Rubber Roller Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for rubber roller

In the competitive landscape of global manufacturing, sourcing the right rubber roller can significantly impact operational efficiency and product quality. International B2B buyers often face the challenge of identifying reliable suppliers who can meet their specific needs, whether it’s for flexographic printing, food processing, or metal treatment applications. This guide serves as a comprehensive resource for navigating the intricacies of the rubber roller market, providing insights into various types of rollers, their applications across diverse industries, and effective strategies for vetting suppliers.

Understanding the nuances of rubber roller specifications—including material composition, durability, and performance characteristics—is essential for making informed purchasing decisions. Additionally, this guide addresses critical factors such as cost considerations, shipping logistics, and compliance with international quality standards, particularly for buyers in Africa, South America, the Middle East, and Europe, including Germany and Vietnam.

By equipping B2B buyers with actionable insights and practical tips, this guide empowers businesses to optimize their sourcing strategies, ensuring that they not only select the most suitable rubber rollers for their operations but also foster long-term relationships with trusted suppliers. As you explore the sections ahead, you’ll gain a clearer understanding of how to leverage the global market for rubber rollers to enhance your manufacturing processes and achieve a competitive edge.

Understanding rubber roller Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Arcoflex Rollers | Premium elastomeric, precise tolerances for ink transfer | Flexographic printing, especially corrugated | Pros: Uniform ink transfer, minimal wear; Cons: Higher initial cost. |

| Astronip Rollers | Durable coverings with high abrasion resistance | Blown film extrusion | Pros: Excellent wear resistance; Cons: Limited to specific applications. |

| Excelnip Rollers | High-temperature tolerance, cosmetic free surface | Cast extrusion and coating | Pros: Long service life, non-transferring surface; Cons: May require specialized handling. |

| Niprite Rollers | High performance with good heat resistance and release properties | Nip roller applications | Pros: Handles high pressures, resistant to wear; Cons: May not suit all environments. |

| V-Series Rollers | Superior hardness and dimensional stability for UV and EB inks | Printing press applications | Pros: Consistent ink transfer, long service life; Cons: Requires specific ink compatibility. |

What are the Characteristics and Suitability of Arcoflex Rollers?

Arcoflex rollers are designed for flexographic printing, particularly in corrugated applications. Their premium elastomeric material ensures precise tolerances, which is crucial for achieving uniform ink transfer while minimizing wear over time. B2B buyers should consider these rollers for their ability to work effectively with both water and solvent-based inks, making them versatile for various printing needs. However, the higher initial investment may be a factor for businesses with tighter budgets.

How Do Astronip Rollers Stand Out in Blown Film Extrusion?

Astronip rollers are known for their exceptional durability and high abrasion resistance, making them ideal for blown film extrusion processes. They are specifically designed to withstand harsh environments and provide high release capabilities, which is essential in applications where materials may stick to the roller surface. Buyers should evaluate their specific operational needs, as these rollers excel in demanding conditions but may be limited to specific uses within the industry.

What Makes Excelnip Rollers Ideal for High-Temperature Applications?

Excelnip rollers are engineered to perform in high-temperature environments, withstanding temperatures up to 400°F. Their unique non-transferring surface ensures that the final product remains free from imperfections, which is critical in cast extrusion and coating processes. B2B buyers should consider Excelnip rollers for applications requiring a cosmetic finish. However, handling these rollers may necessitate specialized knowledge to maintain their performance.

Why Choose Niprite Rollers for High-Pressure Applications?

Niprite rollers combine the performance characteristics of silicone and EPDM, making them suitable for high-pressure nip applications. They exhibit excellent heat resistance and wear properties, ensuring longevity and reliability in demanding environments. When purchasing, businesses should consider the operational pressures and temperatures to ensure compatibility, as these rollers may not be the best fit for all applications.

What Are the Advantages of V-Series Rollers in Printing Press Applications?

V-Series rollers offer superior hardness and dimensional stability, essential for printing applications using UV and EB energy curing inks. Their ability to resist end picking and provide consistent ink transfer leads to enhanced productivity and reduced downtime. For B2B buyers, it’s crucial to assess the compatibility of these rollers with the specific inks used in their processes, as this can significantly impact performance and longevity.

Key Industrial Applications of rubber roller

| Industry/Sector | Specific Application of Rubber Roller | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Printing | Ink fountain rollers for flexographic printing | Ensures uniform ink transfer and minimizes wear | Taper, straightness, and concentricity tolerances |

| Food & Beverage | Coating rollers for food packaging | Enhances product quality and extends service life | Compliance with food safety regulations |

| Pulp & Paper | Forming and pressure rollers in paper production | Improves production efficiency and reduces downtime | Material durability and resistance to wear |

| Plastic Film & Sheet | Feed rollers for film extrusion processes | Provides consistent feed and reduces material waste | Compatibility with different film types and thicknesses |

| Tire & Rubber | Rollers for tire manufacturing processes | Increases production speed and product consistency | High temperature resistance and durability |

How are Rubber Rollers Used in Printing Applications?

In the printing industry, rubber rollers are integral to flexographic printing processes, particularly as ink fountain rollers. These rollers ensure uniform ink transfer, which is crucial for achieving high-quality prints. Buyers in this sector must consider the tight tolerances required for taper, straightness, and concentricity to minimize wear and maintain consistent performance. For international buyers, sourcing from manufacturers that adhere to stringent quality standards can significantly impact the reliability of their printing operations.

What Role do Rubber Rollers Play in Food & Beverage Packaging?

In the food and beverage sector, rubber rollers are commonly used for coating applications in packaging processes. These rollers help create a consistent coating film, which is vital for product quality and shelf life. Businesses benefit from extended service life due to the durability of the rubber materials used. International buyers should prioritize suppliers that offer rollers compliant with food safety regulations, ensuring that their products meet local and international standards.

How are Rubber Rollers Utilized in Pulp & Paper Production?

Rubber rollers are essential in the pulp and paper industry, particularly as forming and pressure rollers. They facilitate the efficient formation of paper sheets and improve the overall production process. The durability of these rollers reduces downtime, which is a significant cost-saving factor for manufacturers. Buyers should focus on sourcing rollers that are specifically designed to withstand the harsh conditions of paper production, including wear resistance and longevity.

In What Ways are Rubber Rollers Important in Plastic Film Production?

In the plastic film and sheet sector, rubber rollers are used primarily in feed applications during extrusion processes. These rollers ensure a consistent feed of materials, which is critical for minimizing waste and maintaining production efficiency. Buyers must consider the compatibility of rubber rollers with various film types and thicknesses to ensure optimal performance. Sourcing from reputable manufacturers with a proven track record can help businesses achieve better operational outcomes.

Why are Rubber Rollers Crucial in Tire Manufacturing?

Rubber rollers are vital in the tire manufacturing process, where they assist in various stages, including molding and curing. Their ability to withstand high temperatures and provide consistent pressure is essential for producing high-quality tires. Businesses benefit from increased production speed and uniformity in tire quality. When sourcing rubber rollers, international buyers should look for suppliers that specialize in high-temperature resistant materials, ensuring that their manufacturing processes remain efficient and effective.

3 Common User Pain Points for ‘rubber roller’ & Their Solutions

Scenario 1: Inconsistent Quality in Printing Processes

The Problem: B2B buyers in the printing industry often face challenges with rubber rollers that lead to inconsistent ink transfer and print quality. Factors such as roller wear, improper specifications, and inadequate maintenance can result in smudged prints or uneven color distribution, ultimately affecting product quality and customer satisfaction. These issues not only cause delays in production but can also lead to costly reprints and loss of client trust.

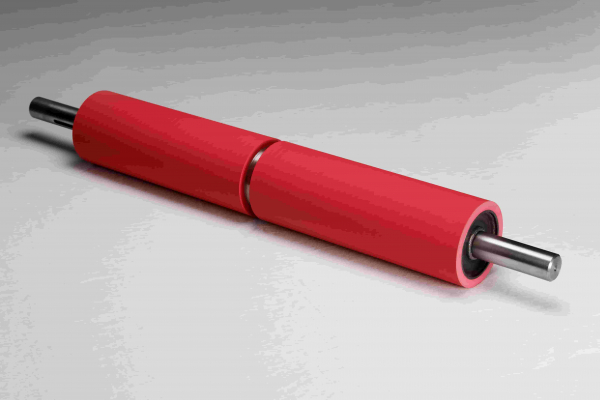

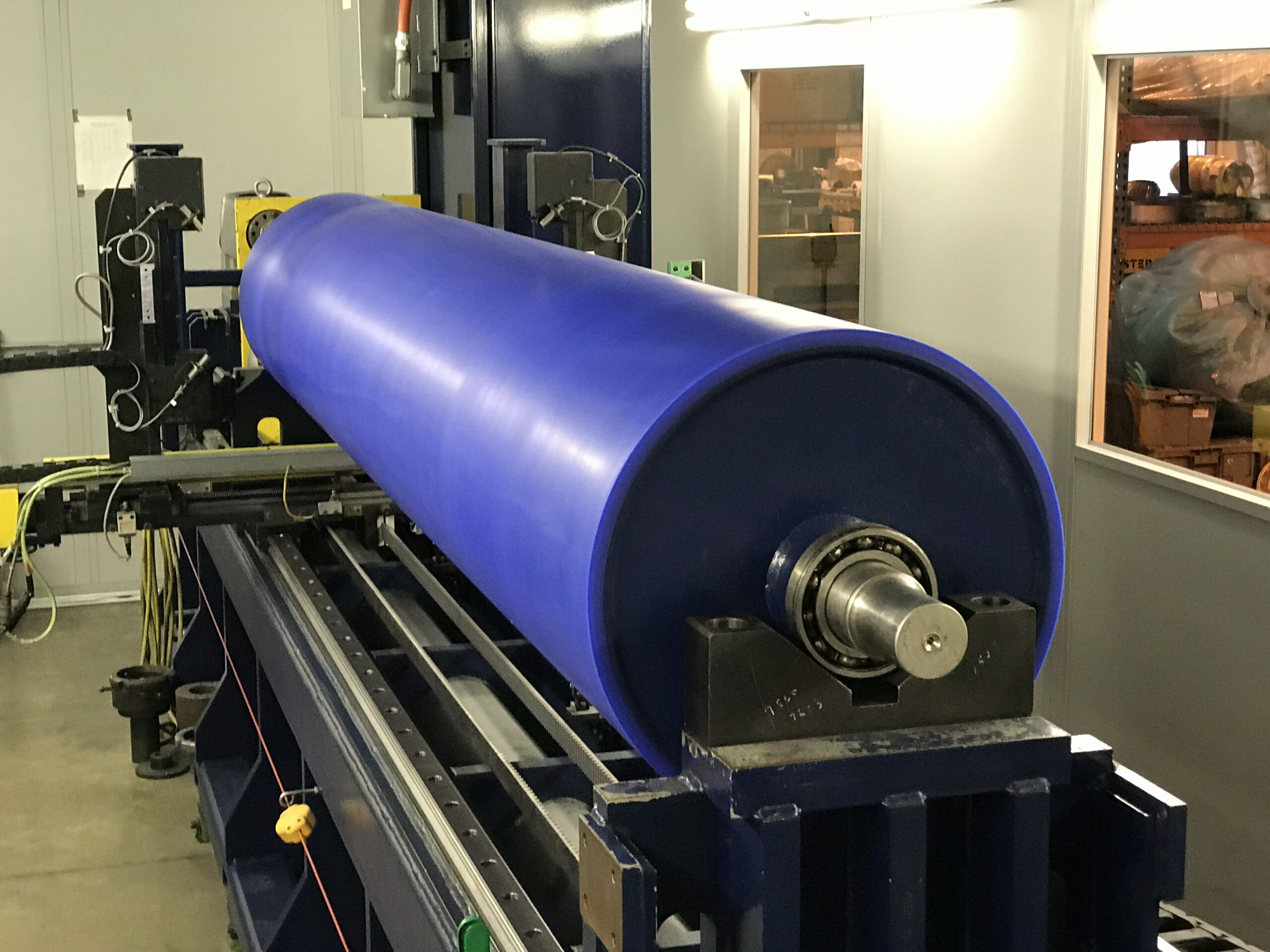

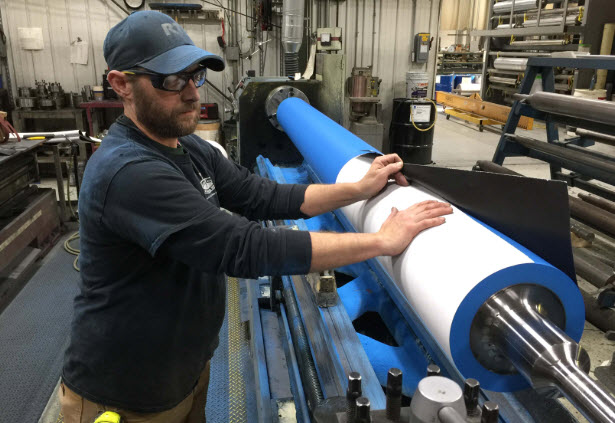

Illustrative image related to rubber roller

The Solution: To combat these quality control issues, it is essential to source rubber rollers that are specifically designed for the printing process in use. Buyers should consider rollers with tight tolerances for taper and straightness, as these features ensure uniform ink transfer. Additionally, selecting rollers made from high-performance materials, such as those that reduce hysteresis and maintain dimensional stability, can significantly improve print consistency. Implementing a regular maintenance schedule, which includes cleaning and inspecting rollers for wear, can help extend their lifespan and maintain optimal performance. Collaborating with suppliers who offer tailored solutions based on specific application needs can also enhance print quality and efficiency.

Scenario 2: High Downtime Due to Roller Failures

The Problem: Manufacturing facilities frequently experience unexpected downtime due to roller failures. This can be particularly detrimental in industries such as food processing or packaging, where production schedules are tight and any delays can lead to significant financial losses. Common causes of roller failures include inadequate heat resistance, wear from abrasives, and chemical exposure, leading to premature breakdowns.

The Solution: To minimize downtime, it is crucial to select rubber rollers that are engineered for the specific environmental conditions of the application. For example, choosing rollers that offer excellent resistance to heat, ozone, and various chemicals can prevent failures in harsh manufacturing settings. Buyers should work closely with suppliers to understand the properties of different rubber compounds and select options that align with their operational needs. Additionally, implementing a predictive maintenance program, using vibration analysis or thermal imaging, can help identify potential issues before they lead to failures, allowing for proactive replacements and minimizing unexpected production halts.

Scenario 3: Difficulty in Sourcing the Right Roller Material

The Problem: B2B buyers often struggle with sourcing the right rubber roller material for their specific applications, leading to inefficiencies and increased costs. With a wide variety of compounds available, such as EPDM, urethane, and silicone, making the right choice can be overwhelming. Incorrect material selection can result in poor performance, such as inadequate abrasion resistance or thermal stability, affecting overall production quality.

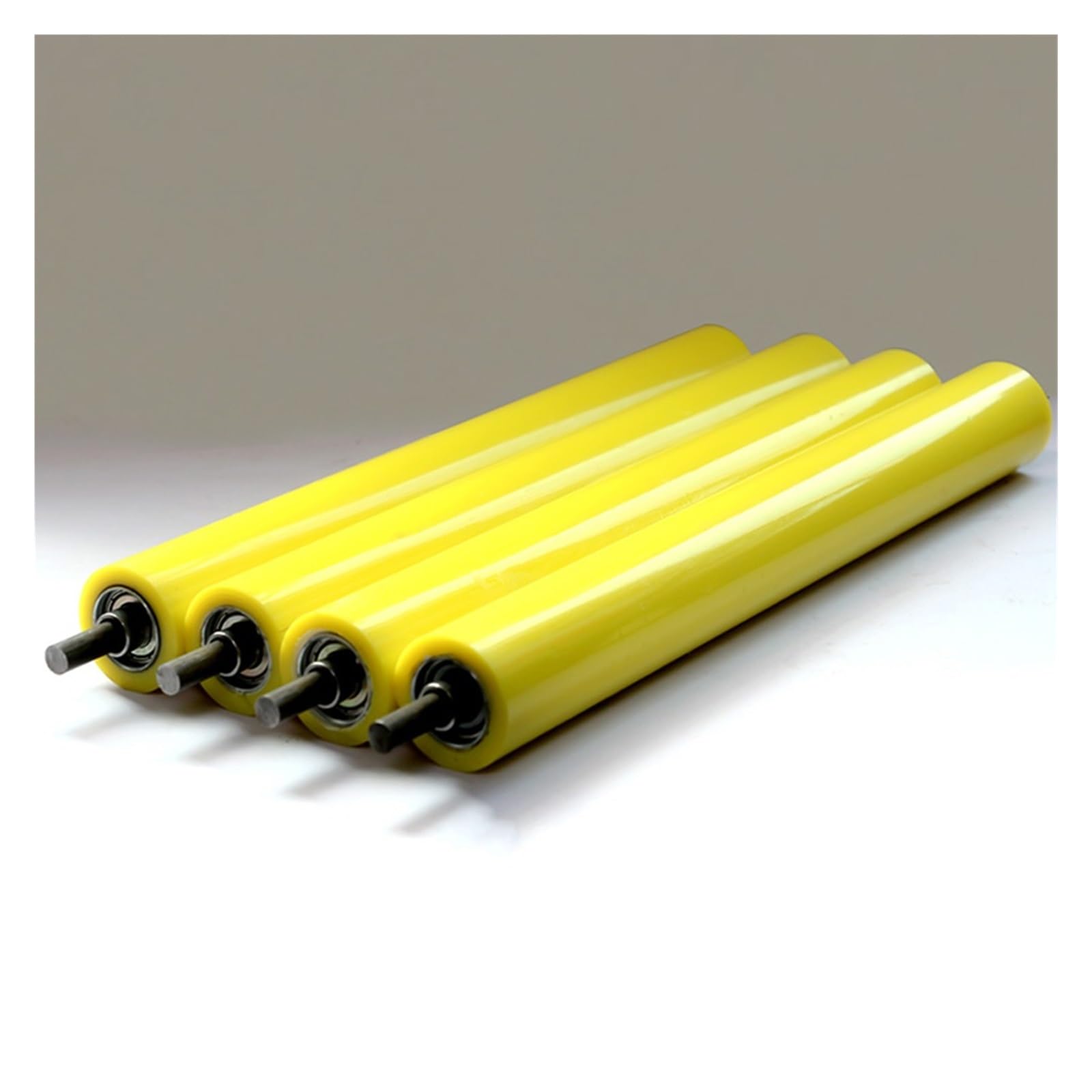

Illustrative image related to rubber roller

The Solution: To simplify the sourcing process, buyers should begin by conducting a thorough analysis of their application requirements, including temperature ranges, exposure to chemicals, and the nature of the materials being processed. Engaging with suppliers who offer a diverse range of roller materials and who can provide expert insights into material properties is crucial. Buyers should also consider custom formulations that meet specific operational demands. Requesting samples for testing and gathering feedback from production teams can provide valuable insights before making a bulk purchase. By establishing a partnership with a knowledgeable supplier, buyers can ensure they select the right roller material that optimizes performance and reduces long-term costs.

Strategic Material Selection Guide for rubber roller

What Are the Key Properties of Common Materials Used in Rubber Rollers?

When selecting materials for rubber rollers, it is essential to consider their specific properties that directly influence performance in various applications. Below, we analyze four common materials used in the manufacturing of rubber rollers: EPDM, Nitrile, Urethane, and Silicone. Each material has unique characteristics that can affect durability, cost, and suitability for specific applications.

How Does EPDM Rubber Perform in Rubber Roller Applications?

EPDM (Ethylene Propylene Diene Monomer) rubber is known for its excellent resistance to heat, ozone, and weathering. It typically operates effectively in temperature ranges from -40°F to 300°F. The material’s resilience to environmental factors makes it ideal for outdoor applications and industries where exposure to harsh conditions is common.

Pros: EPDM rubber is highly durable, cost-effective, and provides good flexibility, making it suitable for various applications, including automotive and industrial uses.

Cons: However, it has limited oil and solvent resistance, which can be a drawback in industries where exposure to such substances is frequent.

Impact on Application: EPDM is particularly effective in applications requiring weather resistance, such as outdoor printing and packaging.

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially for buyers in Europe and North America. EPDM is widely accepted and used, but buyers in regions like Africa and South America should ensure local suppliers meet these standards.

What Makes Nitrile Rubber a Preferred Choice for Certain Applications?

Nitrile rubber, or NBR, is renowned for its excellent oil and chemical resistance, making it a preferred choice for applications involving petroleum-based products. It can withstand temperatures up to 250°F and is particularly effective in environments where exposure to oils and greases is common.

Pros: The material offers high durability and resistance to wear and tear, making it suitable for heavy-duty applications in industries such as automotive and manufacturing.

Illustrative image related to rubber roller

Cons: Nitrile rubber can be more expensive than other materials, which may deter cost-sensitive buyers. Additionally, it has limited resistance to ozone and weathering.

Impact on Application: Nitrile is ideal for rubber rollers used in printing, packaging, and automotive applications where oil exposure is prevalent.

Considerations for International Buyers: Buyers should verify compliance with ASTM and ISO standards. In regions like the Middle East, where oil exposure is common, Nitrile’s properties can be particularly advantageous.

Why Choose Urethane for High-Performance Rubber Rollers?

Urethane rubber is celebrated for its exceptional abrasion resistance and durability. It can operate in temperatures ranging from -40°F to 200°F and is known for its ability to withstand harsh chemicals and solvents.

Pros: Urethane rollers provide longer service life and reduced downtime, making them ideal for high-performance applications in industries like printing, packaging, and food processing.

Cons: The manufacturing complexity can result in higher costs compared to other materials, which may not be suitable for all budgets.

Impact on Application: Urethane is particularly effective in applications requiring high wear resistance, such as in food processing and packaging.

Considerations for International Buyers: Buyers should ensure that Urethane rollers meet relevant food safety standards, especially in regions with strict regulations like Europe.

When is Silicone Rubber the Best Option for Rubber Rollers?

Silicone rubber is known for its excellent temperature resistance, functioning effectively from -100°F to 500°F. It is also highly resistant to UV light, ozone, and extreme weather conditions.

Pros: Silicone’s flexibility and stability make it suitable for a wide range of applications, including those requiring high-temperature resistance.

Cons: However, silicone can be less durable than other materials when exposed to abrasive conditions, and it is generally more expensive.

Impact on Application: Silicone is often used in specialized applications such as food processing and medical devices due to its non-toxic properties.

Considerations for International Buyers: Compliance with FDA and other health standards is critical for buyers in the food and medical sectors, especially in Europe and North America.

Summary Table of Material Selection for Rubber Rollers

| Material | Typical Use Case for rubber roller | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EPDM | Outdoor applications, automotive | Excellent weather resistance | Limited oil and solvent resistance | Low |

| Nitrile | Automotive, printing, packaging | High oil and chemical resistance | More expensive, limited ozone resistance | Med |

| Urethane | Food processing, high-performance | Exceptional abrasion resistance | Higher manufacturing complexity | High |

| Silicone | Food processing, medical devices | Excellent temperature resistance | Less durable in abrasive conditions | High |

This guide provides actionable insights for international B2B buyers, helping them navigate material selection based on performance needs and regional compliance requirements.

Illustrative image related to rubber roller

In-depth Look: Manufacturing Processes and Quality Assurance for rubber roller

What Are the Key Stages in the Manufacturing Process of Rubber Rollers?

The manufacturing process for rubber rollers involves several critical stages that ensure the final product meets the high standards required by various industries. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

Material Preparation: Selecting the Right Rubber Compound

The initial stage of manufacturing rubber rollers is material preparation. This involves selecting the appropriate rubber compound, which can vary based on the intended application. Common materials include natural rubber, synthetic rubbers like EPDM and Butyl, and specialized compounds designed for specific performance characteristics, such as heat resistance or abrasion resistance.

Once the right material is selected, it undergoes mixing, where additives such as accelerators, fillers, and colorants are incorporated to enhance properties like durability and elasticity. This stage is crucial because the composition of the rubber directly affects the roller’s performance in its application.

How Is the Forming Process Conducted for Rubber Rollers?

After material preparation, the next stage is forming the rubber into the desired shape. This can be achieved through several techniques, including:

- Extrusion: This method involves forcing the rubber compound through a die to create a continuous shape, which is then cut to the required length.

- Molding: In this technique, rubber is placed into a mold, where heat and pressure are applied to cure the rubber, allowing it to take the mold’s shape. Compression molding and injection molding are common methods used in this stage.

These forming techniques are essential in achieving the precise dimensions and surface characteristics required for effective performance in applications such as printing, packaging, and manufacturing.

What Happens During the Assembly and Finishing Stages?

Following the forming process, the rubber rollers undergo assembly and finishing. This stage may involve:

- Bonding: If the roller consists of multiple components (e.g., a core and a rubber cover), bonding techniques such as adhesive bonding or vulcanization are used to ensure a strong and durable connection.

- Trimming and Grinding: Once assembled, the rollers are often trimmed to remove excess material and ground to achieve the desired surface finish and dimensions. Precision in this step is crucial for ensuring that the roller operates smoothly and efficiently in its application.

Finishing processes may also include surface treatments, such as polishing or coating, to enhance durability and performance under specific conditions.

What Quality Assurance Measures Are Essential in Rubber Roller Manufacturing?

Quality assurance (QA) is a vital component of the rubber roller manufacturing process, ensuring that each product meets industry standards and customer specifications. Several international standards and industry-specific certifications guide these QA processes.

What International Standards Should B2B Buyers Be Aware Of?

Many manufacturers adhere to ISO 9001, an international standard focused on quality management systems. This certification ensures that the manufacturer has established processes for continuous improvement and customer satisfaction.

Additionally, industry-specific certifications like CE (Conformité Européenne) or API (American Petroleum Institute) may be relevant, depending on the roller’s application. For instance, rollers used in the food and beverage sector may need to comply with FDA regulations, while those in the oil and gas industry may require API certification.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. Materials that do not meet requirements are rejected or sent back to suppliers.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters such as temperature, pressure, and dimensions are monitored. This ensures that any deviations from specifications are caught early in the process.

-

Final Quality Control (FQC): After production, the finished rubber rollers undergo a comprehensive inspection, including dimensional checks, surface quality assessments, and functional testing to ensure they meet performance standards.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, verifying a supplier’s quality assurance practices is crucial to ensure product reliability and performance. Here are some effective strategies:

Illustrative image related to rubber roller

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess manufacturing processes, quality control measures, and adherence to international standards. This firsthand evaluation can provide significant insights into the supplier’s capabilities.

-

Requesting Quality Reports: Buyers can ask suppliers for documentation of their quality control processes, including test results, certifications, and compliance with industry standards. This transparency helps build trust and confidence in the supplier’s reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. These inspections can occur at various stages of the manufacturing process and help ensure that products meet the specified standards.

What Common Testing Methods Are Used for Quality Assurance in Rubber Rollers?

Testing methods are essential for validating the performance and durability of rubber rollers. Common tests include:

-

Hardness Testing: This evaluates the rubber’s hardness using durometers, which measure resistance to indentation. Different applications may require specific hardness levels.

-

Tensile Strength Testing: This assesses the rubber’s ability to withstand stretching and pulling forces, ensuring it can perform under operational stresses.

-

Abrasion Resistance Testing: This measures how well the rubber can resist wear and tear during use, which is critical for rollers in high-friction applications.

-

Thermal Stability Testing: This determines the rubber’s performance under high-temperature conditions, ensuring it will not degrade or lose functionality during operation.

How Do Quality Control Nuances Affect International B2B Buyers?

For international buyers, understanding the nuances of quality control is essential. Different regions may have varying standards and regulations that impact product quality. For example, European buyers may prioritize CE certification, while buyers in the Middle East may focus on compliance with local regulations.

Additionally, cultural differences in business practices can influence how quality assurance is perceived and implemented. Buyers should consider these factors when selecting suppliers and negotiating contracts to ensure they align with their expectations for quality and compliance.

Illustrative image related to rubber roller

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for rubber rollers is vital for B2B buyers looking to source reliable products. By focusing on the key stages of production, relevant standards, and effective verification methods, buyers can make informed decisions that contribute to their operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber roller’

Introduction

When sourcing rubber rollers for your industrial applications, a systematic approach is essential. This guide provides a step-by-step checklist to help international B2B buyers navigate the complexities of procurement, ensuring you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the rubber rollers you need. Consider factors such as the roller’s diameter, length, hardness (durometer), and the specific materials used for coating. This step is critical because the right specifications directly impact the roller’s performance in your application, whether it’s printing, packaging, or manufacturing.

- Material Considerations: Identify whether you need specific types of rubber such as EPDM or Butyl for heat and weather resistance.

- Application Requirements: Specify the operational environment, such as temperature limits or exposure to chemicals.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in rubber rollers relevant to your industry. Look for companies with a strong reputation in the market, especially those recognized in regions like Africa, South America, the Middle East, and Europe.

- Industry Experience: Prioritize suppliers with experience in your specific sector, such as printing or food processing.

- Product Range: Ensure the supplier offers a diverse range of roller types to meet various needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet your shortlisted suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability and performance.

- Quality Assurance: Inquire about their manufacturing processes and quality control measures.

- Customer Feedback: Look for testimonials or reviews from previous clients to assess satisfaction levels.

Step 4: Request Samples

Once you have narrowed down your options, request samples of the rubber rollers. This step allows you to physically assess the quality and suitability of the rollers for your specific applications.

- Performance Testing: Evaluate how the samples perform under your operational conditions.

- Durability Assessment: Check for wear and tear resistance, especially if they will be used in high-stress environments.

Step 5: Verify Supplier Certifications

Ensure that the suppliers you are considering have relevant certifications that demonstrate compliance with industry standards. Certifications can serve as a benchmark for quality and safety.

- ISO Certifications: Look for suppliers with ISO 9001 certifications or other relevant quality management standards.

- Industry-Specific Certifications: Depending on your application, verify compliance with certifications specific to industries like food safety (e.g., FDA compliance).

Step 6: Negotiate Terms and Pricing

After selecting a suitable supplier, engage in negotiations regarding pricing, lead times, and payment terms. Ensure you understand the total cost of ownership, including potential shipping fees and import duties.

- Bulk Discounts: Inquire about pricing breaks for larger orders.

- Payment Flexibility: Discuss payment terms that align with your budget and cash flow needs.

Step 7: Establish a Long-Term Relationship

Once you finalize your purchase, focus on building a long-term relationship with your supplier. This can lead to better pricing, improved service, and priority access to new products.

- Regular Communication: Maintain open lines of communication for ongoing support and updates.

- Feedback Loop: Provide feedback on product performance to help the supplier improve their offerings.

By following this checklist, B2B buyers can effectively source rubber rollers that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for rubber roller Sourcing

What Are the Key Cost Components in Sourcing Rubber Rollers?

When sourcing rubber rollers, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of rubber compounds significantly influences costs. Common materials include EPDM, butyl rubber, and specialty formulations for specific applications. Prices can vary based on the quality and availability of these materials.

-

Labor: Labor costs are influenced by the region of production. Countries with lower labor costs may offer competitive pricing, but this could impact quality and lead times.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can minimize overhead, which may be reflected in the final product price.

-

Tooling: Custom tooling for unique roller specifications can add substantial costs. Buyers should consider whether the investment in tooling is justified by the expected volume of orders.

-

Quality Control: Rigorous QC processes ensure that rollers meet industry standards. Suppliers with advanced QC measures may charge higher prices, but this often results in lower failure rates and longer service life.

-

Logistics: Transportation costs vary significantly based on the shipping method, distance, and destination. Incoterms can affect who bears these costs, influencing the overall pricing structure.

-

Margin: Supplier margins can vary widely based on their market position and the perceived value of their product. Established suppliers with strong reputations may command higher prices.

How Do Price Influencers Affect Rubber Roller Sourcing?

Several factors can influence the pricing of rubber rollers, making it crucial for buyers to understand these dynamics.

-

Volume/MOQ: Larger orders often qualify for discounts due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize costs.

-

Specifications and Customization: Custom rollers tailored to specific applications or industries may carry higher prices. Buyers need to balance the need for customization with budget constraints.

-

Quality and Certifications: Certifications such as ISO or industry-specific standards can justify higher prices. Buyers should assess whether these certifications align with their operational needs.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can impact pricing. Suppliers with a history of consistent quality may charge a premium.

-

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital. These terms dictate cost responsibilities, affecting the total landed cost.

What Buyer Tips Can Help in Negotiating Rubber Roller Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in rubber roller procurement.

Illustrative image related to rubber roller

-

Negotiation Strategies: Engage suppliers in discussions about pricing flexibility, especially regarding larger orders or long-term contracts. Highlighting the potential for future business can motivate suppliers to offer better terms.

-

Evaluating Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also the total cost of ownership, including maintenance, downtime, and replacement costs. A slightly higher upfront cost can be justified if it leads to lower TCO.

-

Understanding Pricing Nuances: Be aware of regional pricing differences. For instance, sourcing from suppliers in Asia may offer lower prices due to reduced labor costs but could involve higher shipping expenses and longer lead times.

-

Leveraging Market Trends: Stay informed about market trends and material prices. This knowledge can empower buyers during negotiations and help them identify the best time to purchase.

-

Building Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms. Suppliers may be more inclined to offer discounts to repeat customers or those who demonstrate loyalty.

Disclaimer on Indicative Prices

It is important to note that prices for rubber rollers can fluctuate based on market conditions, supplier negotiations, and regional factors. Buyers should conduct thorough research and request quotes from multiple suppliers to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing rubber roller With Other Solutions

Introduction to Alternatives for Rubber Rollers

When considering solutions for material handling and processing, rubber rollers are a popular choice due to their versatility and performance. However, various alternative solutions exist that may better suit specific applications or business needs. This section will explore viable alternatives to rubber rollers, comparing them on key aspects that matter to international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

Comparison Table of Rubber Roller and Alternatives

| Comparison Aspect | Rubber Roller | Urethane Roller | Steel Roller |

|---|---|---|---|

| Performance | Excellent grip and flexibility; good for various materials | Superior abrasion resistance; ideal for heavy-duty applications | High durability; effective for high-speed operations |

| Cost | Moderate initial investment; cost-effective for long-term use | Higher upfront cost but longer lifespan | Generally lower upfront cost; may require more frequent replacement |

| Ease of Implementation | Simple installation; adaptable to various setups | Requires precise fitting; may need specialized tools | Straightforward installation; standard fittings available |

| Maintenance | Low maintenance; occasional cleaning required | Moderate maintenance; may require periodic replacement | Low maintenance; regular inspections needed to prevent wear |

| Best Use Case | Printing, packaging, and textile industries | Heavy-duty applications in manufacturing and processing | High-speed operations in metal and plastic processing |

Detailed Breakdown of Alternatives

Urethane Roller

Urethane rollers are known for their exceptional abrasion resistance, making them an excellent choice for heavy-duty applications. Their durability allows them to withstand harsh operating conditions, which can reduce the frequency of replacements. However, urethane rollers typically come with a higher initial cost, which may deter some buyers. Additionally, they often require precise fitting and may need specialized tools for installation, which can complicate implementation in some settings.

Steel Roller

Steel rollers offer a robust alternative, particularly suited for high-speed operations in industries such as metal and plastic processing. Their durability is unmatched, making them ideal for environments where heavy loads and fast speeds are the norm. While they generally have a lower upfront cost compared to urethane rollers, they may require more frequent replacements due to wear and tear. Steel rollers are also straightforward to install, utilizing standard fittings that simplify integration into existing machinery. However, they lack the grip and flexibility of rubber and urethane alternatives, which may limit their effectiveness in certain applications.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate roller solution hinges on a thorough analysis of performance requirements, cost considerations, and operational environments. For businesses prioritizing flexibility and grip in applications like printing and packaging, rubber rollers may be the best option. In contrast, those needing durability and abrasion resistance in heavy-duty applications might lean towards urethane rollers. Steel rollers are ideal for high-speed operations but may not suit all applications due to their rigidity. By carefully assessing these factors, B2B buyers can make informed decisions that align with their specific operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for rubber roller

What Are the Key Technical Properties of Rubber Rollers?

Rubber rollers are vital components in various industrial applications, and understanding their technical properties can help B2B buyers make informed purchasing decisions. Here are some critical specifications:

-

Material Grade

The material grade of a rubber roller often determines its performance characteristics. Common materials include EPDM, neoprene, and butyl rubber, each offering unique properties such as heat resistance, abrasion resistance, and flexibility. Selecting the right material grade is essential for ensuring that the roller meets specific application requirements, particularly in industries like printing, food processing, and manufacturing. -

Durometer Hardness

Durometer hardness measures the softness or hardness of rubber on a scale from 0 to 100. A lower durometer indicates softer rubber, while a higher durometer indicates a harder material. The hardness of the roller impacts its grip, wear resistance, and overall performance. Understanding durometer ratings is crucial for applications that require precise control over material handling, such as flexographic printing. -

Tolerance

Tolerance refers to the allowable deviation from a specified dimension. For rubber rollers, maintaining tight tolerances ensures consistent performance and reduces the risk of wear or failure during operation. Industries that rely on high-speed processes, such as packaging and textiles, benefit significantly from rollers that adhere to strict tolerance specifications. -

Temperature Resistance

Temperature resistance indicates the range of temperatures a rubber roller can withstand without degrading or losing performance. Certain applications, such as those involving high-speed printing or food processing, may expose rollers to extreme temperatures. Selecting rollers with appropriate temperature resistance can minimize downtime and extend service life. -

Chemical Resistance

The ability of a rubber roller to resist various chemicals is crucial for applications in industries like metal processing and food manufacturing. Rollers that are resistant to acids, oils, and other chemicals help ensure operational efficiency and reduce maintenance costs. B2B buyers should assess the chemical compatibility of rollers based on their specific working environment. -

Surface Finish

The surface finish of a rubber roller can influence its interaction with materials being processed. Smooth finishes are ideal for applications that require minimal friction, while textured surfaces may enhance grip and control. Choosing the right surface finish is essential for optimizing performance in printing, packaging, and other applications.

What Common Trade Terms Should B2B Buyers Understand?

In addition to technical properties, understanding industry-specific terminology is vital for effective communication and negotiation in the rubber roller market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that may be marketed by another company under its brand. B2B buyers often engage with OEMs for custom rubber roller solutions tailored to their specific machinery or processes. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQs helps buyers determine the feasibility of placing orders, especially for specialized or custom rollers that may have higher production costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. Issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive the best value for their investment in rubber rollers. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms helps B2B buyers understand the logistics involved in acquiring rubber rollers, including shipping costs and risk management. -

Lead Time

Lead time is the amount of time it takes for a supplier to fulfill an order after it has been placed. Knowing the lead time is crucial for buyers to plan their production schedules and manage inventory effectively. -

Durability

Durability refers to the ability of a rubber roller to withstand wear, pressure, and environmental conditions over time. Understanding durability helps buyers select rollers that will perform reliably in demanding applications, reducing the need for frequent replacements.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions, ensuring they select the right rubber rollers for their specific needs.

Illustrative image related to rubber roller

Navigating Market Dynamics and Sourcing Trends in the rubber roller Sector

What Are the Key Market Dynamics and Trends Shaping the Rubber Roller Sector?

The rubber roller sector is experiencing significant growth driven by diverse global factors. Key drivers include the expanding manufacturing and packaging industries, particularly in emerging markets across Africa and South America, where infrastructure development is rapidly advancing. The rise of e-commerce has also increased demand for efficient packaging solutions, further propelling the rubber roller market. Additionally, the ongoing shift towards automation and digitalization in manufacturing processes is leading to increased adoption of advanced rubber roller technologies, enhancing production efficiency and product quality.

Emerging B2B tech trends include the integration of IoT and smart manufacturing principles, which allow for real-time monitoring and maintenance of rubber rollers. This technology not only reduces downtime but also enhances the overall performance of production lines. Buyers are increasingly looking for suppliers that can provide customized solutions tailored to specific applications, such as flexographic printing or food processing. Moreover, sustainability has become a central theme, with companies prioritizing suppliers who offer eco-friendly materials and production processes.

International buyers, particularly from regions like Europe and the Middle East, are also influenced by stringent quality standards and regulations. The European market, for example, emphasizes high-performance and durable rubber rollers that can withstand extreme conditions, pushing suppliers to innovate continuously. As a result, understanding these dynamics and trends is essential for B2B buyers to make informed sourcing decisions.

How Is Sustainability Impacting Sourcing Decisions for Rubber Rollers?

The environmental impact of manufacturing processes has placed sustainability at the forefront of sourcing decisions in the rubber roller sector. B2B buyers are increasingly aware of the need for sustainable practices, leading to a demand for suppliers who can demonstrate commitment to reducing their carbon footprint and utilizing eco-friendly materials. This shift is particularly evident in markets across Europe and North America, where consumers and businesses alike are advocating for greener products.

Illustrative image related to rubber roller

Ethical sourcing is gaining traction as companies strive to build transparent supply chains. Buyers are seeking suppliers who can provide assurances of ethical practices, including fair labor conditions and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable forestry are becoming essential criteria in the supplier selection process.

Furthermore, the development of “green” rubber materials, such as those derived from renewable resources or recycled materials, is reshaping product offerings in the rubber roller market. These innovations not only help mitigate environmental impact but also appeal to a growing segment of eco-conscious consumers. As sustainability continues to influence market dynamics, B2B buyers should prioritize suppliers who demonstrate a strong commitment to ethical sourcing and environmental stewardship.

How Has the Rubber Roller Sector Evolved Over Time?

The rubber roller sector has a rich history that reflects broader industrial advancements. Initially, rubber rollers were primarily used in basic printing applications. Over time, as industries evolved, so did the materials and technologies used in roller production. The introduction of synthetic rubbers in the mid-20th century significantly improved durability and performance, allowing for applications in various sectors, including food processing, packaging, and textiles.

The evolution of manufacturing technologies, such as the development of precision engineering and advanced coating techniques, has further enhanced the functionality of rubber rollers. Today, they are designed to meet specific industry requirements, such as high-temperature resistance and chemical durability, making them indispensable in modern manufacturing processes. This historical context highlights the sector’s adaptability and ongoing innovation, which are crucial for meeting the demands of contemporary B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber roller

-

How do I solve issues with rubber roller wear and tear?

To address wear and tear on rubber rollers, start by identifying the root causes, such as inappropriate material selection, misalignment, or excessive pressure. Regular maintenance, including cleaning and inspection, can prevent premature wear. Consider upgrading to higher-grade materials or specialized coatings that enhance durability. If issues persist, consult with your supplier for tailored solutions and potential roller redesigns to fit your operational needs better. -

What is the best rubber roller material for high-temperature applications?

For high-temperature applications, consider rollers made from silicone or specialized elastomers like EPDM and Butyl rubber. These materials exhibit excellent heat resistance and maintain performance under extreme conditions. Additionally, look for products with high abrasion resistance and stability to ensure longevity and consistent performance, particularly in industries like metal processing and packaging where temperature fluctuations are common. -

How can I customize rubber rollers for my specific application?

Customization of rubber rollers typically involves selecting the right material, hardness, and surface finish based on your application requirements. Suppliers often offer a range of compounds that can be blended to meet specific needs, such as chemical resistance or static dissipative properties. Engage with your supplier to discuss your operational parameters, and they can recommend the best custom formulations or designs to optimize performance in your processes. -

What are the minimum order quantities (MOQ) for rubber rollers?

Minimum order quantities (MOQ) can vary significantly by supplier and the type of roller required. Typically, MOQs range from a few units for standard rollers to larger quantities for custom designs. It’s essential to discuss your needs with potential suppliers to understand their MOQ policies and explore options for bulk purchasing or combining orders to meet your production requirements while minimizing costs. -

How do I vet suppliers of rubber rollers for international trade?

Vetting suppliers involves several steps: research their industry reputation through reviews and testimonials, check certifications for quality standards (like ISO), and assess their production capabilities. Consider visiting their facilities if possible or request virtual tours. Additionally, inquire about their experience with international shipping and customs regulations, as well as their after-sales support to ensure reliability in your supply chain. -

What payment terms should I expect when sourcing rubber rollers internationally?

Payment terms can vary widely among suppliers. Common options include upfront payments, letters of credit, or payment upon delivery. Be sure to clarify these terms early in negotiations and consider using escrow services for added security. Understanding the financial stability of your supplier can also influence payment terms; established companies may offer more flexible arrangements compared to newer firms. -

What quality assurance processes should I expect for rubber rollers?

Quality assurance (QA) processes for rubber rollers should include rigorous testing for material properties, performance under stress, and compliance with industry standards. Reputable suppliers conduct inspections at various stages of production and may offer certifications for their products. Request detailed QA documentation and inquire about their procedures for handling defects or issues post-delivery to ensure you receive high-quality rollers. -

What logistics considerations should I keep in mind when importing rubber rollers?

When importing rubber rollers, consider shipping methods, lead times, and customs regulations for your destination country. Work with suppliers who have experience in international logistics and can provide accurate shipping estimates. Be aware of potential tariffs and duties, and ensure that all necessary documentation, such as bills of lading and certificates of origin, is prepared in advance to facilitate smooth customs clearance.

Top 5 Rubber Roller Manufacturers & Suppliers List

1. IQS Directory – Rubber Rollers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Rubber rollers are crucial components in machinery, featuring an internal cylindrical shaft or tube wrapped with an external layer of elastomer materials. The core shaft is typically made from robust substances like steel or aluminum alloys, while the exterior is crafted from polymers such as polyurethane, silicone, EPDM, neoprene, or natural rubber. They are used in various applications including…

2. CTS Industries – Rubber Rollers

Domain: ctsindustries.com

Introduction: Rubber Rollers manufactured in America with a quality assurance guarantee. Lead time of 10 days or less for manufacturing and recovering. Free center hole repairs for quantities of 10 or more. Rubber materials used include BN (Buna Nitrile) for water-based inks, EP (EPDM) for UV and solvent inks, SL/EP (Silicone Blend) for durability, and Sil (Pure Silicone) for release applications. Available dur…

3. Rol-Tec – Custom Rubber Rollers

Domain: rol-tec.com

Registered: 1999 (26 years)

Introduction: Rol-Tec specializes in industrial rubber rollers and rubber covered rollers, offering custom molded rubber rollers since 1991. Key features include:

– Manufacturing capabilities for rollers and cores up to 31″ OD by 280″ face lengths.

– Services include dynamic roller balancing, laser engraving, precision sleeves, roller recovering, and complete core fabrication.

– Repair services for damaged roll…

4. Speedball vs. Takach – Brayer Comparison

Domain: reddit.com

Introduction: Comparison between Speedball and Takach brayers. Speedball costs $18, while Takach is $250. Users noted that the Takach brayer is softer, holds more ink due to its larger diameter, and has a higher quality butile rubber surface. The Takach is easier to use, reduces fatigue, and minimizes ink flinging compared to the Speedball.

5. Mid American Rubber – Precision Rubber Rolls & Tint Sleeves

Domain: midamericanrubber.com

Registered: 1998 (27 years)

Introduction: Mid American Rubber is a full-service manufacturer specializing in precision rubber rolls and tint sleeves. Key products include: 1. Printing Rollers: Custom-engineered flexographic, offset, digital, and gravure printing rolls, as well as recovering used rollers. 2. Tint Sleeves: High-quality tinting and coating sleeves, including the MagnaFlex® 55 for water-based or UV inks, with popular sizes av…

Strategic Sourcing Conclusion and Outlook for rubber roller

How Can Strategic Sourcing Enhance Your Rubber Roller Procurement?

In the competitive landscape of rubber roller procurement, strategic sourcing emerges as a crucial component for international B2B buyers. By carefully evaluating suppliers based on their product offerings, industry expertise, and service capabilities, companies can secure high-quality rollers that enhance operational efficiency and product quality. Understanding the specific applications of various rubber roller types—such as those designed for printing, packaging, or metal processing—enables buyers to make informed decisions that align with their unique needs.

Moreover, leveraging strategic sourcing allows businesses to mitigate risks associated with supply chain disruptions, especially in regions like Africa, South America, the Middle East, and Europe. Establishing strong relationships with reliable suppliers can lead to better pricing, improved service levels, and access to innovative solutions tailored for diverse manufacturing environments.

As you consider your next procurement strategy, embrace the opportunity to explore partnerships with reputable manufacturers. Take proactive steps to enhance your sourcing processes, ensuring that your operations remain resilient and competitive. The future of rubber roller procurement is bright, and those who invest in strategic sourcing will be well-positioned to capitalize on emerging market trends and technological advancements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.