Rubber Gasket Sheets: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for rubber gasket sheets

In today’s global marketplace, sourcing high-quality rubber gasket sheets can present significant challenges for international B2B buyers. With diverse industrial applications ranging from automotive to food processing, the need for reliable, durable, and compliant materials is paramount. This guide serves as an essential resource for navigating the complexities of rubber gasket sheet procurement, addressing key considerations such as types of materials, their specific applications, supplier vetting processes, and cost analysis.

Understanding the nuances of various gasket sheet options—such as EPDM, silicone, and PTFE—enables businesses to make informed decisions that align with their operational needs and regulatory requirements. This guide not only illuminates the characteristics of different gasket materials but also provides insights into the best practices for evaluating suppliers, ensuring that buyers can identify trustworthy partners in regions like Africa, South America, the Middle East, and Europe, including countries like Brazil and Nigeria.

By leveraging this comprehensive resource, B2B buyers can enhance their purchasing strategies, mitigate risks associated with substandard materials, and ultimately secure the best value for their investments. Whether you’re seeking to optimize performance in high-pressure environments or ensure compliance with local standards, this guide equips you with the knowledge to navigate the rubber gasket sheet market effectively.

Understanding rubber gasket sheets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| EPDM (Ethylene Propylene Diene Monomer) | Excellent weather resistance and thermal stability | Automotive, HVAC, and construction | Pros: Durable, good for outdoor use; Cons: Limited chemical resistance. |

| Nitrile (BUNA-N) | High oil and fuel resistance | Oil and gas, automotive, food processing | Pros: Great for oily environments; Cons: Not suitable for high temperatures. |

| Silicone | High-temperature tolerance and flexibility | Food processing, medical, aerospace | Pros: Biocompatible, withstands extreme temperatures; Cons: Higher cost. |

| Neoprene | Good chemical resistance and flexibility | Refrigeration, automotive, electrical | Pros: Versatile, good for various applications; Cons: Moderate weather resistance. |

| PTFE (Polytetrafluoroethylene) | Exceptional chemical resistance and low friction | Chemical processing, pharmaceuticals | Pros: Very high resistance to chemicals; Cons: More expensive and difficult to machine. |

What Are the Characteristics of EPDM Rubber Gasket Sheets?

EPDM rubber gasket sheets are known for their outstanding resistance to weather, ozone, and UV radiation. This makes them ideal for outdoor applications such as automotive seals and roofing membranes. They also exhibit excellent thermal stability, making them suitable for HVAC systems. B2B buyers should consider EPDM’s durability against environmental stressors, although they should note its limited resistance to certain chemicals, which could affect its application in specific industries.

How Do Nitrile Gasket Sheets Stand Out?

Nitrile, or BUNA-N, gasket sheets are particularly valued in sectors that handle oils, fuels, and other hydrocarbons. They possess excellent oil and fuel resistance, making them a top choice for the oil and gas industry. Their ability to maintain flexibility and integrity in varying temperatures further enhances their appeal. However, buyers must be cautious about using nitrile in high-temperature applications, as it may not perform optimally under such conditions.

Why Choose Silicone Gasket Sheets for Your Applications?

Silicone gasket sheets are renowned for their ability to withstand extreme temperatures, making them suitable for industries like food processing and aerospace. Their flexibility and biocompatibility are significant advantages in medical applications, where safety and performance are paramount. While silicone is generally more expensive than other rubber types, its longevity and resistance to degradation can provide significant value over time, particularly in demanding environments.

What Advantages Do Neoprene Gasket Sheets Offer?

Neoprene gasket sheets offer a versatile solution with a good balance of chemical resistance and flexibility. They are widely used in refrigeration and automotive applications due to their ability to withstand temperature fluctuations and exposure to various chemicals. While neoprene is effective for many applications, buyers should be aware that it has moderate resistance to weathering, which may limit its use in outdoor settings.

What Makes PTFE Gasket Sheets Unique?

PTFE gasket sheets are distinguished by their exceptional chemical resistance and low friction properties. They are often used in highly corrosive environments, such as chemical processing and pharmaceuticals, where other materials may fail. While PTFE is highly effective in these applications, its higher cost and machining difficulties can be a drawback for some buyers. Understanding these trade-offs is crucial for businesses looking to invest in high-performance gasket materials.

Key Industrial Applications of rubber gasket sheets

| Industry/Sector | Specific Application of rubber gasket sheets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Sealing flanges in pipelines | Prevents leaks, enhancing safety and efficiency | Resistance to extreme temperatures and chemicals required |

| Food & Beverage | Gaskets for processing equipment | Ensures compliance with health standards | FDA-approved materials necessary for safety compliance |

| Automotive | Engine components sealing | Improves performance and reduces emissions | Compatibility with various fluids and temperatures |

| Chemical Processing | Sealing tanks and reactors | Minimizes contamination and ensures safety | Chemical resistance and durability against harsh conditions |

| Construction & Infrastructure | Gaskets in HVAC systems | Enhances energy efficiency and reduces noise | Custom sizing and material specifications required |

How Are Rubber Gasket Sheets Used in the Oil & Gas Industry?

In the oil and gas sector, rubber gasket sheets are primarily used for sealing flanges in pipelines and other critical connections. These gaskets prevent leaks, which can lead to environmental hazards and financial losses. Buyers in this industry must ensure that the gasket materials are resistant to extreme temperatures and various chemicals typically encountered in oil and gas applications. Sourcing high-quality rubber sheets that meet industry standards is essential for operational safety and efficiency.

What Role Do Rubber Gasket Sheets Play in Food & Beverage Applications?

Rubber gasket sheets are crucial in the food and beverage industry, where they are used in processing equipment to ensure tight seals. This application is vital for preventing contamination and maintaining product integrity, which is essential for compliance with health regulations. Buyers should prioritize FDA-approved materials that can withstand frequent cleaning and exposure to food substances. Ensuring that gaskets meet stringent health standards is a key consideration for international buyers, especially in regions with strict food safety regulations.

Why Are Rubber Gasket Sheets Important in Automotive Sealing?

In automotive applications, rubber gasket sheets are utilized for sealing engine components, such as valve covers and oil pans. These gaskets play a significant role in improving engine performance and reducing emissions by preventing oil leaks. Buyers must consider the compatibility of the gasket material with various automotive fluids and the operating temperatures they will encounter. Selecting the right type of rubber, such as silicone or nitrile, is critical for ensuring durability and longevity in automotive applications.

How Do Rubber Gasket Sheets Enhance Safety in Chemical Processing?

Rubber gasket sheets are essential in the chemical processing industry, where they seal tanks and reactors to minimize contamination and ensure safety. These gaskets must be resistant to harsh chemicals and high pressures, making material selection crucial. Buyers should focus on sourcing durable rubber sheets that can withstand aggressive environments while maintaining their sealing properties. Additionally, international buyers must consider local regulations regarding chemical safety when sourcing these materials.

What Benefits Do Rubber Gasket Sheets Provide in Construction and HVAC Systems?

In construction and infrastructure, rubber gasket sheets are commonly used in HVAC systems to provide effective sealing. They help enhance energy efficiency by preventing air leaks and reducing noise levels. Buyers should ensure that the gaskets are custom-sized to fit specific applications and are made from materials suitable for varying environmental conditions. Understanding the specifications needed for different HVAC configurations is vital for effective sourcing and ensuring long-term performance.

3 Common User Pain Points for ‘rubber gasket sheets’ & Their Solutions

Scenario 1: Inconsistent Sizing Leading to Production Delays

The Problem: One of the primary challenges B2B buyers face when procuring rubber gasket sheets is inconsistent sizing. This issue often arises when suppliers provide sheets that do not meet the specified dimensions, leading to difficulties during installation. For businesses in sectors such as manufacturing or automotive, where precision is crucial, receiving incorrectly sized gaskets can halt production lines, resulting in costly delays and operational inefficiencies. This not only affects the immediate project but can also damage relationships with clients due to unmet deadlines.

The Solution: To avoid issues with sizing, buyers should prioritize working with reputable suppliers who offer customization options for rubber gasket sheets. When placing orders, it is essential to provide clear specifications, including precise measurements, thickness, and material type. Additionally, requesting samples before the full order can help verify the dimensions and quality. Implementing a quality control process upon receipt of materials ensures that any discrepancies are identified early, allowing for prompt resolution and minimizing disruption to production.

Scenario 2: Material Compatibility Concerns

The Problem: Another significant pain point for B2B buyers is the compatibility of rubber gasket materials with various fluids and temperatures. Buyers in industries such as chemical processing or oil and gas often face the challenge of selecting the right gasket material that can withstand specific environmental conditions. Using an incompatible material can lead to gasket failure, leaks, and ultimately, costly downtime or environmental hazards.

The Solution: To effectively address material compatibility concerns, buyers should conduct thorough research on the properties of different rubber gasket materials, such as EPDM, Nitrile, and Silicone. Each material has unique characteristics that make it suitable for specific applications. For instance, EPDM is excellent for ozone resistance, while Nitrile performs well in oil applications. Collaborating with a knowledgeable supplier can provide insights into which material best suits the intended application. Additionally, utilizing compatibility charts and conducting field tests can ensure the selected gasket performs optimally under expected conditions.

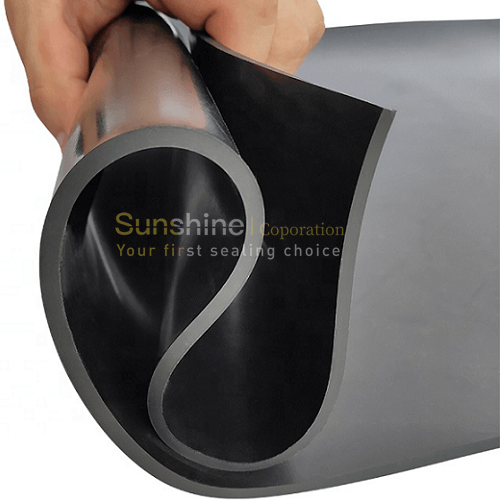

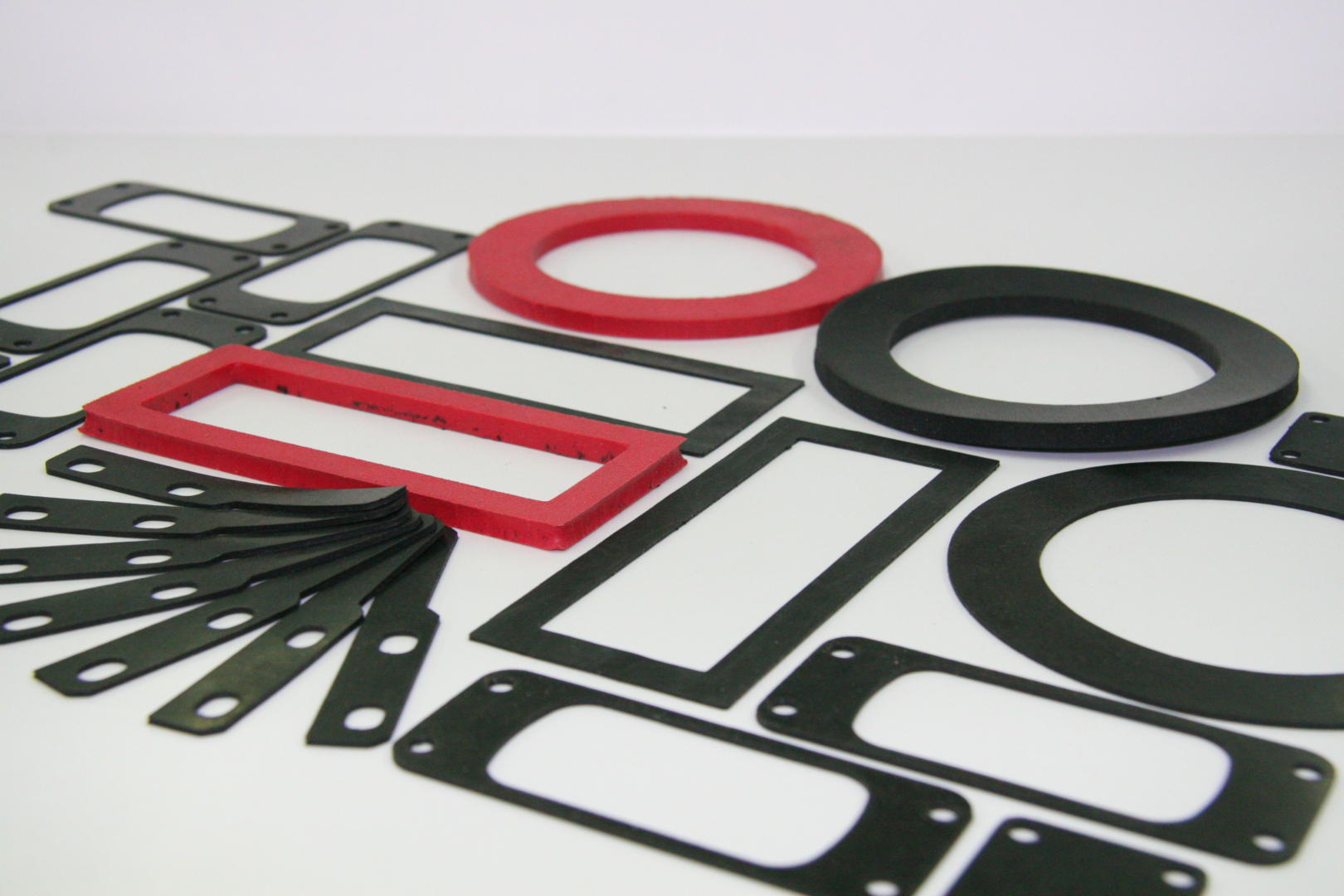

Illustrative image related to rubber gasket sheets

Scenario 3: Limited Supplier Options Affecting Pricing and Availability

The Problem: Many B2B buyers experience challenges related to limited supplier options, which can impact pricing and availability of rubber gasket sheets. In regions with fewer suppliers, businesses often find themselves paying higher prices due to lack of competition or facing delays in order fulfillment. This can be particularly detrimental for companies that require gaskets on short notice or in large quantities, leading to increased operational costs and project delays.

The Solution: To mitigate this issue, B2B buyers should explore global sourcing options and establish relationships with multiple suppliers across different regions. Utilizing online platforms and trade shows can help identify potential suppliers who may offer competitive pricing and reliable delivery times. Additionally, negotiating long-term contracts with suppliers can lock in favorable pricing and guarantee availability during peak demand periods. Implementing an inventory management system can also assist in tracking stock levels, allowing companies to anticipate their needs and reorder materials before running low. This proactive approach ensures that businesses can maintain operational continuity without incurring unexpected costs.

Strategic Material Selection Guide for rubber gasket sheets

When selecting rubber gasket sheets for various applications, understanding the properties, advantages, and limitations of different materials is crucial. Below, we analyze four common materials used in rubber gasket sheets, focusing on their performance attributes, suitability for specific applications, and considerations for international B2B buyers.

What Are the Key Properties of Nitrile Rubber (BUNA-N) for Gasket Sheets?

Nitrile rubber, commonly known as BUNA-N, is renowned for its excellent resistance to oils, fuels, and other hydrocarbons. It typically operates effectively within a temperature range of -40°F to 250°F (-40°C to 121°C) and can withstand moderate pressures. This material exhibits good mechanical strength and is often used in automotive and industrial applications where oil resistance is paramount.

Pros: Nitrile rubber is relatively affordable and easy to manufacture, making it a popular choice for various gasket applications. Its oil resistance and durability contribute to long service life in demanding environments.

Cons: However, it has limited resistance to ozone and weathering, which can lead to degradation over time when exposed to outdoor conditions. Additionally, it may not perform well in high-temperature applications beyond its rated limits.

International Considerations: Buyers from regions like Africa and South America should ensure that Nitrile rubber meets local compliance standards, such as ASTM or ISO certifications, particularly for automotive or industrial uses.

How Does EPDM Rubber Compare for Gasket Applications?

Ethylene Propylene Diene Monomer (EPDM) rubber is another widely used material for gasket sheets, especially in outdoor and high-temperature environments. EPDM offers excellent resistance to ozone, UV radiation, and weathering, making it ideal for applications exposed to the elements. It can typically handle temperatures from -40°F to 300°F (-40°C to 149°C) and moderate pressures.

Illustrative image related to rubber gasket sheets

Pros: The primary advantage of EPDM is its superior resistance to environmental factors, making it suitable for roofing, automotive, and HVAC applications. Its flexibility and durability ensure a reliable seal over time.

Cons: On the downside, EPDM is not suitable for use with petroleum-based fluids, which limits its application in certain industries. Additionally, it can be more expensive than Nitrile rubber.

International Considerations: For buyers in the Middle East, where UV exposure is significant, EPDM’s weather resistance is a key selling point. Compliance with local standards regarding environmental impact may also be a consideration.

What Makes Silicone Rubber a Preferred Choice for Gasket Sheets?

Silicone rubber is highly regarded for its exceptional temperature resistance, typically ranging from -100°F to 500°F (-73°C to 260°C). It is also resistant to a wide range of chemicals, making it suitable for applications in food processing, pharmaceuticals, and high-temperature environments.

Pros: The flexibility and resilience of silicone rubber allow it to maintain its integrity under extreme conditions, making it ideal for high-performance applications. Additionally, it is often FDA-compliant for food-grade applications.

Cons: However, silicone rubber can be more costly than other materials, and its mechanical strength is generally lower than that of Nitrile or EPDM. It is also not recommended for use with certain solvents.

International Considerations: Buyers in Europe and South America should verify that silicone rubber products meet stringent food safety and environmental regulations, such as REACH compliance in the EU.

Illustrative image related to rubber gasket sheets

What Are the Advantages of PTFE (Teflon) for Gasket Sheets?

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance material known for its outstanding chemical resistance and ability to withstand extreme temperatures, typically from -450°F to 500°F (-268°C to 260°C). It is often used in applications involving aggressive chemicals and high pressures.

Pros: PTFE’s non-stick properties and chemical resistance make it ideal for use in industries such as chemical processing and pharmaceuticals. Its durability ensures a long service life even in harsh environments.

Cons: The primary drawback of PTFE is its high cost and complexity in manufacturing, which can lead to higher overall project costs. Additionally, it can be more challenging to bond compared to other rubber materials.

International Considerations: B2B buyers should ensure that PTFE gaskets meet international standards, such as ASTM or DIN, particularly in industries where chemical compatibility is critical.

Summary Table of Material Selection for Rubber Gasket Sheets

| Material | Typical Use Case for rubber gasket sheets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nitrile Rubber (BUNA-N) | Automotive and industrial applications | Excellent oil resistance | Limited ozone and weather resistance | Low |

| EPDM Rubber | Outdoor and HVAC applications | Superior weather and UV resistance | Not suitable for petroleum-based fluids | Medium |

| Silicone Rubber | Food processing and high-temperature applications | Exceptional temperature resistance | Higher cost and lower mechanical strength | High |

| PTFE (Teflon) | Chemical processing and pharmaceuticals | Outstanding chemical resistance | High cost and complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various rubber gasket sheet materials, facilitating informed purchasing decisions tailored to their specific industry needs.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber gasket sheets

What Are the Key Stages in the Manufacturing Process of Rubber Gasket Sheets?

The manufacturing of rubber gasket sheets involves a systematic process that ensures the final product meets the required specifications for performance and durability. The primary stages in this manufacturing process include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, including various rubber compounds such as EPDM, silicone, and nitrile. These materials are often blended with fillers, plasticizers, and curing agents to achieve specific mechanical properties. The mixing of these compounds is typically done in an internal mixer or a Banbury mixer, where the materials are heated and blended until uniform.

-

Forming: Once the materials are prepared, they are shaped into sheets using various techniques. The most common methods include calendering, where the rubber is passed through a series of rollers to produce sheets of desired thickness, and extrusion, which forces the rubber through a die to create continuous sheets. The thickness of the sheets can be adjusted based on customer specifications, often ranging from a few millimeters to several centimeters.

-

Assembly: In some cases, additional components may be incorporated into the gasket sheets, such as metal reinforcements or adhesive layers. This stage involves precise alignment and bonding of these components to ensure the integrity and functionality of the gasket.

-

Finishing: The final stage of the manufacturing process includes cutting the sheets to the required dimensions and applying any necessary surface treatments. This may involve processes such as surface grinding or polishing to enhance the gasket’s sealing properties. The sheets are then packaged for shipment, ensuring they are protected from contamination and damage.

How is Quality Assurance Implemented in the Production of Rubber Gasket Sheets?

Quality assurance (QA) is crucial in the production of rubber gasket sheets, ensuring that each product meets industry standards and customer expectations. Various international standards, such as ISO 9001, guide the quality management systems in place, while industry-specific certifications like CE and API are also relevant.

-

International and Industry-Specific Standards: ISO 9001 provides a framework for a quality management system, focusing on continuous improvement and customer satisfaction. For rubber gasket sheets, compliance with additional standards such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for gaskets used in the oil and gas industry ensures that the products are safe and reliable.

-

Quality Control Checkpoints: Quality control (QC) is integrated at various stages of the manufacturing process through checkpoints such as:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are conducted to monitor parameters like temperature, pressure, and material consistency. This helps identify and rectify issues before they escalate.

– Final Quality Control (FQC): After the production process, finished products undergo rigorous testing, including visual inspections, dimensional checks, and performance tests under simulated operating conditions. -

Common Testing Methods for Rubber Gasket Sheets: Various testing methods are employed to evaluate the performance and quality of rubber gasket sheets, including:

– Compression Set Test: Measures the ability of the rubber to return to its original shape after being compressed.

– Tensile Strength Test: Assesses the maximum stress the material can withstand while being stretched.

– Leakage Tests: Evaluate the effectiveness of the gasket in preventing leaks under pressure.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several actionable steps:

Illustrative image related to rubber gasket sheets

-

Supplier Audits: Conducting supplier audits can provide insights into their manufacturing practices and adherence to quality standards. These audits should evaluate the supplier’s compliance with international standards, production processes, and overall quality management systems.

-

Requesting Quality Reports: B2B buyers can request quality assurance documentation from suppliers. This includes certificates of compliance, test reports, and records of previous audits. Reviewing these documents can help buyers assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging a third-party inspection agency to evaluate the supplier’s manufacturing facility and processes can provide an unbiased assessment of quality control measures. These agencies can perform tests and inspections to confirm that products meet specified standards.

-

Understanding QC/CERT Nuances for International Trade: B2B buyers should be aware of the nuances in quality certifications required in their respective regions. For instance, products exported to the European Union must comply with CE marking regulations, while those used in industrial applications might require API certification. Understanding these requirements can help buyers avoid compliance issues and ensure product safety.

What Challenges Do International B2B Buyers Face Regarding Quality Assurance?

International B2B buyers often encounter several challenges related to quality assurance when sourcing rubber gasket sheets. These challenges can include:

-

Variability in Standards: Different regions may have varying quality standards and regulations. Buyers must ensure that their suppliers are compliant with the relevant standards in their target markets.

-

Communication Barriers: Language differences and cultural misunderstandings can hinder effective communication regarding quality expectations and specifications.

-

Logistical Issues: Shipping rubber gasket sheets internationally can pose risks of damage or contamination. Buyers should work with suppliers who have robust packaging and shipping procedures to mitigate these risks.

-

Supplier Reliability: Establishing trust with suppliers is crucial. Buyers should consider engaging in long-term partnerships with suppliers who consistently demonstrate quality assurance and reliability.

By understanding the manufacturing processes and quality assurance measures associated with rubber gasket sheets, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber gasket sheets’

Introduction

Sourcing rubber gasket sheets effectively is crucial for ensuring the reliability and longevity of machinery and equipment in various industries. This guide provides a step-by-step checklist to assist B2B buyers in making informed decisions, ensuring they choose the right products and suppliers to meet their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as material type (e.g., EPDM, silicone, nitrile), thickness, and temperature resistance. These specifications will help narrow down options and ensure the selected gasket sheets will perform effectively in your intended application.

Step 2: Identify Your Application Requirements

Different applications require distinct gasket properties. Determine the operating conditions, such as pressure, chemical exposure, and temperature ranges. For instance, if you’re working with corrosive substances, materials like PTFE may be more suitable. This will guide you in selecting the right material and design for your specific needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies that demonstrate their experience in your industry. Seek references from other buyers who have sourced similar products to gauge supplier reliability and service quality.

Illustrative image related to rubber gasket sheets

- Look for certifications: Ensure suppliers have relevant certifications (e.g., ISO, FDA) that confirm their compliance with industry standards.

- Assess capacity and delivery times: Understand the supplier’s production capacity to ensure they can meet your volume requirements within your desired time frame.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the gasket sheets you are considering. Testing these samples in your specific application will help verify their performance and compatibility. This step can prevent costly mistakes associated with unsuitable materials.

Step 5: Compare Pricing and Terms

Once you’ve narrowed down your options, compare pricing among suppliers while considering the total cost of ownership. Look beyond the initial price to evaluate factors such as shipping costs, lead times, and payment terms. A slightly higher price may be justified by superior quality or service.

Step 6: Verify Quality Control Processes

Understanding a supplier’s quality control processes is vital for ensuring product reliability. Inquire about their testing methods, inspection criteria, and any certifications that validate their quality assurance practices. A robust quality control system can significantly reduce the risk of defects and failures.

Step 7: Establish a Communication Plan

Effective communication with your chosen supplier is key to a successful partnership. Establish clear lines of communication regarding order status, delivery schedules, and any potential issues. Regular updates can help avoid misunderstandings and ensure timely responses to any concerns that may arise.

By following this checklist, B2B buyers can navigate the complexities of sourcing rubber gasket sheets with confidence, ensuring they make informed decisions that support their operational needs.

Comprehensive Cost and Pricing Analysis for rubber gasket sheets Sourcing

What Are the Key Cost Components in Sourcing Rubber Gasket Sheets?

When sourcing rubber gasket sheets, understanding the cost structure is crucial for effective budget planning and supplier negotiations. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of rubber used—such as EPDM, silicone, or neoprene—significantly affects the overall cost. Specialty materials, like PTFE or Viton, may command higher prices due to their enhanced properties and certifications.

-

Labor: Labor costs can vary based on the complexity of the manufacturing process and the region where production occurs. Skilled labor in countries with higher wage standards can increase costs.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, thereby impacting pricing favorably.

-

Tooling: Initial tooling costs for custom gaskets can be substantial. If a buyer requires specific shapes or sizes, these costs need to be factored into the overall pricing.

-

Quality Control: Ensuring that products meet international standards (e.g., FDA compliance for food-grade applications) may add to the cost but is essential for maintaining quality and reliability.

-

Logistics: Shipping costs can be significant, especially for international buyers. Factors such as distance, transport mode, and incoterms chosen will influence logistics costs.

-

Margin: Finally, suppliers will add a margin to cover their risks and make a profit. This can vary widely based on market conditions and the supplier’s pricing strategy.

How Do Price Influencers Affect Rubber Gasket Sheet Costs?

Several factors influence the pricing of rubber gasket sheets that international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce per-unit costs due to economies of scale. Negotiating for a better MOQ can be beneficial for budget-conscious buyers.

-

Specifications and Customization: Custom gaskets tailored to specific applications can significantly increase costs. Buyers should weigh the need for customization against potential cost savings from standard products.

-

Material Quality and Certifications: Higher-quality materials or those with certifications (e.g., ISO, NSF) often come at a premium. However, these certifications can lead to cost savings in the long run by reducing failures and improving system performance.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can impact pricing. Established suppliers may charge higher prices but offer better service, quality assurance, and reliability.

-

Incoterms: Understanding the implications of different Incoterms is essential. For instance, opting for FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) can affect the total landed cost significantly.

What Are the Best Negotiation Tips for B2B Buyers of Rubber Gasket Sheets?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings. Here are some actionable tips:

-

Conduct a Total Cost of Ownership (TCO) Analysis: Beyond initial pricing, consider long-term costs associated with maintenance, replacements, and logistics. This holistic view can provide leverage during negotiations.

-

Leverage Competitive Quotes: Obtain quotes from multiple suppliers to create a competitive environment. This can help in negotiating better prices or terms.

-

Build Long-term Relationships: Establishing a good relationship with suppliers can lead to better pricing, priority service, and flexibility in future orders.

-

Understand Local Market Conditions: Being aware of local economic factors and currency fluctuations can aid in negotiations, especially when dealing with international suppliers.

-

Consider Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce the immediate financial burden.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers must navigate various pricing nuances that can affect their purchasing decisions:

-

Currency Fluctuations: Prices may vary based on exchange rates. It’s wise to negotiate prices in a stable currency or consider fixed-rate contracts.

-

Import Duties and Taxes: Be aware of any tariffs or taxes that may apply when importing rubber gasket sheets. These can significantly increase the total cost.

-

Cultural Differences: Understanding cultural norms and business practices in the supplier’s country can facilitate smoother negotiations and better outcomes.

-

Shipping and Handling: International logistics can introduce unforeseen costs. Ensure that all potential costs are discussed and agreed upon before finalizing contracts.

In summary, a thorough understanding of the cost components, price influencers, and negotiation strategies can empower B2B buyers to make informed sourcing decisions for rubber gasket sheets. Prices can vary widely based on numerous factors, so conducting due diligence is essential for achieving cost-effective procurement.

Alternatives Analysis: Comparing rubber gasket sheets With Other Solutions

Exploring Alternatives to Rubber Gasket Sheets

When evaluating sealing solutions for industrial applications, it’s essential to consider alternatives to rubber gasket sheets. These alternatives may offer unique benefits in specific contexts, making it crucial for B2B buyers to understand their options. This analysis compares rubber gasket sheets with two viable alternatives: PTFE gaskets and metal gaskets. Each solution has its own strengths and weaknesses, tailored to different operational needs and environments.

| Comparison Aspect | Rubber Gasket Sheets | PTFE Gaskets | Metal Gaskets |

|---|---|---|---|

| Performance | Excellent for sealing in moderate temperatures and pressures. | Superior chemical resistance; ideal for extreme conditions. | High durability; good for high-pressure applications. |

| Cost | Generally affordable; prices vary by material and size. | Higher initial investment due to manufacturing complexity. | Cost-effective for large-scale applications but can vary significantly. |

| Ease of Implementation | Easy to cut and install; requires minimal tools. | Requires precision cutting and special fittings for installation. | May require machining and specialized installation techniques. |

| Maintenance | Moderate; periodic checks recommended for wear. | Low maintenance; resistant to degradation. | Requires regular inspection and potential replacement due to wear. |

| Best Use Case | General-purpose applications, including automotive and plumbing. | Chemical processing, food service, and pharmaceuticals. | High-pressure and high-temperature environments, like power plants and engines. |

What Are the Advantages and Disadvantages of PTFE Gaskets?

PTFE gaskets are renowned for their exceptional chemical resistance and stability at extreme temperatures. They are particularly advantageous in applications involving aggressive chemicals or high temperatures, making them suitable for industries such as pharmaceuticals and chemical processing. However, the complexity involved in their installation can be a drawback, as they often require specialized cutting and fittings, which may increase overall project costs and time.

How Do Metal Gaskets Compare in Industrial Applications?

Metal gaskets provide a robust sealing solution for high-pressure and high-temperature environments. Their durability makes them ideal for applications in power generation, oil and gas, and heavy machinery. The primary advantage of metal gaskets lies in their ability to withstand extreme conditions without deformation. However, they often require precise machining and may involve higher labor costs for installation. Regular maintenance and inspection are also necessary to ensure their effectiveness over time, as wear can lead to failures.

How Can B2B Buyers Choose the Right Sealing Solution?

Selecting the appropriate sealing solution depends on several factors, including the specific operational environment, budget constraints, and maintenance capabilities. B2B buyers should evaluate the performance requirements of their applications—considering factors such as temperature, pressure, and chemical exposure—before making a decision. While rubber gasket sheets may suffice for general applications, industries dealing with harsh chemicals or extreme conditions may benefit more from PTFE or metal gaskets. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for rubber gasket sheets

What Are the Essential Technical Properties of Rubber Gasket Sheets?

Understanding the technical properties of rubber gasket sheets is crucial for international B2B buyers, especially when selecting materials for specific applications. Here are key specifications that influence performance and suitability:

1. Material Grade

The material grade refers to the specific type of rubber used in the gasket sheets, such as EPDM, NBR, or silicone. Each type has unique properties; for example, EPDM is known for its excellent weather resistance, while NBR offers superior oil resistance. Choosing the correct material grade is essential for ensuring that the gasket can withstand the operational conditions of the intended application, thus preventing leaks and prolonging equipment life.

Illustrative image related to rubber gasket sheets

2. Thickness

Thickness is a critical specification that impacts sealing performance and compressibility. Common thickness ranges for gasket sheets are between 1/16 inch and 1 inch. Thicker gaskets may offer better sealing capabilities but can also require more torque to compress effectively. Selecting the appropriate thickness helps in achieving optimal sealing under specific pressure and temperature conditions, reducing the risk of gasket failure.

3. Temperature Resistance

Temperature resistance indicates the range of temperatures a gasket can endure without losing its integrity. Some materials can withstand extreme temperatures, while others may degrade quickly. For instance, silicone gaskets can operate in high-temperature environments, making them suitable for applications in the automotive and aerospace industries. Understanding temperature resistance is vital for ensuring the gasket performs reliably in the intended environment.

4. Tensile Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking. This property is particularly important in applications where the gasket is subjected to high pressure or mechanical stress. A gasket with high tensile strength will provide better durability and reliability, reducing the need for frequent replacements and downtime.

5. Compression Set

Compression set refers to the material’s ability to return to its original thickness after being compressed. A low compression set indicates that the gasket will maintain its sealing properties over time, even under continuous pressure. This property is crucial for applications requiring long-term reliability, such as in piping systems or heavy machinery.

What Are the Common Trade Terms in the Rubber Gasket Sheet Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you might encounter:

Illustrative image related to rubber gasket sheets

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of rubber gaskets, OEMs often require specific materials and designs that meet their standards. Understanding OEM requirements is crucial for suppliers to ensure compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers, as it can impact purchasing decisions, especially for smaller companies or those looking to test a new product. Knowing the MOQ helps in budgeting and inventory planning.

3. RFQ (Request for Quotation)

An RFQ is a formal document that a buyer submits to suppliers to request pricing and terms for specific products. It typically includes specifications like material grade, dimensions, and quantities. Providing a detailed RFQ helps ensure accurate quotes, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They outline who is responsible for shipping, insurance, and tariffs, which is critical for international buyers to understand to avoid unexpected costs.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. This is a crucial factor in supply chain management, as longer lead times can affect project timelines and inventory levels. Understanding lead times helps buyers plan their operations more effectively.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing rubber gasket sheets, ensuring they meet their specific needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the rubber gasket sheets Sector

What Are the Key Drivers and Trends in the Rubber Gasket Sheets Market?

The global rubber gasket sheets market is experiencing significant growth, driven by the increasing demand across various industries, including automotive, oil and gas, and manufacturing. As companies look to enhance their operational efficiency and reduce emissions, there is a marked shift towards high-performance materials such as aramid fiber and PTFE (polytetrafluoroethylene). These materials not only offer superior sealing capabilities but also contribute to improved torque retention and reduced leakage, making them essential in critical applications.

Illustrative image related to rubber gasket sheets

Emerging technologies such as advanced manufacturing processes, including 3D printing, are reshaping sourcing strategies for international B2B buyers. This innovation allows for rapid prototyping and customization of gasket sheets, catering to specific industry requirements. Furthermore, the rise of e-commerce platforms is facilitating easier access to a wider range of products, enabling buyers from Africa, South America, the Middle East, and Europe to compare prices and specifications more efficiently.

Market dynamics are also influenced by geopolitical factors and trade agreements, which affect material availability and pricing. For example, fluctuations in raw material costs due to environmental regulations can impact the overall pricing strategies of suppliers. Buyers should stay informed about these trends to make strategic sourcing decisions that align with their operational goals.

How Is Sustainability Influencing Sourcing Trends in the Rubber Gasket Sheets Sector?

Sustainability is becoming a paramount concern for B2B buyers in the rubber gasket sheets sector. With increasing awareness of environmental issues, businesses are prioritizing ethical sourcing practices. This includes selecting suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing sustainable materials. The demand for ‘green’ certifications, such as ISO 14001, is on the rise, as companies seek to ensure that their suppliers adhere to environmental management standards.

The environmental impact of rubber production, including deforestation and pollution, underscores the importance of sourcing from suppliers who implement responsible practices. Buyers are increasingly looking for gasket sheets made from recycled or bio-based materials, which not only mitigate environmental harm but can also enhance brand reputation. By choosing sustainable products, companies can demonstrate their commitment to corporate social responsibility, which is becoming a critical factor in business partnerships.

Moreover, the trend towards sustainability is leading to innovations in product formulations. Manufacturers are exploring alternatives to traditional rubber compounds, such as silicone and EPDM (ethylene propylene diene monomer), which often have lower environmental impacts. For B2B buyers, understanding these trends is crucial for maintaining compliance with regulatory requirements and meeting customer expectations for sustainable practices.

Illustrative image related to rubber gasket sheets

What Is the Historical Context of Rubber Gasket Sheets in B2B Markets?

The evolution of rubber gasket sheets can be traced back to the industrial revolution, where the need for effective sealing solutions became apparent with the rise of machinery and manufacturing processes. Initially, natural rubber was the primary material used, valued for its elasticity and durability. However, as industries advanced, the limitations of natural rubber prompted the development of synthetic alternatives, such as neoprene and EPDM, which offered enhanced chemical resistance and thermal stability.

The introduction of advanced manufacturing techniques in the late 20th century further transformed the market. The ability to produce high-performance gasket sheets tailored to specific applications allowed businesses to optimize their operations significantly. Today, the market continues to evolve, driven by technological advancements and a growing emphasis on sustainability, reflecting the dynamic needs of international B2B buyers.

In summary, understanding the market dynamics, sustainability practices, and historical context is essential for B2B buyers seeking to make informed decisions in the rubber gasket sheets sector. By staying ahead of these trends, companies can leverage opportunities for growth and innovation while aligning with global standards and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber gasket sheets

-

How do I select the right rubber gasket sheet for my application?

Choosing the right rubber gasket sheet involves considering factors such as the operating environment, temperature range, chemical exposure, and pressure conditions. For instance, EPDM is ideal for outdoor applications due to its weather resistance, while silicone is preferred for high-temperature settings. Additionally, understanding your specific application requirements will help you determine the appropriate thickness and hardness (durometer) of the gasket. Consulting with suppliers or industry experts can provide tailored recommendations based on your unique needs. -

What are the common materials used in rubber gasket sheets and their applications?

Rubber gasket sheets are commonly made from materials such as EPDM, Nitrile (BUNA-N), Neoprene, and Silicone. EPDM is excellent for outdoor applications due to its resistance to UV and ozone. Nitrile is ideal for oil and fuel applications, while Neoprene offers good weather resistance and flexibility. Silicone is suitable for high-temperature applications and food-grade environments. Understanding the properties of each material will help you select the most suitable gasket sheet for your specific application. -

What should I consider when vetting suppliers for rubber gasket sheets?

When vetting suppliers, consider their experience in the industry, product quality, and compliance with international standards. Look for certifications such as ISO or FDA, especially if the gaskets are used in food or pharmaceutical applications. Request samples to assess material quality and ensure they can meet your specifications for thickness, hardness, and chemical resistance. Additionally, evaluate their customer service and responsiveness, as these factors can significantly impact your overall experience. -

What is the typical minimum order quantity (MOQ) for rubber gasket sheets?

The minimum order quantity for rubber gasket sheets can vary significantly between suppliers and depends on factors such as material type and customization. Many suppliers offer MOQs ranging from 10 to 100 sheets, while some may allow smaller orders for standard sizes. For customized gaskets, MOQs may be higher due to setup costs. It’s advisable to discuss your requirements with potential suppliers to understand their policies and negotiate terms that meet your needs. -

What are the payment terms typically offered by suppliers of rubber gasket sheets?

Payment terms can vary by supplier and region, but common practices include net 30, 60, or 90 days, depending on the buyer’s creditworthiness and the supplier’s policies. Some suppliers may require a deposit upfront, especially for larger orders or custom products. It’s essential to clarify payment methods accepted (e.g., bank transfer, credit card) and any potential discounts for early payments. Discussing these terms upfront can help prevent misunderstandings and facilitate smoother transactions. -

How can I ensure quality assurance for my rubber gasket sheets?

To ensure quality assurance, request detailed specifications and certifications from your supplier, such as ISO 9001 for quality management systems. Establish a clear quality control process, including the inspection of raw materials and finished products. Consider implementing third-party testing for critical applications. Additionally, maintain open communication with your supplier about any quality concerns and be proactive in addressing issues to ensure consistent product performance. -

What logistics considerations should I keep in mind when importing rubber gasket sheets?

When importing rubber gasket sheets, consider shipping methods, customs regulations, and potential tariffs that may apply. Choose a reliable logistics partner familiar with international shipping and customs clearance to minimize delays. Ensure all documentation is accurate and complete to facilitate smooth transit through customs. Additionally, factor in lead times for production and shipping when planning your inventory, especially if you are sourcing from overseas suppliers. -

Can rubber gasket sheets be customized to fit specific dimensions and shapes?

Yes, rubber gasket sheets can be customized to meet specific dimensions and shapes according to your application requirements. Many suppliers offer cutting services to create gaskets of various sizes, shapes, and thicknesses. When placing a custom order, provide detailed specifications, including drawings if necessary. Some suppliers also offer additional services such as adhesive backing or surface treatments to enhance the gasket’s performance in your application.

Top 8 Rubber Gasket Sheets Manufacturers & Suppliers List

1. Gasket Supply – Garlock BLUE-GARD Style 3000 Sheet

Domain: gasketsupply.com

Registered: 2014 (11 years)

Introduction: Gasket Sheets available from Gasket Supply include various types and materials. Key products include: 1. Garlock BLUE-GARD Style 3000 Sheet – Price: $50.17 – Material: Aramid fiber with NBR binder, designed for improved torque retention and reduced emissions. 2. Diversified Silicone Heat Resistant Red Silicone Rubber Sheet – Price: $36.23 – Material: SBR Red Rubber with a smooth plate finish. 3. G…

2. American Material Supply – Neoprene Rubber Sheets

Domain: americanmaterialsupply.com

Registered: 2015 (10 years)

Introduction: NEOPRENE RUBBER SHEET – Available in various thicknesses: 1/32″ ($26.00), 1/16″ ($15.00), 3/32″ ($19.00), 1/8″ ($16.00), 3/16″ ($20.00), 1/4″ ($23.00), 3/8″ ($33.00), 1/2″ ($42.00), 3/4″ ($318.00), 1.00″ ($100.00), and 2.00″ x 36.00″ x 36.00″ ($601.00). Options include self-stick adhesive back and custom sizes available up to 6′ by 12′.

3. McMaster – EPDM Rubber Sheet Gaskets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – EPDM Rubber Sheet Gaskets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Garlock – Premium Rubber Gasket Sheets

5. Durlon® – 36X36X1/16 in Sheet Gasket Material

Domain: porterpipe.com

Registered: 1996 (29 years)

Introduction: [{‘size’: ’36X36X1/16 in’, ‘material’: ‘SHEET GASKET MATERIAL’, ‘manufacturer’: ‘Durlon Sealing Solutions’, ‘brand’: ‘Durlon®’, ‘part_number’: ‘3636116GM’, ‘mpn’: ‘3636116GM’, ‘min_order_qty’: 1, ‘qty_interval’: 1}, {‘size’: ’36X36X1/8 in’, ‘material’: ‘RR SHEET GASKET MATERIAL’, ‘manufacturer’: ‘Flexitallic’, ‘brand’: ‘Flexitallic®’, ‘part_number’: ‘183636RRGM’, ‘mpn’: ‘3318RRGM’, ‘min_order_qty’…

6. Rubber Sheet Warehouse – Neoprene Rubber Rolls & Sheets

Domain: rubbersheetwarehouse.com

Registered: 2015 (10 years)

Introduction: {“products”: [{“name”: “Neoprene Rubber Rolls & Sheets”,”widths”: [36, 48],”hardness”: “60A Medium Hardness”},{“name”: “Neoprene Rubber Rolls & Sheets with Adhesive Backing”,”width”: 36,”hardness”: “60A Medium Hardness”},{“name”: “Neoprene Rubber Strips”,”length”: “10 foot lengths”,”hardness”: “60A Medium Hardness”},{“name”: “Neoprene Rubber Strips with Adhesive Backing”,”length”: “10 foot lengths…

7. Ram Gaskets – Rubber Gasket Materials

Domain: ramgaskets.com

Registered: 2010 (15 years)

Introduction: Rubber Gasket Materials include various types such as Buna N/Nitrile, EPDM, Neoprene, Silicone, and Viton. Each type has specific properties and applications.

1. **Buna-N/Nitrile Rubber**:

– Temperature Range: -20ºC to +110ºC

– Thicknesses Available: 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm

– Sheet Size: 1.4M x any multiple up to 20M

– Properties: Good for water and oil, resistance to…

8. UIP International – Industrial and Commercial Sheet Rubber Products

Domain: uipintl.com

Registered: 2017 (8 years)

Introduction: UIP International offers an extensive variety of industrial and commercial grade sheet rubber products and gasket materials suitable for various applications. Key offerings include:

1. **Types of Sheet Rubber**:

– Commercial Grade Neoprene Rubber

– Cloth Inserted Neoprene Rubber

– Industrial Grade Neoprene Rubber

– Diaphragm Inserted Neoprene Rubber

– Cloth Inserted Nitrile (BUNA-N…

Strategic Sourcing Conclusion and Outlook for rubber gasket sheets

What Are the Key Takeaways for Strategic Sourcing of Rubber Gasket Sheets?

In today’s competitive landscape, strategic sourcing of rubber gasket sheets is essential for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. Understanding the diverse range of materials—such as aramid fiber, EPDM, and PTFE—ensures that buyers select the most suitable products for their specific applications. Additionally, leveraging suppliers who prioritize quality and compliance with industry standards can significantly enhance operational efficiency and reduce long-term costs.

How Can Buyers Optimize Their Sourcing Strategy?

Investing in long-term supplier relationships is crucial. Buyers should seek partners that not only provide high-quality products but also demonstrate a commitment to innovation and sustainability. This proactive approach can lead to improved product performance and a competitive edge in various industries.

Illustrative image related to rubber gasket sheets

What Does the Future Hold for Rubber Gasket Sheets in Global Markets?

As the demand for reliable and durable sealing solutions continues to grow, staying informed about market trends and technological advancements will be vital. B2B buyers are encouraged to explore emerging suppliers and materials that can offer enhanced performance and cost-effectiveness. By adopting a forward-thinking sourcing strategy, businesses can position themselves for success in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.