Pressure Switch Diagram Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for pressure switch diagram

In today’s interconnected industrial landscape, understanding the intricacies of pressure switch diagrams is crucial for international B2B buyers. Whether you are sourcing components for manufacturing in Nigeria or optimizing equipment in Saudi Arabia, navigating the complexities of pressure switch specifications can pose significant challenges. This guide demystifies the various types of pressure switches, their applications across different industries, and the standardized symbols that facilitate clear communication among engineers and technicians.

Our comprehensive resource covers essential topics, including the different configurations of pressure switches—such as normally closed, normally open, and changeover types—alongside their specific use cases in systems ranging from hydraulic pumps to HVAC applications. Furthermore, we delve into supplier vetting processes to ensure you partner with reliable manufacturers who meet international standards, as well as providing insights on cost considerations that can impact your procurement strategies.

By equipping yourself with this knowledge, you can make informed purchasing decisions that enhance operational efficiency and reduce the risk of costly errors. This guide is tailored specifically for B2B buyers in Africa, South America, the Middle East, and Europe, enabling you to confidently navigate the global market for pressure switch diagrams and optimize your sourcing processes.

Understanding pressure switch diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Normally Closed (NC) | Default position is closed; opens on pressure rise | High-pressure systems, safety shutdowns | Pros: Reliable safety mechanism; Cons: May not suit applications requiring immediate response to pressure drop. |

| Normally Open (NO) | Default position is open; closes on pressure rise | Compressors, pneumatic systems | Pros: Quick activation; Cons: Risk of unintended activation if pressure fluctuates unexpectedly. |

| Changeover (SPDT) | Switches between contacts based on pressure changes | Versatile applications, dual-function systems | Pros: Flexible operation; Cons: More complex wiring and setup. |

| Reverse Action | Activates to turn off the pump when pressure builds | Water systems, irrigation setups | Pros: Prevents over-pressurization; Cons: Requires careful adjustment for optimal performance. |

| Adjustable Pressure | Allows customization of pressure settings | Industrial processes, HVAC systems | Pros: Tailored performance; Cons: Complexity in setup and maintenance. |

What are the characteristics of Normally Closed (NC) pressure switches?

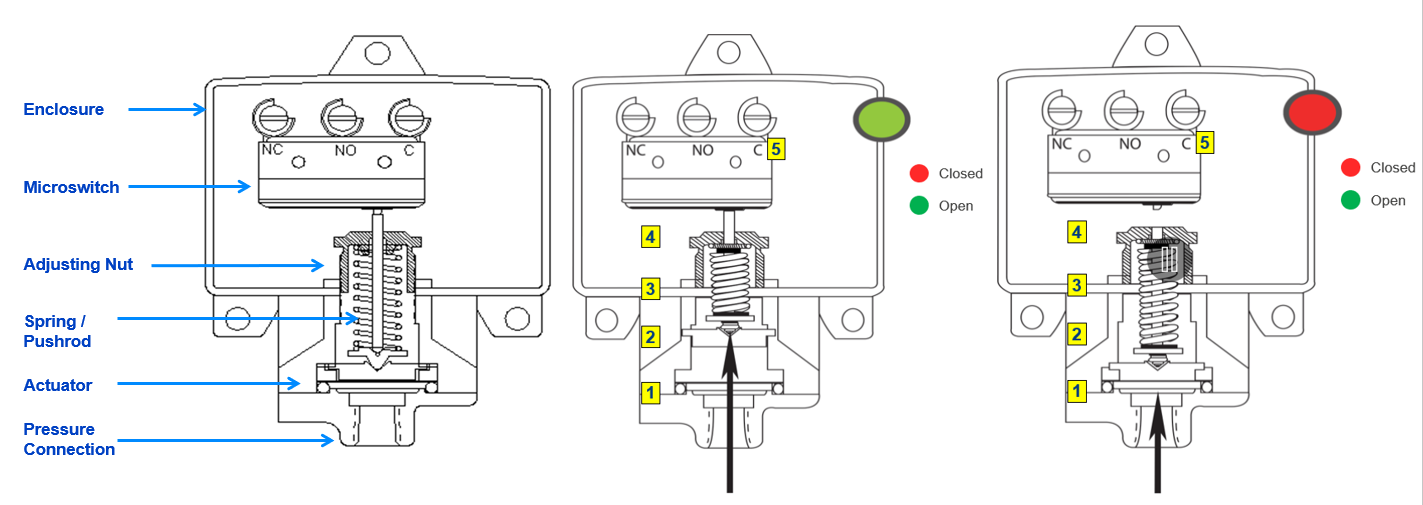

Normally Closed (NC) pressure switches are designed to maintain a closed circuit until a specified pressure threshold is exceeded. This type is commonly used in high-pressure applications, where safety is paramount, such as in hydraulic systems or safety shutdowns for pumps. When the pressure rises beyond the set point, the switch opens the circuit, effectively shutting down the system to prevent damage. Buyers should consider the reliability and safety aspects of NC switches, especially in critical applications where failure could lead to significant risks.

How do Normally Open (NO) pressure switches function?

Normally Open (NO) pressure switches maintain an open circuit under standard conditions and close when pressure reaches a predetermined level. They are ideal for applications like compressors and pneumatic systems, where activation is required during pressure drops. The quick activation feature can be beneficial, but buyers must be cautious of potential unintended activations if pressure fluctuates unexpectedly. Understanding the specific operational environment is crucial for ensuring the NO switch is suitable for the intended application.

What makes Changeover (SPDT) pressure switches versatile?

Changeover or Single Pole Double Throw (SPDT) pressure switches are unique in that they can operate as either Normally Closed (NC) or Normally Open (NO) depending on the application needs. This flexibility makes them suitable for a wide range of industrial applications where dual functionality is required. Buyers should weigh the advantages of versatility against the complexity of wiring and potential for misconfiguration. Proper installation and understanding of the operational requirements are key to maximizing their benefits.

Why are Reverse Action pressure switches used in specific applications?

Reverse Action pressure switches activate to turn off a pump when pressure builds up, making them essential in systems like water supply and irrigation. This design helps prevent over-pressurization, which can lead to equipment damage or failure. Buyers should consider the specific settings required for their applications, as improper adjustments can lead to performance issues. The focus should be on ensuring the switch meets the operational demands of the system it will serve.

What advantages do Adjustable Pressure switches provide?

Adjustable pressure switches allow users to customize pressure settings according to specific operational needs. This adaptability makes them ideal for varied industrial processes and HVAC systems, where precise pressure control is crucial. However, the complexity involved in setting and maintaining these switches can be a drawback for some buyers. It’s important to consider the skill level required for installation and maintenance to ensure optimal performance and longevity of the switch in its application.

Key Industrial Applications of pressure switch diagram

| Industry/Sector | Specific Application of pressure switch diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Monitoring well pressure and flow rates | Enhances safety by preventing over-pressurization and equipment failure | Compliance with local standards, durability in harsh environments |

| Water Treatment | Control of pumps in filtration systems | Ensures consistent water quality and operational efficiency | Compatibility with existing systems, resistance to corrosion |

| HVAC Systems | Regulation of pressure in refrigeration and air conditioning units | Improves energy efficiency and prolongs equipment lifespan | Temperature range specifications, accuracy in pressure settings |

| Manufacturing Processes | Automation in hydraulic systems | Increases productivity and minimizes downtime | Customization for specific machinery, reliability under varying loads |

| Agriculture | Irrigation system pressure management | Optimizes water usage and enhances crop yield | Adaptability to different irrigation setups, ruggedness for outdoor use |

How is the Pressure Switch Diagram Utilized in the Oil & Gas Industry?

In the oil and gas sector, pressure switches are crucial for monitoring well pressure and flow rates. The pressure switch diagram provides a clear representation of how these switches function, indicating their role in maintaining safe pressure levels. By preventing over-pressurization, businesses can avoid costly equipment failures and enhance safety protocols. Buyers in this industry must consider sourcing pressure switches that comply with local safety standards and are durable enough to withstand harsh environmental conditions.

Illustrative image related to pressure switch diagram

What Role Does the Pressure Switch Diagram Play in Water Treatment?

In water treatment facilities, pressure switches control pumps within filtration systems, ensuring optimal performance. The pressure switch diagram illustrates the operational logic, helping technicians understand how to set and adjust pressure thresholds. This application is vital for maintaining consistent water quality and operational efficiency. International buyers should prioritize sourcing switches that are compatible with existing systems and resistant to corrosion, given the often aggressive nature of water treatment chemicals.

How is the Pressure Switch Diagram Applied in HVAC Systems?

In HVAC systems, pressure switches regulate the pressure in refrigeration and air conditioning units. The pressure switch diagram showcases the relationship between pressure changes and system responses, such as activating or deactivating compressors. This application is essential for improving energy efficiency and prolonging equipment lifespan. Buyers should ensure that sourced pressure switches meet specific temperature range specifications and provide accurate pressure settings to maintain optimal system performance.

Why is the Pressure Switch Diagram Important for Manufacturing Processes?

In manufacturing, pressure switches play a pivotal role in automating hydraulic systems. The pressure switch diagram serves as a guide for integrating these switches into production lines, illustrating how they contribute to increased productivity and reduced downtime. For businesses, selecting reliable pressure switches that can be customized for specific machinery is critical, especially under varying load conditions. Buyers should focus on sourcing high-quality components that align with their operational requirements.

How Does the Pressure Switch Diagram Enhance Agricultural Practices?

In agriculture, pressure switches are utilized for managing irrigation system pressures. The pressure switch diagram helps farmers understand how to effectively monitor and control water flow, optimizing water usage and enhancing crop yield. This application is particularly relevant in regions with limited water resources. Buyers should look for switches that can adapt to different irrigation setups and are rugged enough for outdoor use, ensuring longevity and reliability in agricultural environments.

3 Common User Pain Points for ‘pressure switch diagram’ & Their Solutions

Scenario 1: Confusion Over Pressure Switch Symbols in Diagrams

The Problem: International B2B buyers often face confusion when interpreting pressure switch diagrams due to the variety of symbols used across different standards. For instance, a buyer in Saudi Arabia may encounter diagrams that utilize IEC 60617 symbols, while another from Nigeria might be more familiar with NFPA or JIC symbols. This inconsistency can lead to miscommunication with engineers and installers, causing delays in projects and potential safety hazards.

The Solution: To overcome this challenge, buyers should invest time in understanding the symbol standards relevant to their region and application. Familiarizing themselves with the most common symbols—such as Normally Closed (NC), Normally Open (NO), and Changeover (SPDT)—is essential. Consider creating a quick-reference guide that consolidates these symbols alongside their respective applications, which can be shared with team members and stakeholders. Additionally, engaging with manufacturers who provide clear documentation on their products can facilitate better understanding. For example, a supplier that offers training sessions on diagram interpretation can significantly improve clarity and operational efficiency.

Scenario 2: Misapplication of Pressure Switch Types

The Problem: Another frequent issue arises from the misapplication of different types of pressure switches in various systems. A company in South America might select a standard pressure switch when a reverse action pressure switch is required, leading to system failures or operational inefficiencies. This oversight is often due to a lack of detailed understanding of the operational environment and requirements, which can be particularly challenging for buyers who are new to pressure systems.

The Solution: To prevent misapplication, buyers should conduct a thorough needs assessment before specifying a pressure switch. This involves understanding the system’s operational parameters, such as the required pressure range and the nature of the pressure fluctuations. Engaging with engineers or technical experts during the selection process can provide valuable insights. Buyers can also leverage simulation tools or software that model system behavior under various conditions to identify the appropriate switch type. Moreover, maintaining clear communication with suppliers about specific application needs can lead to more accurate recommendations, ensuring that the selected pressure switch aligns with system requirements.

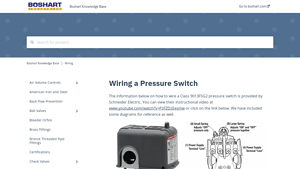

Scenario 3: Lack of Clear Wiring Instructions

The Problem: A common pain point for B2B buyers dealing with pressure switch diagrams is the absence of clear and straightforward wiring instructions. In many cases, diagrams may not provide adequate detail on how to wire the pressure switches correctly, leading to improper installations. This can result in malfunctioning systems and increased maintenance costs, particularly for businesses operating in remote areas where technical support is limited.

The Solution: To address this issue, buyers should seek suppliers that offer comprehensive installation guides that include detailed wiring instructions and troubleshooting tips. These guides should ideally include visual aids, such as step-by-step diagrams or videos, to enhance understanding. Additionally, investing in training sessions for technicians can ensure that the installation and maintenance teams are well-versed in the proper procedures. Establishing a relationship with a reliable supplier who can provide ongoing support and clarification on wiring issues can further enhance operational reliability. By prioritizing clear communication and training, businesses can mitigate installation errors and improve overall system performance.

Illustrative image related to pressure switch diagram

Strategic Material Selection Guide for pressure switch diagram

What Are the Common Materials Used in Pressure Switch Diagrams?

When selecting materials for pressure switches, several factors must be considered, including the operating environment, pressure and temperature ratings, and compatibility with the media being measured. Below, we analyze four common materials used in pressure switch diagrams, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Stainless Steel Perform in Pressure Switch Applications?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and high strength, making it suitable for high-pressure applications. It typically withstands temperatures ranging from -200°C to 800°C, depending on the specific alloy used.

Pros & Cons: The durability of stainless steel ensures a long service life, which is beneficial for applications requiring reliability. However, it can be more expensive than other materials, and its manufacturing processes may involve complex machining, increasing production costs.

Impact on Application: Stainless steel is compatible with a wide range of media, including aggressive chemicals, making it ideal for industrial applications in sectors like oil and gas, water treatment, and food processing.

Considerations for International Buyers: Buyers in regions like Saudi Arabia and Nigeria should ensure compliance with local standards such as ASTM or DIN. The availability of specific stainless steel grades may vary, impacting lead times and costs.

Illustrative image related to pressure switch diagram

Why Choose Brass for Pressure Switch Components?

Key Properties: Brass offers good corrosion resistance and excellent machinability. It can handle moderate pressures and temperatures, typically up to 200°C.

Pros & Cons: The cost-effectiveness of brass makes it a popular choice for many applications. However, its lower temperature and pressure ratings compared to stainless steel may limit its use in high-demand environments.

Impact on Application: Brass is commonly used in plumbing and HVAC applications, where it can effectively manage water and air pressures. Its compatibility with non-corrosive media is a significant advantage.

Illustrative image related to pressure switch diagram

Considerations for International Buyers: In regions like South America, where humidity can be high, buyers should consider the potential for dezincification in brass. Compliance with local standards is essential to ensure product safety and reliability.

What Are the Advantages of Using Plastic in Pressure Switch Designs?

Key Properties: Plastics, such as polycarbonate or nylon, are lightweight and resistant to corrosion. They generally have lower temperature ratings, typically around 80°C to 120°C.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, which can lead to lower overall production costs. However, its lower mechanical strength and temperature limitations may restrict its application in high-pressure environments.

Impact on Application: Plastic is suitable for applications involving non-corrosive fluids, such as water or air. Its lightweight nature can be beneficial in portable devices.

Considerations for International Buyers: Buyers in the Middle East should assess the impact of high temperatures on plastic materials. Compliance with international standards for plastics, such as ISO or ASTM, is crucial to ensure product quality.

How Does Aluminum Compare as a Material for Pressure Switches?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with temperature ratings typically up to 150°C. It is also relatively strong for its weight.

Pros & Cons: The lightweight nature of aluminum makes it ideal for applications where weight is a concern, such as in automotive or aerospace industries. However, it can be more susceptible to corrosion in certain environments, necessitating protective coatings.

Impact on Application: Aluminum is often used in applications where weight savings are critical, such as in mobile or portable pressure switches. Its compatibility with various media, including air and water, makes it versatile.

Considerations for International Buyers: In Europe, compliance with environmental regulations regarding aluminum production and recycling is essential. Buyers should also consider the availability of aluminum alloys that meet their specific performance requirements.

Illustrative image related to pressure switch diagram

Summary Table of Material Selection for Pressure Switch Diagrams

| Material | Typical Use Case for pressure switch diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure industrial applications | Excellent corrosion resistance and durability | Higher cost and complex manufacturing | High |

| Brass | Plumbing and HVAC applications | Cost-effective and good machinability | Limited pressure and temperature ratings | Medium |

| Plastic | Non-corrosive fluid applications | Lightweight and low cost | Lower strength and temperature limits | Low |

| Aluminum | Portable pressure switches | Lightweight and good corrosion resistance | Susceptible to corrosion in harsh environments | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for pressure switch diagram

What Are the Main Stages of Manufacturing Pressure Switch Diagrams?

The manufacturing of pressure switches, particularly those represented in diagrams, involves several critical stages that ensure high-quality and reliable performance. These stages encompass material preparation, forming, assembly, and finishing.

How is Material Prepared for Pressure Switch Manufacturing?

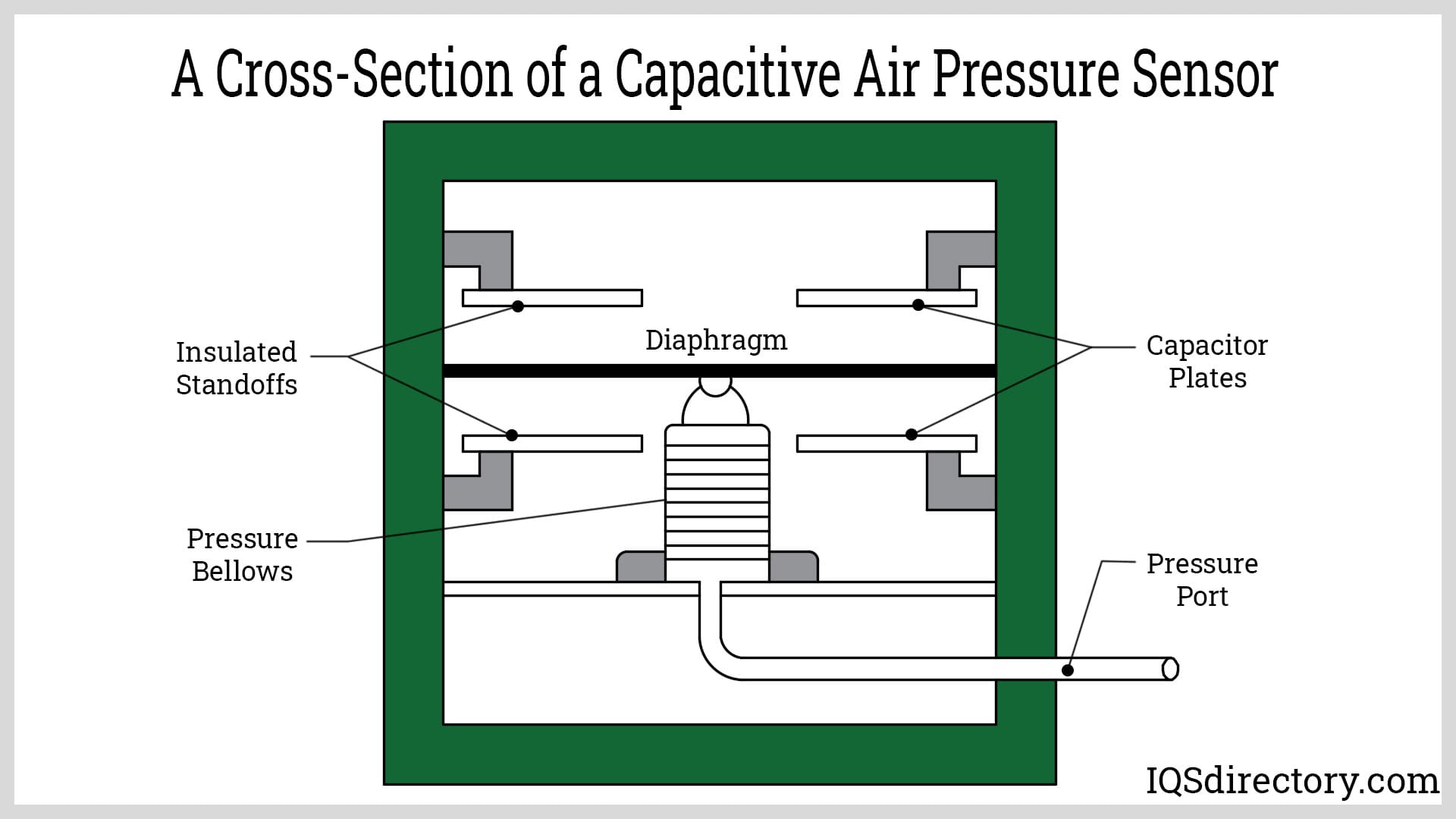

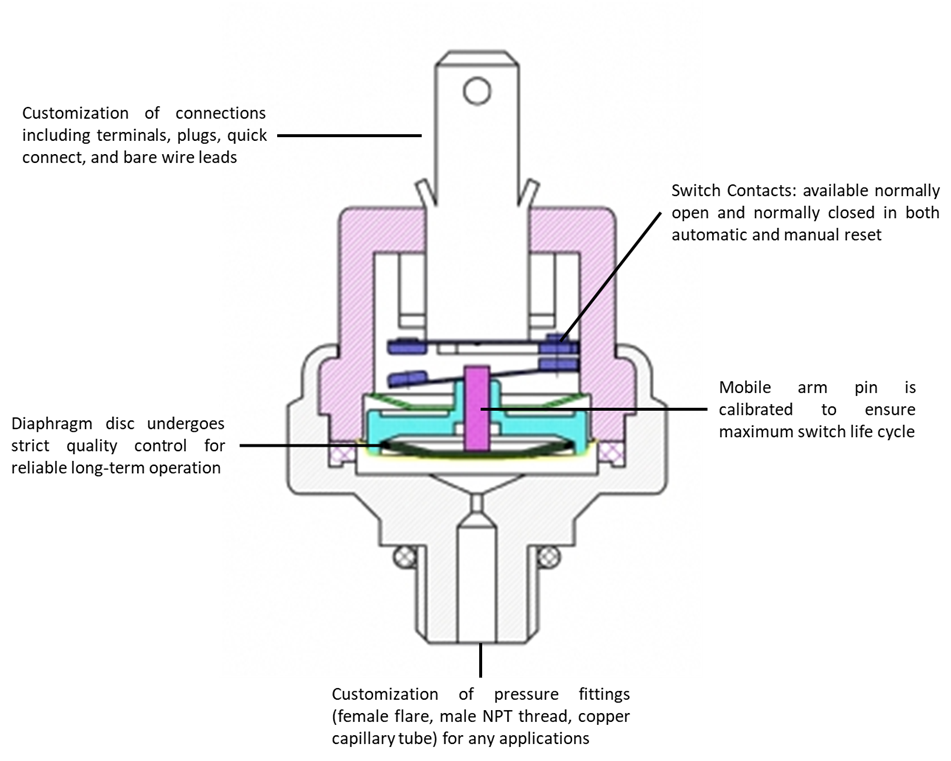

The manufacturing process begins with material selection, which typically includes durable metals and high-quality plastics that can withstand the operational pressures and environmental conditions. Common materials include stainless steel for the housing and various polymers for the diaphragm and seals.

Once materials are selected, they undergo preparation, including cutting, machining, and surface treatment. Machining processes like CNC (Computer Numerical Control) milling ensure precision in the components, which is essential for the accurate functioning of the pressure switches. This stage also involves quality checks on raw materials to ensure they meet specified standards.

What Forming Techniques Are Used in Pressure Switch Production?

Forming techniques play a vital role in shaping components of pressure switches. Common techniques include stamping, injection molding, and die casting.

- Stamping is often used for creating metal housings and terminals, providing high precision and consistency.

- Injection molding is crucial for producing diaphragms and plastic components, allowing for complex shapes that enhance the switch’s functionality.

- Die casting is employed for parts requiring intricate designs, particularly in high-volume production.

These forming techniques must adhere to strict tolerances to ensure that the components fit together correctly during assembly.

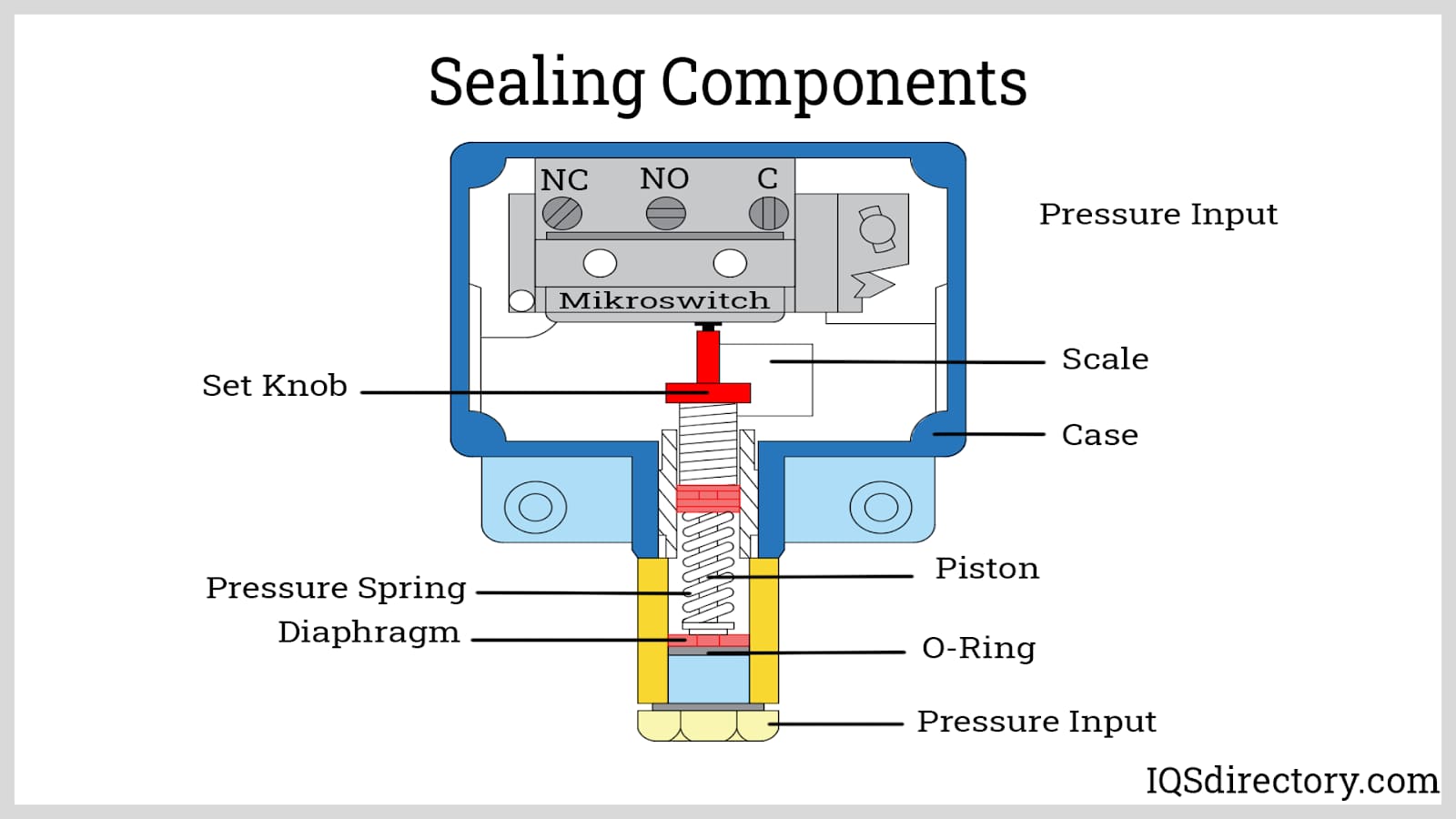

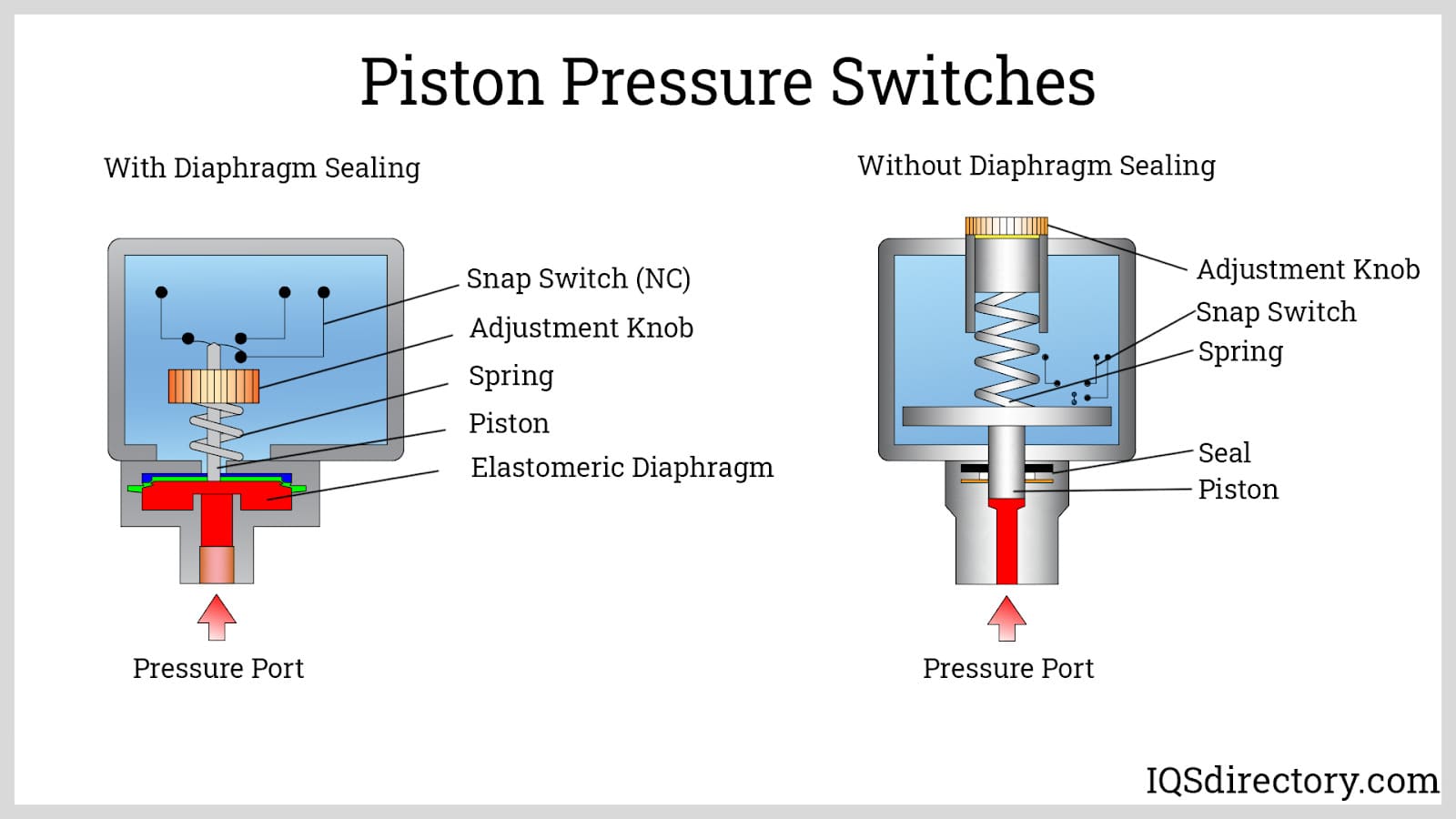

How is Assembly Conducted for Pressure Switches?

Assembly is a critical stage where individual components are brought together to create the final product. This stage may involve manual labor or automated processes, depending on the production scale.

Components such as the diaphragm, springs, and electrical terminals are carefully assembled. The assembly process includes:

- Sealing: Ensuring that all joints are tight and leak-proof is essential for maintaining pressure integrity.

- Electrical connections: Proper wiring is crucial, particularly for pressure switches that feature normally open (NO) or normally closed (NC) configurations.

- Testing: Each assembled unit is subjected to initial testing to ensure it meets operational specifications before moving to the finishing stage.

What Quality Assurance Standards Should Pressure Switch Manufacturers Follow?

Quality assurance is integral to the manufacturing of pressure switches, as it guarantees that the final product meets international standards and customer expectations.

Which International Standards Are Relevant for Pressure Switches?

Manufacturers should adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 ensures that manufacturers consistently produce quality products and continually improve processes.

Additionally, industry-specific standards like CE marking in Europe and API (American Petroleum Institute) standards for pressure devices are crucial. CE marking indicates compliance with health, safety, and environmental protection standards, while API standards are vital for oil and gas applications.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are critical to maintaining the integrity of the manufacturing process. These include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the manufacturing process. Suppliers must provide certificates of compliance to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to ensure that each stage meets quality standards. This may involve measuring tolerances, checking assembly integrity, and testing functionality.

-

Final Quality Control (FQC): Before shipping, each pressure switch undergoes final testing, which includes pressure testing, electrical testing, and performance verification. This ensures that each unit functions correctly under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential for ensuring reliability and compliance.

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Audits: Conducting on-site audits of the manufacturing facility can provide insights into the quality control processes in place. Buyers should assess whether suppliers have implemented necessary standards and practices.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspections can help identify any potential issues before large orders are placed.

What Nuances Should International Buyers Consider?

When dealing with suppliers across different regions, buyers should be aware of potential discrepancies in quality standards. For instance, while ISO certifications are recognized globally, local regulations may vary. Buyers must ensure that suppliers are compliant with both international standards and local regulations specific to their market.

Additionally, language barriers and cultural differences can affect communication regarding quality expectations. Establishing clear and documented quality requirements at the outset can mitigate misunderstandings and ensure that the products delivered meet the buyer’s standards.

Conclusion

Manufacturing pressure switches involves a comprehensive process that requires attention to detail at every stage, from material preparation through to quality assurance. By understanding these processes and the relevant quality control standards, international B2B buyers can make informed decisions when selecting suppliers, ensuring they receive reliable and high-quality products suitable for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure switch diagram’

In the quest for effective procurement of pressure switch diagrams, having a structured approach is crucial for international B2B buyers. This guide offers a practical checklist to ensure that you source high-quality diagrams that meet your operational needs.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the pressure switch diagrams you need. Consider factors such as the type of pressure switch (e.g., normally closed, normally open, or changeover), the pressure ranges, and the application context (e.g., HVAC, water systems). A well-defined specification helps in identifying suppliers who can meet your exact needs.

Illustrative image related to pressure switch diagram

Step 2: Research Applicable Standards

Familiarize yourself with relevant standards that govern pressure switch symbols and diagrams. Key standards include IEC 60617 and NFPA/JIC. Understanding these standards ensures that the diagrams you procure are universally recognized and can be integrated seamlessly into your systems.

Step 3: Evaluate Potential Suppliers

Before making a commitment, assess potential suppliers thoroughly. Request detailed company profiles, case studies, and references, particularly from buyers in similar industries or regions. This step is critical to ensure reliability and quality, as well as to understand how well the supplier can meet your specific requirements.

Step 4: Request Sample Diagrams

Always ask for sample diagrams before finalizing your order. This allows you to evaluate the clarity, accuracy, and usability of the diagrams. Look for details such as the correctness of symbols used and how well the diagrams convey the necessary information for installation and troubleshooting.

Step 5: Assess Support and Documentation

Investigate the level of technical support and documentation provided by the supplier. Quality diagrams should come with comprehensive manuals or guides that explain the symbols and their applications. This information is crucial for your engineering and maintenance teams to ensure proper implementation.

Step 6: Verify Supplier Certifications

Confirm that your chosen suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management practices. This verification helps mitigate risks associated with product defects or non-compliance with regulations.

Illustrative image related to pressure switch diagram

Step 7: Negotiate Terms and Conditions

Before finalizing the procurement, engage in negotiations regarding pricing, delivery timelines, and payment terms. Ensure that you clarify aspects such as warranty conditions and after-sales support. A clear agreement helps avoid misunderstandings and ensures a smoother procurement process.

By following these steps, international B2B buyers can effectively source pressure switch diagrams that align with their operational requirements and standards. This structured approach not only enhances procurement efficiency but also contributes to the overall reliability and safety of the systems in which these components will be integrated.

Comprehensive Cost and Pricing Analysis for pressure switch diagram Sourcing

What Are the Key Cost Components for Sourcing Pressure Switch Diagrams?

When sourcing pressure switch diagrams, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. High-quality materials, such as corrosion-resistant metals and durable plastics, may lead to higher initial costs but can enhance longevity and performance.

-

Labor: Skilled labor is required for the design and production of pressure switches and their diagrams. The complexity of the diagram, including the symbols used and the level of detail, can influence labor costs.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and maintenance of machinery. Efficient production processes can help reduce these costs.

-

Tooling: Specialized tools and equipment may be necessary for creating detailed pressure switch diagrams. The investment in tooling can vary based on the complexity and customization of the diagrams.

-

Quality Control (QC): Ensuring that diagrams meet international standards (like IEC or NFPA) incurs additional costs. Implementing rigorous QC processes helps mitigate risks associated with non-compliance.

-

Logistics: Transportation and storage costs are essential considerations, especially for international buyers. The geographical location of suppliers can impact shipping costs and lead times.

-

Margin: Suppliers will typically include a profit margin, which can vary based on competition, demand, and perceived value.

How Do Pricing Influencers Affect the Cost of Pressure Switch Diagrams?

Several factors influence the pricing of pressure switch diagrams:

-

Volume/MOQ: Larger orders often lead to bulk pricing advantages. Establishing a minimum order quantity (MOQ) can significantly impact unit costs, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom diagrams tailored to specific applications or industries can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials can vary widely in price. Opting for standard materials rather than specialized options can result in cost savings.

-

Quality and Certifications: Compliance with industry standards and certifications can raise costs. However, investing in certified products may reduce long-term risks and liabilities.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer greater assurance of quality and service.

-

Incoterms: The terms of shipping and delivery can influence the total cost. Understanding Incoterms helps buyers manage logistics expenses effectively.

What Buyer Tips Can Help Optimize Sourcing Costs for Pressure Switch Diagrams?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance cost efficiency:

-

Negotiate Terms: Leverage your purchasing power to negotiate better pricing, payment terms, and delivery schedules. Building a strong relationship with suppliers can lead to favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with maintenance, operation, and potential failures. A slightly higher upfront cost for a reliable product may yield savings over time.

-

Understand Pricing Nuances for International Markets: Currency fluctuations and import duties can significantly impact total costs. Conduct thorough market research to anticipate these variables.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide a clearer picture of the market rate and help identify cost-effective options.

-

Standardize Specifications: Where possible, standardizing specifications can lead to cost savings by reducing customization needs and allowing for bulk purchasing.

Disclaimer

Pricing for pressure switch diagrams can vary widely based on numerous factors mentioned above. The information provided is indicative and should be used as a guideline. Buyers are encouraged to conduct their own market research and consult with suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing pressure switch diagram With Other Solutions

Exploring Alternatives to Pressure Switch Diagrams

When it comes to controlling pressure in industrial applications, understanding the various solutions available is crucial for B2B buyers. While pressure switch diagrams are a common method for visualizing and implementing pressure control systems, several alternatives exist that can also effectively manage pressure levels. This section will compare pressure switch diagrams with two notable alternatives: pressure transducers and programmable logic controllers (PLCs).

Comparison Table

| Comparison Aspect | Pressure Switch Diagram | Pressure Transducer | Programmable Logic Controller (PLC) |

|---|---|---|---|

| Performance | Reliable for discrete control, limited by mechanical wear | High precision, continuous monitoring | Highly flexible, can integrate multiple inputs/outputs |

| Cost | Generally low initial cost | Moderate cost, more expensive than switches | Higher cost, requires programming and setup |

| Ease of Implementation | Simple diagrams easy to implement | Requires calibration and installation | Complex installation and programming needed |

| Maintenance | Low maintenance, periodic checks | Moderate, calibration needed over time | High, requires regular updates and troubleshooting |

| Best Use Case | Simple systems with clear on/off needs | Applications needing precise pressure measurement | Complex systems requiring automation and integration |

Detailed Breakdown of Alternatives

What are Pressure Transducers and Their Benefits?

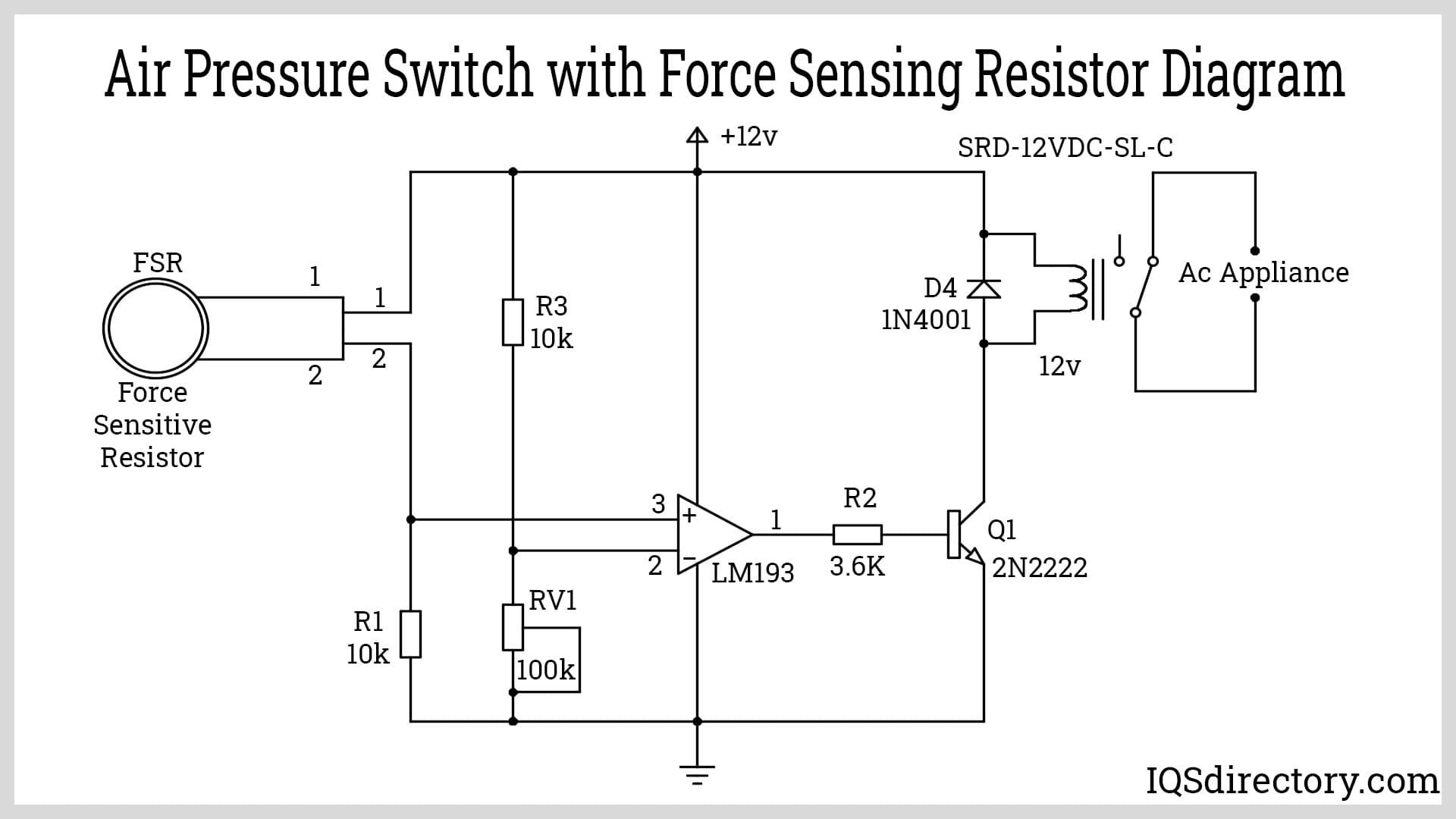

Pressure transducers convert pressure into an electrical signal, providing continuous monitoring of pressure levels. They offer high precision and can relay real-time data, making them suitable for applications where pressure fluctuations must be closely monitored. However, they typically come at a higher cost than mechanical pressure switches and require calibration to ensure accuracy. Maintenance is moderate, as they may need recalibration over time.

How Do Programmable Logic Controllers (PLCs) Compare?

PLCs are advanced devices that automate various industrial processes, including pressure control. They can integrate multiple inputs and outputs, allowing for complex control strategies that adapt to varying conditions. While they provide significant flexibility and scalability, the initial setup and programming can be complex and costly. Maintenance demands are higher as well, given the need for regular updates and troubleshooting.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a pressure control solution, B2B buyers should consider their specific operational requirements and budget constraints. Pressure switch diagrams are ideal for straightforward applications where simple on/off control suffices. However, for systems requiring precise measurements or automation, pressure transducers and PLCs may be more appropriate despite their higher costs and complexity. Ultimately, the choice will depend on the specific context of the application, including factors such as the required precision, system complexity, and available resources for installation and maintenance.

Essential Technical Properties and Trade Terminology for pressure switch diagram

What Are the Key Technical Properties of Pressure Switch Diagrams?

Understanding the technical properties of pressure switch diagrams is crucial for B2B buyers involved in industries such as manufacturing, oil and gas, and automation. Here are some essential specifications:

-

Material Grade

– Definition: The quality and type of materials used in pressure switches, often including metals like stainless steel or brass.

– Importance: Material grade affects durability, corrosion resistance, and overall functionality. High-grade materials ensure long-lasting performance, especially in harsh environments common in regions like the Middle East and Africa. -

Pressure Rating

– Definition: The maximum pressure that a pressure switch can handle, usually specified in PSI (pounds per square inch) or bar.

– Importance: Choosing a pressure switch with an appropriate pressure rating is vital for safety and operational efficiency. Incorrect ratings can lead to equipment failure, which can be costly in terms of repairs and downtime. -

Electrical Specifications

– Definition: These include voltage and current ratings, typically expressed in volts (V) and amperes (A).

– Importance: Electrical specifications determine compatibility with existing systems. Buyers must ensure that the pressure switch can handle the electrical load to avoid failures or hazards. -

Tolerance Levels

– Definition: The acceptable variation in the pressure switch’s set point, often expressed in PSI or percentage.

– Importance: Tighter tolerances allow for more precise control in applications requiring exact pressure settings. This is particularly important in industries like pharmaceuticals or food processing, where precision is critical. -

Response Time

– Definition: The time it takes for the pressure switch to react to changes in pressure.

– Importance: A quick response time can be crucial in applications where rapid pressure changes occur. Delayed response can lead to system inefficiencies or failures, impacting production and safety. -

Mounting Type

– Definition: The configuration for how the pressure switch is installed, such as panel-mounted or inline.

– Importance: The mounting type can influence installation complexity and the switch’s integration into existing systems. Understanding this can help buyers select the right product for their specific needs.

What Are Common Trade Terms Related to Pressure Switch Diagrams?

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding whether a supplier is an OEM can help buyers assess the quality and reliability of the products they are sourcing. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of product a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers must align their purchase plans with the supplier’s MOQ to avoid unnecessary costs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products.

– Importance: Issuing an RFQ allows buyers to compare quotes from multiple suppliers, ensuring they secure the best deal based on price, quality, and terms. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers for the delivery of goods.

– Importance: Understanding Incoterms is essential for international transactions, as they clarify shipping responsibilities, risk, and costs, which can vary significantly across regions like Africa and Europe. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Importance: Knowing the lead time is vital for project planning and inventory management. Long lead times can affect production schedules, especially in industries with tight deadlines. -

Warranty Period

– Definition: The time frame during which the manufacturer guarantees the product against defects.

– Importance: A longer warranty period can indicate higher confidence in product quality and provide peace of mind for buyers, especially in critical applications.

By understanding these properties and terms, B2B buyers can make informed decisions, ensuring they select the right pressure switches for their specific applications and environments.

Navigating Market Dynamics and Sourcing Trends in the pressure switch diagram Sector

What Are the Current Market Dynamics and Key Trends Influencing the Pressure Switch Diagram Sector?

The pressure switch diagram sector is undergoing significant transformations driven by technological advancements and shifting global demands. One of the primary global drivers is the increasing automation in various industries, such as oil and gas, manufacturing, and water management. This demand for precision and efficiency is leading to a surge in the adoption of advanced pressure switch technologies, which are integral for monitoring and controlling systems effectively.

Illustrative image related to pressure switch diagram

Emerging trends include the integration of Internet of Things (IoT) capabilities in pressure switches, allowing for real-time data monitoring and remote management. This trend is particularly relevant for international buyers in Africa, South America, the Middle East, and Europe, where businesses are increasingly looking to optimize operations and reduce downtime. Furthermore, the push towards Industry 4.0 is compelling manufacturers to innovate, resulting in more sophisticated pressure switch diagrams that accommodate complex automation systems.

Another noteworthy trend is the focus on standardization across different regions, with adherence to international standards such as IEC 60617 and NFPA/JIC. This standardization is crucial for international B2B buyers, as it ensures compatibility and simplifies the sourcing process across borders. Additionally, the growing emphasis on energy efficiency and sustainability is influencing sourcing decisions, prompting buyers to seek suppliers that prioritize eco-friendly manufacturing practices.

How Are Sustainability and Ethical Sourcing Addressed in the Pressure Switch Diagram Sector?

Sustainability and ethical sourcing are becoming paramount in the pressure switch diagram sector as global awareness regarding environmental impact grows. The manufacturing process of pressure switches can involve materials and practices that significantly affect the environment. As a result, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as minimizing waste and utilizing environmentally friendly materials.

The importance of ethical supply chains is underscored by the need for transparency and accountability. Buyers are now more inclined to partner with manufacturers who provide clear documentation on sourcing practices, particularly regarding the raw materials used in pressure switches. Certifications like ISO 14001 for environmental management systems and RoHS (Restriction of Hazardous Substances) compliance are becoming critical factors in supplier selection.

Moreover, the use of ‘green’ certifications and materials in pressure switch manufacturing is gaining traction. Buyers are encouraged to look for suppliers who invest in research and development to create products that not only meet performance requirements but also reduce their carbon footprint. Emphasizing sustainability in procurement strategies not only helps businesses align with global environmental goals but also enhances brand reputation and customer loyalty.

What Historical Developments Have Shaped the Pressure Switch Diagram Sector?

The evolution of pressure switches can be traced back to the early industrial revolution when simple mechanical devices were used to monitor pressure levels. Over the decades, technological advancements have dramatically transformed these devices, leading to the introduction of electronic pressure switches that offer enhanced accuracy and reliability.

In the late 20th century, the advent of microelectronics paved the way for the development of more sophisticated pressure switches capable of integrating with control systems. This innovation not only improved operational efficiency but also enabled real-time data communication, which is vital for modern industrial applications. As industries began to prioritize automation and data analytics, the demand for advanced pressure switch diagrams surged, ultimately leading to the complex and standardized symbols used today.

Today, the pressure switch diagram sector stands at the intersection of innovation and sustainability, driven by the need for precision in increasingly automated environments. Understanding this historical context is essential for international B2B buyers looking to navigate the complexities of sourcing pressure switch technologies that align with modern operational demands.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure switch diagram

-

How do I choose the right pressure switch diagram for my application?

Choosing the right pressure switch diagram involves understanding your specific application requirements, including the type of pressure switch (Normally Open, Normally Closed, or Changeover) and the operational context (e.g., high or low-pressure systems). Research the relevant standards (IEC, NFPA) for diagram symbols to ensure clarity and compatibility. Consult with suppliers to verify that the diagrams align with your operational needs and equipment specifications. Additionally, consider the manufacturer’s documentation for detailed explanations of each symbol’s function in practical scenarios. -

What are the standard symbols used in pressure switch diagrams?

The most commonly used symbols for pressure switches are defined by international standards like IEC 60617 and NFPA. Key symbols include Normally Closed (NC), Normally Open (NO), and Changeover (SPDT). Each symbol represents different operational states: NC switches open on pressure rise, NO switches close on pressure rise, and changeover contacts can operate as either NC or NO depending on system needs. Familiarizing yourself with these symbols is crucial for effective communication and troubleshooting in your projects. -

How can I ensure the quality of pressure switch diagrams from suppliers?

To ensure the quality of pressure switch diagrams, vet suppliers thoroughly by checking their certifications, industry experience, and customer reviews. Request samples of their diagrams and technical documentation to assess their accuracy and adherence to standards. Engaging in direct communication can clarify any concerns regarding the diagrams’ usability in your specific application. Additionally, consider conducting a pilot project with the supplier to evaluate their products in real-world conditions before committing to larger orders. -

What customization options are available for pressure switch diagrams?

Many manufacturers offer customization options for pressure switch diagrams to better suit your operational needs. Customization may include specific symbol representations, additional notes on operational parameters, or tailored diagrams that reflect unique system configurations. When discussing customization, provide detailed requirements to your supplier, such as operational pressures, environmental conditions, and integration with existing systems, to ensure the diagrams meet your expectations. -

What is the minimum order quantity (MOQ) for pressure switch diagrams?

The minimum order quantity (MOQ) for pressure switch diagrams can vary significantly between suppliers. Some may offer single units or low quantities for specialized needs, while others might have higher MOQs for bulk orders. When sourcing, clarify the MOQ with each potential supplier and explore the possibility of negotiation based on your purchasing volume. This approach allows you to balance your budget with the requirement for accurate and reliable diagrams. -

What payment terms should I consider when sourcing pressure switch diagrams internationally?

When sourcing pressure switch diagrams internationally, it’s essential to negotiate payment terms that protect your financial interests. Common payment methods include letters of credit, bank transfers, or payment upon receipt. Consider factors such as lead times, order value, and supplier reputation when determining the payment structure. It’s also advisable to discuss currency exchange rates and potential fees that may arise, ensuring transparency and minimizing risks in your transaction. -

How can I manage logistics for international shipping of pressure switch diagrams?

Managing logistics for international shipping involves selecting reliable freight forwarders familiar with handling technical documentation. Ensure that all diagrams are well-packaged to prevent damage during transit. It’s essential to understand customs regulations in your destination country to avoid delays; this includes proper labeling and documentation. Establish clear communication with your supplier regarding shipping times and tracking options to maintain oversight throughout the shipping process. -

What quality assurance (QA) measures should be in place for pressure switch diagrams?

Quality assurance measures for pressure switch diagrams include rigorous testing and validation against industry standards. Suppliers should implement a comprehensive QA process that includes reviews of diagram accuracy, compliance checks with relevant standards, and feedback loops for continuous improvement. Request documentation of their QA procedures and ensure they conduct regular audits. This proactive approach will help mitigate the risks associated with inaccurate diagrams and ensure reliability in your operations.

Top 7 Pressure Switch Diagram Manufacturers & Suppliers List

1. Tameson – Pressure Switch Symbol Standards Explained

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: Pressure switch symbol standards explained, including IEC 60617, NFPA/JIC, ANSI Y32.2-1975, and IEEE Std 91. Types of electrical contacts: Normally Closed (NC), Normally Open (NO), and Changeover (SPDT). Each function has specific symbols. NC switches open on pressure rise, NO switches close on pressure rise, and Changeover switches can operate as either NC or NO. Examples of applications include …

2. RPS – Pressure Switches

Domain: rps-solar-pumps.zendesk.com

Registered: 2005 (20 years)

Introduction: Pressure Switch Types: Reverse Action Pressure Switch (RAPS) and A9 pressure switch. Function: Automatically shuts off a pump when pressure builds up in pipes. Pressure Range: Typically set between 30 PSI to 50 PSI, adjustable up to 70 PSI. Wiring: Two wires connected on the same side of the pressure switch. Settings: AUTO (allows switch to open/close with pressure fluctuations) and ON (shuts off …

3. RPS Water Pumps – 220V Pressure Switch Wiring Guide

Domain: rpswaterpumps.com

Registered: 2022 (3 years)

Introduction: This company, RPS Water Pumps – 220V Pressure Switch Wiring Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Facebook – Pressure Switch Wiring Diagram

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Pressure Switch Wiring Diagram, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Instrumentation Toolbox – Pressure Switch

Domain: instrumentationtoolbox.com

Registered: 2013 (12 years)

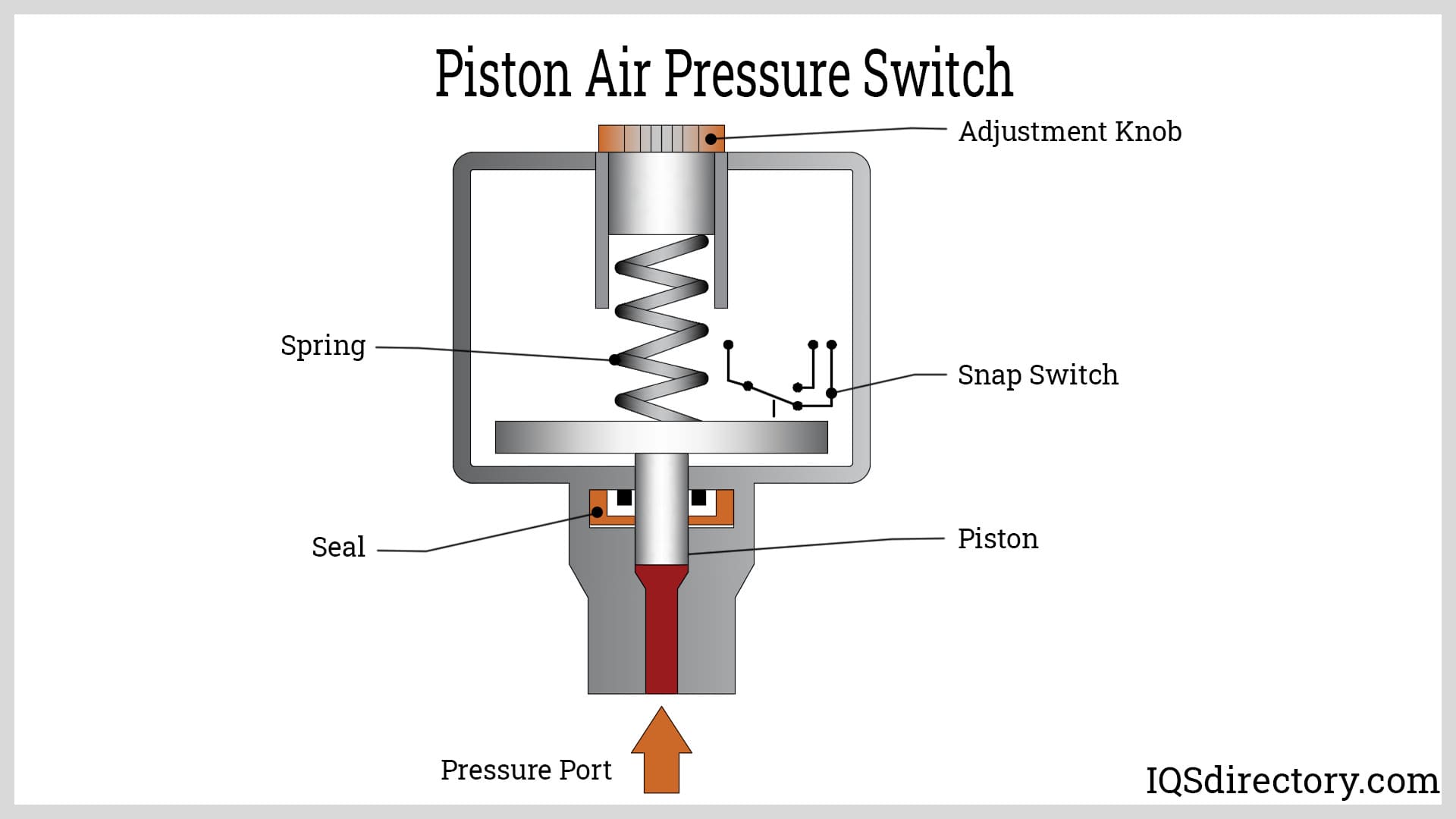

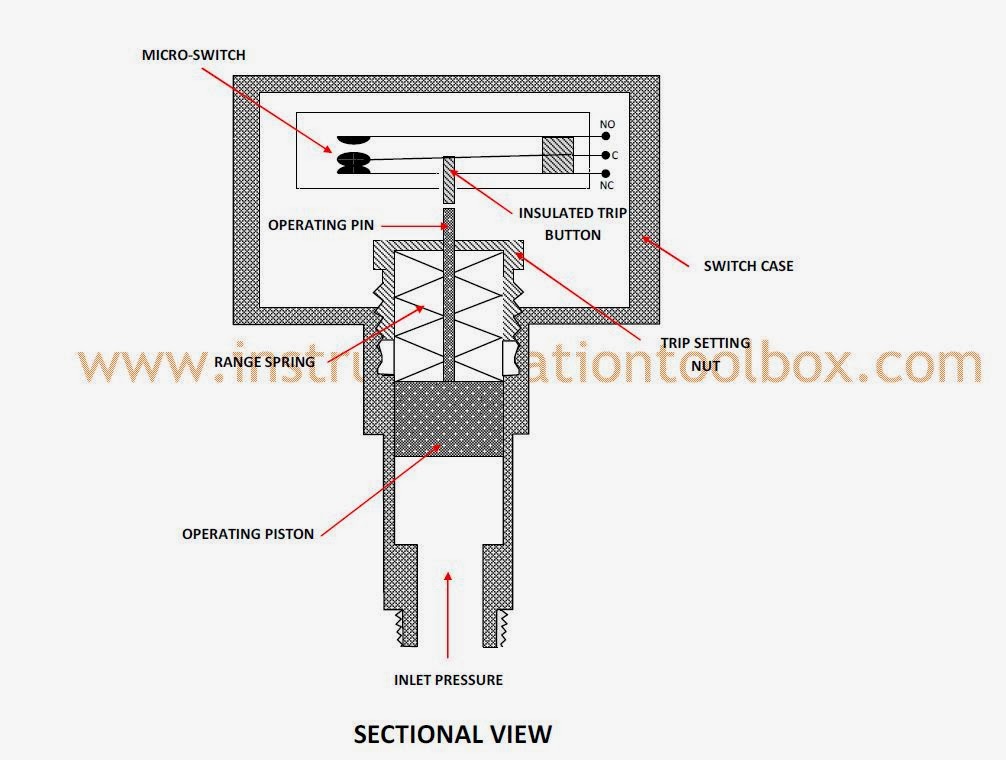

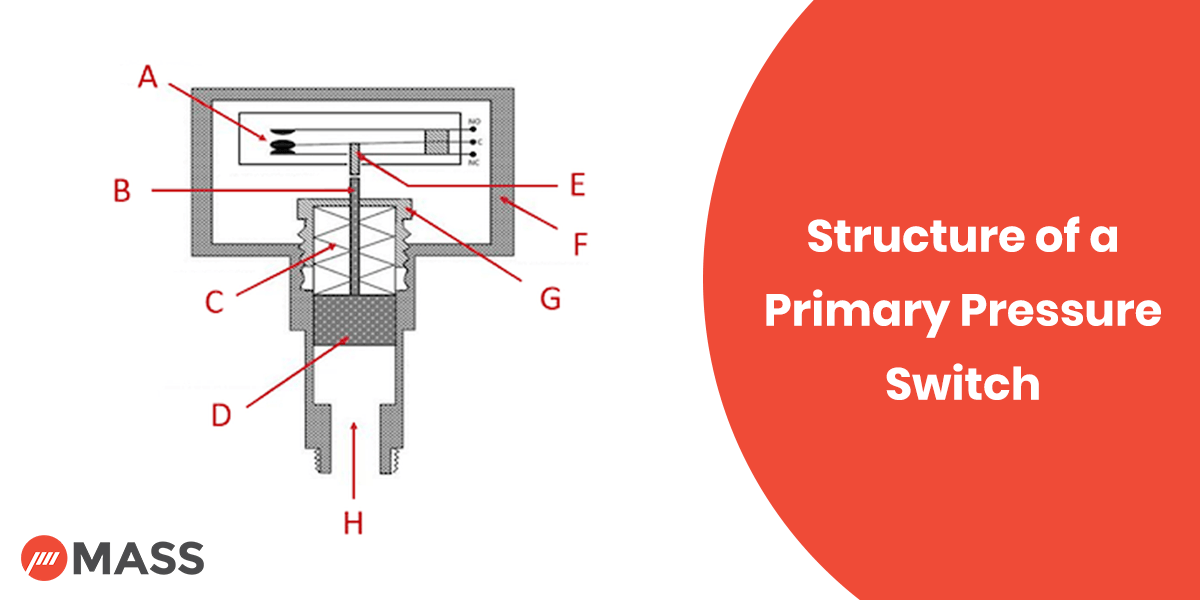

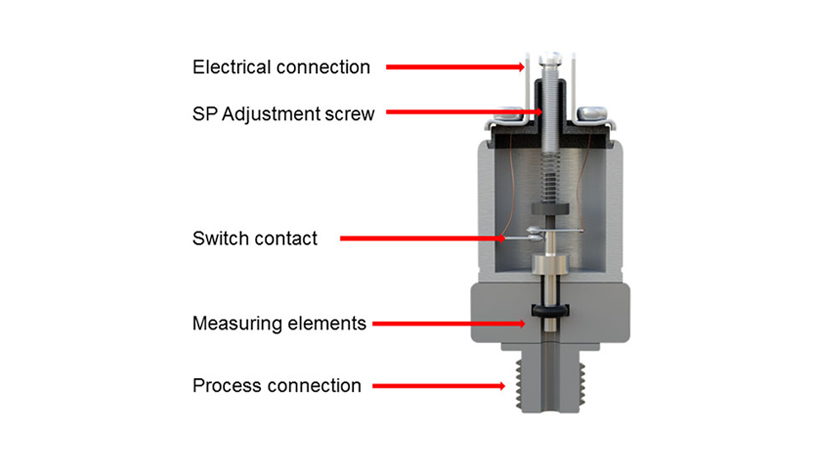

Introduction: Pressure Switch: A device designed to monitor process pressure and provide an output when a set pressure (setpoint) is reached. It uses a diaphragm or piston to generate a force compared to a pre-compressed range spring. Basic parts include: Micro-switch (single-pole double-throw), Insulated trip button, Operating pin, Trip setting nut (adjusts setpoint), Range spring (determines operating pressur…

6. Reddit – Wiring a Well Pressure Switch

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Wiring a Well Pressure Switch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Boshart – Class 9013FSG2 Pressure Switch Installation

Domain: support.boshart.com

Registered: 1997 (28 years)

Introduction: Wiring a Class 9013FSG2 pressure switch; intended for installation by technically qualified personnel; compliance with national and local electrical codes required; potential hazards include electrical shock, fire hazard, unsatisfactory performance, and equipment failure; instructional video available at www.youtube.com/watch?v=PzFZDzEesmw.

Strategic Sourcing Conclusion and Outlook for pressure switch diagram

In navigating the complexities of pressure switch sourcing, international buyers must prioritize strategic sourcing to optimize operational efficiency and ensure product reliability. Understanding the various symbols and functionalities of pressure switches, as outlined in this guide, is essential for making informed decisions. Key factors such as the differences between normally closed, normally open, and changeover contacts can significantly influence the performance of your systems.

For businesses operating in diverse markets like Africa, South America, the Middle East, and Europe, aligning with reputable suppliers who adhere to recognized standards—such as IEC and NFPA—can enhance product quality and compliance. This strategic approach not only mitigates risks but also fosters long-term partnerships that can drive innovation and cost-effectiveness.

As you move forward, consider leveraging digital tools and platforms to streamline your sourcing processes and connect with global manufacturers. By adopting a forward-thinking approach, you can secure the best solutions tailored to your specific needs, ultimately positioning your business for success in a competitive landscape. Engage with industry experts and continually assess market trends to stay ahead of the curve.

Illustrative image related to pressure switch diagram

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.