Rf Interference Filter Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for rf interference filter

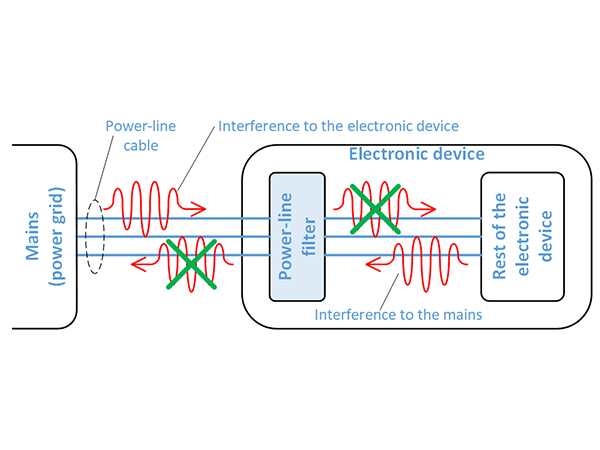

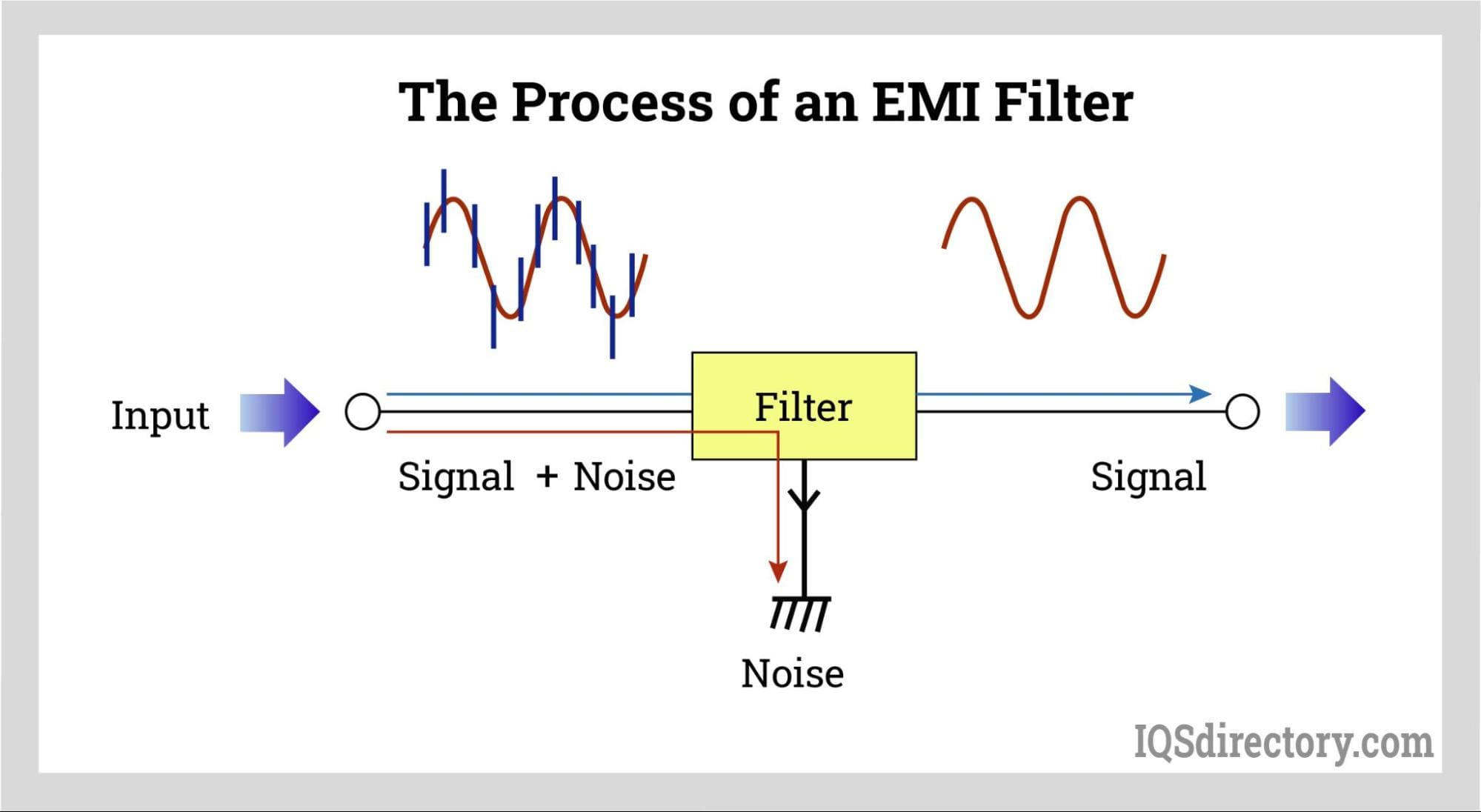

In today’s increasingly interconnected world, sourcing reliable RF interference filters poses a significant challenge for businesses navigating the complexities of electronic equipment and systems. Radio frequency interference (RFI) can disrupt operations, degrade performance, and lead to costly downtimes, making the selection of appropriate filtering solutions crucial for maintaining operational integrity. This comprehensive guide delves into the nuances of RF interference filters, addressing various types, applications, and the critical factors to consider when sourcing these essential components.

International B2B buyers, particularly those in dynamic markets across Africa, South America, the Middle East, and Europe, will benefit from insights into supplier vetting processes, cost considerations, and the latest technological advancements in RF filtering. By understanding the diverse applications of RF interference filters—from industrial machinery to consumer electronics—businesses can make informed purchasing decisions that align with their operational needs and regulatory requirements.

This guide empowers buyers to navigate the global market effectively, equipping them with the knowledge to identify high-quality suppliers and assess the performance capabilities of RF interference filters. By leveraging these insights, businesses can mitigate the risks associated with RFI, ensuring enhanced reliability and efficiency in their electronic systems.

Understanding rf interference filter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Passive RFI Filters | Simple design, no active components | Industrial machinery, consumer electronics | Pros: Cost-effective, reliable; Cons: Limited performance in high-frequency ranges |

| Active RFI Filters | Incorporate active components for better performance | Telecommunications, aerospace, medical devices | Pros: Superior performance, adaptable; Cons: Higher cost, complexity in installation |

| Common Mode Chokes | Reduces conducted RFI by blocking common mode signals | Power supply units, automotive applications | Pros: Effective against noise; Cons: May require tuning for optimal performance |

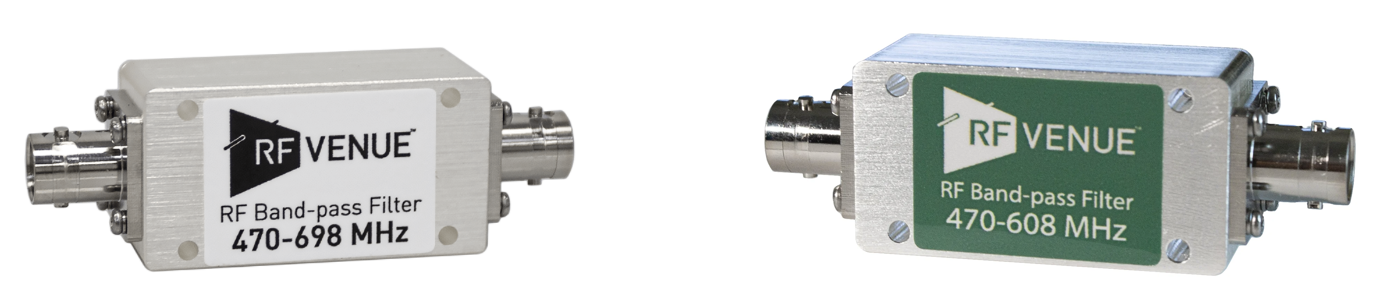

| Bandpass Filters | Allows specific frequency ranges to pass while blocking others | RF communication systems, broadcasting | Pros: Precision in frequency selection; Cons: Narrow bandwidth may limit versatility |

| Low-Pass Filters | Attenuates signals above a certain frequency | Audio equipment, data transmission systems | Pros: Protects sensitive components; Cons: Ineffective against high-frequency RFI |

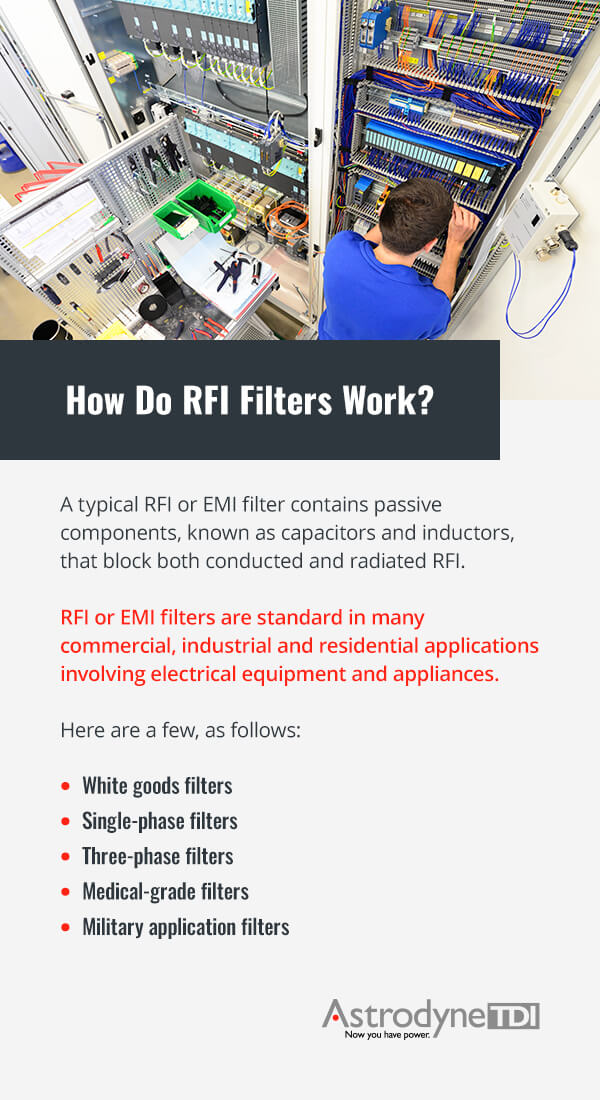

What Are Passive RFI Filters and When Should Businesses Use Them?

Passive RFI filters are designed with no active components, relying solely on passive elements like capacitors and inductors to reduce interference. These filters are particularly suitable for industrial machinery and consumer electronics, where cost-effectiveness and reliability are paramount. Buyers should consider the operating frequency range and the specific application environment since passive filters may struggle with high-frequency interference. They are often the first choice for businesses aiming to minimize RFI without significant investment.

How Do Active RFI Filters Enhance Performance in Specific Applications?

Active RFI filters utilize electronic components to enhance their filtering capabilities, making them ideal for applications that demand higher performance, such as telecommunications and aerospace. These filters adapt to varying interference levels, providing superior noise reduction. While they offer significant advantages, such as improved adaptability and performance, the complexity and cost associated with installation can be a consideration for buyers. Businesses should assess their operational requirements and budget constraints before investing in active solutions.

Why Are Common Mode Chokes Essential for Power Supply Units?

Common mode chokes are specialized filters that effectively reduce conducted RFI by blocking unwanted signals that share the same path as the desired signal. They are widely used in power supply units and automotive applications, where electrical noise can lead to performance degradation. While they are effective against noise, common mode chokes may require tuning for optimal performance in specific applications. Buyers should evaluate their equipment’s noise environment and the potential need for adjustments during installation.

What Role Do Bandpass Filters Play in RF Communication Systems?

Bandpass filters are designed to allow specific frequency ranges to pass through while blocking others, making them essential in RF communication systems and broadcasting. These filters provide precision in frequency selection, ensuring that only the desired signals are transmitted or received. However, their narrow bandwidth may limit versatility, making them less suitable for applications with varying frequency requirements. Businesses should carefully consider their frequency needs and the potential for future changes when selecting bandpass filters.

How Do Low-Pass Filters Protect Sensitive Components in Data Transmission?

Low-pass filters are effective at attenuating signals above a certain frequency, which is crucial in applications involving audio equipment and data transmission systems. By protecting sensitive components from high-frequency RFI, they help maintain signal integrity and prevent equipment damage. While low-pass filters excel in their protective role, they may not be effective against high-frequency interference, which should be considered by buyers. Evaluating the specific frequency environment and the critical nature of the equipment can guide purchasing decisions.

Key Industrial Applications of rf interference filter

| Industry/Sector | Specific Application of rf interference filter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Signal enhancement in cellular base stations | Reduces noise and interference, improving signal quality | Compliance with international standards, durability, and frequency range specifications |

| Automotive | Noise reduction in electronic control units (ECUs) | Enhances reliability and performance of vehicle electronics | Temperature tolerance, compact size, and automotive-grade certification |

| Medical Devices | Interference suppression in diagnostic equipment | Ensures accurate readings and patient safety | Biocompatibility, compliance with medical regulations, and reliability under varying conditions |

| Industrial Automation | Protection for sensors and control systems in factories | Minimizes downtime and equipment failure | Robust design for harsh environments, customization options, and compatibility with existing systems |

| Consumer Electronics | Filtering in smart home devices | Improves user experience by reducing device interference | Design flexibility, aesthetic integration, and cost-effectiveness |

How Are RF Interference Filters Used in Telecommunications?

In the telecommunications sector, RF interference filters are crucial for enhancing signal quality in cellular base stations. These filters mitigate noise and interference from various sources, ensuring that signals are transmitted and received clearly. For international buyers, especially in Africa and South America, sourcing filters that comply with local telecommunications regulations and standards is essential. Additionally, durability and the ability to operate across a wide frequency range are critical factors to consider.

What Role Do RF Filters Play in Automotive Electronics?

In the automotive industry, RF interference filters are employed to reduce noise in electronic control units (ECUs), which manage various vehicle functions. By minimizing electromagnetic interference, these filters enhance the reliability and performance of automotive electronics, contributing to safer driving experiences. Buyers from Europe and the Middle East should prioritize sourcing filters that meet automotive-grade certifications and can withstand extreme temperature variations.

How Do RF Filters Benefit Medical Devices?

Medical devices utilize RF interference filters to suppress interference in diagnostic equipment such as MRI machines and patient monitors. This suppression is vital for ensuring accurate readings and maintaining patient safety. Buyers, particularly from regions with stringent medical device regulations, must ensure that sourced filters meet biocompatibility standards and are reliable under varying operational conditions.

Why Are RF Filters Important in Industrial Automation?

In industrial automation, RF interference filters protect sensors and control systems from electromagnetic interference, which can lead to equipment failure and downtime. By implementing these filters, businesses can significantly reduce operational disruptions and enhance productivity. International B2B buyers should look for filters designed to withstand harsh industrial environments and that offer customization options to fit specific applications.

How Do RF Filters Enhance Consumer Electronics?

In the realm of consumer electronics, RF interference filters are essential for improving the performance of smart home devices by filtering out unwanted signals. This enhancement leads to a better user experience, as devices operate more reliably without interference. Buyers should consider design flexibility and aesthetic integration when sourcing these filters to ensure they complement the overall product design while remaining cost-effective.

3 Common User Pain Points for ‘rf interference filter’ & Their Solutions

Scenario 1: Intermittent Equipment Failures Due to RFI

The Problem: B2B buyers often face the challenge of intermittent equipment failures that can be attributed to radio frequency interference (RFI). In environments with a high density of electronic devices—such as manufacturing plants or data centers—uncontrolled RFI can lead to unpredictable equipment malfunctions. These failures not only disrupt operations but can also result in costly downtime, loss of productivity, and potential damage to sensitive electronic components.

The Solution: To mitigate these failures, buyers should focus on selecting the right RF interference filter tailored to their specific operational needs. Start by conducting a thorough assessment of the equipment in use and the types of RFI they are exposed to. A combination of conducted and radiated RFI filters may be necessary to address the interference effectively. When sourcing filters, prioritize those with high insertion loss ratings to ensure they adequately attenuate unwanted frequencies. Additionally, integrating these filters into the power supply lines of sensitive devices can significantly reduce the risk of interference, ensuring stable and reliable operation.

Scenario 2: Increased Compliance Costs from RFI Regulations

The Problem: Many industries are subject to stringent electromagnetic compatibility (EMC) regulations that require adherence to specific RFI emission limits. Non-compliance can lead to hefty fines, product recalls, and damage to brand reputation. As businesses expand into new markets—particularly in regions like Africa and South America—they may encounter varying compliance standards that add complexity to their operations and increase costs.

The Solution: To navigate these regulatory challenges, it is crucial for buyers to invest in high-quality RF interference filters that meet or exceed local compliance standards. When specifying these filters, consult with compliance experts who can guide you on the latest regulations applicable to your industry and region. Additionally, consider employing testing services that can validate the effectiveness of the filters in reducing emissions. By integrating filters early in the design phase and ensuring they are compliant with international standards, businesses can avoid costly penalties and streamline their market entry processes.

Scenario 3: Inefficient Signal Integrity in Communication Equipment

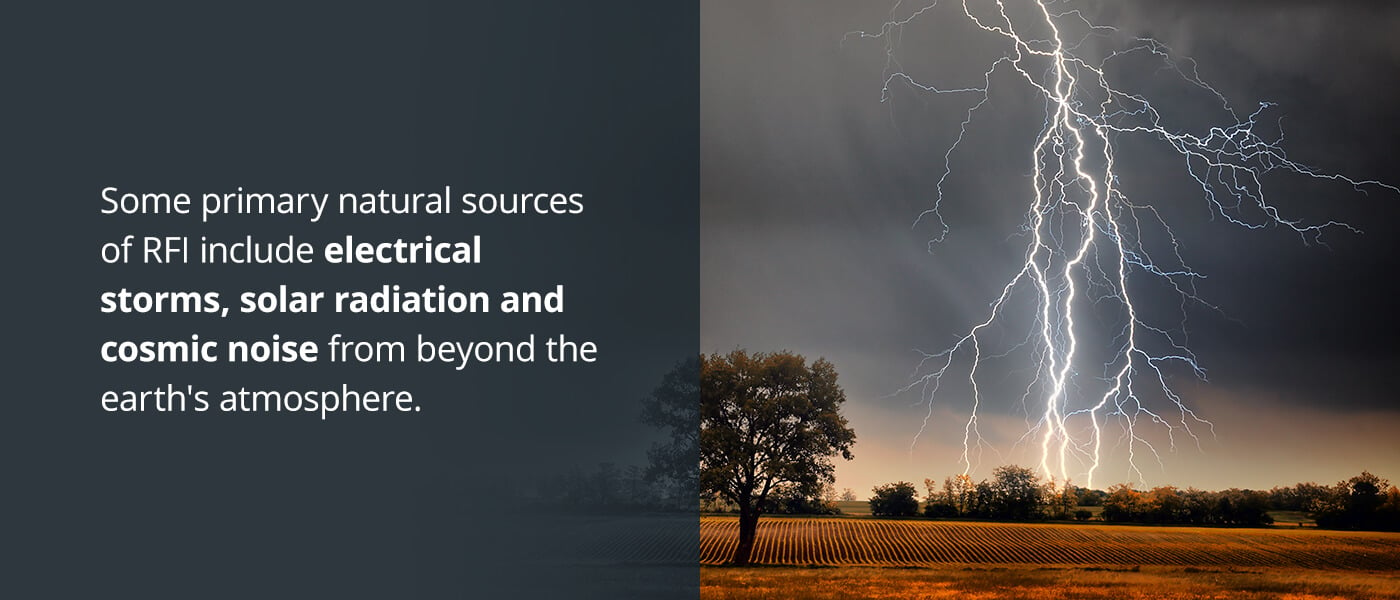

The Problem: In industries reliant on communication equipment, such as telecommunications or broadcasting, maintaining signal integrity is paramount. RFI can degrade the quality of signals, leading to data loss, poor audio/video quality, and overall reduced system performance. This issue is particularly pressing in regions with high electromagnetic activity, where natural and artificial sources of interference are prevalent.

The Solution: To enhance signal integrity, buyers should implement specialized RF interference filters designed for communication systems. It is essential to choose filters that can handle the specific frequencies relevant to the communication protocols in use. For instance, narrowband filters can be particularly effective in suppressing unwanted signals while allowing desired frequencies to pass through. Additionally, ensure that installation practices are optimized; filters should be placed as close to the source of interference as possible, and proper grounding techniques should be employed to minimize noise. Collaborating with manufacturers who offer customization options can also help in creating solutions tailored to unique communication challenges, ultimately leading to improved system performance and reliability.

Strategic Material Selection Guide for rf interference filter

What Materials Are Commonly Used for RF Interference Filters?

When selecting materials for RF interference filters, it is essential to consider properties that directly impact performance, durability, and suitability for various applications. Below, we analyze four common materials used in RF interference filters, highlighting their key properties, advantages, disadvantages, and considerations for international buyers.

1. Ferrite

Key Properties: Ferrite materials exhibit high magnetic permeability and low electrical conductivity, making them excellent for filtering high-frequency signals. They can operate effectively at temperatures up to 200°C and are generally resistant to corrosion.

Pros & Cons: Ferrite filters are durable and can handle high temperatures, making them suitable for industrial applications. However, they can be relatively expensive and may require complex manufacturing processes, particularly when precision is necessary for high-performance applications.

Impact on Application: Ferrite materials are ideal for applications involving high-frequency RF signals, such as telecommunications and industrial electronics. Their magnetic properties help suppress unwanted signals effectively.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and JIS. The availability of ferrite materials can vary, so sourcing from reputable suppliers is crucial.

2. Metal

Key Properties: Metals such as copper and aluminum are commonly used in RF filters due to their excellent conductivity and durability. They can withstand high temperatures and pressures, with copper having a melting point of 1,984°F (1,085°C).

Pros & Cons: Metal filters are highly effective at blocking unwanted RF signals and are generally less expensive than ferrite options. However, they can be prone to corrosion if not properly treated, and their weight can be a disadvantage in portable applications.

Impact on Application: Metal filters are widely used in consumer electronics and industrial equipment where space and weight are less of a concern. Their conductivity makes them suitable for applications requiring rapid signal processing.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the need for corrosion-resistant coatings, especially in humid environments. Compliance with relevant standards is essential to ensure product reliability.

3. Ceramic

Key Properties: Ceramic materials are known for their excellent thermal stability and electrical insulation properties. They can operate effectively in high-temperature environments, often exceeding 1,000°F (538°C).

Pros & Cons: Ceramics are highly durable and resistant to wear and tear, making them suitable for long-term applications. However, they can be brittle, which may complicate manufacturing and handling processes.

Impact on Application: Ceramic filters are particularly useful in high-frequency applications, such as RF amplifiers and oscillators, where stability and precision are critical.

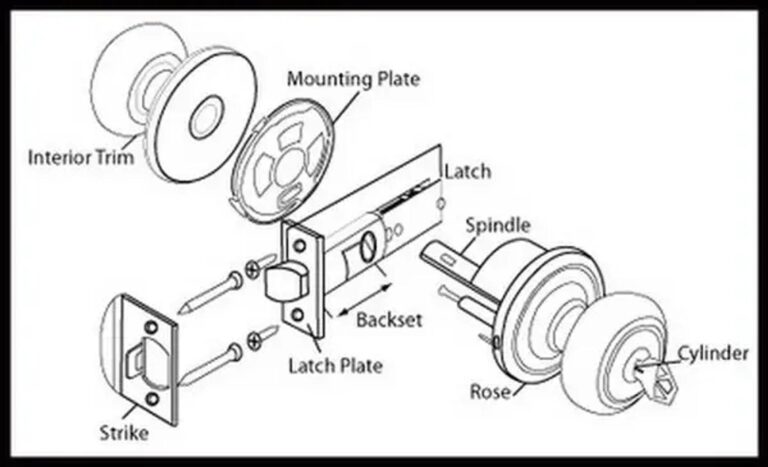

Illustrative image related to rf interference filter

Considerations for International Buyers: For buyers in emerging markets like Nigeria and Vietnam, sourcing high-quality ceramic materials may be challenging. Ensuring compliance with international quality standards can help mitigate risks associated with material defects.

4. Polymer

Key Properties: Polymers can be engineered to provide specific electrical properties, including dielectric strength and flexibility. They typically operate effectively at lower temperatures compared to metals and ceramics.

Pros & Cons: Polymer filters are lightweight and can be produced at a lower cost, making them attractive for mass production. However, they may not offer the same level of performance in high-frequency applications as metals or ceramics.

Illustrative image related to rf interference filter

Impact on Application: Polymers are often used in consumer electronics and portable devices where weight is a critical factor. They can effectively filter out lower frequency signals but may struggle with higher frequency interference.

Considerations for International Buyers: Buyers should consider the environmental impact of polymer materials, especially in regions with strict regulations on plastic use. Understanding local compliance requirements is crucial for successful market entry.

Summary Table of Material Selection for RF Interference Filters

| Material | Typical Use Case for RF Interference Filter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ferrite | Telecommunications, industrial electronics | High magnetic permeability | Expensive, complex manufacturing | High |

| Metal | Consumer electronics, industrial equipment | Excellent conductivity | Corrosion-prone, heavier | Medium |

| Ceramic | RF amplifiers, oscillators | High thermal stability | Brittle, complex handling | Medium |

| Polymer | Portable devices, consumer electronics | Lightweight, low cost | Limited high-frequency performance | Low |

This guide provides a comprehensive overview of material options for RF interference filters, helping international B2B buyers make informed decisions based on application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rf interference filter

What Are the Key Stages in the Manufacturing Process of RF Interference Filters?

The manufacturing of RF interference filters involves several critical stages, each designed to ensure that the final product meets stringent performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

How Are Materials Prepared for RF Interference Filters?

The first step in the manufacturing process is material preparation, which involves selecting the appropriate materials based on the filter’s specifications. Common materials used include ferrite cores, capacitors, resistors, and inductors. The choice of materials is crucial, as they must possess high electrical conductivity and low electromagnetic interference characteristics.

During this stage, raw materials are inspected for defects and compliance with required specifications. Quality assurance checks are performed to ensure that the materials meet international standards, such as ISO 9001. This initial scrutiny helps prevent defects in later stages of production.

What Techniques Are Used in Forming RF Interference Filters?

Once materials are prepared, the next step is forming. This stage typically involves processes such as winding, molding, or stamping, depending on the type of filter being produced. For example, in the case of ferrite filters, coils are wound around ferrite cores to create inductors.

Advanced techniques such as automated winding machines may be used to enhance precision and efficiency. Additionally, processes like laser cutting can be employed for high-precision components, ensuring that the dimensions are consistent with design specifications. Each of these techniques contributes to the overall performance of the RF filter.

How Is the Assembly Process Conducted for RF Interference Filters?

After forming, the assembly stage begins, where all components are brought together to create the final product. This typically involves soldering components onto a printed circuit board (PCB) or integrating them into a housing. The assembly process must adhere to strict guidelines to maintain the integrity of the filter.

Automated assembly lines are often used to enhance efficiency and reduce the risk of human error. However, manual assembly may still play a role in more complex filters, where skilled technicians ensure that each component is placed correctly. Throughout this stage, inline quality checks are conducted to catch any assembly defects early.

What Finishing Techniques Are Applied to RF Interference Filters?

The finishing stage encompasses processes that enhance the durability and performance of the RF interference filter. This may include applying protective coatings, such as epoxy or silicone, to shield the components from environmental factors like moisture and dust.

Additionally, finishing may involve testing the filter’s performance under various conditions to ensure it meets specified standards. This is crucial, as the performance of RF interference filters can significantly impact the overall reliability of electronic systems in which they are used.

What Quality Control Measures Are Essential in RF Interference Filter Manufacturing?

Quality control (QC) is a pivotal part of the manufacturing process, ensuring that RF interference filters meet the required performance and safety standards. Various international and industry-specific standards guide these QC measures.

Which International Standards Are Relevant for RF Interference Filters?

One of the most recognized international standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established effective processes for ensuring consistent product quality.

Additionally, depending on the application of the RF filters, other standards may apply. For instance, CE marking is crucial for products sold within the European Union, indicating compliance with safety and health regulations. For products used in the oil and gas industry, adherence to API standards may be necessary.

Illustrative image related to rf interference filter

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, inline inspections are conducted to catch defects early. This includes monitoring the forming and assembly stages.

-

Final Quality Control (FQC): Once the filters are assembled, they undergo comprehensive testing to verify their performance against required specifications. This may include electrical testing, environmental testing, and reliability testing.

What Common Testing Methods Are Used for RF Interference Filters?

Testing methods are crucial for validating the performance and reliability of RF interference filters. Common tests include:

- Impedance Testing: Measures the filter’s impedance across its operating frequency range to ensure it meets design specifications.

- Insertion Loss Testing: Assesses how much signal is lost when passing through the filter, which is vital for maintaining signal integrity.

- Temperature and Humidity Testing: Evaluates the filter’s performance under varying environmental conditions to ensure reliability in real-world applications.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies to ensure compliance with quality standards:

What Auditing Processes Should Buyers Consider?

Buyers can conduct audits of potential suppliers to evaluate their manufacturing processes and quality assurance measures. This may involve reviewing their compliance with international standards like ISO 9001 and any industry-specific certifications.

Illustrative image related to rf interference filter

How Important Are Quality Assurance Reports?

Requesting quality assurance reports from suppliers can provide insights into their QC processes. These reports should detail the results of various tests conducted on the products, including any corrective actions taken in response to identified defects.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further enhance the verification process. Independent inspectors can conduct audits and tests, providing an unbiased assessment of the supplier’s quality control measures. This is particularly valuable for international buyers who may face challenges in assessing suppliers firsthand.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of additional nuances related to quality control. These may include understanding local regulations that affect product quality and compliance in different regions. For example, products exported to the European Union must meet CE marking requirements, while those destined for the Middle East may need to comply with Gulf Standards.

Understanding these regional differences can help buyers make informed decisions and ensure that the RF interference filters they procure meet the necessary quality and performance standards for their specific applications.

Illustrative image related to rf interference filter

In conclusion, the manufacturing processes and quality assurance measures for RF interference filters are intricate and vital for ensuring reliability in electronic applications. By understanding these processes and implementing robust verification methods, international B2B buyers can secure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rf interference filter’

Introduction

This guide provides a practical checklist for B2B buyers looking to procure RF interference filters. These filters are essential in mitigating radio frequency interference (RFI) that can disrupt electronic operations. A well-structured sourcing process ensures you select the right filter for your specific needs, enhancing equipment reliability and performance.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first crucial step in sourcing RF interference filters. Consider the frequency range (typically between 3 kHz and 300 GHz) and the type of RFI you need to address—conducted or radiated. This foundational knowledge will guide your subsequent choices and help you communicate effectively with potential suppliers.

Illustrative image related to rf interference filter

Step 2: Research Market Options

Conduct thorough market research to identify available RF interference filter types that meet your specifications. Familiarize yourself with different filter designs, such as low-pass, high-pass, and band-pass filters, to understand which best suits your application. Utilize industry reports, supplier catalogs, and online forums to gather insights on the latest technologies and market trends.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers meticulously. Review company profiles, request case studies, and seek references from buyers in similar industries or regions. Look for suppliers with a proven track record in manufacturing high-quality filters and those who understand the specific challenges of your sector.

Step 4: Verify Compliance and Certifications

Ensure that the RF interference filters comply with relevant industry standards and certifications. This may include ISO certifications, CE marking, or RoHS compliance, depending on your geographical region and industry regulations. Compliance not only assures quality but also reduces the risk of regulatory issues in your operations.

Step 5: Request Samples for Testing

Before placing a large order, request samples of the filters you are considering. Testing samples in your specific operational environment is critical to assess their effectiveness in reducing RFI. This hands-on evaluation allows you to determine if the filters meet your performance expectations and compatibility with existing systems.

Step 6: Assess Pricing and Terms of Sale

Once you have shortlisted potential suppliers, compare their pricing structures and terms of sale. Look beyond the initial cost; consider factors such as shipping fees, payment terms, and warranty conditions. A supplier offering better terms can significantly impact your total cost of ownership, making it crucial to evaluate the overall value proposition.

Step 7: Establish Ongoing Support and Communication

Finally, ensure that your chosen supplier offers robust customer support and open communication channels. This is vital for addressing any issues that may arise post-purchase, such as installation assistance or troubleshooting. A supplier committed to customer service will enhance your experience and foster a long-term partnership beneficial for both parties.

By following this checklist, B2B buyers can navigate the complexities of sourcing RF interference filters effectively, ensuring they select products that meet their operational needs and enhance equipment performance.

Comprehensive Cost and Pricing Analysis for rf interference filter Sourcing

What Are the Key Cost Components in RF Interference Filter Sourcing?

When considering the sourcing of RF interference filters, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

Illustrative image related to rf interference filter

-

Materials: The choice of materials significantly impacts the overall cost. High-grade components such as capacitors, inductors, and specialized shielding materials can elevate expenses but enhance performance and durability. Buyers should evaluate the trade-off between cost and quality to ensure they are investing in filters that meet their operational needs.

-

Labor: Labor costs encompass the workforce involved in the design, assembly, and testing of filters. Skilled labor is often required to ensure precise manufacturing processes. Companies with advanced automation might experience lower labor costs, which can be a competitive advantage in pricing.

-

Manufacturing Overhead: This includes expenses related to the facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help minimize overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tooling may be necessary for specific filter designs or configurations. This one-time investment can add to initial costs but should be considered as part of the total cost of ownership, especially for custom orders.

-

Quality Control (QC): Implementing rigorous QC measures ensures that filters meet industry standards and specifications. While this may increase costs, it is vital for long-term reliability and compliance, particularly in regulated industries.

-

Logistics: Shipping and handling costs can vary widely based on the origin and destination of the filters. International buyers should account for import duties, taxes, and shipping fees, which can significantly affect the total cost.

-

Margin: Supplier margins can vary based on market conditions, competition, and the perceived value of the product. Understanding these factors can aid in negotiation strategies.

What Influences Pricing for RF Interference Filters?

Several factors influence the pricing of RF interference filters, making it essential for buyers to be informed and strategic.

-

Volume/MOQ: Minimum order quantities (MOQ) can affect unit pricing. Larger orders often attract discounts, while smaller orders may incur higher per-unit costs. Buyers should consider their projected needs to optimize purchasing.

-

Specifications and Customization: Custom filters designed to meet specific performance requirements generally cost more than off-the-shelf options. Buyers should balance customization needs with budget constraints.

-

Materials and Quality Certifications: Filters made from premium materials and those with quality certifications (such as ISO or RoHS compliance) will typically command higher prices. Buyers should assess the importance of these certifications for their application.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The terms of trade can significantly impact total costs. Buyers should be aware of responsibilities for shipping, insurance, and tariffs, as these can alter the effective price of the filters.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, navigating the complexities of sourcing RF interference filters can be challenging. Here are some actionable tips:

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and operational costs over the filter’s lifespan. A lower initial price may not always be the most cost-effective choice.

-

Leverage Volume Discounts: If your business anticipates future needs, negotiate bulk purchase agreements. This can lead to significant savings and foster a long-term partnership with suppliers.

-

Do Your Research: Gather market intelligence on supplier pricing, lead times, and quality benchmarks. This knowledge can empower you during negotiations and help you identify the best value.

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms and pricing flexibility. Consider long-term partnerships that benefit both parties rather than focusing solely on transactional relationships.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, tariffs, and economic factors. Understanding these nuances can help you make informed decisions.

Conclusion

Sourcing RF interference filters involves a multifaceted cost structure and a range of pricing influencers. By understanding these elements and employing strategic negotiation techniques, international B2B buyers can optimize their purchasing decisions, ensuring they secure high-quality filters at competitive prices. Always remember to consider the total cost of ownership to make well-informed investments.

Illustrative image related to rf interference filter

Alternatives Analysis: Comparing rf interference filter With Other Solutions

Exploring Alternatives to RF Interference Filters

When dealing with radio frequency interference (RFI), businesses often seek reliable solutions to ensure optimal performance of their electronic devices. While RF interference filters are a popular choice, it’s essential to explore alternative methods that can also mitigate RFI. This analysis compares RF interference filters with two viable alternatives: Shielding and Active Noise Cancellation (ANC). Understanding the strengths and weaknesses of each can help B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Rf Interference Filter | Shielding | Active Noise Cancellation (ANC) |

|---|---|---|---|

| Performance | High effectiveness in reducing conducted RFI | Effective for radiated RFI, but less for conducted | Good for specific environments, but variable effectiveness |

| Cost | Moderate to high initial investment | Varies widely based on materials | Generally high due to technology and implementation costs |

| Ease of Implementation | Requires integration into existing systems | Can be complex depending on design | Requires specialized knowledge for installation |

| Maintenance | Low maintenance once installed | Low, but may require checks for integrity | Moderate, requires regular calibration |

| Best Use Case | Industrial applications with high levels of conducted RFI | Environments with high radiated RFI exposure | Audio or communication devices where noise interference is prevalent |

What Are the Benefits and Drawbacks of Shielding?

Shielding involves enclosing sensitive electronic equipment within conductive materials that block radiated RFI. This method is particularly effective in environments where devices are exposed to high levels of electromagnetic interference from external sources, such as industrial settings or urban areas with dense electronic activity.

Pros:

– Provides a robust barrier against external RFI.

– Can be tailored to specific frequencies and environments.

– Low maintenance once properly installed.

Cons:

– Effectiveness may diminish if the shielding design is compromised or if there are gaps.

– Installation can be complex, requiring precise engineering and knowledge of electromagnetic principles.

Illustrative image related to rf interference filter

How Does Active Noise Cancellation Work and What Are Its Limitations?

Active Noise Cancellation (ANC) technology uses microphones and speakers to identify and counteract unwanted noise. While typically associated with audio devices, ANC can also be applied in electronic systems to reduce RFI, particularly in communication devices.

Pros:

– Can adapt to changing noise environments in real-time.

– Effective in reducing specific frequencies of interference.

Cons:

– Generally more expensive than passive solutions due to the technology involved.

– Requires regular calibration and maintenance to ensure optimal performance.

– May not be as effective in high interference environments compared to passive methods like filtering and shielding.

How Should B2B Buyers Choose the Right Solution for RFI Mitigation?

Selecting the appropriate solution for RFI mitigation requires a careful assessment of operational requirements, budget constraints, and the specific nature of the interference. RF interference filters are ideal for environments where conducted RFI is prevalent and require integration into existing systems. Shielding is more suited for scenarios where radiated RFI is a significant concern, providing a robust physical barrier against external noise. Meanwhile, ANC is best for applications that demand high audio fidelity and are sensitive to noise interference, albeit at a higher cost.

Ultimately, understanding the unique challenges of your environment and the specific types of RFI you face will guide you in selecting the most effective solution, ensuring the longevity and reliability of your electronic operations.

Essential Technical Properties and Trade Terminology for rf interference filter

What Are the Key Technical Properties of RF Interference Filters?

When selecting RF interference filters, understanding the technical properties is crucial for ensuring optimal performance in various applications. Here are some essential specifications to consider:

1. Material Grade

The material used in the construction of RF filters significantly influences their performance and durability. Common materials include ceramics, ferrites, and various metals. Each material has specific dielectric properties that determine the filter’s effectiveness at certain frequencies. Choosing the right material grade ensures that the filter can withstand environmental factors and electromagnetic interference, thus prolonging the lifespan of your electronic devices.

2. Cut-off Frequency

The cut-off frequency is a critical specification indicating the frequency at which the filter begins to significantly attenuate the signal. It defines the operational range of the filter and is vital for ensuring that unwanted frequencies are effectively blocked while allowing desired signals to pass through. For B2B buyers, selecting a filter with the appropriate cut-off frequency is essential to meet the specific needs of their applications.

3. Insertion Loss

Insertion loss refers to the reduction in signal power resulting from the filter being inserted into a transmission line. This property is typically measured in decibels (dB) and is crucial for assessing the efficiency of the filter. Lower insertion loss indicates better performance, which is particularly important in high-frequency applications where signal integrity is paramount. Understanding insertion loss helps businesses maintain the quality of their operations and minimize signal degradation.

4. Impedance

Impedance is a measure of how much a filter resists the flow of alternating current at a given frequency. It is essential that the impedance of the filter matches that of the system in which it is installed to prevent reflections that can cause further interference. For B2B buyers, ensuring impedance compatibility is vital for optimizing the performance of their electronic systems.

5. Tolerance

Tolerance indicates the allowable deviation from the specified value of a filter’s properties, such as cut-off frequency or insertion loss. It is typically expressed as a percentage. A tighter tolerance means higher precision in the filter’s performance, which is critical in applications requiring strict adherence to operational specifications. Businesses should consider the tolerance levels based on their operational requirements to ensure reliability.

Illustrative image related to rf interference filter

What Are the Common Trade Terms in RF Interference Filters?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in B2B transactions. Here are some common terms related to RF interference filters:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of RF interference filters, buyers often work with OEMs to ensure that filters are designed to integrate seamlessly with their existing equipment. Understanding OEM relationships can help buyers secure the best products tailored to their needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers as it affects inventory management and cost efficiency. Understanding MOQ can help businesses negotiate better terms and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is essential for B2B buyers to evaluate multiple suppliers and ensure they receive competitive pricing for RF interference filters.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Understanding these terms is crucial for B2B transactions, as they affect shipping costs, risk management, and delivery timelines.

5. EMI (Electromagnetic Interference)

EMI is a term that encompasses all forms of interference that can disrupt the performance of electronic devices. Knowing about EMI and its relationship with RF interference filters helps buyers understand the importance of selecting the right filters to mitigate these risks.

By grasping these essential technical properties and trade terminology, international B2B buyers can make informed decisions when sourcing RF interference filters, ensuring they choose the right solutions for their applications.

Navigating Market Dynamics and Sourcing Trends in the rf interference filter Sector

What Are the Key Trends Shaping the RF Interference Filter Market?

The global RF interference filter market is experiencing dynamic growth, driven by the increasing demand for reliable electronic systems across various sectors, including telecommunications, automotive, and industrial applications. As electronic devices proliferate, so does the challenge of managing radio frequency interference (RFI), leading to heightened investment in effective filtering solutions. Emerging technologies such as 5G networks and the Internet of Things (IoT) are significant contributors to this trend, as they require advanced filtering capabilities to maintain signal integrity and device performance.

International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that offer advanced filtering solutions tailored to local market needs. For instance, the demand for customized RF filters that can withstand harsh environmental conditions is rising, particularly in industries like oil and gas in the Middle East and mining in South America. Moreover, the trend towards miniaturization in electronics is pushing manufacturers to develop compact, efficient filters that can fit within smaller devices without compromising performance.

Additionally, the focus on digital transformation in various industries is driving the adoption of smart filters equipped with real-time monitoring capabilities. This aligns with the growing emphasis on predictive maintenance, allowing businesses to proactively address RFI issues before they escalate, thereby reducing downtime and maintenance costs.

How Can Sustainability and Ethical Sourcing Impact RF Interference Filter Procurement?

Sustainability is becoming a central pillar in the procurement strategies of B2B buyers, including those in the RF interference filter sector. Environmental concerns related to electronic waste and resource depletion necessitate a shift towards more sustainable manufacturing practices. Buyers are increasingly looking for suppliers who prioritize eco-friendly materials and processes, such as those using recyclable components or reducing hazardous substances in their filters.

The importance of ethical supply chains cannot be overstated, particularly for international buyers who must navigate diverse regulatory landscapes. Sourcing from suppliers that adhere to strict environmental and ethical standards not only mitigates risks associated with compliance but also enhances brand reputation. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential criteria for supplier selection.

Moreover, the growing consumer demand for ‘green’ products is influencing the RF interference filter market. Companies that can demonstrate their commitment to sustainability through transparent sourcing and manufacturing processes are likely to gain a competitive advantage. By investing in suppliers with established green certifications and sustainable practices, businesses can enhance their market position while contributing to broader environmental goals.

What Is the Historical Context of RF Interference Filters in the B2B Market?

The evolution of RF interference filters dates back to the early days of radio communication, where the need to mitigate electromagnetic interference became apparent. Initially, basic filtering solutions were employed to address the disruptive effects of radio waves on communication devices. As technology advanced, particularly with the advent of digital electronics in the late 20th century, the demand for more sophisticated filtering solutions emerged.

In the 1990s and 2000s, the proliferation of consumer electronics and telecommunications devices led to significant advancements in filter technology, resulting in the development of specialized filters designed to handle a wider range of frequencies and interference types. This period saw the emergence of digital signal processing techniques that enhanced the performance of RF filters, allowing for better noise reduction and signal clarity.

Today, RF interference filters are integral components in various applications, from consumer gadgets to critical industrial systems. The ongoing advancements in materials science and engineering continue to shape the market, ensuring that RF filters can meet the demands of increasingly complex electronic environments. This historical context underscores the importance of innovation in the RF interference filter sector, positioning it as a vital area for investment and development in the B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of rf interference filter

-

How do I solve radio frequency interference in my equipment?

To effectively address radio frequency interference (RFI) in your equipment, consider implementing RFI filters that can reduce or eliminate unwanted signals. Start by identifying the sources of RFI, which may include external electromagnetic fields or internal circuit issues. Use a combination of shielding and filtering techniques to minimize the effects. Additionally, ensure that your equipment enclosures are well-designed to contain RFI emissions. Regular maintenance and testing can also help you identify and rectify potential RFI problems before they escalate. -

What is the best RF interference filter for industrial applications?

The best RF interference filter for industrial applications typically depends on the specific frequencies and levels of interference you are dealing with. For robust environments, consider filters that offer both conducted and radiated RFI suppression. Look for filters with high attenuation rates and those that meet relevant industry standards. Additionally, consider the filter’s size, ease of installation, and compatibility with your existing equipment. Consulting with a supplier who specializes in RFI solutions can help you choose the most effective filter for your needs. -

What factors should I consider when sourcing RF interference filters internationally?

When sourcing RF interference filters internationally, consider factors such as the supplier’s reputation, product certifications, and compliance with international standards. It’s essential to evaluate the supplier’s experience in your specific industry and their ability to provide customized solutions. Additionally, assess logistics capabilities, including shipping times and costs, as well as after-sales support and warranty terms. Understanding the local regulations in your region regarding imported electronic components is also crucial to ensure compliance and smooth operations. -

What are the typical minimum order quantities (MOQ) for RF interference filters?

Minimum order quantities (MOQ) for RF interference filters can vary significantly depending on the manufacturer and the complexity of the filters. Generally, MOQs can range from a few pieces for standard filters to several hundred for custom solutions. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your operational requirements. Some manufacturers may offer flexibility in MOQs for first-time orders or bulk purchases, so it’s worth inquiring about these options. -

How can I ensure the quality of RF interference filters from international suppliers?

To ensure the quality of RF interference filters from international suppliers, request detailed product specifications and certifications. Look for filters that comply with industry standards such as IEC or MIL-STD. Consider asking for samples before placing a bulk order, allowing you to test the filters in your equipment. Establishing a clear quality assurance process, including regular audits and performance reviews, will help maintain standards. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What payment terms are commonly offered by suppliers of RF interference filters?

Payment terms offered by suppliers of RF interference filters can vary widely but typically include options such as upfront payment, net 30, or net 60 days. Some suppliers may offer discounts for early payments or bulk orders. It’s crucial to negotiate terms that suit your cash flow and budget. Additionally, consider using secure payment methods, such as letters of credit or escrow services, especially for large international transactions, to mitigate risks associated with overseas purchases. -

What logistics considerations should I keep in mind when importing RF interference filters?

When importing RF interference filters, logistics considerations include shipping methods, customs duties, and lead times. Determine whether air freight or sea freight is more cost-effective based on your urgency and budget. Understand the customs regulations in your country to ensure smooth clearance, including tariffs and documentation requirements. Establishing a reliable logistics partner can help streamline the import process, ensuring timely delivery and minimizing disruptions in your supply chain. -

How can I customize RF interference filters to meet my specific needs?

Customizing RF interference filters typically involves collaborating with your supplier to define specific requirements such as frequency ranges, attenuation levels, and physical dimensions. Many manufacturers offer design services that can help you develop filters tailored to your operational environment. Providing detailed specifications and testing requirements will ensure that the final product meets your performance criteria. Be prepared for a potential lead time increase for custom solutions, as they may require additional engineering and testing phases.

Top 5 Rf Interference Filter Manufacturers & Suppliers List

1. Rugged Radios – Clamp On RF Noise Reducing Filter Choke Clip

Domain: ruggedradios.com

Registered: 2006 (19 years)

Introduction: {‘product_name’: ‘Clamp On RF Noise Reducing Filter Choke Clip’, ‘sku’: ‘AUDIO-CHOKE-3MM’, ‘regular_price’: ‘$4.25’, ‘sale_price’: ‘$4.25’, ‘sizes_available’: [‘Small (3mm and Under)’, ‘Large (Up to 5mm)’], ‘description’: ‘Eliminate audible interference caused by high frequency radio waves (RFI) by using this ferrite radio frequency noise reducer. Compatible with most cables.’, ‘usage_instructions…

2. CRFS – RF Interference Filters

Domain: crfs.com

Registered: 1999 (26 years)

Introduction: An RF interference (RFI) filter is an electronic device designed to block or attenuate unwanted signals or noise in the RF spectrum while permitting the desired signal. It utilizes various filter technologies, including low-pass, high-pass, band-pass, and band-stop filters. Additionally, RF interference filters protect sensitive equipment from damage caused by high levels of RF energy.

3. Curtis Industries – EMI/RFI Filters

Domain: curtisind.com

Registered: 1998 (27 years)

Introduction: EMI Filters/RFI Filters include Single Phase Power Line Filters, General Purpose High Performance/Switching Single Phase Filters, Wide Band Power Entry Modules, Filtered Combination Modules, Medical Power Line Filters, Medical Filtered Combination Modules, Medical EMI Filter Combination Modules, Medical Grade Filter, DC Power Line Filters, Three Phase Power Line Filters, and Tri-Mag Power Supplies…

4. Focal – Shape 65 Studio Monitors

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Focal Shape 65 studio monitors, balanced cables (TRS to XLR), PYLE PRO PHE400 ground loop isolator, ART PDS8U power conditioner.

5. RadioShack – RF Interference Filter #9437239

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”RadioShack RF Interference Filter # 9437239″,”Brand”:”RadioShack”,”MPN”:”1500025″,”GTIN”:”0040293026387″,”UPC”:”0040293026387″,”Price”:”$44.99″,”Shipping”:”Free shipping”,”Estimated Delivery”:”Mon, Sep 22 – Sat, Sep 27″,”Returns”:”No returns, but backed by eBay Money back guarantee”,”Condition”:”New”,”Specifications”:{“Type”:”Filter”,”Impedance”:”75-Ohm”,”Frequency Range”:”54-900M…

Strategic Sourcing Conclusion and Outlook for rf interference filter

In navigating the complex landscape of radio frequency interference (RFI), strategic sourcing of RF interference filters is essential for businesses across diverse industries. By understanding the nuances of RFI, including its sources and impact, international B2B buyers can make informed decisions that enhance equipment reliability and operational efficiency. Filters serve as a critical line of defense, mitigating the risks posed by both conducted and radiated RFI, ultimately safeguarding investments and reducing costly downtime.

Moreover, the proactive approach to sourcing high-quality RF interference filters can yield substantial long-term benefits. As industries in Africa, South America, the Middle East, and Europe increasingly rely on sophisticated electronic systems, the demand for effective RFI solutions will only grow. Buyers should prioritize partnerships with reputable suppliers who offer robust filtering technologies tailored to their specific operational needs.

Looking ahead, the importance of integrating advanced RF interference filters into your sourcing strategy cannot be overstated. Embrace this opportunity to enhance your operational resilience and maintain a competitive edge in the market. Engage with industry experts, explore innovative solutions, and make strategic choices that will position your business for future success in an increasingly interconnected world.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.