Rubber Shock Cord Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for rubber shock cord

In today’s dynamic global marketplace, sourcing rubber shock cord can be a significant challenge for B2B buyers, particularly when faced with varying quality standards and inconsistent supplier reliability. As a versatile solution for applications ranging from cargo securing to DIY projects, rubber shock cord is indispensable across industries. This comprehensive guide aims to equip international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—with the knowledge needed to navigate the complexities of this product category.

We delve into various types of rubber shock cord, exploring their specific applications and benefits. Buyers will gain insights into the nuances of materials, such as the differences between EPDM rubber and polyester jackets, which impact durability and performance in diverse environmental conditions. Additionally, this guide covers critical aspects of supplier vetting, enabling businesses to identify trustworthy manufacturers and distributors.

Furthermore, we provide an overview of pricing structures and cost factors, ensuring buyers can make informed financial decisions. By the end of this guide, B2B buyers will be empowered to make strategic purchasing choices, enhancing their operational efficiency and product quality. Whether you are securing loads for transport or engaging in innovative DIY projects, understanding the global market for rubber shock cord will ensure you meet your specific needs with confidence.

Understanding rubber shock cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Shock Cord | Braided nylon sheath with a rubber core; available in various diameters | General purpose tie-downs and securing loads | Pros: Versatile, durable; Cons: Limited stretch compared to other types. |

| Rubber Rope | Made from EPDM rubber; available in hollow or solid core variations | Truck tarping systems, custom tie-downs | Pros: High elasticity; Cons: Hollow may wear faster. |

| Marine-Grade Shock Cord | Polyester jacket for UV and abrasion resistance; excellent stretch factor | Boat and outdoor equipment securing | Pros: Long-lasting, UV-resistant; Cons: Higher cost than standard options. |

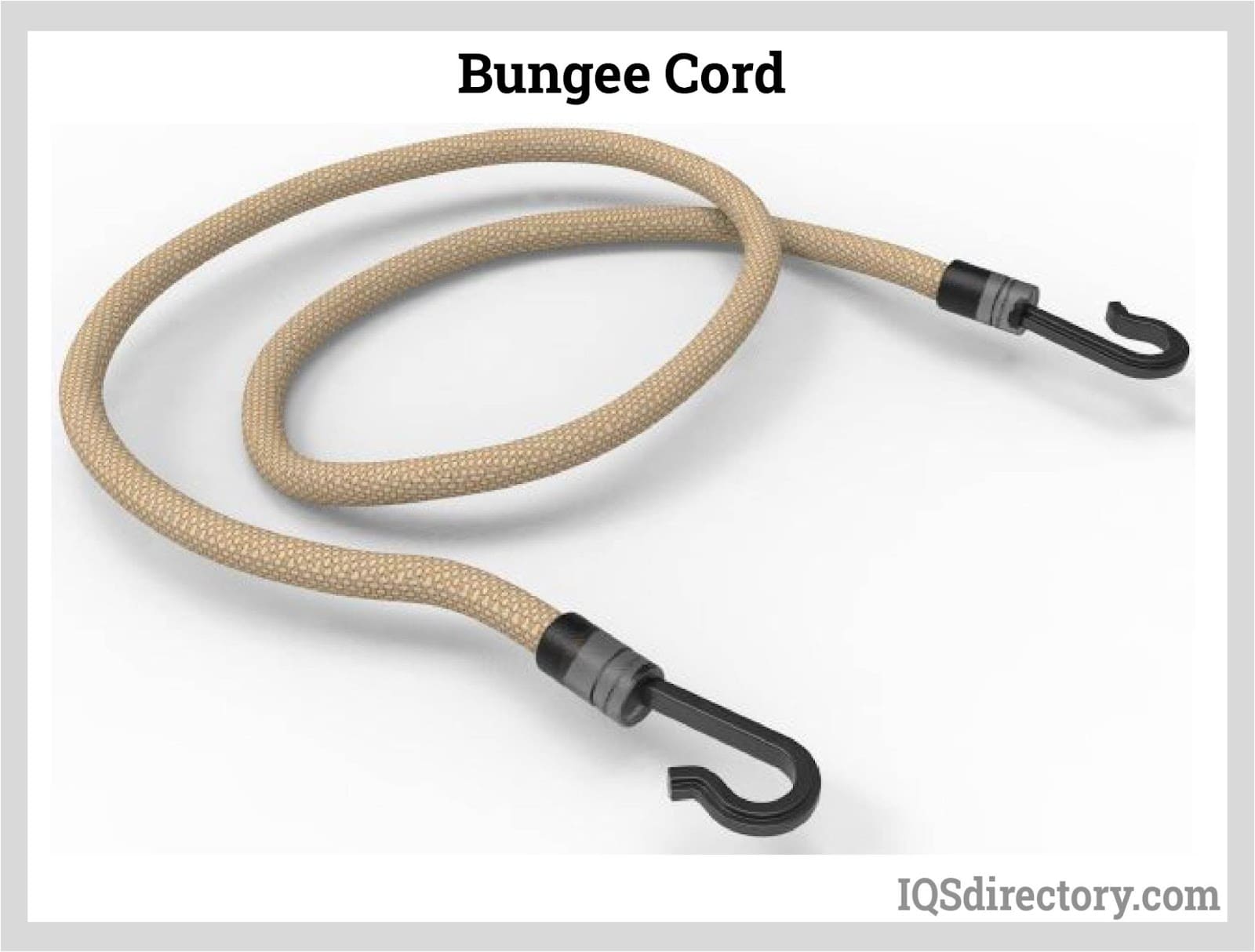

| Bungee Cord | Typically includes hooks; designed for quick attachment and release | Sports, camping, and recreational use | Pros: Easy to use, customizable lengths; Cons: May not hold heavy loads. |

| Custom Shock Cord | Tailored specifications for specific applications; various materials available | Specialized industrial applications | Pros: Tailored solutions; Cons: Longer lead times for production. |

What are the Characteristics and Suitability of Standard Shock Cord?

Standard shock cord is characterized by its braided nylon sheath that encapsulates a rubber core, making it a highly versatile option for various applications. This type of shock cord is available in multiple diameters, allowing B2B buyers to select the appropriate size for their specific needs. It is ideal for general-purpose tie-downs, securing loads, or even DIY projects. Buyers should consider the cord’s tensile strength and stretch capacity, ensuring it meets the demands of their application.

How Does Rubber Rope Differ from Other Types of Shock Cord?

Rubber rope, often made from EPDM rubber, is distinguished by its hollow or solid core options. The hollow core provides greater elasticity, making it easier to stretch, while the solid core offers enhanced durability and longevity. This type of shock cord is primarily used in truck tarping systems and for creating custom tie-downs. When purchasing rubber rope, B2B buyers should assess the environmental conditions it will face, such as exposure to UV rays or extreme temperatures, to choose the most suitable option.

Why Choose Marine-Grade Shock Cord for Outdoor Applications?

Marine-grade shock cord features a polyester jacket that provides superior UV and abrasion resistance, making it an excellent choice for outdoor and marine applications. Its stretch factor of approximately 100-125% under full load ensures effective securing of equipment in challenging environments, such as boats or trailers. B2B buyers should consider the higher initial investment of marine-grade options, which often yield longer service life and reduced replacement costs over time.

What Advantages Does Bungee Cord Offer for Quick Attachments?

Bungee cords are commonly recognized for their ease of use, often equipped with hooks for quick attachment and release. This type of shock cord is particularly popular in sports, camping, and recreational settings, where rapid securing of items is essential. While bungee cords are user-friendly and customizable in length, buyers should be mindful of their load-bearing capacity, as they may not be suitable for heavy-duty applications.

Illustrative image related to rubber shock cord

When is Custom Shock Cord the Right Choice for Businesses?

Custom shock cord is tailored to meet specific application requirements, including diameter, material composition, and elasticity. This type of shock cord is particularly beneficial for specialized industrial applications where standard options may fall short. B2B buyers should consider the lead times associated with custom orders, as well as the potential for enhanced functionality, ensuring that the investment aligns with their operational needs.

Key Industrial Applications of rubber shock cord

| Industry/Sector | Specific Application of rubber shock cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Securing cargo in trucks and trailers | Enhances cargo safety, reducing damage and loss | Look for durable materials and appropriate tensile strength ratings. |

| Agriculture | Tarping systems for farm equipment | Protects equipment from weather, prolonging lifespan | Ensure UV resistance and compatibility with local climates. |

| Construction | Temporary support for scaffolding and tarps | Provides flexibility and safety in dynamic environments | Consider load-bearing capacity and material quality for durability. |

| Outdoor Recreation | Tent and canopy setup | Facilitates quick assembly and stability in adverse conditions | Assess elasticity and weather resistance for outdoor use. |

| Manufacturing | Custom assembly of products | Streamlines production processes and enhances product reliability | Evaluate consistency in quality and availability of various diameters. |

How is Rubber Shock Cord Utilized in Transportation?

In the transportation sector, rubber shock cord is primarily used for securing cargo within trucks and trailers. Its elasticity allows for a snug fit that accommodates movement during transit, significantly reducing the risk of damage to goods. For international B2B buyers, especially in regions like Africa and South America where road conditions may vary, sourcing high-quality shock cord with appropriate tensile strength ratings is crucial. This ensures that the cord can withstand dynamic forces and environmental factors, safeguarding valuable cargo.

What Role Does Rubber Shock Cord Play in Agriculture?

In agriculture, rubber shock cord is essential for tarping systems that protect farm equipment from harsh weather conditions. By securing tarps effectively, it helps prolong the lifespan of machinery and prevents weather-related damage. Buyers in the Middle East and Europe should prioritize UV-resistant materials, particularly in regions with high sun exposure. Additionally, understanding the local climate can guide the selection of shock cord to ensure optimal performance throughout the year.

How is Rubber Shock Cord Applied in Construction?

Construction sites benefit from rubber shock cord for temporary support of scaffolding and tarps. Its flexible nature accommodates the shifting dynamics of construction environments, providing safety and adaptability. For businesses operating in Europe, where compliance with safety regulations is stringent, sourcing shock cord with a high load-bearing capacity is vital. This ensures that the materials used meet safety standards while enhancing operational efficiency.

Why is Rubber Shock Cord Important for Outdoor Recreation?

In outdoor recreation, rubber shock cord is commonly used for setting up tents and canopies. Its elasticity allows for quick assembly and stability, even in windy conditions. For B2B buyers in Africa and Brazil, where outdoor activities are prevalent, evaluating the weather resistance and elasticity of the shock cord is essential. This ensures that the products can withstand various environmental conditions, providing reliable performance during outdoor events.

How Does Rubber Shock Cord Enhance Manufacturing Processes?

In manufacturing, rubber shock cord is often utilized for custom assembly of products, providing a reliable method for joining components. Its ability to stretch and maintain tension makes it ideal for applications requiring consistent performance. Buyers should consider the consistency in quality and availability of various diameters when sourcing shock cord. This ensures that their production processes remain efficient and that the final products are reliable and durable.

3 Common User Pain Points for ‘rubber shock cord’ & Their Solutions

Scenario 1: Inconsistent Quality Leading to Product Failures

The Problem: B2B buyers often face the challenge of sourcing rubber shock cords that do not meet the required quality standards. This inconsistency can lead to product failures during critical operations, such as securing loads on trucks or during manufacturing processes. For instance, a buyer might receive a batch of shock cord that fails to stretch as expected or breaks under load, resulting in potential financial losses and damage to their reputation. Such issues become particularly acute when dealing with international suppliers who may not adhere to the same quality control measures as local manufacturers.

The Solution: To mitigate these risks, buyers should establish a robust supplier evaluation process. Begin by requesting product samples from potential suppliers to assess quality firsthand. Look for certifications that indicate adherence to international standards, such as ISO 9001 for quality management systems. Additionally, specify the type of rubber and construction methods used in the shock cord, as these directly influence performance. For ongoing purchases, consider implementing a quality assurance protocol that includes regular inspections and feedback loops with suppliers to ensure consistency over time. By prioritizing quality and developing strong supplier relationships, buyers can significantly reduce the risk of product failures.

Illustrative image related to rubber shock cord

Scenario 2: Difficulty in Choosing the Right Specifications for Applications

The Problem: Selecting the appropriate rubber shock cord for specific applications can be daunting for B2B buyers. With various diameters, stretch ratios, and material compositions available, making the right choice can feel overwhelming. For example, a company might need a shock cord for outdoor tarping systems but may inadvertently choose one with insufficient UV resistance, leading to premature wear and increased replacement costs. This scenario is common among buyers who lack technical knowledge or experience with rubber shock cords.

The Solution: Buyers should start by clearly defining the application requirements, including load capacity, environmental conditions, and intended use. Collaborate with manufacturers or suppliers who offer technical support and can provide detailed specifications and recommendations tailored to your needs. Consider investing in a consultation with a rope and cordage expert who can guide you through the selection process. Additionally, utilize product datasheets that outline critical factors such as tensile strength, elongation, and material properties. By taking a proactive approach to understanding specifications, buyers can ensure they select the right shock cord for their applications, minimizing future complications.

Scenario 3: High Costs Associated with Frequent Replacements

The Problem: Many businesses experience high operational costs due to frequent replacements of rubber shock cords. This issue often arises from using inferior products that wear out quickly or from improper usage that leads to premature failure. For example, a logistics company might continuously replace shock cords used in cargo securing, which can lead to increased downtime and unexpected expenditures. Such financial strain can affect profitability, particularly for businesses operating in competitive markets.

Illustrative image related to rubber shock cord

The Solution: To address this pain point, companies should focus on investing in higher-quality rubber shock cords that offer greater durability and performance longevity. When sourcing, prioritize products made from premium materials, such as EPDM rubber, known for its excellent resistance to UV rays and temperature fluctuations. Additionally, educate staff on best practices for using and storing rubber shock cords, including avoiding over-stretching and ensuring proper installation. Implementing a maintenance schedule to inspect and replace cords as needed can also prevent unexpected failures. By shifting focus to quality and proper usage, businesses can significantly reduce replacement frequency and associated costs, leading to more stable financial performance.

Strategic Material Selection Guide for rubber shock cord

What Are the Key Materials Used in Rubber Shock Cord?

When selecting rubber shock cord for various applications, understanding the materials involved is crucial for B2B buyers. The performance of shock cords can significantly vary based on the material used, impacting durability, cost, and suitability for specific applications. Below are analyses of four common materials used in rubber shock cords: natural rubber, EPDM rubber, polyester, and polyethylene.

How Does Natural Rubber Perform in Rubber Shock Cords?

Natural rubber is derived from the sap of rubber trees and is known for its excellent elasticity and tensile strength. It performs well in applications that require significant stretch and recovery. However, natural rubber has limitations in extreme temperatures and UV exposure, which can lead to degradation over time.

Pros: Natural rubber is highly elastic, making it ideal for applications requiring frequent stretching. It also offers good tear resistance.

Cons: Its susceptibility to UV light and temperature extremes can limit its lifespan, especially in outdoor applications. Additionally, natural rubber can be more expensive due to sourcing and processing.

Illustrative image related to rubber shock cord

Impact on Application: Natural rubber shock cords are suitable for light-duty applications such as securing lightweight items or indoor use. However, they may not be ideal for prolonged outdoor exposure.

Considerations for International Buyers: Compliance with ASTM standards is essential when sourcing natural rubber shock cords, especially for markets in Europe and North America. Buyers should also consider local climate conditions, as natural rubber performs poorly in extreme heat or cold.

What Advantages Does EPDM Rubber Offer for Shock Cord Applications?

EPDM (ethylene propylene diene monomer) rubber is a synthetic rubber known for its excellent resistance to UV rays, ozone, and extreme temperatures. This makes it a popular choice for outdoor applications, including automotive and construction uses.

Pros: EPDM rubber has superior durability and can withstand harsh weather conditions without cracking or degrading.

Cons: While it is cost-effective, EPDM rubber may not provide the same level of elasticity as natural rubber, which could affect performance in some applications.

Illustrative image related to rubber shock cord

Impact on Application: EPDM shock cords are ideal for heavy-duty applications, such as securing tarps on trucks or outdoor canopies, where exposure to the elements is a concern.

Considerations for International Buyers: EPDM products often meet international standards, making them suitable for various markets, including Africa and South America. Buyers should verify compliance with local regulations and standards like DIN or JIS.

How Do Polyester and Polyethylene Contribute to Shock Cord Performance?

Polyester and polyethylene are commonly used as outer materials for shock cords. Polyester provides a robust outer layer that enhances UV resistance and abrasion resistance, while polyethylene offers a lightweight and cost-effective alternative.

Pros: Polyester shock cords are durable and resistant to cracking and splitting, making them suitable for marine and outdoor applications. Polyethylene, while less durable, is cost-effective and lightweight.

Cons: Polyester can be more expensive than polyethylene, and while polyethylene is lightweight, it may not withstand heavy loads as effectively as polyester.

Impact on Application: Polyester shock cords are excellent for marine uses, while polyethylene shock cords are suitable for light-duty applications, such as securing small items.

Illustrative image related to rubber shock cord

Considerations for International Buyers: Buyers should ensure that polyester shock cords meet ASTM standards for marine use, particularly in European markets. In contrast, polyethylene options may be more appealing for budget-conscious buyers in developing regions.

Summary Table of Material Properties

| Material | Typical Use Case for rubber shock cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Indoor applications, lightweight items | Excellent elasticity and tear resistance | Poor UV and temperature resistance | Med |

| EPDM Rubber | Heavy-duty outdoor applications | Superior UV and weather resistance | Lower elasticity compared to natural rubber | Med |

| Polyester | Marine and outdoor applications | High durability and abrasion resistance | Higher cost compared to polyethylene | High |

| Polyethylene | Light-duty applications | Cost-effective and lightweight | Less durable under heavy loads | Low |

This guide provides a comprehensive overview of the materials used in rubber shock cords, helping B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber shock cord

What Are the Key Stages in the Manufacturing Process of Rubber Shock Cord?

The manufacturing of rubber shock cord involves a series of well-defined stages, each critical to ensuring the final product meets performance and quality standards. The process typically includes material preparation, forming, assembly, and finishing.

Material Preparation

The first stage in the manufacturing process is material preparation, which involves sourcing high-quality raw materials. The primary components of rubber shock cord include a rubber core and an outer covering, often made from polyester or nylon. Manufacturers select materials based on their intended application, climate conditions, and required elasticity. This selection process is crucial, as the choice of rubber—such as EPDM (ethylene propylene diene monomer) or natural rubber—affects the cord’s durability and resistance to environmental factors like UV rays and temperature fluctuations.

Illustrative image related to rubber shock cord

How Is the Forming Process Executed?

Following material preparation, the forming stage begins. This involves the extrusion of the rubber core, where raw rubber is heated and forced through a die to create a continuous length of rubber cord. The diameter and elasticity of the cord are controlled during this process to meet specific customer requirements. After the core is formed, the outer sheath is typically braided or woven around the rubber core. This not only enhances the cord’s strength but also provides protection against wear and tear.

What Techniques Are Commonly Used in the Assembly Stage?

The assembly stage involves combining the formed rubber cord with any additional components, such as hooks or loops, if required for bungee applications. Manufacturers may use techniques such as crimping or sewing to secure these components. Quality checks at this stage are vital, as any defects in assembly can lead to product failure in practical applications.

What Finishing Processes Are Involved?

Finishing processes include cutting the shock cord to specified lengths, applying any necessary coatings for added protection, and packaging the product for distribution. In some cases, additional treatments may be applied to enhance UV resistance or abrasion resistance, particularly for products intended for outdoor use.

How Is Quality Assurance Integrated into Rubber Shock Cord Manufacturing?

Quality assurance is a cornerstone of the manufacturing process, ensuring that each batch of rubber shock cord meets international and industry-specific standards.

What International Standards Are Relevant for Quality Control?

The most commonly referenced international standard is ISO 9001, which outlines requirements for a quality management system (QMS). This standard helps manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for specific applications, especially where safety and performance are critical.

What Are the Key Quality Control Checkpoints?

Quality control in rubber shock cord manufacturing typically involves several checkpoints throughout the production process, including:

- Incoming Quality Control (IQC): Inspection of raw materials to ensure they meet specified standards before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify issues in real-time.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all performance and safety standards before shipment.

What Testing Methods Are Commonly Used?

Common testing methods for rubber shock cord include tensile strength tests, elongation tests, and environmental exposure tests. Tensile strength tests determine how much force the cord can withstand before breaking, while elongation tests measure how much the cord can stretch under load. Environmental exposure tests assess the cord’s durability against UV light, temperature variations, and other environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, ensuring quality is paramount. Here are several strategies to verify supplier QC practices:

- Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality management processes and adherence to international standards.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results, compliance certifications, and any corrective actions taken in response to past quality issues.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and the quality of the products being supplied.

What Nuances Should International Buyers Consider in Quality Control?

When sourcing rubber shock cord internationally, buyers should consider the nuances of quality assurance that may vary by region. For example, European markets may have stricter compliance requirements compared to South American markets. Understanding these regional standards and regulations is essential for ensuring that the products meet local market expectations.

Illustrative image related to rubber shock cord

Moreover, cultural differences in business practices may affect communication and transparency regarding quality control. Establishing clear lines of communication and setting expectations upfront can help bridge these gaps and foster a successful partnership.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance practices for rubber shock cord is crucial for B2B buyers. By understanding the stages of production, relevant standards, and effective verification methods, buyers can make informed decisions and ensure they are sourcing high-quality products that meet their specific needs. This proactive approach not only minimizes risks but also enhances the overall value of the procurement process in a competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber shock cord’

In the dynamic landscape of sourcing rubber shock cord, B2B buyers must navigate various considerations to ensure they procure high-quality products that meet their specific needs. This checklist serves as a practical guide to streamline the sourcing process and enhance decision-making.

Illustrative image related to rubber shock cord

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right rubber shock cord. Consider factors such as diameter, material composition, and stretch characteristics. For instance, different applications may require varying levels of elasticity and durability; hence, knowing whether you need a hollow or solid core can significantly impact performance.

Step 2: Assess Your Application Requirements

Understanding the specific application for which the rubber shock cord will be used is essential. Different industries have unique demands; for example, truck tarping systems may require a higher tensile strength compared to general DIY projects. Evaluate conditions such as temperature, UV exposure, and load capacity to ensure the selected cord can withstand operational demands.

Step 3: Evaluate Potential Suppliers

Before finalizing any supplier, it’s imperative to conduct thorough evaluations. Request detailed company profiles, product samples, and references from similar industries to assess reliability. Look for suppliers with a proven track record in delivering quality products and consider their ability to meet your volume requirements consistently.

Illustrative image related to rubber shock cord

Step 4: Verify Supplier Certifications

Confirming that suppliers hold relevant certifications can provide peace of mind regarding product quality and safety. Check for ISO certifications or compliance with industry standards applicable to rubber and cord materials. Certifications not only reflect quality assurance but also adherence to environmental and safety regulations, which is particularly important for international buyers.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the rubber shock cord for testing. This step allows you to assess the product’s elasticity, durability, and overall performance in real-world conditions. Ensure that the samples meet your specifications and perform adequately under the expected loads.

Step 6: Negotiate Terms and Conditions

Once you identify a suitable supplier, enter negotiations regarding pricing, delivery schedules, and payment terms. Clear communication about expectations can prevent misunderstandings later. Consider discussing volume discounts or long-term contracts, which can be advantageous for both parties.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the rubber shock cord’s performance throughout its lifecycle. Regular inspections and feedback loops with your supplier can help address any quality issues promptly. Establishing this process ensures that the materials consistently meet your operational needs and standards.

By following these steps, B2B buyers can make informed decisions when sourcing rubber shock cord, ultimately leading to improved operational efficiency and product reliability.

Illustrative image related to rubber shock cord

Comprehensive Cost and Pricing Analysis for rubber shock cord Sourcing

What Are the Key Cost Components in Rubber Shock Cord Production?

When analyzing the cost structure of rubber shock cord sourcing, several key components must be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

Materials: The choice of materials significantly influences the overall cost. Rubber shock cords are often made from EPDM rubber or latex, with variations in quality affecting price. The outer sheath is typically constructed from polyester or nylon, which also contributes to the final cost.

-

Labor: Labor costs vary depending on the location of production. In regions with higher labor costs, such as Europe, manufacturers may charge more, whereas sourcing from countries with lower labor costs can provide significant savings.

-

Manufacturing Overhead: This includes the expenses associated with factory operations, such as utilities, maintenance, and administration. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The initial investment in tooling and equipment is substantial but is amortized over production runs. Custom tooling for specific shock cord designs can increase initial costs but may be justified by higher quality or unique specifications.

-

Quality Control (QC): Investing in robust QC processes ensures that the shock cords meet safety and performance standards, which is crucial for B2B buyers. However, enhanced QC can also increase production costs.

-

Logistics: Shipping and handling costs can vary significantly based on the distance from the manufacturer to the buyer. Factors such as the choice of shipping method and Incoterms (International Commercial Terms) also play a critical role in determining logistics costs.

-

Margin: Supplier margins are influenced by market competition, brand reputation, and the level of customer service provided. Buyers should consider these factors when evaluating quotes.

What Influences the Pricing of Rubber Shock Cord?

Several factors can influence the pricing of rubber shock cords beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom specifications can significantly affect price. Unique diameters, lengths, or material requirements may lead to higher costs due to specialized production processes.

-

Quality and Certifications: Products that meet specific certifications or industry standards (e.g., ISO, ASTM) may command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more, but they often deliver superior products and service.

-

Incoterms: The chosen Incoterms can affect pricing by determining who is responsible for shipping, insurance, and tariffs. Understanding these terms is essential for accurately calculating the total cost of ownership.

What Are the Best Buyer Tips for Negotiating Rubber Shock Cord Prices?

International B2B buyers from Africa, South America, the Middle East, and Europe should consider the following tips to enhance negotiation outcomes and achieve cost efficiency:

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider all associated costs, including shipping, customs duties, and potential warranty or replacement costs. This holistic view ensures better budgeting and financial planning.

-

Market Research: Conduct thorough research on market prices and supplier offerings to have a baseline for negotiations. Understanding average pricing can help in identifying competitive quotes.

-

Negotiation Leverage: Build relationships with suppliers to enhance negotiation power. Long-term partnerships can lead to better pricing and terms.

-

Flexibility in Specifications: Being open to alternative specifications or materials can provide leverage in negotiations. Suppliers may offer discounts for standard products over custom solutions.

-

Payment Terms: Negotiate favorable payment terms, such as extended payment periods or discounts for early payments, to improve cash flow management.

Disclaimer for Indicative Prices

The pricing information provided herein is indicative and can vary based on market conditions, supplier negotiations, and other factors. It is advisable for buyers to request quotes directly from suppliers to obtain accurate pricing tailored to their specific needs.

Illustrative image related to rubber shock cord

Alternatives Analysis: Comparing rubber shock cord With Other Solutions

Understanding Alternatives to Rubber Shock Cord

When evaluating the best solution for securing and tying down loads, it’s essential to consider various options available in the market. Rubber shock cord is popular for its elasticity and durability, but alternative solutions may offer benefits that better meet specific operational needs. This analysis compares rubber shock cord against bungee cords and ratchet straps, two viable alternatives, focusing on key performance aspects.

| Comparison Aspect | Rubber Shock Cord | Bungee Cord | Ratchet Strap |

|---|---|---|---|

| Performance | High elasticity; durable | Excellent stretch; versatile | Very strong; low stretch |

| Cost | Moderate cost per foot | Typically lower cost | Higher upfront cost |

| Ease of Implementation | Easy to customize lengths | Ready to use; various sizes | Requires more setup |

| Maintenance | Low; generally durable | Moderate; can wear over time | Low; high durability |

| Best Use Case | Custom tie-downs, outdoor use | Casual use, light loads | Heavy-duty applications |

Exploring the Pros and Cons of Each Alternative

What are the Advantages and Disadvantages of Bungee Cords?

Bungee cords are made from elastic materials and are designed for quick and easy use. They come pre-manufactured in various sizes, making them convenient for securing items quickly. However, their strength can vary significantly based on the size and quality, and they may not provide the same level of durability as rubber shock cords in harsh environments. Bungee cords are ideal for lighter applications, such as securing garden equipment or bicycles, but may not be suitable for heavy-duty tarping or long-term outdoor use due to wear and tear.

How Do Ratchet Straps Compare to Rubber Shock Cord?

Ratchet straps are designed for heavy-duty securing and are known for their strength and reliability. They utilize a ratcheting mechanism that allows for tight tension, making them perfect for transporting heavy loads. However, they require more time to set up and can be cumbersome to adjust. Ratchet straps are best for applications where maximum security is necessary, such as in transportation of goods or securing large loads on trucks. While they come at a higher initial cost, their durability and strength can justify the investment for businesses dealing with heavy cargo.

Making the Right Choice for Your Business Needs

When selecting between rubber shock cord, bungee cords, and ratchet straps, B2B buyers should consider the specific requirements of their applications. Rubber shock cord is ideal for custom solutions requiring flexibility and adaptability, while bungee cords offer convenience for lighter tasks. For those needing maximum security for heavy loads, ratchet straps are the optimal choice despite their higher cost and setup time. Ultimately, the decision should align with the operational demands, budget constraints, and expected durability in the specific working environment.

Essential Technical Properties and Trade Terminology for rubber shock cord

What Are the Key Technical Properties of Rubber Shock Cord?

Rubber shock cord is a versatile material used in various applications, from securing cargo to creating custom tie-downs. Understanding its technical properties is essential for B2B buyers to make informed purchasing decisions.

1. Material Composition

Rubber shock cord typically consists of a rubber core encased in a braided polyester or nylon sheath. The rubber provides elasticity, while the outer layer offers durability and resistance to wear and UV exposure. This combination is crucial for applications that require both stretchability and strength, ensuring that the shock cord can withstand varying loads without degradation.

2. Diameter and Length Specifications

Rubber shock cords are available in various diameters, typically ranging from 1/8″ to 1/2″. Each diameter serves different applications; for instance, smaller diameters are ideal for lightweight tasks like tent pole repairs, while larger diameters are suited for heavy-duty use, such as securing tarps on trucks. Length options often range from 50 feet to 500 feet, allowing buyers to select the appropriate length for their specific needs.

3. Breaking Strength and Working Load Limit

The breaking strength of rubber shock cord varies with diameter, generally ranging from 100 lbs for smaller diameters up to 500 lbs for larger ones. Understanding the breaking strength is vital for B2B buyers to ensure that the cord can handle the intended load without failure. The working load limit, which is typically a fraction of the breaking strength, indicates the safe operational capacity of the cord under normal use.

4. Elongation Factor

Rubber shock cords usually exhibit an elongation factor of approximately 100-125% under full load, meaning that a 6-inch piece can stretch significantly when tension is applied. This characteristic is crucial for applications requiring flexibility and movement, allowing the cord to absorb shocks and maintain tension without snapping.

5. Durability and Weather Resistance

The outer sheath of rubber shock cord is designed to resist UV rays, abrasion, and weather conditions. This durability is particularly important for outdoor applications, where exposure to elements can compromise the cord’s integrity. B2B buyers should prioritize cords with high UV resistance to ensure longevity and reliability in various environments.

Illustrative image related to rubber shock cord

What Are Common Trade Terms in the Rubber Shock Cord Industry?

Navigating the terminology associated with rubber shock cord can enhance communication between buyers and suppliers, ensuring clarity in transactions.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. For rubber shock cord, buyers may engage with OEMs to source custom solutions tailored to their specific needs, ensuring compatibility with their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to plan their inventory and budget effectively. Suppliers often set MOQs based on production costs, which can affect pricing.

Illustrative image related to rubber shock cord

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. By issuing an RFQ for rubber shock cord, buyers can compare prices, quality, and delivery times from multiple suppliers, enabling better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including delivery, risk, and costs. Familiarity with Incoterms is crucial for B2B buyers, especially when importing rubber shock cord from other countries, as it clarifies shipping terms and responsibilities.

5. Lead Time

Lead time refers to the amount of time it takes for an order to be processed and shipped. Understanding lead times for rubber shock cord can help buyers manage their supply chains effectively and plan for product availability.

6. Customs Duties and Tariffs

These are taxes imposed on imported goods. B2B buyers must be aware of any customs duties and tariffs associated with importing rubber shock cord, as these can significantly impact total costs and pricing strategies.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions, ensuring they select the right rubber shock cord for their applications while navigating the complexities of international trade.

Illustrative image related to rubber shock cord

Navigating Market Dynamics and Sourcing Trends in the rubber shock cord Sector

What Are the Current Market Dynamics and Key Trends in the Rubber Shock Cord Sector?

The global rubber shock cord market is experiencing significant growth driven by the increasing demand for versatile, durable, and flexible cord solutions across various industries. One of the primary drivers is the booming logistics and transportation sector, particularly in regions like Africa, South America, and the Middle East, where efficient load securing is critical. The European market, especially in countries like Germany, is also witnessing a rise in demand due to stringent safety regulations regarding cargo securing.

Emerging B2B technology trends are reshaping sourcing dynamics. The adoption of e-commerce platforms allows international buyers to access a broader range of suppliers and products, facilitating price comparisons and procurement efficiency. Additionally, advancements in manufacturing technology, such as the use of synthetic materials and improved production techniques, are enhancing product performance, leading to increased interest from buyers seeking high-quality rubber shock cords.

Sourcing trends indicate a shift towards customization, as businesses seek tailored solutions for specific applications. For instance, industries requiring unique elastic properties, such as automotive or outdoor recreation, are driving demand for specialized shock cords. Furthermore, the rise of global supply chains emphasizes the importance of establishing reliable partnerships with manufacturers who can offer consistent quality and timely delivery.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Rubber Shock Cord Procurement?

Sustainability is becoming a cornerstone of procurement strategies in the rubber shock cord sector. Environmental concerns related to synthetic rubber production and disposal have led buyers to prioritize suppliers who demonstrate a commitment to reducing their ecological footprint. The importance of ethical supply chains cannot be overstated, as consumers increasingly demand transparency about product origins and manufacturing practices.

B2B buyers should look for suppliers that utilize ‘green’ certifications and materials, such as EPDM rubber, which is known for its longevity and resistance to environmental degradation. Engaging with manufacturers who adopt eco-friendly production methods and responsible sourcing practices not only mitigates environmental impact but also enhances brand reputation.

Illustrative image related to rubber shock cord

Moreover, incorporating sustainable practices in supply chains can lead to cost savings in the long run, as energy-efficient production processes and waste reduction strategies often translate into lower operational costs. Buyers are encouraged to conduct thorough due diligence on potential suppliers, evaluating their sustainability initiatives and certifications to ensure alignment with corporate social responsibility goals.

What Is the Brief Evolution and History of Rubber Shock Cord for B2B Buyers?

Rubber shock cord has evolved significantly since its inception, initially used primarily in military applications and outdoor gear. Its unique elastic properties made it indispensable for securing loads and providing tension in various scenarios. Over the decades, advancements in materials science have led to the development of synthetic alternatives, enhancing durability and performance.

The introduction of braided nylon sheaths around rubber cores has provided added protection against wear and tear, making shock cords suitable for a wider array of applications, from recreational activities to industrial uses. As the market has expanded, so too has the diversity of product offerings, with manufacturers now providing options tailored to specific industry needs, such as UV resistance for outdoor applications or varying stretch capacities for different load requirements.

This evolution reflects a broader trend in B2B procurement towards specialization and customization, enabling buyers to find solutions that precisely match their operational needs. Understanding the historical context of rubber shock cord development can help international buyers appreciate the technological advancements that drive current offerings and market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber shock cord

-

How do I choose the right rubber shock cord for my application?

Selecting the appropriate rubber shock cord requires understanding your specific needs. Consider factors such as the cord’s diameter, material (like EPDM for UV resistance), and the maximum load it will support. Smaller diameters are ideal for lightweight applications, while larger diameters provide higher strength for heavy-duty use. Additionally, evaluate the environmental conditions, such as exposure to sunlight or extreme temperatures, to ensure the cord will perform effectively. -

What are the key characteristics of high-quality rubber shock cord?

High-quality rubber shock cord should feature a durable outer jacket made from materials like polyester, which offers UV and abrasion resistance. The core should consist of continuous strands of rubber, providing consistent elasticity and a reliable stretch factor, typically between 100-125%. Look for cords that maintain their performance over time and under various load conditions, ensuring they can withstand repeated use without significant wear. -

What minimum order quantities (MOQs) should I expect when sourcing rubber shock cord?

MOQs for rubber shock cord can vary significantly based on the supplier and the type of cord you require. Typically, you may find MOQs ranging from 100 to 500 meters for standard products, while custom orders may require higher quantities. Always communicate your needs upfront to suppliers, as some may offer flexibility for first-time buyers or larger contracts, especially in international markets. -

What payment terms are common when purchasing rubber shock cord internationally?

Payment terms can differ among suppliers, but common practices include options like advance payment, letters of credit, or payment upon delivery. For international transactions, suppliers often prefer secure payment methods that mitigate risks. Discussing payment options early in negotiations can help establish trust and ensure that both parties are comfortable with the arrangement. -

How can I ensure the quality of the rubber shock cord I purchase?

To guarantee quality, consider requesting certifications or test reports from your supplier that demonstrate compliance with industry standards. It’s also beneficial to conduct a sample inspection before placing a large order, allowing you to assess the material, strength, and elasticity firsthand. Establishing a relationship with reputable suppliers who have a proven track record in quality assurance can further enhance your confidence in the products. -

What logistics considerations should I keep in mind when importing rubber shock cord?

When importing rubber shock cord, consider factors such as shipping methods, customs regulations, and potential tariffs. Work with logistics partners experienced in international trade to navigate shipping routes and delivery timelines effectively. Additionally, ensure that your supplier can provide the necessary documentation for customs clearance, such as bills of lading and certificates of origin, to avoid delays. -

How do I vet potential suppliers of rubber shock cord?

Vetting suppliers involves researching their reputation, production capabilities, and quality assurance processes. Look for suppliers with industry certifications and positive customer reviews. Conducting site visits or requesting virtual tours can provide insights into their operations. Additionally, consider engaging in small trial orders to evaluate their reliability and responsiveness before committing to larger contracts. -

Can I customize rubber shock cord for specific applications?

Yes, many suppliers offer customization options for rubber shock cord, including variations in diameter, length, and material composition. If you have specific requirements, such as color coding or unique stretch characteristics, communicate these needs to your supplier. Custom orders may involve higher MOQs and longer lead times, so plan accordingly to ensure that your specific applications are met effectively.

Top 5 Rubber Shock Cord Manufacturers & Suppliers List

1. Paracord Planet – Heavy Duty Shock Cord

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: Heavy Duty Shock for Marine and Rugged Use. Variations include: 2.5MM Shock Cord, 1/8″ Shock Cord, 3/16″ Shock Cord, 1/4″ Shock Cord, 5/16″ Shock Cord, 3/8″ Shock Cord, 1/2″ Shock Cord, 5/8″ Shock Cord, and Reflective Shock Cord. Prices range from $4.99 to $349.99 with free standard shipping on orders of $8.99 or more (US only). Shock cord features a braided nylon sheath surrounding a rubber core,…

2. Harris Co – Rubber Rope

Domain: harriscos.com

Registered: 1997 (28 years)

Introduction: Rubber Rope is a type of bungee cord made from EPDM rubber, commonly used for truck tarping systems. Available in both domestic and import options, it comes in hollow or solid core variants. Hollow core stretches slightly more and is easier to pull, while solid core offers more tenacity and durability. Sizes available are 3/8″ and 7/16″, sold in 150′ rolls, with additional options for large volume…

3. Rope.com – Elastic Shock Cord

Domain: rope.com

Registered: 1996 (29 years)

Introduction: Elastic Shock Cord Bungee Cord

– Type: All-purpose bungee shock cord

– Material: Durable braided nylon cover over elastic core

– Features: UV and abrasion resistant, extremely strong, easy to cut

– Available Colors: White/Black, Solid Black

– Braid Type: Double Braid

– Uses: General Purpose Utility

– Sizes and Pricing:

– 1/8″ / White and Black / 1,000 Feet – $121.84

– 1/8″ / Black / 1,000 Feet…

4. Rigging Warehouse – Shock Cord & Rubber Rope

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: {“product_name”: “Shock Cord & Rubber Rope”, “available_sizes”: [{“size”: “1/2″ – Per Foot”, “color”: “White/Black”, “sku”: “176-SHOCK0500-0000”}, {“size”: “1/2″ x 100′”, “color”: “White/Black”, “sku”: “176-SHOCK0500-0100”}, {“size”: “1/4″ x 300′”, “color”: “White/Black”, “sku”: “176-SHOCK0250-0300”}, {“size”: “1/4″ x 500′”, “color”: “Black”, “sku”: “176-SHOCK0250B-0500”}, {“size”: “1/4″ x 500′”, …

5. Dive Gear Express – Shock Cord Bungee

Domain: divegearexpress.com

Registered: 2004 (21 years)

Introduction: Shock Cord Bungee – Per Foot, constructed of synthetic rubber with a nylon braided jacket, rot-proof, waterproof, resistant to mold, mildew, and UV. Stretches 100% of its original length. Suitable for marine applications. Available in four diameters: Thin (1/8 in | 3 mm), Medium (5/32 in | 4 mm), Thick (3/16 in | 5 mm), Extra Thick (1/4 in | 6 mm). Priced as low as $0.40 per foot, ships as one con…

Strategic Sourcing Conclusion and Outlook for rubber shock cord

In conclusion, the strategic sourcing of rubber shock cord is essential for businesses looking to enhance their operational efficiency and product offerings. Key takeaways highlight the versatility of shock cord, which is ideal for a wide range of applications from truck tarping systems to DIY projects. Understanding the differences between materials, such as EPDM and natural rubber, can significantly impact performance and durability, particularly in varying climates.

Moreover, the ability to customize lengths and diameters provides buyers the flexibility needed to meet specific project requirements. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize partnerships with reliable suppliers who can offer quality products, competitive pricing, and responsive service.

As the demand for high-performance elastic solutions continues to grow, now is the time to reassess your sourcing strategies. By investing in quality rubber shock cord, businesses can ensure they are equipped to meet evolving market needs. We encourage you to explore potential suppliers and leverage strategic sourcing to enhance your product lines and operational capabilities. The future is bright for those ready to adapt and innovate in their sourcing practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to rubber shock cord