Rotary Vane Vacuum Pump: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for rotary vane vacuum pump

In today’s competitive landscape, sourcing a reliable rotary vane vacuum pump can pose significant challenges for international B2B buyers. With diverse applications across industries such as manufacturing, food processing, and pharmaceuticals, the demand for these pumps is rising globally. However, navigating the complexities of product specifications, supplier credibility, and pricing can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe, including key markets like Germany and Nigeria.

This comprehensive guide addresses these challenges head-on, offering valuable insights into various types of rotary vane vacuum pumps, their applications, and critical factors to consider when selecting a supplier. We delve into the nuances of performance metrics such as CFM ratings and energy efficiency, ensuring that buyers understand how to match their specific operational needs with the right equipment. Additionally, the guide provides actionable strategies for vetting suppliers and negotiating costs, empowering businesses to make informed purchasing decisions.

By equipping international B2B buyers with knowledge and practical tools, this guide aims to simplify the procurement process, enabling companies to enhance operational efficiency and maintain a competitive edge in their respective markets. Whether you are looking to upgrade existing equipment or invest in new technology, understanding the global market for rotary vane vacuum pumps is essential for success.

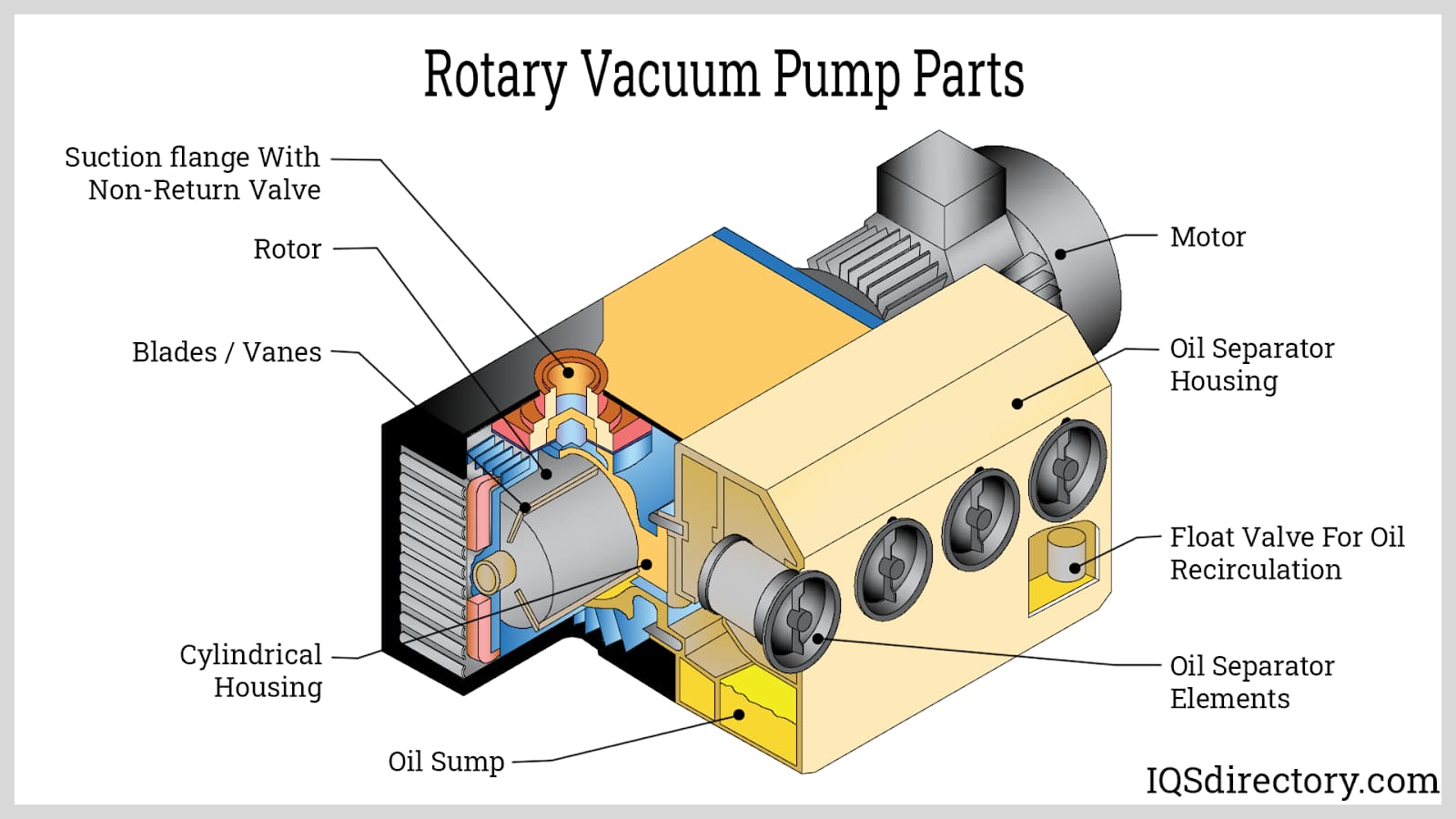

Understanding rotary vane vacuum pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Oil-Sealed Rotary Vane | Utilizes oil for sealing and lubrication; provides high vacuum levels. | Pharmaceutical manufacturing, food packaging, and chemical processing. | Pros: High efficiency, reliable vacuum levels. Cons: Requires regular oil changes and maintenance. |

| Dry Rotary Vane | No oil used; operates without lubrication, reducing contamination risk. | Electronics manufacturing, medical devices, and vacuum packaging. | Pros: Minimal maintenance, cleaner operation. Cons: Generally lower ultimate vacuum than oil-sealed types. |

| Multi-Stage Rotary Vane | Features multiple vanes for improved performance and higher vacuum levels. | Research laboratories, aerospace applications, and industrial processes. | Pros: Higher efficiency and vacuum levels. Cons: More complex and potentially higher initial costs. |

| Compact Rotary Vane | Smaller footprint, designed for space-constrained applications. | Laboratory settings, small-scale production, and portable equipment. | Pros: Space-saving design, suitable for small systems. Cons: Limited pumping capacity compared to larger models. |

| Variable Speed Rotary Vane | Adjustable speed control to optimize performance based on demand. | Automotive testing, HVAC systems, and flexible manufacturing. | Pros: Energy-efficient, adaptable to varying workload. Cons: Higher upfront investment and complexity. |

What Are the Characteristics of Oil-Sealed Rotary Vane Pumps?

Oil-sealed rotary vane pumps are renowned for their ability to achieve high vacuum levels, making them suitable for applications that demand precision and reliability. These pumps utilize oil for lubrication and sealing, which enhances their performance but also necessitates regular maintenance, including oil changes. B2B buyers should consider the operational costs related to maintenance and the potential for oil contamination in sensitive applications.

How Do Dry Rotary Vane Pumps Operate?

Dry rotary vane pumps operate without oil, making them ideal for industries where contamination is a concern, such as electronics manufacturing and medical devices. The absence of oil eliminates the need for regular lubrication maintenance, resulting in lower operational costs. However, they may not achieve the same ultimate vacuum levels as their oil-sealed counterparts, which is a critical consideration for applications requiring stringent vacuum levels.

What Advantages Do Multi-Stage Rotary Vane Pumps Offer?

Multi-stage rotary vane pumps incorporate several vanes to enhance their efficiency and vacuum capabilities. This design allows them to achieve higher vacuum levels, making them suitable for demanding applications in research laboratories and aerospace. Buyers should weigh the benefits of improved performance against the potential for higher costs and complexity in maintenance due to the intricate design.

Why Choose Compact Rotary Vane Pumps?

Compact rotary vane pumps are specifically designed for environments where space is limited. These pumps are perfect for laboratory settings and small-scale production lines. While they offer a space-saving solution, buyers should be aware that their smaller size often translates to a reduced pumping capacity, which may not meet the demands of larger systems.

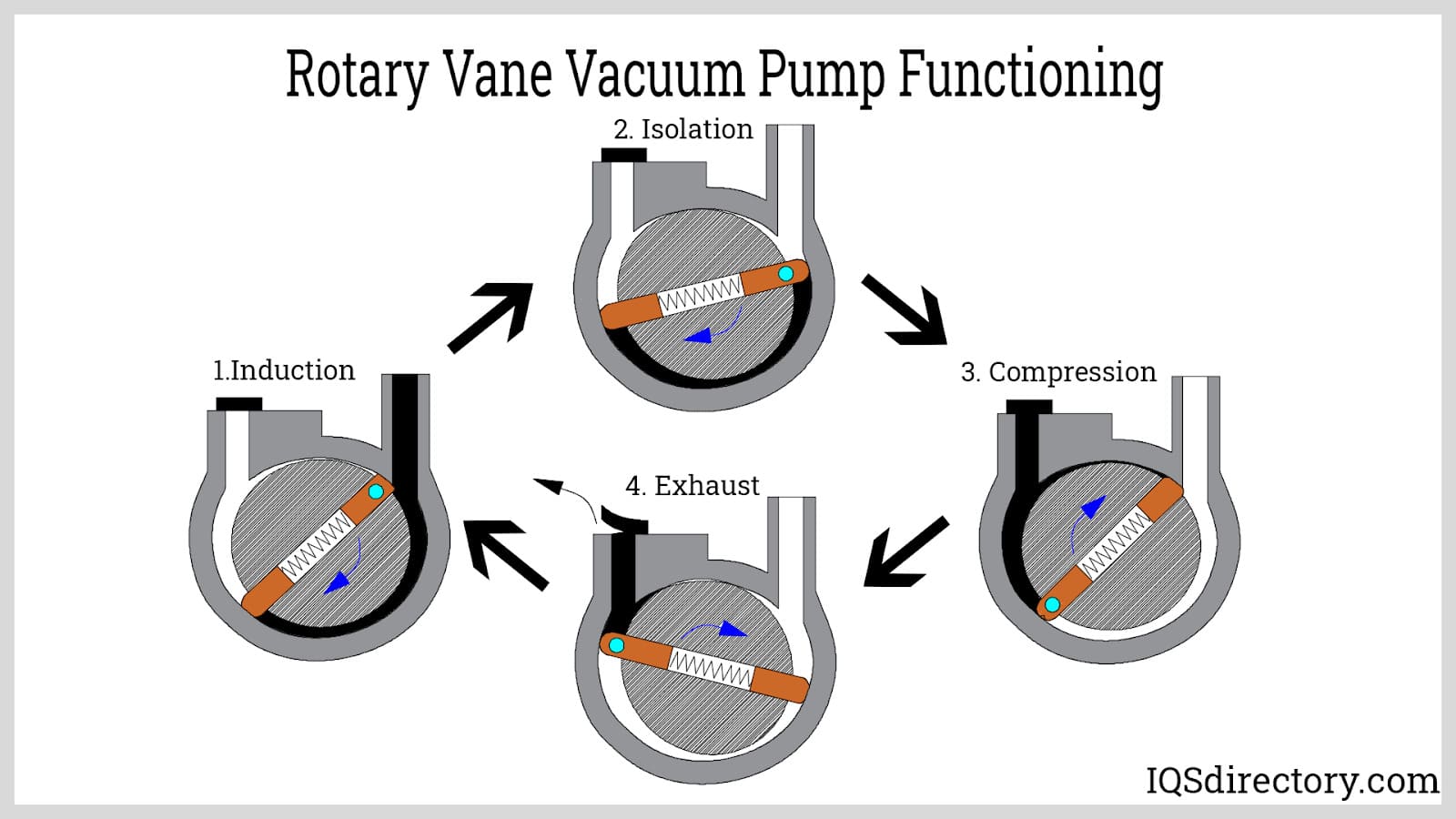

Illustrative image related to rotary vane vacuum pump

How Do Variable Speed Rotary Vane Pumps Benefit Businesses?

Variable speed rotary vane pumps provide the flexibility of adjustable speed control, allowing businesses to optimize performance based on specific operational needs. This adaptability can lead to energy savings and increased efficiency, making them suitable for automotive testing and HVAC systems. However, the complexity and higher initial investment may deter some buyers, necessitating a careful evaluation of long-term benefits versus upfront costs.

Key Industrial Applications of rotary vane vacuum pump

| Industry/Sector | Specific Application of rotary vane vacuum pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Vacuum packaging of perishable goods | Extends shelf life and maintains product quality | Compliance with food safety standards and certifications; energy efficiency of pumps. |

| Pharmaceutical Manufacturing | Sterilization and packaging of medical products | Ensures product safety and extends shelf life | Reliability and maintenance services; ability to handle varying pressure levels. |

| Automotive | Brake system vacuum assist | Enhances vehicle performance and safety | Durability under high operational loads; compatibility with existing systems. |

| Electronics | Vacuum deposition for semiconductor manufacturing | Improves product quality and reliability | Precision control of vacuum levels; adaptability to different materials. |

| Chemical Processing | Solvent recovery and distillation | Reduces waste and improves operational efficiency | Robustness in harsh chemical environments; ease of maintenance and servicing. |

How is Rotary Vane Vacuum Pump Used in Food Processing?

In the food processing industry, rotary vane vacuum pumps are critical for vacuum packaging applications. These pumps help remove air from packaging, which significantly extends the shelf life of perishable goods while maintaining their freshness and flavor. For international buyers, especially in regions with varying climate conditions, it’s essential to select pumps that comply with food safety standards and certifications. Energy efficiency is also a key consideration, as it impacts operational costs over time.

What Role Do Rotary Vane Vacuum Pumps Play in Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, rotary vane vacuum pumps are utilized for sterilization and packaging processes. These pumps create a sterile environment necessary for the safe production and packaging of medical products, ensuring that contamination is minimized. Buyers in this sector must prioritize reliability and maintenance services, as any downtime can lead to significant financial losses. Additionally, the ability to handle varying pressure levels is crucial to meet the stringent requirements of pharmaceutical applications.

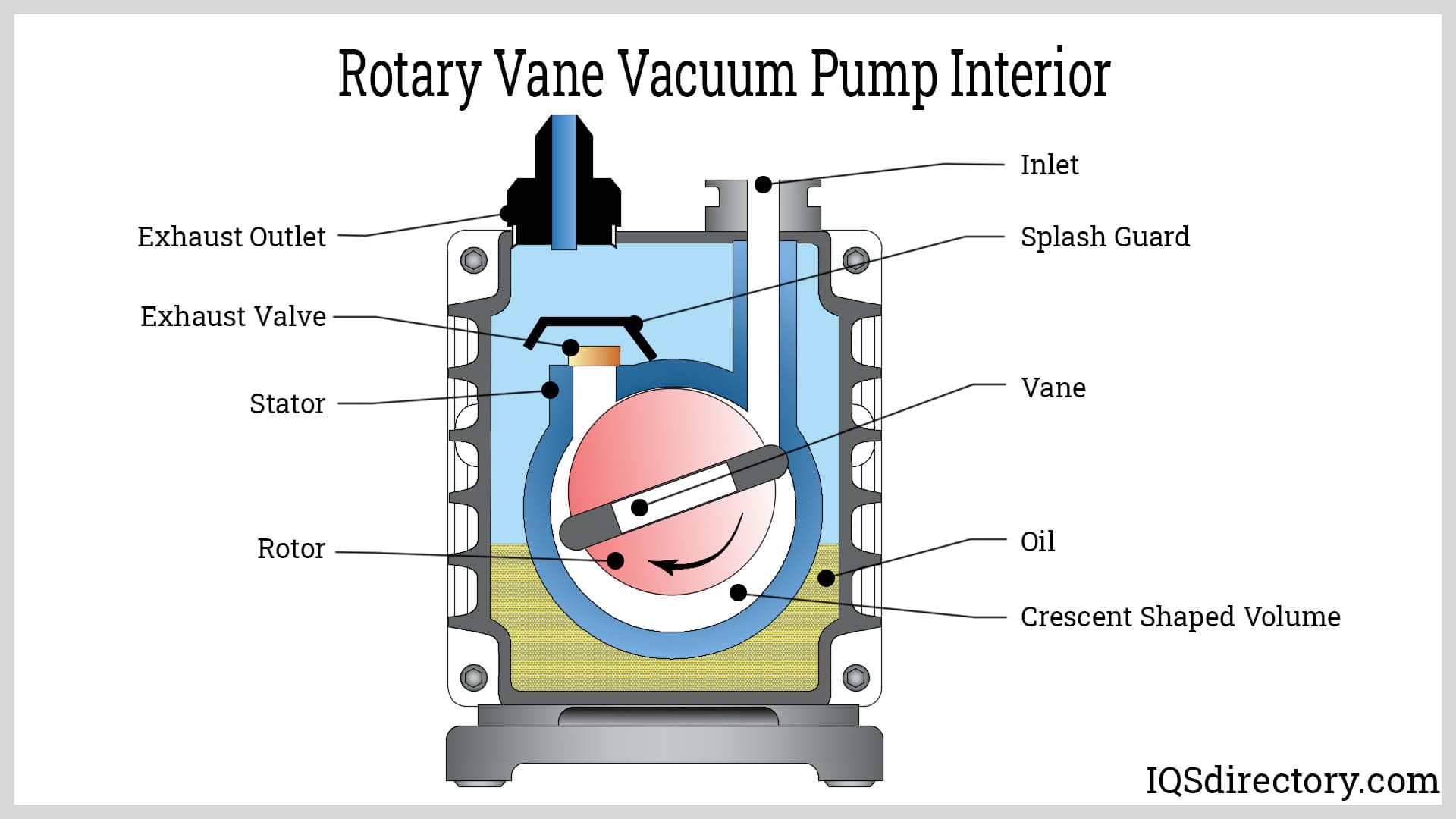

Illustrative image related to rotary vane vacuum pump

How Do Rotary Vane Vacuum Pumps Enhance Automotive Systems?

Rotary vane vacuum pumps are integral to automotive brake systems, providing vacuum assist that enhances braking performance. By creating a vacuum, these pumps ensure that the brake system operates efficiently, improving vehicle safety and responsiveness. For automotive manufacturers, sourcing durable pumps that can withstand high operational loads is essential. Compatibility with existing systems is also a consideration, as it affects the ease of installation and integration into current vehicle designs.

In What Ways Are Rotary Vane Vacuum Pumps Essential for Electronics Manufacturing?

In the electronics industry, rotary vane vacuum pumps are employed in vacuum deposition processes critical for semiconductor manufacturing. They help create a controlled environment for depositing thin films, which are essential for the performance and reliability of electronic components. Buyers must consider the precision control of vacuum levels to ensure high-quality results. Additionally, adaptability to different materials used in electronics production is important for maintaining flexibility in manufacturing processes.

How Are Rotary Vane Vacuum Pumps Used in Chemical Processing?

Rotary vane vacuum pumps are vital in chemical processing for solvent recovery and distillation applications. They efficiently remove solvents from mixtures, reducing waste and improving overall operational efficiency. For businesses in this sector, sourcing pumps that can withstand harsh chemical environments is crucial. Furthermore, ease of maintenance and servicing can significantly impact operational continuity, making it an essential consideration for international buyers looking to optimize their processes.

3 Common User Pain Points for ‘rotary vane vacuum pump’ & Their Solutions

Scenario 1: Insufficient Pump Performance in Industrial Applications

The Problem: Many B2B buyers face challenges when their rotary vane vacuum pumps do not deliver the expected performance, leading to inefficiencies in production processes. This can occur due to inadequate specifications or a mismatch between the pump’s capabilities and the specific requirements of the application. For instance, in industries like food packaging or pharmaceuticals, where vacuum levels are critical, insufficient performance can result in product spoilage or contamination, ultimately affecting the bottom line.

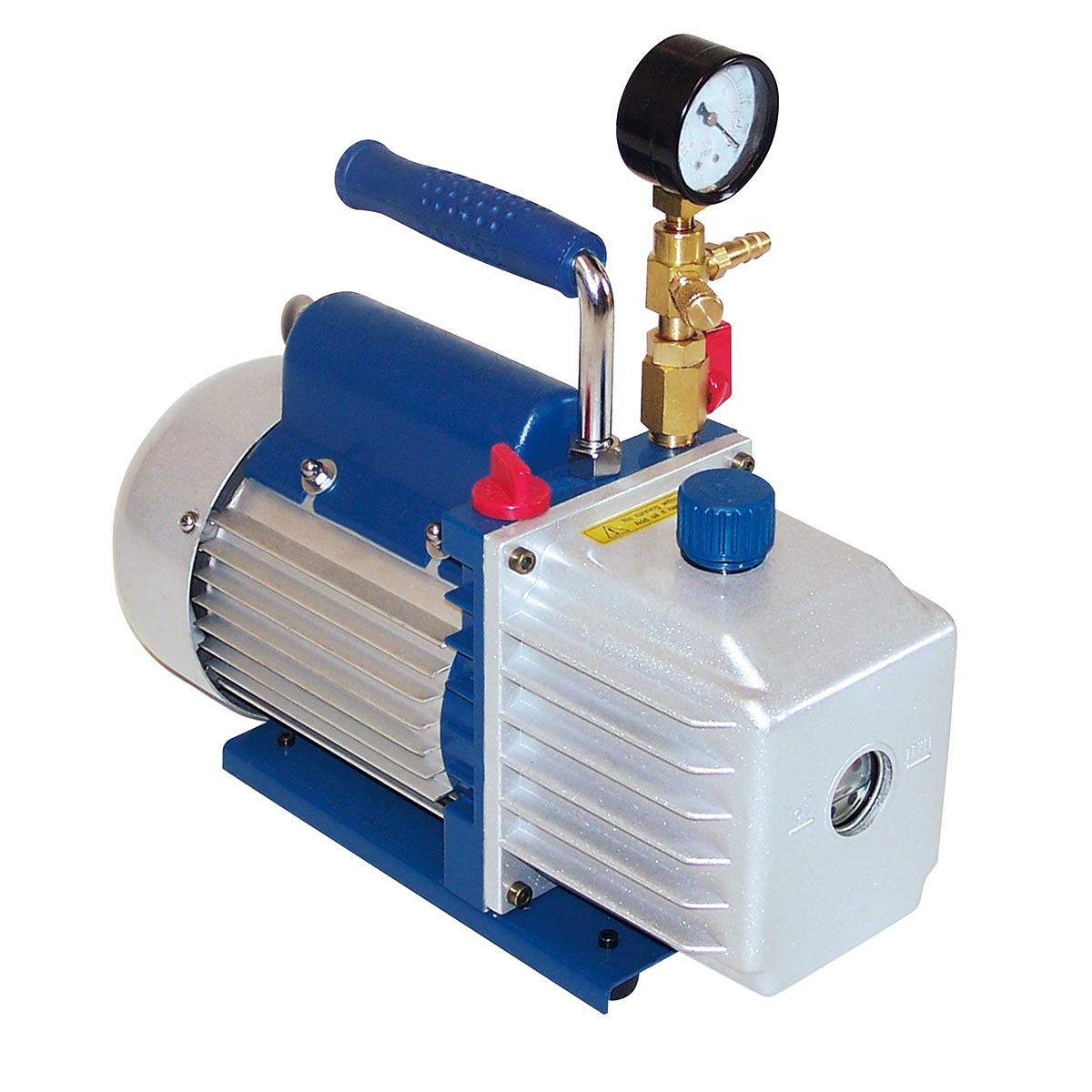

Illustrative image related to rotary vane vacuum pump

The Solution: To overcome performance issues, buyers should conduct a thorough analysis of their application needs before purchasing a rotary vane vacuum pump. This involves understanding the required vacuum levels, flow rates, and the nature of the materials being processed. Engaging with suppliers to discuss specific application requirements can help ensure that the selected pump is adequately sized and specified. Additionally, consider investing in pumps with adjustable speed drives, which allow for greater flexibility and improved performance across varying operational conditions. Regular maintenance and monitoring of pump performance can also preemptively identify potential issues before they escalate.

Scenario 2: High Operating Costs Due to Energy Inefficiency

The Problem: Many businesses, particularly in energy-sensitive markets, struggle with high operating costs associated with rotary vane vacuum pumps. These pumps often require significant energy input to maintain desired performance levels, and inefficient models can lead to unexpectedly high electricity bills. This concern is especially prevalent in regions like Africa and South America, where energy costs are a considerable part of operational expenditures.

The Solution: Buyers should prioritize energy efficiency when selecting a rotary vane vacuum pump. Investigate models that incorporate advanced technologies such as variable frequency drives (VFDs) or energy-efficient motors, which can significantly reduce energy consumption. Additionally, consider the total cost of ownership (TCO) rather than just the initial purchase price. An upfront investment in a more efficient pump can lead to substantial savings over its operational life. Regularly scheduled maintenance is crucial as well; a well-maintained pump operates more efficiently, thereby lowering energy costs. Implementing energy audits can also provide insights into how to optimize usage and further reduce expenses.

Scenario 3: Frequent Downtime Due to Maintenance Issues

The Problem: Frequent downtime caused by maintenance issues is a common pain point for companies relying on rotary vane vacuum pumps. Unexpected breakdowns can halt production, leading to lost revenue and strained client relationships. In industries such as automotive manufacturing or electronics, where timing is critical, any downtime can be particularly detrimental.

The Solution: To minimize downtime, companies should adopt a proactive maintenance strategy rather than a reactive one. This includes creating a detailed maintenance schedule that outlines routine checks and servicing intervals based on the manufacturer’s recommendations. Buyers should also invest in training for their staff to perform basic maintenance tasks and troubleshooting, which can expedite repairs and reduce reliance on external service providers. Additionally, consider investing in predictive maintenance technologies that utilize IoT sensors to monitor pump performance in real-time, allowing for data-driven decisions about when to perform maintenance. This not only extends the lifespan of the pump but also enhances operational reliability.

Strategic Material Selection Guide for rotary vane vacuum pump

What Materials Are Commonly Used in Rotary Vane Vacuum Pumps?

When selecting materials for rotary vane vacuum pumps, several factors must be considered, including performance characteristics, environmental conditions, and regulatory compliance. Below, we analyze four common materials used in the construction of rotary vane vacuum pumps.

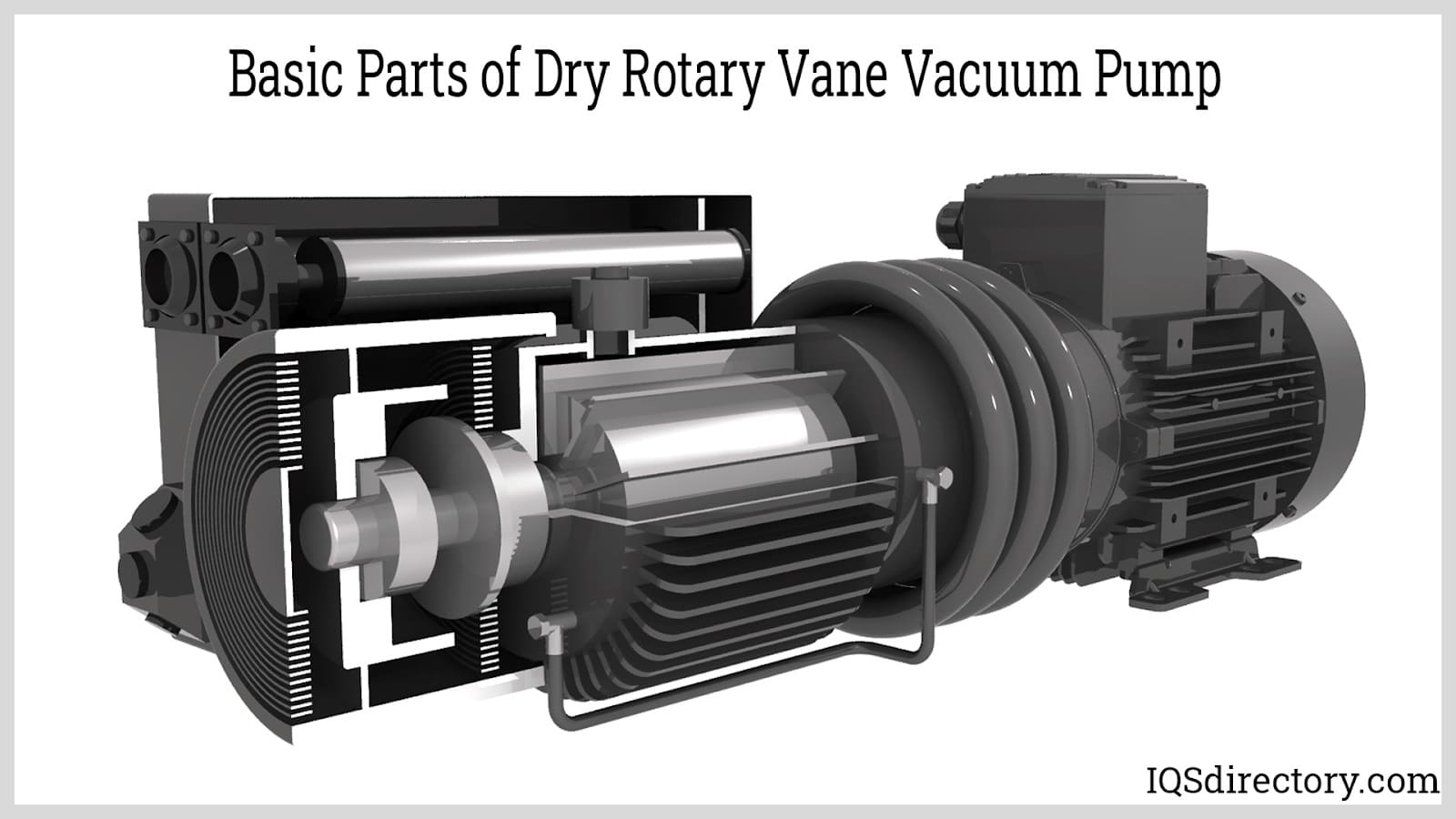

Illustrative image related to rotary vane vacuum pump

How Does Aluminum Perform in Rotary Vane Vacuum Pumps?

Aluminum is frequently used in rotary vane vacuum pumps due to its lightweight nature and good corrosion resistance. It typically has a temperature rating up to 150°C and can handle pressures up to 1 bar. The key advantages of aluminum include its ease of fabrication, which allows for complex shapes and designs, and its relatively low cost. However, it may not be suitable for high-temperature applications or aggressive chemical environments, as it can corrode under certain conditions.

For international buyers, aluminum components must comply with standards such as ASTM B221 for wrought aluminum and DIN 1725 for aluminum alloys. Buyers in regions like Europe and the Middle East often prefer aluminum due to its availability and cost-effectiveness.

What Role Does Stainless Steel Play in Rotary Vane Vacuum Pumps?

Stainless steel is another popular choice for rotary vane vacuum pumps, especially in applications requiring high strength and excellent corrosion resistance. With a temperature rating of up to 300°C and pressure ratings exceeding 3 bar, stainless steel is suitable for a wide range of applications. Its durability makes it ideal for harsh environments, but the higher cost and manufacturing complexity can be limiting factors.

Illustrative image related to rotary vane vacuum pump

International buyers should ensure compliance with standards such as ASTM A240 for stainless steel sheets and DIN EN 10088 for stainless steel grades. In regions like Africa and South America, where corrosive environments may be prevalent, stainless steel is often the preferred material.

How Does Cast Iron Compare in Rotary Vane Vacuum Pump Applications?

Cast iron is known for its excellent wear resistance and ability to dampen vibrations, making it suitable for heavy-duty applications. It can withstand high temperatures (up to 500°C) and pressures, but its weight and brittleness can be disadvantages in certain applications. Cast iron is generally more cost-effective than stainless steel but may require more complex manufacturing processes.

Buyers from Europe, particularly Germany, often favor cast iron for industrial applications due to its robustness. Compliance with standards such as DIN 1691 for cast iron is crucial for international buyers.

Why Is Composite Material Gaining Popularity in Rotary Vane Vacuum Pumps?

Composite materials, particularly carbon-fiber-reinforced polymers, are gaining traction due to their lightweight and high-strength properties. They can operate effectively at temperatures up to 200°C and pressures around 1.5 bar. The primary advantage of composites is their resistance to corrosion and low thermal conductivity, which can enhance pump efficiency. However, they can be more expensive and complex to manufacture than traditional materials.

For B2B buyers, especially in emerging markets in Africa and South America, the initial investment in composite materials may be higher, but the long-term benefits in terms of durability and maintenance can justify the cost. Compliance with international standards for composites, such as ASTM D3039, is essential.

Summary Table of Material Selection for Rotary Vane Vacuum Pumps

| Material | Typical Use Case for rotary vane vacuum pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications | Good corrosion resistance | Limited high-temperature suitability | Low |

| Stainless Steel | High-strength, corrosive environments | Excellent durability | Higher cost and complexity | High |

| Cast Iron | Heavy-duty industrial applications | Excellent wear resistance | Weight and brittleness | Medium |

| Composite | Lightweight, high-performance applications | Corrosion resistance | Higher initial cost | High |

This guide provides essential insights into material selection for rotary vane vacuum pumps, helping international B2B buyers make informed decisions based on their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rotary vane vacuum pump

What Are the Key Manufacturing Processes for Rotary Vane Vacuum Pumps?

The manufacturing of rotary vane vacuum pumps involves several critical stages, each designed to ensure that the final product meets rigorous performance standards. Below are the main stages of the manufacturing process along with key techniques utilized.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first stage of manufacturing involves selecting appropriate materials that can withstand the operational demands of vacuum pumps. Common materials include high-grade alloys for the pump casing and special composites or plastics for the vanes.

Material preparation encompasses several steps:

1. Material Selection: Choosing materials based on their mechanical properties, such as strength and resistance to wear.

2. Cutting and Shaping: Using CNC (Computer Numerical Control) machines to cut materials to specified dimensions. This precision is crucial, as even minor deviations can affect pump performance.

3. Surface Treatment: Applying coatings or treatments to enhance corrosion resistance and reduce friction, thus improving longevity.

Forming: How Are the Components Shaped?

Once the materials are prepared, they move to the forming stage. This involves shaping the components through various techniques:

– Casting: For complex shapes, the use of sand or die casting ensures that the components are uniform.

– Machining: Precision machining processes, such as turning and milling, are employed to achieve exact specifications and tolerances for parts like the rotor and housing.

– Injection Molding: For plastic components, injection molding is used to create intricate shapes that cannot be easily machined.

Illustrative image related to rotary vane vacuum pump

Assembly: What Is Involved in the Assembly Process?

The assembly stage is where various components come together to form the complete pump. Key steps include:

1. Component Inspection: Each part undergoes an inspection to ensure it meets quality standards before assembly.

2. Sub-Assembly: Components such as the rotor, vanes, and stator are assembled in stages. This may involve aligning and fastening parts using screws, bolts, or adhesives.

3. Final Assembly: The sub-assemblies are integrated into the pump casing, followed by the installation of seals and other protective components.

Finishing: What Techniques Are Used for Final Touches?

After assembly, the pump undergoes finishing processes to enhance its performance and aesthetics. This may involve:

– Surface Finishing: Techniques such as polishing or anodizing to reduce friction and improve the appearance.

– Painting and Coating: Applying protective coatings to enhance durability and resistance to environmental factors.

What Quality Assurance Standards Are Relevant for Rotary Vane Vacuum Pumps?

Quality assurance is paramount in the manufacturing of rotary vane vacuum pumps, especially for international B2B buyers. Compliance with relevant standards ensures product reliability and safety.

What International Standards Should Buyers Be Aware Of?

- ISO 9001: This standard outlines the requirements for a quality management system. Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European market, CE marking signifies compliance with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas sector, adherence to API standards ensures that pumps are suitable for high-pressure environments.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to catch defects early.

What Are the Common QC Checkpoints?

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, inspections are conducted at various stages to verify that processes are being followed correctly.

- Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing to ensure it meets performance standards.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Testing methods are essential for validating the performance and reliability of rotary vane vacuum pumps. Common methods include:

– Pressure Testing: Ensures that the pump can withstand operational pressures without leaking.

– Vacuum Testing: Verifies the pump’s ability to create and maintain a vacuum.

– Performance Testing: Involves running the pump under simulated conditions to evaluate efficiency and functionality.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to quality standards, buyers can take several steps:

- Supplier Audits: Conducting regular audits of suppliers can help assess their manufacturing processes and QC practices.

- Quality Assurance Reports: Requesting detailed QA reports can provide insights into a supplier’s adherence to international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can add an additional layer of verification, ensuring that products meet specified requirements before shipment.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

– Regulatory Compliance: Different regions may have varying requirements for compliance. Understanding these can help avoid delays or penalties.

– Language Barriers: Documentation may be in different languages; thus, ensuring clarity in specifications and requirements is crucial.

– Cultural Differences: Negotiations and business practices may vary, necessitating a tailored approach to each region.

Conclusion

Understanding the manufacturing processes and quality assurance practices for rotary vane vacuum pumps is essential for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming, assembly, and finishing stages, alongside rigorous quality control measures, buyers can ensure they procure products that meet their operational needs and international standards. Being proactive in verifying supplier quality through audits and certifications will further bolster confidence in their purchasing decisions.

Illustrative image related to rotary vane vacuum pump

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rotary vane vacuum pump’

This guide provides a comprehensive checklist for B2B buyers looking to procure rotary vane vacuum pumps. Sourcing the right pump is crucial for ensuring operational efficiency and reliability in various industrial applications. This checklist will help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements of the rotary vane vacuum pump that will suit your operational needs. Consider factors such as the desired vacuum level, flow rate (CFM), and whether you need a vacuum-only or vacuum/pressure pump.

– Key Considerations:

– Identify the application (e.g., food processing, pharmaceuticals, or industrial manufacturing).

– Determine the necessary pump size and power ratings to ensure compatibility with your existing systems.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of rotary vane vacuum pumps. Utilize online resources, industry directories, and trade shows to compile a list of potential vendors.

– What to Look For:

– Suppliers with a strong market presence and positive customer reviews.

– Specialization in rotary vane vacuum pumps, ensuring they understand your specific requirements.

Step 3: Evaluate Supplier Certifications

It is essential to verify that your selected suppliers hold relevant industry certifications and adhere to quality standards. This step ensures that you are sourcing from manufacturers committed to quality and safety.

– Important Certifications:

– ISO 9001 for quality management systems.

– CE marking for compliance with European health, safety, and environmental protection standards.

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, warranties, and delivery times. Comparing quotes will help you identify the best value for your investment.

– Additional Considerations:

– Look for transparency in pricing, including potential hidden costs such as shipping and installation.

– Evaluate the warranty terms and after-sales support offered by each supplier.

Step 5: Assess After-Sales Support and Service

Strong after-sales support is crucial for maintaining the performance of your rotary vane vacuum pump. Ensure that the supplier provides comprehensive service options, including installation, maintenance, and repair services.

– Key Questions to Ask:

– What is the average response time for service requests?

– Are spare parts readily available, and what is the expected lead time for replacements?

Step 6: Check References and Case Studies

Before finalizing your decision, ask potential suppliers for references and case studies from clients in similar industries or applications. This step provides insights into the supplier’s reliability and customer satisfaction.

– What to Evaluate:

– The types of projects completed and the performance of the rotary vane pumps.

– Feedback regarding the supplier’s responsiveness and problem-solving capabilities.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier, ensure that all terms of the purchase agreement are clearly defined. This includes payment terms, delivery schedules, and warranty conditions.

– Important Points:

– Ensure the agreement includes a clause for handling any potential issues post-purchase.

– Review the terms to protect your business interests in case of delays or defects.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for rotary vane vacuum pumps, ensuring they make informed decisions that align with their operational requirements.

Illustrative image related to rotary vane vacuum pump

Comprehensive Cost and Pricing Analysis for rotary vane vacuum pump Sourcing

What Are the Key Cost Components in Rotary Vane Vacuum Pump Manufacturing?

When sourcing rotary vane vacuum pumps, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly influence the overall cost. High-grade metals and specialized components can increase the price but offer enhanced durability and efficiency.

-

Labor: Labor costs vary by region and can be influenced by the complexity of the manufacturing process. Skilled labor is often necessary for assembly and quality assurance.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and factory management. Efficient operations can help reduce these overhead costs, benefiting the final price.

-

Tooling: Investment in tooling and machinery is essential for producing rotary vane pumps. Custom tooling for specialized products can add to initial costs but may be amortized over higher production volumes.

-

Quality Control (QC): Implementing rigorous QC processes ensures reliability and performance, which may add to costs but is crucial for maintaining standards, especially for buyers in regulated industries.

-

Logistics: Shipping, handling, and warehousing contribute to the overall cost. International buyers should consider the implications of shipping distances and customs clearance.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition and market demand.

How Do Pricing Influencers Affect Rotary Vane Vacuum Pump Costs?

Several factors influence the pricing of rotary vane vacuum pumps, which can vary significantly across regions such as Africa, South America, the Middle East, and Europe:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to discounted rates. Buyers should assess their needs and negotiate for better pricing on larger orders.

-

Specifications and Customization: Customized pumps that meet specific operational requirements can command higher prices. Buyers must weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Pumps made from premium materials and those that meet specific certifications (e.g., ISO, CE) may have higher upfront costs but provide better reliability and efficiency over time.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a history of quality may charge more but often provide superior service and support.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they dictate responsibilities for shipping, insurance, and tariffs, impacting the total landed cost.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Rotary Vane Vacuum Pumps?

To achieve cost-efficiency in sourcing rotary vane vacuum pumps, buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for larger orders. Suppliers may be willing to offer discounts based on commitment or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with operation, maintenance, and potential downtime. A lower initial price may lead to higher operational costs.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should consider currency fluctuations and local economic conditions when negotiating prices. Additionally, understanding local market practices can help in making informed decisions.

-

Research and Compare: Conduct thorough research and compare prices across multiple suppliers. Utilizing online platforms and industry connections can provide insights into fair market pricing.

-

Consider After-Sales Support: Evaluate the level of after-sales support and warranty offered by suppliers, as this can significantly affect long-term satisfaction and costs associated with maintenance and repairs.

Disclaimer for Indicative Prices

Prices for rotary vane vacuum pumps vary widely based on specifications and suppliers. The figures provided in reference materials serve as indicative and may fluctuate based on market conditions, material costs, and supplier negotiations. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing rotary vane vacuum pump With Other Solutions

Exploring Alternative Solutions to Rotary Vane Vacuum Pumps

In the world of industrial vacuum technology, rotary vane vacuum pumps are widely recognized for their effectiveness and reliability. However, there are several alternative solutions that may better fit specific applications or operational needs. Understanding these alternatives allows B2B buyers to make informed decisions that align with their unique requirements and budget constraints.

| Comparison Aspect | Rotary Vane Vacuum Pump | Diaphragm Vacuum Pump | Scroll Vacuum Pump |

|---|---|---|---|

| Performance | Moderate to high CFM; suitable for a range of applications. | Lower CFM; ideal for small-scale operations or specific tasks. | High reliability with consistent performance across varying conditions. |

| Cost | Moderate initial investment ($1,372.63 – $3,286.76). | Lower initial cost, generally more budget-friendly. | Higher upfront costs, but lower operating costs over time. |

| Ease of Implementation | Relatively straightforward installation; requires oil for operation. | Simple installation; typically oil-free, which reduces complexity. | Requires careful installation; usually maintenance-free. |

| Maintenance | Regular maintenance required; oil changes needed to maintain efficiency. | Minimal maintenance; designed for long-term use without extensive upkeep. | Very low maintenance; no lubrication required, enhancing reliability. |

| Best Use Case | Versatile; suitable for industrial applications, food processing, and packaging. | Best for applications requiring clean, oil-free vacuum, such as pharmaceuticals. | Ideal for applications needing constant vacuum levels, such as semiconductor manufacturing. |

What Are the Advantages and Disadvantages of Diaphragm Vacuum Pumps?

Diaphragm vacuum pumps offer a significant advantage in applications where oil contamination must be avoided, making them a prime choice for pharmaceutical and food processing industries. Their lower initial costs make them attractive for small-scale operations or startups. However, they typically provide lower airflow (CFM), which may limit their effectiveness in larger industrial applications. Additionally, diaphragm pumps can experience wear over time, requiring periodic replacement of diaphragm components.

How Do Scroll Vacuum Pumps Compare?

Scroll vacuum pumps are known for their quiet operation and high reliability, making them ideal for environments where noise reduction is a priority. They are maintenance-free due to their oil-free design, leading to lower operational costs over time. However, the initial investment is higher than that of rotary vane pumps, which can be a consideration for budget-conscious buyers. Scroll pumps excel in applications that require consistent vacuum levels and are particularly well-suited for semiconductor manufacturing, where precision is critical.

Choosing the Right Vacuum Pump for Your Business Needs

When deciding between rotary vane vacuum pumps and their alternatives, businesses must assess their specific operational needs, budget constraints, and application requirements. Buyers should consider factors such as the required airflow, the importance of oil-free operation, maintenance expectations, and overall cost of ownership. Engaging with suppliers to evaluate these aspects can help businesses select the most suitable vacuum solution that enhances operational efficiency and meets industry standards. By thoroughly understanding the strengths and weaknesses of each option, B2B buyers can make strategic decisions that drive productivity and profitability.

Essential Technical Properties and Trade Terminology for rotary vane vacuum pump

What Are the Key Technical Properties of Rotary Vane Vacuum Pumps?

When assessing rotary vane vacuum pumps, it is essential to understand several critical specifications that influence performance, reliability, and suitability for various applications. Here are some of the most important properties:

-

Flow Rate (CFM)

– The flow rate, measured in cubic feet per minute (CFM), indicates the volume of air the pump can move. A higher CFM is crucial for applications requiring rapid evacuation, such as in food packaging or industrial processes. Buyers should consider their operational needs to choose a pump with an appropriate flow rate, ensuring efficiency and effectiveness in their processes. -

Ultimate Pressure (Torr or mbar)

– This specification defines the lowest pressure the pump can achieve. For rotary vane pumps, the ultimate pressure typically ranges from 10^-3 Torr to 10^-2 Torr. Understanding the ultimate pressure is vital for industries like pharmaceuticals or electronics, where precise vacuum levels are necessary for product integrity and quality. -

Motor Power (HP or kW)

– The motor power, measured in horsepower (HP) or kilowatts (kW), influences the pump’s operational efficiency and capability. A more powerful motor can handle higher workloads and extended operational periods without overheating. Selecting the right motor power ensures that the pump can meet the demands of the intended application without compromising performance. -

Material Construction

– The materials used in manufacturing the pump components, such as aluminum, stainless steel, or special alloys, affect durability and compatibility with various gases or vapors. For instance, stainless steel is preferred for corrosive environments. Buyers should assess the environmental conditions in which the pump will operate to select the right material, thereby enhancing the pump’s lifespan and performance. -

Noise Level (dBA)

– The noise level produced by the pump, measured in decibels (dBA), is a critical consideration for environments where sound pollution is a concern. Lower noise levels contribute to a better working environment and compliance with local regulations. Understanding this specification helps buyers choose pumps suitable for both operational efficiency and workplace comfort.

What Are Common Trade Terms Related to Rotary Vane Vacuum Pumps?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to rotary vane vacuum pumps:

Illustrative image related to rotary vane vacuum pump

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces components or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure that they are sourcing high-quality parts and systems, which can enhance the reliability of their vacuum solutions. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ helps in planning purchases and ensuring that supply meets demand without incurring excess costs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for specific products or services. It outlines the requirements and specifications needed. Utilizing RFQs can streamline the procurement process, allowing buyers to compare offers and make informed decisions based on price and service levels. -

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify who pays for shipping, insurance, and tariffs, thus minimizing misunderstandings and disputes. Understanding these terms is crucial for buyers engaged in international trade, ensuring clarity in logistics and cost management. -

Lead Time

– Lead time is the duration from placing an order to the delivery of goods. It is a critical factor for B2B operations, impacting project timelines and inventory levels. Knowing the lead time helps buyers manage expectations and plan accordingly, ensuring that production schedules remain on track.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding rotary vane vacuum pumps, ultimately enhancing their operational efficiency and supply chain effectiveness.

Navigating Market Dynamics and Sourcing Trends in the rotary vane vacuum pump Sector

What Are the Current Market Dynamics and Key Trends Affecting Rotary Vane Vacuum Pumps?

The rotary vane vacuum pump sector is witnessing significant growth, driven by increasing demand across various industries such as food processing, pharmaceuticals, and packaging. As industrial operations become more sophisticated, the need for reliable vacuum solutions has surged, particularly in emerging markets in Africa and South America. These regions are experiencing a boom in manufacturing, prompting international B2B buyers to seek advanced vacuum technology that enhances production efficiency.

Current sourcing trends indicate a shift towards integrated solutions that combine vacuum pumps with automation technologies. This trend is particularly relevant in Europe, where Industry 4.0 principles are being adopted to streamline manufacturing processes. Additionally, the rise of digitalization in the supply chain is enabling buyers to leverage data analytics for better decision-making, ultimately driving competitive pricing and reducing lead times.

Moreover, the sustainability narrative is gaining traction, with companies increasingly prioritizing energy-efficient models that reduce operational costs. B2B buyers are encouraged to explore suppliers who offer products designed for lower energy consumption and longer service life, as these features are becoming pivotal in procurement decisions.

How Is Sustainability Influencing Sourcing Decisions in the Rotary Vane Vacuum Pump Industry?

Sustainability is becoming a core consideration for international B2B buyers in the rotary vane vacuum pump sector. With growing awareness of environmental issues, companies are now scrutinizing their supply chains for ethical sourcing practices. This includes evaluating the environmental impact of materials used in vacuum pump manufacturing and ensuring compliance with global sustainability standards.

Illustrative image related to rotary vane vacuum pump

Buyers are increasingly seeking suppliers who possess certifications such as ISO 14001, which signifies an effective environmental management system. Additionally, the use of recyclable materials in pump construction is gaining popularity. Suppliers that can demonstrate a commitment to sustainability not only enhance their marketability but also align with the values of conscientious buyers.

Furthermore, adopting energy-efficient rotary vane pumps can significantly reduce a company’s carbon footprint. This aspect is particularly appealing to businesses in Europe and the Middle East, where regulatory pressures for sustainability are strong. As a result, buyers are encouraged to prioritize suppliers who emphasize eco-friendly practices and provide transparency in their sourcing processes.

What Is the Historical Context of Rotary Vane Vacuum Pumps in B2B Applications?

The rotary vane vacuum pump has evolved significantly since its inception in the early 20th century. Originally designed for industrial applications, these pumps have become integral to various sectors due to their reliability and efficiency. Over the decades, advancements in engineering and materials have enhanced their performance, leading to the development of models that cater to specific industrial needs, such as higher flow rates and reduced maintenance requirements.

The historical context is crucial for B2B buyers as it highlights the proven track record of rotary vane pumps in demanding applications. Understanding the evolution of these pumps provides insights into their technological advancements, enabling buyers to make informed decisions based on performance and reliability. As the market continues to evolve, staying abreast of historical trends can inform future sourcing strategies and investment decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of rotary vane vacuum pump

1. How do I solve issues with rotary vane vacuum pump performance?

To address performance issues with rotary vane vacuum pumps, first, check for common problems such as oil levels, leaks, or blockages in the inlet and outlet. Ensure that the pump is adequately lubricated, as insufficient oil can lead to overheating and reduced efficiency. Regular maintenance, including cleaning and oil changes, is essential. If problems persist, consult the manufacturer’s troubleshooting guide or seek assistance from a qualified technician to identify more complex issues.

Illustrative image related to rotary vane vacuum pump

2. What is the best rotary vane vacuum pump for my specific application?

The best rotary vane vacuum pump for your application depends on several factors, including the required vacuum level, pumping speed (CFM), and the nature of the gases being handled. For instance, if you need a pump for the food packaging industry, look for one with high reliability and low oil contamination. For industrial applications, consider pumps with higher CFM ratings for greater throughput. Consult with suppliers to determine which model fits your operational needs and budget.

3. What are the key features to look for when sourcing rotary vane vacuum pumps?

When sourcing rotary vane vacuum pumps, consider features such as durability, maintenance requirements, noise levels, and energy efficiency. Look for models with robust construction materials that can withstand your operating conditions. Ease of maintenance is crucial; pumps with accessible components reduce downtime. Additionally, energy-efficient pumps can lower operational costs, making them a wise investment. Always check the manufacturer’s specifications and certifications to ensure compliance with industry standards.

4. How do I vet suppliers of rotary vane vacuum pumps for international trade?

To effectively vet suppliers for rotary vane vacuum pumps, start by researching their reputation through customer reviews and industry ratings. Verify their experience in the market and check for certifications relevant to your region. Request references from previous clients and inquire about their warranty and after-sales support. It’s advisable to conduct a factory audit, if possible, to assess their manufacturing capabilities and quality control processes. Engaging with a local agent familiar with the region can also facilitate the vetting process.

5. What is the typical minimum order quantity (MOQ) for rotary vane vacuum pumps?

Minimum order quantities (MOQs) for rotary vane vacuum pumps can vary significantly depending on the supplier and the type of pump. Generally, MOQs can range from 1 to several units, especially for customized solutions. Larger manufacturers may offer lower MOQs for standard models while imposing higher MOQs for specialized products. Discuss your needs with potential suppliers to find flexibility in their MOQs, especially if you are a smaller business or a new buyer.

6. What are the standard payment terms for purchasing rotary vane vacuum pumps internationally?

Standard payment terms for international purchases of rotary vane vacuum pumps typically range from 30% to 50% upfront, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment through escrow services for larger transactions. It’s crucial to clarify payment terms before finalizing the order, including acceptable payment methods (wire transfer, PayPal, etc.) and any potential currency exchange implications. Always ensure that terms are documented in the purchase agreement to avoid disputes.

7. How is quality assurance handled for rotary vane vacuum pumps?

Quality assurance for rotary vane vacuum pumps involves several stages, including design validation, material selection, production monitoring, and final testing. Reputable manufacturers adhere to international quality standards such as ISO 9001. Request detailed information about the supplier’s quality control processes, including certification documents and testing protocols. Many suppliers provide test reports for each unit, ensuring that the pump meets specified performance criteria. Establishing a clear quality agreement before purchase can help safeguard your investment.

8. What logistics considerations should I be aware of when importing rotary vane vacuum pumps?

When importing rotary vane vacuum pumps, logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose between air freight for expedited delivery or sea freight for cost-effectiveness, weighing the urgency of your need against budget constraints. Familiarize yourself with the customs clearance process in your country, as this can significantly impact delivery timelines. Ensure that all necessary documentation, such as commercial invoices and packing lists, is complete to avoid delays or additional charges during transit.

Top 5 Rotary Vane Vacuum Pump Manufacturers & Suppliers List

1. Masport – Rotary Vane Pumps

Domain: masportpump.com

Registered: 1998 (27 years)

Introduction: Masport’s Rotary Vane Pumps are designed for versatility and durability across various applications and tank sizes. Key features include:

– **Product Series**: H1 Series, H2 Series, H3 Series, H4 Series, H75 Series, H400W, VIPER, TITAN, HYDRA, SIDEWINDER, MAMBA, COBRA.

– **Discontinued Models**: HXL15, HXL20WV, H1F, HXL2V, HXL2F, HXL3V, HXL3F, HXL4V, HXL4F.

– **Port Sizes**: Available in sizes ra…

2. Busch – Rotary Vane Vacuum Pumps

Domain: buschvacuum.com

Registered: 2011 (14 years)

Introduction: Busch Rotary Vane Vacuum Pumps and Compressors are available in single- and two-stage versions, with options for oil-lubricated or dry-running operation. Key models include: R5 single-stage oil-lubricated (proven and reliable with over 3 million units in operation), HUCKEPACK two-stage oil-lubricated (robust solution for difficult applications), and SECO single-stage dry-running (reliable medium v…

3. Becker – Oil-less Rotary Vane Vacuum Pumps

Domain: beckerpumps.com

Registered: 1996 (29 years)

Introduction: Becker’s oil-less rotary vane vacuum pumps are designed for medium or variable vacuum range applications. Key features include: straightforward construction with single shaft direct drive, robust and long-life design, low operation and maintenance costs, positive-displacement mechanism with sliding vanes, self-compensating for wear, lower maintenance requirements, and sustained peak performance. S…

4. Atlas Copco – Dry Rotary Vane Vacuum Pumps

Domain: atlascopco.com

Registered: 1995 (30 years)

Introduction: This company, Atlas Copco – Dry Rotary Vane Vacuum Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. KJLC – Rotary Vane Vacuum Pumps

Domain: lesker.com

Registered: 1995 (30 years)

Introduction: KJLC Rotary Vane Vacuum Pumps: KJLC-RV series with four models for various applications, high performance, and competitive pricing. Adixen Rotary Vane Vacuum Pumps: Five versions for demanding applications. Agilent Technologies DS & HS series: High pumping stability for light gases, low noise, long operating life, two-stage design for low temperature and efficiency. Edwards RV pumps: Excellent ult…

Strategic Sourcing Conclusion and Outlook for rotary vane vacuum pump

In the evolving landscape of industrial applications, rotary vane vacuum pumps stand out for their efficiency and reliability. These pumps are essential for a myriad of sectors including food processing, pharmaceuticals, and manufacturing, making them a critical component in many production processes. For B2B buyers, understanding the nuances of rotary vane technology, from performance metrics such as CFM ratings to maintenance requirements, is vital for making informed purchasing decisions.

Strategic sourcing plays a pivotal role in enhancing the supply chain, ensuring that buyers can secure the best quality products while optimizing costs. By establishing strong relationships with reputable suppliers, businesses can not only enhance their operational capabilities but also gain access to valuable insights and support services that can lead to improved system performance and longevity.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize collaboration with trusted manufacturers and distributors. This proactive approach will not only foster innovation but also ensure that organizations are equipped to meet the challenges of tomorrow. Embrace the opportunity to enhance your procurement strategy today, and position your business for success in a competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.