the rubber is processed to remove impurities and ensure consistency in texture and elasticity. Additionally, additives such as colorants, UV inhibitors, and anti-fungal agents may be incorporated to enhance durability and appearance.

2. Forming

Once the materials are prepared, the next stage is forming. This process usually employs techniques like injection molding or extrusion. In injection molding, molten rubber is injected into a mold that shapes the tote bag. This method allows for intricate designs and uniform thickness. Alternatively, extrusion involves forcing rubber through a die to create sheets or continuous shapes, which can be cut and sewn into the desired bag design.

3. Assembly

After forming, the rubber components are assembled. This stage often involves cutting the molded or extruded rubber into the appropriate shapes and sizes, followed by stitching or bonding the pieces together. High-frequency welding techniques are also common for creating seams without stitching, which can enhance waterproof capabilities. Accessories such as handles, zippers, and pockets are added during this phase, ensuring that the final product is both functional and aesthetically pleasing.

4. Finishing

The final manufacturing stage is finishing, where the bags undergo surface treatment to improve their appearance and functionality. This may include processes such as polishing, applying coatings for additional waterproofing, or adding decorative elements. Quality checks are conducted during this stage to ensure that all bags meet the required specifications before they are packaged for shipment.

What International Quality Standards Should B2B Buyers Consider?

For B2B buyers, understanding the quality assurance processes in the manufacturing of rubber tote bags is crucial. Various international standards can guide the evaluation of product quality.

ISO 9001 Certification

ISO 9001 is a widely recognized standard that outlines the criteria for a quality management system. Manufacturers who achieve this certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements. B2B buyers should prioritize suppliers with ISO 9001 certification as it indicates a commitment to quality and continuous improvement.

CE Marking

For products sold within the European Economic Area (EEA), CE marking is crucial. It signifies that the product complies with EU safety, health, and environmental protection standards. B2B buyers in Europe, particularly those from countries like Germany, should ensure that their suppliers can provide evidence of CE compliance for rubber tote bags.

API Standards

In specific industries, such as oil and gas or healthcare, adherence to American Petroleum Institute (API) standards may be necessary. These standards ensure that products meet rigorous safety and quality criteria, particularly for applications involving hazardous materials.

What Quality Control Checkpoints are Essential in the Manufacturing Process?

Quality control (QC) is integral to the manufacturing process of rubber tote bags. Several checkpoints are established to ensure that products meet the required specifications throughout the production process.

Incoming Quality Control (IQC)

The first checkpoint occurs during Incoming Quality Control (IQC). This involves inspecting raw materials upon arrival to ensure they meet specified standards. This step helps to prevent defects caused by subpar materials, which can lead to product failures down the line.

In-Process Quality Control (IPQC)

During the manufacturing process, In-Process Quality Control (IPQC) is implemented. This involves regular inspections at various stages of production, such as during forming and assembly. IPQC helps identify defects early, allowing for corrective actions before the product reaches the finishing stage.

Final Quality Control (FQC)

Finally, Final Quality Control (FQC) is conducted before packaging and shipping. This thorough inspection checks for overall product integrity, including dimensions, functionality, and aesthetic quality. It is the last opportunity to ensure that the products meet customer expectations and regulatory standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of suppliers is essential to ensure the reliability of their products. Here are some effective strategies to achieve this:

Conducting Supplier Audits

One of the most effective ways to verify a supplier’s quality control processes is through on-site audits. By visiting the manufacturing facility, buyers can assess the production methods, quality management systems, and adherence to international standards firsthand. This also provides an opportunity to discuss any concerns directly with the supplier.

Requesting Quality Control Reports

B2B buyers should request comprehensive quality control reports from their suppliers. These reports should detail the results of IQC, IPQC, and FQC processes, including any corrective actions taken for identified issues. Consistent and transparent reporting indicates a supplier’s commitment to quality.

Engaging Third-Party Inspectors

Employing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspectors can conduct random checks during production and provide detailed reports on compliance with international standards and specifications.

What Nuances Should International Buyers Consider in Quality Control?

International buyers, particularly those in Africa, South America, and the Middle East, should be aware of specific nuances when it comes to quality control in rubber tote bag manufacturing.

Understanding Regional Standards

Different regions may have unique quality standards and regulations. Buyers should familiarize themselves with the specific requirements in their target markets to ensure compliance. For instance, products imported into the EU must meet specific CE marking requirements, while buyers in the Middle East may need to adhere to Gulf Standards Organization (GSO) regulations.

Currency and Payment Terms

When engaging with international suppliers, currency fluctuations can impact pricing and payment terms. Buyers should negotiate clear payment terms and consider including clauses that account for currency changes to protect their investments.

Cultural Sensitivity in Communication

Cultural differences can influence communication and business practices. B2B buyers should approach negotiations and discussions with an understanding of local customs and practices to foster better relationships with suppliers.

By paying close attention to these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions that enhance their supply chain reliability and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber tote bag’

When sourcing rubber tote bags for your business, it’s essential to follow a systematic approach that ensures quality, compliance, and alignment with your business needs. This guide will provide you with a comprehensive checklist to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Establish clear specifications for the rubber tote bags you intend to purchase. Consider factors such as size, color, material quality, and any additional features like waterproofing or reinforced straps. Defining these requirements upfront helps streamline the sourcing process and ensures that the products meet your operational needs.

Step 2: Conduct Market Research

Research the market to identify potential suppliers and understand current pricing trends. Look for suppliers that specialize in rubber products and assess their reputations through online reviews and industry feedback. This step is crucial to ensure that you are aware of available options and can make informed decisions based on quality and cost.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider the following:

– Supplier Experience: Look for suppliers with a proven track record in producing rubber tote bags.

– Production Capacity: Ensure they can meet your demand in terms of volume and delivery timelines.

Step 4: Verify Compliance and Certifications

Check that potential suppliers comply with relevant industry standards and regulations, particularly those pertaining to environmental safety and product quality. Certifications such as ISO 9001 or similar can indicate a commitment to quality management. This step is vital to mitigate risks associated with product recalls or compliance violations.

Step 5: Request Samples

Always request samples before finalizing any order. Evaluating the quality, durability, and design of the rubber tote bags firsthand allows you to make a more informed decision. Look for:

– Material Quality: Assess the thickness and flexibility of the rubber.

– Finishing Details: Examine stitching, handles, and any additional features to ensure they meet your standards.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms including pricing, payment schedules, and delivery timelines. Clear agreements on these aspects can prevent misunderstandings and ensure smoother transactions. Pay attention to:

– Minimum Order Quantities: Ensure they align with your purchasing capabilities.

– Return Policies: Understand the process for handling defective items or unsatisfactory products.

Step 7: Establish a Relationship with Your Supplier

Building a strong relationship with your supplier can lead to better service and potential cost savings in the long run. Maintain open lines of communication, provide feedback on product quality, and discuss future needs. A collaborative approach fosters trust and can enhance your supply chain efficiency.

By following these steps, you can effectively source rubber tote bags that meet your business needs while ensuring quality and compliance throughout the procurement process.

Comprehensive Cost and Pricing Analysis for rubber tote bag Sourcing

What Are the Key Cost Components in Sourcing Rubber Tote Bags?

When sourcing rubber tote bags for international markets, understanding the cost structure is crucial for B2B buyers. The main cost components include:

-

Materials: The type and quality of rubber significantly affect costs. Natural rubber tends to be more expensive but offers superior durability compared to synthetic alternatives. Additionally, any additives for color or texture will also impact material costs.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the potential trade-offs in quality and craftsmanship.

-

Manufacturing Overhead: This encompasses costs related to the facilities, utilities, and administrative expenses of the manufacturing process. Efficient manufacturers often pass on savings to buyers, so it’s beneficial to assess the operational efficiency of potential suppliers.

-

Tooling: Custom molds and tooling for specific designs can represent a significant initial investment. Buyers should evaluate the potential return on this investment based on expected order volumes.

-

Quality Control (QC): Robust QC processes ensure the final products meet required standards, which can add to the overall cost. However, investing in QC can reduce returns and enhance customer satisfaction.

-

Logistics: Transportation costs can fluctuate based on distance, shipping methods, and the selected Incoterms. Understanding logistics is crucial for total cost estimation.

-

Margin: Suppliers typically apply a margin to cover their costs and profit. This can vary based on the supplier’s market position and the complexity of the product.

How Do Price Influencers Impact the Cost of Rubber Tote Bags?

Several factors influence the pricing of rubber tote bags in the B2B market:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes can lead to significant price reductions due to economies of scale. Buyers should negotiate MOQs that align with their sales forecasts to optimize costs.

-

Specifications and Customization: Custom designs, sizes, and features can increase costs. Clear specifications can help suppliers provide accurate quotes and minimize unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., eco-friendly or safety standards) can justify higher prices. Buyers should assess the value of these certifications against their target market’s demands.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers with a proven track record may charge a premium but offer peace of mind regarding quality and delivery times.

-

Incoterms: Understanding Incoterms is vital as they define the responsibilities of buyers and sellers in shipping arrangements. Different terms can lead to varying costs and risks associated with logistics.

What Are the Best Practices for Negotiating Rubber Tote Bag Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiation is key to achieving cost efficiencies:

-

Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including shipping, customs, and potential returns. This comprehensive view can aid in more informed negotiations.

-

Leverage Relationships: Building a strong relationship with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable deals compared to one-off transactions.

-

Be Transparent: Sharing your purchasing forecasts and needs can encourage suppliers to offer better pricing and terms. Transparency fosters trust and can lead to mutually beneficial agreements.

-

Monitor Market Trends: Keeping an eye on market trends and competitor pricing can provide leverage during negotiations. Being informed allows buyers to push back against unjustified price increases.

Conclusion: Why Is It Important to Understand Pricing Nuances?

Understanding the nuances of rubber tote bag pricing is essential for international B2B buyers to ensure cost-effective sourcing. By analyzing cost components and price influencers, buyers can make informed decisions that enhance their supply chain efficiency. As always, it is recommended to seek multiple quotes and conduct thorough due diligence before finalizing any supplier agreements.

Disclaimer: The prices discussed herein are indicative and may vary based on specific supplier negotiations and market conditions.

Alternatives Analysis: Comparing rubber tote bag With Other Solutions

Understanding Alternatives for Rubber Tote Bags in B2B Applications

When considering the best solutions for transporting goods, promotional materials, or personal items, businesses often face a choice between various products. Rubber tote bags are a popular option due to their durability and versatility. However, it is essential to evaluate alternative solutions that can also meet business needs effectively. This analysis compares rubber tote bags against two viable alternatives: canvas tote bags and polypropylene bags, focusing on key performance factors.

| Comparison Aspect | Rubber Tote Bag | Canvas Tote Bag | Polypropylene Bag |

|---|---|---|---|

| Performance | Highly durable, waterproof, and resistant to wear | Strong but less water-resistant; limited lifespan | Lightweight, strong, and waterproof |

| Cost | Mid-range ($60-$120) | Generally lower ($10-$40) | Low-cost ($0.50-$5) |

| Ease of Implementation | Readily available in various designs and colors | Easy to print and customize | Simple to source; available in bulk |

| Maintenance | Low maintenance; easy to clean | Requires more care; may fade over time | Low maintenance; easily recyclable |

| Best Use Case | Ideal for outdoor and beach activities | Best for promotional events and daily use | Suitable for bulk shipping and lightweight storage |

What Are the Advantages and Disadvantages of Canvas Tote Bags?

Canvas tote bags are a popular alternative due to their eco-friendly nature and customization potential. They are made from natural fibers, making them more sustainable than synthetic options. Canvas bags can be printed with company logos or designs, enhancing branding during promotional events. However, they are not as waterproof as rubber bags and can absorb moisture, potentially leading to mold or mildew if not dried properly. Their lifespan is generally shorter compared to rubber options, particularly with frequent use in wet conditions.

How Do Polypropylene Bags Compare to Rubber Tote Bags?

Polypropylene bags are an economical choice for businesses looking for lightweight and durable solutions. They are waterproof and resistant to tears, making them suitable for shipping and storage. Their cost-effectiveness, with prices as low as $0.50 per bag, is appealing for companies operating on tight budgets. However, polypropylene bags lack the aesthetic appeal and branding opportunities offered by rubber and canvas bags. They are typically less sturdy for everyday use and may not convey the same quality image as more robust options.

Conclusion: How to Choose the Right Bag for Your Business Needs

Selecting the right bag for your business requires careful consideration of your specific needs and circumstances. Rubber tote bags stand out for their durability and versatility, especially for outdoor activities or high-end branding. On the other hand, canvas tote bags offer customization and a sustainable option for promotional efforts, while polypropylene bags are ideal for cost-sensitive projects focusing on bulk transportation. Understanding these alternatives will empower B2B buyers to make informed decisions that align with their operational requirements and brand image.

Essential Technical Properties and Trade Terminology for rubber tote bag

What Are the Key Technical Properties of Rubber Tote Bags for B2B Buyers?

When sourcing rubber tote bags for commercial purposes, understanding their technical properties is crucial. Here are some essential specifications to consider:

1. Material Grade

Rubber tote bags are often made from various grades of synthetic rubber or natural rubber. The material grade affects durability, flexibility, and resistance to environmental factors such as UV exposure and water. For B2B buyers, selecting the appropriate material grade ensures that the bags meet the required performance standards for specific applications, such as outdoor events or retail use.

2. Tolerance

Tolerance refers to the allowable variation in dimensions and specifications during the manufacturing process. It is essential for ensuring that the tote bags are consistent in size and shape, which is critical for stacking, shipping, and display purposes. For international buyers, understanding tolerance levels can help mitigate issues related to product quality and compatibility with existing inventory systems.

3. Weight Capacity

The weight capacity of a rubber tote bag indicates how much load it can safely carry without compromising structural integrity. This property is vital for B2B buyers, especially those in retail or promotional sectors, as it impacts customer satisfaction and the overall utility of the product. Ensuring that the bags have an adequate weight capacity can prevent returns and enhance customer loyalty.

4. Waterproof Rating

Many rubber tote bags are designed to be waterproof, making them suitable for various applications, including beach outings and outdoor activities. The waterproof rating is typically measured in millimeters of water resistance. For B2B buyers, this property is essential for marketing purposes and can be a unique selling point, especially in regions with high rainfall or humidity.

5. Customization Options

Customization options, such as color, size, and branding capabilities, are important for businesses looking to create a unique identity. Many suppliers offer a range of customization, which can enhance brand visibility and appeal to target markets. Understanding the available customization options helps B2B buyers align their product offerings with customer expectations.

What Are Common Trade Terminology Terms Related to Rubber Tote Bags?

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rubber tote bags, buyers may work with OEMs to create custom designs or specifications that fit their branding needs. Understanding OEM relationships is crucial for negotiating terms and ensuring product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest order that a supplier is willing to accept. This term is significant for B2B buyers as it affects inventory levels and cash flow management. Knowing the MOQ allows businesses to plan their purchases effectively and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability for specific products. For buyers, issuing an RFQ for rubber tote bags can streamline the procurement process and enable comparison of multiple suppliers, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping responsibilities, risk allocation, and cost implications, which are critical for effective supply chain management.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is essential for inventory planning and meeting customer demands. Longer lead times may require advanced planning, especially in seasonal or promotional contexts.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing rubber tote bags, enhancing their operational efficiency and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the rubber tote bag Sector

What Are the Key Trends Influencing the Global Rubber Tote Bag Market?

The global rubber tote bag market is experiencing significant growth driven by various factors. Firstly, the increasing consumer preference for durable, waterproof, and versatile bags is shaping product offerings. Rubber tote bags, known for their resilience and ease of cleaning, are particularly appealing to consumers in regions with diverse climates, such as Africa and the Middle East. Additionally, the rise of eco-consciousness among consumers is influencing buying behaviors, pushing manufacturers to innovate with sustainable materials and production methods.

Emerging B2B tech trends, including the adoption of e-commerce platforms and digital marketplaces, are facilitating international trade in the rubber tote bag sector. This is particularly relevant for buyers from South America and Europe, where online shopping has surged. Moreover, advancements in supply chain management technology, such as blockchain for traceability and AI for demand forecasting, are improving operational efficiency and transparency for B2B buyers.

In terms of market dynamics, competition is intensifying as new entrants leverage unique designs and customizable options to differentiate their products. The trend of personalization, where businesses offer tailored designs for corporate branding or promotional events, is gaining traction. International buyers must stay attuned to these trends to ensure they source products that meet evolving consumer expectations and market demands.

How Important Is Sustainability and Ethical Sourcing in the Rubber Tote Bag Industry?

Sustainability and ethical sourcing have become paramount in the rubber tote bag industry. As consumers increasingly prioritize environmental responsibility, B2B buyers are urged to seek suppliers who demonstrate commitment to eco-friendly practices. This includes the use of recycled materials, sustainable rubber sourcing, and low-impact manufacturing processes that minimize carbon footprints.

Moreover, certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can enhance product credibility and appeal to eco-conscious consumers. For buyers in Europe, particularly in Germany, these certifications are often critical factors in purchasing decisions. The emphasis on ethical supply chains extends beyond materials; it also encompasses fair labor practices and transparency in sourcing, which are essential for building trust with consumers.

Investing in sustainable and ethically sourced rubber tote bags not only aligns with global environmental goals but can also provide a competitive advantage in the marketplace. As regulations surrounding sustainability tighten, particularly in regions like the EU, B2B buyers who prioritize these values will likely find themselves better positioned to navigate future market challenges.

What Is the Historical Context of Rubber Tote Bags in B2B Markets?

The evolution of rubber tote bags traces back to the early 20th century, originally designed for practical uses such as carrying goods in various industries. However, their journey into the fashion and lifestyle sectors began in the late 20th century, coinciding with the rise of casual, outdoor lifestyles. This shift led to the development of more stylish, colorful, and functional designs, appealing to a broader audience.

In recent years, the integration of technology into manufacturing processes has transformed the rubber tote bag sector. Innovations such as waterproof coatings and customizable features have made these bags not only functional but also trendy. For B2B buyers, understanding this historical context is essential as it highlights the adaptability of rubber tote bags to changing consumer preferences, reinforcing their relevance in today’s diverse market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber tote bag

-

How do I choose the right rubber tote bag for my business needs?

When selecting rubber tote bags for your business, consider factors such as the intended use, size, durability, and design. Evaluate the bag’s material quality to ensure it withstands wear and tear, especially if used for outdoor activities or transport. Additionally, think about branding opportunities—customizable options allow you to add your logo or unique design. Assess the target market demographics to select colors and styles that resonate with your audience, ensuring the bags align with your brand image. -

What are the key features to look for in a high-quality rubber tote bag?

A high-quality rubber tote bag should possess durability, waterproof properties, and ease of cleaning. Look for bags made from thick, flexible rubber that can handle heavy loads without tearing. Features like reinforced handles, breathable materials, and additional compartments for organization enhance functionality. Consider bags with UV protection if they will be exposed to sunlight frequently, ensuring that colors remain vibrant over time. Lastly, check for any certifications that guarantee the bag’s safety and environmental standards. -

What is the minimum order quantity (MOQ) for rubber tote bags?

Minimum order quantities for rubber tote bags can vary significantly among suppliers. Generally, MOQs may range from 50 to 500 units depending on the manufacturer and customization options. It’s crucial to discuss your specific requirements with potential suppliers to understand their MOQ policies. Some manufacturers may offer flexibility for new businesses or bulk order discounts, so it’s beneficial to negotiate terms that align with your purchasing strategy and budget. -

How can I verify the credibility of a rubber tote bag supplier?

To ensure a supplier’s credibility, start by checking their business licenses and certifications. Look for reviews or testimonials from previous clients and request references. Conduct a background check on their production capabilities, quality control processes, and delivery timelines. If possible, visit their manufacturing facility or attend trade shows to assess their operations firsthand. Using platforms like Alibaba or Global Sources can also provide insights into supplier ratings and transaction histories. -

What payment terms are typically offered by rubber tote bag suppliers?

Payment terms can vary widely based on the supplier’s policies and the buyer’s negotiation. Common options include upfront payment, partial payment with the balance due upon delivery, or payment after inspection. Many suppliers prefer secure methods such as PayPal, bank transfers, or letters of credit. Be sure to clarify payment terms before finalizing any agreements to avoid misunderstandings. Establishing trust through clear communication about payment schedules can facilitate smoother transactions. -

What logistics considerations should I keep in mind when importing rubber tote bags?

When importing rubber tote bags, consider shipping methods, customs regulations, and associated costs. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your timeline and budget. Familiarize yourself with the customs clearance process, including tariffs and import duties applicable in your country. Engaging a freight forwarder can help streamline logistics, ensuring that your goods arrive on time and comply with local regulations. -

How can I customize rubber tote bags to enhance my brand identity?

Customizing rubber tote bags can significantly enhance brand visibility. Start by selecting colors and designs that align with your brand’s aesthetic. Consider adding your logo, tagline, or unique patterns through printing or embossing techniques. You might also explore functional customizations, such as pockets or compartments that cater to your target audience’s needs. Collaborate with your supplier to discuss available customization options and ensure they can meet your quality and design expectations. -

What quality assurance measures should I implement when sourcing rubber tote bags?

To maintain quality assurance, establish clear specifications for your rubber tote bags, including material standards and manufacturing processes. Request samples before placing large orders to assess quality firsthand. Implement regular inspections during production and upon delivery to ensure compliance with your standards. Consider third-party quality control services for additional oversight, especially when sourcing from international suppliers. Having a robust quality assurance strategy can mitigate risks and ensure that your products meet customer expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Rubber Tote Bag Manufacturers & Suppliers List

1. BOGG BAG – The Original Bogg Bag

Domain: boggbag.com

Registered: 2008 (17 years)

Introduction: BOGG BAG offers a variety of bags and accessories designed for beach and everyday use. Key products include: 1. The Original Bogg Bag – Large Tote, available in 79 colors, priced at $100. 2. Baby Bogg Bag – Medium Tote, available in 91 colors, priced at $80. 3. Bitty Bogg Bag – Small Tote, available in 74 colors, priced at $60. 4. Bogg Decorative Insert Zipper Pouch Set, available in 32 colors, pr…

2. Target – Durable Rubber Beach Bags

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Durable Rubber Beach Bags, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

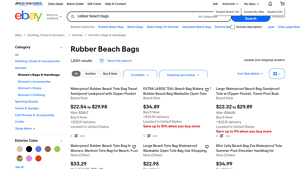

3. eBay – Rubber Beach Bags

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Rubber Beach Bags available on eBay include various styles such as Tote, Crossbody, Shoulder Bag, Satchel/Top Handle Bag, Backpack, Clutch, Hobo Bag, and Gym Bag. The bags come in multiple sizes ranging from Nano to Extra Large. The exterior colors include Beige, Black, Blue, Brown, Green, Multicolor, Pink, and White. The primary material is rubber, with options also available in plastic, PVC, nyl…

4. Facebook – Mexican Bordado Tote Bag

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Mexican Bordado Tote Bag, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Simple Modern – Beach Bag Rubber Tote

Domain: in.pinterest.com

Registered: 2009 (16 years)

Introduction: Simple Modern Beach Bag Rubber Tote

– Made of EVA Material: Lightweight, Waterproof & Easy to Clean

– Included: Detachable water-resistant zipper pocket to hold phones or small items

– Sturdy: Tip-proof and treaded non-slip bottom

Strategic Sourcing Conclusion and Outlook for rubber tote bag

In the rapidly evolving market for rubber tote bags, strategic sourcing remains a pivotal element for B2B buyers. By leveraging insights into consumer trends and supplier capabilities, companies can enhance their product offerings while ensuring sustainability and quality. The growing preference for eco-friendly materials and multifunctional designs presents a significant opportunity for businesses in Africa, South America, the Middle East, and Europe. Focusing on innovative designs and durable materials not only appeals to consumers but also strengthens brand loyalty.

As you consider your sourcing strategies, prioritize partnerships with reliable suppliers who demonstrate a commitment to sustainability and quality craftsmanship. Engaging in direct communication with manufacturers can lead to favorable pricing and customization options that align with market demands.

Looking ahead, the rubber tote bag market is set for expansion, driven by increasing environmental awareness and the versatility of these products. Now is the time to invest in strategic sourcing practices that will position your business for success in this competitive landscape. Embrace the potential of rubber tote bags and explore new avenues for growth in your international markets.