Protective Covers: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for protective covers

In today’s global marketplace, sourcing high-quality protective covers is paramount for businesses aiming to safeguard their investments against the elements and extend the lifespan of their assets. With the increasing demand for durable, weather-resistant solutions, international B2B buyers face the challenge of identifying reliable suppliers that meet diverse needs—from outdoor furniture to industrial equipment. This comprehensive guide addresses the complexities of navigating the protective cover market, offering insights into various types, applications, and key considerations for supplier vetting.

Throughout this guide, you will discover the distinct categories of protective covers tailored to specific industries and environments, enabling you to make informed decisions that align with your operational requirements. We delve into the nuances of material selection, the importance of sizing and fit, and the implications of cost versus quality, ensuring that you are equipped to evaluate potential suppliers effectively.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Vietnam and Germany—this guide empowers you to approach purchasing decisions with confidence. By understanding the critical factors that influence product performance and supplier reliability, you can protect your investments and enhance the longevity of your equipment and furniture, ultimately driving better business outcomes.

Understanding protective covers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Outdoor Furniture Covers | Weather-resistant, breathable materials, custom sizing | Hospitality (hotels, restaurants), retail | Pros: Prolongs lifespan, easy maintenance. Cons: Initial investment may be high. |

| Equipment Covers | Heavy-duty, often made of PVC or vinyl for industrial use | Manufacturing, construction, agriculture | Pros: Robust protection from dirt and moisture. Cons: Can be cumbersome to handle. |

| Vehicle Covers | Tailored fit, UV-resistant, often includes padded lining | Automotive industry, rental services | Pros: Protects against weather and scratches. Cons: Limited ventilation can cause moisture buildup. |

| Custom Protective Covers | Tailored to specific dimensions and applications | Specialty equipment, custom furniture | Pros: Perfect fit for unique items. Cons: Longer lead times and higher costs. |

| Seasonal Covers | Designed for specific seasons, often insulated for winter | Homeowners, outdoor retailers | Pros: Seasonal protection, can enhance aesthetics. Cons: Requires storage when not in use. |

What Are the Key Characteristics of Outdoor Furniture Covers?

Outdoor furniture covers are designed to protect patio and garden furniture from various weather conditions. Made from durable, weather-resistant materials, these covers often feature breathable designs to prevent moisture buildup, which can lead to mold and mildew. B2B buyers in the hospitality and retail sectors find these covers essential for prolonging the lifespan of their outdoor assets, ensuring they remain clean and ready for use. When purchasing, consider the fit, material quality, and warranty options to ensure long-term value.

How Do Equipment Covers Differ in Purpose?

Equipment covers are typically constructed from heavy-duty materials like PVC or vinyl, providing robust protection for industrial machinery and tools. These covers are crucial for businesses in manufacturing, construction, and agriculture, as they shield equipment from dust, moisture, and other environmental factors. Buyers should evaluate the cover’s durability, ease of use, and compatibility with their specific equipment to make informed decisions.

What Are the Benefits of Vehicle Covers for B2B Buyers?

Vehicle covers are tailored to fit specific automotive models and are often UV-resistant to protect against sun damage. They serve a dual purpose by safeguarding vehicles from weather elements and preventing scratches or dings. B2B applications include automotive dealerships and rental services, where maintaining the appearance of vehicles is vital. Buyers should consider the cover’s breathability to avoid moisture accumulation, which can lead to rust and deterioration.

Illustrative image related to protective covers

Why Choose Custom Protective Covers?

Custom protective covers are designed to fit unique dimensions and specifications, making them ideal for specialty equipment or custom furniture. These covers provide a tailored solution for businesses needing specific protection for non-standard items. While they offer a perfect fit, buyers should be prepared for longer lead times and potentially higher costs, as customization often involves additional design and manufacturing processes.

What Is the Importance of Seasonal Covers?

Seasonal covers are specifically designed to provide protection during particular times of the year, such as insulated covers for winter or UV-resistant options for summer. They are popular among homeowners and outdoor retailers seeking to maintain the aesthetic and functional integrity of outdoor items. While they offer excellent seasonal protection, buyers must also consider storage needs when the covers are not in use, as this can impact overall convenience.

Key Industrial Applications of protective covers

| Industry/Sector | Specific Application of Protective Covers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Furniture | Covers for Patio and Garden Furniture | Prolongs lifespan, reduces maintenance costs, and enhances aesthetics. | Material durability, weather resistance, and fit. |

| Construction | Equipment and Machinery Covers | Protects machinery from harsh weather, reduces downtime, and lowers repair costs. | Custom sizing, material strength, and ease of handling. |

| Automotive | Vehicle and Parts Covers | Guards against environmental damage, maintains vehicle value, and reduces cleaning needs. | UV resistance, custom fit, and breathability. |

| Agriculture | Crop and Equipment Covers | Shields crops from adverse weather conditions, preventing loss and improving yield. | Material type, size specifications, and weather resistance. |

| Electronics | Device and Component Covers | Prevents dust, moisture, and physical damage, ensuring product reliability. | Compatibility, anti-static properties, and ease of use. |

How Are Protective Covers Used in Outdoor Furniture Applications?

In the outdoor furniture sector, protective covers play a critical role in safeguarding investments against environmental elements such as UV rays, rain, and debris. By using high-quality covers, businesses can extend the life of their patio and garden furniture, minimizing the need for repairs or replacements. Buyers in regions like Africa and South America should prioritize materials that are both breathable and water-resistant to prevent mold, while ensuring the covers fit snugly to withstand wind. The aesthetic appeal of the covers can also enhance the overall look of outdoor spaces, making them an attractive investment.

What Role Do Protective Covers Play in the Construction Industry?

In construction, protective covers are essential for safeguarding machinery and equipment from the elements, which can lead to significant downtime and repair costs. These covers help maintain equipment functionality, ensuring that it remains operational in various weather conditions. International buyers, especially in the Middle East and Europe, should consider sourcing robust, custom-sized covers made from durable materials that can withstand harsh environments. The ability to easily handle and secure these covers is also a crucial factor to consider for efficient operations.

How Do Protective Covers Benefit the Automotive Sector?

In the automotive industry, protective covers are used to shield vehicles and parts from environmental damage, such as UV exposure, rain, and dust. This protection not only helps maintain the vehicle’s appearance but also preserves its resale value. B2B buyers, particularly in regions like Germany, should look for covers that offer UV resistance and a custom fit to ensure maximum protection. Additionally, breathable materials can prevent moisture buildup, which is vital for maintaining the integrity of vehicle components.

What Are the Advantages of Protective Covers in Agriculture?

Agricultural applications of protective covers include shielding crops and equipment from adverse weather conditions, which can lead to crop loss and reduced yields. These covers help in maintaining optimal growth conditions by protecting against frost, excessive moisture, and pests. Buyers in countries with variable climates should focus on sourcing durable, weather-resistant materials that can withstand local conditions while ensuring proper ventilation. This is crucial for maximizing crop productivity and minimizing agricultural risks.

How Are Protective Covers Used in the Electronics Industry?

In the electronics sector, protective covers are critical for preventing dust, moisture, and physical damage to devices and components. These covers ensure the reliability and longevity of electronic products, which is particularly important for B2B buyers in the technology sector. When sourcing covers, it’s essential to consider compatibility with the specific devices, anti-static properties to prevent damage, and ease of application. This attention to detail can significantly enhance product performance and customer satisfaction.

3 Common User Pain Points for ‘protective covers’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Size for Protective Covers

The Problem: Many B2B buyers struggle with selecting the correct size for protective covers. This issue often arises from the diverse range of outdoor furniture shapes and sizes, coupled with the varying specifications provided by different manufacturers. A mismatch can lead to inadequate protection, exposing valuable assets to weather damage, dirt, and pests. This not only increases replacement costs but also diminishes the appearance and functionality of the furniture, leading to dissatisfaction among clients and end-users.

The Solution: To ensure the right fit, B2B buyers should begin by meticulously measuring the dimensions of their outdoor furniture, including height, width, and depth. This measurement should account for any unique features like armrests or table extensions. Once measurements are gathered, buyers should consult product specifications from manufacturers, ensuring that the covers provide a snug fit without being overly tight. Additionally, exploring options for custom-sized covers can be beneficial. Many suppliers offer tailored solutions that accommodate unique furniture styles, providing optimal protection. Finally, utilizing covers with adjustable features, such as buckle straps or drawcords, can help secure the cover against wind, ensuring it remains in place during inclement weather.

Scenario 2: Concerns Over Durability and Weather Resistance

The Problem: B2B buyers often face anxiety regarding the durability and weather resistance of protective covers. With various materials available, it can be challenging to determine which ones will withstand harsh environmental conditions, such as intense UV rays, heavy rainfall, or extreme cold. Inadequate covers can lead to rapid deterioration of outdoor furniture, resulting in increased maintenance costs and potential loss of investment.

The Solution: To address durability concerns, buyers should prioritize covers made from high-denier polyester or similar materials known for their robust weather resistance. Specifically, materials rated between 600 to 900 denier are typically more resilient against the elements. Buyers should also look for covers with water-resistant yet breathable properties, as this prevents moisture buildup that can cause mold and mildew. Furthermore, investing in covers with reinforced seams and UV protection can significantly extend their lifespan. Engaging with manufacturers that provide detailed product specifications and warranties can also instill confidence in the investment, as these guarantees often reflect the quality and longevity of the covers.

Scenario 3: Managing Logistics for Seasonal Storage

The Problem: For many businesses, managing the logistics of seasonal storage for outdoor furniture can be a daunting task. Without appropriate protective covers, furniture can suffer damage during off-seasons, leading to increased costs and operational disruptions when the furniture needs to be replaced or repaired. Additionally, the physical challenge of moving and storing bulky furniture can strain resources and affect overall efficiency.

The Solution: To streamline the storage process, B2B buyers should implement a comprehensive inventory management strategy that includes protective covers. Using lightweight, weather-resistant covers allows for easier handling and transportation of furniture during seasonal transitions. Covers that can be quickly applied and removed save time and labor costs. Buyers should also consider investing in modular storage solutions that allow for stacking or nesting of furniture, maximizing space efficiency. A thorough training program for staff on proper handling and storage techniques can further mitigate risks of damage. Lastly, creating a clear schedule for when to cover and uncover furniture based on seasonal changes can help maintain consistency and ensure that all items are adequately protected throughout the year.

Strategic Material Selection Guide for protective covers

What Are the Key Properties of Common Materials Used for Protective Covers?

When selecting protective covers, understanding the properties of various materials is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in protective covers: polyester, vinyl, canvas, and polyethylene.

How Does Polyester Perform as a Material for Protective Covers?

Polyester is a synthetic fabric known for its durability and resistance to various environmental factors. It typically has a temperature rating of -40°F to 140°F (-40°C to 60°C) and can withstand moderate pressure. Polyester is resistant to UV rays, mold, and mildew, making it suitable for outdoor applications.

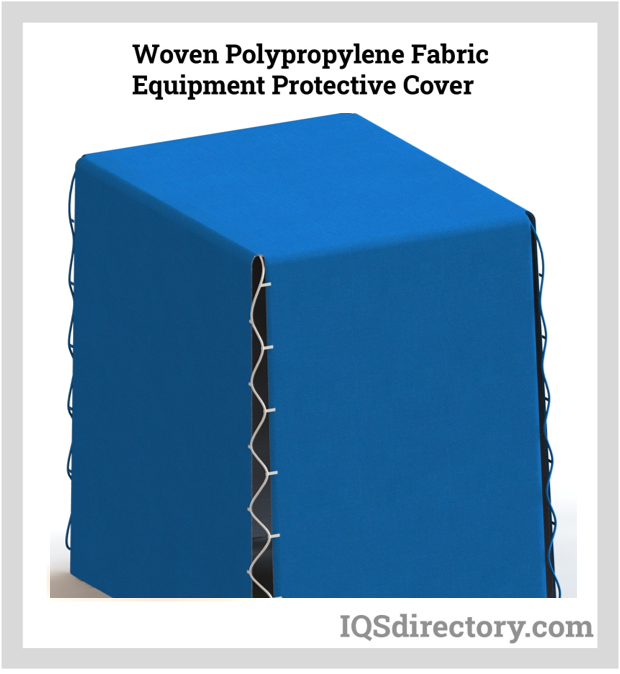

Illustrative image related to protective covers

Pros: Polyester covers are lightweight, easy to handle, and relatively inexpensive compared to other materials. They also offer good breathability, which helps prevent moisture buildup.

Cons: While durable, polyester can degrade over time with prolonged exposure to harsh weather conditions. It may require additional treatments for enhanced waterproofing, which can complicate manufacturing.

Impact on Application: Polyester is compatible with various media, including moisture and UV exposure, making it ideal for outdoor furniture covers.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the polyester meets local compliance standards, such as ASTM or DIN. Additionally, the availability of high-quality polyester may vary by region.

What Are the Advantages of Using Vinyl for Protective Covers?

Vinyl is a robust, waterproof material often used in protective covers for its exceptional resistance to water and chemicals. It can handle temperatures ranging from -10°F to 120°F (-23°C to 49°C) and offers excellent pressure resistance.

Pros: Vinyl covers are highly durable and provide superior protection against moisture, making them ideal for heavy-duty applications. They are also easy to clean and maintain.

Cons: The primary drawback of vinyl is its weight, which can make handling and storage more cumbersome. Additionally, prolonged exposure to UV light can lead to cracking and fading.

Impact on Application: Vinyl is particularly effective in environments with high moisture or chemical exposure, making it suitable for industrial applications.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure compliance with local safety and environmental regulations regarding vinyl materials.

Is Canvas a Viable Option for Protective Covers?

Canvas is a natural fabric made from cotton or linen, known for its strength and durability. It typically has a temperature rating of -20°F to 100°F (-29°C to 38°C) and offers good pressure resistance.

Pros: Canvas is breathable and offers a classic aesthetic, making it popular for residential applications. It is also relatively easy to repair if damaged.

Cons: Canvas is not inherently waterproof, which means it may require additional treatments to enhance its water resistance. It can also be heavier and bulkier compared to synthetic options.

Impact on Application: Canvas is suitable for applications where breathability is essential, such as covering furniture in temperate climates.

Considerations for International Buyers: Buyers should look for canvas that meets local quality standards, particularly in regions with high humidity, where mold and mildew resistance is critical.

What Makes Polyethylene a Popular Choice for Protective Covers?

Polyethylene is a lightweight, flexible plastic material that offers excellent water resistance. It can handle temperatures ranging from -40°F to 180°F (-40°C to 82°C) and is resistant to chemicals and UV light.

Pros: Polyethylene covers are cost-effective and lightweight, making them easy to transport and store. They provide excellent protection against moisture and debris.

Cons: The main limitation of polyethylene is its lower durability compared to other materials, as it can tear or puncture more easily.

Impact on Application: Polyethylene is ideal for temporary or seasonal use, such as covering outdoor furniture during winter months.

Considerations for International Buyers: Buyers should verify that polyethylene products meet relevant safety standards in their regions, particularly in Europe, where environmental regulations may affect the use of plastic materials.

Summary Table of Material Selection for Protective Covers

| Material | Typical Use Case for Protective Covers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor furniture covers | Lightweight and breathable | Can degrade with prolonged exposure | Medium |

| Vinyl | Heavy-duty industrial applications | Superior water and chemical resistance | Heavier and can crack under UV | High |

| Canvas | Residential furniture covers | Aesthetic appeal and easy repairs | Not inherently waterproof | Medium |

| Polyethylene | Temporary outdoor furniture protection | Cost-effective and lightweight | Lower durability | Low |

This guide provides a comprehensive overview of material options for protective covers, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for protective covers

What Are the Key Stages in the Manufacturing Process of Protective Covers?

Manufacturing protective covers involves several critical stages, each designed to ensure that the final product meets both functional and aesthetic requirements. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

This initial stage focuses on selecting high-quality materials that meet specific performance criteria. Common materials for protective covers include high-density polyethylene (HDPE), polyester, and vinyl, which offer durability and weather resistance. During this phase, manufacturers conduct tests to confirm that the materials possess the necessary properties such as UV resistance, waterproofing, and breathability. Proper storage and handling are crucial to prevent material degradation before production begins.

Forming

The forming stage involves cutting and shaping the prepared materials into the desired dimensions and patterns. This process may utilize various techniques such as die-cutting or laser cutting, ensuring precise measurements that align with the specifications of outdoor furniture or equipment. Computer-aided design (CAD) systems are often employed to create detailed templates that guide the cutting process, reducing waste and enhancing accuracy.

Assembly

Once the individual pieces are cut, they are assembled using techniques such as sewing or heat sealing. The choice of assembly technique can significantly impact the durability and water resistance of the final product. For instance, double-stitched seams are common in high-quality covers, providing additional strength and preventing fraying. Manufacturers may also incorporate features like zippers, buckles, or drawstrings during assembly to enhance functionality.

Finishing

The finishing stage includes quality checks and the application of additional protective coatings or treatments. This may involve the use of waterproofing sprays or UV-resistant finishes to extend the cover’s lifespan. The covers are then inspected for defects, and any necessary adjustments are made. Packaging is also a vital part of this stage, ensuring that the covers reach the buyer in pristine condition.

How Do Quality Assurance Processes Ensure Protective Covers Meet International Standards?

Quality assurance (QA) is integral to the manufacturing of protective covers, ensuring that products meet both industry standards and customer expectations. Various international and industry-specific standards guide these processes.

Relevant International Standards

Many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. In addition, products may need to comply with CE marking requirements in Europe, indicating conformity with health, safety, and environmental protection standards.

Industry-Specific Standards

Depending on the application, other certifications may be relevant. For example, covers used in marine environments may need to meet standards set by the American Boat and Yacht Council (ABYC) or the International Marine Certification Institute (IMCI). These standards help ensure that products can withstand specific environmental conditions.

What Are the Key Quality Control Checkpoints in Protective Cover Manufacturing?

Quality control (QC) checkpoints are critical throughout the manufacturing process to ensure that protective covers are produced to the highest standards. Key checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials before they enter the production process. This may include testing fabric for tensile strength, UV resistance, and water permeability. Any materials that do not meet the required specifications are rejected, ensuring that only high-quality components are used in production.

In-Process Quality Control (IPQC)

During manufacturing, IPQC involves monitoring the production process at various stages. This can include checking the accuracy of cutting patterns, inspecting seams during assembly, and testing for water resistance before moving to the finishing stage. Regular audits during this phase help identify potential issues early, reducing waste and rework.

Illustrative image related to protective covers

Final Quality Control (FQC)

Once the covers are fully assembled and finished, FQC is conducted to ensure the final product meets all specifications. This may involve visual inspections, functionality tests (e.g., fit and fastening), and performance evaluations (e.g., water resistance and UV durability). Only products that pass these checks are approved for shipment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and performance.

Conducting Supplier Audits

One effective way to verify QC processes is through on-site audits. Buyers can assess the manufacturing facility, review quality control documentation, and interact with staff to understand their processes. This hands-on approach provides valuable insights into the supplier’s commitment to quality.

Requesting Quality Control Reports

Suppliers should be willing to provide documentation related to their quality control practices, including inspection reports, test results, and certifications. These documents serve as proof of compliance with relevant standards and can help buyers assess the supplier’s reliability.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an objective assessment of the supplier’s quality control processes. These services can conduct random inspections during the manufacturing process and provide comprehensive reports on product quality, offering additional peace of mind for buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers need to be aware of specific nuances that may affect quality control when sourcing protective covers.

Understanding Regional Standards

Different regions may have varying quality standards and certifications. For example, European buyers may prioritize CE marking, while buyers in the Middle East may focus on local compliance regulations. Understanding these differences is crucial for ensuring that products meet the necessary requirements.

Logistical Considerations

Shipping protective covers internationally can introduce risks related to damage or degradation during transit. Buyers should ensure that suppliers use appropriate packaging and handling procedures to mitigate these risks. Additionally, understanding local customs regulations can help avoid delays and additional costs.

Building Long-Term Relationships

Establishing long-term relationships with reliable suppliers can enhance quality assurance. By fostering collaboration and open communication, buyers can work closely with suppliers to ensure ongoing compliance with quality standards and adapt to changing market needs.

By understanding the manufacturing processes and quality assurance practices for protective covers, B2B buyers can make informed decisions that ensure they are sourcing high-quality, reliable products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘protective covers’

When sourcing protective covers for outdoor furniture or equipment, it’s essential to adopt a structured approach. This guide provides a step-by-step checklist designed to help international B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select high-quality protective covers that meet your specific needs.

Illustrative image related to protective covers

Step 1: Identify Your Requirements

Begin by defining the specific types of protective covers you need. Consider the dimensions of the furniture or equipment, the material composition, and the environmental conditions they will face.

– Key considerations: Assess whether you need waterproof, breathable, or UV-resistant covers based on your climate and usage patterns.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in protective covers. Look for companies with a proven track record and positive reviews from clients in your region.

– What to look for: Supplier certifications, years in business, and any industry-specific experience, especially if you’re sourcing from regions like Africa or Europe.

Step 3: Evaluate Material Quality

The durability of protective covers largely depends on the materials used. Ensure that the covers are made from high-quality, weather-resistant materials that can withstand extreme conditions.

– Material types to consider: Look for options like 600 to 900 denier polyester, which provides excellent protection against rain, snow, and UV rays.

Step 4: Assess Customization Options

Not all furniture or equipment is standard size. Check if the supplier offers customization to ensure a snug fit for your items.

– Customization details: Inquire about tailoring options, such as specific dimensions, colors, and additional features like ventilation or securing mechanisms.

Step 5: Request Samples or Prototypes

Before making a bulk order, request samples or prototypes of the protective covers. This allows you to evaluate the fit, material quality, and overall functionality.

– Importance of testing: Assess how well the covers perform in real-world conditions, including their resistance to moisture and ease of use.

Step 6: Review Warranty and Return Policies

Examine the warranty and return policies offered by suppliers. A robust warranty can indicate confidence in the product’s durability and quality.

– What to check: Look for warranties that cover material defects and consider the duration—longer warranties may suggest higher quality.

Step 7: Negotiate Terms and Finalize the Order

Once you have selected a supplier, negotiate terms that benefit both parties. Discuss pricing, payment terms, and delivery timelines to ensure a smooth transaction.

– Final considerations: Ensure that you understand all contractual obligations, including shipping costs and responsibilities for damages during transit.

By following this checklist, B2B buyers can streamline the process of sourcing protective covers, ensuring that they invest in products that enhance the longevity and appearance of their outdoor furniture and equipment.

Comprehensive Cost and Pricing Analysis for protective covers Sourcing

What Are the Key Cost Components for Protective Covers Sourcing?

When sourcing protective covers, understanding the cost structure is crucial for B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to protective covers

-

Materials: The choice of fabric significantly influences the overall cost. High-quality, weather-resistant materials such as 600 to 900 denier polyester or specialized blends increase durability but also the price. Buyers should consider the long-term benefits of investing in superior materials that can withstand harsh climates.

-

Labor: Skilled labor is necessary for the production of high-quality covers, particularly if custom designs are involved. Labor costs can vary significantly by region, with countries in Europe typically facing higher wages compared to those in Africa or South America.

-

Manufacturing Overhead: This includes operational costs associated with running production facilities, which can vary based on location and efficiency. Facilities in regions with advanced technology may incur lower overhead costs due to automation.

-

Tooling: Custom tooling for unique designs adds to the initial investment but can lead to cost savings in mass production. For instance, companies that frequently order customized covers may benefit from investing in their tooling.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can increase costs but is essential for minimizing returns and maintaining customer satisfaction.

-

Logistics: Shipping costs depend on the size, weight, and destination of the covers. International shipments may involve additional fees related to customs and handling, which can significantly impact the total cost.

-

Margin: Suppliers typically add a margin to cover operational costs and profit. This margin can be negotiable, especially for bulk purchases.

How Do Price Influencers Affect Protective Covers Procurement?

Several factors influence pricing and should be carefully evaluated:

-

Volume/MOQ: Minimum order quantities (MOQs) can vary widely among suppliers. Purchasing in bulk can reduce per-unit costs, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom features, such as specific dimensions or unique design elements, can lead to higher costs. Buyers should balance the need for customization with budget constraints.

-

Quality and Certifications: Products with recognized quality certifications (e.g., ISO, CE) often come at a premium but offer assurance of durability and compliance with international standards.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities play a significant role in pricing. Engaging with reputable suppliers can ensure better quality and service, justifying higher costs.

-

Incoterms: Understanding delivery terms is crucial. Incoterms determine who bears responsibility for shipping costs and risks, affecting the overall pricing strategy.

What Tips Can Help Buyers Optimize Their Sourcing Costs?

To maximize value while minimizing costs, B2B buyers should consider the following strategies:

-

Negotiation: Establishing strong relationships with suppliers can facilitate better pricing. Buyers should be prepared to negotiate terms, especially when placing large orders.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and potential replacement costs. Investing in higher-quality covers may reduce TCO in the long run.

-

Understanding Pricing Nuances for International Buyers: International procurement, especially from regions like Africa, South America, the Middle East, and Europe, involves understanding local market dynamics, currency fluctuations, and potential tariffs. Buyers should factor these elements into their pricing strategy to avoid unexpected costs.

-

Market Research: Conduct thorough market research to compare pricing and quality across suppliers. This can provide leverage during negotiations and help identify the best value options.

Conclusion

Sourcing protective covers involves navigating a complex cost structure influenced by various factors. By understanding these components and employing strategic procurement practices, B2B buyers can optimize their purchasing decisions, ensuring they receive quality products at competitive prices. This comprehensive approach not only aids in immediate cost savings but also contributes to long-term investment in quality and durability.

Alternatives Analysis: Comparing protective covers With Other Solutions

Exploring Alternatives to Protective Covers for Outdoor Furniture

In the quest for optimal protection of outdoor furniture, businesses often seek alternatives to traditional protective covers. While these covers offer numerous advantages, it is essential to evaluate other solutions that may provide similar benefits. This analysis will compare protective covers against two viable alternatives: indoor storage solutions and custom-built enclosures.

Comparison Table

| Comparison Aspect | Protective Covers | Indoor Storage Solutions | Custom-Built Enclosures |

|---|---|---|---|

| Performance | Excellent protection against weather and debris | Effective but limited to available space | Highly effective, tailored to specific needs |

| Cost | Moderate initial investment, long-term savings | Potentially high costs for storage space | High upfront costs, but durable long-term |

| Ease of Implementation | Simple to use, requires minimal setup | Requires planning and space management | Complex design and construction needed |

| Maintenance | Minimal; occasional cleaning required | Regular cleaning and maintenance | Low; once built, requires little upkeep |

| Best Use Case | Ideal for seasonal protection and outdoor settings | Best for limited outdoor space | Suitable for permanent, high-value setups |

Detailed Breakdown of Alternatives

Indoor Storage Solutions

Indoor storage for outdoor furniture can be a practical alternative, especially for businesses with limited outdoor space. This method involves moving furniture indoors during adverse weather conditions. The primary advantage is that it provides comprehensive protection from all elements, including humidity and pests. However, this solution may not be feasible for larger items or businesses with inadequate storage space. Additionally, the labor involved in moving furniture can be a deterrent for frequent use.

Illustrative image related to protective covers

Custom-Built Enclosures

Custom-built enclosures offer a robust solution for protecting outdoor furniture. These structures are designed to fit specific furniture pieces, providing superior protection from the elements. The durability and customization options are significant advantages, as enclosures can be constructed from various materials like wood, metal, or weather-resistant plastics. However, the initial investment can be substantial, and the construction process may require considerable time and planning. Once installed, enclosures require minimal maintenance, making them a long-term solution for businesses looking for high-value protection.

Conclusion

Choosing the right solution for protecting outdoor furniture depends on various factors, including the specific needs of the business, available space, and budget. Protective covers provide a flexible and cost-effective option for seasonal use, while indoor storage is suitable for businesses with limited outdoor space. Custom-built enclosures, while more expensive, offer tailored protection for long-term investments. B2B buyers should assess their unique circumstances, weigh the pros and cons of each alternative, and select a solution that aligns with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for protective covers

What Are the Key Technical Properties of Protective Covers?

When selecting protective covers, understanding their technical specifications is crucial for ensuring optimal performance and longevity. Here are some of the essential properties to consider:

1. Material Grade

The material grade of a protective cover typically refers to the thickness and quality of the fabric used, often measured in denier (D). For instance, covers made of 600 to 900 denier polyester are common for outdoor furniture, providing durability against harsh weather. A higher denier indicates a tougher fabric, which is critical for B2B buyers looking to invest in covers that withstand wear and tear over time. Choosing the right material grade can significantly reduce replacement costs and enhance customer satisfaction.

2. Water Resistance vs. Waterproofing

Water resistance indicates a fabric’s ability to repel water while allowing moisture to escape, preventing mold and mildew. In contrast, waterproof fabrics can trap moisture underneath, leading to potential damage. B2B buyers should prioritize water-resistant covers for outdoor applications, as they provide a balance between protection and breathability. This choice is essential for maintaining the integrity of the furniture underneath, especially in regions with variable climates.

3. UV Protection Rating

UV protection ratings indicate the cover’s ability to shield furniture from harmful ultraviolet rays that can cause fading and degradation. Materials with a high UV protection rating are vital for businesses operating in sun-drenched regions, as they help extend the lifespan of the furniture beneath the cover. This specification is particularly relevant for B2B buyers in sectors such as hospitality and outdoor recreation, where the appearance of furniture is paramount.

4. Breathability

Breathable fabrics allow air circulation, reducing moisture buildup inside the cover. This property is crucial for preventing mold growth and preserving the quality of the furniture. B2B buyers should look for covers with ventilation features, such as mesh vents, that facilitate airflow while still providing protection from the elements. This is especially important in humid climates where moisture retention can lead to significant damage.

5. Fit and Customization Options

The fit of a protective cover is vital for ensuring complete coverage and protection. Many manufacturers offer custom sizes to match specific furniture dimensions, which can be particularly advantageous for businesses with unique or high-end outdoor furniture. Ensuring a proper fit minimizes the risk of damage from wind or rain, making this a critical consideration for B2B buyers looking to maintain their investment.

What Are the Common Trade Terms Related to Protective Covers?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of protective covers, understanding OEM relationships can help buyers identify quality sources for custom or branded covers.

Illustrative image related to protective covers

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory costs effectively and ensure they are not over-committing to a supplier’s requirements.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For protective covers, submitting an RFQ can help buyers compare different suppliers’ offerings, ensuring they get the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with these terms can help B2B buyers navigate shipping logistics and costs associated with importing protective covers from different countries.

5. Lead Time

This term refers to the time it takes from placing an order until it is delivered. Understanding lead times is crucial for B2B buyers to ensure timely availability of protective covers, especially in industries where seasonal demand can affect inventory levels.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their procurement strategies for protective covers.

Navigating Market Dynamics and Sourcing Trends in the protective covers Sector

What Are the Current Trends Influencing the Protective Covers Market?

The protective covers market is experiencing dynamic shifts driven by several global factors. Increasing consumer awareness regarding the longevity of outdoor investments has led to a surge in demand for high-quality protective solutions. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are focusing on durability and functionality in their sourcing decisions. Key trends include the integration of advanced materials that offer better resistance to environmental factors such as UV rays, moisture, and temperature fluctuations. B2B buyers are increasingly seeking custom-fit solutions tailored to specific furniture styles, ensuring optimal protection.

Additionally, the rise of e-commerce platforms has transformed how businesses connect with suppliers. Buyers can now access a wide range of products and compare features, prices, and customer reviews more efficiently. Emerging technologies, such as AI-driven supply chain analytics, are also enabling better inventory management and demand forecasting, allowing suppliers to respond swiftly to market changes. Furthermore, the trend towards personalization in products is gaining traction, with buyers looking for unique designs and sizes that cater to their specific needs.

How Is Sustainability Shaping the Protective Covers Industry?

Sustainability is becoming a critical component in the decision-making process for B2B buyers in the protective covers sector. The environmental impact of materials used in manufacturing protective covers is under scrutiny, pushing companies to adopt greener practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainability. This includes using recycled materials and biodegradable options that reduce the overall carbon footprint of the products.

Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX indicate that materials meet high environmental and safety standards, giving buyers assurance in their sourcing decisions. Moreover, companies that focus on sustainable practices often experience enhanced brand loyalty and customer retention, as they align with the values of environmentally conscious consumers. This trend is particularly significant in regions like Europe, where regulations on environmental standards are stringent, influencing buyers to seek compliant suppliers. As the market evolves, those who invest in sustainable practices will likely gain a competitive edge.

What Historical Developments Have Shaped the Protective Covers Market?

The protective covers market has evolved significantly over the decades, transitioning from simple tarpaulins to sophisticated, purpose-built products. Initially, protective covers were primarily utilitarian, designed to shield items from the elements without much consideration for aesthetics or material quality. However, as outdoor living spaces gained popularity, particularly in Europe and North America, the demand for stylish and durable covers surged.

Advancements in textile technology have enabled the development of high-performance materials that offer water resistance, breathability, and UV protection. This evolution has been further accelerated by consumer demand for products that not only protect but also enhance the visual appeal of outdoor settings. The growth of e-commerce has also played a pivotal role, allowing manufacturers and suppliers to reach a broader audience and facilitate international trade more efficiently. As a result, the protective covers market is now characterized by innovation, customization, and a strong focus on sustainability, reflecting the changing needs and preferences of B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of protective covers

-

How do I choose the right protective cover for my outdoor furniture?

Selecting the right protective cover involves assessing the dimensions and style of your furniture. Measure each piece carefully, considering any additional features like armrests or umbrella holes. Look for covers made from durable, weather-resistant materials that provide breathability to prevent mold and mildew. Additionally, consider the climate in your region; for instance, heavier materials may be necessary in areas with harsh winters. Custom sizing options are also available from many suppliers, ensuring a perfect fit for your furniture. -

What are the benefits of using protective covers for outdoor furniture?

Protective covers significantly extend the lifespan of outdoor furniture by shielding it from environmental damage such as UV rays, moisture, and debris. They help maintain the appearance of furniture, reducing the need for repairs or replacements. In regions with extreme weather, using covers can also prevent issues like rust, mold, and fading. Overall, investing in high-quality protective covers saves costs over time by minimizing maintenance and replacement needs. -

What is the minimum order quantity (MOQ) for protective covers when sourcing internationally?

The MOQ for protective covers varies by supplier and product type. Typically, it can range from as few as 50 units to several hundred, depending on customization options and materials used. It’s advisable to discuss MOQs with suppliers during the initial negotiation phase to ensure they align with your business needs. Additionally, some manufacturers may offer flexibility for first-time orders or larger contracts, so it’s worth exploring these options. -

How can I ensure quality assurance (QA) when sourcing protective covers?

To ensure quality assurance, request samples before placing a bulk order to evaluate the materials and craftsmanship. Establish clear quality standards and specifications in your purchase agreement. It’s also beneficial to inquire about the supplier’s QA processes, such as inspections during production and before shipment. Consider visiting the manufacturing facility if feasible, or utilizing third-party inspection services to verify that products meet your standards. -

What payment terms are commonly offered by suppliers for protective covers?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upfront with the remaining balance due prior to shipping. Some suppliers may offer net 30 or net 60 payment terms, allowing you to pay after receiving the goods. It’s essential to negotiate terms that suit your cash flow needs and to confirm accepted payment methods, which may include bank transfers, letters of credit, or online payment platforms. -

How do I handle logistics and shipping for international orders of protective covers?

Handling logistics involves coordinating with freight forwarders or shipping companies to ensure timely delivery. Be aware of the shipping options available, such as air freight for faster delivery or sea freight for cost-effective shipping. It’s crucial to understand customs regulations in your country to avoid delays. Ensure that the supplier provides all necessary documentation, including commercial invoices and packing lists, to facilitate a smooth import process. -

What customization options should I consider when sourcing protective covers?

Customization options can include size, color, material, and branding features such as logos. Consider your target market’s preferences when deciding on colors and styles. Additionally, discuss the possibility of adding features like adjustable straps or ventilation to enhance functionality. Custom options can set your products apart in a competitive market, so it’s beneficial to work closely with suppliers to explore all available choices. -

What should I look for in a supplier of protective covers?

When vetting suppliers, prioritize their experience in the industry, product quality, and customer reviews. Request references from other businesses to gauge reliability and service quality. Additionally, assess their manufacturing capabilities, including lead times and flexibility in production. Sustainability practices can also be important; suppliers using eco-friendly materials may appeal more to environmentally conscious consumers. Establishing a strong communication line is essential for a successful partnership, so ensure they are responsive and transparent.

Top 6 Protective Covers Manufacturers & Suppliers List

1. Hineighbor – Haven Protective Covers

Domain: hineighbor.com

Registered: 1998 (27 years)

Introduction: Outdoor Furniture Covers are crafted with durable and weather-resistant materials, providing optimal protection for outdoor furniture to ensure longevity. Key products include: 1. Haven Protective Covers – $250 2. Loveseat – Terra Protective Covers – $280 3. Haven Protective Covers – $170 4. Haven Protective Covers – $510 5. Chair – Leedo Protective Covers – $220 6. Low Chair Protective Covers – $…

2. Covercraft – Patio Covers

Domain: covercraft.com

Registered: 1995 (30 years)

Introduction: Patio Covers include a variety of options such as Patio Seating Covers, Patio Table Covers, Patio Grill Covers, Patio Umbrella Covers, Patio Heater & FirePit Covers, Patio Seat Covers, Patio Chair Covers, Patio Sofa Covers, Patio Chaise Lounge Covers, Patio Glider Covers, Patio Sectional Covers, Patio Chair Cushion Covers, and Outdoor Table Covers. They are available in different shapes including …

3. Chicory – Teak Seating Protective Covers

Domain: chicoryhome.com

Registered: 2019 (6 years)

Introduction: Protective Covers for Teak Seating | Chicory x Dwell™ Collection

– Quick-Use Outdoor Cushion Cover for Modular Teak Unit: $55.20 (originally $69.00)

– All-Season Outdoor Protective Cover for Teak Armchair: $103.20 (originally $129.00)

– All-Season Outdoor Protective Cover for Modular Teak Unit – Corner Chair or End Chair: $79.20 (originally $99.00)

– All-Season Outdoor Protective Cover for Modular…

4. Peachtree Covers – Walkway Covers & Canopies

Domain: peachtreecovers.com

Registered: 1997 (28 years)

Introduction: {“Walkway Covers & Canopies”: {“description”: “Leading supplier of extruded aluminum walkway covers, focusing on innovative and cost-effective designs.”, “features”: [“Custom designs for owners and architects”, “Durable extruded aluminum construction”]}, “Sun Control Devices / Vision Screens”: {“description”: “Development of solar control devices providing maintenance-free features and solutions f…

5. McKinnon Harris – Luxury Outdoor Furniture Protective Covers

Domain: mckinnonharris.com

Registered: 1998 (27 years)

Introduction: Protective Covers are designed for luxury outdoor furniture when not in use for extended periods. Each cover is tailored to fit specific furniture pieces and is made from High Performance Marine Protective Fabric available in four colors: Antique Beige, Cadet Gray, Captain’s Navy, and Taupe. The fabric is 100% Acrylic with a soft tricot polyester underside, resistant to sun, rain, and mildew. Cove…

6. STI – Protective Covers & Polycarbonate Cases

Domain: sti-global.com

Registered: 2023 (2 years)

Introduction: STI’s protective covers and polycarbonate cases provide durable defense against vandalism, accidental damage, and environmental wear. Designed for high-traffic and high-risk areas, these enclosures safeguard fire alarms, emergency buttons, and other critical devices. Ideal for construction contractors and building maintenance supervisors, they extend equipment lifespan, reduce maintenance costs, a…

Strategic Sourcing Conclusion and Outlook for protective covers

How Can Strategic Sourcing Enhance Your Procurement of Protective Covers?

In the competitive landscape of protective covers, strategic sourcing emerges as a critical approach for international B2B buyers. By identifying reliable suppliers who offer high-quality, weather-resistant materials, businesses can ensure the longevity and functionality of their outdoor furniture. This not only protects investments but also reduces long-term costs associated with repairs and replacements. Furthermore, leveraging relationships with manufacturers can lead to custom solutions tailored to specific needs, enhancing overall satisfaction.

What Are the Long-term Benefits of Investing in Quality Protective Covers?

Investing in high-quality protective covers is not just a matter of immediate protection; it is a strategic decision that promotes sustainability and durability. With the right covers, businesses can maintain the aesthetic appeal of their outdoor furniture while minimizing maintenance efforts. This is particularly vital for buyers in diverse climates, where varying weather conditions can significantly impact the integrity of outdoor assets.

How Should International Buyers Approach Future Sourcing Strategies?

As we look to the future, international B2B buyers from regions like Africa, South America, the Middle East, and Europe should prioritize collaboration with manufacturers who understand regional needs and offer versatile solutions. Engaging in strategic sourcing can unlock access to innovative products and services that align with evolving market demands. By taking proactive steps now, businesses can secure a competitive edge and ensure their outdoor investments remain protected for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.