Pressure Switch For Air Compressor Diagram: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for pressure switch for air compressor diagram

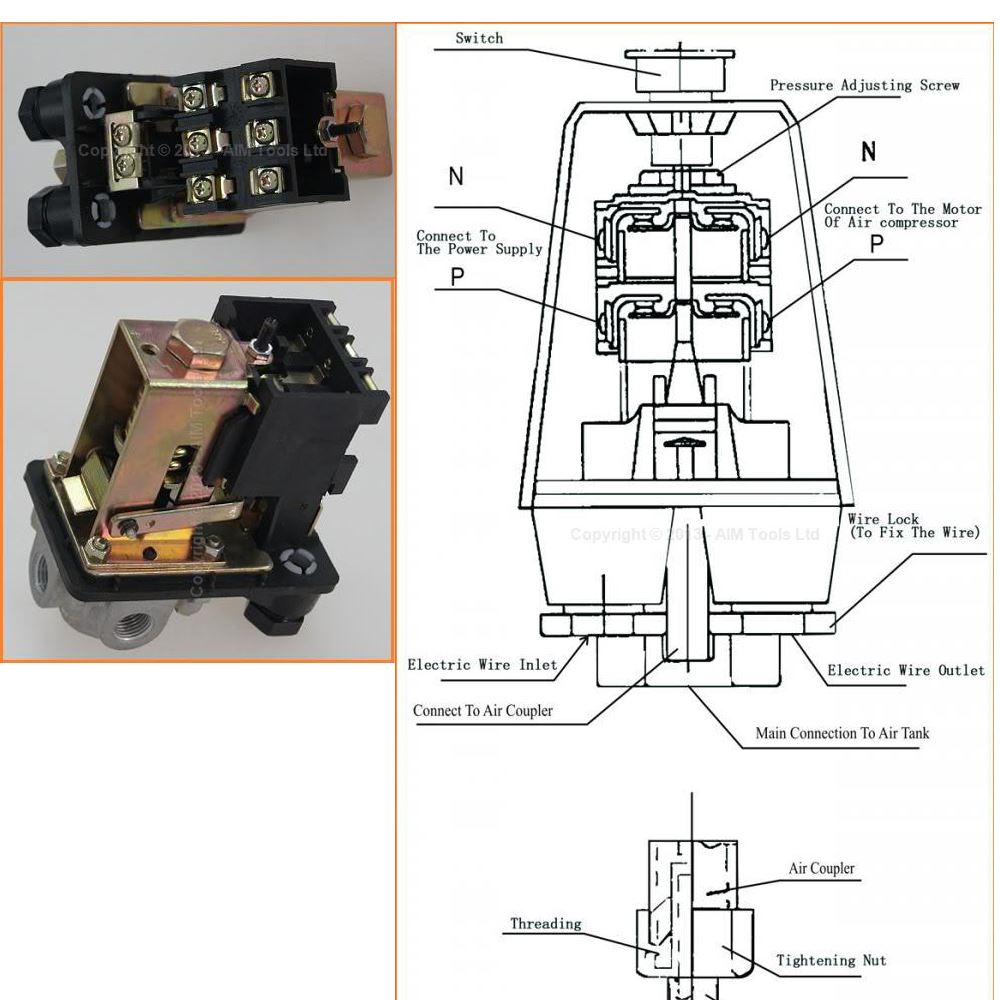

In the intricate world of industrial machinery, sourcing a reliable pressure switch for air compressors can pose significant challenges for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. These essential components act as the control center for air compressors, regulating pressure levels to prevent overpressurization and ensuring optimal performance. However, with a myriad of options available, understanding the various types, applications, and technical specifications is crucial for making informed purchasing decisions.

This comprehensive guide offers a thorough exploration of pressure switches for air compressors, delving into their functional mechanics, common wiring practices, and the potential pitfalls to avoid during installation. Additionally, it provides insights into supplier vetting processes, cost considerations, and best practices for selecting the right components tailored to specific operational needs.

By empowering international B2B buyers with the knowledge and tools needed to navigate this complex landscape, this guide not only enhances the understanding of pressure switch diagrams but also facilitates smarter procurement strategies. Whether you are a manufacturer in Brazil or a contractor in Saudi Arabia, this resource will help you streamline your sourcing efforts and ensure that your air compressor systems operate safely and efficiently, ultimately contributing to your bottom line.

Understanding pressure switch for air compressor diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Pressure Switch | Basic on/off control based on preset pressure levels. | General manufacturing and workshops. | Pros: Cost-effective, easy to install. Cons: Limited functionality, may not suit advanced applications. |

| Electronic Pressure Switch | Utilizes digital sensors for precise pressure readings. | Automotive and aerospace industries. | Pros: High accuracy, programmable settings. Cons: Higher initial cost, may require specialized installation. |

| Adjustable Pressure Switch | Allows manual adjustment of pressure settings. | HVAC systems and industrial equipment. | Pros: Customizable, versatile for various applications. Cons: Complexity can lead to user error in settings. |

| Dual Pressure Switch | Controls two separate pressure points (cut-in and cut-out). | Oil and gas, heavy machinery sectors. | Pros: Enhanced control, prevents overpressure. Cons: Higher cost, requires careful calibration. |

| Mechanical Pressure Switch | Operates using mechanical components to detect pressure changes. | Construction and pneumatic tools. | Pros: Durable, reliable for high-pressure environments. Cons: Limited flexibility, less precise than electronic options. |

What are the Characteristics of Standard Pressure Switches?

Standard pressure switches are fundamental components widely used in various industrial applications. They operate by engaging or disengaging based on predefined pressure levels, making them suitable for general manufacturing and workshop environments. Buyers appreciate their affordability and straightforward installation process. However, their simplicity means they lack advanced features that may be needed in more complex systems, which can limit their applicability in specialized industries.

How Do Electronic Pressure Switches Enhance Precision?

Electronic pressure switches employ digital sensors to provide accurate pressure readings, making them ideal for applications in automotive and aerospace industries. These switches often come with programmable settings, allowing for customization to specific operational needs. While the initial investment may be higher, the precision and reliability they offer can lead to significant long-term savings and efficiency improvements. Buyers should consider the need for specialized installation when opting for these advanced switches.

Why Choose Adjustable Pressure Switches for Versatility?

Adjustable pressure switches are designed to give users the ability to manually set and modify pressure levels according to their specific requirements. This feature makes them particularly useful in HVAC systems and industrial equipment where varying pressure conditions are common. Although they offer great flexibility, the complexity of these switches can sometimes lead to user error in settings. Buyers should weigh the benefits of customization against the potential for misconfiguration.

What Advantages Do Dual Pressure Switches Offer?

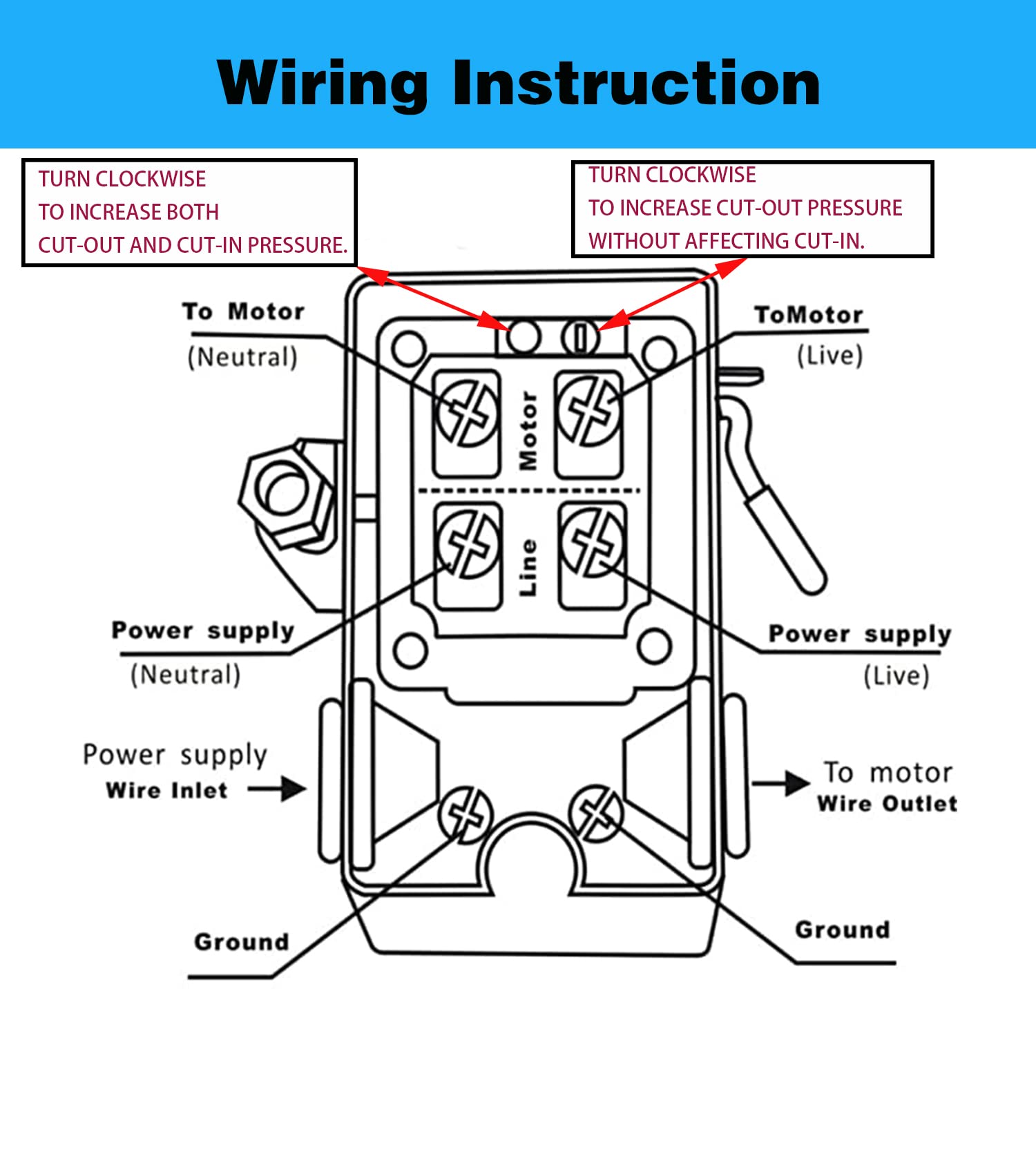

Dual pressure switches are engineered to manage two distinct pressure points, which can be particularly beneficial in sectors like oil and gas or heavy machinery. By providing enhanced control over both cut-in and cut-out pressures, these switches help prevent overpressure situations, thus improving safety and operational efficiency. However, they tend to be more expensive and require careful calibration, making them better suited for buyers with specific high-pressure needs.

In What Situations are Mechanical Pressure Switches Ideal?

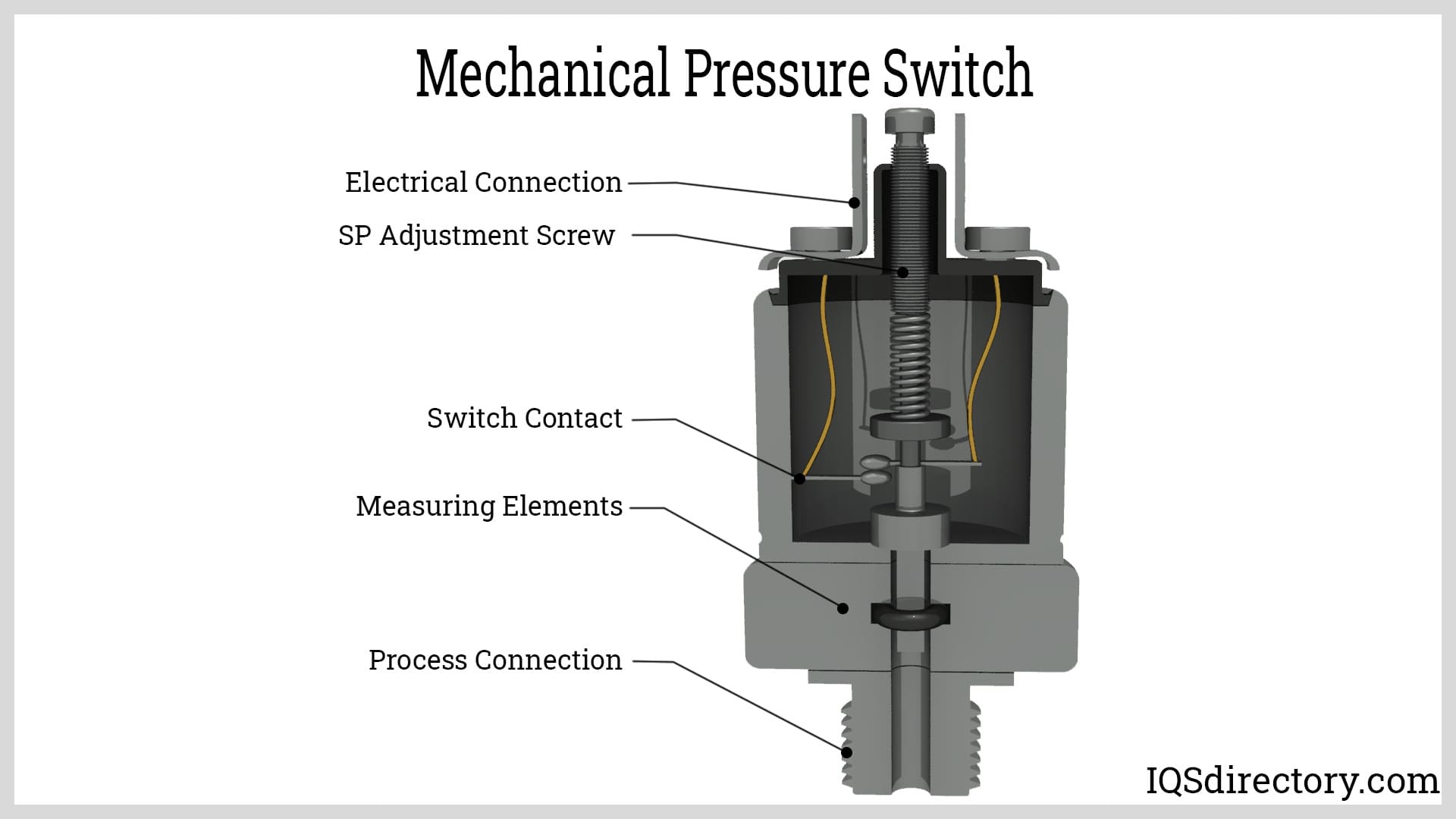

Mechanical pressure switches utilize physical components to detect changes in pressure, making them a reliable choice for rugged environments such as construction sites and pneumatic tool applications. Their durability and straightforward operation are significant advantages. However, they may lack the precision of electronic switches, which could be a drawback for buyers needing highly accurate pressure control. Overall, they are best suited for straightforward applications where reliability is paramount.

Key Industrial Applications of pressure switch for air compressor diagram

| Industry/Sector | Specific Application of pressure switch for air compressor diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines | Enhances productivity by controlling air supply efficiently | Compatibility with existing systems and safety certifications |

| Construction | Pneumatic tools operation | Reduces downtime by ensuring optimal pressure levels | Durability in harsh environments and local standards compliance |

| Food and Beverage | Packaging machinery | Ensures consistent pressure for quality packaging | Hygiene standards and resistance to corrosive substances |

| Automotive | Paint spray systems | Improves finish quality by maintaining stable pressure | Precision in pressure settings and reliability under varying conditions |

| Oil and Gas | Drilling equipment | Prevents overpressurization, enhancing safety | High-pressure tolerance and compliance with industry regulations |

How is the Pressure Switch for Air Compressor Diagram Used in Manufacturing?

In the manufacturing sector, pressure switches are vital for automated assembly lines where pneumatic tools are used. These switches regulate the air supply, ensuring that tools operate at optimal pressure levels for consistent performance. By preventing overpressurization, they reduce equipment wear and tear, thereby enhancing productivity and minimizing operational downtime. International buyers should prioritize sourcing pressure switches that are compatible with existing systems and meet safety certifications to ensure seamless integration.

What Role Does the Pressure Switch Play in Construction Applications?

In the construction industry, pressure switches are essential for the effective operation of pneumatic tools. They maintain the correct air pressure, which is crucial for tools such as nail guns and air hammers. This regulation not only enhances efficiency but also reduces the risk of equipment failure. Buyers in this sector should consider the durability of pressure switches to withstand harsh environments and ensure compliance with local safety standards, especially in diverse climatic conditions prevalent in regions like Africa and South America.

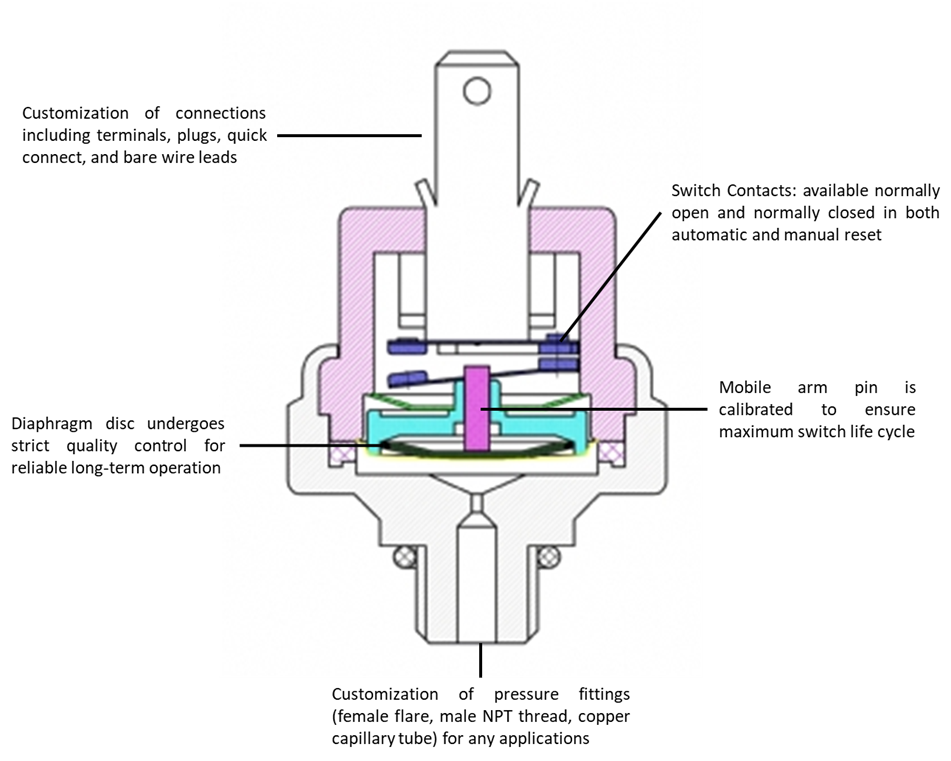

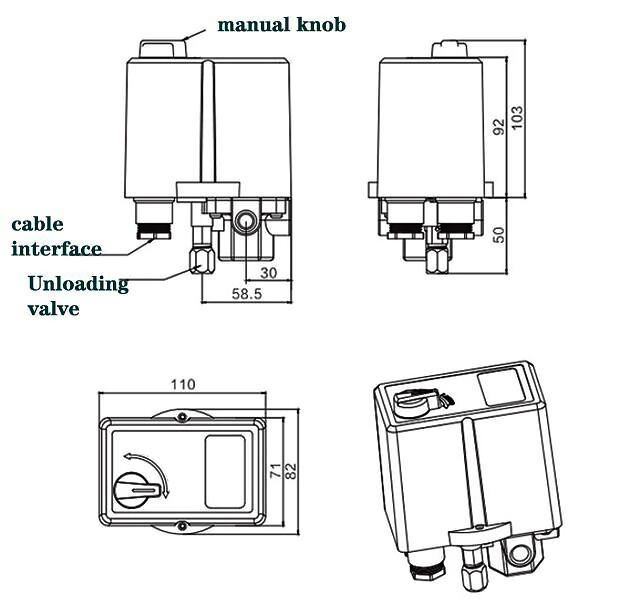

Illustrative image related to pressure switch for air compressor diagram

How Does the Pressure Switch Benefit the Food and Beverage Sector?

In the food and beverage industry, pressure switches are employed in packaging machinery to ensure that products are sealed correctly. Maintaining consistent pressure is critical for preserving product quality and extending shelf life. As this sector is highly regulated, international buyers must ensure that the pressure switches they source adhere to stringent hygiene standards and can resist corrosive substances commonly found in food processing environments.

Why are Pressure Switches Important in Automotive Applications?

For the automotive industry, pressure switches are crucial in paint spray systems, where they help maintain stable air pressure for a smooth finish. Fluctuations in pressure can lead to poor quality and increased waste. Therefore, sourcing precision pressure switches that can reliably operate under varying conditions is essential. Buyers should focus on switches that offer adjustable pressure settings to accommodate different types of spray applications, ensuring high-quality results.

What are the Key Considerations for Pressure Switches in Oil and Gas?

In the oil and gas sector, pressure switches are critical for drilling equipment to prevent overpressurization, which can lead to catastrophic failures. These switches are designed to operate under extreme conditions, making reliability and safety paramount. International buyers should look for pressure switches that have a high-pressure tolerance and comply with industry regulations, ensuring they can withstand the rigorous demands of drilling operations while maintaining safety standards.

3 Common User Pain Points for ‘pressure switch for air compressor diagram’ & Their Solutions

Scenario 1: Misconfigured Pressure Settings Leading to Equipment Damage

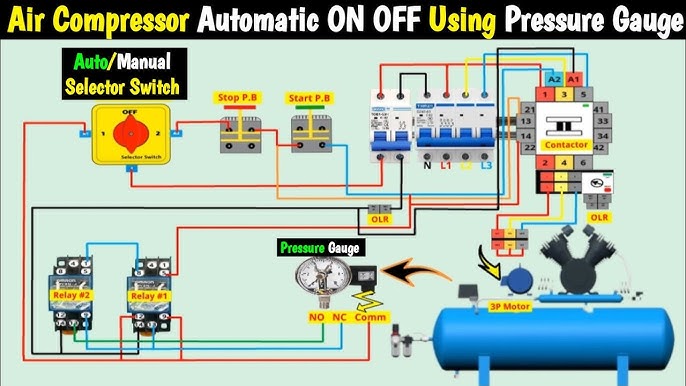

The Problem: B2B buyers often face the issue of misconfigured pressure settings on air compressor pressure switches. This can happen due to a lack of understanding of the specifications required for different applications. If the pressure switch is set too high, it can lead to excessive wear on the compressor and connected tools, potentially resulting in equipment failure and costly downtime. Conversely, if the pressure is set too low, it may not provide sufficient air supply for operational needs, hampering productivity.

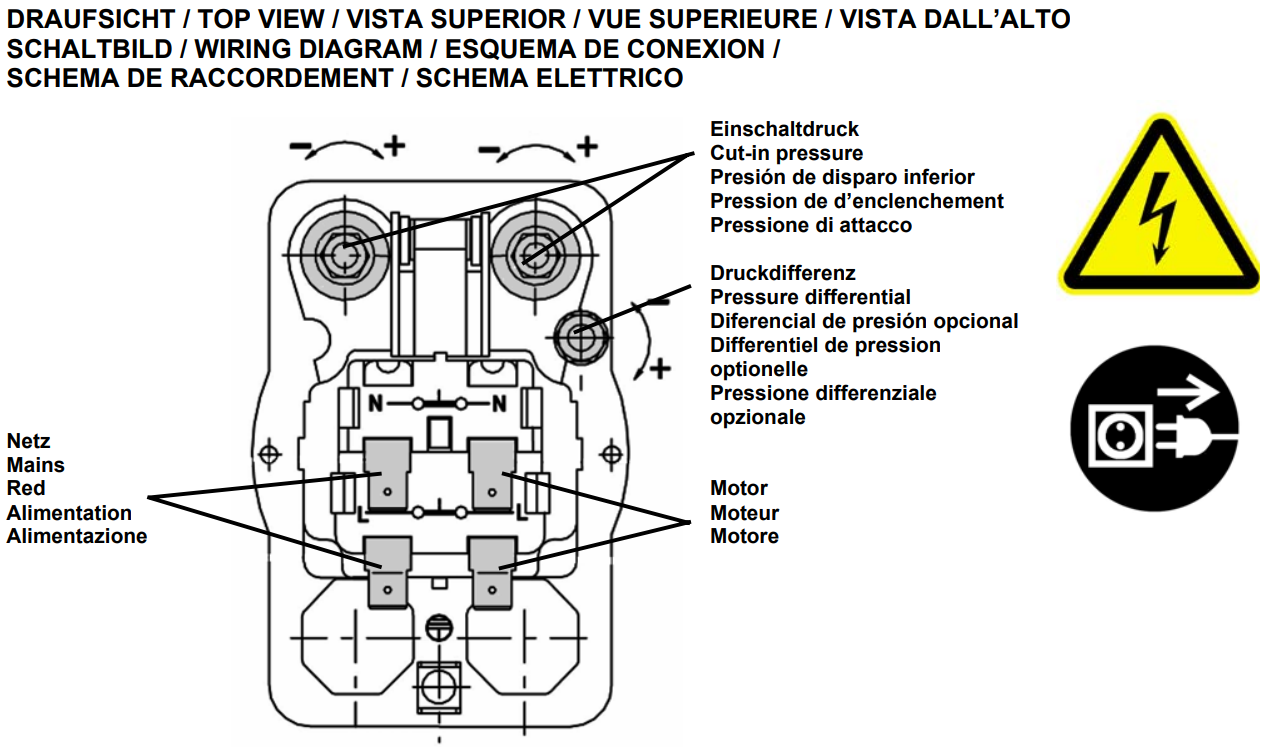

The Solution: To avoid these pitfalls, it’s crucial to carefully review the operational requirements of your air compressor and the tools it serves. Start by consulting the manufacturer’s specifications for both the compressor and the devices being powered. Create a pressure switch diagram that clearly outlines the desired cut-in and cut-out pressures based on your specific applications. This diagram should be easily accessible to all operators. Additionally, regular training sessions on how to adjust these settings can help ensure that all team members are equipped with the knowledge to maintain optimal performance and prevent equipment damage.

Scenario 2: Wiring Mistakes Resulting in System Failures

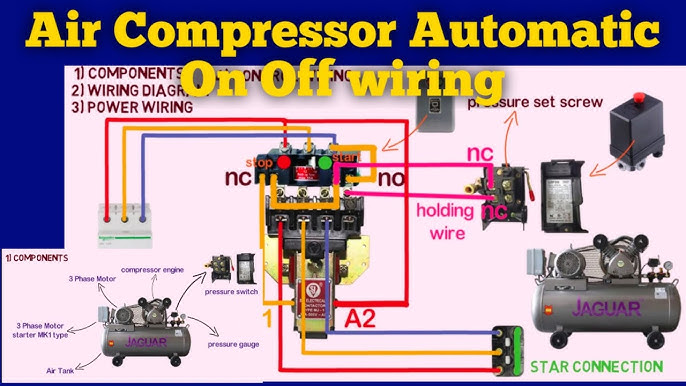

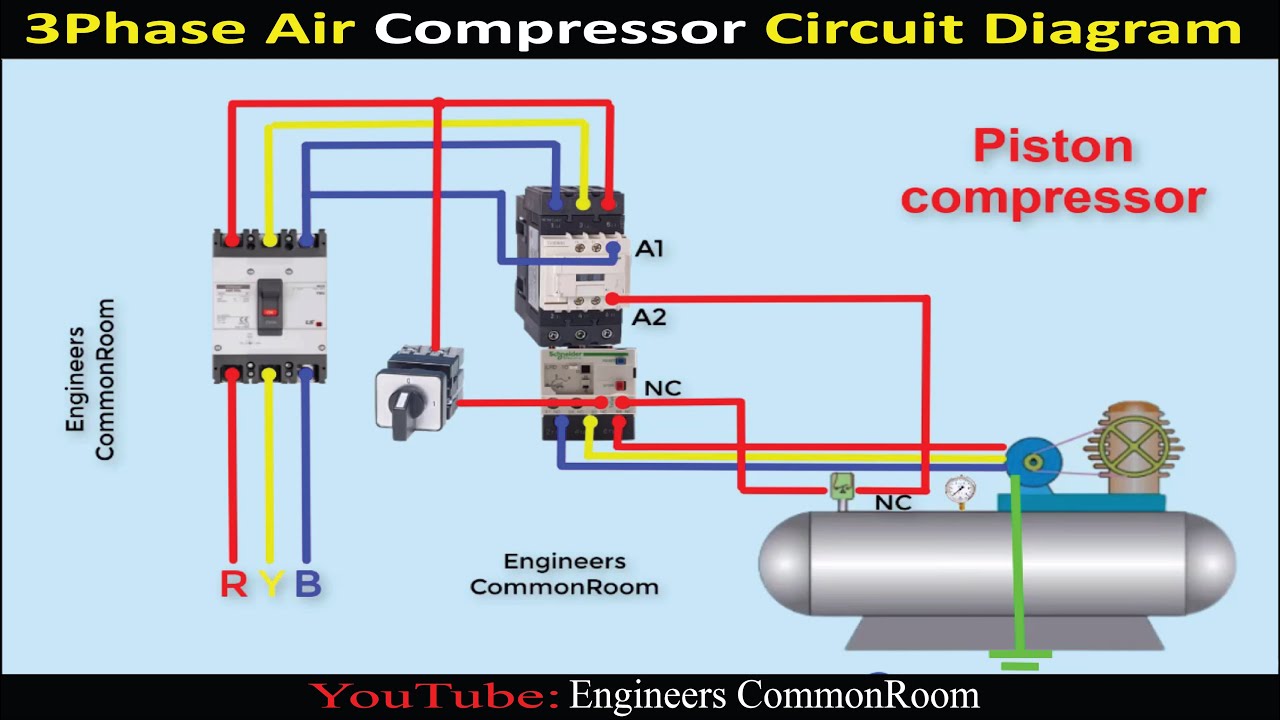

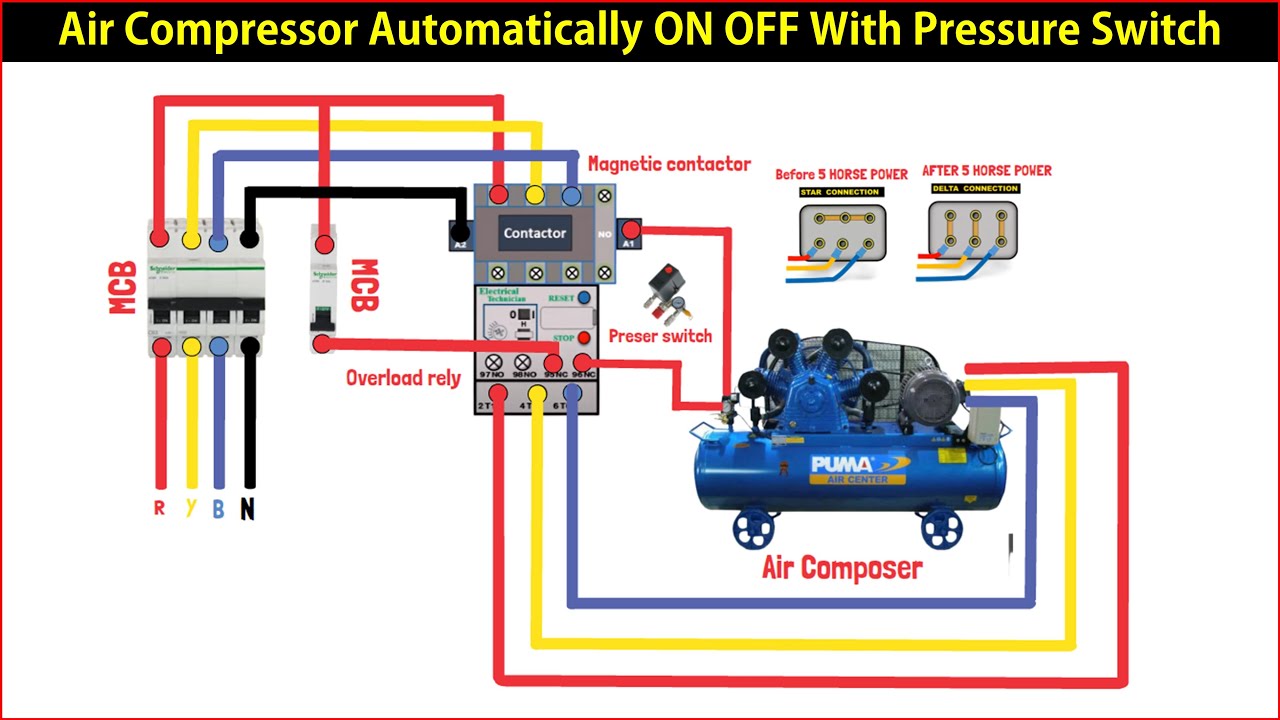

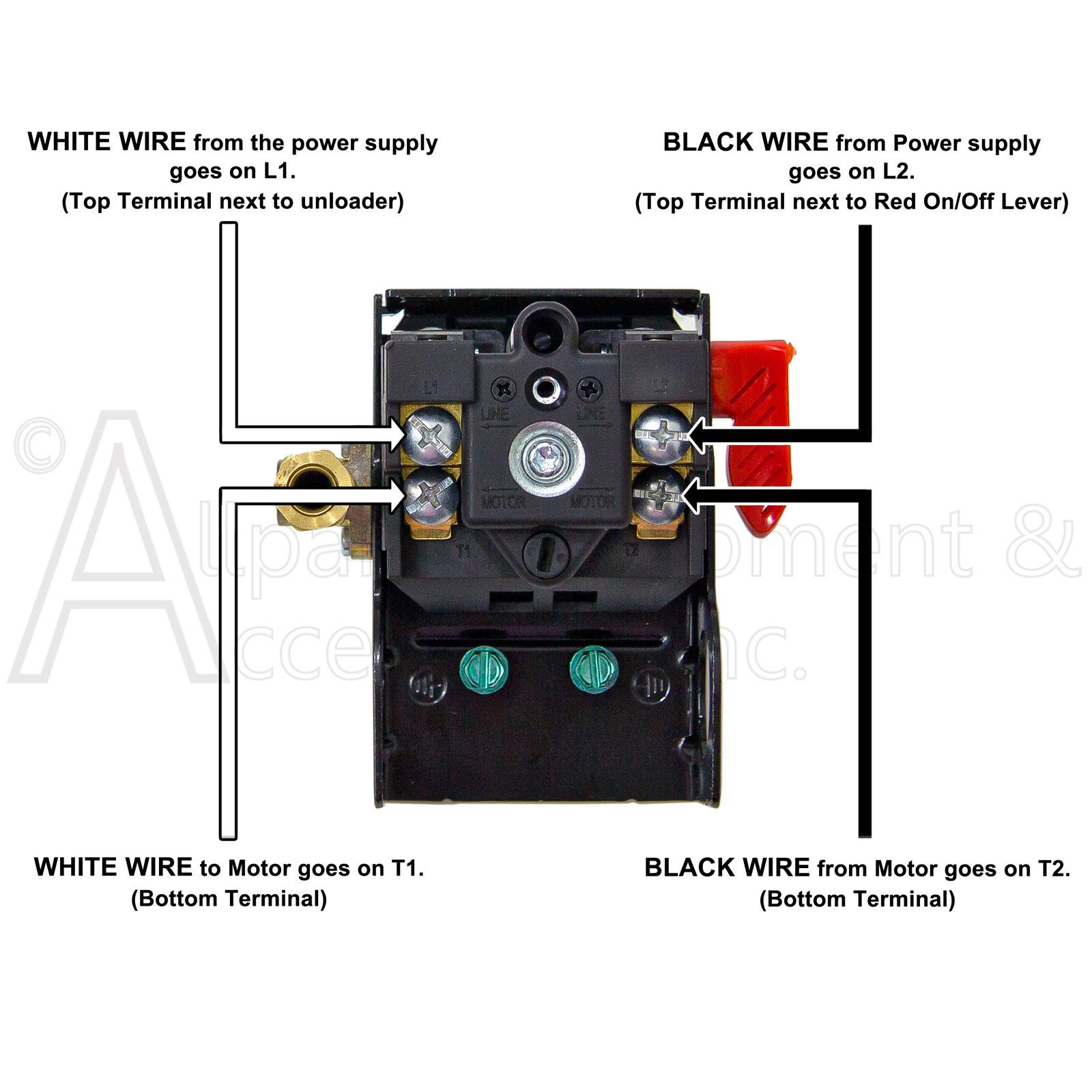

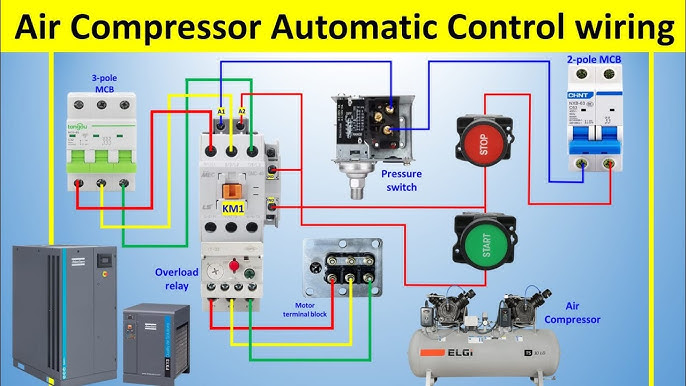

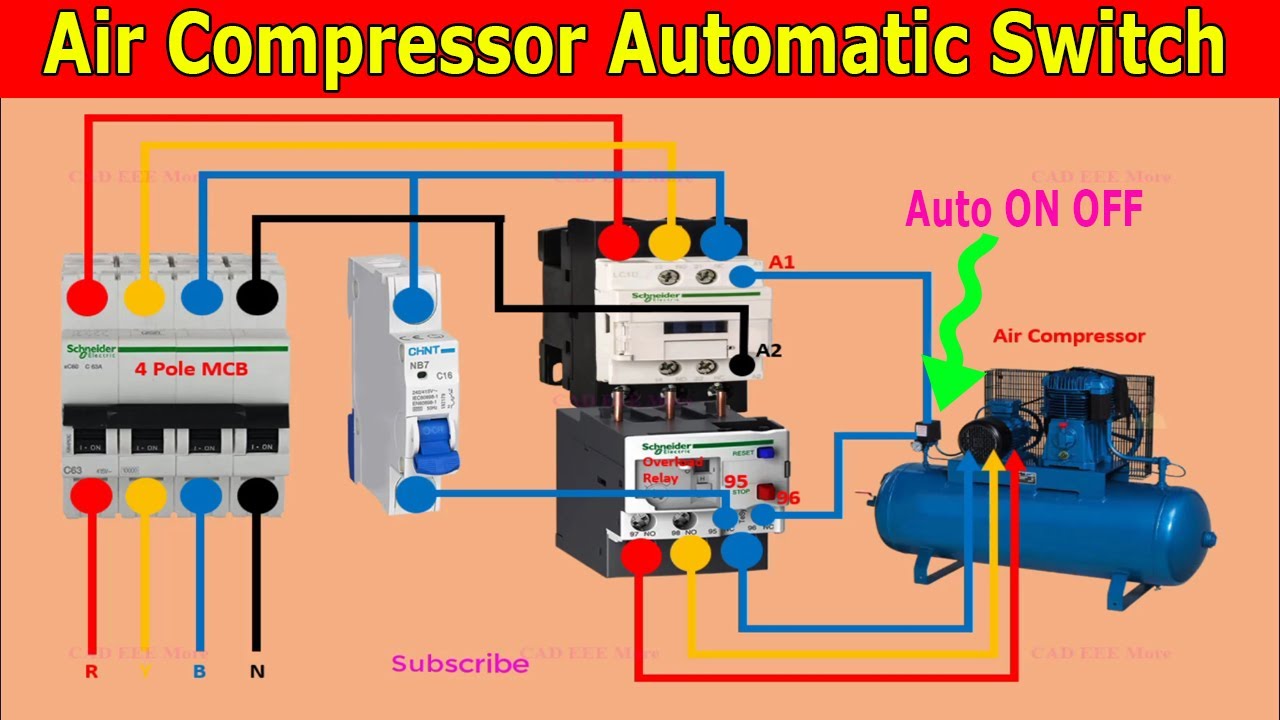

The Problem: Wiring errors are a common concern when integrating a pressure switch into an air compressor system. For instance, many buyers mistakenly connect the power supply directly to the motor, bypassing the pressure switch. This oversight can lead to the compressor running continuously, risking overpressurization and triggering safety features, which could ultimately lead to costly repairs or replacements.

The Solution: To mitigate wiring mistakes, it’s essential to follow a detailed wiring diagram specific to the pressure switch being installed. Begin by ensuring that all team members involved in the installation process are trained on the importance of the wiring configuration. Before proceeding with any installation, conduct a thorough review of the wiring diagram, ensuring that all connections are made to the correct terminals—power input (L1 and L2) and motor output (T1 and T2). It may also be beneficial to implement a checklist to confirm that all steps are correctly followed. If possible, consider having a qualified technician oversee the installation to ensure compliance with safety standards.

Scenario 3: Inconsistent Performance Due to Faulty Pressure Switches

The Problem: Inconsistent compressor performance can often be traced back to faulty pressure switches. When these switches fail, they can cause the compressor to cycle on and off erratically or not engage at all. For B2B buyers, this not only disrupts workflow but can also lead to increased operational costs due to energy waste and potential damage to other components in the system.

The Solution: To ensure reliable operation, it’s important to choose high-quality pressure switches from reputable manufacturers. Conduct thorough research and read reviews from other users in your industry to identify brands known for durability and reliability. Incorporate regular maintenance checks into your operational protocol to test the functionality of the pressure switch. This should include inspecting for leaks, verifying settings, and ensuring that all connections are secure. Additionally, consider investing in pressure switches with built-in diagnostics or alerts that can notify operators of performance issues before they escalate. This proactive approach can save both time and money in the long run.

Strategic Material Selection Guide for pressure switch for air compressor diagram

What Are the Common Materials Used in Pressure Switches for Air Compressors?

When selecting materials for pressure switches in air compressors, it’s essential to consider their properties, advantages, disadvantages, and how they align with specific application needs. Below, we analyze four common materials used in pressure switches, providing insights for international B2B buyers.

What Are the Key Properties of Brass in Pressure Switch Applications?

Brass is a popular choice for pressure switch housings due to its excellent mechanical properties and corrosion resistance. It can withstand high pressures and temperatures, making it suitable for various compressor applications. Brass typically has a temperature rating of up to 150°C (302°F) and can handle pressures exceeding 300 psi.

Pros: Brass is durable, resistant to corrosion, and has good machinability, which simplifies manufacturing. Its aesthetic appeal also makes it suitable for visible applications.

Illustrative image related to pressure switch for air compressor diagram

Cons: The primary drawback of brass is its cost, which can be higher than alternative materials like plastic or aluminum. Additionally, brass can be susceptible to dezincification in certain environments, potentially compromising its integrity.

Impact on Application: Brass is compatible with a wide range of media, including air and various gases, making it versatile for different compressor types.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN for brass components. The cost may vary significantly based on local availability and import tariffs.

Illustrative image related to pressure switch for air compressor diagram

How Does Stainless Steel Perform in Pressure Switch Applications?

Stainless steel is another widely used material for pressure switches, known for its exceptional strength and corrosion resistance. It can operate effectively at temperatures up to 200°C (392°F) and pressures above 500 psi, making it suitable for heavy-duty applications.

Pros: Stainless steel offers superior durability and resistance to harsh environments, including high humidity and corrosive gases. It also has a long lifespan, reducing the frequency of replacements.

Cons: The high cost of stainless steel can be a deterrent for some buyers. Additionally, its machining can be more complex compared to softer metals, potentially increasing manufacturing costs.

Impact on Application: Stainless steel is compatible with a variety of media, including aggressive gases and liquids, making it ideal for industrial applications.

Considerations for International Buyers: Compliance with international standards is crucial, especially in Europe, where regulations regarding material safety are stringent. Buyers should also consider the availability of stainless steel in their region, as it may affect lead times and costs.

What Are the Advantages of Using Plastic in Pressure Switches?

Plastic materials, particularly polycarbonate and nylon, are increasingly used in pressure switches due to their lightweight and cost-effective nature. These materials can typically withstand temperatures up to 80°C (176°F) and pressures around 150 psi.

Pros: The primary advantage of plastic is its low cost and ease of manufacturing. It is also resistant to corrosion and can be molded into complex shapes, which is beneficial for compact designs.

Cons: However, plastics generally have lower strength and temperature resistance compared to metals. They may not be suitable for high-pressure or high-temperature applications.

Impact on Application: While plastic is compatible with air and some gases, it may not be suitable for applications involving corrosive substances or extreme temperatures.

Illustrative image related to pressure switch for air compressor diagram

Considerations for International Buyers: Buyers should ensure that the selected plastic meets relevant standards, such as JIS in Japan or ASTM in the U.S. Additionally, the environmental impact of plastic should be considered, especially in regions with stringent regulations regarding waste.

Why Is Aluminum a Viable Option for Pressure Switches?

Aluminum is often used in pressure switches due to its lightweight and good strength-to-weight ratio. It can handle temperatures up to 120°C (248°F) and pressures around 200 psi.

Pros: Aluminum is relatively inexpensive and has good corrosion resistance, especially when anodized. Its lightweight nature makes it ideal for portable compressor applications.

Cons: While aluminum is durable, it is not as robust as stainless steel or brass, which may limit its use in high-stress environments. It can also be more prone to wear over time.

Impact on Application: Aluminum is suitable for air and non-corrosive gases but may not perform well in applications involving aggressive chemicals.

Considerations for International Buyers: Compliance with international standards is essential, especially for buyers in Europe and South America, where material specifications are closely regulated. The availability of aluminum may vary, impacting lead times and costs.

Summary Table of Material Comparisons

| Material | Typical Use Case for pressure switch for air compressor diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General-purpose pressure switches in moderate environments | Excellent corrosion resistance | Higher cost, prone to dezincification | High |

| Stainless Steel | Heavy-duty industrial applications requiring durability | Superior strength and longevity | High cost, complex manufacturing | High |

| Plastic | Lightweight, cost-effective switches for low-pressure applications | Low cost, easy to mold | Lower strength and temperature limits | Low |

| Aluminum | Portable compressors and moderate applications | Lightweight and good corrosion resistance | Not as robust as metals, wear over time | Medium |

This analysis provides a comprehensive overview of the materials used in pressure switches for air compressors, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure switch for air compressor diagram

What Are the Main Stages of the Manufacturing Process for Pressure Switches for Air Compressors?

The manufacturing process for pressure switches designed for air compressors involves several critical stages, each contributing to the overall performance and reliability of the final product. Understanding these stages is essential for B2B buyers, especially those sourcing from international markets.

Material Preparation: What Materials Are Used?

The first stage involves the selection and preparation of raw materials. Common materials include high-grade plastics for housings, brass or stainless steel for contacts, and specialized silicone or rubber for seals. Each material is chosen for its durability and resistance to pressure and temperature variations.

Once materials are selected, they undergo rigorous quality checks to ensure they meet industry standards. This includes evaluating material properties such as tensile strength, thermal resistance, and corrosion resistance. Only materials that pass these tests will proceed to the next stage.

How Are Pressure Switches Formed?

After material preparation, the forming process begins. This typically includes machining, injection molding, and stamping.

- Machining involves cutting materials to specific dimensions. For metal components, CNC (Computer Numerical Control) machines are often used to ensure precision.

- Injection molding is commonly used for plastic parts. This technique allows for complex shapes and designs while maintaining tight tolerances.

- Stamping is employed for creating metal contacts and other flat components.

This stage is crucial as it sets the foundation for the switch’s performance and durability.

What Does the Assembly Process Entail?

Assembly is the next step, where individual components are brought together to form the complete pressure switch. This process can be manual or automated, depending on the scale of production.

Key assembly tasks include:

- Component Integration: This involves fitting the electrical contacts, sealing elements, and housing together.

- Wiring: Ensuring that all electrical connections are made according to specific wiring diagrams is crucial. Proper wiring is essential for the pressure switch to function effectively and safely.

- Quality Inspections: At this stage, initial quality checks ensure that all components are correctly assembled and that there are no visible defects.

What Finishing Techniques Are Used for Pressure Switches?

Finishing processes enhance the appearance and functionality of the pressure switches. Common techniques include:

- Surface Treatment: This can involve anodizing or plating to improve corrosion resistance.

- Coating: A protective coating may be applied to plastic components to enhance durability.

- Labeling and Marking: Clear labels and markings are applied to indicate pressure ranges, wiring instructions, and safety warnings.

These finishing touches not only improve the aesthetic appeal but also ensure compliance with international safety and performance standards.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance is paramount in the manufacturing of pressure switches, particularly for international buyers who must navigate various regulations and standards.

Illustrative image related to pressure switch for air compressor diagram

Which International Standards Are Relevant?

B2B buyers should look for manufacturers that comply with international standards such as ISO 9001. This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality throughout the production process.

Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in the European market, and API (American Petroleum Institute) standards for oil and gas applications, are crucial indicators of quality and safety.

What Are the Key Quality Control Checkpoints?

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial check ensures that raw materials meet specified quality criteria before they enter the production line.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early. This includes monitoring dimensions, electrical connections, and assembly integrity.

- Final Quality Control (FQC): After assembly, a comprehensive examination is performed to ensure that the finished product meets all specifications and standards.

These checkpoints are crucial for maintaining the integrity of the pressure switches and ensuring they perform reliably in various applications.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is essential for B2B buyers, especially when sourcing internationally.

What Audit Procedures Should Be Followed?

Buyers should request detailed documentation of a supplier’s quality management practices, including:

Illustrative image related to pressure switch for air compressor diagram

- Quality Management System Audits: Regular audits by internal teams or third-party inspectors help maintain compliance with international standards.

- Certificates of Compliance: Suppliers should provide certificates proving adherence to relevant standards like ISO 9001 or CE marking.

Conducting on-site audits can also provide insights into the supplier’s manufacturing processes and quality control measures.

What Common Testing Methods Are Used?

Common testing methods for pressure switches include:

- Functional Testing: Verifying that the switch activates and deactivates at the correct pressure levels.

- Electrical Testing: Ensuring that there are no electrical faults, such as short circuits.

- Durability Testing: Subjecting switches to extreme conditions to confirm they can withstand operational demands.

How Do Quality Control Nuances Affect International Buyers?

Understanding quality control nuances is vital for international buyers, especially those from regions like Africa, South America, the Middle East, and Europe.

What Regional Considerations Should Be Made?

Different regions may have specific regulations and standards. For instance, buyers in Europe may prioritize CE marking, while those in the Middle East might focus on compliance with local standards.

Additionally, buyers should be aware of potential language barriers and cultural differences that may affect communication with suppliers. Establishing clear expectations and documentation can mitigate these challenges.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing pressure switches for air compressors, ensuring they select reliable and compliant suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure switch for air compressor diagram’

In the competitive landscape of B2B procurement, sourcing the right pressure switch for air compressors is crucial for ensuring operational efficiency and safety. This guide provides a practical checklist to assist international buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes understanding the pressure range, electrical ratings, and compatibility with existing systems. Having precise specifications will help narrow down potential suppliers and ensure the selected pressure switch meets your operational needs.

Illustrative image related to pressure switch for air compressor diagram

Step 2: Research Reliable Suppliers

Conduct thorough research to identify suppliers with a proven track record in the industry. Look for companies specializing in pressure switches and related components, as their expertise is vital for product quality. Focus on suppliers that have positive reviews and a history of serving clients in your region or industry.

- Check for Industry Experience: Suppliers with extensive experience are more likely to offer reliable products and support.

- Evaluate Geographic Reach: Ensure the supplier can deliver to your location efficiently, considering any logistical challenges.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential for ensuring product quality and compliance with industry standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. These certifications can also provide insights into the supplier’s adherence to safety and environmental regulations.

- Request Documentation: Ask suppliers for copies of their certifications and quality assurance processes.

- Cross-Check Validity: Verify the authenticity of certifications through relevant regulatory bodies or industry associations.

Step 4: Request Product Samples

Once you’ve shortlisted potential suppliers, request samples of their pressure switches. Testing samples allows you to assess the quality, functionality, and compatibility with your air compressor systems. Pay attention to the build quality, response time, and accuracy of the switches during testing.

Illustrative image related to pressure switch for air compressor diagram

- Conduct Performance Tests: Evaluate the switches under real operating conditions to ensure they meet your specifications.

- Assess Customer Support: During this phase, interact with the supplier’s support team to gauge their responsiveness and expertise.

Step 5: Compare Pricing and Terms

Gather detailed quotes from multiple suppliers to facilitate a comparative analysis. While price is a significant factor, consider the overall value, including warranty terms, after-sales support, and delivery schedules. A slightly higher price may be justified by superior quality or better service.

- Analyze Total Cost of Ownership: Consider long-term costs, including maintenance and potential downtime associated with inferior products.

- Negotiate Terms: Don’t hesitate to negotiate pricing and payment terms to better fit your budget and cash flow.

Step 6: Check References and Case Studies

Before finalizing your purchase, request references or case studies from the supplier. Engaging with past clients can provide valuable insights into the supplier’s reliability and product performance. It’s particularly beneficial to connect with businesses in your industry or region.

- Ask Specific Questions: Inquire about the supplier’s responsiveness, product quality, and any challenges faced during the procurement process.

- Review Case Studies: Analyze how the supplier has addressed similar needs for other clients, focusing on outcomes and satisfaction levels.

Step 7: Finalize the Order and Monitor Delivery

After selecting a supplier, finalize your order with clear specifications and expectations. Monitor the delivery process closely to ensure timely receipt of the pressure switches. Maintain open communication with the supplier throughout to address any potential issues swiftly.

- Establish Clear Communication Channels: Ensure you have a direct line of communication with the supplier for updates and queries.

- Prepare for Installation: Plan for the integration of the new pressure switches into your existing systems, including any necessary training for your team.

By following this checklist, you can streamline the procurement process for pressure switches, ensuring a reliable and efficient operation for your air compressor systems.

Illustrative image related to pressure switch for air compressor diagram

Comprehensive Cost and Pricing Analysis for pressure switch for air compressor diagram Sourcing

What Are the Key Cost Components for Sourcing Pressure Switches for Air Compressors?

When sourcing pressure switches for air compressors, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly affects the price. High-quality components made from durable materials, such as brass and high-grade plastics, can increase initial costs but offer better longevity and performance.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Regions with lower labor costs may offer more competitive pricing, but it’s essential to assess the quality of workmanship.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities and facility maintenance. Efficient manufacturing processes can help mitigate overhead costs, which can be a crucial factor in the overall price.

-

Tooling: Initial investments in tooling can be significant, especially for custom pressure switches. Buyers should inquire about tooling costs, as these may be amortized over larger production runs, impacting unit pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with industry standards. While this may add to costs, it is essential for minimizing defects and enhancing customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely depending on the supplier’s location, shipping method, and Incoterms. Buyers should consider the total logistics costs, including potential tariffs and duties, particularly for international transactions.

-

Margin: Suppliers typically build in a profit margin that reflects their business model and market conditions. Understanding the margin can aid in assessing pricing fairness and negotiating better deals.

How Do Price Influencers Affect the Cost of Pressure Switches?

Several factors influence the pricing of pressure switches, making it essential for buyers to consider them during negotiations:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to bulk pricing advantages. Establishing a consistent purchasing pattern can further incentivize suppliers to offer favorable terms.

-

Specifications and Customization: Custom specifications can drive up costs. Buyers should assess whether standard models meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: The level of certification (e.g., ISO, CE) can affect pricing. High-quality, certified products typically command higher prices but can lead to lower maintenance and replacement costs over time.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may charge more but provide added value through better service and product assurance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) can clarify responsibilities for shipping, insurance, and tariffs. This knowledge helps buyers anticipate additional costs associated with their orders.

What Buyer Tips Can Help Optimize Costs for International Sourcing?

Navigating the international market for pressure switches requires strategic planning to optimize costs:

-

Negotiate Wisely: Leverage volume purchases to negotiate better pricing. Building a strong relationship with suppliers can also lead to discounts and favorable terms.

-

Focus on Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, maintenance, and replacement costs. A lower upfront cost may not always be the most economical in the long run.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations, import regulations, and potential tariffs that can affect final costs. Staying informed about market trends in regions like Africa, South America, the Middle East, and Europe can help in making educated purchasing decisions.

-

Request Samples: Before committing to large orders, request samples to evaluate quality and performance. This step can prevent costly mistakes associated with poor product choices.

-

Understand Local Regulations: Compliance with local standards and regulations is crucial, especially in international transactions. Ensure that the sourced products meet the necessary certifications to avoid complications.

Disclaimer

Prices for pressure switches can vary widely based on the factors discussed above. This analysis serves as a guideline and does not represent fixed pricing. Buyers are encouraged to conduct thorough market research and supplier evaluations to obtain the most accurate and competitive quotes.

Alternatives Analysis: Comparing pressure switch for air compressor diagram With Other Solutions

Exploring Alternatives to Pressure Switch for Air Compressor Diagram

In the realm of air compressor control systems, the pressure switch serves as a vital component for regulating performance and preventing overpressurization. However, buyers should also consider alternative solutions that can achieve similar objectives while varying in functionality, cost, and complexity. This analysis will compare the traditional pressure switch diagram with two viable alternatives: electronic pressure sensors and programmable logic controllers (PLCs).

Comparison Table

| Comparison Aspect | Pressure Switch For Air Compressor Diagram | Electronic Pressure Sensor | Programmable Logic Controller (PLC) |

|---|---|---|---|

| Performance | Reliable for basic pressure regulation | High accuracy; real-time monitoring | Advanced control; customizable operations |

| Cost | Lower initial investment | Moderate cost; price varies by accuracy | Higher upfront cost; includes programming |

| Ease of Implementation | Straightforward wiring and setup | Requires calibration and integration | Complex setup; needs programming expertise |

| Maintenance | Low maintenance; simple mechanical parts | Moderate; requires periodic calibration | High; dependent on software updates and troubleshooting |

| Best Use Case | Small to medium-sized applications | Precision applications; sensitive systems | Industrial automation and complex systems |

Detailed Breakdown of Alternatives

Electronic Pressure Sensor

Electronic pressure sensors utilize advanced technology to provide precise pressure readings. They offer real-time monitoring and can send data to a control system, allowing for dynamic adjustments. While they boast higher accuracy and flexibility, they come with a moderate cost and require calibration to ensure optimal performance. Additionally, integrating these sensors into existing systems can be complex, necessitating a certain level of technical expertise.

Programmable Logic Controller (PLC)

PLCs represent a sophisticated solution for managing air compressor systems. They allow for customized control strategies, enabling users to program specific operational parameters tailored to their needs. This flexibility makes PLCs ideal for large-scale industrial applications where multiple variables need to be monitored and adjusted. However, the initial investment is significantly higher, and the setup process demands advanced programming skills. Maintenance can also be more intensive, as it may require software updates and troubleshooting.

Conclusion: Choosing the Right Solution for Your Air Compressor Needs

When selecting the most suitable solution for air compressor control, B2B buyers should evaluate their specific operational needs and budget constraints. The traditional pressure switch diagram remains a reliable choice for straightforward applications due to its cost-effectiveness and ease of installation. However, for businesses requiring high precision or complex control, electronic pressure sensors and PLCs offer advanced capabilities that can enhance operational efficiency. Ultimately, the decision should align with the operational goals, technical capacity, and financial resources of the buyer’s organization.

Illustrative image related to pressure switch for air compressor diagram

Essential Technical Properties and Trade Terminology for pressure switch for air compressor diagram

What are the Key Technical Properties of a Pressure Switch for Air Compressors?

When selecting a pressure switch for air compressors, understanding its technical properties is crucial for ensuring optimal performance, safety, and compatibility with existing systems. Here are several essential specifications:

1. Pressure Range

The pressure range indicates the operational limits of the pressure switch, typically measured in psi (pounds per square inch). This specification is vital as it determines the pressure levels at which the switch will activate or deactivate the compressor. Buyers must ensure that the selected range aligns with their compressor’s operational requirements to prevent malfunction or safety hazards.

2. Differential Pressure

Differential pressure refers to the difference between the cut-in and cut-out pressure settings. This property is significant because it affects the compressor’s cycling frequency. A narrow differential can lead to frequent on-off cycling, which may reduce the lifespan of the compressor. In contrast, a wider differential can improve energy efficiency but may not maintain consistent pressure. Buyers should consider their application needs when selecting a differential pressure setting.

3. Electrical Rating

The electrical rating of a pressure switch specifies the maximum voltage and current it can handle, typically expressed in volts (V) and amperes (A). This specification is essential for ensuring that the switch can safely manage the electrical load from the compressor motor without overheating or failing. Buyers should verify that the electrical rating matches or exceeds the compressor’s requirements to avoid potential failures.

4. Material Grade

The materials used in the construction of the pressure switch, such as brass, plastic, or stainless steel, significantly influence durability and resistance to environmental factors like humidity or corrosive substances. Selecting the right material grade is important for ensuring longevity, especially in demanding industrial environments. Buyers should assess the environmental conditions in which the switch will operate to choose an appropriate material.

Illustrative image related to pressure switch for air compressor diagram

5. Mounting Type

The mounting type, such as panel mount or surface mount, defines how the pressure switch is installed. This specification is crucial for compatibility with the compressor setup and space constraints. Buyers should consider the installation environment and any spatial limitations when selecting a mounting type to ensure seamless integration.

What Common Trade Terminology Should B2B Buyers Understand?

Familiarity with industry jargon can significantly enhance communication and decision-making in B2B transactions involving pressure switches for air compressors. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is critical for buyers seeking high-quality components that meet specific standards or certifications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers, especially in bulk purchasing, as it affects budget planning and inventory management.

Illustrative image related to pressure switch for air compressor diagram

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process by allowing them to compare prices and terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms helps buyers clarify shipping responsibilities, risk management, and cost allocation, which is crucial for cross-border transactions.

5. NEMA Rating (National Electrical Manufacturers Association)

NEMA ratings classify the degree of protection provided by electrical enclosures against environmental hazards. This specification is crucial for buyers to ensure that the pressure switch will perform reliably in its intended environment, particularly in industrial applications.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when selecting pressure switches for air compressors, ensuring compatibility, safety, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the pressure switch for air compressor diagram Sector

What Are the Key Market Drivers and Trends for Pressure Switches in Air Compressors?

The global market for pressure switches used in air compressors is witnessing notable growth, driven by several key factors. The rising demand for compressed air across various sectors, including manufacturing, automotive, and construction, is a primary driver. This demand is particularly strong in emerging markets like Brazil, Saudi Arabia, and various African nations, where industrialization and infrastructure development are accelerating. Additionally, the proliferation of automation and smart technologies in manufacturing processes is leading to increased adoption of advanced pressure switch systems.

Another significant trend is the shift towards digitalization, where pressure switches are increasingly integrated with IoT capabilities. This allows for real-time monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency. Moreover, the push for energy efficiency is prompting manufacturers to innovate and design pressure switches that minimize power consumption while maintaining performance.

International buyers should also note the trend toward modular and customizable pressure switch solutions, which offer flexibility and adaptability to specific operational needs. As industries evolve, the capacity to tailor components to fit distinct applications becomes essential, particularly in diverse markets with varying operational requirements.

How Are Sustainability and Ethical Sourcing Influencing the Pressure Switch Market?

Sustainability is becoming a critical consideration in the procurement of pressure switches for air compressors. B2B buyers are increasingly focusing on the environmental impact of their sourcing decisions. Manufacturers are responding by adopting greener practices, such as utilizing recyclable materials and reducing waste in production processes. Certifications such as ISO 14001 for environmental management systems are becoming essential for suppliers to demonstrate their commitment to sustainability.

Ethical sourcing also plays a vital role in the decision-making process for international buyers. Ensuring that suppliers adhere to fair labor practices and operate within legal environmental frameworks is crucial for building trust and maintaining brand integrity. Buyers are encouraged to seek suppliers who can provide transparency regarding their supply chain practices, ensuring that all components, including pressure switches, are sourced ethically.

Furthermore, the integration of eco-friendly materials in the manufacturing of pressure switches is gaining traction. This includes the use of biodegradable plastics and low-impact metals, which not only reduce environmental footprints but also appeal to consumers and businesses looking to enhance their sustainability credentials.

How Has the Pressure Switch Market Evolved Over Time?

The evolution of pressure switches for air compressors can be traced back to the early days of industrial automation when basic mechanical switches were employed. These early devices relied on simple mechanical principles to regulate pressure, often leading to inconsistencies and maintenance challenges.

As technology advanced, the introduction of electronic pressure switches marked a significant turning point. These modern devices provided more precise control and enhanced reliability, paving the way for widespread adoption across various industries. The integration of digital technology and IoT capabilities further revolutionized the market, allowing for smarter, more efficient systems that can adapt to the dynamic needs of contemporary operations.

Today, the pressure switch market continues to innovate, with trends focused on energy efficiency, customization, and sustainability. This ongoing evolution not only enhances performance but also aligns with the broader goals of industries striving for operational excellence and environmental stewardship.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure switch for air compressor diagram

-

1. How do I solve wiring issues with my pressure switch for an air compressor?

To solve wiring issues, first, ensure that you have correctly identified the terminals for power input and output. Common mistakes include wiring directly to the compressor motor or confusing motor and line contacts. Review the wiring diagram that comes with the pressure switch and double-check all connections for security. If the compressor runs continuously or fails to cycle properly, re-evaluate your wiring setup and consult technical support or an expert if necessary. -

2. What is the best type of pressure switch for air compressors in humid environments?

For humid environments, look for a pressure switch that is rated for moisture resistance and has a durable housing, such as those made from stainless steel or plastic with protective coatings. Additionally, consider switches with weatherproof features or sealed terminals to prevent corrosion. Consult with suppliers about specific models designed for high-humidity applications to ensure reliability and longevity in challenging conditions. -

3. How can I verify the quality of pressure switches from international suppliers?

To verify quality, request certifications such as ISO 9001 or CE marking from potential suppliers. Conduct factory audits or inspections if feasible, and ask for product samples to test performance before committing to larger orders. Reviews and references from previous clients can also provide insights into the supplier’s reliability and product quality. Engage with third-party inspection services for additional assurance. -

4. What customization options are available for pressure switches?

Many suppliers offer customization options, including pressure settings, differential ranges, and terminal configurations tailored to specific applications. You can also inquire about custom labeling or branding to match your company’s requirements. Discuss your needs with the supplier early in the process to understand the feasibility and any associated costs or lead times for custom products. -

5. What are the typical minimum order quantities (MOQ) for pressure switches?

Minimum order quantities can vary widely among suppliers, typically ranging from 50 to 500 units depending on the manufacturer and product type. For customized pressure switches, MOQs may be higher due to the additional setup costs. It’s advisable to communicate your needs clearly with suppliers to negotiate MOQs that align with your purchasing capabilities and project requirements. -

6. What payment terms should I expect when sourcing pressure switches internationally?

Payment terms can vary based on the supplier’s policies and your negotiation. Common terms include payment in advance, 30% deposit with the balance before shipment, or net 30/60 days after delivery. Be sure to clarify payment methods accepted, including letters of credit, bank transfers, or online payment platforms. Establishing clear terms in a purchase agreement can help avoid misunderstandings. -

7. How do I handle logistics and shipping for international orders of pressure switches?

When handling logistics, choose a reliable freight forwarder familiar with shipping to your destination country. Consider factors such as shipping costs, lead times, and customs clearance procedures. Discuss delivery terms (e.g., FOB, CIF) with your supplier to clarify responsibilities. It’s also essential to factor in potential delays due to customs or regulatory compliance and plan accordingly to maintain your project timelines. -

8. What are the common quality assurance practices for pressure switches?

Quality assurance practices often include rigorous testing for performance under specified pressure ranges, durability assessments, and compliance with industry standards. Suppliers may conduct routine inspections during the manufacturing process and final quality checks before shipment. Request documentation of these practices, such as test reports or certificates of compliance, to ensure that the pressure switches meet your quality expectations and operational standards.

Top 6 Pressure Switch For Air Compressor Diagram Manufacturers & Suppliers List

1. Tameson – Air Compressor Pressure Switches

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: Air compressor pressure switch adjustment involves setting the cut-in and cut-out pressures to maintain tank pressure within specified limits. The switches can be Normally Closed (NC) or Normally Open (NO), with hysteresis defined as the difference between cut-in and cut-out pressures. Adjustment typically involves two set screws: one for cut-in/cut-out and another for hysteresis. The Condor MDR 2…

2. Air Compressor Guide – Air Pressure Switches

Domain: air-compressor-guide.com

Registered: 2011 (14 years)

Introduction: Air pressure switches are designed to switch on or off at specific pressure setpoints. They come in various designs and types, including adjustable and non-adjustable models. Key features include: 1. On/Off/Auto settings: Some switches have an auto setting that starts/stops the compressor based on pressure setpoints, while others are always in auto mode. 2. Electrical contacts: Vary in number and …

3. Pinterest – Air Compressor Solutions

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Air Compressor Pressure Switch Wiring Diagram, Air Switch For Air Compressor, Craftsman Air Compressor, Coleman Air Compressor Switch, High-capacity Air Compressor, Compressor Tank, A/c Compressor Kit For Car, Air Compressor Parts, Air Compressor Pressure Switch Troubleshooting & Buying Guide, Compressor Pressure Switch Parts, Compressor Pressure Switch Repair & Assembly, Air Compressor Setup Diag…

4. Do It Yourself – Pressure Control Switch for Air Compressor

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: Pressure control switch for air compressor wiring, requires understanding of wiring diagram, involves connecting incoming power wires (white and black for 120v or one on each for 240v) and motor wires (blue and gray, typically black).

5. Sears – Pressure Switch Replacement Guide

Domain: searspartsdirect.com

Registered: 1998 (27 years)

Introduction: This DIY repair guide explains how to replace the pressure switch on an air compressor. The pressure switch starts the pump motor as the tank empties and pressure drops to the cut-in pressure; it stops the motor when the tank reaches the cut-out pressure. Over time, the pressure switch wears out. If the pressure switch won’t start the pump when tank pressure drops below the cut-in pressure or won’…

6. Cdsentec – Air Compressor Pressure Switch

Domain: cdsentec.com

Registered: 2018 (7 years)

Introduction: Air compressor pressure switch is used to adjust the start and stop status of the air compressor. It has two pressure set-points: cut-in and cut-out. The compressor stops at the cut-out pressure and starts again at the cut-in pressure. Typical operating pressures are set between 120-150 psi (8-10 Bar), but can be adjusted lower based on application needs. Adjustment methods vary, with some switche…

Strategic Sourcing Conclusion and Outlook for pressure switch for air compressor diagram

In today’s competitive landscape, strategic sourcing for pressure switches in air compressors is essential for optimizing operational efficiency and ensuring safety. By understanding the critical role these components play in regulating air pressure and preventing overpressurization, international buyers can make informed purchasing decisions. Key takeaways include the importance of proper wiring to avoid common mistakes that could lead to costly downtime and safety hazards.

As industries in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and high-quality pressure switches is expected to grow. Building relationships with reputable manufacturers and suppliers will not only enhance procurement strategies but also contribute to the sustainability and performance of air compressor systems.

Looking ahead, businesses should focus on integrating advanced technologies and best practices in their sourcing strategies. By prioritizing quality and investing in robust support systems, you can ensure your operations remain resilient and efficient. Embrace the opportunity to connect with industry experts and suppliers who can guide you in selecting the best pressure switch solutions for your needs. Your proactive approach today will set the foundation for success in tomorrow’s market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.