Quartz Glasses: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for quartz glasses

Navigating the global market for quartz glasses can be a daunting task for international B2B buyers, particularly when it comes to sourcing high-quality protective eyewear that meets specific industrial standards. With a diverse range of products available, including split lens designs and specialized UV and IR protection, understanding the nuances of quartz glasses is essential for making informed purchasing decisions. This guide offers a comprehensive overview of the types of quartz glasses, their applications in various industries, and essential criteria for vetting suppliers.

By delving into factors such as cost analysis, shipping logistics, and product specifications, this resource equips buyers from regions like Africa, South America, the Middle East, and Europe—such as Nigeria and Vietnam—with the knowledge needed to navigate supplier negotiations effectively. Whether you are seeking quartz glasses for glassworking, medical applications, or industrial use, this guide serves as a valuable tool to streamline your sourcing process. Empowering you with actionable insights, we aim to help you choose the right products that not only enhance safety but also align with your operational needs. With this knowledge, you can confidently approach suppliers and secure the best solutions for your business.

Understanding quartz glasses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Quartz Split Lens | Clear top section with shaded lower section | Glassworking, welding, industrial applications | Pros: Versatile protection, enhanced visibility; Cons: May not fit all face shapes. |

| Quartz Green IR Lenses | IR protection with various shading options | Metal fabrication, glass manufacturing | Pros: UV and IR protection; Cons: Limited sodium flare absorption. |

| BorotruView 6.0 | Filters sodium flare, IR 6.0 green protection | Precision quartz work, detailed tasks | Pros: Clear visibility, high protection; Cons: Higher price point. |

| BorotruView 8.0 | Darker shade for enhanced UV and IR protection | High-intensity quartz environments | Pros: Maximum safety, excellent visibility; Cons: May be too dark for low-light tasks. |

| Fine Line Quartz Drinkware | Elegant design with a white rim | Hospitality, events, upscale dining | Pros: Stylish presentation, dishwasher safe; Cons: Not suitable for industrial use. |

What are the Key Characteristics of Quartz Split Lens Glasses?

Quartz Split Lens glasses are designed for professionals who require both visibility and protection during quartz working tasks. The unique split lens design allows for a clear upper section that aids in visibility while the shaded lower section protects against bright light and harmful rays. These glasses are ideal for glassworking and welding applications, providing versatile protection. Buyers should consider the fit and comfort level, as these glasses may not suit all face shapes.

How Do Quartz Green IR Lenses Benefit B2B Users?

Quartz Green IR Lenses offer essential infrared protection while providing various shading options to cater to different working environments. These glasses are particularly suited for metal fabrication and glass manufacturing, where UV and IR exposure is a concern. Businesses should evaluate the specific needs of their operations, as these lenses lack sodium flare absorption, which may be critical in certain applications.

Why Choose BorotruView 6.0 Glasses for Detailed Work?

The BorotruView 6.0 glasses are engineered for precision quartz work, effectively filtering sodium flare while providing IR 6.0 protection. These glasses are perfect for tasks requiring accuracy and clarity, making them a valuable asset in detailed quartz operations. Buyers should be prepared for a higher investment, as the advanced technology ensures superior visibility and protection compared to standard options.

What Makes BorotruView 8.0 Glasses Ideal for High-Intensity Environments?

BorotruView 8.0 glasses are designed for environments where maximum UV and IR protection is crucial. The darker shade ensures safety in high-intensity quartz working scenarios while still filtering sodium flare for optimal visibility. Companies operating in such conditions should prioritize these glasses despite their higher cost, as they offer unparalleled safety and performance.

Why Invest in Fine Line Quartz Drinkware for Hospitality?

Fine Line Quartz drinkware combines elegance with functionality, making it an excellent choice for hospitality and event settings. The subtle white rim adds a touch of sophistication, while the dishwasher-safe feature ensures easy maintenance. Businesses in the hospitality sector should consider this stylish option for upscale dining experiences, although it may not be suitable for industrial applications.

Key Industrial Applications of quartz glasses

| Industry/Sector | Specific Application of quartz glasses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Glassworking | Protective eyewear for glassblowing and glass shaping | Enhances worker safety and productivity | Durability, UV/IR protection, comfort, and fit |

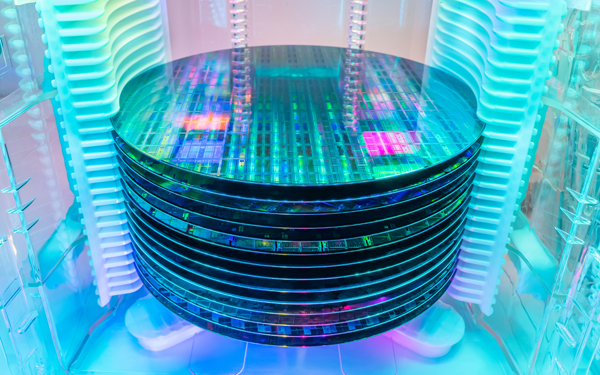

| Semiconductor Manufacturing | Quartz glass substrates for photolithography | Ensures precision in microchip production | High purity, thermal stability, and compatibility |

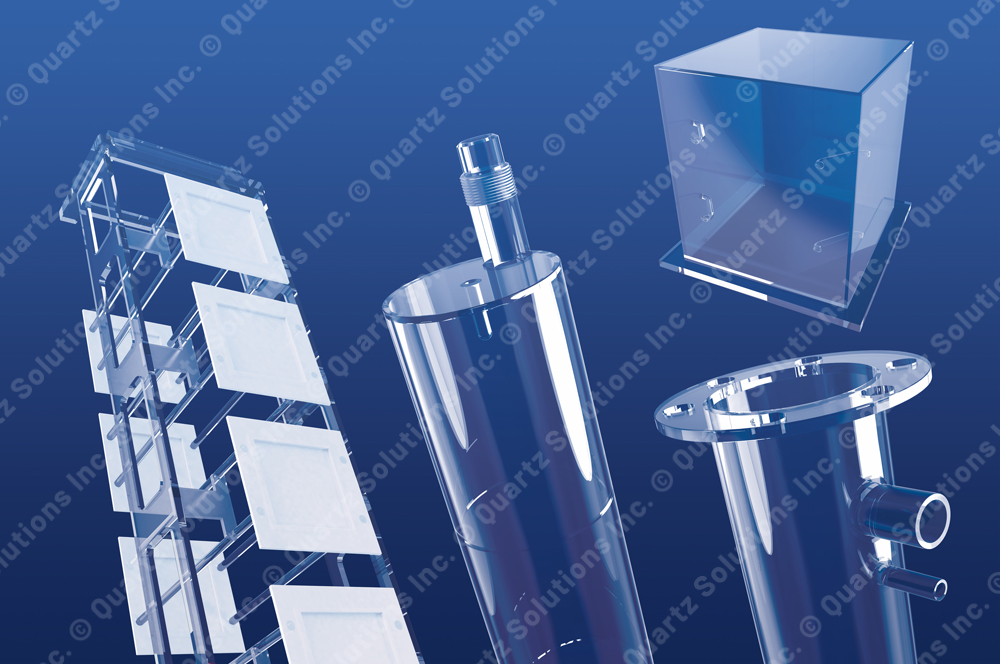

| Laboratory and Research | Optical components and lab equipment | Provides clarity and chemical resistance | Customization options, optical properties, and sourcing reliability |

| Solar Energy | Components in solar panels (e.g., covers and lenses) | Improves efficiency of solar energy conversion | UV resistance, thermal stability, and long-term durability |

| Medical Devices | Components in diagnostic and therapeutic devices | Enhances performance and reliability in medical applications | Compliance with medical standards, biocompatibility, and optical clarity |

How Are Quartz Glasses Used in Glassworking Applications?

In the glassworking industry, quartz glasses are primarily utilized as protective eyewear for professionals engaged in glassblowing and shaping. These glasses are designed to provide superior protection against harmful UV and infrared radiation, as well as thermal stress from high-temperature environments. For international buyers, particularly in regions like Africa and South America, sourcing high-quality quartz glasses can enhance worker safety and productivity, ensuring compliance with local safety regulations. Buyers should prioritize durability, comfort, and a proper fit when selecting protective eyewear for glassworking applications.

What Role Do Quartz Glasses Play in Semiconductor Manufacturing?

Quartz glasses serve a critical role in semiconductor manufacturing, particularly as substrates for photolithography processes. The high purity and thermal stability of quartz glasses are essential for producing microchips with precise specifications. Businesses in the semiconductor sector, especially in Europe and the Middle East, must ensure that their quartz glass suppliers can deliver products that meet stringent quality standards. Key considerations include sourcing from reputable manufacturers with a track record of providing high-purity materials that can withstand the rigorous conditions of semiconductor fabrication.

How Are Quartz Glasses Utilized in Laboratory and Research Settings?

In laboratory and research environments, quartz glasses are used for various applications, including optical components and lab equipment like cuvettes and reaction vessels. Their chemical resistance and optical clarity make them ideal for experiments that require precise measurements and reactions. For B2B buyers in Africa and Europe, it’s crucial to identify suppliers that offer customizable options to meet specific laboratory needs. Additionally, sourcing reliability and the ability to provide products that comply with relevant standards can significantly impact operational efficiency in research settings.

Why Are Quartz Glasses Important in Solar Energy Applications?

Quartz glasses are integral to the solar energy sector, particularly in the manufacturing of solar panels where they are used as protective covers and lenses. Their ability to withstand UV radiation and thermal stress enhances the efficiency of solar energy conversion. Businesses in regions like the Middle East, where solar energy is a growing market, should focus on sourcing high-quality quartz glasses that offer long-term durability and performance. Key factors to consider include the glasses’ UV resistance, thermal stability, and overall lifespan to ensure optimal energy generation.

How Are Quartz Glasses Used in Medical Devices?

In the medical device industry, quartz glasses are utilized in diagnostic and therapeutic applications, including optical components in imaging systems and laser equipment. The clarity and biocompatibility of quartz glasses enhance the performance and reliability of medical devices. For international buyers, particularly in Africa and South America, ensuring compliance with medical standards is paramount when sourcing these materials. Buyers should also consider the optical properties and sourcing capabilities of suppliers to guarantee that they receive high-quality quartz glasses that meet the specific needs of their medical applications.

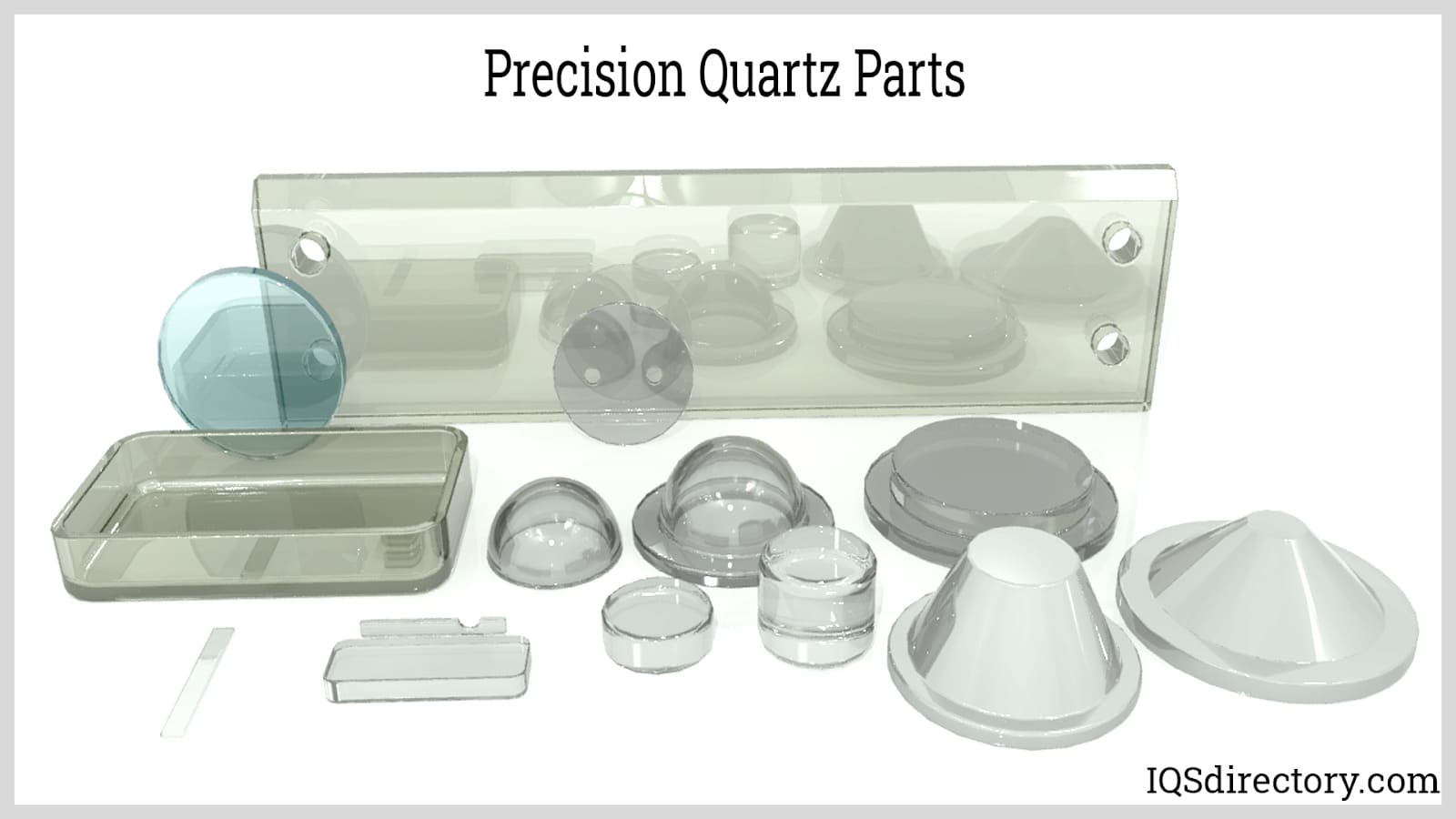

Illustrative image related to quartz glasses

3 Common User Pain Points for ‘quartz glasses’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Lens Protection for Specific Tasks

The Problem: B2B buyers, especially those in industries involving quartz glass manipulation, often struggle to find the appropriate lens protection tailored to their specific tasks. For instance, a manufacturer in Nigeria might be engaged in a process that generates intense UV and IR radiation but does not require sodium flare filtration. This lack of clarity on which quartz glasses to choose can lead to inadequate protection, resulting in safety risks and potential work interruptions.

The Solution: To effectively address this issue, buyers should conduct a thorough assessment of their operational requirements. Begin by identifying the specific environmental conditions and risks associated with your quartz working tasks. Utilize suppliers that offer a range of lens options, such as split lenses for versatile protection or specialized green IR lenses that block UV and IR without sodium flare absorption. For instance, consider investing in BorotruView 6.0 or 8.0 quartz glasses for high-intensity environments. Additionally, engage with suppliers who provide detailed product specifications and expert consultations to ensure that your team is equipped with the right protective eyewear that meets industry standards.

Scenario 2: Challenges with Timely Delivery and Inventory Management

The Problem: International B2B buyers frequently face challenges related to the timely delivery of quartz glasses, which can disrupt project timelines. For example, a glassworking company in South America may place an order for quartz safety glasses only to experience delays due to shipping logistics or inventory shortages. These delays can lead to operational bottlenecks, increased costs, and a potential compromise on workplace safety standards during the waiting period.

Illustrative image related to quartz glasses

The Solution: To mitigate delivery issues, it’s crucial to establish relationships with reputable suppliers known for their reliability and customer service. When placing an order, inquire about lead times and shipping options. Opt for suppliers that offer expedited shipping services and have a robust inventory management system to ensure stock availability. Additionally, consider maintaining a safety stock of critical eyewear items based on your usage rates to cushion against unforeseen delays. Regularly review your inventory levels and collaborate with suppliers to forecast demand, ensuring that you have the necessary protective gear on hand when you need it.

Scenario 3: High Costs and Budget Constraints

The Problem: B2B buyers often grapple with the high costs associated with purchasing quality quartz glasses, particularly in regions where budget constraints are a significant concern. For instance, a small-scale manufacturing firm in Europe may find it challenging to allocate sufficient funds for top-tier protective eyewear, leading to compromises in safety and product quality. The fear of investing in lower-quality options that do not provide adequate protection adds to the dilemma.

The Solution: To navigate budget constraints while ensuring quality protection, buyers should explore options for bulk purchasing or long-term contracts with suppliers. Many suppliers offer volume discounts that can significantly reduce the per-unit cost of quartz glasses. Additionally, consider investing in models with replaceable components, such as lenses and side shields, which can lower long-term costs. Conduct a cost-benefit analysis to compare the potential expenses of workplace injuries due to inadequate protection versus the upfront investment in quality eyewear. Leveraging industry contacts and networking with other businesses can also provide insights into cost-effective purchasing strategies and trusted suppliers.

Strategic Material Selection Guide for quartz glasses

What Are the Key Materials Used in Quartz Glasses?

When selecting quartz glasses for industrial or commercial applications, understanding the materials used is crucial. Different materials offer varying performance characteristics, which can significantly impact their suitability for specific applications. Below, we analyze four common materials used in quartz glasses, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

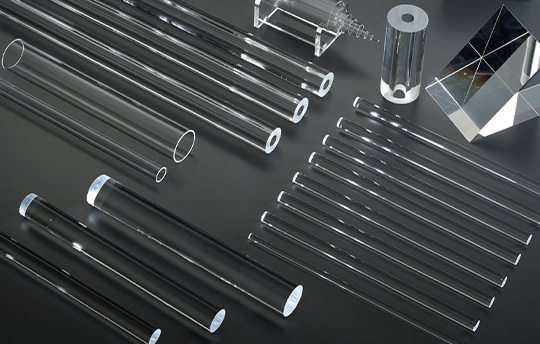

How Does Fused Quartz Perform in High-Temperature Applications?

Fused quartz is a high-purity silica glass known for its excellent thermal stability and resistance to thermal shock. It can withstand temperatures up to 1,200°C (2,192°F) and maintains its integrity under rapid temperature changes. This makes it ideal for applications such as semiconductor manufacturing and laboratory equipment.

Pros: Fused quartz offers exceptional clarity and low thermal expansion, making it suitable for precision optics and high-temperature environments. Its chemical resistance is also noteworthy, allowing it to handle corrosive substances without degrading.

Cons: The primary drawback of fused quartz is its cost, which is relatively high compared to other materials. Additionally, it can be more challenging to manufacture due to the need for specialized equipment and processes.

Impact on Application: Fused quartz is compatible with various media, including aggressive chemicals and high-temperature gases, making it a preferred choice in industries like pharmaceuticals and electronics.

International Considerations: Buyers from regions such as Africa and South America should ensure compliance with international standards like ASTM E-438 for fused quartz, which governs its optical and physical properties.

What Advantages Does Borosilicate Glass Offer for Everyday Use?

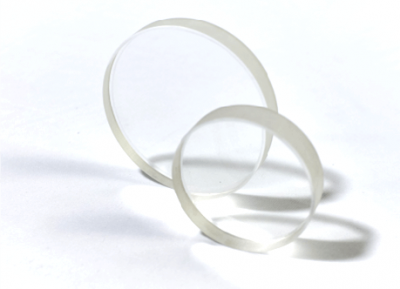

Borosilicate glass is another popular material for quartz glasses, particularly in laboratory settings. It is known for its excellent thermal shock resistance and can withstand temperatures up to 500°C (932°F).

Illustrative image related to quartz glasses

Pros: The durability of borosilicate glass makes it less prone to breakage compared to regular glass. It is also more affordable than fused quartz, making it a cost-effective option for many applications.

Cons: While borosilicate glass offers good chemical resistance, it is not as robust as fused quartz when exposed to extreme conditions. Additionally, it may not be suitable for high-precision optical applications due to its lower clarity.

Impact on Application: Borosilicate glass is compatible with various chemicals, making it ideal for laboratory glassware and general-purpose containers.

International Considerations: Compliance with standards such as ISO 3585 is essential for ensuring the quality and safety of borosilicate glass products, particularly in European markets.

How Does Polycarbonate Compare in Terms of Safety and Versatility?

Polycarbonate is a synthetic thermoplastic that is increasingly used in safety glasses and protective eyewear. It is known for its impact resistance and lightweight properties.

Pros: Polycarbonate glasses are highly durable and can withstand significant impact, making them ideal for safety applications. They are also lightweight, providing comfort for extended wear.

Cons: However, polycarbonate is less heat resistant than fused quartz and can warp under high temperatures. Additionally, it may scratch more easily than glass, which can affect visibility over time.

Impact on Application: Polycarbonate is suitable for environments where safety is a priority, such as construction sites or laboratories, but may not be suitable for high-temperature applications.

Illustrative image related to quartz glasses

International Considerations: Buyers should look for compliance with ANSI Z87.1 standards for safety eyewear, especially in regions like the Middle East and Europe, where safety regulations are stringent.

What Role Does Soda-Lime Glass Play in Cost-Effective Solutions?

Soda-lime glass is the most common type of glass used in various applications, including quartz glasses. It is known for its affordability and ease of production.

Pros: The primary advantage of soda-lime glass is its low cost, making it an attractive option for bulk purchases. It is also readily available and can be manufactured in various shapes and sizes.

Cons: However, soda-lime glass has lower thermal and chemical resistance compared to other materials like fused quartz and borosilicate. It is more prone to breakage and may not withstand extreme conditions.

Illustrative image related to quartz glasses

Impact on Application: Soda-lime glass is suitable for general-purpose applications but may not be ideal for specialized environments that require high durability or thermal resistance.

International Considerations: Compliance with standards such as ASTM C1036 is important for ensuring quality, particularly for buyers in Europe and South America.

Summary Table of Quartz Glass Materials

| Material | Typical Use Case for quartz glasses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Quartz | Semiconductor manufacturing | Excellent thermal stability | High cost and manufacturing complexity | High |

| Borosilicate Glass | Laboratory glassware | Good thermal shock resistance | Lower clarity and chemical resistance | Med |

| Polycarbonate | Safety eyewear | Impact-resistant and lightweight | Less heat resistance and prone to scratching | Low |

| Soda-Lime Glass | General-purpose applications | Cost-effective and widely available | Lower thermal and chemical resistance | Low |

This strategic material selection guide aims to provide B2B buyers with comprehensive insights into the various materials used in quartz glasses, enabling informed purchasing decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for quartz glasses

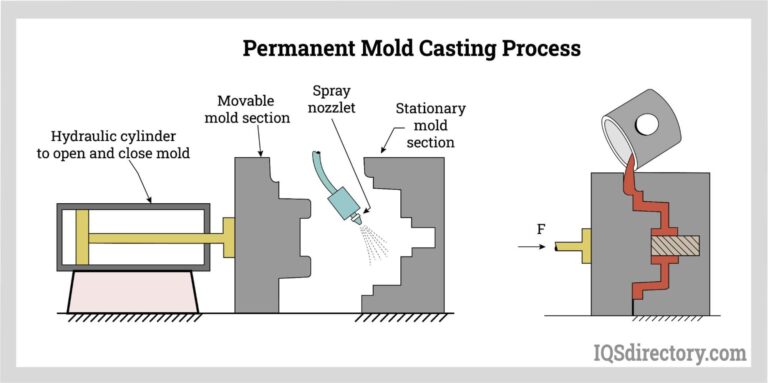

What Are the Main Stages in the Manufacturing Process of Quartz Glasses?

The manufacturing of quartz glasses involves several critical stages, each contributing to the overall quality and functionality of the final product. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to quartz glasses

-

Material Preparation: The process begins with sourcing high-purity silica sand, which is the primary raw material for quartz glass. This sand is subjected to rigorous cleaning and refining to eliminate impurities that could affect the optical clarity and strength of the glass. Other additives may be included based on specific product requirements, such as stabilizers or colorants.

-

Forming: Once the materials are prepared, they are melted in a furnace at extremely high temperatures, typically exceeding 1,700 degrees Celsius. The molten glass is then shaped using various techniques, including blowing, pressing, or casting, depending on the desired form and thickness. Advanced molding technologies can ensure precise dimensions and reduce waste.

-

Assembly: After forming, different components may need to be assembled, particularly for specialized quartz glasses like those with split lenses or multi-layer designs. This stage involves meticulous alignment and bonding of parts to ensure structural integrity and functionality.

-

Finishing: The final stage involves polishing, coating, and inspecting the quartz glasses. Polishing enhances optical clarity, while coatings may be applied for additional protection against scratches, UV rays, or chemical exposure. This stage is critical for ensuring that the glasses meet both aesthetic and performance standards.

Which Key Techniques Are Used in the Manufacturing of Quartz Glasses?

The manufacturing process employs several key techniques to ensure that quartz glasses meet industry standards. These include:

-

High-Temperature Melting: This technique is essential for achieving the necessary viscosity and homogeneity of the glass, facilitating uniform forming.

-

Precision Molding: Advanced molds are designed to create complex shapes and ensure that the final product adheres to specified tolerances.

-

Controlled Cooling: The cooling process is carefully managed to prevent thermal shock, which can lead to cracking or warping. Annealing is often employed to relieve internal stresses.

-

Surface Treatment: Techniques such as acid etching or chemical vapor deposition may be used to enhance surface properties, improving resistance to scratches and chemicals.

How Is Quality Assurance Implemented in Quartz Glass Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process for quartz glasses, ensuring that products are safe, effective, and compliant with international standards.

-

Relevant International Standards: Many manufacturers adhere to ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific standards such as CE marking for the European market and API specifications for certain applications may apply.

-

Quality Control Checkpoints: Several checkpoints throughout the manufacturing process help maintain quality:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify and rectify any deviations in real-time.

– Final Quality Control (FQC): This final inspection ensures that the finished products meet all specifications and standards before shipment. -

Common Testing Methods: Various testing methods are employed to assess the performance and safety of quartz glasses, including:

– Optical Testing: Evaluates clarity, distortion, and light transmission.

– Mechanical Testing: Assesses strength and resistance to impact.

– Thermal Testing: Determines the glass’s ability to withstand temperature fluctuations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, ensuring that suppliers maintain robust quality control processes is vital. Here are some strategies:

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their adherence to quality standards and practices. This includes evaluating manufacturing processes, quality control measures, and compliance with international standards.

-

Requesting Quality Assurance Reports: Buyers should ask for detailed QA reports that outline the testing methods used, results obtained, and any corrective actions taken. This documentation can provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These inspectors can assess compliance with relevant standards and provide certifications that enhance buyer confidence.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing quartz glasses from international suppliers, buyers must navigate various certification requirements and quality nuances:

Illustrative image related to quartz glasses

-

Regional Compliance: Different regions may have specific compliance requirements. For example, CE marking is mandatory for products sold in the European Union, while other regions may prioritize different certifications.

-

Documentation: Buyers should ensure that all necessary documentation, including certificates of compliance, testing reports, and quality control records, are provided and verifiable.

-

Cultural Considerations: Understanding the cultural context of the supplier’s country can help buyers navigate potential misunderstandings regarding quality expectations and compliance.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing quartz glasses, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘quartz glasses’

When sourcing quartz glasses for your business, it’s essential to follow a structured approach to ensure that you meet both your quality requirements and budget constraints. This checklist serves as a practical guide for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical to ensure that the quartz glasses you procure meet your operational needs. Consider factors such as lens type (e.g., split lens, green IR lenses), UV protection levels, and any specific requirements for sodium flare absorption. This clarity will facilitate better communication with suppliers and help you avoid incompatible products.

Step 2: Research Potential Suppliers

Thorough research is vital in identifying reliable suppliers. Look for manufacturers or distributors with a proven track record in producing quartz glasses. Utilize online directories, industry forums, and trade shows to gather information. Pay attention to reviews and testimonials from other businesses, especially those in your region.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, verify their certifications to ensure compliance with industry standards. Check for ISO certifications, safety standards, and product quality assurances. This step is crucial for mitigating risks associated with subpar products and ensuring that your procurement aligns with regulatory requirements in your market.

Step 4: Request Samples for Evaluation

Always request samples of the quartz glasses you intend to purchase. This hands-on evaluation allows you to assess the quality, comfort, and suitability of the glasses for your specific applications. Pay attention to factors such as lens clarity, fit, and the effectiveness of any protective features.

Step 5: Assess Pricing and Payment Terms

Understanding the pricing structure and payment terms is essential for budgeting and financial planning. Compare quotes from different suppliers, but be cautious of prices that seem too good to be true, as they may indicate inferior quality. Discuss payment terms, including deposits, credit options, and any potential discounts for bulk orders.

Step 6: Evaluate Shipping and Delivery Times

Timely delivery is crucial for maintaining your operational flow. Inquire about shipping methods, estimated delivery times, and any potential delays. Consider the supplier’s location and your own logistical capabilities, especially if you’re importing goods across international borders.

Step 7: Establish a Communication Plan

Effective communication with your supplier throughout the procurement process can prevent misunderstandings and ensure that your needs are met. Establish a clear point of contact and agree on regular updates regarding order status, shipping, and any potential issues. This proactive approach fosters a stronger partnership and enhances the overall procurement experience.

By following this step-by-step checklist, you can navigate the complexities of sourcing quartz glasses more effectively, ensuring that you make informed decisions that align with your business needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for quartz glasses Sourcing

What Are the Key Cost Components in Quartz Glasses Sourcing?

When sourcing quartz glasses, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The quality of quartz and any additional materials, such as coatings or frame components, significantly influences costs. High-purity quartz, which offers better optical clarity and durability, typically commands a premium price.

-

Labor: Labor costs vary by region and production complexity. Skilled labor is often required for processes like lens shaping and assembly, impacting overall pricing.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and equipment maintenance. Efficient manufacturing practices can help mitigate these costs.

-

Tooling: Custom molds and tools for unique designs or specifications can represent a significant upfront investment. Buyers seeking customized products should be prepared for higher initial costs.

-

Quality Control (QC): Rigorous testing and certification processes ensure that the glasses meet safety and performance standards, particularly for applications in industrial settings. Enhanced QC measures can add to the overall cost.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location, chosen shipping method, and delivery timelines. It’s essential to consider these factors when evaluating total costs.

-

Margin: Suppliers typically include a profit margin that can vary based on competition, product uniqueness, and market demand.

How Do Price Influencers Affect Quartz Glasses Sourcing?

Several factors influence the pricing of quartz glasses, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ is crucial for cost-effective sourcing.

-

Specifications and Customization: Unique specifications, such as specific lens types or coatings, can increase costs. Buyers should clearly define their requirements to receive accurate quotes.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO or ASTM compliance) generally lead to higher prices. However, investing in quality can reduce long-term costs associated with replacements or failures.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Established suppliers may offer better quality but at a higher price point.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate who is responsible for shipping costs, insurance, and tariffs, influencing the total landed cost of the goods.

What Tips Can Help Buyers Negotiate Better Prices for Quartz Glasses?

Navigating the complexities of sourcing quartz glasses requires strategic negotiation and an understanding of cost-efficiency:

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing structures. Highlight potential long-term partnerships, which could encourage suppliers to offer better rates.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, durability, and potential savings from fewer replacements. A higher initial cost may be justified if the product offers longevity and performance.

-

Understanding Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local regulations that could affect pricing.

-

Seek Multiple Quotes: Don’t settle for the first offer. Gathering quotes from various suppliers can provide leverage in negotiations and help identify the best overall value.

-

Assess Supplier Flexibility: Inquire about the potential for customized solutions and varying payment terms, which can enhance cash flow and reduce upfront costs.

Conclusion

When sourcing quartz glasses, a thorough understanding of the cost components and pricing influencers is essential for making informed purchasing decisions. By leveraging negotiation strategies and considering the total cost of ownership, international B2B buyers can maximize their investments while ensuring they receive high-quality products tailored to their specific needs. Always remember that prices can vary significantly based on numerous factors, so it’s prudent to approach sourcing with a well-researched strategy.

Alternatives Analysis: Comparing quartz glasses With Other Solutions

In the field of quartz working, selecting the appropriate eyewear is critical for ensuring safety and performance. While quartz glasses are a popular choice due to their specialized design and protective features, there are alternative solutions that may also cater to specific industry needs. This analysis will compare quartz glasses with two viable alternatives: polycarbonate safety glasses and traditional safety goggles.

| Comparison Aspect | Quartz Glasses | Polycarbonate Safety Glasses | Traditional Safety Goggles |

|---|---|---|---|

| Performance | High IR and UV protection, tailored for quartz work | Good UV protection, lightweight, but lower IR resistance | Excellent all-around protection, but can fog up |

| Cost | $55 – $230 depending on features | $20 – $100 | $10 – $50 |

| Ease of Implementation | Requires specific fitting for optimal protection | Generally fits well, easy to wear | Can be cumbersome; may require adjustments |

| Maintenance | Generally low; may need lens replacement | Low; easy to clean and maintain | Moderate; prone to fogging, may need anti-fog treatments |

| Best Use Case | High-intensity quartz work requiring specific lens features | General industrial applications, suitable for various tasks | Environments with high debris or liquid exposure |

What are the Advantages and Disadvantages of Polycarbonate Safety Glasses?

Polycarbonate safety glasses are lightweight and provide excellent impact resistance, making them suitable for a range of industrial applications. They generally offer good UV protection but fall short in terms of infrared (IR) resistance compared to quartz glasses. The cost is lower, making them an attractive option for budget-conscious buyers. However, their performance may not meet the stringent requirements for high-intensity quartz work, where specific IR filtration is crucial. Additionally, they may not provide the same level of clarity and detail as quartz glasses, which can be a significant drawback for tasks requiring precision.

How Do Traditional Safety Goggles Compare?

Traditional safety goggles offer a high level of protection against physical hazards, such as dust and liquid splashes. They are often more affordable, making them accessible for various industries. However, they can be cumbersome and may require adjustments to fit securely, leading to discomfort during prolonged use. One of the main issues with goggles is fogging, which can obstruct vision and hinder productivity. While they are suitable for environments with high debris, they may not provide the specific protection needed for quartz working, particularly against UV and IR radiation.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When evaluating the right eyewear for quartz working or similar tasks, B2B buyers should consider the specific requirements of their operations. Quartz glasses are ideal for environments where high levels of UV and IR protection are essential, particularly in quartz fabrication or glassworking. If budget constraints are a priority, polycarbonate safety glasses may provide a satisfactory alternative for general industrial use. In scenarios where exposure to debris or liquids is a concern, traditional safety goggles can be effective, although they may not meet the specialized needs of quartz working. Ultimately, the choice should be guided by the specific hazards present in the working environment, the required level of protection, and budget considerations.

Essential Technical Properties and Trade Terminology for quartz glasses

What Are the Key Technical Properties of Quartz Glasses?

1. Material Grade

Quartz glasses are typically categorized by their material grade, which defines their purity and physical properties. High-purity quartz glass (often 99.99% SiO2) is preferred for applications requiring minimal contamination, such as semiconductor manufacturing and optical devices. In B2B transactions, understanding the material grade ensures that buyers select products that meet their specific application needs, enhancing product performance and longevity.

2. Tolerance Levels

Tolerance levels refer to the allowable deviation from specified dimensions and properties in quartz glass products. These tolerances are critical in precision applications where exact measurements are necessary, such as in optical components or laboratory settings. For B2B buyers, awareness of tolerance levels helps to prevent costly errors in manufacturing processes, ensuring that components fit together correctly and operate as intended.

3. UV and IR Protection Ratings

Quartz glasses often provide varying degrees of ultraviolet (UV) and infrared (IR) protection, essential for applications involving intense light sources, such as welding or glassworking. The protection ratings, usually indicated by specific numerical values, inform buyers about the level of safety and comfort the eyewear will provide. This knowledge is vital for ensuring compliance with safety regulations and protecting workers’ health in hazardous environments.

Illustrative image related to quartz glasses

4. Sodium Flare Absorption

Sodium flare absorption measures the ability of quartz glasses to filter out sodium emissions, which can interfere with visual clarity during high-temperature operations. Certain glasses are designed specifically to minimize this effect, making them ideal for precise tasks. B2B buyers should consider sodium flare absorption when selecting eyewear for quartz working, as it directly impacts visibility and work quality.

5. Lens Coating Options

Lens coatings can enhance the performance of quartz glasses, providing features like anti-scratch protection or anti-fogging capabilities. These coatings are particularly important in environments where glasses are subjected to harsh conditions. Understanding the available coatings allows B2B buyers to make informed decisions that can lead to improved durability and user satisfaction.

What Are Common Trade Terms in the Quartz Glass Industry?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the quartz glass industry, OEM partnerships are common for buyers seeking customized solutions or specific product features. Understanding OEM relationships can facilitate more effective negotiations and product sourcing.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively and avoid overstocking or understocking situations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. In the quartz glass sector, submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, enabling better decision-making and negotiation leverage.

Illustrative image related to quartz glasses

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify issues such as shipping costs, risk transfer, and delivery points. For B2B buyers in the quartz glass market, understanding Incoterms is essential for ensuring smooth logistics and avoiding misunderstandings in cross-border transactions.

5. Customization

Customization refers to the ability to modify products according to specific customer requirements. In the quartz glass industry, this can include alterations in size, shape, or additional features like coatings. Recognizing the potential for customization allows B2B buyers to tailor products to their unique operational needs, enhancing product efficacy.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational objectives, ultimately leading to enhanced productivity and cost savings.

Navigating Market Dynamics and Sourcing Trends in the quartz glasses Sector

What Are the Key Market Dynamics and Trends Influencing the Quartz Glasses Sector?

The quartz glasses sector is experiencing notable growth, driven by technological advancements and increasing demand across various industries, including healthcare, manufacturing, and scientific research. A major driver is the rising need for precision instruments that require high-quality optical materials. As industries evolve, the demand for specialized quartz glasses, such as those with split lenses or advanced UV and IR protection, is on the rise. Furthermore, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly sourcing these products to meet stringent safety and operational standards.

Emerging trends in sourcing include the adoption of digital platforms for procurement, enabling buyers to access a wider range of suppliers and product options efficiently. The rise of e-commerce and online marketplaces is transforming traditional sourcing methods, allowing for direct communication and transaction capabilities between manufacturers and buyers. Additionally, customization is becoming a key trend, with businesses seeking tailored solutions that meet specific operational needs, such as varying lens shades and protective features.

Market dynamics are also influenced by geopolitical factors and trade regulations. Buyers must remain vigilant about changes in tariffs and import/export regulations that can affect pricing and availability. Understanding these dynamics is crucial for B2B buyers looking to navigate the complexities of sourcing quartz glasses in an ever-evolving global marketplace.

How Important Is Sustainability and Ethical Sourcing in the Quartz Glasses Industry?

Sustainability and ethical sourcing are becoming increasingly critical in the quartz glasses sector. As global awareness of environmental issues rises, businesses are prioritizing suppliers that adhere to sustainable practices. The production of quartz glasses can have a significant environmental impact, particularly in terms of energy consumption and waste generation. Therefore, sourcing from manufacturers that utilize eco-friendly materials and processes is essential for reducing carbon footprints.

Ethical supply chains are also gaining prominence, as consumers and businesses alike demand transparency in sourcing practices. Companies are encouraged to seek partnerships with suppliers who can demonstrate responsible sourcing of raw materials and ethical labor practices. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can enhance a supplier’s credibility and appeal to environmentally conscious buyers.

Incorporating green materials into quartz glasses, such as recycled glass or responsibly sourced quartz, not only meets regulatory requirements but also resonates with a growing segment of environmentally aware consumers. By prioritizing sustainability, B2B buyers can enhance their brand reputation and build trust with their stakeholders.

What Is the Historical Context of Quartz Glasses in B2B Markets?

The use of quartz glasses dates back several centuries, with its origins rooted in the need for durable and heat-resistant materials in scientific and industrial applications. Historically, quartz was favored for its optical clarity and resistance to thermal shock, making it an ideal choice for laboratory glassware and optical components.

As industries advanced, so too did the technology surrounding quartz glass production. The introduction of specialized manufacturing techniques in the 20th century led to the development of various types of quartz glasses, including those tailored for specific applications such as welding, medical devices, and high-performance optics. This evolution has positioned quartz glasses as a critical component in modern manufacturing and technology sectors, making them indispensable to contemporary B2B operations.

Illustrative image related to quartz glasses

Understanding the historical context of quartz glasses not only highlights their significance but also informs current trends and sourcing strategies, guiding international buyers toward making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of quartz glasses

-

How do I choose the right quartz glasses for my business needs?

When selecting quartz glasses, consider the specific applications within your industry. Evaluate factors such as the required level of UV and IR protection, the type of work being performed (e.g., glassworking, welding, or medical applications), and the comfort of the fit for your employees. It’s also important to assess whether you need features like split lenses or additional coatings for enhanced protection. Engaging with suppliers to understand their product specifications and testing samples can also aid in making an informed decision. -

What are the advantages of split lens quartz glasses?

Split lens quartz glasses provide versatile protection by combining different shades in a single pair. This allows workers to have optimal visibility and protection based on varying light conditions, particularly in environments where both high-intensity and low-intensity tasks are performed. The design helps reduce eye strain and enhances focus, which can lead to increased productivity. Additionally, these glasses often come with protective features against UV and IR radiation, crucial for safety in industries like glassworking and welding. -

What is the typical lead time for ordering quartz glasses internationally?

The lead time for international orders of quartz glasses varies based on factors such as supplier location, order volume, and shipping method. Generally, you can expect a timeframe of 10 to 30 business days for production and delivery. To ensure timely fulfillment, it’s advisable to communicate with your supplier regarding their processing times and consider using expedited shipping options if necessary. Always factor in customs clearance times, which can add additional days to your delivery schedule. -

What are the minimum order quantities (MOQs) for quartz glasses?

Minimum order quantities for quartz glasses can vary significantly by supplier and product type. Typically, MOQs may range from 50 to 100 pairs, especially for customized options. It’s essential to discuss your specific needs with potential suppliers to negotiate MOQs that align with your business requirements. If you are looking for a smaller quantity, some suppliers may offer sample packs or smaller batches for initial orders. -

How can I vet suppliers of quartz glasses for quality assurance?

Vetting suppliers involves several steps to ensure product quality and reliability. Start by researching their reputation through customer reviews and industry certifications. Request samples to assess the quality of the quartz glasses before placing larger orders. Additionally, inquire about their quality control processes, manufacturing standards, and whether they comply with international safety regulations. Building a relationship with suppliers who are transparent about their practices will contribute to a more successful partnership. -

What payment terms should I expect when purchasing quartz glasses?

Payment terms for purchasing quartz glasses can vary widely among suppliers, but common practices include net 30 or net 60 days, requiring payment within 30 or 60 days of invoice receipt. Some suppliers may request partial payment upfront, particularly for large orders or custom products. It’s important to clarify payment terms before finalizing any agreements and to consider using secure payment methods to protect your transaction. -

Can I customize quartz glasses for my brand?

Yes, many suppliers offer customization options for quartz glasses, including branding with logos, specific color choices, and adjustments to lens specifications. Customization can enhance your brand identity and ensure the products meet your specific operational requirements. Be sure to discuss customization capabilities during your initial communications with suppliers, as there may be additional costs and MOQs associated with personalized products. -

What logistics considerations should I keep in mind when ordering quartz glasses?

When ordering quartz glasses, consider the logistics of shipping, including costs, delivery times, and the best shipping methods for your location. Assess whether the supplier provides support with customs documentation and duties, as this can significantly impact the overall cost and timeline of your order. Additionally, consider warehousing options if you anticipate large orders, as storing products closer to your market can reduce future shipping times and costs.

Top 7 Quartz Glasses Manufacturers & Suppliers List

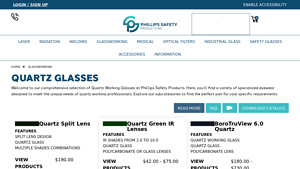

1. Phillips Safety – Quartz Working Glasses

Domain: phillips-safety.com

Registered: 2001 (24 years)

Introduction: Quartz Working Glasses at Phillips Safety include specialized eyewear for quartz working professionals. Key categories include: 1. Quartz Split Lens: Features a split lens design with the top 1/3 or 1/2 clear or with Phillips 202 lenses, and the bottom 2/3 or 1/2 shaded with green welding shades (4 to 8). 2. Quartz Green IR Lenses: Shaded between 4 and 10, providing standard IR and UV protection w…

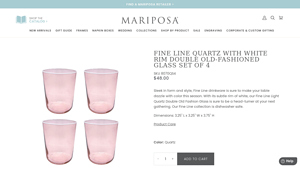

2. Mariposa – Fine Line Quartz Double Old-Fashioned Glass Set

Domain: mariposa.com

Registered: 1995 (30 years)

Introduction: Fine Line Quartz with White Rim Double Old-Fashioned Glass Set of 4 | SKU 8070QS4 | Price: $48.00 | Dimensions: 3.25″ L x 3.25″ W x 3.75″ H | Dishwasher safe | Color: Quartz | Sleek design with a subtle white rim | Ideal for gatherings.

3. Blenders Eyewear – Mave X2 Golden Quartz

Domain: blenderseyewear.com

Registered: 2011 (14 years)

Introduction: {“name”: “Mave X2 Golden Quartz”, “price”: “$79”, “rating”: “4.7 out of 5 stars”, “reviews_count”: “129”, “color”: “Golden Quartz”, “frame”: “Gloss Multi-Tort”, “lens_color”: “Polarized Pure Blend ™ Amber Gradient”, “uv_rating”: “100% UV Protection”, “fit_size”: “Small – Medium”, “vibe”: “Iconic”, “in_the_box”: “Microfiber Pouch & Sticker Pack”, “features”: {“polarized_lens”: “Yes”, “scratch_resis…

4. Warby Parker – Daisy Eyeglasses

Domain: warbyparker.com

Registered: 2009 (16 years)

Introduction: {‘name’: ‘Daisy Eyeglasses’, ‘color’: ‘Violet Quartz Crystal with Polished Silver’, ‘made_in’: ‘Italy’, ‘frame_widths’: {‘narrow’: ‘127 mm’, ‘medium’: ‘133 mm’}, ‘starting_price’: {‘single_vision’: ‘$175’, ‘progressives’: ‘$405’, ‘readers’: ‘$175’, ‘non_prescription’: ‘$175’}, ‘lens_types’: {‘classic’: ‘Free’, ‘blue_light_filtering’: ‘+ $50’, ‘anti_fatigue’: ‘+ $100’, ‘light_responsive’: ‘+ $125’}…

5. PGO Online – Fused Silica & Fused Quartz

Domain: pgo-online.com

Registered: 2000 (25 years)

Introduction: Fused Silica and Fused Quartz are two distinct types of quartz glass. Fused Silica is an optical-grade synthetic quartz glass made from high-purity silica powder, offering high light transmission (over 80% at 185 nm) and better optical properties, suitable for demanding applications. Fused Quartz is made from natural quartz crystals, has moderate purity, lower light transmission in the UVC range, …

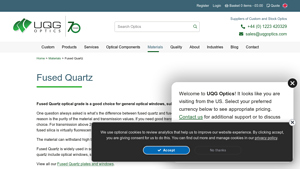

6. UQG Optics – Fused Quartz Optical Components

Domain: uqgoptics.com

Registered: 2001 (24 years)

Introduction: Fused Quartz optical grade is suitable for general optical windows, substrates, and optical components. Key differences between fused quartz and fused silica include purity and transmission values; fused silica is preferred for transmission below 260nm, while fused quartz is better for above 260nm. Fused quartz fluoresces, whereas fused silica is virtually fluorescent free. It can withstand temper…

7. Zightglass – Circular Sight Glass Quartz

Domain: zightglass.com

Registered: 2023 (2 years)

Introduction: {“Product Name”: “Circular Sight Glass Quartz”,”Material”: “Fused Silica (min. 95% purity)”,”Key Features”: [“Exceptional thermal resistance”,”Chemical stability”,”Durability”,”High-temperature performance”,”Clear visual inspection”],”Technical Information”: {“Minimum Diameter”: “10mm”,”Maximum Diameter”: “350mm”,”Minimum Thickness”: “3mm”,”Maximum Thickness”: “35mm”,”Max Working Temperature”: “95…

Strategic Sourcing Conclusion and Outlook for quartz glasses

In the rapidly evolving market for quartz glasses, strategic sourcing remains a critical element for B2B buyers aiming to enhance operational efficiency and product quality. By understanding the diverse range of quartz glasses available—such as split lens designs for varying light conditions and specialized lenses that filter harmful radiation—businesses can tailor their purchases to meet specific application needs. This not only ensures compliance with safety standards but also optimizes performance in demanding environments.

For international buyers in Africa, South America, the Middle East, and Europe, the importance of establishing strong relationships with suppliers cannot be overstated. Engaging with reputable manufacturers can lead to better pricing, timely delivery, and access to the latest innovations in quartz glass technology. As global demand for high-quality quartz glasses continues to rise, staying informed about market trends and sourcing strategies will empower businesses to make informed purchasing decisions.

Looking ahead, the quartz glass market presents significant opportunities for growth. By prioritizing strategic sourcing, buyers can position themselves advantageously, ensuring they are well-equipped to meet future challenges and capitalize on emerging trends. Now is the time to connect with trusted suppliers and leverage high-quality quartz glasses to enhance your business operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.