Rf Protection: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for rf protection

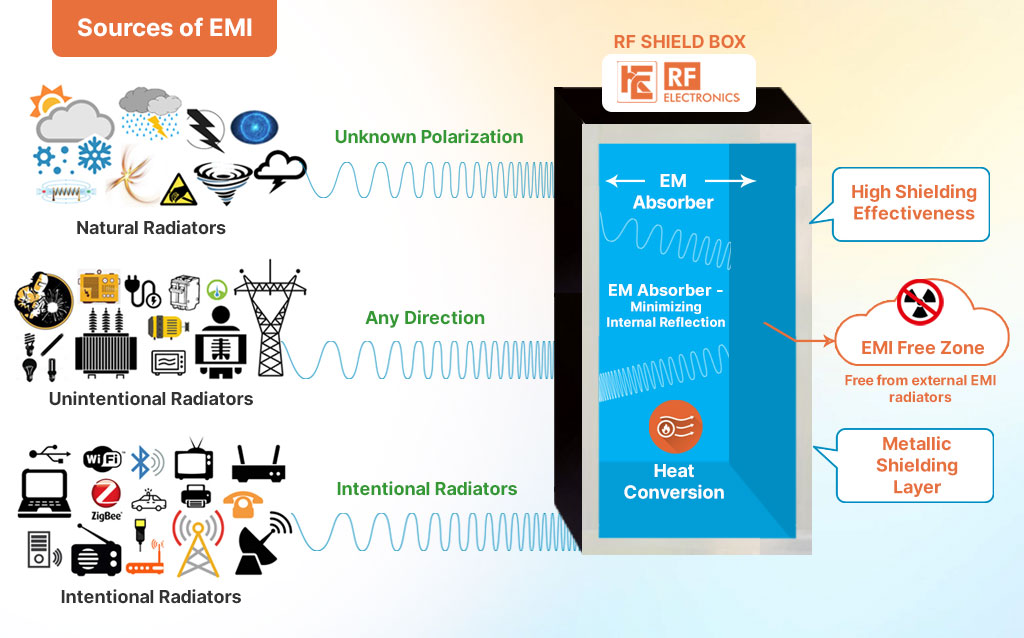

Navigating the complexities of sourcing effective RF protection solutions can be a daunting challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The increasing prevalence of electromagnetic interference and the need for secure environments necessitate a robust understanding of RF shielding products. This guide comprehensively explores various types of RF protection, including paints, fabrics, and specialized enclosures, while delving into their applications across multiple industries—from telecommunications to military facilities.

In this resource, buyers will find essential insights on supplier vetting processes, ensuring quality and reliability in their sourcing decisions. The guide also addresses cost considerations, providing a range of pricing options to suit different budgetary constraints without compromising on quality. By empowering stakeholders with actionable knowledge, this guide enables informed purchasing decisions, facilitating the selection of RF protection solutions tailored to specific operational needs.

Whether you are a procurement officer in Saudi Arabia or a facility manager in Germany, understanding the nuances of RF protection is crucial for safeguarding sensitive information and enhancing operational efficiency. Equip your organization with the knowledge to navigate the global market effectively and make sound investments in RF shielding technologies that align with your strategic goals.

Understanding rf protection Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| RF Shielding Paints | Versatile application, easy to apply, various formulations | Telecommunications, healthcare, military | Pros: Cost-effective, customizable. Cons: May require multiple coats for optimal effectiveness. |

| RF Fabrics and Wallpaper | Lightweight, flexible, aesthetically pleasing | Office spaces, residential areas, data centers | Pros: Easy installation, decorative options. Cons: Limited shielding effectiveness compared to rigid materials. |

| Faraday Enclosures | Rigid, highly effective barrier against RF interference | Secure data storage, military applications | Pros: High attenuation, robust protection. Cons: Higher cost, requires precise installation. |

| RF Safety Monitors | Real-time monitoring of RF levels, alerts for exposure | Industrial settings, laboratories, healthcare | Pros: Enhances safety, compliance with regulations. Cons: Ongoing maintenance and calibration required. |

| Wideband Adaptive RF Protection | Advanced filtering and signal cancellation for diverse signals | Military, telecommunications, research facilities | Pros: Adaptable to changing environments, protects sensitive equipment. Cons: Complex technology, potentially higher investment. |

What Are RF Shielding Paints and Their B2B Relevance?

RF shielding paints offer a versatile solution for businesses needing to mitigate electromagnetic interference (EMI). These paints can be applied to walls, ceilings, and other surfaces, providing a customizable level of protection based on the specific RF environment. Commonly used in telecommunications and healthcare facilities, RF paints are cost-effective and relatively easy to apply, although multiple coats may be necessary for optimal performance. B2B buyers should consider the specific frequency ranges they need to shield against and the paint’s application requirements before purchasing.

How Do RF Fabrics and Wallpaper Function in RF Protection?

RF fabrics and wallpaper are lightweight options that combine functionality with aesthetics, making them suitable for office and residential applications. These materials are designed to reduce RF interference while maintaining a visually appealing environment. They are particularly effective in areas where traditional shielding solutions may be impractical. While they are easy to install and come in various designs, their shielding effectiveness is generally lower than that of rigid materials. Buyers should evaluate their shielding needs alongside the desired interior design when considering these products.

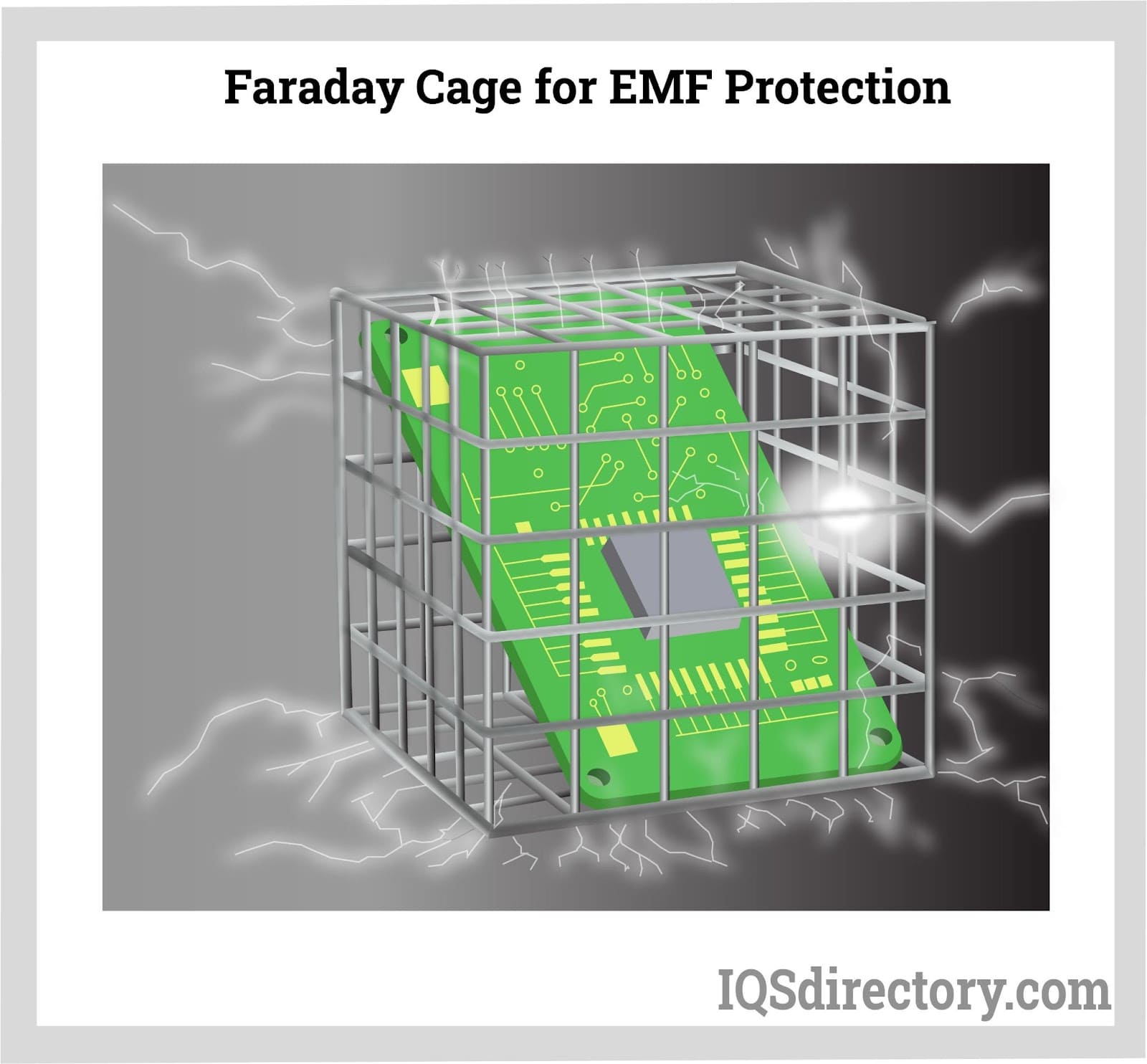

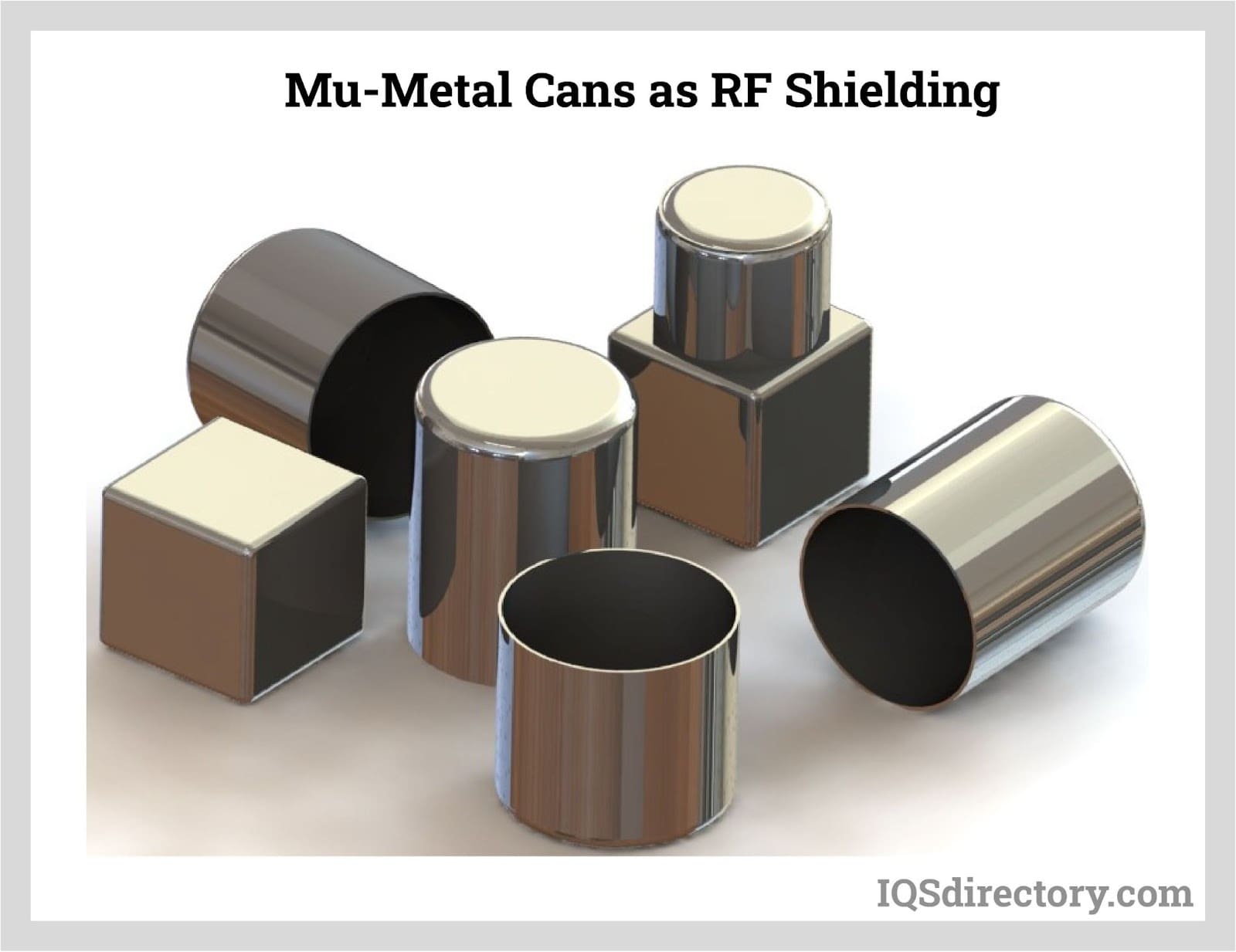

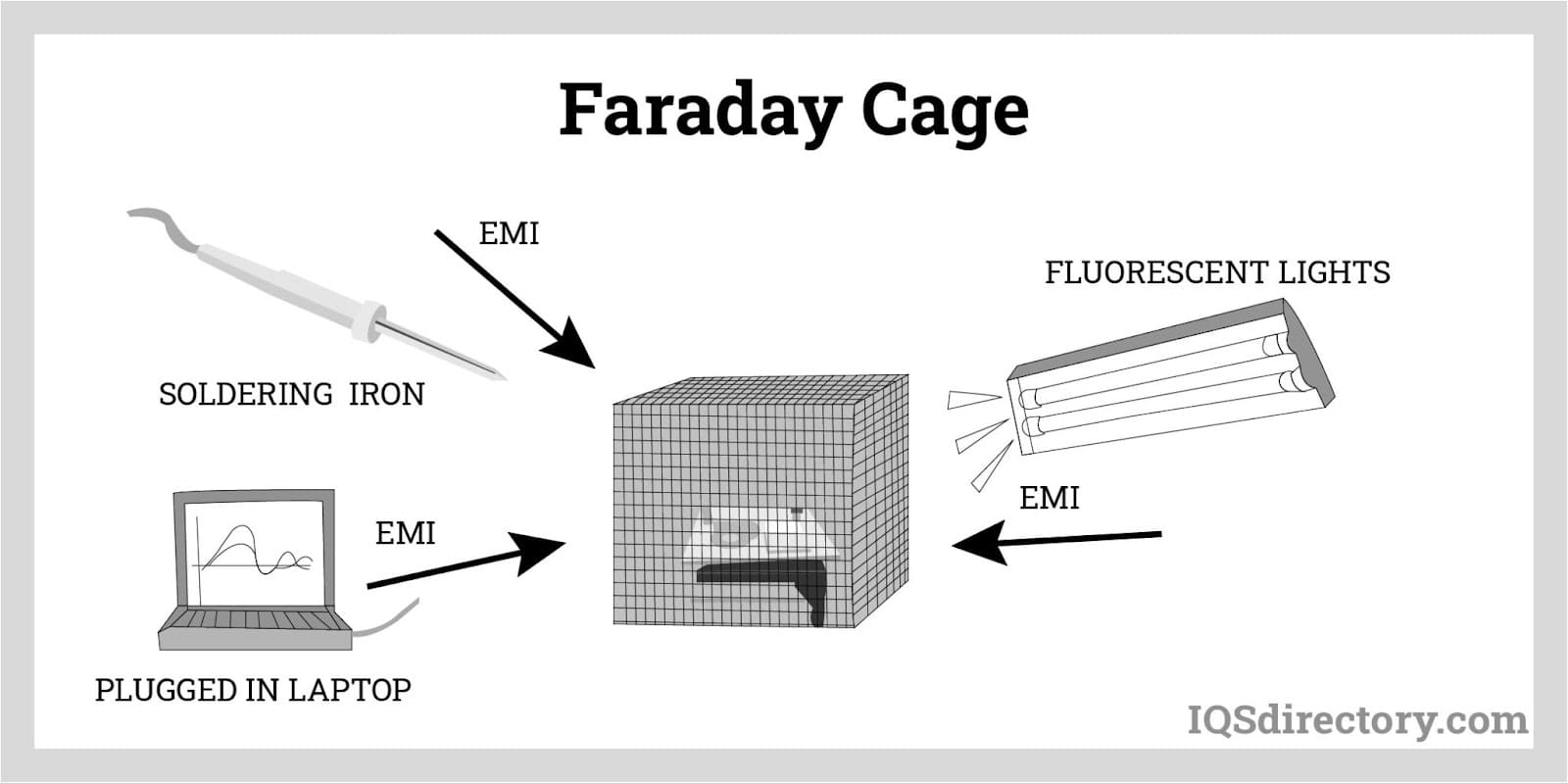

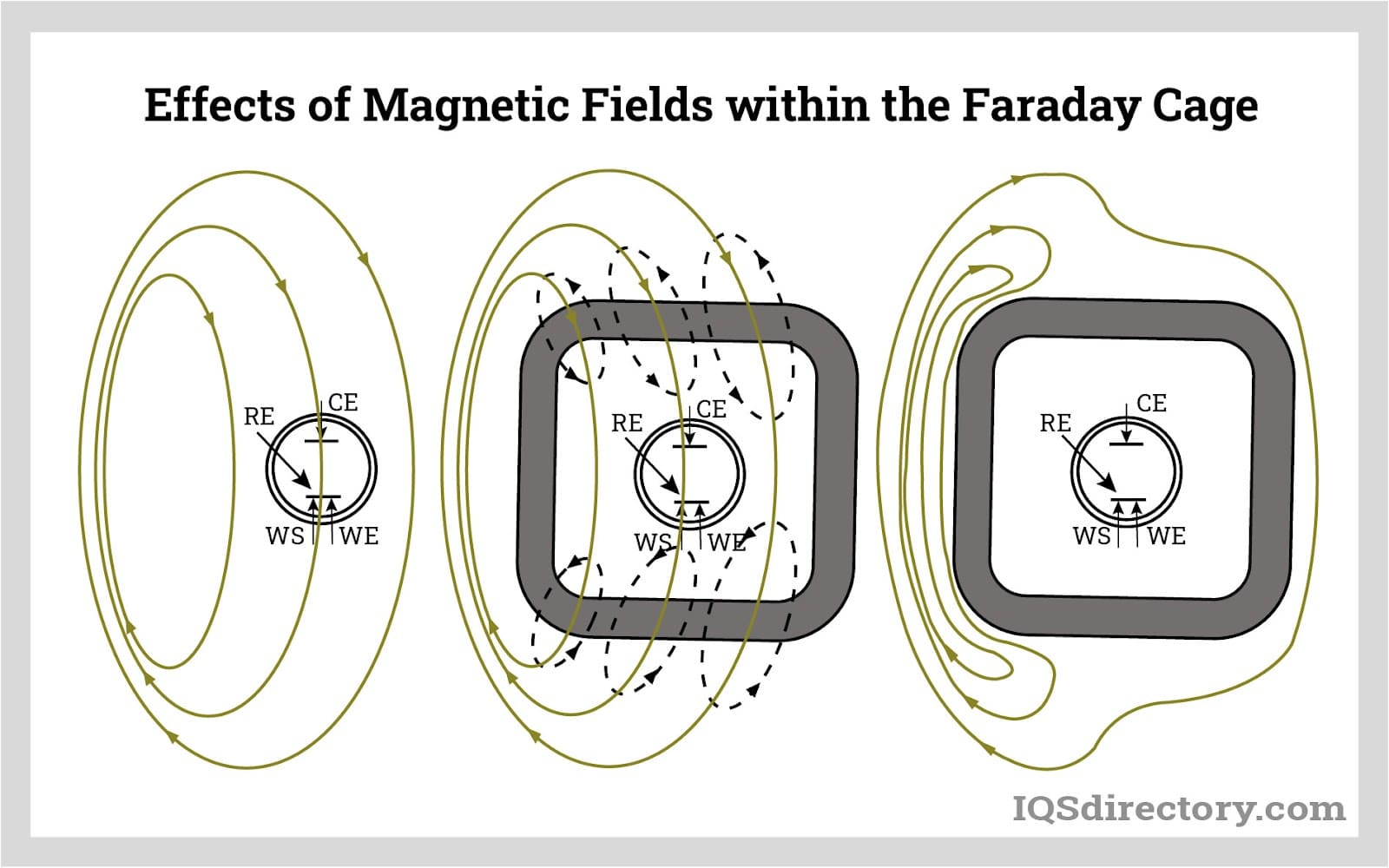

What Advantages Do Faraday Enclosures Offer for B2B Buyers?

Faraday enclosures provide a robust solution for protecting sensitive equipment from RF interference. These rigid structures create a highly effective barrier, ensuring that electromagnetic signals do not penetrate. Commonly utilized in secure data storage and military applications, Faraday enclosures offer high attenuation levels, making them ideal for environments where data security is paramount. However, they often come with a higher price point and require precise installation. Buyers must weigh the cost against the level of protection needed for their specific applications.

Why Are RF Safety Monitors Essential in Various Industries?

RF safety monitors are critical for ensuring compliance with health and safety regulations in environments exposed to RF radiation. These devices provide real-time monitoring of RF levels and can alert personnel to potentially hazardous exposure. Industries such as telecommunications, laboratories, and healthcare benefit from the enhanced safety provided by these monitors. However, they require ongoing maintenance and calibration to ensure accuracy. B2B buyers should assess their regulatory requirements and workplace safety needs when considering the purchase of RF safety monitors.

How Does Wideband Adaptive RF Protection Enhance Signal Integrity?

Wideband adaptive RF protection utilizes advanced filtering and signal cancellation techniques to safeguard sensitive equipment from both external and self-interference. This technology is particularly relevant in military and telecommunications applications, where signal integrity is crucial. By adapting to the spectral environment in real-time, these systems provide a flexible and effective solution for managing RF interference. However, the complexity and potential cost of these systems can be a consideration for buyers. Organizations should evaluate their specific operational needs and budget constraints when exploring wideband adaptive RF protection solutions.

Key Industrial Applications of rf protection

| Industry/Sector | Specific Application of rf protection | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | RF Shielding for Cell Towers | Reduces interference, enhances signal clarity | Compliance with local regulations, material durability |

| Defense & Security | SCIF Construction with RF Shielding Barriers | Protects sensitive information from espionage | Certification standards, installation expertise |

| Healthcare | RF Shielding in Medical Facilities | Ensures reliable operation of medical devices | Biocompatibility, ease of installation, regulatory compliance |

| Manufacturing | RF Protection for Industrial Equipment | Minimizes electromagnetic interference, improves uptime | Compatibility with existing systems, maintenance support |

| Aerospace & Aviation | RF Shielding for Aircraft Systems | Enhances safety and communication reliability | Weight considerations, certification for aviation standards |

How is RF Protection Used in Telecommunications and What Problems Does It Solve?

In the telecommunications sector, RF protection is crucial for cell tower installations where interference can significantly degrade service quality. RF shielding materials help reduce unwanted signals and enhance the clarity of communications. For international buyers, particularly in regions like Africa and the Middle East, sourcing materials that comply with local regulations and can withstand environmental challenges is essential. Durability and resistance to weather conditions are key considerations, as they directly affect the operational lifespan of the equipment.

Why is RF Shielding Important for Defense and Security Applications?

In defense and security, RF shielding is vital for constructing Sensitive Compartmented Information Facilities (SCIFs). These facilities require stringent protection against unauthorized access to sensitive information. The use of high-performance RF shielding barriers ensures that electromagnetic emissions do not leak, thus safeguarding critical data. Buyers in this sector must prioritize materials that meet military standards and are certified for effectiveness, as well as ensure that installation is performed by qualified personnel to maintain security integrity.

How Does RF Protection Benefit Healthcare Facilities?

Healthcare facilities utilize RF shielding to protect the functionality of sensitive medical devices from electromagnetic interference. This application is critical for ensuring reliable operation of equipment such as MRI machines and pacemakers. For buyers, particularly in South America and Europe, it is essential to consider the biocompatibility of shielding materials and their compliance with health regulations. Additionally, ease of installation and the ability to integrate with existing infrastructure are significant factors that can influence purchasing decisions.

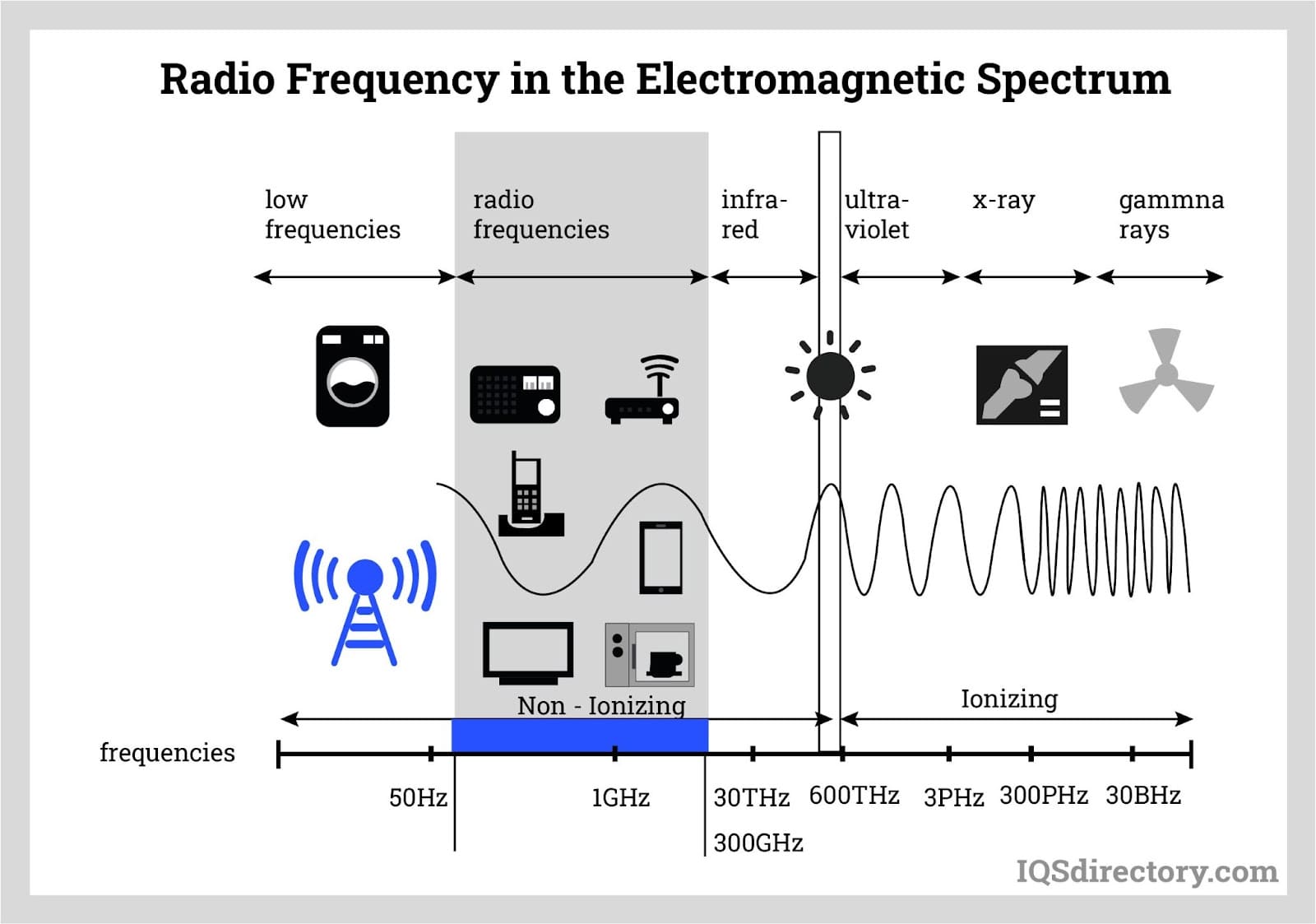

Illustrative image related to rf protection

What Role Does RF Protection Play in Manufacturing Industries?

In manufacturing, RF protection is employed to shield industrial equipment from electromagnetic interference, which can disrupt operations and lead to costly downtime. Effective RF shielding materials improve equipment reliability and performance. Buyers in this sector should assess the compatibility of RF protection solutions with existing machinery and consider the availability of maintenance support. Furthermore, sourcing from suppliers with proven experience in industrial applications can enhance the assurance of product effectiveness.

Why is RF Shielding Essential in Aerospace and Aviation?

RF shielding is critical in aerospace and aviation to ensure the safety and reliability of communication systems onboard aircraft. Given the stringent safety regulations in this industry, effective RF protection minimizes the risk of interference that could jeopardize flight operations. Buyers in this field must consider weight and material properties to ensure compliance with aviation standards. Additionally, sourcing from manufacturers that specialize in aerospace applications can provide confidence in the quality and performance of RF shielding solutions.

3 Common User Pain Points for ‘rf protection’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent RF Shielding Across Different Environments

The Problem: B2B buyers often face challenges when implementing RF protection solutions in diverse environments, such as manufacturing facilities or sensitive information compartments. The inconsistency in RF shielding effectiveness can lead to vulnerabilities in sensitive data transmission and operational disruptions due to electromagnetic interference. For example, a facility may have sections with heavy machinery that emit high levels of RF noise, making it difficult to maintain the necessary shielding performance throughout the entire space. This inconsistency can lead to costly downtime or security breaches, significantly impacting business operations.

The Solution: To address these challenges, buyers should consider a multi-layered approach to RF shielding. Start by conducting a comprehensive RF survey of the facility to identify high-risk areas and specific RF interference sources. Based on this analysis, select tailored RF shielding materials, such as high-performance RF paints and fabrics, that can be applied in various forms (e.g., wall coverings, window films) to ensure consistent coverage. Additionally, integrating RF safety monitors can help continuously assess the effectiveness of the shielding and alert facility managers to any significant RF breaches. Regular maintenance and re-evaluation of shielding materials should also be part of the ongoing strategy to adapt to any environmental changes or new RF sources.

Illustrative image related to rf protection

Scenario 2: Compliance with International RF Protection Standards

The Problem: Buyers in international markets often struggle with compliance issues regarding RF protection regulations, which can vary significantly by country. For instance, a company operating in Europe may find it challenging to meet the stringent electromagnetic compatibility (EMC) standards required for their products, while simultaneously attempting to enter the South American market, where regulations may be less defined. This discrepancy can lead to delays in product launches, increased costs due to redesigns, and potential legal liabilities if compliance is not met.

The Solution: To navigate these complex regulatory landscapes, it’s essential for buyers to engage with experienced consultants or regulatory bodies early in the product development process. Buyers should invest time in understanding the specific RF protection standards applicable in their target markets. Utilizing third-party testing services can help ensure that products are compliant with local regulations before entering the market. For example, using materials that have been certified for their RF shielding effectiveness, such as those tested under IEEE 299 standards, can help streamline compliance. Additionally, establishing partnerships with local distributors or compliance experts in target regions can facilitate a smoother entry into international markets while ensuring adherence to local regulations.

Scenario 3: High Costs of Implementing Comprehensive RF Protection Solutions

The Problem: Many B2B buyers encounter budget constraints when looking to implement comprehensive RF protection solutions. High-quality RF shielding materials and technology can be expensive, and the initial investment might deter companies from investing adequately in necessary protections. This cost concern often leads to suboptimal solutions that only partially address the RF protection needs, leaving the organization vulnerable to interference and potential data breaches.

The Solution: To optimize costs while ensuring effective RF protection, companies should consider a phased implementation strategy. Start by prioritizing the most critical areas that require immediate attention, such as data centers or production lines where sensitive information is processed. Explore cost-effective RF shielding solutions, such as RF shielding paints and modular shielding enclosures that can be adjusted or expanded as needed. Additionally, consider leveraging bulk purchasing agreements with suppliers to negotiate better pricing on high-quality shielding materials. Investing in RF testing equipment can also provide valuable insights into the effectiveness of existing shielding and guide future investments, ensuring funds are allocated to areas that will yield the highest return on investment. By taking a strategic approach to RF protection, businesses can achieve robust shielding without exceeding budget limitations.

Illustrative image related to rf protection

Strategic Material Selection Guide for rf protection

When selecting materials for RF protection, it is essential to consider their properties, advantages, disadvantages, and suitability for various applications. Here, we analyze four common materials used in RF shielding: aluminum, copper, conductive polymers, and RF shielding paints.

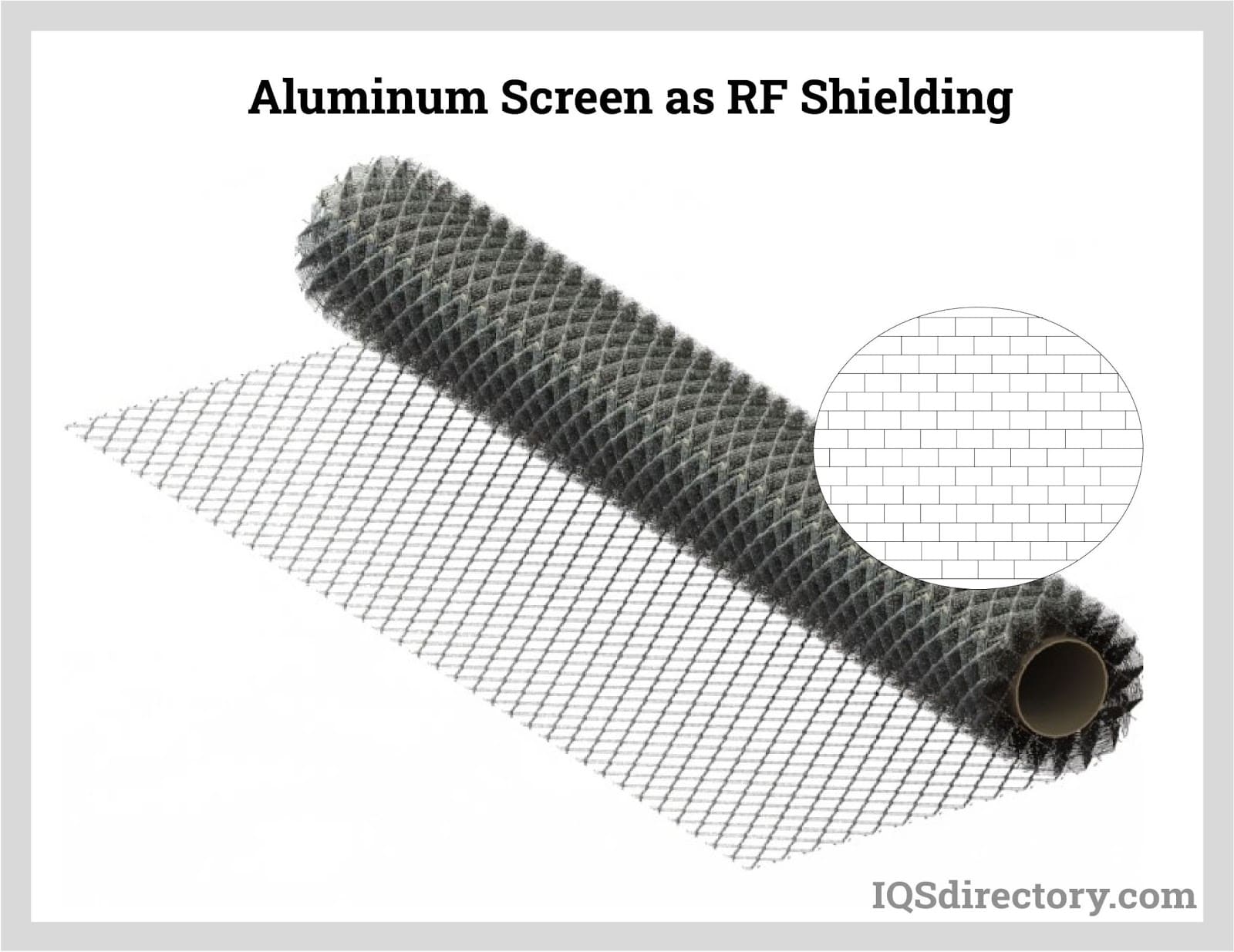

What Are the Key Properties of Aluminum for RF Protection?

Aluminum is widely used in RF shielding due to its excellent conductivity and lightweight nature. It typically offers good corrosion resistance, making it suitable for various environmental conditions. Aluminum’s temperature rating can vary, but it generally withstands temperatures up to 600°F (315°C) without significant degradation.

Pros and Cons: The primary advantages of aluminum include its low weight, high strength-to-weight ratio, and cost-effectiveness. However, it can be prone to scratches and may require surface treatments to enhance durability. Additionally, while aluminum is relatively easy to fabricate, complex shapes may increase manufacturing complexity.

Illustrative image related to rf protection

Impact on Application: Aluminum is compatible with various media, including air and water, but may not perform well in highly corrosive environments without protective coatings.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN for structural integrity and shielding effectiveness.

How Effective is Copper as an RF Shielding Material?

Copper is renowned for its superior electrical conductivity, making it one of the most effective materials for RF shielding. It offers excellent corrosion resistance and can handle high temperatures, typically rated up to 400°F (204°C) in many applications.

Pros and Cons: The key advantage of copper is its high shielding effectiveness, often exceeding that of aluminum. However, copper is more expensive than aluminum, which can be a significant drawback for large-scale applications. Additionally, its weight can be a concern in applications where minimizing mass is critical.

Impact on Application: Copper is compatible with various media but may require additional treatments in humid environments to prevent oxidation.

Considerations for International Buyers: Compliance with international standards such as JIS and ASTM is crucial, especially for industries in Europe and the Middle East where stringent regulations apply.

What Role Do Conductive Polymers Play in RF Protection?

Conductive polymers are increasingly used in RF shielding due to their lightweight and flexible nature. These materials can be engineered to provide specific conductivity levels and are often resistant to corrosion and chemical degradation.

Pros and Cons: The flexibility of conductive polymers allows for easy integration into various applications, including textiles and coatings. However, they generally offer lower shielding effectiveness compared to metals, which may limit their use in high-frequency applications. Additionally, the manufacturing process can be complex and costly.

Impact on Application: Conductive polymers are suitable for applications requiring lightweight and flexible solutions, such as wearable technology or portable devices.

Considerations for International Buyers: Buyers should verify compliance with industry-specific standards, as the performance of conductive polymers can vary significantly based on formulation and application.

Illustrative image related to rf protection

How Do RF Shielding Paints Compare in Terms of Performance?

RF shielding paints are specialized coatings that provide RF protection when applied to surfaces. These paints typically contain conductive materials like carbon or metal particles, allowing them to attenuate electromagnetic interference effectively.

Pros and Cons: The primary advantage of RF shielding paints is their ease of application and versatility. They can be used on various substrates, making them ideal for retrofitting existing structures. However, their effectiveness can vary widely based on the thickness of the application and the specific formulation. Additionally, they may not provide the same level of durability as solid materials.

Impact on Application: RF shielding paints are suitable for indoor applications and environments where aesthetics are important, but they may not hold up well in outdoor conditions without additional protective layers.

Considerations for International Buyers: Compliance with local regulations and standards is essential, especially in regions like Europe where environmental regulations may dictate the use of certain materials.

Illustrative image related to rf protection

Summary Table of RF Protection Materials

| Material | Typical Use Case for rf protection | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural RF shielding in buildings | Lightweight and cost-effective | Prone to scratches, may require coatings | Medium |

| Copper | High-performance RF shielding applications | Superior shielding effectiveness | Higher cost and weight | High |

| Conductive Polymers | Flexible RF shielding in textiles/devices | Lightweight and flexible | Lower shielding effectiveness, complex mfg | Medium |

| RF Shielding Paints | Retrofitting existing structures | Easy application and versatile | Variable effectiveness and durability | Low |

This guide provides an overview of materials used for RF protection, helping international B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rf protection

What Are the Key Stages of Manufacturing RF Protection Products?

The manufacturing process for RF protection products involves several critical stages, each designed to ensure that the final products meet stringent performance and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for RF Protection Manufacturing?

The first step in the manufacturing process is material preparation, which involves selecting high-quality raw materials that provide effective RF shielding. Common materials include specialized coatings, fabrics, and metals such as aluminum or copper. These materials are often tested for their electromagnetic shielding effectiveness (EMSE) and must meet specific industry standards before they can be used in production.

Once the materials are selected, they undergo rigorous testing for parameters such as conductivity, durability, and resistance to environmental factors. This ensures that only the best materials are utilized, which is crucial for the performance of RF protection products.

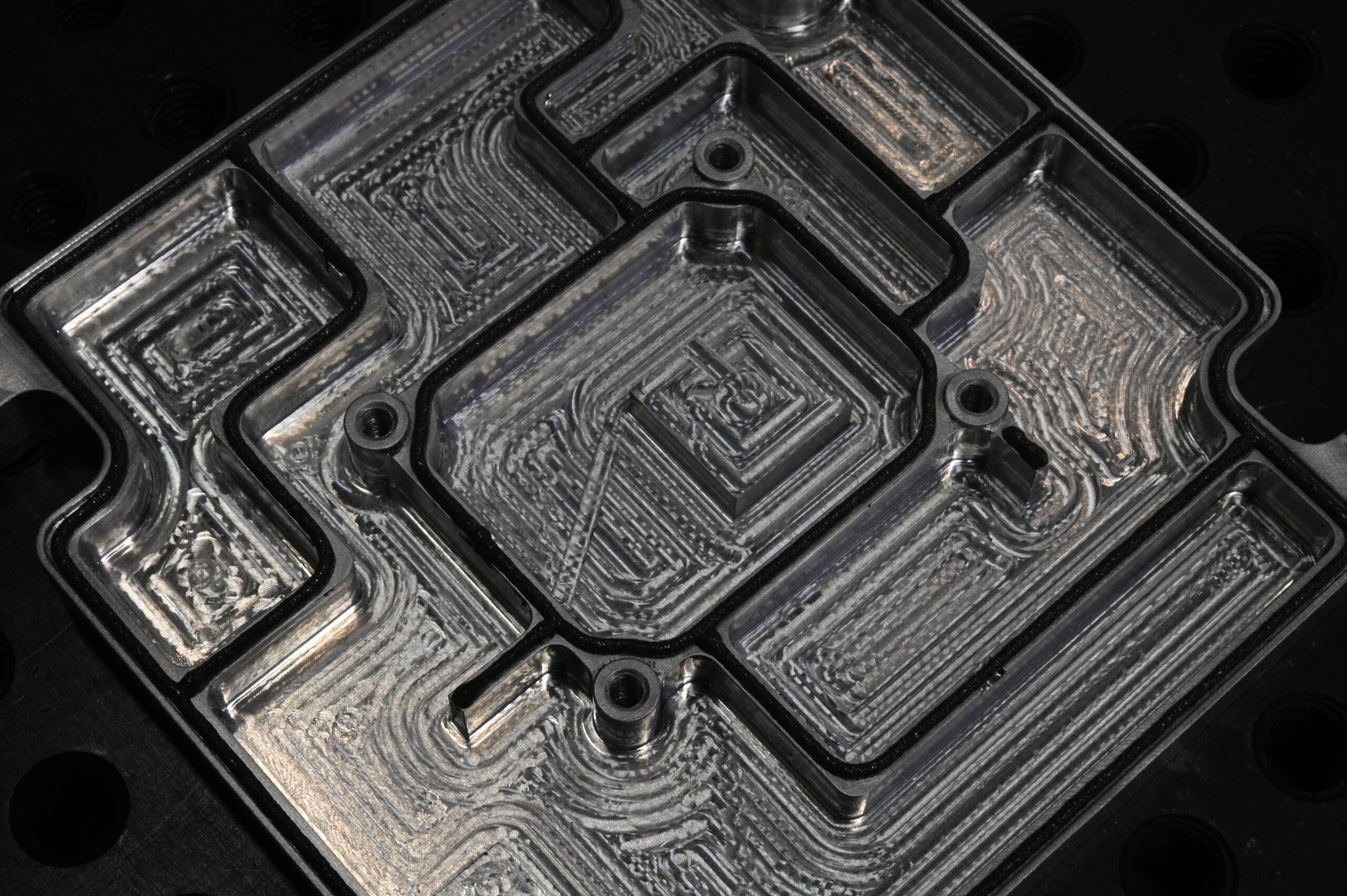

What Techniques Are Used in the Forming Process?

The forming stage focuses on shaping the prepared materials into the desired forms. Techniques such as cutting, molding, and weaving are commonly employed, depending on the type of RF protection product being manufactured. For instance, RF shielding fabrics may be woven using advanced textile techniques, while coatings might be applied through spraying or dipping methods.

Illustrative image related to rf protection

The forming process is critical for ensuring that the materials achieve the necessary thickness and surface characteristics required for effective RF shielding. Precision in this stage is vital, as even minor deviations can affect the overall performance of the product.

How Is Assembly Conducted for RF Protection Products?

Once the individual components are formed, the assembly process begins. This typically involves combining various materials and parts into a final product. For RF enclosures, for example, the assembly might include integrating RF shielding materials with structural components to create a Faraday cage or other protective barriers.

Quality control checkpoints are integrated throughout the assembly process to ensure that each component meets the required specifications. This includes verifying the integrity of joints, connections, and seals, which are critical for maintaining shielding effectiveness.

What Finishing Techniques Enhance RF Protection Products?

The finishing stage involves applying final touches to the assembled products. This may include surface treatments, additional coatings, or packaging. Finishing techniques can enhance properties such as corrosion resistance, durability, and aesthetic appeal. For RF protection products, coatings that improve RF attenuation and environmental resistance are often applied.

Additionally, products may undergo further testing during the finishing stage to verify that they meet all relevant standards. This ensures that the final product not only performs effectively but is also ready for the specific environments in which it will be used.

What Quality Assurance Practices Are Critical for RF Protection Manufacturing?

Quality assurance (QA) is a fundamental aspect of manufacturing RF protection products, ensuring they meet rigorous standards for performance and safety. This includes adherence to both international standards like ISO 9001 and industry-specific certifications.

Which International Standards Are Relevant for RF Protection Manufacturing?

ISO 9001 is one of the most recognized quality management standards globally, applicable to various industries, including manufacturing. Compliance with ISO 9001 indicates that a manufacturer has established a systematic approach to managing quality, ensuring consistency in product delivery.

In addition to ISO certifications, RF protection products may require compliance with industry-specific standards such as CE marking for products sold in Europe, which ensures they meet EU safety, health, and environmental protection standards. Other certifications, like those from Underwriters Laboratories (UL) or American National Standards Institute (ANSI), may also be relevant depending on the application and market.

Illustrative image related to rf protection

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are crucial for maintaining high standards throughout the manufacturing process. Typical checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components before they enter the production process. Ensuring that materials meet specifications is essential to the overall quality of the final product.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to verify that processes are being followed correctly and that products meet quality standards at every stage. This includes checking dimensions, conductivity, and shielding effectiveness.

-

Final Quality Control (FQC): Once products are assembled and finished, they undergo final inspections and testing. This stage often includes performance testing to ensure that the products meet or exceed the required specifications for RF shielding.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is critical to ensuring product reliability. Here are some effective strategies:

-

Conduct Audits: Schedule regular audits of the manufacturing facilities to assess compliance with quality standards. This provides insight into the supplier’s quality management practices and production capabilities.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications. This transparency helps buyers assess the supplier’s commitment to quality.

-

Utilize Third-Party Inspections: Engage third-party inspection services to conduct independent assessments of the manufacturing process and product quality. This adds an extra layer of assurance regarding the reliability of the products.

What Are the Unique Quality Control Considerations for International Markets?

When dealing with suppliers from different regions, B2B buyers must be aware of the nuances in quality assurance practices. For instance, regulations and certifications can vary significantly between markets like Africa, South America, the Middle East, and Europe.

Illustrative image related to rf protection

Buyers should ensure that suppliers understand and comply with local regulations, which may require additional certifications or testing. Furthermore, cultural differences in business practices can impact communication and transparency, making it essential for buyers to establish clear expectations and maintain open channels of communication.

Conclusion

In summary, the manufacturing processes and quality assurance practices for RF protection products are intricate and highly specialized. By understanding the key stages of manufacturing and the importance of quality control, B2B buyers can make informed decisions when selecting suppliers. Ensuring compliance with international standards and conducting thorough evaluations of supplier capabilities will help secure high-quality RF protection solutions tailored to specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rf protection’

Introduction

In today’s technologically advanced landscape, ensuring effective radio frequency (RF) protection is critical for safeguarding sensitive information and maintaining operational integrity. This guide serves as a practical checklist for B2B buyers looking to procure RF protection solutions. By following these steps, buyers can make informed decisions that align with their specific needs and compliance requirements.

Illustrative image related to rf protection

Step 1: Define Your Technical Specifications

Before engaging suppliers, it’s essential to clearly outline your technical requirements for RF protection. This includes understanding the frequency ranges you need to shield against, the level of attenuation required, and any environmental factors that may influence the performance of the materials.

- Identify specific applications (e.g., SCIFs, industrial settings).

- Determine regulatory compliance standards relevant to your region or industry.

Step 2: Research Available RF Protection Products

Explore the variety of RF shielding solutions available in the market. This may include RF paints, fabrics, enclosures, and more specialized products like Faraday bags or SCIF barriers.

- Analyze product specifications, including shielding effectiveness and material composition.

- Consider both performance and ease of installation to ensure long-term effectiveness.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and deliver quality products. Request detailed company profiles, case studies, and references from buyers in similar industries or regions.

- Look for suppliers who have experience with your specific application.

- Verify their history with compliance certifications and third-party testing results.

Step 4: Assess Pricing and Value

Compare pricing among different suppliers, but focus on the value offered rather than just the lowest cost. Evaluate the total cost of ownership, including installation, maintenance, and potential downtime due to ineffective products.

- Inquire about bulk purchasing discounts or long-term contracts.

- Factor in warranty and support services as part of the overall value proposition.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier holds the necessary certifications for their products. This includes compliance with international standards such as IEEE or ASTM, which verify the effectiveness of RF shielding materials.

- Request documentation that demonstrates compliance with relevant standards.

- Confirm that products have been tested in accredited laboratories for reliability.

Step 6: Plan for Installation and Maintenance

Consider the logistics of installing RF protection solutions. Assess whether your team has the necessary expertise or if you need to hire professionals for installation.

- Develop a maintenance schedule to ensure long-term performance of RF shielding materials.

- Discuss with suppliers about training options for your team on proper installation and maintenance practices.

Step 7: Monitor and Evaluate Performance Post-Implementation

After installation, it’s crucial to monitor the performance of RF protection solutions to ensure they meet your initial specifications. Conduct regular assessments to identify any areas needing improvement.

Illustrative image related to rf protection

- Use RF monitoring tools to measure the effectiveness of shielding.

- Solicit feedback from team members regarding the performance of the installed solutions.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for RF protection solutions, ensuring they select the best products and suppliers to meet their needs.

Comprehensive Cost and Pricing Analysis for rf protection Sourcing

What Are the Key Cost Components in RF Protection Sourcing?

When sourcing RF protection products, understanding the cost structure is critical. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts pricing. High-performance materials such as specialized RF shielding fabrics, coatings, and metals can raise costs. For example, products like YSHIELD® shielding paint range from $72.50 to $895, depending on specifications and sizes.

-

Labor and Manufacturing Overhead: Labor costs can vary based on the complexity of the manufacturing process. Highly specialized RF shielding products may require skilled labor, which can increase costs. Additionally, manufacturing overhead—covering utilities, equipment maintenance, and other operational expenses—also plays a role in the final price.

-

Tooling and Quality Control: The need for specialized tooling to produce RF protection products can lead to significant upfront costs. Moreover, rigorous QC processes, especially for products intended for sensitive environments like SCIFs, ensure compliance with industry standards, which can add to the overall price.

-

Logistics: Shipping and handling costs can vary widely based on location and shipping method. International buyers, particularly those in regions like Africa and South America, should consider these costs when evaluating total expenses.

-

Supplier Margin: The profit margin included by suppliers can also fluctuate based on their market positioning and the competitive landscape.

How Do Price Influencers Affect RF Protection Costs?

Several factors can influence pricing in the RF protection market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can lead to significant discounts. Suppliers often have a MOQ that, if met, can lower the price per unit.

-

Specifications and Customization: Custom solutions tailored to specific requirements can increase costs. Buyers should assess whether standard products can meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Products that meet stringent certifications (like those verified by NSA for SCIF environments) typically come at a premium. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: The choice of supplier can greatly impact pricing. Established brands with a reputation for quality may charge more, while newer or less-known suppliers might offer lower prices but with varying quality.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can significantly affect the total cost of ownership.

What Tips Can Buyers Use to Optimize Costs in RF Protection Sourcing?

To achieve cost efficiency in sourcing RF protection, buyers should consider the following tips:

-

Negotiate Pricing: Always engage in negotiations. Suppliers may have room to adjust pricing, especially for large orders or long-term contracts.

-

Evaluate Total Cost of Ownership: Beyond initial purchase price, consider long-term costs such as maintenance, durability, and replacement frequency. Investing in higher-quality products may result in lower long-term costs.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and potential tariffs that could influence pricing.

-

Research Multiple Suppliers: Gathering quotes from multiple suppliers can provide a better understanding of the market rate and help identify the best value.

-

Stay Informed on Industry Trends: Keeping abreast of technological advancements and changes in regulations can help buyers make informed decisions about product specifications and sourcing strategies.

Disclaimer on Indicative Prices

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and fluctuations in raw material costs. Buyers are encouraged to obtain current quotes and conduct thorough due diligence when sourcing RF protection products.

Alternatives Analysis: Comparing rf protection With Other Solutions

Understanding Alternatives to RF Protection Solutions

In the realm of safeguarding sensitive information and equipment from electromagnetic interference (EMI) and radio frequency (RF) threats, various solutions are available. While RF protection products like shielding paints, fabrics, and barriers have proven effective, it’s crucial to explore alternative technologies that might better fit specific operational needs, budgets, or environments. This section will provide a comparative analysis of RF protection against two viable alternatives: electromagnetic interference (EMI) filters and wideband adaptive RF filtering systems.

Comparison Table

| Comparison Aspect | RF Protection | EMI Filters | Wideband Adaptive RF Filtering |

|---|---|---|---|

| Performance | High attenuation (up to 73 dB) across various frequencies | Effective at specific frequency ranges | Dynamic adaptation to changing signals |

| Cost | Varies ($72.50 – $6,900) based on material type | Moderate ($50 – $1,000) depending on specifications | High initial R&D and implementation costs |

| Ease of Implementation | Generally straightforward; requires surface application or installation | Relatively easy; often integrated into devices | Complex; requires advanced technology and expertise |

| Maintenance | Low; durable materials need minimal upkeep | Moderate; periodic checks needed for functionality | High; requires regular updates and recalibration |

| Best Use Case | Secure facilities, SCIFs, and sensitive data environments | Consumer electronics, telecommunications | Military applications, advanced communications systems |

Pros and Cons of Alternative Solutions

What Are the Benefits and Drawbacks of EMI Filters?

EMI filters are designed to suppress unwanted electromagnetic interference in electronic devices. They are effective for specific frequency ranges and can be easily integrated into existing systems. Their cost-effectiveness and moderate maintenance requirements make them a popular choice for consumer electronics and telecommunications. However, their performance is limited to certain frequencies, which may not suffice for environments requiring broad-spectrum RF protection.

How Does Wideband Adaptive RF Filtering Work, and What Are Its Limitations?

Wideband adaptive RF filtering technology is an advanced solution that dynamically adjusts to the spectral environment, providing robust protection against interference. This adaptability makes it suitable for military applications and environments where signal conditions can change rapidly. However, the complexity and high costs associated with the development and maintenance of these systems can be prohibitive for many businesses, particularly in emerging markets.

Choosing the Right RF Protection Solution for Your Business

When selecting an RF protection solution, B2B buyers should carefully assess their specific needs, including the operational environment, budget constraints, and required performance levels. RF protection products are generally suitable for environments where high attenuation is critical, such as secure facilities handling sensitive information. In contrast, EMI filters may be ideal for consumer electronics, while wideband adaptive RF filtering is best suited for specialized military or advanced communication scenarios.

Ultimately, the right choice will depend on a thorough evaluation of the trade-offs between performance, cost, implementation ease, and maintenance requirements. By aligning the chosen solution with organizational objectives, businesses can ensure optimal protection against RF threats while maintaining operational efficiency.

Essential Technical Properties and Trade Terminology for rf protection

What Are the Key Technical Properties of RF Protection Materials?

When evaluating RF protection materials, several critical specifications should be considered to ensure optimal performance for your specific application.

-

Material Grade: The quality of the materials used in RF shielding, such as aluminum foil or specialized conductive fabrics, is paramount. High-grade materials provide better shielding effectiveness, durability, and resistance to environmental factors. For B2B buyers, selecting the right material grade can directly influence the longevity and reliability of RF protection solutions, particularly in critical environments like SCIFs (Sensitive Compartmented Information Facilities).

-

Shielding Effectiveness: Measured in decibels (dB), shielding effectiveness indicates how well a material can attenuate RF signals. A higher dB value signifies better performance. For instance, products with an average RF attenuation of 73 dB, such as the RF Shield™ SCIF Barrier, are essential for protecting sensitive information. Understanding this specification allows buyers to gauge whether a product meets the specific requirements of their operational environments.

-

Frequency Range: Different RF protection materials are designed to shield against specific frequency ranges. It is crucial to choose materials that provide adequate coverage for the frequencies of concern in your application. This ensures that the RF protection is effective against the types of signals that may be present, especially in diverse operational settings.

-

Flammability Rating: The flammability of RF shielding materials is vital for safety compliance, particularly in sectors like aerospace and military. Materials with a Class A flammability rating are preferred, as they indicate lower risk of ignition. Buyers should verify flammability ratings to align with regulatory standards and safety protocols within their operations.

-

Environmental Resistance: RF protection solutions should be durable enough to withstand various environmental conditions, including moisture, temperature fluctuations, and potential chemical exposure. Products that meet rigorous testing standards for mold resistance and thermal performance can significantly reduce maintenance costs and ensure long-term effectiveness.

What Trade Terms Are Commonly Used in the RF Protection Industry?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions related to RF protection.

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, engaging with OEMs can ensure that they receive components that meet specific technical requirements and standards.

-

MOQ (Minimum Order Quantity): This term indicates the smallest order size a supplier is willing to accept. Understanding MOQ is essential for budgeting and inventory management, especially for companies that may not require large quantities of RF protection materials.

-

RFQ (Request for Quotation): A formal process where buyers request price quotes from suppliers for specific quantities of products. An effective RFQ can lead to competitive pricing and better terms, ensuring that procurement aligns with budget constraints.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is critical for international transactions, as they help mitigate risks associated with cross-border trade.

-

TEMPEST: A U.S. government acronym that refers to the study and control of compromising emanations from electronic equipment. Understanding TEMPEST standards is essential for companies dealing with sensitive data, as compliance can influence the selection of RF protection solutions.

-

SCIF (Sensitive Compartmented Information Facility): A secure area where sensitive information can be processed and discussed. Knowledge of SCIF requirements is vital for companies operating in defense, intelligence, and other sectors where information security is paramount.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance their RF protection strategies, ensuring compliance, safety, and efficiency in their operations.

Illustrative image related to rf protection

Navigating Market Dynamics and Sourcing Trends in the rf protection Sector

What Are the Key Drivers Shaping the RF Protection Market?

The RF protection sector is witnessing significant growth, driven by the increasing demand for wireless communication technologies and the proliferation of electronic devices across various industries. Global connectivity trends, particularly in emerging markets in Africa, South America, and the Middle East, are accelerating the need for robust RF shielding solutions to mitigate interference and ensure data security. For instance, regions like Saudi Arabia and Germany are investing heavily in telecommunications infrastructure, which necessitates high-performance RF protection products to safeguard sensitive information from electromagnetic interference.

Emerging technologies such as wideband adaptive RF protection are also influencing sourcing trends. These advancements focus on mitigating interference through innovative filtering and signal cancellation techniques, which are crucial for industries reliant on secure communication. B2B buyers are increasingly seeking suppliers who can offer not only high-quality products but also cutting-edge technology that ensures compliance with stringent regulatory standards. Moreover, the rise of remote work and smart technologies has further increased the demand for RF shielding in workplaces, prompting buyers to consider solutions like RF paints, fabrics, and enclosures that can be seamlessly integrated into existing environments.

How Is Sustainability and Ethical Sourcing Impacting RF Protection Procurement?

Sustainability has become a pivotal consideration for B2B buyers in the RF protection sector. As global awareness of environmental issues rises, companies are increasingly prioritizing suppliers that adhere to ethical sourcing practices and provide sustainable materials. The production of RF shielding products can have significant environmental impacts, particularly concerning the use of non-renewable resources and waste generation. Therefore, buyers are urged to evaluate potential suppliers based on their commitment to reducing environmental footprints through sustainable manufacturing processes.

Illustrative image related to rf protection

Moreover, the demand for ‘green’ certifications is growing. Products that are eco-friendly, such as RF shielding materials made from recycled or sustainably sourced components, are gaining traction in the marketplace. For instance, companies that utilize materials with certifications like LEED (Leadership in Energy and Environmental Design) or ISO 14001 (Environmental Management Systems) demonstrate their commitment to sustainability, making them more appealing to conscientious buyers. By aligning procurement strategies with sustainability goals, B2B buyers can not only enhance their corporate social responsibility profiles but also gain a competitive edge in increasingly eco-conscious markets.

What Is the Historical Context of RF Protection and Its Evolution?

The evolution of RF protection can be traced back to the early days of radio technology, where the need to shield sensitive equipment from electromagnetic interference became apparent. Initially, RF shielding solutions were rudimentary, often involving basic metallic barriers. However, as technology advanced, so did the sophistication of RF protection products. The introduction of specialized materials such as conductive fabrics, paints, and advanced enclosures marked a significant turning point in the industry.

Over the decades, the development of standards and testing methodologies has also played a crucial role in shaping the RF protection landscape. Regulatory bodies have established guidelines for shielding effectiveness, which has led to the emergence of high-performance products that cater to specific needs across various sectors, including telecommunications, military, and healthcare. Today, RF protection solutions are not only essential for compliance but also integral to ensuring the integrity of communications in an increasingly interconnected world, paving the way for future innovations in shielding technologies.

Frequently Asked Questions (FAQs) for B2B Buyers of rf protection

-

How do I solve RF interference problems in my facility?

To effectively mitigate RF interference, start by assessing the specific frequencies causing disruptions. Utilize RF shielding solutions like specialized paints, fabrics, or enclosures that are designed to block or absorb unwanted signals. Ensure that the chosen products meet relevant industry standards for shielding effectiveness. Additionally, consider consulting with a supplier who can conduct an RF site survey to identify the best solutions tailored to your environment. -

What is the best RF shielding material for my specific application?

The optimal RF shielding material depends on your application’s frequency range and environmental conditions. For instance, if you require protection from a wide spectrum of frequencies, multi-layered materials like those used in SCIF barriers may be ideal. Alternatively, if space is limited, RF shielding paints or films can provide effective solutions without the need for bulkier installations. Always consult with suppliers to determine the best fit for your specific needs. -

What are the minimum order quantities (MOQs) for RF protection products?

Minimum order quantities for RF protection products can vary significantly by supplier and product type. While some manufacturers may offer low MOQs for items like RF shielding paint or fabrics, others, especially for custom solutions, may require larger orders. It’s advisable to inquire directly with suppliers about their MOQ policies and any potential discounts for bulk purchases, particularly if you’re sourcing internationally. -

What payment terms can I expect when sourcing RF protection products?

Payment terms for RF protection products can differ based on the supplier’s policies and your negotiation. Common terms include payment upon order, 30-day net terms, or partial payments with a deposit. For international transactions, consider the implications of currency exchange and potential transaction fees. Establish clear terms upfront to ensure a smooth procurement process, and consider using secure payment methods to mitigate risks. -

How can I vet suppliers for RF protection products?

To vet suppliers, start by checking their industry reputation and customer reviews. Look for certifications that indicate compliance with international standards, such as ISO certifications or specific RF testing validations. Request case studies or references from previous clients, particularly those within your industry. Engaging in direct communication can also help assess their responsiveness and willingness to customize solutions to meet your specific needs. -

What logistics considerations should I keep in mind when importing RF protection products?

When importing RF protection products, consider shipping times, customs regulations, and potential tariffs. Collaborate with logistics providers familiar with international shipping to ensure compliance with local regulations in your country. It’s crucial to account for lead times in production and shipping when planning your procurement strategy. Additionally, explore options for tracking shipments to maintain visibility throughout the delivery process. -

How do I ensure quality assurance for RF protection materials?

To ensure quality assurance, request detailed product specifications and testing certifications from your supplier. Look for third-party testing results that validate the shielding effectiveness of the materials. Establish a quality control process that includes inspection upon arrival and periodic assessments during use. Building a strong relationship with your supplier can also facilitate better communication regarding quality standards and any necessary adjustments. -

What customization options are available for RF shielding products?

Many suppliers offer customization options for RF shielding products, including tailored dimensions, colors, and specific performance characteristics. You can also inquire about custom formulations for paints or specific fabric blends that meet unique requirements. Discuss your project needs with suppliers early in the procurement process to explore available customization options and any associated costs or lead times.

Top 7 Rf Protection Manufacturers & Suppliers List

1. FIFOIL – RF Shield™ SCIF Barrier

Domain: fifoil.com

Registered: 1998 (27 years)

Introduction: RF Shield™ SCIF Barrier is designed for Sensitive Compartmented Information Facilities (SCIFs). It features a tear-resistant layer of woven polyethylene material sandwiched between two reflective aluminum surfaces. Key specifications include:

– Two outer layers of 99% Pure Aluminum Foil

– Inner layer of Fiberglass reinforcing and Kraft paper

– Average RF Attenuation of 73 dB

– High-performance…

2. DARPA – WARP Program

Domain: darpa.mil

Introduction: WARP: Wideband Adaptive RF Protection program aims to develop wideband adaptive filtering and signal cancellation architectures to protect wideband receivers against external and self-interference. Key technical areas include: 1) Mitigating external interference in the 2-18 GHz band with tunable filtering achieving a 2:1 and 3:1 tuning ratio in Phases 1 and 2, respectively, culminating in full-ban…

3. EcoFoil – Ultra NT RF Shielding Foil

Domain: ecofoil.com

Registered: 2007 (18 years)

Introduction: RF Shielding Foil | Ultra NT Radiant Barrier for SCIFs

– Protects against electronic surveillance in secure SCIF rooms

– Used for government, military, corporate, and other ICD 705 compliant projects

– Available in solid and perforated options

– Dimensions: 4′ x 125′ (500 sq ft) and 4′ x 250′ (1,000 sq ft)

– Regular prices: Solid – $218.00 (500 sq ft), $425.00 (1,000 sq ft); Perforated – $189.00 (…

4. Signals Defense – RF and IR Shielding Solutions

Domain: signalsdefense.com

Registered: 2006 (19 years)

Introduction: RF and IR Shielding Products: RF/IR window films (SD2500/SD2510, SD1000/SD1010), RF Foil and Adhesives (Ultra NT Radiant Barrier® rFoil™), RF shielding paint and caulks, architectural window films, decorative window films, solar control window film, cloaking film, DAS shield glass and polycarbonate laminates, window treatments (commercial shades, blinds, shutters), and Spray-Lock FRP adhesive. Des…

5. SafeSleeve – EMF Protection Cases

Domain: safesleevecases.com

Registered: 2012 (13 years)

Introduction: EMF Protection – EMF / RFID Blocking Phone Cases | SafeSleeve offers a range of products including cases for various iPhone models (iPhone 17, 16, 15, 14, 13, 12, 11, X/Xs, etc.), Samsung Galaxy Series, Google Pixel Series, and most other cell phones and tablets. The cases provide lab-tested EMF radiation protection, blocking over 99% of RF radiation and 92% of ELF radiation. They feature military…

6. Reddit – RF Shields for Home Electronics

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: RF shields in home electronics protect devices from electromagnetic radiation and interference. They are necessary because electronic components like processors and graphics cards can generate RF noise that disrupts signals, especially in the 2.4GHz range used by WiFi and Bluetooth. Devices are tested for RF emissions and interference in controlled environments to ensure compliance with legal stan…

7. FilterEMF – RF Shielded Nickel-Copper Fabric

Domain: filteremf.com

Registered: 2013 (12 years)

Introduction: Products include: Aluminum Foil Tape ($9.95), Heel Ground ($9.95), AL60 Wall Shield ($9.99), EX-STATIC Conductive Fabric ($9.99), ShieldIt Super ($13.95), RF Shielded Nickel-Copper Fabric (42.5″ Wide X 1 Linear Foot Long) ($17.00), HertzCloth (High Conductivity & All Natural Shielding Fabric) ($18.95), Stick E Shield ($18.95), RF Microwave Absorbing Sheet (48″ Wide X 1 Linear Foot Long) ($18.95), …

Strategic Sourcing Conclusion and Outlook for rf protection

How Can Strategic Sourcing Enhance Your RF Protection Strategy?

In the evolving landscape of RF protection, strategic sourcing plays a pivotal role in ensuring that businesses acquire high-quality materials and solutions tailored to their specific needs. The diverse range of RF shielding products—from paints and coatings to fabrics and enclosures—offers international buyers a wealth of options to enhance their infrastructure against electromagnetic interference. Selecting suppliers that adhere to stringent quality standards not only improves operational efficiency but also safeguards sensitive information, particularly in sectors like defense and telecommunications.

As global markets expand, particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for reliable RF protection solutions is set to rise. Buyers should prioritize partnerships with manufacturers who demonstrate innovation and a commitment to meeting international standards. This proactive approach will not only mitigate risks associated with RF exposure but also position businesses for future growth.

Illustrative image related to rf protection

Looking ahead, the integration of advanced technologies, such as wideband adaptive filtering, will further revolutionize RF protection capabilities. Now is the time for B2B buyers to engage with leading suppliers and invest in cutting-edge solutions that will secure their operations against evolving RF threats. Embrace the future of RF protection—strategize, source wisely, and ensure your business remains competitive in a rapidly changing environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.