Rotate Latch Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for rotate latch

In the dynamic landscape of global trade, sourcing reliable rotate latches can pose significant challenges for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The need for secure and efficient fastening solutions is universal, yet navigating the myriad of options available can be daunting. This comprehensive guide delves into the essential aspects of rotate latches, exploring their various types and applications across industries ranging from construction to automotive.

Buyers will gain insights into the critical factors for supplier vetting, ensuring that partnerships are built on quality and reliability. Additionally, we will cover cost considerations, helping businesses make informed financial decisions without compromising on safety or performance. By equipping international B2B buyers with actionable knowledge, this guide empowers them to confidently select the right rotate latch solutions tailored to their specific operational needs.

Whether you are in Brazil seeking durable latches for agricultural equipment or in Nigeria looking for robust solutions for construction projects, this guide serves as a vital resource. By understanding the intricacies of the rotate latch market, businesses can enhance their procurement strategies, ultimately driving operational efficiency and profitability. Prepare to unlock new avenues for success in your sourcing endeavors with this expert-led exploration of the rotate latch market.

Understanding rotate latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rotate Latch | Simple design, typically metal or plastic, manual operation | General purpose machinery and equipment | Pros: Cost-effective, easy to install. Cons: Limited security features. |

| Heavy-Duty Rotate Latch | Robust construction, often stainless steel, higher load capacity | Industrial applications, outdoor use | Pros: High durability, weather-resistant. Cons: Higher cost, may require more complex installation. |

| Adjustable Rotate Latch | Features a mechanism to adjust latch tension or fit | Custom applications, varied sizes | Pros: Versatile, adaptable to different needs. Cons: Can be more complicated to adjust. |

| Lockable Rotate Latch | Incorporates a locking mechanism for added security | Security-sensitive applications, cabinets | Pros: Enhanced security, prevents unauthorized access. Cons: More expensive, requires key management. |

| Spring-Loaded Rotate Latch | Automatic return mechanism, allows for quick closure | Fastening doors, hatches, and lids | Pros: Quick operation, reliable closure. Cons: May wear out faster due to moving parts. |

What are the Characteristics of Standard Rotate Latches?

Standard rotate latches are characterized by their straightforward design, often made from either metal or plastic materials. They operate manually, making them an economical choice for general-purpose applications across various machinery and equipment. When considering a standard rotate latch, buyers should assess the specific requirements of their equipment, including weight and frequency of use, to ensure compatibility. Their affordability and ease of installation make them a popular choice, particularly for businesses operating on a tight budget.

How Do Heavy-Duty Rotate Latches Differ?

Heavy-duty rotate latches stand out due to their robust construction, often crafted from stainless steel or other durable materials designed to withstand high loads and harsh environments. These latches are typically used in industrial applications and outdoor settings where reliability is critical. For B2B buyers, investing in heavy-duty latches may come at a higher initial cost, but their longevity and resistance to weather-related wear make them a cost-effective choice in the long run. Businesses should evaluate their operational demands to determine if the enhanced durability justifies the investment.

Why Choose Adjustable Rotate Latches?

Adjustable rotate latches are designed with a mechanism that allows users to modify the latch’s tension or fit. This adaptability makes them ideal for custom applications where variations in door or lid sizes are common. B2B buyers should consider the flexibility that adjustable latches offer, particularly in environments where equipment dimensions may change or where multiple configurations are necessary. However, the complexity of adjustment may require additional training or resources, which should be factored into purchasing decisions.

What Security Benefits Do Lockable Rotate Latches Provide?

Lockable rotate latches integrate a locking mechanism, providing an added layer of security for sensitive applications such as cabinets or storage containers. They are particularly beneficial in environments where unauthorized access must be prevented. While these latches can enhance security, buyers should be aware of the higher costs associated with them and the need for effective key management. For businesses prioritizing safety, the investment in lockable rotate latches can be justified by the peace of mind they offer.

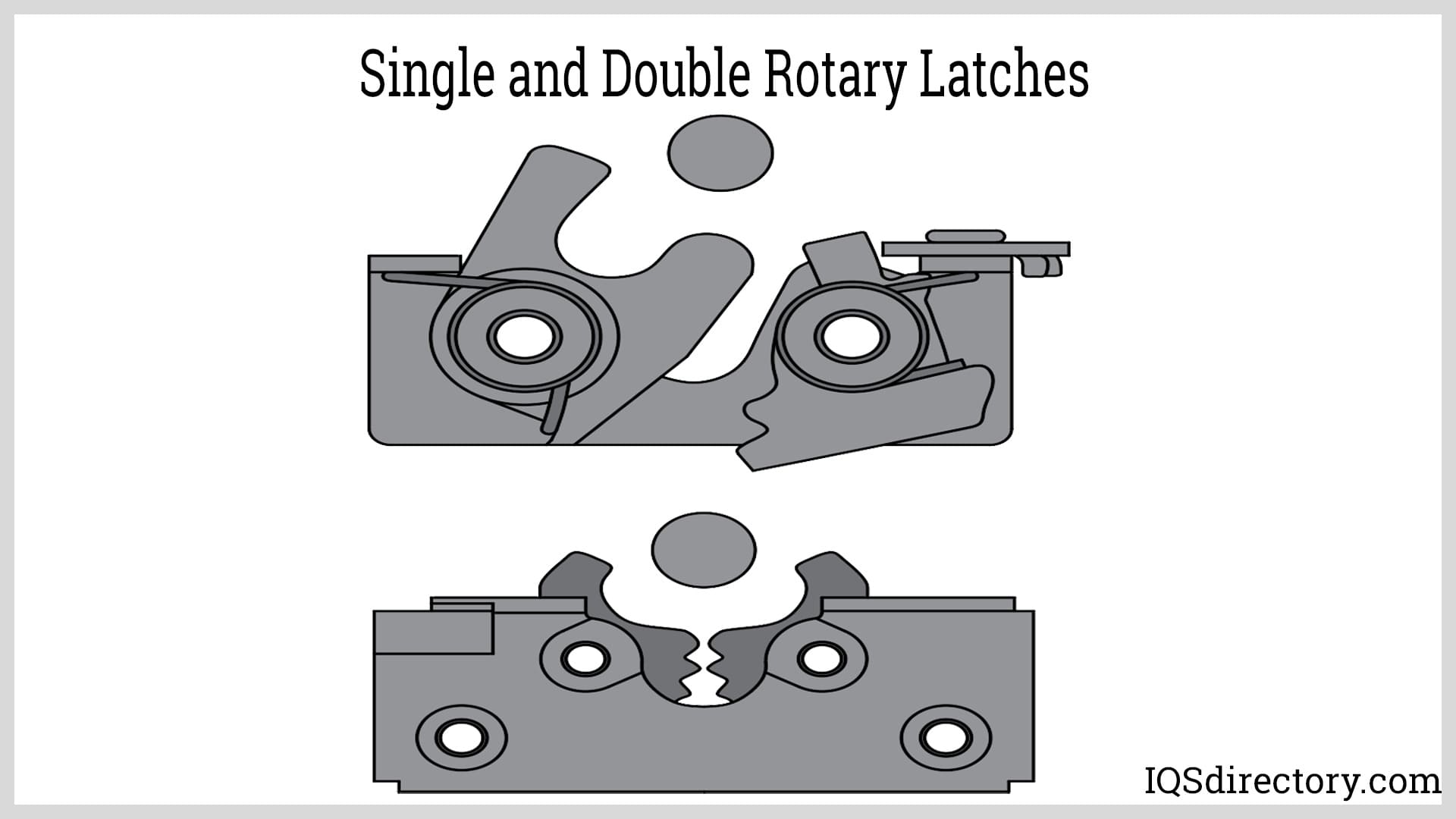

How Do Spring-Loaded Rotate Latches Enhance Efficiency?

Spring-loaded rotate latches feature an automatic return mechanism, allowing for quick closure and reliable fastening of doors, hatches, and lids. Their design promotes operational efficiency, making them suitable for fast-paced environments where time is of the essence. However, buyers should consider the potential for wear and tear due to moving parts, which may necessitate more frequent replacements. For businesses looking to streamline operations, the benefits of quick operation often outweigh the drawbacks.

Key Industrial Applications of rotate latch

| Industry/Sector | Specific Application of rotate latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Securing machinery access panels | Enhances safety and prevents unauthorized access | Durability, resistance to environmental factors, and ease of installation |

| Transportation & Logistics | Locking cargo containers and trailers | Ensures cargo security during transit | Corrosion resistance, compliance with international shipping standards |

| Construction & Building | Fastening doors and gates in commercial buildings | Provides reliable access control and safety | Material strength, weather resistance, and aesthetic compatibility |

| Agriculture | Securing equipment and storage units in farms | Protects valuable assets and improves efficiency | Compatibility with various equipment types and environmental durability |

| Automotive | Latching engine compartments and hoods | Enhances vehicle safety and performance | Vibration resistance, ease of use, and compliance with automotive standards |

How is Rotate Latch Used in Manufacturing and What Problems Does It Solve?

In the manufacturing sector, rotate latches are commonly employed to secure access panels on machinery. These latches enhance safety by preventing unauthorized access to potentially dangerous equipment. For international buyers, especially those in emerging markets like Nigeria and Brazil, it is crucial to source latches that are durable and resistant to harsh industrial environments. Buyers should consider the latch’s material, ensuring it can withstand wear and tear while remaining easy to install.

What Role Does Rotate Latch Play in Transportation & Logistics?

In transportation and logistics, rotate latches are essential for securing cargo containers and trailers. They provide a reliable locking mechanism that ensures cargo remains intact during transit, reducing the risk of theft or damage. For businesses operating in regions like the Middle East and South America, sourcing latches that meet international shipping standards is paramount. Key considerations include corrosion resistance and the ability to withstand varying weather conditions.

How Do Rotate Latches Enhance Security in Construction & Building?

Rotate latches are widely used in commercial construction to fasten doors and gates, offering robust access control. They not only improve security but also contribute to the overall safety of the building environment. Buyers in Europe and Africa should prioritize latches that offer a balance between aesthetic appeal and material strength, ensuring they can withstand both usage and environmental factors.

Why Are Rotate Latches Important in Agriculture?

In agriculture, rotate latches are crucial for securing equipment and storage units, protecting valuable assets from theft and environmental damage. Efficient operation is vital in this sector, as any downtime can lead to significant losses. Buyers should focus on latches that are compatible with various agricultural equipment and are designed to endure the rigors of outdoor use, particularly in regions with extreme weather.

How Do Rotate Latches Contribute to Automotive Safety?

In the automotive industry, rotate latches are used to secure engine compartments and hoods, playing a vital role in vehicle safety and performance. These latches must be vibration-resistant and easy to operate, particularly in high-performance vehicles. For international B2B buyers, it is essential to ensure compliance with automotive standards, as well as sourcing latches that can provide long-term reliability under diverse driving conditions.

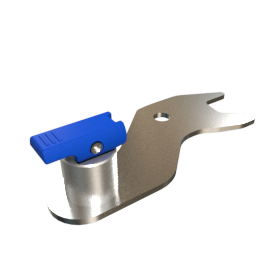

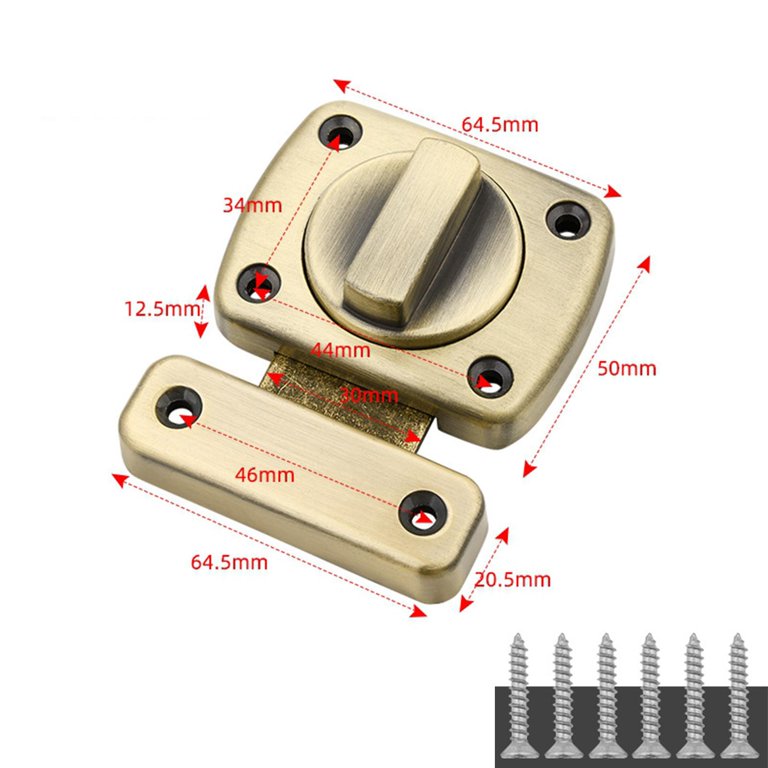

Illustrative image related to rotate latch

3 Common User Pain Points for ‘rotate latch’ & Their Solutions

Scenario 1: Inconsistent Performance in High-Volume Operations

The Problem: B2B buyers in industries like logistics or manufacturing often face challenges with rotate latches that do not perform consistently under high-volume conditions. For example, a manufacturing plant might experience frequent latch failures during the rapid opening and closing of doors or equipment covers, leading to delays, increased maintenance costs, and safety hazards. This inconsistency can result in a loss of trust from clients and can impact overall operational efficiency.

The Solution: To address this issue, buyers should prioritize sourcing high-quality rotate latches specifically designed for high-cycle operations. When evaluating suppliers, look for products that are made from robust materials like stainless steel or heavy-duty plastics that can withstand wear and tear. Additionally, consider latches with features such as adjustable tension or locking mechanisms that provide a secure fit even under stress. Collaborating with suppliers who offer performance guarantees or warranty options can also provide peace of mind. Investing in thorough testing of the latches in real-world conditions before finalizing a bulk purchase can help ensure reliability.

Scenario 2: Installation Challenges Leading to Increased Downtime

The Problem: Many B2B buyers encounter installation challenges with rotate latches, especially when integrating them into existing systems or structures. This could be due to a lack of compatibility with current hardware, leading to increased downtime during installation and potentially causing project delays. Companies often find themselves spending more time and resources trying to make incompatible products work rather than focusing on their core operations.

The Solution: To mitigate installation challenges, it is crucial to conduct a thorough compatibility assessment before purchasing rotate latches. Buyers should engage with suppliers to obtain detailed specifications and installation guides. This can include dimensions, required tools, and installation techniques. Additionally, opting for latches that come with comprehensive installation kits or technical support can simplify the process. For companies operating in diverse regions, it might be beneficial to consider local suppliers who understand the specific installation needs and conditions of the area, thus ensuring a smoother integration.

Scenario 3: Limited Customization Options Affecting Business Needs

The Problem: In competitive markets, B2B buyers often find that off-the-shelf rotate latches do not meet their specific operational needs. For example, a company in the agricultural sector may require latches that are resistant to corrosion and can handle extreme temperatures, but find that standard options lack these features. This limitation can lead to operational inefficiencies and increased costs due to frequent replacements.

The Solution: To address the need for customization, buyers should actively seek suppliers that offer bespoke solutions for rotate latches. This can involve reaching out to manufacturers who specialize in custom designs, allowing businesses to specify materials, sizes, and functionalities that align with their specific applications. Additionally, establishing long-term relationships with suppliers can facilitate future customization requests, ensuring that the latches evolve alongside the buyer’s changing business needs. Participating in industry trade shows or forums can also provide insights into innovative latch solutions that may not be widely advertised but could meet unique requirements.

Strategic Material Selection Guide for rotate latch

When selecting materials for rotate latches, it is essential for B2B buyers to consider various factors, including performance characteristics, cost implications, and regional compliance standards. Below is an analysis of four common materials used in the manufacture of rotate latches, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What are the Key Properties of Stainless Steel for Rotate Latches?

Stainless steel is renowned for its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for a wide range of applications. The material is often used in environments where hygiene is critical, such as in food processing or pharmaceutical industries.

Pros and Cons:

The primary advantage of stainless steel is its longevity and resistance to rust and tarnishing. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase production costs.

Impact on Application:

Stainless steel rotate latches are compatible with various media, including water and chemicals, making them versatile for different industries.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN for quality assurance. In Africa and South America, the availability of stainless steel may vary, impacting supply chain logistics.

How Does Aluminum Compare as a Material for Rotate Latches?

Aluminum is lightweight and offers good corrosion resistance, especially when anodized. It is often used in applications where weight is a critical factor, such as in aerospace or automotive industries.

Illustrative image related to rotate latch

Pros and Cons:

The key advantage of aluminum is its low weight, which can reduce overall product weight and shipping costs. However, it is less durable than stainless steel and may not withstand high-stress applications as effectively.

Impact on Application:

Aluminum rotate latches are suitable for environments with moderate exposure to moisture but may not be ideal for highly corrosive settings.

Considerations for International Buyers:

In regions like Brazil and Nigeria, aluminum’s cost-effectiveness can be appealing. However, buyers should verify compliance with local standards to ensure product reliability.

What are the Benefits of Using Plastic for Rotate Latches?

Plastic materials, such as nylon or polycarbonate, are increasingly popular for rotate latches due to their lightweight and non-corrosive properties. They can be molded into complex shapes, allowing for design flexibility.

Pros and Cons:

The main advantage of plastic is its low cost and ease of manufacturing. However, plastics typically have lower temperature and pressure ratings compared to metals, which may limit their applications.

Illustrative image related to rotate latch

Impact on Application:

Plastic rotate latches are suitable for light-duty applications, such as in furniture or lightweight enclosures, but may not perform well in high-stress or high-temperature environments.

Considerations for International Buyers:

For buyers in South America and Africa, the availability of high-quality plastics can vary significantly. Compliance with material safety standards is crucial to ensure product integrity.

How Does Brass Perform as a Material for Rotate Latches?

Brass is an alloy of copper and zinc that offers excellent corrosion resistance and a classic aesthetic appeal. It is often used in decorative applications where appearance is essential.

Pros and Cons:

Brass rotate latches provide a unique look and are highly resistant to corrosion, particularly in marine environments. However, they can be more expensive than other materials and may require more maintenance to preserve their appearance.

Illustrative image related to rotate latch

Impact on Application:

Brass is suitable for applications where aesthetics and corrosion resistance are prioritized, such as in luxury furniture or marine hardware.

Considerations for International Buyers:

In Europe, brass products often comply with strict environmental regulations, while in regions like Nigeria, the cost may be a significant factor in procurement decisions.

| Material | Typical Use Case for rotate latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial applications | High durability and corrosion resistance | Higher manufacturing cost | High |

| Aluminum | Aerospace and automotive | Lightweight and cost-effective | Less durable under high stress | Medium |

| Plastic | Furniture and lightweight enclosures | Low cost and design flexibility | Limited temperature and pressure ratings | Low |

| Brass | Decorative and marine hardware | Aesthetic appeal and corrosion resistance | Higher maintenance needs | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance needs, cost considerations, and compliance requirements in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for rotate latch

What Are the Main Stages in the Manufacturing Process of Rotate Latches?

The manufacturing process of rotate latches involves several critical stages, each contributing to the final product’s quality and functionality.

Material Preparation: What Materials Are Commonly Used?

The first stage is material preparation, where raw materials are selected based on the desired characteristics of the latch. Common materials include stainless steel, aluminum, and high-strength plastics, known for their durability and corrosion resistance. The choice of material can significantly affect the latch’s performance in different environments, such as humid or coastal areas.

How Are Rotate Latches Formed?

Following material preparation, the forming stage employs techniques such as stamping, forging, or CNC machining. Stamping is often used for mass production due to its efficiency in creating precise shapes and sizes. Forging enhances the strength of the latch, making it less prone to failure under load. CNC machining allows for intricate designs and tight tolerances, which are essential for ensuring smooth operation.

What Is Involved in the Assembly Process?

The assembly stage involves putting together various components, such as the latch body, pivot pin, and mounting hardware. This process may include automated assembly lines for high-volume production or manual assembly for customized solutions. Quality assurance practices at this stage ensure that components fit correctly and operate smoothly.

How Is the Finishing Process Conducted?

Finishing is the final stage, which may include surface treatments like anodizing, powder coating, or plating. These treatments not only enhance the aesthetic appeal of the latch but also improve its resistance to environmental factors. Proper finishing techniques can prevent rust, wear, and tear, extending the product’s lifespan.

What Quality Assurance Measures Are Standard in Rotate Latch Manufacturing?

Quality assurance (QA) in rotate latch manufacturing is crucial for meeting international standards and ensuring customer satisfaction.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer has implemented a quality management framework that consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking (for products sold in Europe) and API standards (for oil and gas applications) ensure that products are safe and reliable.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to detect any deviations from quality standards in real-time.

- Final Quality Control (FQC): Conducting thorough inspections of the finished product before it is shipped to customers.

Each checkpoint serves to identify defects early, reducing the risk of non-compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, especially in regions like Africa, South America, and the Middle East, verifying a supplier’s quality assurance processes is essential for ensuring product reliability.

Illustrative image related to rotate latch

What Methods Can Be Used for Supplier Audits?

One effective method is conducting supplier audits, where buyers evaluate the manufacturer’s processes, facilities, and quality control measures. This can include reviewing documentation related to quality management systems and inspecting the manufacturing environment.

Are There Reports or Certifications That Buyers Should Request?

Buyers should request quality reports, which often include data on defect rates, compliance with international standards, and results from internal quality audits. Certifications from recognized bodies can provide additional assurance of a manufacturer’s commitment to quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can further enhance confidence in the supplier’s quality processes. These independent organizations can conduct audits and inspections, providing an unbiased assessment of the manufacturer’s compliance with relevant standards.

What Testing Methods Are Commonly Used for Rotate Latches?

Testing is an essential component of the quality assurance process, ensuring that rotate latches meet performance specifications.

Which Common Testing Methods Are Employed?

Common testing methods include:

- Functional Testing: Assessing the latch’s operation under normal and extreme conditions to ensure it performs as intended.

- Durability Testing: Subjecting the latch to repeated use cycles to evaluate its longevity and resistance to wear.

- Environmental Testing: Exposing the latch to various environmental conditions, such as humidity and temperature extremes, to determine its resilience.

These tests are designed to simulate real-world conditions, ensuring that the latch will perform reliably in its intended application.

Illustrative image related to rotate latch

What Nuances Should International B2B Buyers Consider?

For B2B buyers, especially those in emerging markets, understanding the nuances of quality assurance and manufacturing processes is crucial.

How Do Regional Standards Affect Purchasing Decisions?

Buyers should be aware of regional standards and regulations that may affect product specifications. For instance, products sold in Europe must comply with CE marking requirements, while those in the Middle East may need to meet specific local standards.

What Should Buyers Know About Supply Chain Challenges?

Supply chain challenges, such as delays in material sourcing or transportation issues, can impact the quality and delivery of products. Establishing strong communication with suppliers and understanding their capabilities can help mitigate these risks.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality standards for rotate latches.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rotate latch’

The following guide serves as a practical checklist for B2B buyers seeking to procure rotate latches. It outlines essential steps to ensure a smooth sourcing process, facilitating informed decision-making and ultimately leading to a successful purchase.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the required materials, dimensions, load capacity, and operational features of the rotate latches needed for your applications. This clarity helps in communicating effectively with suppliers and ensures that the products meet your performance requirements.

- Material Considerations: Look for durable materials, such as stainless steel or zinc alloy, to ensure longevity and resistance to corrosion, particularly in challenging environments.

- Operational Mechanisms: Decide if you need manual or automatic operation, as this will influence the type of latches you consider.

Step 2: Conduct Market Research

Before engaging with suppliers, conduct thorough market research to understand the range of options available. This step helps you identify leading manufacturers and the latest innovations in rotate latch technology.

- Competitor Analysis: Review competitors’ offerings to benchmark features, pricing, and quality standards.

- Industry Trends: Stay informed about emerging trends in your sector that may impact your latch requirements, such as sustainability or smart technology integration.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, product catalogs, and references from businesses in similar industries or regions to ensure credibility.

- Supplier Background: Investigate the supplier’s history, production capacity, and market reputation to gauge reliability.

- Quality Assurance: Inquire about their quality control processes and certifications, such as ISO, to ensure compliance with international standards.

Step 4: Request Samples and Prototypes

Obtaining samples or prototypes of the rotate latches is critical for assessing quality and functionality. This step allows you to evaluate the latch’s performance in real-world applications.

- Testing for Fit and Functionality: Ensure the sample meets your technical specifications and operates as expected.

- Feedback from Stakeholders: Involve relevant team members in testing to gather diverse feedback on usability and performance.

Step 5: Negotiate Pricing and Terms

Once you’ve narrowed down your suppliers, enter negotiations focusing on pricing, payment terms, and delivery schedules. Effective negotiation can lead to significant cost savings and improved terms.

- Volume Discounts: Discuss potential discounts for bulk purchases, which can enhance your overall budget efficiency.

- Payment Flexibility: Explore options for payment terms that suit your cash flow, such as extended payment periods or installment plans.

Step 6: Verify Compliance with Local Regulations

Ensure that the rotate latches comply with local regulations and industry standards in your target markets. This step is crucial to avoid legal complications and ensure product safety.

- Import Regulations: Research any specific requirements for importing hardware products in your region, particularly in African, South American, or Middle Eastern markets.

- Safety Standards: Verify that the latches meet any applicable safety or performance standards relevant to your industry.

Step 7: Establish a Relationship for Future Orders

Building a long-term relationship with your supplier can streamline future orders and enhance collaboration. Consider establishing a partnership that includes regular communication and feedback loops.

- Continuous Improvement: Share insights and experiences to foster innovation and better product offerings.

- Support and Service: Discuss ongoing support options, such as technical assistance or product training, to ensure optimal usage of the latches.

By following this checklist, B2B buyers can navigate the sourcing process for rotate latches effectively, ensuring they secure the right products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for rotate latch Sourcing

What Are the Key Cost Components in Rotate Latch Sourcing?

When sourcing rotate latches, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include stainless steel, brass, and plastic, with stainless steel often being the preferred choice for its durability and resistance to corrosion. The quality of the material will also influence the price, as higher-grade options generally come at a premium.

-

Labor: Labor costs vary by region and manufacturing process. In countries with lower wage standards, such as Nigeria or Brazil, labor costs may be more favorable, impacting the final price. However, it’s essential to balance labor cost with quality, as cheaper labor may lead to lower-quality products.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Manufacturers often factor these costs into the pricing structure, so it’s important to inquire about overhead when evaluating suppliers.

-

Tooling: The initial investment in tooling is a key factor, especially for custom designs. Buyers should consider whether the supplier has the necessary tooling to meet their specifications, as this can significantly affect both lead times and costs.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability but can add to costs. Buyers should assess the level of QC implemented by suppliers to ensure it aligns with their quality standards.

-

Logistics: Shipping costs can vary greatly depending on the origin of the product and the chosen shipping method. Factors such as distance, mode of transport, and customs duties should be taken into account when calculating total costs.

-

Margin: Suppliers typically add a margin to cover their expenses and profit. Understanding the competitive landscape can help buyers negotiate better margins.

How Do Price Influencers Affect Rotate Latch Costs?

Several factors can influence the pricing of rotate latches:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Establishing a good relationship with suppliers can also lead to more favorable MOQs.

-

Specifications and Customization: Custom designs can significantly increase costs. Buyers should clearly outline their specifications to avoid unexpected expenses.

-

Quality and Certifications: Products that meet specific industry standards or certifications may come with a higher price tag. Buyers should assess the need for these certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The terms of shipping and delivery can greatly impact overall costs. Understanding Incoterms is essential for managing logistics costs and responsibilities.

What Are Effective Buyer Tips for Cost-Efficient Rotate Latch Sourcing?

To navigate the complexities of rotate latch sourcing effectively, B2B buyers should consider the following strategies:

-

Negotiate Wisely: Leverage competitive quotes from multiple suppliers to negotiate better pricing. Building long-term relationships can also yield discounts over time.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but also factors such as shipping, customs, and potential maintenance costs. A lower initial cost may lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances for International Buyers: When sourcing from regions like Africa or South America, be aware of local economic conditions and currency fluctuations that may affect pricing. Establishing contracts in stable currencies can mitigate risks.

-

Research Supplier Backgrounds: Before making a commitment, conduct thorough due diligence on potential suppliers. Verify their production capabilities, quality assurance practices, and customer reviews to ensure they meet your standards.

Conclusion

In conclusion, understanding the comprehensive cost structure and pricing influencers of rotate latch sourcing can empower international B2B buyers to make informed purchasing decisions. By focusing on effective negotiation strategies, total cost considerations, and supplier evaluations, buyers can optimize their sourcing process and achieve better value in their procurement efforts.

Alternatives Analysis: Comparing rotate latch With Other Solutions

Exploring Alternative Solutions to Rotate Latches

In the realm of mechanical fastening and securing solutions, the rotate latch is a popular choice for many applications due to its functionality and ease of use. However, various alternatives exist that may better suit specific needs or preferences. This analysis will compare the rotate latch with two viable alternatives: the turn latch and the flip door latch. By examining key aspects such as performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their operational requirements.

| Comparison Aspect | Rotate Latch | Turn Latch | Flip Door Latch |

|---|---|---|---|

| Performance | Reliable for secure closures | Adequate for light to moderate loads | Strong for heavy-duty applications |

| Cost | Moderate price point | Generally lower cost | Slightly higher due to materials |

| Ease of Implementation | Simple installation process | Very easy to install | Requires precise alignment |

| Maintenance | Low maintenance required | Minimal upkeep | Moderate, depending on usage |

| Best Use Case | General-purpose applications | Suitable for cabinets and doors | Ideal for barn doors and gates |

What Are the Advantages and Disadvantages of Each Alternative?

Turn Latch:

The turn latch is a straightforward mechanism that consists of a lever that turns to secure or release a door or panel. Its main advantage lies in its simplicity and low cost, making it an attractive option for budget-conscious buyers. The ease of installation is another strong point; it can typically be mounted without specialized tools. However, turn latches may not provide the same level of security or durability as rotate latches, particularly in high-stress environments.

Flip Door Latch:

The flip door latch is engineered for heavier applications, making it particularly suitable for barn doors and gates. Its robust design provides excellent security and can withstand more significant wear and tear compared to other options. While it is slightly more expensive due to its materials and construction, the investment may be worthwhile for those requiring durability. The main drawback is the need for precise alignment during installation, which can complicate the setup process for some users.

How Can B2B Buyers Choose the Right Solution?

When selecting between a rotate latch and its alternatives, B2B buyers should carefully assess their specific needs and operational contexts. Consider the performance requirements of the application; if security and durability are paramount, a flip door latch may be the better choice. Conversely, for lighter applications where cost and ease of installation are more critical, a turn latch could suffice. Additionally, evaluating the maintenance needs of each option can help streamline operational efficiency. Ultimately, the right solution will depend on balancing cost, performance, and the specific use case to achieve the best outcome for the business.

Essential Technical Properties and Trade Terminology for rotate latch

What Are the Key Technical Properties of a Rotate Latch?

Understanding the technical specifications of a rotate latch is essential for ensuring optimal performance in various applications. Here are some critical properties to consider:

-

Material Grade: Rotate latches are typically made from materials such as stainless steel, brass, or zinc-plated steel. The choice of material affects durability, resistance to corrosion, and overall strength. For instance, stainless steel is favored for outdoor applications due to its resistance to rust, making it ideal for industries operating in humid or corrosive environments.

-

Load Rating: This specification indicates the maximum weight the latch can securely hold. Knowing the load rating is crucial for B2B buyers, as it ensures that the latch will perform effectively in its intended application, whether it’s securing heavy doors or lightweight cabinets.

-

Tolerance: Tolerance refers to the permissible limits of variation in the dimensions of the latch components. Precise tolerances are vital for compatibility with other hardware and ensure smooth operation. Inaccurate tolerances can lead to misalignment, resulting in operational failures.

-

Finish Type: The finish type affects both aesthetics and functionality. Options like powder coating, anodizing, or plating can enhance the latch’s resistance to environmental factors and wear. Buyers should consider the finish based on their specific application requirements, such as exposure to chemicals or outdoor conditions.

-

Actuation Mechanism: This involves the method by which the latch is engaged or disengaged. Options include manual, spring-loaded, or electronic actuation. Understanding the actuation mechanism can help buyers select the appropriate latch for their operational needs, especially in automated systems.

-

Mounting Style: Rotate latches come in various mounting styles, including surface-mounted and flush-mounted designs. The choice of mounting style can significantly impact installation ease and the latch’s overall functionality within the application.

Which Trade Terms Are Commonly Used in the Rotate Latch Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to rotate latches:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for custom solutions or specific designs in rotate latches.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest quantity of a product that a supplier is willing to sell. This is important for budget planning and inventory management, as some suppliers may require a minimum order that could affect purchasing decisions.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers asking for pricing and terms on specific products. B2B buyers should use RFQs to compare prices and negotiate better deals for rotate latches, ensuring they get the best value for their investment.

-

Incoterms: These are international commercial terms that outline the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms is vital for international transactions, as they clarify who is responsible for shipping costs, insurance, and liability during transport.

-

Lead Time: This term refers to the time it takes from placing an order until the product is delivered. Knowing lead times helps buyers plan their projects more effectively and manage their supply chain expectations.

-

Compliance Standards: These are regulations and guidelines that products must meet for safety, quality, and performance. Familiarity with compliance standards relevant to rotate latches ensures that buyers select products that adhere to industry regulations, minimizing risks in their operations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing rotate latches, ultimately leading to more successful procurement outcomes.

Navigating Market Dynamics and Sourcing Trends in the rotate latch Sector

What Are the Current Market Dynamics and Key Trends Influencing the Rotate Latch Sector?

The global rotate latch market is experiencing significant growth, driven by several key factors. The increasing demand for secure and efficient fastening solutions across various industries, including construction, automotive, and manufacturing, is a primary driver. In particular, the rise of modular construction and the adoption of smart home technologies are pushing the need for innovative latch solutions that offer enhanced security and ease of use. Additionally, as international supply chains become more interconnected, B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly looking for reliable suppliers who can provide high-quality products at competitive prices.

Illustrative image related to rotate latch

Emerging technologies are also shaping sourcing trends in the rotate latch sector. The integration of automation in manufacturing processes is enhancing production efficiency and reducing lead times. Moreover, digital platforms are enabling buyers to easily compare product specifications, pricing, and supplier ratings, facilitating informed purchasing decisions. As a result, the ability to leverage data analytics and market intelligence is becoming crucial for B2B buyers aiming to stay ahead of the curve.

Furthermore, sustainability is gaining traction, with buyers increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility. This shift is prompting manufacturers to adopt eco-friendly practices and materials in their production processes, making sustainability a pivotal consideration in sourcing decisions.

How Is Sustainability and Ethical Sourcing Shaping the Rotate Latch Market?

In today’s business landscape, sustainability and ethical sourcing are not just trends; they are essential components of corporate strategy. B2B buyers are increasingly aware of the environmental impact of their purchasing decisions. The production of rotate latches, often involving metals and plastics, can contribute to pollution and resource depletion if not managed responsibly.

Ethical supply chains are crucial for ensuring that materials are sourced sustainably and that labor practices are fair. Buyers are encouraged to seek out suppliers who adhere to recognized sustainability certifications, such as ISO 14001 for environmental management and Fair Trade certifications. These certifications not only enhance a company’s brand reputation but also resonate with consumers who prefer eco-conscious products.

Moreover, many manufacturers are exploring alternative materials, such as recycled metals and biodegradable plastics, to produce rotate latches. These innovations not only reduce environmental impact but also appeal to a growing market segment that prioritizes sustainability. As a result, B2B buyers who incorporate sustainability into their sourcing strategies can differentiate themselves in a competitive marketplace, attract new customers, and foster long-term partnerships.

What Is the Evolution of the Rotate Latch Sector and Its Relevance Today?

The rotate latch has evolved significantly from its inception, originally designed for simple applications in woodworking and furniture. Over the decades, advancements in materials science and manufacturing techniques have led to the development of more durable and versatile latches suitable for a variety of applications, including automotive and industrial uses.

Today, the rotate latch sector is characterized by a diverse range of products, from heavy-duty latches for industrial settings to lightweight options for consumer goods. This evolution reflects the changing needs of manufacturers and end-users, with a focus on improved functionality, security, and aesthetics. As B2B buyers navigate this dynamic landscape, understanding the historical context of rotate latches can inform their sourcing strategies and help them identify reliable suppliers who are equipped to meet contemporary demands.

In conclusion, the rotate latch market is influenced by a blend of technological advancements, sustainability considerations, and evolving buyer preferences. By staying informed about these trends, B2B buyers can make strategic sourcing decisions that align with their business objectives and contribute positively to the broader market.

Frequently Asked Questions (FAQs) for B2B Buyers of rotate latch

-

How do I choose the right rotate latch for my application?

Selecting the appropriate rotate latch depends on the specific requirements of your application. Consider factors such as the material (stainless steel, plastic, etc.), load capacity, and environmental conditions (moisture, temperature). Assess the latch’s compatibility with your door or enclosure type, and ensure it provides the necessary security features. Consulting with suppliers about their product specifications and testing samples can also help in making an informed choice. -

What is the best rotate latch for heavy-duty applications?

For heavy-duty applications, look for rotate latches made from high-strength materials like stainless steel or reinforced polymers. These latches should offer robust locking mechanisms and resistance to corrosion and wear. Brands with a proven track record in industrial applications often provide models designed for high-stress environments. Always check the manufacturer’s specifications for load ratings and operational limits to ensure optimal performance. -

What customization options are available for rotate latches?

Many suppliers offer customization options for rotate latches, including size, color, and material. You can also request specific features such as additional locking mechanisms, finishes, or branding. Customization is particularly useful when catering to unique industry needs or aesthetic requirements. It’s advisable to discuss your specifications with potential suppliers early in the sourcing process to ensure they can meet your demands. -

What are the minimum order quantities (MOQs) for rotate latches?

Minimum order quantities (MOQs) for rotate latches can vary significantly between suppliers. Some manufacturers may have low MOQs, while others may require larger orders to justify production costs. When sourcing, inquire about MOQs upfront, especially if you are a small or medium-sized enterprise. This will help you assess the feasibility of working with different suppliers based on your project scale. -

What payment terms should I expect when sourcing rotate latches internationally?

Payment terms can differ widely among suppliers, particularly in international trade. Common arrangements include upfront payments, net 30/60/90 terms, or letters of credit for larger orders. It’s crucial to negotiate terms that align with your cash flow and risk management strategies. Always clarify payment methods accepted (e.g., bank transfers, PayPal) and any applicable fees, especially for cross-border transactions. -

How can I ensure the quality of rotate latches from suppliers?

To guarantee the quality of rotate latches, conduct thorough supplier vetting. Request samples to evaluate the product’s durability and functionality. Look for suppliers who comply with international quality standards, such as ISO certifications. Additionally, consider implementing a quality assurance (QA) process, which includes inspections at various production stages, to ensure that the latches meet your specifications before shipment. -

What logistics considerations should I keep in mind when sourcing rotate latches?

When sourcing rotate latches internationally, logistics plays a critical role in ensuring timely delivery. Consider factors such as shipping methods (air vs. sea), customs regulations, and potential tariffs that could affect your total cost. Work closely with your supplier to understand their shipping capabilities and timelines. It’s also beneficial to partner with a reliable freight forwarder who can navigate logistics challenges and provide tracking updates. -

Are there specific regulations I need to be aware of when importing rotate latches?

Yes, importing rotate latches may be subject to various regulations, including safety standards and import tariffs, which can vary by country. Familiarize yourself with the import requirements of your target market, including necessary documentation, labeling, and compliance certifications. Consulting with a trade compliance expert or legal advisor can help you navigate these regulations effectively, minimizing the risk of delays or penalties during the import process.

Top 4 Rotate Latch Manufacturers & Suppliers List

1. Falcon – MA-Series Mortise Lock

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Latch bolt, 180-degree rotation, door opens outward, Falcon brand, may require ordering left-hand or right-hand version, some models are not reversible, reference to MA-Series mortise locks.

2. Gate Latch – Rotate Bolt Lock

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, Gate Latch – Rotate Bolt Lock, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

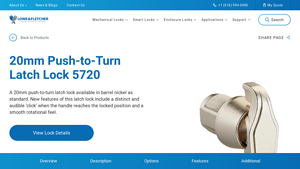

3. Lowe & Fletcher – 20mm Push-to-Turn Latch Lock 5720

Domain: loweandfletcherinc.com

Registered: 2018 (7 years)

Introduction: {“Product Name”: “20mm Push-to-Turn Latch Lock 5720”, “Finish Options”: [“Barrel Nickel”, “Bright Chrome”, “Satin Chrome (available on request)”], “Body Length”: “20mm”, “Max Panel Thickness”: “13mm”, “Shackle Diameter”: {“Min”: “5mm”, “Max”: “8mm”}, “Lock Features”: [“Distinct and audible ‘click’ when locked”, “Smooth rotational feel”, “Free-wheel system with padlock fitted”, “Zinc diecast constr…

4. Essentra Components – Quarter-Turn Latches with Wing Knobs

Domain: essentracomponents.com

Registered: 2012 (13 years)

Introduction: Quarter-Turn Latches with Wing Knobs designed for securing doors, cabinets, and enclosures. Operated by twisting the knob 90 degrees for engagement/disengagement. Includes outer sealing gasket and assembly nut for easy installation. Available in various materials (Die Cast Zinc Alloy, Nylon, Stainless Steel) and finishes (Black Powder-Coated, Chrome Plated). Knob lengths: 0.906 in (23.0 mm) and 1….

Strategic Sourcing Conclusion and Outlook for rotate latch

In the ever-evolving landscape of hardware procurement, the strategic sourcing of rotate latches presents a significant opportunity for international B2B buyers. Key takeaways emphasize the importance of selecting durable, high-quality materials, such as stainless steel, which ensure longevity and reliability in various applications. By fostering relationships with trustworthy suppliers, businesses can not only secure competitive pricing but also benefit from innovative solutions that enhance product offerings.

Strategic sourcing transcends mere purchasing; it involves a comprehensive understanding of market dynamics, supplier capabilities, and regional requirements. For buyers in Africa, South America, the Middle East, and Europe, this approach facilitates access to diverse product ranges, tailored to meet specific operational needs. Leveraging local suppliers, when possible, can further enhance supply chain efficiency and reduce lead times.

As we look ahead, it is vital for businesses to embrace a proactive sourcing strategy. Engaging with suppliers who prioritize sustainability and technological advancements will not only future-proof operations but also align with global trends. International buyers are encouraged to evaluate their sourcing strategies now, ensuring they are well-positioned to capitalize on emerging opportunities in the rotate latch market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to rotate latch

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.