Rubber Toe Kick: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for rubber toe kick

In today’s competitive landscape, sourcing high-quality rubber toe kicks poses a significant challenge for international B2B buyers, especially those operating across diverse markets in Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Germany. As businesses strive to enhance their interior environments, the demand for durable and aesthetically pleasing rubber toe kicks has surged. This guide is meticulously crafted to navigate the complexities of the global rubber toe kick market, offering insights into various types, applications, and installation techniques that cater to both commercial and residential needs.

Buyers will find detailed information on evaluating and selecting suppliers, ensuring they partner with reputable manufacturers who adhere to international quality standards. The guide also addresses pricing dynamics, helping businesses understand cost structures and negotiate better deals. By equipping B2B buyers with actionable insights, this comprehensive resource aims to empower them to make informed purchasing decisions that align with their project requirements and budget constraints. Whether you’re outfitting a retail space or renovating an office, understanding the nuances of rubber toe kicks can significantly influence the overall success of your interior design projects. With this guide, you will be well-prepared to source effectively and ensure your spaces are both functional and visually appealing.

Understanding rubber toe kick Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rubber Toe Kick | Typically 4 inches high, available in various colors and finishes | Commercial kitchens, retail spaces | Pros: Durable, easy to clean. Cons: Limited design options. |

| Coved Rubber Toe Kick | Features a curved design for seamless wall integration | Healthcare facilities, schools | Pros: Hygienic, minimizes dirt accumulation. Cons: Higher installation cost. |

| Toeless Rubber Toe Kick | Lacks a toe, providing a sleek, modern appearance | High-end retail, offices | Pros: Aesthetic appeal, versatile installation. Cons: May require more maintenance. |

| Thermoplastic Rubber Toe Kick | Made from flexible TPR, resistant to chemicals and stains | Laboratories, industrial settings | Pros: High durability, excellent flexibility. Cons: Can be more expensive than traditional options. |

| Decorative Rubber Toe Kick | Available in various textures and patterns | Hospitality, upscale environments | Pros: Enhances visual appeal, customizable. Cons: May compromise on durability compared to standard options. |

What are the Key Characteristics of Standard Rubber Toe Kicks?

Standard rubber toe kicks are typically 4 inches in height and come in a variety of colors and finishes, making them a versatile choice for many commercial environments. They are commonly used in spaces like commercial kitchens and retail stores, where durability and ease of cleaning are paramount. Buyers should consider their specific aesthetic needs and whether the limited design options may impact their overall project goals.

How Does Coved Rubber Toe Kick Enhance Hygiene in Facilities?

Coved rubber toe kicks feature a curved design that allows for seamless integration with walls, minimizing potential dirt accumulation and making them ideal for healthcare facilities and schools. This design enhances hygiene, as it eliminates sharp corners where dirt and bacteria can gather. Buyers should weigh the higher installation costs against the long-term benefits of reduced maintenance and improved cleanliness in sensitive environments.

What Advantages Does Toeless Rubber Toe Kick Offer?

Toeless rubber toe kicks provide a sleek, modern appearance that suits high-end retail spaces and contemporary offices. Their design allows for versatile installation, as they can easily blend with various flooring types. However, buyers should be aware that while aesthetically pleasing, these options may require more frequent maintenance to keep them looking pristine.

Why Choose Thermoplastic Rubber Toe Kick for Industrial Settings?

Thermoplastic rubber (TPR) toe kicks are known for their exceptional flexibility and resistance to chemicals and stains, making them ideal for laboratories and industrial settings. Their durability ensures they withstand heavy foot traffic and harsh cleaning agents. Buyers should consider their higher upfront costs, but the long-term value and reduced replacement frequency can justify the investment.

What Makes Decorative Rubber Toe Kicks Suitable for Upscale Environments?

Decorative rubber toe kicks come in various textures and patterns, allowing businesses in the hospitality and upscale environments to enhance their visual appeal. These customizable options can significantly contribute to the overall aesthetic of a space. However, buyers should note that while they may enhance design, they could compromise some durability compared to standard rubber options, making careful selection essential.

Key Industrial Applications of rubber toe kick

| Industry/Sector | Specific Application of rubber toe kick | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Installation in hotels and restaurants | Enhances aesthetic appeal while providing wall protection | Durability, ease of maintenance, color options |

| Healthcare | Use in hospitals and clinics | Improves hygiene and safety in high-traffic areas | Non-porous material, easy to clean, compliance with health standards |

| Retail | Retail store fixtures and display areas | Protects walls from damage and enhances visual merchandising | Customizable designs, flexibility in installation, color matching with branding |

| Education | Classrooms and school facilities | Provides a safe, clean environment for students | Compliance with safety regulations, variety of colors, durability against wear |

| Manufacturing | Industrial and manufacturing facilities | Reduces maintenance costs by preventing wall damage | Resistance to chemicals, impact resistance, suitable for heavy-duty environments |

How is rubber toe kick used in the hospitality sector?

In the hospitality industry, rubber toe kicks are commonly installed in hotels and restaurants to protect walls from damage caused by foot traffic, cleaning equipment, and furniture. Their aesthetic appeal enhances the overall design of the space while providing a durable barrier against scuffs and scratches. Buyers in this sector should prioritize options that are easy to clean and available in a variety of colors to match the establishment’s branding.

What are the applications of rubber toe kick in healthcare facilities?

Healthcare facilities, such as hospitals and clinics, utilize rubber toe kicks for their hygienic properties and ability to withstand high traffic. These installations help maintain a clean environment by preventing dirt accumulation and are easy to disinfect. Buyers in this sector must ensure that the materials used comply with health standards and are non-porous to minimize germ transmission.

How do retail businesses benefit from rubber toe kicks?

In retail environments, rubber toe kicks are installed in display areas and around fixtures to protect walls from damage caused by shopping carts and foot traffic. They also enhance the visual merchandising of the store by providing a polished look. Retail buyers should focus on customizable designs that can be tailored to their branding, as well as options that offer flexibility in installation to accommodate various display configurations.

Why is rubber toe kick essential in educational institutions?

Educational institutions, such as schools and universities, employ rubber toe kicks in classrooms and hallways to create a safe and clean environment for students. These installations help prevent damage to walls from backpacks and other equipment, while also being easy to maintain. Buyers in this sector should consider durability and compliance with safety regulations, as well as a variety of color options to align with school branding.

What role does rubber toe kick play in manufacturing settings?

In manufacturing facilities, rubber toe kicks are used to protect walls from damage caused by machinery and heavy equipment. These toe kicks help reduce maintenance costs by preventing wear and tear on wall surfaces. Buyers in this industry should prioritize materials that offer resistance to chemicals and impacts, ensuring longevity and performance in a heavy-duty environment.

3 Common User Pain Points for ‘rubber toe kick’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Rubber Toe Kicks

The Problem: B2B buyers often face challenges when sourcing rubber toe kicks that meet specific quality standards. Many suppliers may offer low-cost options that compromise on durability, leading to rapid wear and tear. This is especially concerning for businesses in sectors like retail or healthcare, where maintaining a polished appearance is crucial. Buyers may struggle with identifying reliable suppliers who can provide consistent quality, colors, and styles that align with their brand’s image.

The Solution: To overcome this sourcing challenge, buyers should establish partnerships with reputable suppliers who specialize in rubber products. Conduct thorough research to evaluate suppliers’ certifications, customer reviews, and past projects. Request samples to assess the material’s quality before making bulk purchases. Additionally, consider suppliers that offer customization options, allowing you to specify colors, sizes, and styles that align with your branding. Building strong supplier relationships can also lead to better pricing and priority service, ensuring that you receive high-quality products consistently.

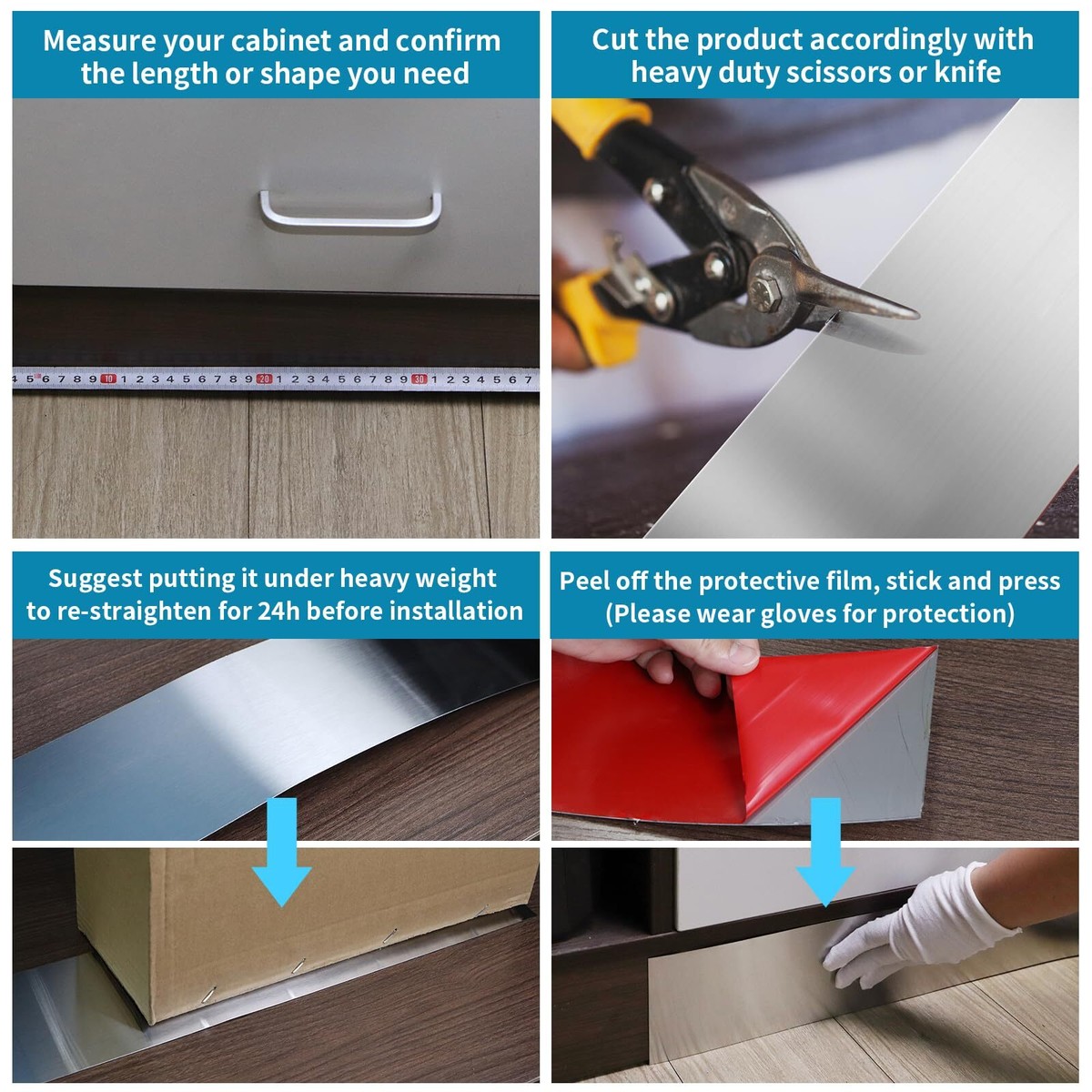

Scenario 2: Installation Challenges with Rubber Toe Kicks

The Problem: Installation of rubber toe kicks can be a complicated process, particularly in spaces with uneven floors or intricate designs. Misalignment during installation can lead to visible gaps and aesthetic issues, which can detract from the overall finish of a space. This is a significant concern for contractors and facility managers who need to ensure a professional look while adhering to tight project timelines.

The Solution: To facilitate a smoother installation process, it is essential to invest in proper training and utilize specialized installation tools. Collaborate with manufacturers that provide detailed installation guides or even on-site training for your team. Consider using adhesive specifically designed for rubber materials to ensure a strong bond and prevent future issues. When dealing with uneven surfaces, use leveling compounds to create a flat base for the toe kicks. Taking the time to prepare adequately can save you both time and resources in the long run.

Scenario 3: Maintenance and Longevity Concerns for Rubber Toe Kicks

The Problem: B2B buyers often express concerns about the maintenance and longevity of rubber toe kicks, especially in high-traffic areas. Over time, rubber can become scuffed, stained, or degraded, leading to an unprofessional appearance. Buyers in industries such as hospitality and healthcare must maintain a clean, polished look, and any deterioration can significantly impact customer perceptions and satisfaction.

The Solution: To enhance the longevity of rubber toe kicks, establish a proactive maintenance schedule. Regular cleaning with pH-neutral cleaners can help prevent the accumulation of dirt and stains. Additionally, consider applying protective coatings that can shield against scratches and scuffs, particularly in high-traffic environments. Educate staff on proper cleaning techniques and the importance of reporting any damage early. By taking these steps, businesses can ensure that their rubber toe kicks remain in excellent condition, ultimately reducing replacement costs and maintaining a professional appearance.

Strategic Material Selection Guide for rubber toe kick

What Are the Key Properties of Common Materials for Rubber Toe Kicks?

When selecting materials for rubber toe kicks, it is essential to consider various options that offer distinct advantages and limitations based on performance, durability, and cost. Below, we analyze four common materials used in rubber toe kicks: Natural Rubber, Thermoplastic Rubber (TPR), Vinyl, and EPDM Rubber.

How Does Natural Rubber Perform in Rubber Toe Kicks?

Natural rubber is known for its excellent elasticity and resilience, making it a popular choice for rubber toe kicks. It can withstand a range of temperatures and pressures, providing a high level of durability in various environments. However, natural rubber is susceptible to degradation from UV exposure and certain chemicals, which can limit its application in outdoor or harsh environments.

Pros:

– High elasticity and flexibility

– Good abrasion resistance

– Cost-effective for bulk orders

Cons:

– Limited UV resistance

– Prone to chemical degradation

For international buyers, particularly in regions with high UV exposure like Africa and the Middle East, it is crucial to consider the environmental conditions that may affect the longevity of natural rubber toe kicks. Compliance with local standards, such as ASTM for the U.S. market, is also important.

Illustrative image related to rubber toe kick

What Advantages Does Thermoplastic Rubber (TPR) Offer?

Thermoplastic rubber (TPR) combines the properties of rubber and plastic, offering a versatile option for rubber toe kicks. TPR is resistant to UV light, chemicals, and extreme temperatures, making it suitable for both indoor and outdoor applications. Its manufacturing process is relatively straightforward, allowing for a variety of shapes and colors.

Pros:

– Excellent chemical and UV resistance

– Versatile design options

– Easy to manufacture and install

Cons:

– Higher cost compared to natural rubber

– Can be less durable under extreme mechanical stress

For B2B buyers in Europe and South America, TPR may be favored due to its compliance with environmental regulations and standards such as DIN in Germany, which emphasizes durability and safety.

Why Consider Vinyl for Rubber Toe Kicks?

Vinyl is another common material used in rubber toe kicks, known for its affordability and ease of maintenance. It is resistant to moisture and many chemicals, making it suitable for environments like kitchens and bathrooms. However, vinyl may not provide the same level of durability and flexibility as rubber materials.

Pros:

– Cost-effective and widely available

– Resistant to moisture and chemicals

– Easy to clean and maintain

Cons:

– Less flexible than rubber options

– Can become brittle over time

International buyers should consider the cost-effectiveness of vinyl, especially in large projects. Compliance with standards such as ASTM or JIS for quality assurance can further enhance the product’s marketability.

What Makes EPDM Rubber a Viable Option?

EPDM (Ethylene Propylene Diene Monomer) rubber is highly regarded for its weather resistance and durability, making it suitable for outdoor applications. EPDM is resistant to UV rays, ozone, and extreme temperatures, which enhances its lifespan. However, it can be more expensive than other rubber options.

Pros:

– Exceptional weather resistance

– Long lifespan and durability

– Suitable for outdoor applications

Cons:

– Higher cost compared to other rubber materials

– More complex manufacturing process

For international buyers, particularly in regions with extreme weather conditions, EPDM rubber toe kicks may be an ideal choice. Compliance with local and international standards can facilitate market entry and acceptance.

Summary Table of Material Selection for Rubber Toe Kicks

| Material | Typical Use Case for Rubber Toe Kick | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Indoor applications with moderate wear | High elasticity and flexibility | Limited UV resistance | Low |

| Thermoplastic Rubber (TPR) | Versatile applications, indoor/outdoor | Excellent UV and chemical resistance | Higher cost compared to natural rubber | Medium |

| Vinyl | Kitchens, bathrooms, low-traffic areas | Cost-effective and easy to maintain | Less flexible, can become brittle | Low |

| EPDM Rubber | Outdoor applications, extreme weather | Exceptional weather resistance | Higher cost, complex manufacturing | High |

This guide provides a comprehensive overview of material options for rubber toe kicks, aiding B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber toe kick

What Are the Key Stages in the Manufacturing Process of Rubber Toe Kicks?

The manufacturing process of rubber toe kicks involves several critical stages that ensure high-quality products suitable for various applications. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing rubber toe kicks is sourcing and preparing the raw materials. Typically, high-grade rubber compounds, including thermoplastic rubber (TPR), are chosen for their durability and flexibility. These materials are often mixed with additives to enhance properties such as UV resistance, color stability, and overall strength. Suppliers should ensure that the rubber meets industry standards and specifications for the intended use.

-

Forming: After preparation, the rubber is shaped into the desired form. This can be done through several techniques, including extrusion and molding. In extrusion, the rubber compound is forced through a die to create continuous profiles, which can be cut to length. Molding, on the other hand, involves placing the rubber in a pre-shaped mold and applying heat and pressure to achieve the final shape. Both methods require precise control of temperature and pressure to maintain product integrity.

-

Assembly: Once the components are formed, they may require assembly. This stage could involve joining multiple pieces, especially in designs that include cove bases or integrated features. Adhesives or mechanical fasteners may be used, depending on the design requirements. The assembly process must be performed under strict guidelines to ensure consistency and durability.

-

Finishing: The final stage is finishing, where the rubber toe kicks undergo surface treatments to enhance aesthetics and functionality. This may include buffing, painting, or applying protective coatings. A thorough inspection is crucial at this stage to ensure that the finished products meet the specified quality standards.

What Quality Assurance Measures Should Be Implemented for Rubber Toe Kicks?

Quality assurance (QA) is essential in the production of rubber toe kicks to ensure that they meet the necessary international standards and customer expectations. Implementing a robust QA framework involves adhering to recognized standards, conducting regular inspections, and employing various testing methods.

Illustrative image related to rubber toe kick

-

International Standards and Certifications: To ensure quality, manufacturers should comply with international standards such as ISO 9001, which focuses on quality management systems. Certifications like CE mark for products sold in Europe and API (American Petroleum Institute) standards for rubber products used in specific industries are also crucial. These certifications demonstrate a commitment to quality and safety.

-

Quality Control Checkpoints: Quality control should be integrated throughout the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): Inspecting raw materials upon receipt to verify compliance with specifications.

– In-Process Quality Control (IPQC): Monitoring production processes to identify and rectify issues in real-time.

– Final Quality Control (FQC): Conducting thorough inspections of finished products before they are packaged and shipped. This includes visual inspections and functional tests. -

Common Testing Methods: Several testing methods can be employed to ensure the quality of rubber toe kicks:

– Mechanical Testing: Evaluates properties such as tensile strength, elongation, and hardness.

– Environmental Testing: Assesses resistance to UV light, temperature variations, and chemical exposure.

– Dimensional Testing: Ensures that products meet specific size and shape requirements.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to ensure that their suppliers maintain high-quality standards. This can be achieved through various verification methods.

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. An audit typically includes reviewing production facilities, quality management systems, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the effectiveness of their quality control processes. These reports should include data on defect rates, testing results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures. These inspections can be conducted at various stages of production and are particularly useful for international buyers who may not be able to visit suppliers in person.

What Are the Unique Quality Control Considerations for International B2B Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, there are specific nuances in quality control that must be considered.

-

Regulatory Compliance: Different regions have varying regulations regarding materials and product safety. Buyers should ensure that their suppliers comply with local laws and international standards relevant to their markets.

-

Cultural and Logistical Factors: Understanding cultural practices and logistical challenges in different regions can impact quality. For instance, transportation conditions may affect product integrity, so it is essential to discuss packaging and shipping methods with suppliers.

-

Language and Communication: Effective communication is vital to ensure that quality expectations are understood and met. Buyers should establish clear channels of communication with suppliers and consider language barriers that may hinder the flow of information.

Conclusion

In summary, the manufacturing processes and quality assurance measures for rubber toe kicks are crucial for ensuring product durability and compliance with international standards. B2B buyers must be diligent in verifying supplier practices through audits, quality reports, and third-party inspections. Understanding the unique challenges faced in different regions can further aid in establishing successful supplier relationships and ensuring high-quality products. By prioritizing these factors, buyers can confidently source rubber toe kicks that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber toe kick’

This guide is designed to assist B2B buyers in effectively sourcing rubber toe kicks, ensuring that your procurement process is thorough and efficient. The rubber toe kick serves as an essential element in both aesthetic and functional capacities, providing protection for walls and enhancing the visual appeal of various spaces. Follow this step-by-step checklist to streamline your purchasing journey.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the rubber toe kick you require. This includes dimensions, material type (e.g., thermoplastic rubber), color options, and any specific design features. Precise specifications help avoid misunderstandings and ensure that the product meets your project’s needs.

- Consider industry standards: Familiarize yourself with any relevant regulations or standards in your region, particularly if you are operating in sectors like healthcare or food services where hygiene and safety are critical.

- Assess installation requirements: Determine if the toe kicks will require special installation tools or techniques, as this can influence your supplier choice.

Step 2: Identify Potential Suppliers

Conduct thorough research to create a list of potential suppliers who specialize in rubber toe kicks. Look for companies with a proven track record in the flooring and wall base industry.

- Use industry directories: Leverage online B2B platforms and trade directories to find reputable suppliers.

- Seek recommendations: Engage with industry peers or associations to gather insights on reliable suppliers.

Step 3: Evaluate Supplier Credentials

Before making a commitment, it is crucial to verify the credentials of your shortlisted suppliers. This step ensures that you are dealing with reputable companies that adhere to quality standards.

- Request certifications: Ask for certifications such as ISO 9001 or product-specific certifications that demonstrate compliance with safety and quality standards.

- Assess experience: Inquire about the supplier’s experience in providing rubber toe kicks to businesses similar to yours, particularly in your geographic region.

Step 4: Request Samples

Obtaining samples is an essential step in the sourcing process. This allows you to physically assess the quality, flexibility, and color of the rubber toe kicks.

- Test for durability: Evaluate the sample for resistance to wear, tear, and environmental factors like moisture or temperature fluctuations.

- Check for color consistency: Ensure that the color of the sample matches your project’s aesthetic requirements.

Step 5: Compare Pricing and Terms

Once you have gathered samples and evaluated suppliers, compare pricing and terms to identify the best value for your investment.

- Consider total cost: Look beyond the initial price; factor in shipping costs, potential tariffs, and installation expenses.

- Review payment terms: Clarify payment options and terms, including any discounts for bulk purchases or early payments.

Step 6: Negotiate and Finalize the Contract

Engage in negotiations with your chosen supplier to ensure that both parties are aligned on expectations and terms. This step is vital for establishing a mutually beneficial relationship.

- Clarify delivery timelines: Confirm lead times and delivery schedules, ensuring they align with your project deadlines.

- Include warranties: Request warranties or guarantees on the products to safeguard against defects or issues post-installation.

Step 7: Plan for Installation and Maintenance

After procurement, develop a plan for the installation and maintenance of the rubber toe kicks. Proper installation and upkeep are crucial for longevity and performance.

Illustrative image related to rubber toe kick

- Train your team: Ensure that the installation team is trained on the specific requirements for the rubber toe kicks being used.

- Establish a maintenance schedule: Create a routine maintenance plan to ensure the longevity and effectiveness of the rubber toe kicks over time.

By following this comprehensive checklist, B2B buyers can confidently navigate the procurement process for rubber toe kicks, ensuring a successful outcome that meets their needs and standards.

Comprehensive Cost and Pricing Analysis for rubber toe kick Sourcing

Understanding the cost structure and pricing dynamics of rubber toe kicks is essential for international B2B buyers looking to make informed sourcing decisions. This analysis will explore the key components that contribute to the pricing of rubber toe kicks, the factors influencing these prices, and strategic tips for buyers aiming to optimize their procurement process.

What Are the Key Cost Components in Rubber Toe Kick Sourcing?

The cost structure of rubber toe kicks typically consists of several critical components:

-

Materials: The type of rubber used (natural vs. synthetic) significantly impacts the cost. Higher-grade materials may command a premium price due to their durability and performance characteristics.

-

Labor: Labor costs vary by region and can influence manufacturing expenses. In countries with higher labor costs, such as Germany, the total price may increase compared to sourcing from regions with lower labor costs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance. Efficient manufacturing processes can help keep these costs in check.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should inquire about tooling costs as they can influence pricing significantly.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability but can add to overall costs. Buyers should evaluate the QC standards employed by suppliers.

-

Logistics: Shipping and handling costs can vary based on the distance from the supplier, chosen transport methods, and Incoterms.

-

Margin: Suppliers will typically apply a profit margin, which varies based on market conditions and competition.

How Do Price Influencers Affect Rubber Toe Kick Pricing?

Several factors can influence the pricing of rubber toe kicks:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced prices per unit. Buyers should negotiate MOQs with suppliers to achieve better pricing.

-

Specifications and Customization: Custom designs or specific color requirements can lead to increased costs due to additional tooling and material expenses. Standard products tend to be more cost-effective.

-

Material Quality and Certifications: High-quality materials and certifications (such as ISO or environmental standards) can raise the price but may offer long-term value through durability and compliance with regulations.

-

Supplier Factors: The supplier’s reputation, reliability, and manufacturing capacity can impact pricing. Established suppliers with a history of quality may charge more but provide greater assurance of product performance.

-

Incoterms: The chosen Incoterms will affect the total cost. Terms like FOB (Free on Board) can mean buyers are responsible for shipping costs, while DDP (Delivered Duty Paid) means the supplier covers shipping and import duties.

What Are Effective Buyer Tips for Sourcing Rubber Toe Kicks?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Suppliers may offer discounts for bulk purchases or long-term contracts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, and potential warranty costs. Sometimes, a higher upfront cost can lead to lower long-term expenses if the product is more durable.

-

Pricing Nuances for International Markets: Be aware of currency fluctuations, import tariffs, and local market conditions that may affect pricing. Establishing a good relationship with suppliers can provide insights into these factors.

-

Request Samples: Before committing to large orders, request samples to assess quality and suitability for your specific applications. This step can prevent costly mistakes.

Conclusion

Sourcing rubber toe kicks involves understanding a complex cost structure and pricing dynamics. By considering key cost components, price influencers, and strategic negotiation tips, international B2B buyers can make informed decisions that align with their project requirements and budget constraints. Always seek multiple quotes and conduct thorough due diligence to ensure optimal procurement outcomes.

Alternatives Analysis: Comparing rubber toe kick With Other Solutions

Introduction to Alternative Solutions for Rubber Toe Kick

In the realm of interior finishing and protection, various solutions exist that serve similar purposes to rubber toe kicks. These alternatives vary significantly in terms of performance, cost, and ease of implementation, allowing B2B buyers to select the most suitable option based on their specific requirements. In this analysis, we will compare rubber toe kicks against two prominent alternatives: vinyl wall base and wooden baseboards.

Comparison Table

| Comparison Aspect | Rubber Toe Kick | Vinyl Wall Base | Wooden Baseboard |

|---|---|---|---|

| Performance | Highly durable and flexible; resistant to moisture and impacts. | Flexible, durable, and resistant to scuffs; available in many colors. | Aesthetic appeal; may not be as durable in high-moisture environments. |

| Cost | Moderate cost, typically $2.50 – $4.00 per linear foot. | Generally lower cost, around $1.50 – $3.00 per linear foot. | Higher initial cost, usually $3.00 – $5.00 per linear foot. |

| Ease of Implementation | Requires adhesive or nails for installation; straightforward process. | Easy to install with adhesive; can be cut to size with standard tools. | Installation may require more skill and tools, such as nails and a saw. |

| Maintenance | Low maintenance; easy to clean and replace if damaged. | Low maintenance; resistant to staining and easy to clean. | Higher maintenance; may require painting or refinishing over time. |

| Best Use Case | Ideal for high-traffic areas, hospitals, and commercial spaces needing moisture resistance. | Suitable for residential and commercial settings with moderate foot traffic. | Best for aesthetic applications in low-traffic residential areas. |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Vinyl Wall Base?

Vinyl wall base is a cost-effective alternative that offers both durability and versatility. Its flexible nature allows for easy installation around corners and curves, making it suitable for various environments. Vinyl is also resistant to scuffs and stains, which is essential in high-traffic areas. However, while it provides a clean and modern look, it may not offer the same level of impact resistance as rubber toe kicks. Additionally, vinyl can be less effective in areas with extreme temperature fluctuations, which could affect its longevity.

How Do Wooden Baseboards Compare to Rubber Toe Kicks?

Wooden baseboards bring a classic aesthetic appeal to interiors, making them a popular choice for residential applications. They can be painted or stained to match any decor, adding significant value to a property. However, wooden baseboards are typically more expensive and require a more complex installation process. They are also less suitable for high-moisture areas, as wood can warp or rot over time. Maintenance is another consideration, as they may require periodic painting or refinishing to maintain their appearance.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between rubber toe kicks, vinyl wall base, and wooden baseboards, B2B buyers should consider the specific requirements of their projects. If durability and moisture resistance are paramount, rubber toe kicks may be the best choice, particularly in commercial settings. For budget-conscious projects, vinyl wall base offers a versatile and cost-effective solution. Meanwhile, for those prioritizing aesthetic appeal in residential applications, wooden baseboards provide a timeless look, albeit with higher costs and maintenance needs. Ultimately, the decision should align with the intended use, budget constraints, and desired aesthetic outcomes.

Essential Technical Properties and Trade Terminology for rubber toe kick

What Are the Key Technical Properties of Rubber Toe Kick?

When sourcing rubber toe kicks for commercial or industrial applications, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

-

Material Grade

Rubber toe kicks are typically made from high-quality synthetic rubber or thermoplastic rubber (TPR). The material grade affects durability, flexibility, and resistance to environmental factors. Higher-grade materials are more resistant to wear and tear, making them ideal for high-traffic areas, thereby reducing replacement costs over time. -

Thickness and Tolerance

Thickness usually ranges from 1/8 inch to 1/4 inch. Tolerance refers to the allowable deviation from specified dimensions. Maintaining proper thickness is essential for ensuring a snug fit and effective protection against impacts, moisture, and dirt. A precise tolerance ensures uniformity across installations, promoting aesthetic consistency and structural integrity. -

Color and Finish Options

Rubber toe kicks are available in various colors and finishes, including matte and gloss. The choice of color can be crucial for branding and aesthetic alignment in commercial settings. A durable finish can enhance resistance to fading, scratches, and stains, thereby maintaining a clean appearance and extending product lifespan. -

Flexibility and Shape Retention

Flexibility is vital for installations that require bending around corners or curves. Quality rubber toe kicks retain their shape over time, preventing unsightly gaps or misalignments. This property is particularly important in environments with varying temperatures and humidity levels, which can cause lesser materials to warp. -

Moisture and Chemical Resistance

Given that toe kicks often encounter spills and cleaning agents, their resistance to moisture and chemicals is paramount. Products with excellent moisture resistance minimize the risk of mold and mildew, while chemical resistance protects against degradation from cleaning products. This feature is particularly relevant in industries such as food service and healthcare. -

Installation Method

Understanding the installation method—adhesive, mechanical fastening, or snap-fit—can impact labor costs and installation time. Some methods allow for quicker installations and easier replacements, which can be advantageous for businesses looking to minimize downtime during renovations.

What Trade Terms Should B2B Buyers Know for Rubber Toe Kick?

Familiarity with industry jargon can streamline communications and negotiations. Here are several essential terms relevant to rubber toe kicks:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand name. For buyers, understanding OEM specifications can help ensure compatibility and quality when integrating rubber toe kicks into existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in one order. Knowing the MOQ is essential for budgeting and inventory management, particularly for smaller businesses or projects with limited funding. -

RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing on specified products. For buyers, issuing an RFQ can facilitate competitive pricing and help identify suppliers who can meet specific technical requirements. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risk transfer, and delivery obligations, ensuring smoother transactions across borders. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is crucial for project planning and inventory management, especially in industries with tight deadlines. -

Warranty and Return Policy

Buyers should be aware of the warranty terms and return policy associated with rubber toe kicks. A strong warranty can provide peace of mind regarding product quality, while a clear return policy can facilitate easier exchanges in case the product does not meet expectations.

By understanding these properties and terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the rubber toe kick Sector

What Are the Key Trends Driving the Rubber Toe Kick Market?

The rubber toe kick market is currently experiencing a surge in demand, driven by the increasing focus on interior aesthetics and functionality across various sectors, including commercial and residential environments. As urbanization continues to rise, particularly in regions like Africa and South America, the need for durable and low-maintenance flooring solutions has become paramount. International B2B buyers are increasingly gravitating toward rubber toe kicks due to their resilience against wear and tear, as well as their ability to enhance the overall design of spaces.

Emerging B2B technology trends are reshaping the sourcing landscape. Digital platforms are facilitating better supply chain transparency and enabling buyers to compare products and prices from various suppliers. Additionally, the integration of AI and data analytics in inventory management allows manufacturers to anticipate demand fluctuations, optimizing production schedules accordingly. In Europe, especially in countries like Germany, sustainable practices are becoming integral to procurement decisions, pushing suppliers to adopt eco-friendly materials and processes.

Moreover, the global emphasis on health and safety is influencing the rubber toe kick market. With increased awareness of hygiene, particularly in commercial settings, buyers are seeking products that are easy to clean and resistant to bacteria. This trend is particularly notable in the Middle East and Europe, where stringent health regulations are in place.

How Can Sustainability and Ethical Sourcing Impact the Rubber Toe Kick Sector?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the rubber toe kick sector. The environmental impact of rubber production, including deforestation and carbon emissions, has prompted a shift toward sourcing materials that adhere to sustainability standards. Buyers are increasingly prioritizing suppliers who can demonstrate commitment to sustainable practices, such as using recycled materials or sourcing from certified rubber plantations.

The importance of ethical supply chains cannot be overstated. Buyers are now scrutinizing the labor practices of their suppliers, ensuring that their products are not only environmentally friendly but also produced under fair working conditions. Certifications such as FSC (Forest Stewardship Council) and Cradle to Cradle can serve as significant differentiators in the marketplace, appealing to environmentally-conscious clients.

Furthermore, innovative products are emerging that incorporate sustainable materials, such as bio-based or recycled rubber, which align with the growing demand for ‘green’ certifications. As buyers increasingly seek transparency and ethical sourcing, suppliers that prioritize sustainability will likely gain a competitive edge, particularly in regions like Europe where consumer awareness is high.

What Is the Evolution of the Rubber Toe Kick Market?

The evolution of the rubber toe kick market has been marked by significant advancements in material technology and design. Initially, rubber toe kicks were primarily functional, serving to protect walls from damage caused by foot traffic and equipment. However, as design trends have evolved, so too has the aesthetic appeal of rubber toe kicks.

In the past two decades, manufacturers have expanded their offerings to include a variety of colors, textures, and styles that cater to diverse interior design preferences. This shift has allowed rubber toe kicks to transition from mere protective elements to integral components of modern interior aesthetics. The rise of eco-conscious materials and production methods has further influenced this evolution, making rubber toe kicks not only practical but also sustainable choices for today’s B2B buyers.

As the market continues to mature, it is essential for buyers to stay informed about these trends and innovations to make strategic sourcing decisions that align with their business goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber toe kick

1. How do I choose the right rubber toe kick for my project?

Selecting the right rubber toe kick involves considering several factors, including the specific requirements of your project, the aesthetic preferences, and the durability needed for the environment. Assess the material quality—opt for commercial-grade rubber for high-traffic areas. Evaluate the color and design options to ensure they match your overall decor. Additionally, think about the installation method; some toe kicks are designed for easy application, while others may require professional installation. Always request samples when possible to test compatibility with your flooring and wall finishes.

Illustrative image related to rubber toe kick

2. What are the advantages of using rubber toe kicks in commercial settings?

Rubber toe kicks provide a range of benefits for commercial applications. They are durable, resistant to wear and tear, and can withstand high foot traffic, making them ideal for busy environments like restaurants and retail spaces. The flexibility of rubber also allows for easy installation around curves and corners. Furthermore, rubber toe kicks are available in various colors and designs, allowing for customization that can enhance the aesthetic appeal of your space while providing essential protection for walls and furniture.

3. What should I consider when vetting suppliers for rubber toe kicks?

When vetting suppliers, prioritize those with a proven track record in the rubber flooring industry. Look for certifications that demonstrate compliance with international quality standards. Assess their product range, focusing on customization options, material quality, and pricing structure. Request references or case studies from previous clients, and inquire about their lead times and delivery capabilities to ensure they align with your project timelines. Finally, evaluate their customer service responsiveness, as effective communication is crucial for a successful partnership.

4. What are the minimum order quantities (MOQ) for rubber toe kicks?

Minimum order quantities for rubber toe kicks can vary significantly between suppliers. Generally, MOQs may range from as low as 100 to several thousand units, depending on the manufacturer and the customization involved. It’s essential to discuss your specific needs with the supplier to understand their MOQ policies. If your project demands a smaller quantity, consider negotiating or exploring suppliers that specialize in smaller batch productions. Always factor in potential shipping costs when calculating your total order budget.

5. How can I customize rubber toe kicks to fit my project needs?

Customization options for rubber toe kicks typically include size, color, and design. Many suppliers offer a variety of colors to match specific décor themes, while some allow for bespoke designs or patterns. When discussing customization, provide detailed specifications, including dimensions and any unique design requirements. It’s also beneficial to request prototypes or samples to ensure the final product meets your expectations. Keep in mind that customized products may have longer lead times and potentially higher costs, so plan accordingly.

6. What payment terms should I expect when sourcing rubber toe kicks internationally?

Payment terms can vary widely among suppliers and regions. Common terms include advance payment, net 30, or letter of credit, especially for international transactions. It’s crucial to establish clear payment agreements upfront to avoid misunderstandings. Assess the supplier’s payment flexibility and inquire about any potential discounts for early payments. Additionally, consider using secure payment methods that offer buyer protection, particularly for large orders, to mitigate risks associated with international trade.

Illustrative image related to rubber toe kick

7. How do I ensure quality assurance for rubber toe kicks?

To ensure quality assurance, request product certifications and compliance documentation from your supplier. Many reputable manufacturers adhere to international standards, such as ISO certifications, which indicate quality control measures. Establish a clear quality assurance process that includes inspection upon receipt, and consider conducting random checks during production if feasible. Additionally, maintain open communication with your supplier regarding any quality concerns to facilitate prompt resolutions.

8. What logistics considerations should I keep in mind when importing rubber toe kicks?

When importing rubber toe kicks, consider logistics factors such as shipping methods, delivery times, and customs regulations. Choose a reliable freight forwarder familiar with your destination country to navigate import duties and taxes effectively. Plan for potential delays by allowing extra time in your project timeline for customs clearance. Additionally, ensure the supplier provides proper documentation, including invoices and packing lists, to streamline the import process and avoid any complications at the border.

Top 4 Rubber Toe Kick Manufacturers & Suppliers List

1. Roppe – Vinyl Wall Base-A500

Domain: kofflersales.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘Roppe Vinyl Wall Base-A500’, ‘description’: ‘Standard Vinyl wall base great for a modern look. Commercial grade 1/8″ vinyl.’, ‘size’: ‘120ft rolls & 4ft strips box/30’, ‘price’: ‘Starting at $48.51’, ‘discount’: ‘10% off regular price’}, {‘name’: ‘Johnsonite | Tarkett Vinyl Wall Base-A505’, ‘description’: ‘Clean finish around the perimeter of your room. Commercial grade 1/8″ vinyl.’, ‘s…

2. Johnsonite – Rubber Wall Base

Domain: installerstore.com

Registered: 2002 (23 years)

Introduction: {“brand”:”Johnsonite”,”product_type”:”Rubber Wall Base”,”available_heights”:[“4 inch”,”6 inch”],”gauge”:”0.125 inch”,”lengths”:[“4 foot strips”,”120 foot coils”,”100 foot coils”],”colors_available”:”Over 30 popular colors and non-stock colors”,”installation_method”:”Cove Base Adhesive or Step Tape”,”features”:[“Long-lasting”,”Fade resistant”,”Scuff resistant”,”Crack resistant”,”Shrink resistant”],…

3. Reddit – Rubber Base Board Molding

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Rubber Base Board Molding is primarily designed for commercial applications, particularly in high traffic areas. It is considered cheap and may not be aesthetically pleasing for residential use. Users have noted that it can be difficult to install, especially when cutting corners accurately. Alternatives like MDF trim are recommended for a more appealing look, though they require nailing. Some use…

4. Houzz – Rubber Cove Base

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Rubber cove base is used to create a seal with the floor, preventing crumbs from accumulating in the crevice between the toe kick and the floor. It is mentioned in the context of kitchen, bath, and garage cabinetry. The user is considering using VCT (Vinyl Composition Tile) in the kitchen and possibly cove it up onto the toe kicks if using linoleum.

Strategic Sourcing Conclusion and Outlook for rubber toe kick

In the dynamic landscape of international sourcing, the strategic procurement of rubber toe kicks offers significant advantages for businesses looking to enhance durability and aesthetic appeal in their flooring solutions. As B2B buyers from regions such as Africa, South America, the Middle East, and Europe continue to seek reliable materials, understanding the nuances of rubber toe kick options is essential. The versatility of rubber, including its resistance to wear, ease of installation, and availability in various colors and styles, positions it as a preferred choice for both commercial and residential applications.

Strategic sourcing not only ensures cost-effectiveness but also fosters long-term partnerships with suppliers who can meet specific quality and compliance standards. By leveraging this approach, buyers can optimize their supply chains, reduce lead times, and enhance product offerings to meet market demands.

Looking ahead, the rubber toe kick market presents an array of opportunities for international buyers. Engaging with reputable manufacturers and distributors can unlock access to innovative products that align with evolving design trends and sustainability goals. Embrace the potential of strategic sourcing today to elevate your business’s competitive edge in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to rubber toe kick