Process Equipment & Supply Inc Eastlake: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for process equipment & supply inc eastlake

In today’s fast-paced global market, sourcing reliable process equipment can be a daunting challenge for B2B buyers, particularly those navigating the diverse landscapes of Africa, South America, the Middle East, and Europe. Process Equipment & Supply Inc. in Eastlake, Ohio, stands out as a premier partner for businesses seeking high-quality ultrasonic cleaning equipment and supplies. With over 50 years of expertise, this family-owned company offers an extensive range of products, including benchtop ultrasonic cleaners, cell disruptors, and specialized cleaning chemicals, catering to various industries such as medical, electronics, and manufacturing.

This comprehensive guide aims to equip international buyers with the essential insights needed to make informed purchasing decisions. We will delve into the types of ultrasonic equipment available, their specific applications, and how to effectively vet suppliers to ensure quality and reliability. Additionally, we will explore cost considerations, enabling buyers to budget effectively while maximizing value. By addressing these key areas, this guide empowers you to navigate the complexities of the global market confidently, ensuring you select the right equipment to meet your operational needs and drive your business forward. Whether you’re in Saudi Arabia, Brazil, or beyond, understanding the nuances of sourcing from Process Equipment & Supply Inc. can enhance your procurement strategy and operational efficiency.

Understanding process equipment & supply inc eastlake Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ultrasonic Cleaners | Available in various sizes from 1 pint to 20 gallons | Cleaning medical instruments, jewelry, automotive parts | Pros: Effective cleaning, versatile applications. Cons: Size limitations for large items. |

| Benchtop Ultrasonic Baths | Compact design, suitable for laboratory use | Sample preparation, laboratory equipment cleaning | Pros: Space-saving, easy to use. Cons: Limited capacity compared to larger tanks. |

| Sonifier Cell Disruptors | Advanced processing capabilities with temperature control | Cell disruption in laboratories, homogenization of samples | Pros: High precision, efficient sample processing. Cons: Higher investment cost. |

| Cleaning Chemicals | Specialized formulas for various cleaning applications | Enhancing cleaning effectiveness in ultrasonic systems | Pros: Tailored solutions for specific needs. Cons: Ongoing supply costs. |

| Ultrasonic Accessories | Complementary tools and parts for ultrasonic systems | Maintenance and optimization of ultrasonic cleaning processes | Pros: Improves equipment longevity, enhances performance. Cons: Additional procurement complexity. |

What Are the Key Characteristics of Ultrasonic Cleaners?

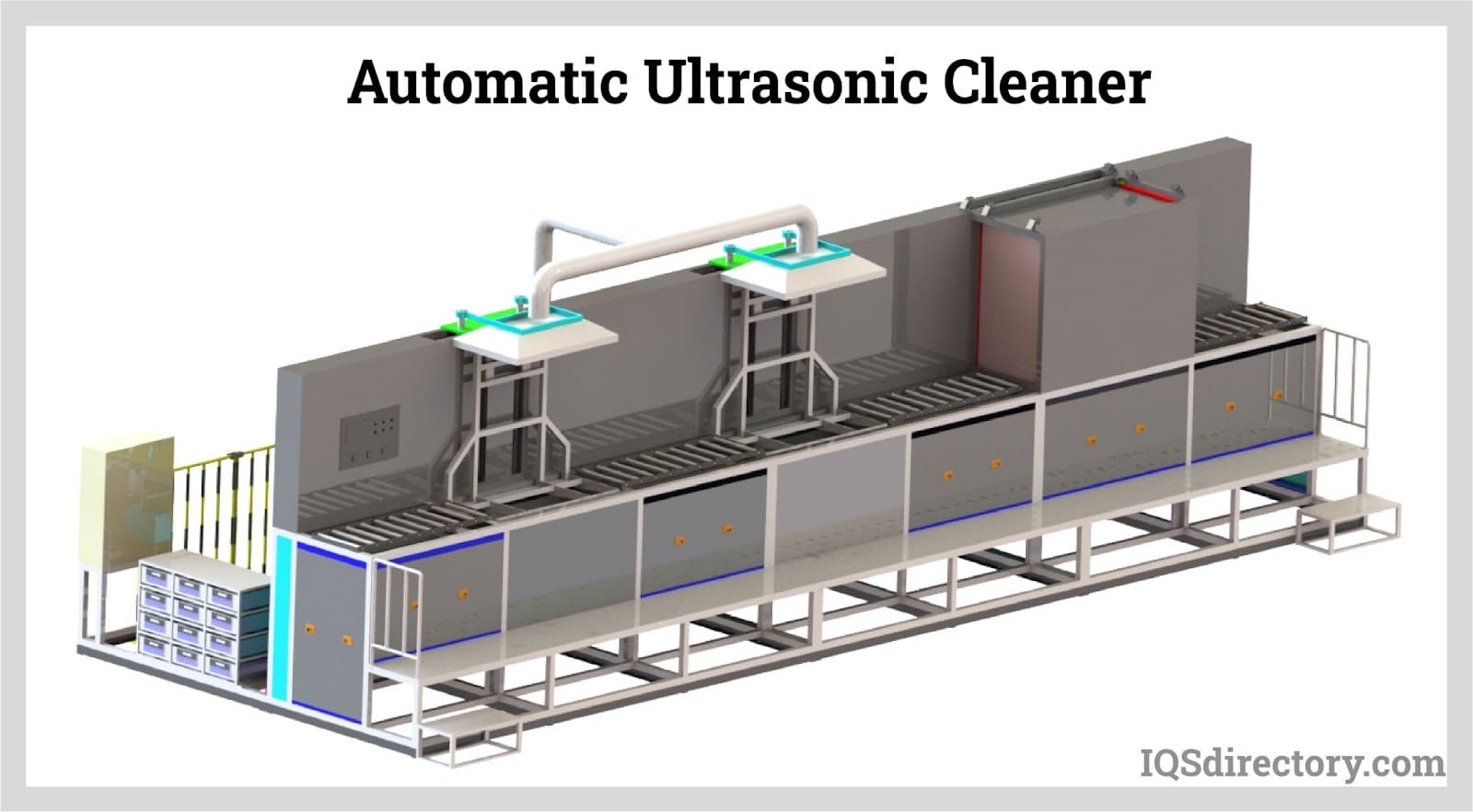

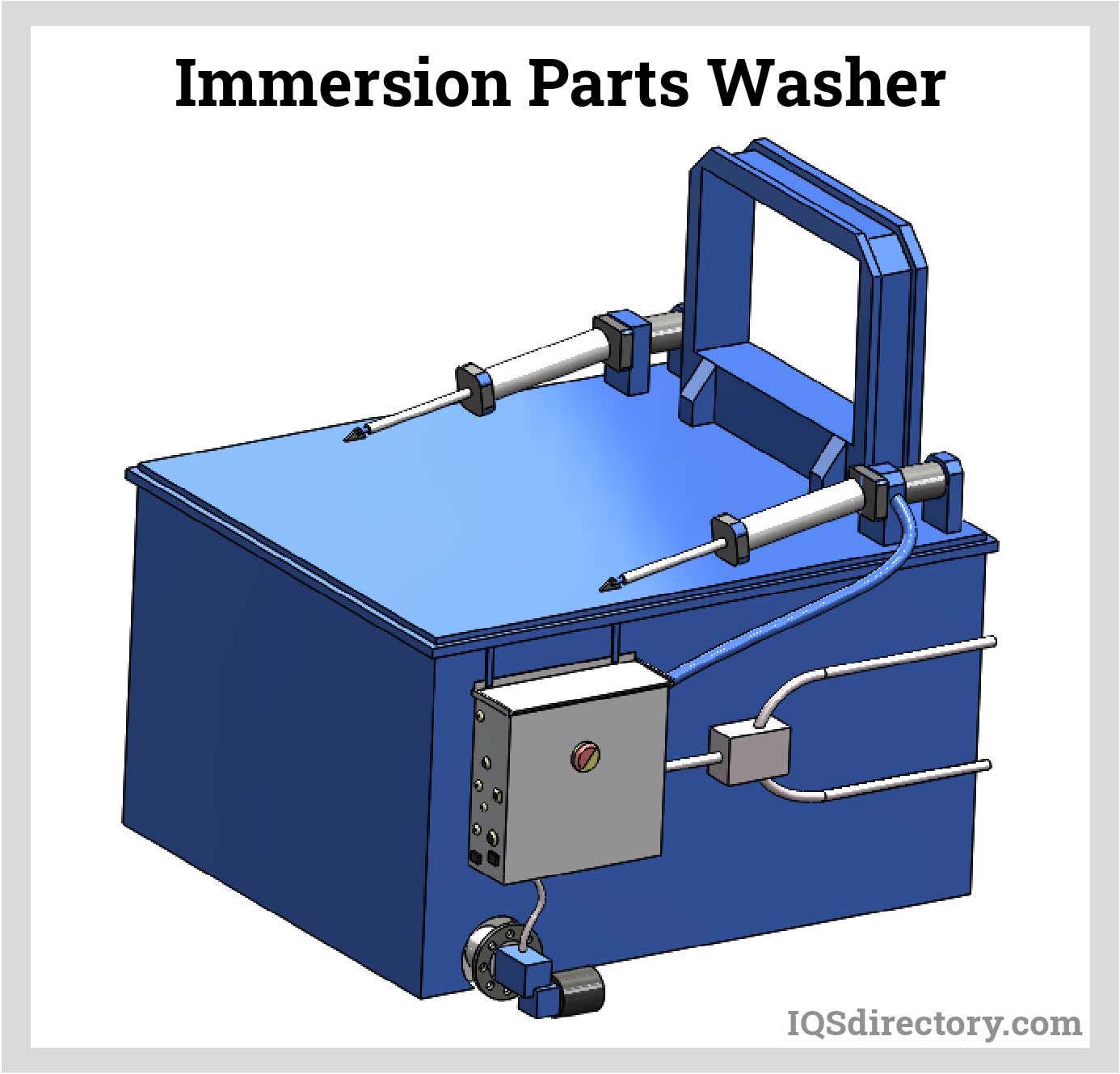

Ultrasonic cleaners are versatile machines that utilize high-frequency sound waves to produce microscopic bubbles in a cleaning solution. These bubbles collapse violently, creating a scrubbing action that removes dirt and contaminants from surfaces. They come in various sizes, making them suitable for applications ranging from delicate jewelry cleaning to heavy-duty industrial cleaning. B2B buyers should consider the specific size and capacity needed for their operations, as well as the types of materials they will be cleaning.

How Do Benchtop Ultrasonic Baths Differ from Larger Units?

Benchtop ultrasonic baths are compact units designed for laboratory environments, ideal for cleaning small parts and samples. Their size allows for easy placement on workbenches, making them accessible for frequent use. While they are effective for laboratory cleaning, their capacity is limited compared to larger industrial units. Buyers should evaluate the volume of items they plan to clean and the frequency of use to determine if a benchtop model meets their needs.

Why Invest in Sonifier Cell Disruptors?

Sonifier cell disruptors are specialized devices used for breaking down cells and homogenizing samples in laboratory settings. With advanced features such as temperature control and energy monitoring, these devices ensure consistent and precise results. They are particularly beneficial in biological and chemical research where sample integrity is crucial. B2B buyers should assess the specific processing requirements of their applications, as the initial investment can be significant, but the return in efficiency may justify the cost.

What Role Do Cleaning Chemicals Play in Ultrasonic Systems?

Cleaning chemicals formulated for ultrasonic systems enhance the cleaning process by targeting specific types of contaminants, such as oils, greases, and biological materials. Using the right cleaning solution can significantly improve cleaning efficiency and speed. Buyers must consider the compatibility of these chemicals with their ultrasonic equipment and the materials being cleaned, as well as the ongoing costs associated with maintaining a supply of these chemicals.

How Do Ultrasonic Accessories Enhance Cleaning Performance?

Ultrasonic accessories, including baskets, lids, and specialized cleaning solutions, play a crucial role in optimizing the performance of ultrasonic cleaning systems. These tools can help improve the effectiveness of the cleaning process and extend the lifespan of the equipment. Buyers should think about the specific accessories that will complement their cleaning tasks and whether they need to invest in these items to achieve optimal results.

Key Industrial Applications of process equipment & supply inc eastlake

| Industry/Sector | Specific Application of process equipment & supply inc eastlake | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical & Healthcare | Ultrasonic cleaning of surgical instruments | Ensures high standards of hygiene and sterilization | Compliance with international health regulations, delivery timelines, and product certifications |

| Electronics Manufacturing | Cleaning of intricate electronic components | Improves product reliability and performance | Availability of various sizes of ultrasonic cleaners and compatibility with specific cleaning agents |

| Automotive | Cleaning of automotive parts and components | Enhances maintenance processes and prolongs equipment life | Access to large-capacity ultrasonic tanks and specialized cleaning solutions |

| Laboratory & Research | Sample preparation and cell disruption using Sonifiers | Increases accuracy in research results and sample integrity | Need for precise control features and reliable technical support for equipment operation |

| Jewelry & Precious Metals | Ultrasonic cleaning of jewelry and precious items | Restores aesthetics and value of items without damage | Sourcing equipment that caters to both small and large-scale cleaning needs, including chemical compatibility |

In the medical and healthcare sector, ultrasonic cleaning is crucial for maintaining the hygiene of surgical instruments. Process Equipment & Supply, Inc. provides specialized ultrasonic cleaners that help hospitals and clinics ensure that all tools are sterilized effectively. This is particularly important for international buyers in regions with strict health regulations, such as the Middle East and Europe, where compliance with safety standards is mandatory. Buyers should consider certification and delivery timelines to ensure timely access to these essential tools.

In electronics manufacturing, the need for cleanliness in intricate components is paramount. Process Equipment & Supply offers ultrasonic cleaners tailored for this application, which remove contaminants without damaging sensitive parts. This not only enhances product reliability but also boosts performance. B2B buyers from South America and Africa should focus on the compatibility of cleaning solutions with specific electronic components to avoid any adverse reactions.

The automotive industry benefits significantly from the use of ultrasonic cleaning for parts and components. By utilizing large-capacity tanks, Process Equipment & Supply allows for efficient cleaning that prolongs the lifespan of automotive equipment. For international buyers, especially in Brazil, sourcing considerations should include the availability of tailored cleaning solutions for various automotive applications, ensuring that all parts are treated effectively.

In laboratories and research facilities, the Sonifiers offered by Process Equipment & Supply are instrumental in sample preparation and cell disruption. These devices enhance the accuracy of research results by providing precise control over the cleaning and processing conditions. Buyers, particularly those in Europe, must ensure that the equipment meets their specific technical requirements and that reliable support is available for troubleshooting and maintenance.

Lastly, in the jewelry and precious metals sector, ultrasonic cleaning revitalizes items without causing damage. Process Equipment & Supply provides solutions that cater to both small-scale jewelers and larger operations, ensuring that all items are cleaned thoroughly. International buyers should focus on sourcing equipment that accommodates a range of cleaning needs while ensuring compatibility with various cleaning agents to maintain the integrity of precious items.

3 Common User Pain Points for ‘process equipment & supply inc eastlake’ & Their Solutions

Scenario 1: Navigating Complex Equipment Specifications

The Problem: B2B buyers often struggle with the technical specifications of ultrasonic cleaning equipment and other process equipment. With varying sizes, capabilities, and intended applications, choosing the right equipment can feel overwhelming. For instance, a medical laboratory in Brazil may need a specific ultrasonic cleaner for sterilizing instruments but finds it challenging to identify which model meets their requirements without in-depth technical knowledge.

The Solution: To effectively navigate equipment specifications, buyers should begin by clearly defining their cleaning requirements, including the types of materials and contaminants they need to address. Process Equipment & Supply, Inc. provides detailed product manuals and application data that can help buyers understand the capabilities of each ultrasonic cleaner. Furthermore, engaging with their knowledgeable sales team for a consultation can provide personalized recommendations tailored to specific use cases. Buyers should also consider requesting demo units where possible to evaluate performance before making a purchase, ensuring the selected equipment meets their operational needs.

Scenario 2: Ensuring Compliance with International Standards

The Problem: International buyers, particularly in the medical and electronics sectors, often face challenges in ensuring that their equipment meets local and international compliance standards. For example, a company in Saudi Arabia may be concerned about whether the ultrasonic cleaning equipment adheres to regional regulations and safety standards, risking potential fines or operational delays if non-compliant equipment is procured.

The Solution: To mitigate compliance risks, buyers should conduct thorough research on applicable standards and regulations in their region before purchasing. Process Equipment & Supply, Inc. offers resources and documentation that outline compliance for their products, including certifications and safety features. Buyers should also engage in proactive communication with the supplier, requesting documentation that verifies compliance with specific international standards such as ISO or FDA guidelines. This due diligence not only ensures compliance but also builds a strong foundation for a trustworthy supplier relationship.

Scenario 3: Managing Supply Chain Disruptions

The Problem: Global supply chain disruptions have become a pressing issue for B2B buyers, leading to delays in equipment delivery and increased costs. A manufacturing facility in South America may face production halts due to delays in receiving essential ultrasonic cleaners from overseas suppliers, impacting their operational efficiency and bottom line.

The Solution: To effectively manage supply chain risks, B2B buyers should consider establishing relationships with local distributors like Process Equipment & Supply, Inc., which stocks a diverse range of equipment. By opting for suppliers with a strong inventory and domestic shipping capabilities, buyers can significantly reduce lead times. Additionally, maintaining open lines of communication with suppliers regarding inventory levels can help buyers anticipate potential delays. Buyers should also explore flexible purchasing options, such as rental agreements or phased deliveries, allowing them to maintain operations while waiting for the full equipment procurement to be fulfilled. This strategic approach helps to ensure continuity in operations, even amidst global supply challenges.

Strategic Material Selection Guide for process equipment & supply inc eastlake

What Are the Key Materials Used in Process Equipment & Supply Inc. Eastlake Products?

When selecting materials for ultrasonic cleaning equipment and related products, it is essential to consider their properties, advantages, and limitations. Below, we analyze four common materials used in the offerings from Process Equipment & Supply Inc. in Eastlake, focusing on their relevance to international B2B buyers.

Stainless Steel: A Versatile Choice for Ultrasonic Cleaners

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures and pressures. It is particularly suitable for applications involving aggressive cleaning agents.

Pros & Cons: The durability of stainless steel makes it ideal for long-term use, especially in industrial settings. However, it can be more expensive than other materials, and its manufacturing complexity may lead to higher production costs.

Impact on Application: Stainless steel is compatible with various cleaning media, including solvents and detergents, making it versatile for multiple applications, from medical instruments to automotive parts.

International Considerations: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM or DIN for stainless steel grades. The preference for specific grades may vary by industry, necessitating thorough understanding.

Polypropylene: Cost-Effective and Chemical Resistant

Key Properties: Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and lightweight nature. It can withstand moderate temperatures and is often used in applications where weight is a concern.

Pros & Cons: This material is cost-effective and easy to mold, making it suitable for mass production. However, its lower temperature tolerance compared to metals can limit its use in high-temperature applications.

Impact on Application: Polypropylene is ideal for use in ultrasonic cleaning baths that require resistance to chemical agents, especially in laboratory environments.

Illustrative image related to process equipment & supply inc eastlake

International Considerations: Compliance with international material safety standards is crucial for buyers, especially in regions like South America, where regulations may differ. Understanding local preferences for material types can influence purchasing decisions.

Aluminum: Lightweight and Conductive

Key Properties: Aluminum is lightweight, has good thermal conductivity, and offers moderate corrosion resistance. It is often used in applications requiring efficient heat dissipation.

Pros & Cons: The light weight of aluminum makes it easy to handle and install, but its corrosion resistance is inferior to stainless steel. Additionally, while it is generally more affordable, it may require protective coatings for specific applications.

Illustrative image related to process equipment & supply inc eastlake

Impact on Application: Aluminum is suitable for components that benefit from its thermal properties, such as parts of ultrasonic cleaners that require rapid heating.

International Considerations: Buyers in Africa and the Middle East should be aware of the potential for corrosion in humid environments and consider protective measures. Compliance with local standards for aluminum alloys is also essential.

Glass: Transparency and Chemical Inertness

Key Properties: Glass is chemically inert and resistant to a wide range of substances, making it ideal for applications where contamination must be avoided. It can also withstand high temperatures.

Pros & Cons: The transparency of glass allows for easy monitoring of cleaning processes. However, it is fragile and can be more expensive than other materials, limiting its use in high-impact environments.

Impact on Application: Glass is often used in laboratory settings for ultrasonic cleaning of sensitive instruments, where contamination must be minimized.

International Considerations: Compliance with safety standards for glass materials is critical, particularly in regions with stringent regulations. Understanding the local market’s acceptance of glass in industrial applications can influence procurement strategies.

Summary Table of Material Selection

| Material | Typical Use Case for process equipment & supply inc eastlake | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Ultrasonic cleaners for industrial and medical applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Polypropylene | Ultrasonic cleaning baths in laboratories | Cost-effective and lightweight | Limited temperature tolerance | Low |

| Aluminum | Components in ultrasonic cleaners requiring heat dissipation | Lightweight and good thermal conductivity | Inferior corrosion resistance | Medium |

| Glass | Cleaning sensitive laboratory instruments | Chemically inert and transparent | Fragile and potentially high cost | Medium to High |

This material selection guide provides insights into the properties and considerations of various materials relevant to Process Equipment & Supply Inc. in Eastlake. Understanding these factors is crucial for international B2B buyers looking to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for process equipment & supply inc eastlake

What Are the Key Stages in the Manufacturing Process at Process Equipment & Supply Inc.?

Process Equipment & Supply Inc. in Eastlake, Ohio, specializes in distributing high-quality ultrasonic cleaning equipment and accessories. Understanding the manufacturing processes involved in their product offerings is crucial for B2B buyers, especially those in diverse markets like Africa, South America, the Middle East, and Europe.

The manufacturing process typically involves several key stages:

-

Material Preparation: This initial stage focuses on sourcing high-quality raw materials. For ultrasonic cleaning equipment, this may include stainless steel for tanks and robust plastics for components. Suppliers often conduct thorough assessments of material suppliers to ensure compliance with international quality standards.

-

Forming: The forming process involves shaping the materials into the desired components. Techniques such as stamping, welding, and machining are commonly employed to create precise parts that meet stringent specifications. Advanced technologies like CNC machining are often used to enhance accuracy and reduce waste.

-

Assembly: Once individual components are formed, they are meticulously assembled. This stage requires skilled labor and may involve automated assembly lines for consistency. Each unit undergoes a series of checks to ensure that all components fit together correctly and function as intended.

-

Finishing: The final stage involves applying protective coatings and surface treatments to enhance durability and performance. This may include electroplating or painting, which not only improves aesthetics but also protects against corrosion and wear.

How Is Quality Control Implemented in Manufacturing Processes?

Quality assurance is a cornerstone of Process Equipment & Supply Inc.’s operations. The company adheres to various international standards, including ISO 9001, which emphasizes a quality management system that ensures continuous improvement and customer satisfaction. For specific product categories, compliance with industry standards such as CE marking and API specifications is also critical.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before entering the production line. Non-conforming materials are rejected or returned to the supplier.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections and tests are conducted to verify that processes are being followed correctly and that products meet design specifications. This may involve monitoring dimensions, assembly accuracy, and performance metrics.

-

Final Quality Control (FQC): Once products are assembled and finished, they undergo a comprehensive inspection. This includes functional testing to ensure that ultrasonic cleaners operate effectively under specified conditions. Any defective units are identified and either repaired or scrapped.

What International Standards and Certifications Are Relevant to B2B Buyers?

For B2B buyers, especially those from international markets, understanding the relevant certifications and quality standards is crucial. Process Equipment & Supply Inc. prioritizes compliance with several key standards:

-

ISO 9001: This globally recognized standard ensures that organizations meet the needs of customers and other stakeholders while meeting statutory and regulatory requirements.

-

CE Marking: This certification indicates that products meet European safety, health, and environmental protection standards. It is particularly important for buyers in Europe and the Middle East.

-

API Standards: For buyers in industries such as oil and gas, adherence to American Petroleum Institute (API) standards ensures that products are safe, reliable, and of high quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying the quality control practices of suppliers like Process Equipment & Supply Inc. is essential to ensure product reliability and compliance with regulations. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational efficiency. This firsthand observation can provide insights into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should ask for detailed quality assurance reports that outline the results of IQC, IPQC, and FQC processes. These reports should include metrics related to defect rates, compliance with standards, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. This is particularly beneficial for buyers in regions with stringent import regulations, ensuring that products meet local standards before shipment.

What Are the Nuances of Quality Control for International B2B Transactions?

When engaging in international B2B transactions, especially with suppliers in the U.S., buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of several nuances:

-

Cultural Differences: Understanding cultural attitudes toward quality and business practices can impact negotiations and expectations. Building strong relationships with suppliers can foster better communication and trust.

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers must ensure that the products not only meet their own country’s standards but also comply with the regulations of the exporting country.

-

Logistics and Supply Chain Considerations: International shipping introduces additional challenges, including potential delays and damage during transit. Ensuring robust packaging and handling processes is essential for maintaining quality during transportation.

Conclusion

In summary, Process Equipment & Supply Inc. employs rigorous manufacturing processes and quality control measures to deliver reliable ultrasonic cleaning solutions. By understanding the stages of manufacturing, relevant standards, and effective verification methods, international B2B buyers can make informed decisions when sourcing equipment. Emphasizing quality not only enhances operational efficiency but also supports long-term partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘process equipment & supply inc eastlake’

Introduction

This practical sourcing guide aims to assist international B2B buyers in procuring equipment and supplies from Process Equipment & Supply, Inc. located in Eastlake, Ohio. By following this step-by-step checklist, you can streamline your purchasing process, ensuring you make informed decisions that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating any procurement process, clearly outline your technical requirements. This includes understanding the specific applications for which you need ultrasonic cleaning equipment or cell disruptors. Defining specifications helps avoid miscommunication and ensures the products you receive meet your operational needs.

- Consider the size and capacity of the equipment, such as whether you need a benchtop ultrasonic cleaner or a larger industrial model.

- Identify the materials that will be processed to ensure compatibility with cleaning solutions and equipment.

Step 2: Research Supplier Reputation

Investigate the reputation of Process Equipment & Supply, Inc. as a supplier. This involves looking for customer reviews, testimonials, and case studies that demonstrate their reliability and service quality.

- Utilize platforms like IndustryNet or LinkedIn to find insights from other B2B buyers.

- Verify any industry certifications that indicate the supplier adheres to quality and safety standards.

Step 3: Evaluate Product Range and Availability

Assess the breadth of products offered by Process Equipment & Supply, Inc. Ensure they have a comprehensive range of ultrasonic cleaners, sonifiers, and accessories that can cater to your needs.

Illustrative image related to process equipment & supply inc eastlake

- Check for stock availability on their website to avoid delays.

- Inquire about the lead times for specialized or custom equipment that may not be readily available.

Step 4: Request Detailed Quotations

Once you’ve identified potential equipment, request detailed quotations. A thorough quote will provide insights into pricing, shipping costs, and payment terms, allowing for better budget management.

- Ask for itemized pricing to understand the cost breakdown, including any additional fees.

- Clarify warranty and service agreements to ensure you have support post-purchase.

Step 5: Verify Supplier Certifications

It’s essential to confirm that Process Equipment & Supply, Inc. holds the necessary certifications to distribute Branson products and other equipment. Certifications can indicate compliance with industry standards and regulations.

- Request copies of certifications and check their validity.

- Ensure they comply with international trade regulations, particularly if you’re importing equipment to regions like Africa or South America.

Step 6: Discuss Shipping and Logistics

Understanding the logistics of shipping is crucial for international buyers. Discuss the shipping options available and the expected delivery times to avoid operational interruptions.

- Confirm whether they handle customs documentation or if you need to manage this independently.

- Discuss potential shipping insurance options to protect your investment during transit.

Step 7: Establish Clear Communication Channels

Effective communication is key throughout the procurement process. Establish clear channels for discussing any questions or concerns that may arise.

- Designate a primary contact at Process Equipment & Supply, Inc. to streamline communication.

- Utilize email and phone support, ensuring you receive timely responses to inquiries.

By following this checklist, international B2B buyers can confidently navigate the procurement process for equipment and supplies from Process Equipment & Supply, Inc., ensuring that they make informed and strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for process equipment & supply inc eastlake Sourcing

What Are the Key Cost Components for Process Equipment & Supply Inc. in Eastlake?

When evaluating the pricing structure of Process Equipment & Supply Inc., several cost components come into play. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials is significant, especially for ultrasonic cleaners and Sonifier® cell disruptors. The prices can vary based on the quality and source of materials used in manufacturing. High-quality components may incur higher costs but often lead to better performance and durability.

-

Labor: Labor costs include both direct labor for assembly and indirect labor for administrative tasks. Given the specialized nature of the equipment, skilled labor is often required, which can elevate costs.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help manage these costs effectively.

-

Tooling: Investment in tooling is necessary for the production of specialized equipment. Custom tooling can increase initial costs but may lower long-term production expenses through improved efficiency.

-

Quality Control (QC): Ensuring that products meet strict quality standards is crucial, particularly for medical and industrial applications. Investments in QC processes can drive up costs but are essential for maintaining compliance and customer satisfaction.

-

Logistics: The distribution of products, especially for international buyers, includes shipping, customs duties, and insurance. These costs can fluctuate based on the destination and shipping method chosen.

-

Margin: The profit margin applied by Process Equipment & Supply Inc. reflects the company’s overall business strategy and market positioning. Understanding this margin is essential for buyers when evaluating total costs.

How Do Price Influencers Impact Sourcing from Process Equipment & Supply Inc.?

Several factors influence pricing for B2B buyers sourcing from Process Equipment & Supply Inc. Understanding these can help in negotiations and procurement strategies.

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers looking to minimize expenses should consider consolidating orders.

-

Specifications and Customization: Custom orders may incur additional costs due to unique requirements. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: The choice of materials and the presence of industry certifications can significantly affect price. Higher-quality materials often come at a premium, but they may offer enhanced performance and longevity.

-

Supplier Factors: Relationships with suppliers can influence pricing. Long-term partnerships or bulk purchasing agreements may provide leverage in negotiations.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers in the shipping process. Understanding these terms can help buyers manage logistics costs effectively.

What Are Essential Buyer Tips for Cost-Efficiency in International B2B Transactions?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency.

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Demonstrating knowledge of market conditions can strengthen your position.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. Investing in higher-quality equipment may reduce TCO over time.

-

Understand Pricing Nuances: Be aware of fluctuations in currency exchange rates and how they may affect pricing. Additionally, customs duties and import taxes can significantly impact the total cost of acquisition.

-

Research Local Regulations: Different regions have varying compliance and certification requirements. Understanding these can prevent unexpected costs and delays in shipping.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices can vary widely based on the factors discussed, maintaining open communication with Process Equipment & Supply Inc. is crucial. Buyers should approach negotiations armed with knowledge about cost components and price influencers. This strategic understanding not only aids in securing the best pricing but also fosters a successful long-term partnership with the supplier.

Alternatives Analysis: Comparing process equipment & supply inc eastlake With Other Solutions

Understanding Alternatives in Process Equipment Solutions

In the realm of industrial cleaning and processing equipment, businesses often face the challenge of selecting the most effective solution for their needs. Process Equipment & Supply Inc. Eastlake specializes in ultrasonic cleaning equipment, but various alternatives exist that may also meet specific operational requirements. This analysis will compare Process Equipment & Supply Inc. with two viable alternatives: ultrasonic cleaning systems from competitor A and manual cleaning methods.

Illustrative image related to process equipment & supply inc eastlake

Comparison Table

| Comparison Aspect | Process Equipment & Supply Inc Eastlake | Alternative 1: Competitor A Ultrasonic Cleaners | Alternative 2: Manual Cleaning Methods |

|---|---|---|---|

| Performance | High efficiency with consistent results | Comparable performance with varied features | Variable results; highly dependent on operator skill |

| Cost | Moderate initial investment | Higher upfront cost, but offers long-term savings | Low initial cost; ongoing labor costs |

| Ease of Implementation | Easy to integrate into existing systems | Requires some training for optimal use | Simple, but time-consuming |

| Maintenance | Low maintenance with regular checks | Moderate maintenance needs | Minimal maintenance, but high labor demands |

| Best Use Case | Industrial applications requiring precision cleaning | Laboratory settings needing versatile cleaning | General cleaning tasks with low precision |

Detailed Breakdown of Alternatives

Alternative 1: Competitor A Ultrasonic Cleaners

Competitor A offers a range of ultrasonic cleaning systems that provide high-performance cleaning capabilities similar to those of Process Equipment & Supply Inc. However, these systems often come with a higher initial cost due to advanced features and technology. While they may offer significant long-term savings through efficiency, the complexity of operation may require additional training for staff. These systems are particularly well-suited for laboratory environments where precision and versatility are paramount, making them a strong choice for specialized applications.

Alternative 2: Manual Cleaning Methods

Manual cleaning methods are the most traditional approach and are characterized by their low initial costs. However, they can lead to inconsistent results, heavily reliant on the operator’s skill and diligence. While maintenance is minimal, the labor costs can accumulate over time, especially in high-volume settings. This method is best for general cleaning tasks where precision is less critical, making it an option for smaller operations or businesses with less stringent cleanliness requirements.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate cleaning solution, B2B buyers should carefully assess their specific operational requirements, including the nature of the materials being cleaned, the desired efficiency, and overall budget constraints. Process Equipment & Supply Inc. stands out for its reliable ultrasonic systems, especially in industrial applications where performance and precision are essential. However, alternatives like Competitor A’s offerings or manual methods may be more suitable depending on the context, budget, and technical capabilities of the workforce. Ultimately, understanding the unique needs of your business will guide you toward the best solution, ensuring that you make an informed and strategic investment.

Essential Technical Properties and Trade Terminology for process equipment & supply inc eastlake

What Are the Essential Technical Properties of Process Equipment?

Understanding the technical specifications of process equipment is crucial for B2B buyers, especially when sourcing equipment for diverse applications such as ultrasonic cleaning and liquid processing. Here are some key specifications to consider:

Illustrative image related to process equipment & supply inc eastlake

-

Material Grade

Material grade refers to the classification of materials based on their physical and chemical properties. For instance, stainless steel is commonly used in ultrasonic cleaners due to its corrosion resistance and durability. Selecting the right material grade ensures the equipment can withstand the specific conditions of use, such as exposure to cleaning chemicals or high temperatures. -

Tank Capacity

Tank capacity is a critical specification for ultrasonic cleaners, indicating the volume of liquid the tank can hold. It ranges from small units (e.g., 1 pint) suitable for jewelry to large tanks (up to 20 gallons) for industrial applications. Understanding the required tank capacity helps buyers choose equipment that meets their operational needs without compromising efficiency. -

Frequency Range

The frequency of ultrasonic cleaning equipment typically ranges between 20 kHz to 400 kHz. Lower frequencies are more effective for heavy-duty cleaning, while higher frequencies are suited for delicate items. Buyers must consider the frequency range to ensure the equipment aligns with the specific cleaning tasks it will perform. -

Power Output

Power output, measured in watts, indicates the cleaning power of the ultrasonic equipment. Higher wattage generally equates to faster and more efficient cleaning. It’s essential for buyers to assess their cleaning requirements and select equipment with adequate power output to achieve desired results. -

Temperature Control

Temperature control features allow operators to set and maintain specific temperatures during the cleaning process. This is vital for optimizing cleaning efficiency and protecting sensitive components. Buyers should evaluate the temperature control capabilities to ensure compatibility with their cleaning applications. -

Process Monitoring Features

Advanced ultrasonic cleaners may include process monitoring capabilities that provide real-time feedback on cleaning parameters. These features enhance the reliability and repeatability of the cleaning process, making it easier for businesses to maintain quality standards. Understanding these capabilities can help buyers select equipment that supports their quality assurance goals.

What Trade Terminology Should International Buyers Know?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to process equipment procurement:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ultrasonic cleaning equipment, knowing whether a product is OEM helps buyers assess quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for budgeting and inventory planning, especially for international buyers who may be subject to shipping costs and customs duties. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. This process is important for buyers to compare offers and ensure they are receiving competitive pricing for the equipment they need. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with these terms is essential for international transactions, as they specify who bears the risk and costs associated with shipping, insurance, and customs clearance. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. Understanding lead time is crucial for inventory management and ensuring timely project execution, particularly for industries with strict deadlines. -

Warranty and Service Agreements

Warranty terms outline the manufacturer’s obligations regarding repairs or replacements within a specified period. Service agreements may include routine maintenance and support. Buyers should carefully evaluate these terms to ensure they are protected against equipment failures and can access necessary support.

By grasping these technical properties and trade terms, B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, can make informed decisions when sourcing process equipment from Process Equipment & Supply, Inc. in Eastlake.

Navigating Market Dynamics and Sourcing Trends in the process equipment & supply inc eastlake Sector

What Are the Current Market Dynamics and Key Trends in the Process Equipment Sector?

The process equipment market is currently experiencing significant transformation driven by technological advancements, increasing automation, and the global push for efficiency. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide not only high-quality equipment but also integrated solutions that enhance operational efficiency. The rise of Industry 4.0 has brought forth innovations such as IoT-enabled equipment, which allows for real-time monitoring and predictive maintenance, thereby reducing downtime and operational costs.

Emerging trends in sourcing include a shift towards online procurement platforms, enabling buyers to access a broader range of suppliers and compare products easily. This trend is particularly advantageous for international buyers who may face geographical barriers. Additionally, the demand for customized solutions is on the rise, as companies seek equipment that can be tailored to their specific operational needs, reflecting a move away from one-size-fits-all products.

Illustrative image related to process equipment & supply inc eastlake

Moreover, sustainability is becoming a critical factor influencing purchasing decisions. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as energy-efficient equipment and environmentally friendly materials. This trend is especially prominent in regions like Europe, where regulatory frameworks are driving the need for greener solutions.

How Is Sustainability Shaping Sourcing Decisions in the Process Equipment Sector?

Sustainability has emerged as a pivotal consideration in the B2B landscape, particularly in the process equipment sector. Companies are recognizing the importance of minimizing their environmental impact, which extends beyond operational practices to include the sourcing of materials and equipment. For international buyers, particularly from regions with stringent environmental regulations, aligning with suppliers that prioritize sustainability can mitigate risks and enhance their brand reputation.

Ethical sourcing practices are gaining traction, with buyers favoring suppliers who can demonstrate transparency in their supply chains. This includes sourcing materials from certified ‘green’ sources and ensuring that manufacturing processes adhere to ethical labor standards. Certifications such as ISO 14001 for environmental management systems and other eco-labels are increasingly being sought after by buyers as indicators of a supplier’s commitment to sustainability.

Furthermore, the integration of sustainable technologies in process equipment, such as energy-efficient ultrasonic cleaners, not only meets environmental standards but also delivers cost savings in the long run. As a result, companies like Process Equipment & Supply, Inc. in Eastlake are positioned favorably, as they offer a range of products that align with these sustainability goals.

What Is the Historical Context of Process Equipment & Supply Inc. in the B2B Landscape?

Founded in 1970, Process Equipment & Supply, Inc. has carved a niche in the distribution of ultrasonic cleaning equipment and liquid processing solutions. Over the past five decades, the company has established itself as the largest stocking distributor of Branson products in the United States, serving a diverse array of industries including medical, industrial, and electronics.

Illustrative image related to process equipment & supply inc eastlake

The family-owned business has thrived by combining extensive product knowledge with a commitment to customer service, making it a reliable partner for B2B buyers. As the market has evolved, so too has the company’s product offerings, which now include advanced ultrasonic cleaning systems and cell disruptors that cater to the growing demand for precision and efficiency in processing applications.

By understanding the historical context and ongoing trends, international buyers can better navigate the complexities of sourcing in the process equipment sector, ensuring they align with suppliers that not only meet their operational needs but also adhere to emerging sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of process equipment & supply inc eastlake

-

How do I effectively evaluate potential suppliers for process equipment?

When evaluating suppliers like Process Equipment & Supply Inc., consider their industry experience, product range, and customer reviews. Check for certifications and compliance with international standards, particularly in your region (e.g., ISO certifications). It’s also beneficial to request case studies or references from similar industries. Additionally, assess their responsiveness to inquiries and ability to provide technical support, which indicates a commitment to customer service. Conducting a site visit, if feasible, can also offer valuable insights into their operations and product quality. -

What types of ultrasonic cleaning equipment are available for various applications?

Process Equipment & Supply Inc. offers a wide array of ultrasonic cleaning equipment, including benchtop cleaners for smaller applications like jewelry and larger industrial tanks for heavy-duty cleaning needs. Their products are suitable for diverse applications, from medical instrument sterilization to cleaning automotive parts and electronics. When selecting equipment, consider the size, frequency, and specific cleaning requirements of your application to ensure optimal performance and efficiency. -

What are the minimum order quantities (MOQs) for international purchases?

Minimum order quantities at Process Equipment & Supply Inc. can vary based on the specific product and the terms of your agreement. Typically, larger orders may lead to more favorable pricing and shipping terms. It’s essential to communicate your needs directly with the sales team to understand any applicable MOQs and to negotiate terms that suit your business requirements. -

What payment terms can I expect when ordering from Process Equipment & Supply Inc.?

Payment terms can vary depending on the buyer’s location and order size. Generally, Process Equipment & Supply Inc. may require a deposit for large orders, with the balance due upon shipment or delivery. For international buyers, options like letter of credit or payment in advance may be available to mitigate risk. It’s advisable to clarify payment terms upfront to ensure smooth transactions. -

How does Process Equipment & Supply Inc. ensure quality assurance for their products?

Process Equipment & Supply Inc. employs rigorous quality assurance protocols, including sourcing equipment from reputable manufacturers and conducting regular inspections. They provide detailed product specifications and user manuals, which help buyers understand the operational parameters and maintenance requirements. For further assurance, customers can request documentation related to certifications and compliance with industry standards. -

What logistics and shipping options are available for international buyers?

International buyers can benefit from various logistics solutions offered by Process Equipment & Supply Inc., including freight forwarding and customs clearance assistance. They typically provide multiple shipping options to accommodate different timelines and budgets, from express shipping to standard freight services. It’s essential to discuss your specific shipping needs and timelines with their logistics team to ensure timely delivery. -

Can I customize the ultrasonic cleaning equipment to fit my specific needs?

Yes, Process Equipment & Supply Inc. offers customization options for their ultrasonic cleaning equipment. Depending on your requirements, you can request modifications in size, frequency, and additional features like temperature control or specific cleaning cycles. Discussing your needs with their technical team will help identify the best solutions for your application, ensuring you receive equipment tailored to your operational needs. -

What support and resources are available for troubleshooting and maintenance?

Process Equipment & Supply Inc. provides comprehensive support for troubleshooting and maintenance through user manuals, application data, and technical resources available on their website. They also offer customer service assistance for direct inquiries, ensuring you have access to expert advice when needed. Regular maintenance schedules and training sessions may also be available to help maximize the performance and longevity of your equipment.

Top 7 Process Equipment & Supply Inc Eastlake Manufacturers & Suppliers List

1. Bransonic® – Ultrasonic Cleaners & Sonifier® Cell Disruptors

Domain: proequip.com

Registered: 1999 (26 years)

Introduction: Process Equipment & Supply, Inc. is an authorized online distributor for Bransonic® Benchtop Ultrasonic Cleaners and Sonifier® Cell Disruptors by Branson. They offer a range of ultrasonic cleaners from 1 pint mini units for jewelry to large 20-gallon tanks for industrial use. Applications include sample preparation, cleaning of medical and dental instruments, laboratory equipment, jewelry, gun par…

2. Branson – Benchtop Ultrasonic Cleaners

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Process Equipment and Supply, Inc. is a stocking distributor for Branson benchtop ultrasonic cleaners, offering quality equipment for various industrial and commercial applications. They provide 24/7 customer service and are dedicated to finding tailored solutions for individual customer needs.

3. Branson – Ultrasonic Cleaning Equipment

Domain: ultrasoniccleaners.com

Registered: 1998 (27 years)

Introduction: UltrasonicCleaners.com is a supplier of Branson ultrasonic equipment for cleaning and liquid processing applications. They are the largest stocking distributor of Branson’s equipment in the United States, serving industrial, medical, electronics, and laboratory markets. The company offers ultrasonic cleaning machines, cleaning chemicals, accessories, and parts, including Sonifiers and Branson Soni…

4. Process Equipment & Supply – Ultrasonic Cleaning Equipment

Domain: marketplace.aviationweek.com

Registered: 1995 (30 years)

Introduction: Process Equipment & Supply, Inc. specializes in ultrasonic cleaning equipment, accessories, chemicals, and cell disruptors. They have the largest inventory of ultrasonic cleaners in the Midwest, offering Branson ultrasonic cleaning equipment, including the B200 ultrasonic jewelry cleaner, Bransonic benchtop ultrasonic cleaners, and industrial ultrasonic cleaning systems with capacities ranging fro…

5. Process Equipment & Supply Inc. – Process Equipment

Domain: yellowpages.com

Registered: 1996 (29 years)

Introduction: This company, Process Equipment & Supply Inc. – Process Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. PROCESS EQUIPMENT & SUPPLY INC – Leadership Expertise

Domain: rocketreach.co

Registered: 2015 (10 years)

Introduction: Bob Dragolic is the Chief Executive Officer at PROCESS EQUIPMENT & SUPPLY INC, located in Eastlake, OH, US. He has extensive experience in various roles including Director of Operations at Process Technology and Plant Manager at Polymer Solutions Group. He holds a Master’s degree in Entrepreneurship/Entrepreneurial Studies from David N. Myers University. His skills include Lean Manufacturing, GMP,…

7. Liquid Process Equipment – Sanitary Fluid Handling Solutions

Domain: liquidprocess.com

Registered: 2006 (19 years)

Introduction: Liquid Process Equipment (LPE) offers a wide range of fluid handling technologies, including: 1. Sanitary & Hygienic Process Equipment: – Sanitary Positive Displacement Pumps – Sanitary Centrifugal Pumps – Sanitary Valves – Sanitary Hose Configurator – Sanitary Heat Exchangers – Sanitary Homogenizers – Sanitary Separators – Sanitary Colloid & Shear Pumps – Sanitary Filters & Strainers – Sanitary M…

Strategic Sourcing Conclusion and Outlook for process equipment & supply inc eastlake

In the competitive landscape of industrial equipment and supply, Process Equipment & Supply, Inc. stands out as a trusted partner for international buyers seeking high-quality ultrasonic cleaning solutions. With over 50 years of experience and a commitment to customer service, they offer an extensive range of products tailored to various industries, including medical, electronics, and laboratory sectors. Their expertise in Branson ultrasonic equipment positions them as a go-to source for businesses looking to enhance their operational efficiency through advanced cleaning technologies.

Strategic sourcing is vital for organizations aiming to optimize costs while ensuring quality and reliability in their supply chains. By partnering with Process Equipment & Supply, buyers from Africa, South America, the Middle East, and Europe can leverage their extensive product knowledge and robust inventory to meet diverse application needs.

Looking ahead, the demand for innovative cleaning solutions will continue to grow, presenting significant opportunities for international buyers. Engaging with Process Equipment & Supply can provide the strategic advantage needed to remain competitive in your market. Don’t hesitate to reach out and explore how their tailored solutions can elevate your business operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.