Rubber Floor Moulding: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for rubber floor moulding

In the dynamic landscape of global commerce, sourcing high-quality rubber floor moulding presents a unique challenge for international B2B buyers. As businesses strive to enhance their interiors while ensuring safety and durability, the need for reliable suppliers becomes paramount. This comprehensive guide delves into the diverse types of rubber floor moulding, including wall bases and cove bases, and their myriad applications across various sectors such as healthcare, hospitality, and retail.

By exploring critical aspects such as supplier vetting, cost considerations, and installation best practices, this guide equips decision-makers in Africa, South America, the Middle East, and Europe—countries like Vietnam and Saudi Arabia—with the insights necessary to make informed purchasing decisions. Whether you are enhancing a commercial space or ensuring compliance with safety standards, understanding the nuances of rubber floor moulding will empower you to select products that not only meet aesthetic demands but also withstand the rigors of daily use.

Navigating this market requires a strategic approach, and this guide serves as your roadmap, offering actionable insights and expert recommendations to streamline your sourcing process. With a focus on quality, sustainability, and design versatility, you can confidently invest in rubber floor moulding solutions that elevate your projects and enhance customer satisfaction.

Understanding rubber floor moulding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rubber Cove Base | Curved design that provides a seamless transition between floors and walls | Commercial, healthcare, and educational facilities | Pros: Easy installation, hygienic, durable. Cons: May be pricier than standard wall bases. |

| Toeless Wall Base | Flat design without a toe, ideal for modern aesthetics | Retail environments, corporate offices | Pros: Sleek appearance, easy to clean. Cons: Less protection against wall damage. |

| Thermoplastic Rubber Base | Made from a blend of rubber and plastic, offering flexibility and durability | High-traffic areas, industrial settings | Pros: Resistant to scratches and fading. Cons: Can be more expensive than traditional options. |

| Decorative Wall Base | Available in various colors and textures, mimicking wood or stone | Hospitality, residential interiors | Pros: Aesthetic appeal, wide variety. Cons: May require more maintenance over time. |

| Sanitary Wall Base | Designed to butt against tile, minimizing germ accumulation | Healthcare and food service environments | Pros: Enhances hygiene, easy to clean. Cons: Limited design options compared to other types. |

What are the Key Characteristics of Rubber Cove Base and Its Suitability for B2B Buyers?

Rubber Cove Base is designed with a curved profile that allows for a smooth transition between flooring and walls, minimizing dirt accumulation and making it easier to clean. This type is particularly suitable for environments such as hospitals, schools, and commercial spaces where hygiene and aesthetics are paramount. B2B buyers should consider the installation ease and durability of this option, especially in high-traffic areas.

Illustrative image related to rubber floor moulding

How Does a Toeless Wall Base Enhance Aesthetic Appeal in Commercial Spaces?

The Toeless Wall Base features a minimalist design that provides a sleek and modern look, making it an excellent choice for corporate offices and retail environments. It allows for easy cleaning and maintenance, appealing to businesses that prioritize aesthetics. However, B2B buyers should weigh the benefits of a stylish appearance against the potential for increased wall damage due to the lack of a toe.

Why Choose Thermoplastic Rubber Base for High-Traffic Areas?

Thermoplastic Rubber Bases are known for their flexibility and resistance to wear and tear, making them ideal for industrial settings and high-traffic areas. These bases combine the durability of rubber with the lightweight characteristics of plastic, ensuring longevity and ease of installation. B2B purchasers should focus on the cost-benefit analysis, as the upfront investment may yield lower maintenance costs over time.

What Are the Benefits of Decorative Wall Bases in Hospitality and Residential Interiors?

Decorative Wall Bases offer a variety of colors and textures, allowing businesses in the hospitality sector to create inviting and stylish environments. These bases can mimic natural materials like wood or stone, enhancing the overall design aesthetic. However, B2B buyers should consider the maintenance requirements, as some decorative options may require more frequent upkeep to maintain their appearance.

How Do Sanitary Wall Bases Contribute to Hygiene in Healthcare Settings?

Sanitary Wall Bases are specifically designed to butt against tiles, creating a barrier that reduces the risk of germ accumulation, making them essential in healthcare and food service environments. Their design facilitates easy cleaning and minimizes the chances of dirt and bacteria build-up. For B2B buyers in these sectors, investing in sanitary options can lead to improved hygiene standards and compliance with health regulations.

Key Industrial Applications of rubber floor moulding

| Industry/Sector | Specific Application of rubber floor moulding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Wall protection in hospitals and clinics | Enhances hygiene, reduces maintenance costs | Durability, easy cleaning, compliance with health regulations |

| Education | Flooring in schools and universities | Improves safety, reduces noise, and enhances aesthetics | Color variety, slip resistance, and ease of installation |

| Hospitality | Moulding in hotels and restaurants | Elevates interior design, enhances guest experience | Customization options, resistance to wear and tear |

| Retail | Wall base in retail stores | Protects walls, improves aesthetics, and attracts customers | Cost-effectiveness, design flexibility, and sustainability |

| Manufacturing & Warehousing | Protective moulding in factories and warehouses | Reduces damage to walls, improves safety | Impact resistance, compliance with safety standards |

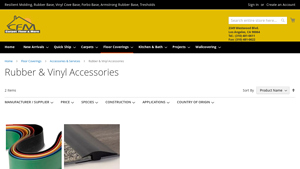

How is Rubber Floor Moulding Used in Healthcare Facilities?

In healthcare settings, rubber floor moulding is crucial for wall protection in hospitals and clinics. It prevents damage from wheeled equipment and spills, enhancing hygiene by creating a seamless transition between flooring and walls. This application addresses the need for easy-to-clean surfaces that resist bacteria accumulation, which is vital in maintaining a sterile environment. International buyers should prioritize sourcing options that meet health regulations and offer durability to withstand high foot traffic.

Illustrative image related to rubber floor moulding

What Role Does Rubber Floor Moulding Play in Educational Institutions?

In schools and universities, rubber floor moulding is utilized for its safety features, helping to reduce slips and falls. It also plays a significant role in noise reduction, contributing to a conducive learning environment. Aesthetic appeal is enhanced through various colors and designs, making spaces more inviting. Buyers from regions like Africa and South America should consider the moulding’s resilience against wear and ease of installation, especially in high-traffic areas.

How Can Hospitality Businesses Benefit from Rubber Floor Moulding?

In the hospitality industry, rubber floor moulding adds a touch of elegance while protecting walls in hotels and restaurants. This moulding not only contributes to the overall aesthetic but also ensures durability against the rigors of daily operations. It helps maintain a clean and polished appearance, which is essential for guest satisfaction. When sourcing, businesses should look for customization options and materials that resist wear and tear, ensuring longevity in high-traffic areas.

What Advantages Does Rubber Floor Moulding Offer to Retail Spaces?

Retail environments benefit from rubber floor moulding as it protects walls from damage caused by shopping carts and foot traffic. It enhances the store’s visual appeal, which can attract customers and encourage purchases. Cost-effectiveness is a significant consideration for retailers, along with design flexibility that allows for branding opportunities. Buyers must assess the sustainability of materials and their aesthetic compatibility with the store’s theme when sourcing.

Why is Rubber Floor Moulding Essential in Manufacturing and Warehousing?

In manufacturing and warehousing, rubber floor moulding serves as a protective barrier that minimizes wall damage from heavy equipment and materials. It plays a vital role in maintaining safety standards by preventing accidents caused by exposed edges. Buyers in this sector should focus on impact-resistant options that comply with safety regulations, ensuring that the moulding can withstand the demanding conditions often found in industrial environments.

3 Common User Pain Points for ‘rubber floor moulding’ & Their Solutions

Scenario 1: The Challenge of Material Durability in High-Traffic Areas

The Problem: B2B buyers in commercial sectors often face the challenge of selecting rubber floor moulding that can withstand high foot traffic without showing signs of wear and tear. For instance, a facility manager overseeing a busy hospital or retail environment may find that standard rubber moulding quickly becomes scuffed, cracked, or discolored. This not only detracts from the aesthetics of the space but can also lead to additional maintenance costs and safety hazards if the moulding becomes damaged.

Illustrative image related to rubber floor moulding

The Solution: To address this issue, it is essential to source rubber floor moulding made from high-grade materials specifically designed for durability. Buyers should look for products that feature thermoplastic rubber (TPR) formulations, which are known for their superior resilience against abrasions, gouging, and fading. It’s advisable to consult with suppliers who can provide detailed specifications about the product’s performance in commercial settings. Additionally, investing in moulding that comes with a warranty can provide peace of mind. Regular maintenance and cleaning with appropriate products can also help extend the lifespan of the moulding, ensuring that it retains its appearance and functionality in high-traffic areas.

Scenario 2: Difficulty in Installation and Compatibility with Existing Structures

The Problem: Many B2B buyers encounter significant hurdles during the installation process of rubber floor moulding, particularly when trying to match it with existing flooring or wall structures. A contractor working on a renovation project may find that the selected moulding does not fit well with the current flooring material, leading to gaps or uneven surfaces. This not only complicates the installation process but can also result in increased labor costs and project delays.

The Solution: To mitigate these installation challenges, buyers should prioritize sourcing moulding that offers flexible installation options. Look for rubber floor moulding that is available in various profiles, lengths, and customizable sizes. Working closely with manufacturers or suppliers who provide technical support can also be beneficial. They can offer installation guidelines and compatibility assessments to ensure that the chosen moulding integrates seamlessly with existing structures. Additionally, investing in a professional installation service can prevent costly mistakes and ensure a perfect fit, saving time and resources in the long run.

Scenario 3: Limited Color and Design Options Affecting Aesthetic Appeal

The Problem: A common pain point for B2B buyers is the limited aesthetic options available with rubber floor moulding. In settings such as hotels, restaurants, or corporate offices, maintaining a certain brand image and interior design theme is crucial. Buyers may struggle to find rubber moulding that not only meets functional requirements but also complements the overall decor. This limitation can lead to dissatisfaction and affect the perceived value of the space.

The Solution: To overcome aesthetic limitations, buyers should seek suppliers who offer a wide range of color and design options for rubber floor moulding. Many manufacturers now provide customizable solutions that can be tailored to match specific design requirements or branding colors. Exploring options such as patterned or textured moulding can also enhance visual appeal without sacrificing durability. Conducting a thorough market research and requesting samples before making a bulk order can help in making informed decisions that align with the desired aesthetic. Engaging with an interior designer can also provide valuable insights into how to effectively incorporate rubber floor moulding into the overall design scheme.

Strategic Material Selection Guide for rubber floor moulding

What Are the Key Materials for Rubber Floor Moulding?

When selecting materials for rubber floor moulding, it is essential to consider the performance characteristics, manufacturing complexities, and application suitability. Below is an analysis of four common materials used in rubber floor moulding, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Natural Rubber

Key Properties:

Natural rubber offers excellent elasticity, resilience, and tensile strength. It performs well under a wide range of temperatures and has good abrasion resistance.

Pros & Cons:

Natural rubber is highly durable and provides a comfortable underfoot feel, making it ideal for high-traffic areas. However, it is susceptible to UV degradation and can become brittle over time when exposed to sunlight. Additionally, sourcing natural rubber can be more expensive due to its reliance on rubber tree plantations.

Impact on Application:

Natural rubber is compatible with various flooring types and is often used in commercial settings such as gyms and schools. Its flexibility allows it to conform to different shapes and surfaces.

Illustrative image related to rubber floor moulding

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM D2240 for hardness and ASTM D412 for tensile strength. Regions with a strong emphasis on sustainability may prefer natural rubber due to its renewable nature.

2. Synthetic Rubber (SBR)

Key Properties:

Styrene-butadiene rubber (SBR) is known for its excellent wear resistance and aging stability. It can withstand moderate temperatures and has good chemical resistance.

Pros & Cons:

SBR is generally less expensive than natural rubber, making it a cost-effective choice for large-scale applications. However, it lacks the elasticity of natural rubber, which may affect comfort in certain applications.

Impact on Application:

SBR is suitable for environments exposed to oils and chemicals, making it ideal for industrial settings. However, it may not perform as well in outdoor applications due to UV sensitivity.

Considerations for International Buyers:

Buyers should verify compliance with standards such as ISO 9001 for quality management systems. Regions with stringent environmental regulations may require certifications that confirm the absence of harmful substances.

3. Thermoplastic Rubber (TPR)

Key Properties:

TPR combines the properties of rubber and thermoplastics, offering flexibility, durability, and ease of processing. It has good impact resistance and can be molded into complex shapes.

Pros & Cons:

TPR is easy to install and can be recycled, making it an environmentally friendly option. However, it may not provide the same level of comfort as natural rubber and can be more expensive due to its processing requirements.

Impact on Application:

TPR is often used in commercial and residential flooring applications, especially in areas that require a seamless finish. Its ability to be molded into various designs allows for aesthetic versatility.

Illustrative image related to rubber floor moulding

Considerations for International Buyers:

Buyers should look for compliance with international standards such as ASTM D624 for tear strength and ASTM D638 for tensile properties. Markets in Europe may prioritize TPR for its recyclability.

4. Ethylene Propylene Diene Monomer (EPDM)

Key Properties:

EPDM is known for its outstanding weather resistance, UV stability, and excellent heat resistance. It performs well in extreme temperatures, both hot and cold.

Pros & Cons:

EPDM is highly durable and suitable for outdoor applications, making it ideal for roofing and flooring in exposed environments. However, it can be more expensive than other rubber types and may require specialized installation techniques.

Impact on Application:

EPDM is often used in applications where exposure to the elements is a concern, such as playgrounds and outdoor sports facilities. Its resilience makes it a preferred choice for regions with harsh climates.

Considerations for International Buyers:

Buyers should ensure that EPDM products meet local building codes and standards, such as EN 13501 for fire classification. Compliance with environmental regulations may also be necessary, particularly in Europe.

Summary Table

| Material | Typical Use Case for rubber floor moulding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | High-traffic commercial areas | Excellent elasticity and durability | Susceptible to UV degradation | High |

| Synthetic Rubber (SBR) | Industrial applications | Cost-effective and wear-resistant | Lower elasticity than natural rubber | Medium |

| Thermoplastic Rubber (TPR) | Residential and commercial flooring | Easy to install and recyclable | May lack comfort compared to natural rubber | Medium |

| Ethylene Propylene Diene Monomer (EPDM) | Outdoor applications | Outstanding weather resistance | Higher cost and specialized installation | High |

This guide provides a comprehensive overview of the materials available for rubber floor moulding, enabling B2B buyers to make informed decisions based on performance, cost, and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber floor moulding

What Are the Key Stages in the Manufacturing Process of Rubber Floor Moulding?

The manufacturing process of rubber floor moulding involves several critical stages, each designed to ensure the final product meets industry standards for quality and performance.

Material Preparation

The process begins with the preparation of raw materials. High-quality rubber, often sourced from natural or synthetic compounds, is selected based on the desired properties, such as durability, flexibility, and color. This stage may involve mixing rubber with additives like color pigments, accelerators, and fillers to enhance performance characteristics. The blending process is crucial, as it affects the consistency and quality of the final product.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. The most common methods include extrusion and compression moulding.

-

Extrusion: In this method, the rubber mixture is fed into an extruder, where it is heated and forced through a die to create long strips or profiles. This technique is efficient for producing continuous lengths of moulding and allows for precise control over dimensions.

-

Compression Moulding: This technique involves placing the rubber material into a heated mould. The mould is then closed, and heat and pressure are applied to form the desired shape. This method is particularly useful for creating complex shapes and is often used for shorter production runs.

Assembly and Finishing

After forming, the moulded pieces may require assembly, especially if they include multiple components or need to be joined with other materials. This stage can involve additional processes like cutting, trimming, or drilling to ensure precise fit and finish.

Finishing processes, such as surface treatment and coating, are also applied to enhance aesthetic appeal and durability. This may include painting, polishing, or applying protective coatings to improve resistance to wear and environmental factors.

How is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing of rubber floor moulding. It ensures that the products not only meet the necessary specifications but also comply with international standards.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a significant role in defining the quality management systems of manufacturers. ISO 9001 focuses on continuous improvement, customer satisfaction, and regulatory compliance, which are essential for B2B buyers.

In addition to ISO standards, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) certifications for specific applications may be relevant, depending on the intended use of the rubber moulding.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials before they enter production. Materials are inspected for conformity to specifications and any discrepancies are addressed immediately.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is conducted to ensure that each stage adheres to the predefined quality standards. This may involve regular sampling and testing of products at different stages of production.

-

Final Quality Control (FQC): After the manufacturing process is complete, the final products undergo rigorous testing to ensure they meet all specifications and standards. This may include physical tests for strength, flexibility, and durability, as well as visual inspections for defects.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are utilized to assess the quality of rubber floor moulding. These include:

-

Physical Testing: Tests such as tensile strength, elongation, and hardness are performed to evaluate the mechanical properties of the rubber.

-

Environmental Testing: Products may undergo tests for resistance to UV light, ozone, and extreme temperatures to ensure they can withstand environmental conditions.

-

Dimensional Testing: Measurements are taken to confirm that the finished products meet specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their certifications and compliance with international standards.

-

Quality Reports: Request detailed quality control reports that outline testing results, quality assurance processes, and any corrective actions taken. This transparency can help establish trust in the supplier’s capabilities.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality. This is particularly beneficial for international transactions where physical inspections may not be feasible.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification:

-

Regulatory Differences: Different countries have varying regulations regarding product standards and certifications. Understanding these differences is crucial for compliance and market entry.

-

Cultural Factors: Business practices and expectations can differ significantly across regions. Establishing clear communication with suppliers regarding quality expectations and certifications can help mitigate misunderstandings.

-

Supply Chain Considerations: The global supply chain may introduce challenges related to quality consistency. Buyers should consider the geographical location of suppliers and the potential for variations in material quality and production standards.

In conclusion, the manufacturing processes and quality assurance practices for rubber floor moulding are critical to ensuring product reliability and performance. By understanding these processes and implementing effective verification strategies, B2B buyers can make informed decisions when sourcing from international suppliers.

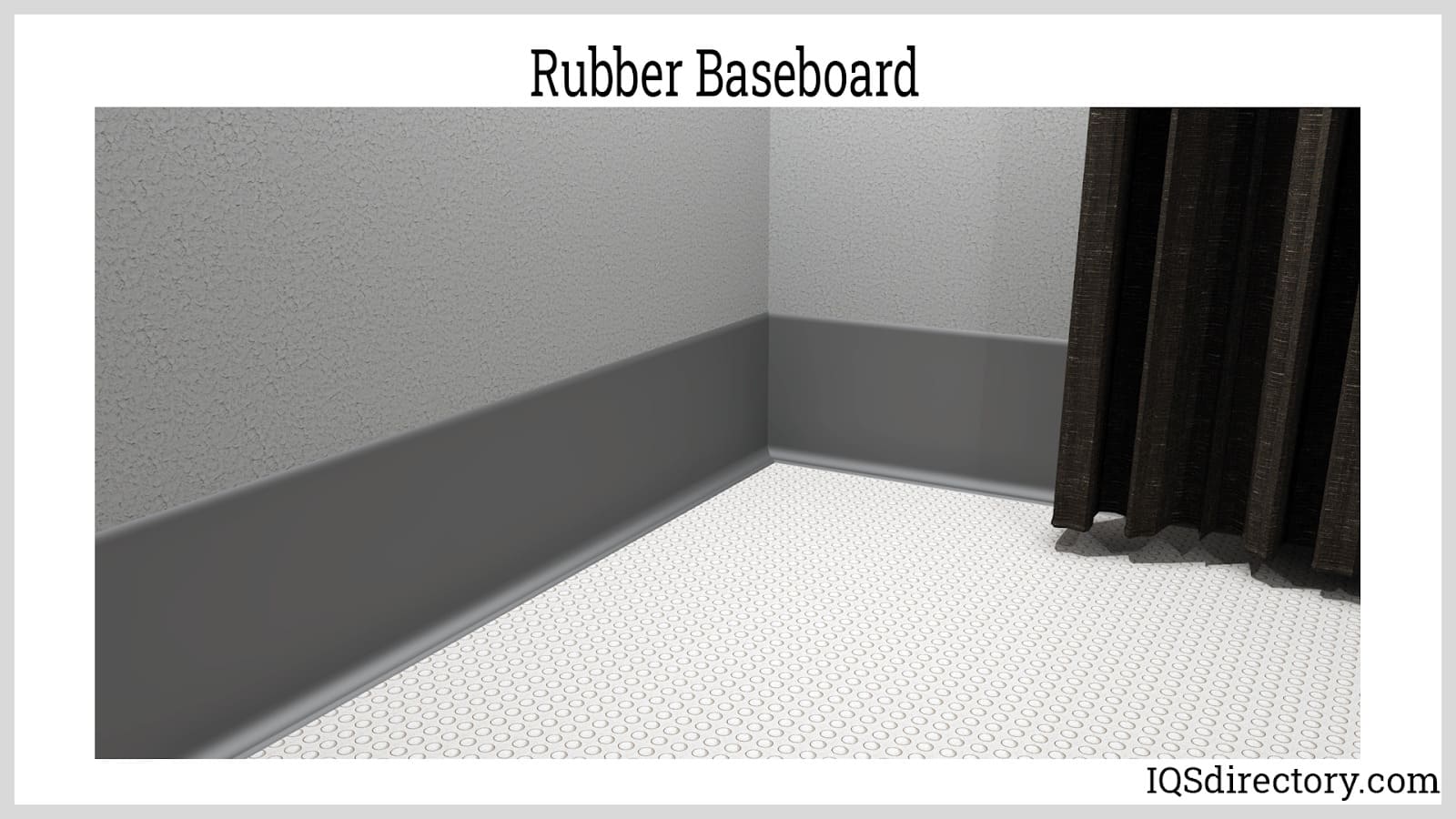

Illustrative image related to rubber floor moulding

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber floor moulding’

Introduction

Sourcing rubber floor moulding for your business requires careful consideration and strategic planning. This guide serves as a practical checklist to help B2B buyers navigate the procurement process, ensuring you select the right products and suppliers to meet your specific needs. By following these steps, you can streamline your sourcing efforts and avoid common pitfalls.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before beginning the sourcing process. Consider factors such as the type of rubber (natural vs. synthetic), dimensions, color options, and required durability for your specific applications. This clarity will not only help you communicate your needs to suppliers but also ensure that the products you receive meet your operational standards.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for rubber floor moulding can provide valuable insights into your sourcing strategy. Analyze competitor offerings and pricing structures, and consider regional variations, especially if you’re sourcing from different continents like Africa or South America. This information will help you set a realistic budget and negotiate effectively with suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. Request company profiles, product samples, and references from clients in similar industries. Look for suppliers with a proven track record of quality and reliability, particularly those who have experience serving clients in your target regions.

- Check Certifications: Ensure that suppliers meet international quality standards, such as ISO certifications, which can indicate their commitment to quality and compliance.

- Assess Production Capabilities: Verify that the supplier has the necessary equipment and processes to meet your volume requirements.

Step 4: Request Samples for Testing

Always request samples of rubber floor moulding before placing a large order. This step allows you to assess the quality, flexibility, and overall appearance of the product. Testing samples in your intended environment can also help determine if they meet your performance expectations, such as resistance to wear, moisture, and chemicals.

Step 5: Negotiate Terms and Conditions

Once you have identified suitable suppliers, it’s time to negotiate terms and conditions. Discuss pricing, payment terms, delivery schedules, and return policies. Establishing clear terms upfront can help prevent misunderstandings later and ensure a smoother transaction process.

Step 6: Verify Logistics and Shipping Options

Understanding the logistics involved in shipping rubber floor moulding is vital, especially for international orders. Confirm the supplier’s shipping methods, lead times, and costs. Additionally, consider local regulations regarding import duties and tariffs, which may affect your overall budget.

Step 7: Establish a Quality Control Process

Before finalizing your order, develop a quality control process to monitor the products upon delivery. This may include conducting inspections for defects or discrepancies against your original specifications. Having a robust quality assurance mechanism in place will help safeguard your investment and maintain the integrity of your projects.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for rubber floor moulding, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for rubber floor moulding Sourcing

When considering the sourcing of rubber floor moulding, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Rubber Floor Moulding Sourcing?

The cost structure for rubber floor moulding typically comprises several key components:

-

Materials: The primary cost driver is the type of rubber used, with options ranging from standard rubber to thermoplastic rubber (TPR). Higher quality materials often come with increased costs but can enhance durability and performance.

-

Labor: Labor costs vary by region and can significantly impact the overall pricing. In regions where labor is more expensive, such as parts of Europe, this may lead to higher product prices.

-

Manufacturing Overhead: This includes costs related to the factory’s operational expenses, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling costs are necessary for custom designs and can be substantial, especially for unique specifications. For standard products, these costs may be amortized over larger production runs.

-

Quality Control (QC): Ensuring that the rubber moulding meets international quality standards can add to costs but is essential for maintaining product integrity and buyer trust.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transport, and shipping terms. Understanding Incoterms is vital for clarifying responsibilities and costs associated with international shipping.

-

Margin: The supplier’s margin can vary widely based on market conditions, competition, and brand reputation. Buyers should be aware that premium brands may command higher prices due to perceived quality.

How Do Price Influencers Affect the Cost of Rubber Floor Moulding?

Several factors influence the pricing of rubber floor moulding:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider consolidating orders to maximize savings.

-

Specifications and Customization: Customized products typically incur higher costs due to specialized manufacturing processes. Buyers should weigh the benefits of customization against the increased expenses.

-

Material Quality and Certifications: Products with certifications (e.g., ISO, environmental certifications) often command higher prices but can provide assurance of quality and compliance with international standards.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better quality and service but at a premium.

-

Incoterms: Understanding terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is crucial, as they delineate cost responsibilities and can significantly affect the total landed cost.

What Are Some Effective Buyer Tips for Negotiating Rubber Floor Moulding Prices?

-

Negotiate Wisely: Always approach negotiations with a clear understanding of your needs and the market. Research competitor pricing to bolster your negotiating position.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and potential replacement costs.

-

Understand Regional Pricing Nuances: Pricing can vary significantly across regions due to local market conditions, tariffs, and trade agreements. Buyers in Africa or South America should be particularly aware of these nuances when sourcing from Europe or Asia.

-

Evaluate Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Consider establishing contracts that offer flexibility for future orders.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes and ensure that the product meets your expectations.

Conclusion

Navigating the cost and pricing landscape of rubber floor moulding sourcing requires a strategic approach. By understanding the cost components, price influencers, and effective negotiation strategies, international B2B buyers can make informed decisions that enhance their operational efficiency and product quality. Always remember that prices may vary, so conducting thorough research and engaging in open communication with suppliers is essential for achieving the best value.

Alternatives Analysis: Comparing rubber floor moulding With Other Solutions

Understanding Alternatives to Rubber Floor Moulding

When selecting flooring solutions, businesses often face the challenge of choosing the most suitable option for their specific needs. Rubber floor moulding is a popular choice due to its durability and flexibility, but it’s essential to explore viable alternatives that may offer different advantages. In this analysis, we will compare rubber floor moulding with two alternative solutions: vinyl floor moulding and metal floor moulding.

Comparison Table

| Comparison Aspect | Rubber Floor Moulding | Vinyl Floor Moulding | Metal Floor Moulding |

|---|---|---|---|

| Performance | Excellent flexibility and shock absorption; resistant to moisture and chemicals | Good durability; available in various colors and designs | High durability; resistant to impact and wear |

| Cost | Moderate ($2.68 – $3.57/sq. ft.) | Low to moderate ($1.50 – $3.00/sq. ft.) | High ($5.00 – $10.00/sq. ft.) |

| Ease of Implementation | Relatively easy to install; can be cut to fit | Easy to install; often comes in pre-cut lengths | More complex; may require professional installation |

| Maintenance | Low maintenance; easy to clean | Low maintenance; resistant to stains | Minimal maintenance; may require polishing |

| Best Use Case | Ideal for high-traffic areas, healthcare, and schools | Suitable for residential and commercial spaces with moderate traffic | Best for industrial settings and areas requiring high durability |

Detailed Breakdown of Alternatives

Vinyl Floor Moulding

Vinyl floor moulding is an economical choice that provides good durability and aesthetic options. It is available in a wide variety of colors and designs, making it suitable for both residential and commercial applications. The ease of installation and low maintenance requirements further enhance its appeal. However, while it offers decent performance, it may not withstand heavy impacts or extreme conditions as effectively as rubber.

Metal Floor Moulding

Metal floor moulding is known for its outstanding durability and resistance to wear and impact. It is an excellent choice for industrial settings where heavy machinery or equipment is present. While metal moulding can provide a modern and sleek aesthetic, it typically comes with a higher price tag and may require professional installation. Maintenance is generally minimal, but it can be prone to scratching and may need periodic polishing to maintain its appearance.

Conclusion: How to Choose the Right Flooring Solution

Selecting the right flooring solution depends on the specific needs of your business. If you prioritize flexibility and moisture resistance, rubber floor moulding is an excellent choice, especially for environments like schools and healthcare facilities. On the other hand, if cost is a significant factor, vinyl moulding offers a budget-friendly alternative with a variety of design options. For industries requiring maximum durability, metal moulding stands out despite its higher cost. Assessing factors such as traffic levels, aesthetic preferences, and budget will help B2B buyers make informed decisions tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for rubber floor moulding

What Are the Essential Technical Properties of Rubber Floor Moulding?

Rubber floor moulding is a critical component in flooring installations, providing both functional and aesthetic benefits. Understanding the essential technical properties is vital for B2B buyers to ensure they select the right products for their projects. Below are some key specifications to consider:

1. Material Grade

Rubber floor moulding is typically made from high-quality natural rubber or synthetic rubber compounds, such as thermoplastic rubber (TPR). The material grade affects durability, flexibility, and resistance to wear and tear. For commercial applications, a higher grade is recommended to withstand heavy foot traffic and harsh cleaning chemicals.

2. Thickness

The thickness of rubber moulding generally ranges from 1/8 inch to 1/4 inch. A thicker profile can provide better cushioning and durability, making it suitable for high-traffic areas. B2B buyers should assess the specific needs of their projects, as thicker options may incur higher costs but offer greater longevity.

3. Color Stability

Color stability refers to the ability of the rubber to maintain its hue over time, especially when exposed to UV light and cleaning agents. High-quality rubber moulding often comes with UV protection, ensuring that colors do not fade, which is crucial for maintaining aesthetic appeal in commercial spaces.

4. Flexibility and Compliance

Flexibility is essential for ease of installation, especially around corners and architectural features. Rubber moulding should be able to bend without cracking or breaking. Compliance with industry standards, such as ASTM (American Society for Testing and Materials), ensures that the product meets safety and performance requirements.

5. Moisture Resistance

Moisture resistance is a critical property for rubber floor moulding, especially in areas prone to spills and humidity. Rubber naturally resists water, but additional treatments can enhance this property, making it suitable for environments like kitchens and bathrooms where moisture exposure is common.

What Are Common Trade Terminology Terms Used in Rubber Floor Moulding?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to rubber floor moulding:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of rubber floor moulding, buyers often work with OEMs to ensure that the products meet specific requirements and standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it can affect inventory management and cash flow. Negotiating MOQs can lead to better pricing or terms.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. Including technical specifications in an RFQ helps suppliers provide accurate quotes, ensuring that buyers receive the best value.

Illustrative image related to rubber floor moulding

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers involved in global sourcing of rubber floor moulding, as they clarify shipping responsibilities, risks, and costs.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For rubber floor moulding, lead times can vary based on the supplier, material availability, and manufacturing processes. Buyers should factor in lead times when planning projects to avoid delays.

6. Certification Standards

Certification standards, such as ISO (International Organization for Standardization) or ASTM, indicate that a product meets specific quality and safety benchmarks. B2B buyers should look for certified products to ensure compliance with industry standards, which can be crucial for commercial applications.

By understanding these technical properties and terminology, B2B buyers can make informed decisions when sourcing rubber floor moulding, ensuring optimal performance and value for their projects.

Navigating Market Dynamics and Sourcing Trends in the rubber floor moulding Sector

What Are the Current Market Dynamics and Key Trends Affecting Rubber Floor Moulding?

The rubber floor moulding market is currently experiencing significant growth driven by several global factors. One primary driver is the increasing demand for durable, low-maintenance flooring solutions across various industries, including healthcare, education, and commercial sectors. As urbanization continues, especially in developing regions like Africa and South America, there is a rising necessity for robust flooring options that can withstand heavy foot traffic and environmental stressors.

Emerging technologies are shaping sourcing trends, with digital platforms facilitating easier access to suppliers worldwide. B2B buyers are increasingly leveraging e-commerce and online marketplaces to compare prices and specifications, enhancing their purchasing efficiency. Additionally, advances in manufacturing technology are enabling the production of customizable rubber moulding solutions, catering to specific design needs and preferences, thus appealing to a broader audience.

Market dynamics are also influenced by fluctuating raw material prices, necessitating that international buyers maintain agile sourcing strategies. Countries such as Vietnam and Saudi Arabia are becoming key players in the rubber moulding supply chain, providing competitive pricing and quality products, which is essential for buyers looking to optimize their costs while ensuring high-quality standards.

How Is Sustainability and Ethical Sourcing Reshaping the Rubber Floor Moulding Industry?

Sustainability has emerged as a critical factor in the rubber floor moulding sector, reflecting a growing awareness of environmental impacts among B2B buyers. The production of rubber flooring materials often involves synthetic components that can have detrimental effects on the environment. Consequently, companies are now prioritizing sustainable practices, including the use of recycled rubber and eco-friendly production processes.

Ethical sourcing has gained prominence, with buyers increasingly favoring suppliers who demonstrate commitment to sustainable practices. Certifications such as the Forest Stewardship Council (FSC) and Global Organic Textile Standard (GOTS) are becoming essential for products to appeal to environmentally conscious businesses. These certifications not only signal compliance with environmental regulations but also enhance brand reputation, making them vital for gaining competitive advantage in the market.

Illustrative image related to rubber floor moulding

Furthermore, the demand for ‘green’ materials is prompting manufacturers to innovate and develop rubber floor moulding solutions that are free from harmful chemicals, contributing to healthier indoor environments. By investing in sustainable and ethically sourced products, businesses can align themselves with the global movement towards environmental responsibility, which is increasingly becoming a decisive factor for consumers and clients alike.

What Is the Historical Context of Rubber Floor Moulding in the B2B Sector?

The evolution of rubber floor moulding can be traced back to the mid-20th century when synthetic rubber began to be widely used in construction and interior design. Initially popular for its durability and flexibility, rubber flooring quickly gained traction in commercial spaces due to its noise reduction and slip-resistance properties.

Over the decades, advancements in manufacturing processes and material technology have significantly enhanced the performance characteristics of rubber floor moulding. The introduction of designs mimicking natural materials, such as wood and stone, has expanded its aesthetic appeal, making it suitable for a wider range of applications. As sustainability concerns grew in the 21st century, the focus shifted towards developing eco-friendly rubber materials, aligning with contemporary consumer values and environmental regulations.

This historical context underscores the importance of adaptability and innovation in the rubber floor moulding sector, providing valuable lessons for B2B buyers seeking to align their sourcing strategies with current market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber floor moulding

-

1. How do I choose the right rubber floor moulding for my project?

Choosing the right rubber floor moulding depends on several factors, including the specific application, environmental conditions, and aesthetic preferences. Consider the thickness, durability, and flexibility of the moulding, especially if it will be used in areas with high foot traffic or around curves and corners. Additionally, assess the available color options to ensure they match your design theme. It’s also advisable to consult with suppliers about the best products for your intended use, as they can provide insights based on industry standards and performance. -

2. What is the best type of rubber floor moulding for commercial use?

For commercial applications, look for rubber floor moulding that is classified as commercial-grade, typically featuring thicker profiles and enhanced durability. Products that resist scuffs, scratches, and fading are ideal, as they can withstand high foot traffic and maintain their appearance over time. Coved or toeless designs are often preferred in commercial settings, as they provide a seamless transition between walls and floors, making cleaning easier while also protecting walls from damage. -

3. How can I ensure the quality of rubber floor moulding before purchasing?

To ensure quality, it’s crucial to vet your suppliers thoroughly. Request samples of the rubber floor moulding to assess its texture, flexibility, and overall finish. Inquire about certifications, such as ASTM standards, which indicate compliance with industry performance benchmarks. Checking customer reviews and case studies can provide insights into the product’s long-term performance. Additionally, consider visiting manufacturing facilities if feasible, as this allows you to observe production practices and quality control measures firsthand. -

4. What are the common payment terms for international B2B transactions in rubber floor moulding?

Payment terms can vary widely among suppliers, but common practices include a deposit (typically 30-50%) upfront with the balance due upon shipment or delivery. Letters of credit are also popular for international transactions, providing security for both parties. It’s advisable to clarify payment methods, such as wire transfers or credit terms, and to negotiate terms that align with your cash flow needs. Always ensure that payment terms are documented in your purchase agreement to avoid potential disputes. -

5. What is the minimum order quantity (MOQ) for rubber floor moulding?

Minimum order quantities (MOQs) for rubber floor moulding can vary by supplier and product type. Typically, MOQs range from 100 to 1,000 linear feet, depending on the material and manufacturing processes. If you are a smaller business or have specific project needs, some suppliers may offer flexibility in MOQs, especially for customized orders. Always discuss your requirements upfront with potential suppliers to find a solution that meets your needs without excessive inventory costs. -

6. How do I handle logistics and shipping for rubber floor moulding?

When arranging logistics for rubber floor moulding, consider factors such as shipping methods, lead times, and import regulations in your country. Collaborate with suppliers who have experience in international shipping to ensure compliance with customs requirements. It’s also wise to choose freight forwarders who can handle the intricacies of logistics, including documentation and delivery. Always factor in potential delays due to customs processing, and maintain open communication with your suppliers regarding shipment status. -

7. Can I customize rubber floor moulding to fit specific design needs?

Yes, many suppliers offer customization options for rubber floor moulding, allowing you to select specific colors, sizes, and profiles to match your project requirements. Customization can be particularly beneficial for unique architectural designs or branding purposes. However, be aware that custom orders may come with higher MOQs and longer lead times. Discuss your needs with suppliers early in the purchasing process to understand the possibilities and any associated costs. -

8. What should I include in my supplier vetting process for rubber floor moulding?

Your supplier vetting process should encompass a comprehensive assessment of their production capabilities, quality control practices, and industry reputation. Start by reviewing their certifications and compliance with relevant standards. Request references from previous clients and inquire about their experience with similar projects. Additionally, evaluate their communication responsiveness and customer service, as these factors will significantly impact your ongoing relationship. Finally, consider conducting an on-site visit if possible to better understand their operations.

Top 8 Rubber Floor Moulding Manufacturers & Suppliers List

1. Roppe – Vinyl Wall Base A500

Domain: kofflersales.com

Registered: 1999 (26 years)

Introduction: Roppe Vinyl Wall Base-A500: Commercial grade 1/8″ vinyl, available in 120ft rolls & 4ft strips, box/30. Johnsonite | Tarkett Vinyl Wall Base-A505: Commercial grade 1/8″ vinyl, available in 120 ft rolls & 4 ft. strips, box/30. Johnsonite | Tarkett Millwork Wall Base-A508: Available in 38 colors, highly durable, extremely flexible for installations around columns and architectural curves. Johnsonite…

2. Floorzz – Rubber Wall Base Molding

Domain: commercial.floorzz.com

Registered: 2014 (11 years)

Introduction: This company, Floorzz – Rubber Wall Base Molding, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Johnsonite – Rubber Wall Base Molding

Domain: installerstore.com

Registered: 2002 (23 years)

Introduction: Johnsonite Rubber Wall Base – Rubber Baseboard Molding

– Available Heights: 4 inch and 6 inch

– Thickness: .125 inch

– Length Options: 4 foot strips, special order coils in 100 foot or 120 foot lengths

– Colors: Over 30 popular colors plus non-stock options

– Installation: Easy application with Cove Base Adhesive or Step Tape

– Durability: Will not fade, scuff, crack, or shrink

– Ideal Use: Suitab…

4. Reddit – Rubber Base Board Molding

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Rubber Base Board Molding is primarily designed for commercial applications, often used in high traffic areas. It is considered cheap and may not be aesthetically pleasing for residential use. Some users recommend against using it in homes, suggesting that it is difficult to install properly, especially when cutting corners. Alternatives like MDF trim are suggested, which require nailing and caulk…

5. Coveworks – Rubber Wall Base Profiles

Domain: coveworks.com

Registered: 2000 (25 years)

Introduction: Coveworks offers rubber wall base profiles that combine the aesthetic of architectural wood moldings with the durability and low maintenance of thermoplastic rubber. They provide 29 distinctive profiles in 83 standard colors of sculptured rubber wall base, along with traditional 1/8″ wallbase available in vinyl or rubber. Additionally, there are 34 profiles of matching accessories to enhance proje…

6. Flexco Floors – Wallflowers Rubber Wall Base

Domain: flexcofloors.com

Registered: 2001 (24 years)

Introduction: {“products”:[{“name”:”Wallflowers Rubber Wall Base”,”price”:”$0.00″},{“name”:”Base Sculptures Profiled Wall Base System”,”price”:”$0.00″},{“name”:”Base 2000 TP Rubber Base”,”price”:”$0.00″},{“name”:”Vinyl Wall Base”,”price”:”$0.00″},{“name”:”Health Design Wall Base”,”price”:”$0.00″},{“name”:”Rubber Corner Blocks”,”price”:”$0.00″}]}

7. Lowe’s – Floor Moulding & Trim

Domain: lowes.com

Registered: 1995 (30 years)

Introduction: Floor Moulding & Trim at Lowe’s includes various types such as Vinyl Moulding, Wood Moulding, Laminate Moulding, Aluminum Moulding, and Rubber Wall Base. Key product types include: Baseboard Trim (protects walls and adds decor), Quarter Round (covers expansion gaps), Reducer (smooth transition between different heights), Floor Transition Strip (bridges different flooring surfaces), Wall Base (cove…

8. Carpet Floor and More – Resilient Molding & Rubber Base

Domain: carpetfloorandmore.com

Registered: 2004 (21 years)

Introduction: Resilient Molding, Rubber Base, Vinyl Cove Base, Forbo Base, Armstrong Rubber Base, Tresholds; Prices: Forbo Rubber Wall Base – $180.00, Mohawk Rubber Transitions – $15.00; Applications: Residential, Commercial, Heavy traffic areas, Industrial, Institutional; Country of Origin: USA.

Strategic Sourcing Conclusion and Outlook for rubber floor moulding

In today’s competitive landscape, effective strategic sourcing for rubber floor moulding can significantly enhance operational efficiency and cost-effectiveness. By focusing on high-quality materials and reliable suppliers, B2B buyers can ensure the longevity and durability of their flooring solutions, thus reducing long-term maintenance costs. The diverse range of rubber wall base options, including various colors and designs, allows businesses to align their choices with branding and aesthetic requirements, making a positive impression on clients and customers.

Furthermore, understanding regional supply chain dynamics is essential, especially for international buyers from Africa, South America, the Middle East, and Europe. Buyers should leverage global sourcing strategies to tap into emerging markets and innovative manufacturing practices, ensuring they remain competitive.

Looking ahead, the demand for sustainable and versatile flooring solutions is expected to grow. Buyers are encouraged to engage with suppliers who prioritize eco-friendly practices and materials. By fostering strong partnerships and investing in strategic sourcing, businesses can position themselves for success in the evolving market landscape. Now is the time to reassess sourcing strategies and explore new opportunities in rubber floor moulding that will drive value and growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.