Polyurethane Bushing Material: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for polyurethane bushing material

In the ever-evolving landscape of industrial components, sourcing high-quality polyurethane bushing material presents both opportunities and challenges for international B2B buyers. As the demand for durable, versatile, and cost-effective solutions grows across markets in Africa, South America, the Middle East, and Europe—including key players like Nigeria and Vietnam—understanding the nuances of polyurethane bushings becomes critical. This guide is designed to empower decision-makers by providing an in-depth exploration of various types of polyurethane bushing materials, their specific applications in industries ranging from automotive to manufacturing, and strategies for effective supplier vetting.

Navigating the complexities of the global market requires a thorough understanding of material properties, production processes, and cost implications. Buyers will gain insights into the latest advancements in polyurethane formulations, ensuring they select the right products for their specific needs. Additionally, this guide addresses key considerations in supplier relationships, including quality assurance, delivery timelines, and compliance with international standards. By leveraging the information presented here, B2B buyers can make informed purchasing decisions that not only enhance operational efficiency but also drive competitive advantage in their respective markets. Whether you’re looking to optimize performance or reduce costs, this comprehensive resource will equip you with the knowledge to navigate the global polyurethane bushing material market effectively.

Understanding polyurethane bushing material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Polyurethane | Durable, flexible, and resistant to abrasion | Automotive suspension, machinery | Pros: Cost-effective, versatile. Cons: Limited temperature resistance. |

| High-Durometer Polyurethane | Increased hardness for enhanced performance | Heavy machinery, high-load applications | Pros: Superior load-bearing capacity. Cons: Reduced flexibility. |

| Low-Durometer Polyurethane | Softer formulation for vibration dampening | Automotive, industrial equipment | Pros: Excellent shock absorption. Cons: Less wear resistance. |

| Urethane-Elastomer Blend | Combination of urethane and elastomer properties | Aerospace, marine, automotive | Pros: Enhanced flexibility and durability. Cons: Higher cost. |

| Moldable Polyurethane | Can be custom-molded for specific applications | Custom machinery, automotive parts | Pros: Tailored solutions, precise fit. Cons: Longer lead times. |

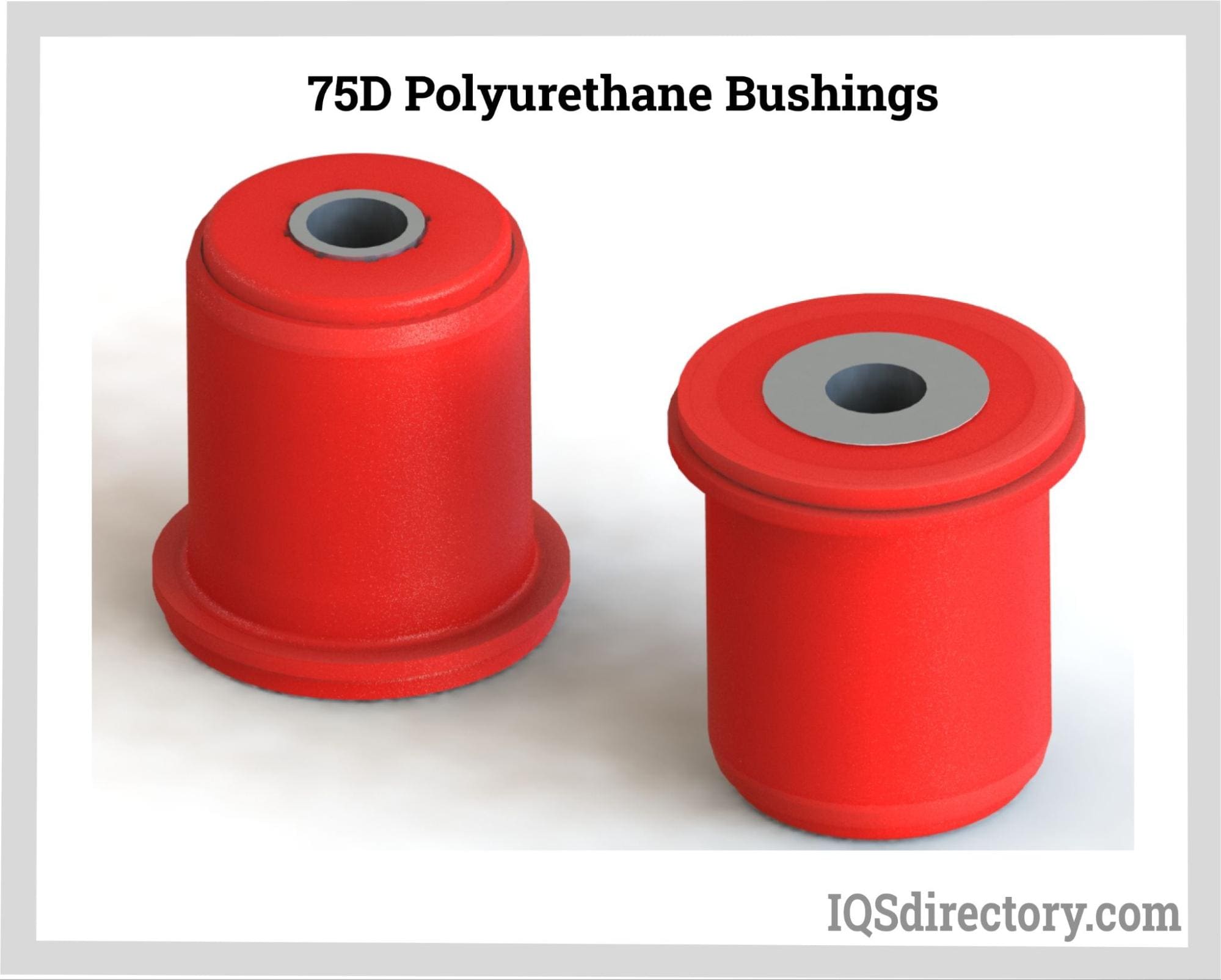

What Are the Characteristics of Standard Polyurethane Bushings?

Standard polyurethane bushings are known for their balance of durability and flexibility, making them suitable for a variety of applications. They are commonly used in automotive suspension systems and machinery due to their resistance to abrasion and wear. When considering a purchase, B2B buyers should evaluate the specific performance requirements of their applications, as these bushings may not perform well under extreme temperatures.

Why Choose High-Durometer Polyurethane for Heavy Loads?

High-durometer polyurethane bushings are designed with increased hardness, making them ideal for heavy machinery and high-load applications. Their superior load-bearing capacity ensures longevity and reliability in demanding environments. Buyers should consider the trade-off between hardness and flexibility, as these bushings may be less suitable for applications that require significant movement or shock absorption.

How Do Low-Durometer Polyurethane Bushings Enhance Vibration Dampening?

Low-durometer polyurethane bushings provide a softer formulation that excels in vibration dampening, making them popular in automotive and industrial equipment. Their excellent shock absorption capabilities help to reduce noise and improve overall performance. However, buyers must note that while they offer superior comfort, they may compromise on wear resistance, necessitating more frequent replacements.

What Are the Benefits of Urethane-Elastomer Blends?

Urethane-elastomer blends combine the properties of urethane and elastomers, resulting in bushings that are both flexible and durable. These materials are often used in aerospace, marine, and automotive applications where a combination of performance characteristics is required. While they provide enhanced flexibility, buyers should be prepared for a higher price point compared to standard polyurethane options.

Why Consider Moldable Polyurethane for Custom Solutions?

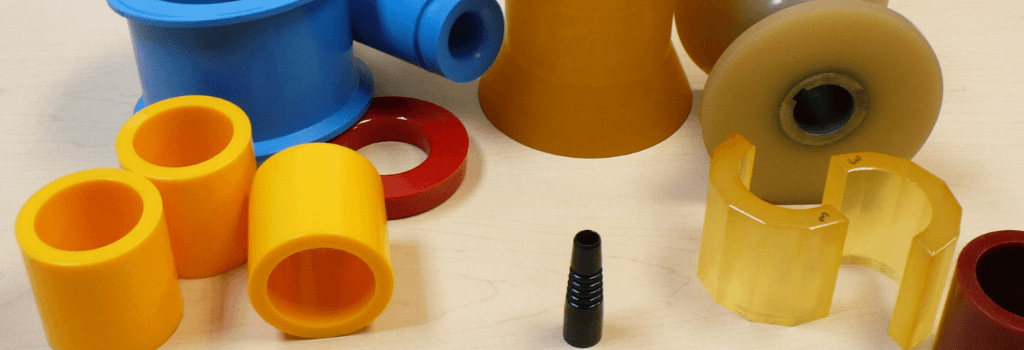

Moldable polyurethane allows for custom formulations tailored to specific applications, making it ideal for custom machinery and automotive parts. This adaptability ensures a precise fit and can enhance performance in unique environments. However, buyers should be aware of the longer lead times associated with custom orders, which can impact project timelines.

Key Industrial Applications of polyurethane bushing material

| Industry/Sector | Specific Application of polyurethane bushing material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

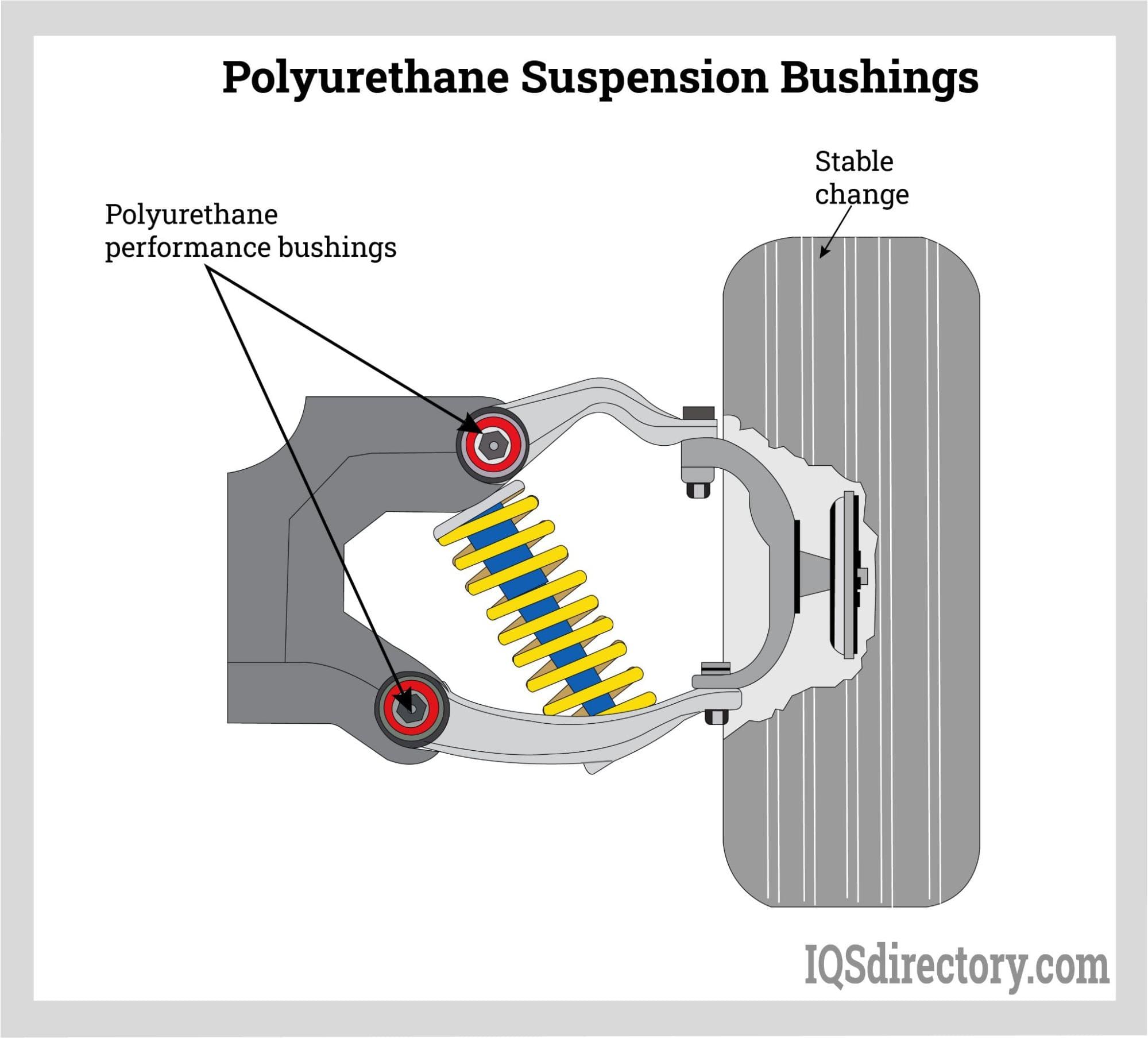

| Automotive | Suspension components in vehicles | Enhanced durability and performance in vehicle handling | Ensure compliance with regional automotive standards, such as ISO or SAE. |

| Manufacturing | Machinery and equipment mounts | Vibration dampening and noise reduction | Consider material hardness and load-bearing capacity based on specific machinery requirements. |

| Construction | Heavy equipment and machinery bushings | Improved resistance to wear and environmental factors | Look for suppliers who offer custom sizes and formulations to match equipment specifications. |

| Aerospace | Aircraft landing gear and control surfaces | Weight reduction and increased operational efficiency | Verify certifications and testing standards for aerospace applications. |

| Marine | Boat trailer and docking systems | Corrosion resistance and longevity in marine environments | Source materials that meet marine-grade standards for durability against saltwater exposure. |

How is Polyurethane Bushing Material Used in the Automotive Industry?

In the automotive sector, polyurethane bushings are commonly employed in suspension systems to enhance vehicle handling and ride quality. Their superior resilience compared to traditional rubber bushings allows them to better absorb shocks and vibrations, leading to improved performance and longevity. Buyers in this industry must ensure that the bushings meet stringent automotive standards and specifications, particularly in regions like Europe and the Middle East, where regulatory compliance is critical.

What Role Does Polyurethane Bushing Material Play in Manufacturing?

In manufacturing, polyurethane bushings are integral to machinery and equipment mounts, where they provide essential vibration dampening and noise reduction. This application is crucial in maintaining operational efficiency and worker comfort. For international buyers, especially in South America and Africa, sourcing should focus on the specific hardness and load-bearing capacities required for different machinery types to ensure optimal performance and durability.

How is Polyurethane Bushing Material Beneficial in Construction?

In the construction industry, polyurethane bushings are utilized in heavy equipment and machinery to withstand harsh operating conditions. Their resistance to wear and environmental factors significantly reduces maintenance costs and downtime. Buyers should prioritize sourcing from suppliers that offer customization options to match the specific dimensions and formulations needed for their equipment, especially in developing markets where equipment specifications may vary.

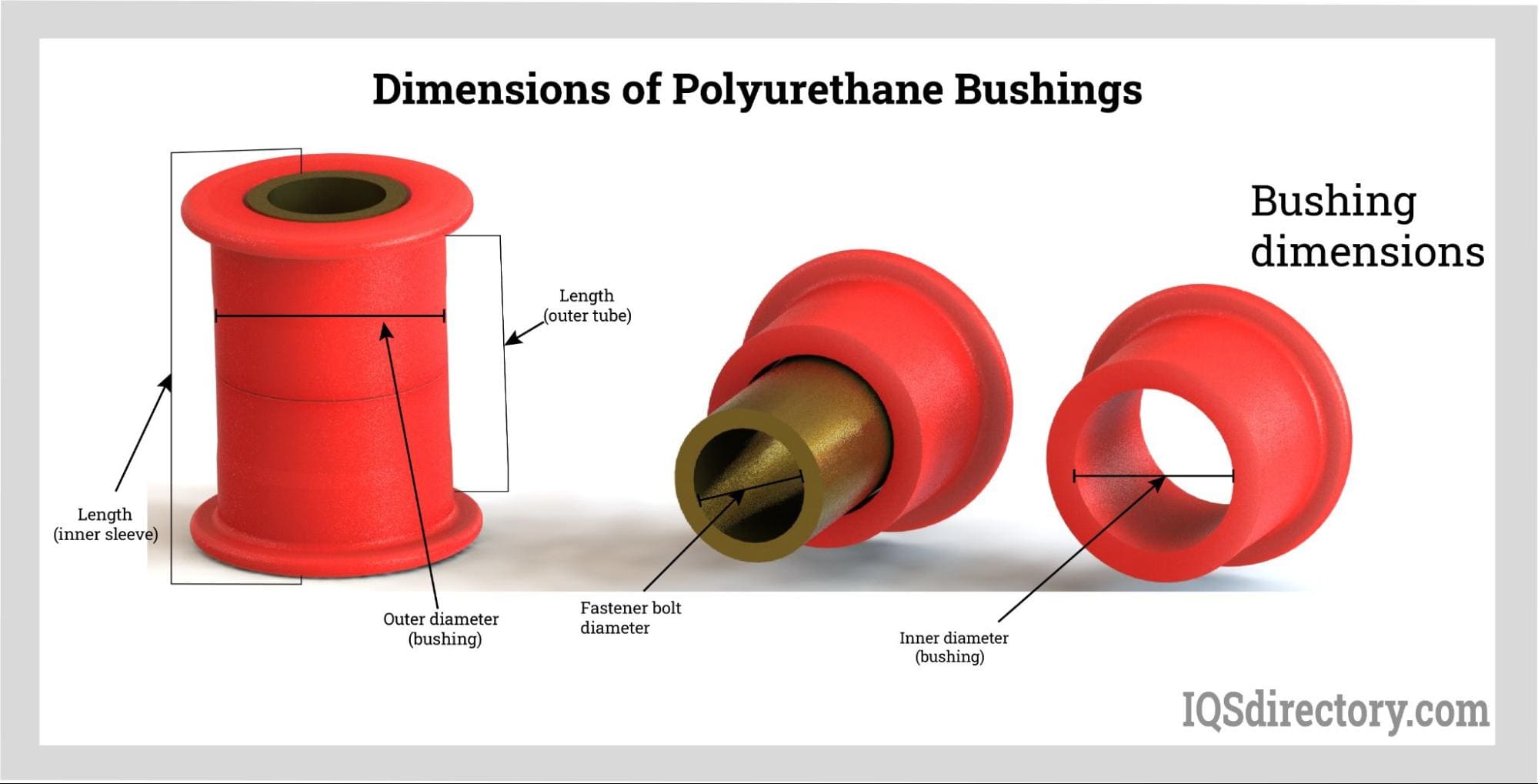

Illustrative image related to polyurethane bushing material

Why is Polyurethane Bushing Material Important in Aerospace Applications?

The aerospace industry benefits from polyurethane bushings in applications such as landing gear and control surfaces. These bushings contribute to weight reduction while enhancing operational efficiency and performance. Buyers in this sector must ensure that the materials sourced meet rigorous aerospace certifications and testing standards to guarantee safety and reliability, particularly in markets with stringent aviation regulations.

How Does Polyurethane Bushing Material Enhance Marine Applications?

In marine applications, polyurethane bushings are used in boat trailers and docking systems due to their exceptional resistance to corrosion and environmental degradation. This durability extends the lifespan of marine equipment, reducing replacement costs. International buyers should seek materials that comply with marine-grade standards, particularly in coastal regions, to ensure long-lasting performance against saltwater exposure and other harsh conditions.

3 Common User Pain Points for ‘polyurethane bushing material’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Hardness for Polyurethane Bushings

The Problem:

Many B2B buyers struggle with choosing the appropriate hardness of polyurethane bushings for their applications. The hardness, typically measured on the Shore scale, can significantly impact performance characteristics such as shock absorption, durability, and overall functionality. Buyers often face confusion over which hardness level is suitable for their specific use case, leading to potential mismatches that can cause premature wear or failure in machinery and automotive components. This misalignment not only results in financial losses due to wasted materials but also affects operational efficiency and product reliability.

The Solution:

To effectively select the right hardness for polyurethane bushings, buyers should first conduct a thorough analysis of their application requirements. This includes assessing load conditions, environmental factors, and the desired performance characteristics. It’s advisable to consult with manufacturers or suppliers who can provide expert recommendations based on similar use cases. Additionally, conducting field tests with different hardness levels can yield valuable insights into how each option performs under operational stresses. By documenting these findings, buyers can make informed decisions that lead to optimal performance and longevity of their polyurethane bushings.

Scenario 2: Challenges with Molded Polyurethane Bushings Production

The Problem:

In many manufacturing settings, the production of molded polyurethane bushings can be a significant bottleneck. This often stems from the complexities involved in the molding process, including the need for precise temperature control, material mixing ratios, and mold design. Buyers may find themselves facing delays due to equipment malfunctions, material shortages, or inefficiencies in the production line. Such challenges can lead to increased lead times, impacting supply chain commitments and customer satisfaction.

The Solution:

To overcome these production challenges, it’s essential for buyers to invest in quality control measures and employee training specific to the molding process. Implementing a robust quality assurance protocol can help monitor each stage of production, ensuring consistency and reliability. Additionally, establishing strong relationships with raw material suppliers can prevent shortages and facilitate smoother operations. Buyers should also consider integrating technology solutions such as real-time monitoring systems that provide data on machine performance and environmental conditions, allowing for immediate adjustments and minimizing downtime.

Illustrative image related to polyurethane bushing material

Scenario 3: Limited Knowledge on Polyurethane Bushing Applications

The Problem:

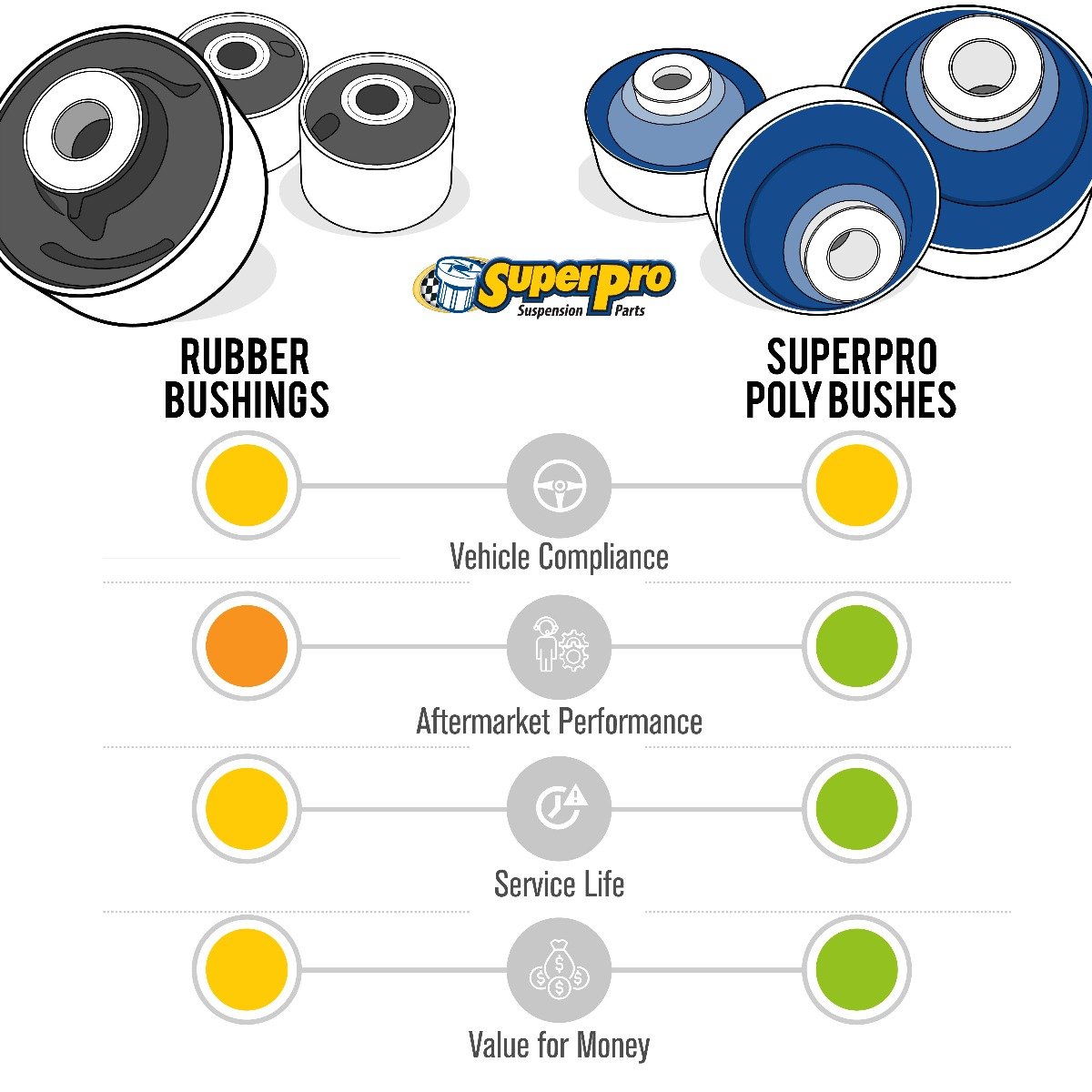

Another common pain point for B2B buyers is the lack of understanding regarding the various applications and benefits of polyurethane bushings compared to traditional materials like rubber. This knowledge gap can lead to missed opportunities for enhancing product performance and operational efficiencies. Buyers may stick to familiar materials out of habit, even when polyurethane options could provide superior durability, reduced noise, and better load handling.

The Solution:

To address this knowledge gap, buyers should proactively seek educational resources and training sessions from manufacturers or industry experts. Participating in webinars, workshops, or trade shows focused on the latest advancements in polyurethane technology can enhance understanding of its applications. Moreover, creating a cross-functional team that includes engineers, procurement specialists, and product managers can facilitate a comprehensive exploration of material options. By fostering a culture of continuous learning and openness to innovation, organizations can leverage the unique benefits of polyurethane bushings to drive competitive advantage in their respective markets.

Strategic Material Selection Guide for polyurethane bushing material

When selecting materials for polyurethane bushings, B2B buyers must consider various factors that influence performance, cost, and suitability for specific applications. Here, we analyze several common materials used in the production of polyurethane bushings, focusing on their properties, advantages, disadvantages, and considerations relevant to international markets.

What Are the Key Properties of Polyurethane Bushing Materials?

1. Polyurethane (PU)

Polyurethane is a versatile polymer known for its elasticity and durability. It typically exhibits excellent temperature resistance (up to 80°C) and can withstand moderate pressures. Its corrosion resistance is generally good, making it suitable for various environments.

Pros: Polyurethane bushings offer high resilience, good abrasion resistance, and can be formulated to achieve specific hardness levels (measured on the Shore scale). They are relatively easy to manufacture and can be molded into complex shapes.

Illustrative image related to polyurethane bushing material

Cons: While durable, polyurethane can degrade under prolonged exposure to UV light and certain chemicals. The cost of high-quality polyurethane can be moderate to high, depending on the formulation.

Impact on Application: Polyurethane is compatible with a wide range of media, including oils and solvents, making it suitable for automotive and industrial applications.

Considerations for International Buyers: Compliance with regional standards such as ASTM (USA) or DIN (Germany) is essential. Buyers in regions like Africa and South America should also consider local climate conditions that may affect material performance.

2. Delrin (Polyoxymethylene)

Delrin is a high-performance acetal resin known for its stiffness and low friction properties. It performs well in temperatures up to 90°C and offers excellent dimensional stability.

Pros: Delrin bushings provide superior wear resistance and low friction, making them ideal for applications requiring high precision. They are also resistant to moisture and many chemicals.

Illustrative image related to polyurethane bushing material

Cons: The manufacturing process can be more complex due to the need for machining, which can increase production costs. Delrin is less flexible than polyurethane, which may limit its applications.

Impact on Application: Delrin is particularly suited for high-load applications where low friction is critical, such as in automotive control arms.

Considerations for International Buyers: Delrin bushings must meet specific mechanical standards, and buyers should ensure that suppliers can provide certification for compliance with international standards.

3. Nylon

Nylon is a synthetic polymer known for its strength and toughness. It can withstand temperatures up to 70°C and has good chemical resistance.

Pros: Nylon bushings are lightweight and have good wear resistance, making them suitable for various applications. They are also relatively inexpensive compared to other materials.

Cons: Nylon can absorb moisture, which may lead to dimensional changes and reduced mechanical properties over time. Its performance can also be affected by exposure to UV light.

Illustrative image related to polyurethane bushing material

Impact on Application: Nylon is often used in applications where weight savings are essential, but it may not be the best choice for high-temperature environments.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding plastic materials and ensure that the nylon used meets the necessary mechanical standards.

4. Rubber

Natural and synthetic rubber materials are commonly used for bushings due to their excellent elasticity and vibration-damping properties.

Pros: Rubber bushings excel in shock absorption and noise reduction, making them ideal for automotive applications. They are also relatively inexpensive and easy to manufacture.

Cons: Rubber has lower temperature and chemical resistance compared to polyurethane and Delrin, which can limit its application range. Over time, rubber can degrade due to environmental exposure.

Impact on Application: Rubber is particularly effective in applications requiring flexibility and vibration dampening, such as suspension systems.

Considerations for International Buyers: Compliance with standards like ASTM D2000 for rubber materials is crucial. Buyers should also consider the effects of local environmental conditions on rubber performance.

Summary Table of Material Selection for Polyurethane Bushings

| Material | Typical Use Case for polyurethane bushing material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Automotive suspension, industrial machinery | High resilience and abrasion resistance | UV degradation under prolonged exposure | Medium |

| Delrin | High-precision automotive components | Superior wear resistance and low friction | Complex machining increases costs | High |

| Nylon | Lightweight applications, automotive parts | Lightweight and cost-effective | Moisture absorption affects performance | Low |

| Rubber | Vibration dampening in automotive applications | Excellent shock absorption | Lower temperature resistance | Low |

This strategic material selection guide provides B2B buyers with actionable insights into the various materials available for polyurethane bushings, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane bushing material

What Are the Key Stages in the Manufacturing Process of Polyurethane Bushings?

The manufacturing process for polyurethane bushings typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages is essential for B2B buyers looking to ensure quality and consistency in their supply chains.

Material Preparation: How Are Raw Materials Sourced and Prepared?

The first step in manufacturing polyurethane bushings is sourcing high-quality raw materials. Polyurethane is made from a mixture of polyols and isocyanates, which are combined to create a polymer that exhibits desirable mechanical properties. Suppliers must ensure that these materials comply with international standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) to ensure safety and environmental compliance.

Once sourced, raw materials undergo rigorous quality checks to assess their purity and consistency. This often involves laboratory testing, including viscosity measurements and molecular weight determination, to guarantee that they meet the specifications required for bushing production.

How Are Polyurethane Bushings Formed?

The forming stage involves several techniques, with the most common being injection molding and compression molding.

-

Injection Molding: This technique is widely used for producing complex shapes with high precision. The raw polyurethane mixture is heated and injected into a mold under high pressure. This method allows for quick production cycles and consistent quality, making it ideal for high-volume orders.

-

Compression Molding: This method is often employed for larger parts or when lower production volumes are needed. The polyurethane material is placed into a heated mold, and pressure is applied to form the desired shape. While this method is slower than injection molding, it can be more cost-effective for specific applications.

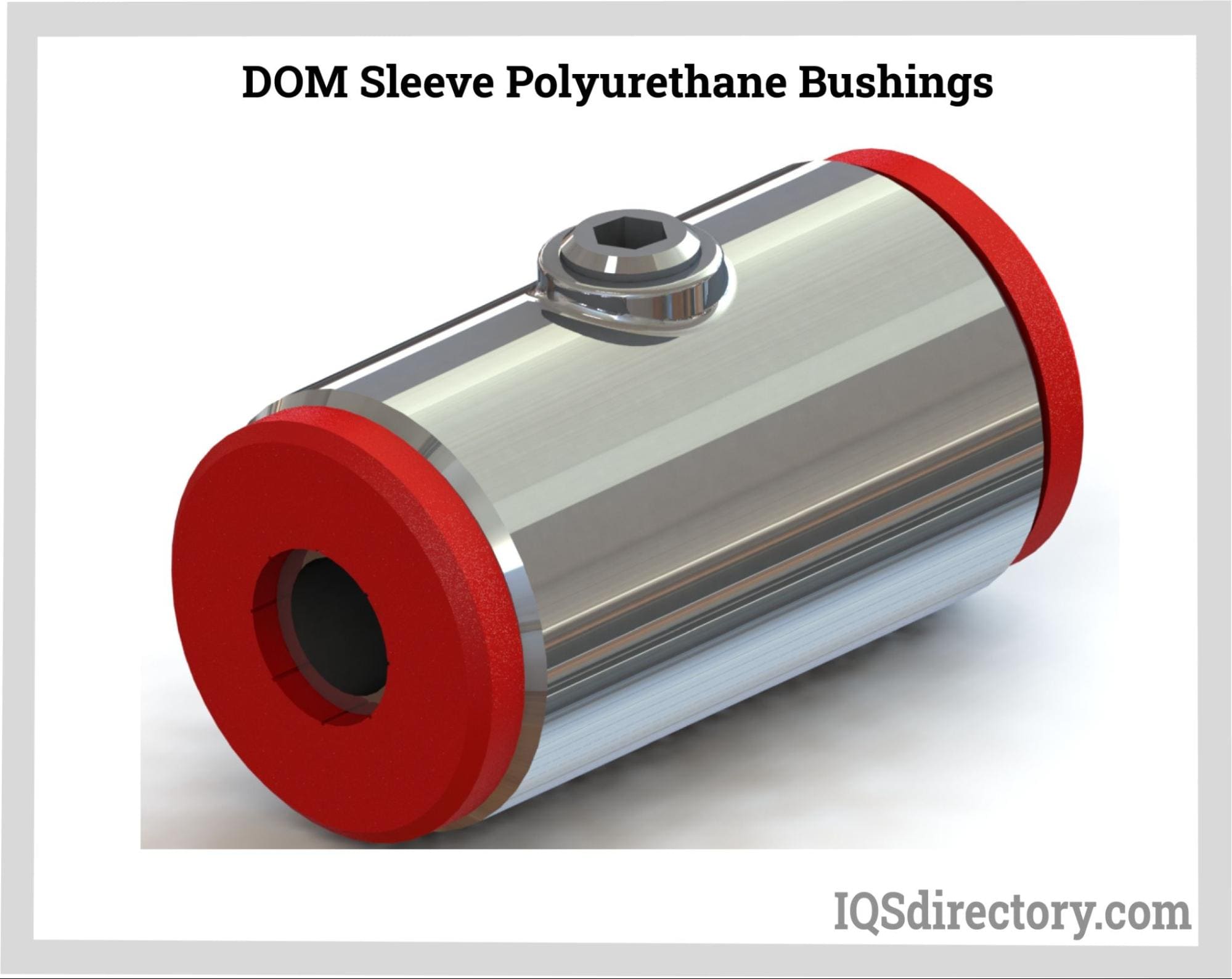

What Is the Assembly Process for Polyurethane Bushings?

After forming, the next stage is assembly, which may involve integrating other components, such as metal sleeves or spacers, to enhance the bushing’s performance and durability. During this stage, manufacturers ensure that the dimensions of the bushing are within specified tolerances to guarantee proper fit and function in their intended applications.

Manufacturers often use automated systems for assembly to enhance precision and efficiency. Quality control checkpoints are established during this phase to ensure that components fit together correctly and meet the required specifications.

How Are Polyurethane Bushings Finished?

Finishing involves processes such as trimming, grinding, and surface treatment to achieve the desired aesthetic and functional characteristics. Trimming removes any excess material from the molding process, while grinding may be used to achieve smooth surfaces and precise dimensions.

Illustrative image related to polyurethane bushing material

Additionally, surface treatments can enhance properties such as abrasion resistance and chemical stability. This is particularly important for bushings used in harsh environments, as they must withstand various stresses and chemical exposures.

What Quality Assurance Measures Are Essential for Polyurethane Bushings?

Quality assurance (QA) is a critical aspect of the manufacturing process for polyurethane bushings. B2B buyers should be aware of the relevant international standards and industry-specific certifications that ensure the quality and reliability of the products.

Which International Standards Should Buyers Look For?

ISO 9001 is the most widely recognized standard for quality management systems. Suppliers adhering to this standard demonstrate their commitment to continuous improvement and customer satisfaction. Other relevant certifications may include:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Certification: Relevant for bushings used in the oil and gas industry, ensuring adherence to specific performance standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are crucial for maintaining high standards throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): Raw materials are inspected for quality before production begins. This includes checking the physical and chemical properties of the materials.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples may be taken at various stages to ensure that production is consistent and meets specifications. This may involve measuring dimensions, hardness, and other critical attributes.

-

Final Quality Control (FQC): The finished bushings are subjected to rigorous testing, including durability tests, load-bearing tests, and dimensional checks, to ensure they meet all performance requirements before shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of supplier quality control practices is vital for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Here are some effective methods for ensuring compliance:

Illustrative image related to polyurethane bushing material

What Steps Should Buyers Take to Audit Suppliers?

-

Supplier Audits: Conducting on-site audits allows buyers to review the supplier’s manufacturing processes, quality control measures, and compliance with international standards. This can also provide insights into the supplier’s operational capabilities and commitment to quality.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess their performance over time. These reports should include data from IQC, IPQC, and FQC processes, demonstrating how the supplier tracks and resolves quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly beneficial for buyers unfamiliar with local suppliers or those looking to establish new partnerships.

What Nuances Should International Buyers Consider in Quality Control?

International buyers, especially those from regions like Africa, South America, and the Middle East, should be aware of specific nuances in quality control. Variations in local regulations, cultural attitudes toward quality, and supply chain complexities can impact product quality.

Buyers should ensure that their suppliers understand and comply with both local and international quality standards. Establishing clear communication channels and expectations regarding quality can help mitigate risks associated with sourcing polyurethane bushings from diverse markets.

By understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their specific needs for polyurethane bushing materials.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane bushing material’

Introduction

This guide aims to equip B2B buyers with a systematic approach to sourcing polyurethane bushing materials. Understanding the nuances of material selection, supplier evaluation, and compliance standards is crucial to ensuring high-quality procurement that meets both technical and operational requirements.

Illustrative image related to polyurethane bushing material

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications required for your polyurethane bushings. This includes understanding hardness ratings (Shore A), dimensions, load capacities, and environmental resistance (e.g., temperature, chemicals). Precise specifications will help you communicate effectively with suppliers and ensure that the materials meet your application needs.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers specializing in polyurethane materials. Use online databases, industry forums, and trade shows to compile a list. Evaluate their market presence, product range, and reputation within the industry to ensure you’re considering credible options.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that suppliers hold relevant certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Certifications indicate a supplier’s commitment to maintaining high standards and can also facilitate smoother import/export processes, especially for international transactions.

Step 4: Request Sample Materials

Always request samples of polyurethane bushing materials before placing a bulk order. This allows you to assess the material’s properties, such as flexibility, durability, and finish. Evaluate the samples against your technical specifications to ensure they meet the desired performance criteria.

Illustrative image related to polyurethane bushing material

Step 5: Understand Lead Times and Production Capacities

Discuss lead times and production capacities with your potential suppliers. Knowing how quickly a supplier can deliver the materials is essential for your project timelines. Additionally, understanding their production capabilities will help you gauge if they can meet your demands, especially during peak seasons or for large orders.

Step 6: Review Pricing and Payment Terms

Analyze the pricing structures of your shortlisted suppliers, taking into account factors such as volume discounts, payment terms, and shipping costs. It’s important to balance cost with quality; the cheapest option may not always provide the best value. Ensure that the payment terms are clear and align with your cash flow requirements.

Step 7: Check References and Past Performance

Finally, request references from other businesses that have sourced polyurethane bushing materials from the suppliers you’re considering. This feedback can provide insights into their reliability, product quality, and customer service. Look for testimonials or case studies that reflect their experience in your industry or region, particularly in Africa, South America, the Middle East, or Europe.

By following this checklist, B2B buyers can systematically approach the procurement of polyurethane bushing materials, ensuring they make informed decisions that support their operational objectives.

Illustrative image related to polyurethane bushing material

Comprehensive Cost and Pricing Analysis for polyurethane bushing material Sourcing

What Are the Key Cost Components for Polyurethane Bushing Material Sourcing?

When sourcing polyurethane bushing materials, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of polyurethane grade significantly impacts cost. Higher quality materials, such as those with specific hardness ratings (measured on the Shore scale), may command a premium. Additionally, sourcing from reputable suppliers ensures consistent quality and compliance with international standards.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor is often required for tasks such as machining and molding, which can influence overall pricing.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, positively affecting pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. However, these costs can be amortized over larger production runs, making it essential to evaluate the scale of your order.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and compliance with specifications. While this adds to upfront costs, it can prevent costly recalls or reworks.

-

Logistics: Transportation costs are influenced by distance, shipping methods, and Incoterms. Buyers should consider the total logistics costs, including customs duties and tariffs, particularly when importing from suppliers in different regions.

-

Margin: Supplier margins vary based on competition, market demand, and the perceived value of the product. Understanding these margins can aid in negotiations.

How Do Price Influencers Impact Polyurethane Bushing Material Costs?

Several factors influence pricing, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically qualify for volume discounts, reducing the per-unit cost. Understanding the supplier’s MOQ can help in budget planning.

-

Specifications and Customization: Tailored solutions often come at a premium. Buyers should weigh the need for custom designs against the potential cost savings of standard products.

-

Material Quality and Certifications: High-quality materials and certifications (such as ISO or ASTM) may increase costs but also enhance product performance and durability, providing long-term value.

-

Supplier Factors: The supplier’s reputation, reliability, and customer service can significantly affect pricing. Established suppliers may offer better terms due to their experience and efficiency.

-

Incoterms: The choice of Incoterms affects the division of costs and responsibilities between buyers and suppliers. It’s vital to understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) in determining the total landed cost.

What Are Effective Buyer Tips for Negotiating Polyurethane Bushing Material Prices?

To achieve cost-efficiency and negotiate effectively, consider the following tips:

-

Conduct Thorough Market Research: Understand current market prices and trends for polyurethane bushings. This knowledge will empower you during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase price, assess the long-term costs associated with maintenance, durability, and performance. A higher upfront cost may lead to savings over time if the product is more durable.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication can help you stay informed about new products or discounts.

-

Be Prepared to Walk Away: If a supplier’s pricing does not align with your budget or expectations, be ready to explore alternative options. This strategy can often lead to more favorable terms.

-

Understand Pricing Nuances for International Trade: For buyers from Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import regulations, and regional tariffs that can impact final costs.

Disclaimer on Indicative Prices

Prices for polyurethane bushing materials can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and specific buyer requirements. It is advisable for buyers to obtain multiple quotes and conduct a comprehensive cost analysis to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing polyurethane bushing material With Other Solutions

Exploring Alternative Solutions for Bushing Materials

When selecting bushing materials for industrial applications, understanding the available alternatives to polyurethane is crucial. Each material offers unique characteristics that can impact performance, cost, and overall application suitability. This analysis compares polyurethane bushing material with two viable alternatives: Delrin (polyoxymethylene) and rubber bushings.

| Comparison Aspect | Polyurethane Bushing Material | Delrin (Polyoxymethylene) | Rubber Bushings |

|---|---|---|---|

| Performance | High durability, excellent load-bearing, and resistance to wear. | Superior stiffness, low friction, and high dimensional stability. | Good shock absorption, but less durable under extreme conditions. |

| Cost | Moderate cost, balancing performance with affordability. | Generally higher cost due to manufacturing complexity. | Low cost, widely available. |

| Ease of Implementation | Requires specific molds for production; DIY options are available but need expertise. | Machining required for custom applications, which may increase lead times. | Simple installation, often a direct replacement for existing bushings. |

| Maintenance | Low maintenance; resistant to oil, grease, and chemicals. | Minimal maintenance; however, potential for wear over time. | Higher maintenance; may require frequent replacement due to wear and tear. |

| Best Use Case | Ideal for high-performance applications like automotive and industrial machinery. | Best suited for precision applications where low friction is critical. | Suitable for general applications where cost is a primary concern. |

In-Depth Analysis of Alternatives

What are the Benefits and Drawbacks of Delrin as an Alternative?

Delrin, known for its high stiffness and low friction, excels in precision applications where dimensional stability is essential. It performs exceptionally well in environments where reduced friction is necessary, making it a preferred choice for machinery components. However, the cost of Delrin is generally higher than polyurethane, which may deter budget-conscious buyers. Additionally, while it offers excellent performance, Delrin can be less forgiving under high-impact conditions, leading to potential failure in demanding applications.

Illustrative image related to polyurethane bushing material

How Do Rubber Bushings Compare to Polyurethane?

Rubber bushings are widely used due to their cost-effectiveness and good shock absorption capabilities. They perform well in general applications and are often found in standard automotive parts. However, rubber has limitations in terms of durability and performance under extreme conditions, such as high temperatures and heavy loads. This makes them less suitable for high-performance applications compared to polyurethane, which provides greater resistance to wear and environmental degradation.

How to Choose the Right Bushing Material for Your Needs

When selecting the appropriate bushing material, B2B buyers should consider the specific requirements of their applications, including load-bearing capacity, environmental exposure, and maintenance capabilities. Polyurethane offers a balanced solution for high-performance needs, while Delrin may be more suitable for precision applications. Rubber bushings can be an excellent choice for cost-sensitive projects but may require more frequent replacements. Ultimately, aligning the choice of material with application demands and budget constraints will ensure optimal performance and longevity.

Essential Technical Properties and Trade Terminology for polyurethane bushing material

What Are the Key Technical Properties of Polyurethane Bushing Material?

Polyurethane bushings are essential components in various mechanical applications, particularly in automotive and industrial settings. Understanding their technical properties is crucial for B2B buyers to ensure optimal performance and longevity. Here are several critical specifications that define the quality and suitability of polyurethane bushings:

Illustrative image related to polyurethane bushing material

-

Material Grade

Material grade refers to the specific formulation of polyurethane used in the manufacturing of bushings. Different grades offer varying levels of hardness, elasticity, and chemical resistance. For instance, a Shore A hardness of 80 is commonly used for automotive applications, providing a balance between flexibility and durability. Selecting the correct material grade is essential for achieving the desired performance characteristics in specific applications. -

Tolerance

Tolerance indicates the allowable deviation from a specified dimension. In the context of polyurethane bushings, tight tolerances are crucial for ensuring proper fitment and function within mechanical assemblies. A tolerance of ±0.005 inches is often acceptable for high-performance applications. This precision helps in reducing wear and tear, thus extending the lifespan of both the bushing and the connected components. -

Load Capacity

Load capacity defines the maximum load a bushing can withstand without failing. It is typically expressed in pounds or kilograms and is influenced by factors such as the material grade and design of the bushing. Understanding the load capacity is vital for buyers to ensure that the bushings can handle the specific operational stresses they will encounter in their applications. -

Temperature Resistance

This property refers to the ability of polyurethane bushings to maintain their integrity and performance under varying temperature conditions. Polyurethane can generally withstand temperatures ranging from -30°C to 80°C, but specialized formulations may offer even broader ranges. Buyers must consider the operating environment’s temperature to prevent premature failure of the bushings. -

Chemical Resistance

Chemical resistance indicates the material’s ability to withstand exposure to various chemicals, oils, and solvents without degrading. This property is particularly important in automotive and industrial applications where bushings may come into contact with lubricants or other harsh substances. Selecting a bushing with adequate chemical resistance can prevent failure and extend the service life.

Which Common Trade Terms Should B2B Buyers Know for Polyurethane Bushings?

Navigating the procurement of polyurethane bushings involves understanding industry-specific terminology. Familiarity with these terms can facilitate smoother transactions and better decision-making.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold to other manufacturers, who then incorporate them into their products. In the context of bushings, OEM parts are typically designed to meet specific performance standards required by vehicle manufacturers. Buyers should consider OEM options for reliability and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and reduce excess costs. For polyurethane bushings, suppliers may set MOQs based on production efficiencies, which can vary widely depending on the manufacturer. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping, insurance, and delivery. Understanding Incoterms is crucial for B2B buyers engaged in global sourcing of polyurethane bushings, as they affect shipping costs and liabilities. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For polyurethane bushings, lead times can vary based on factors like production capacity and supply chain efficiency. Buyers should account for lead times in their project planning to avoid delays in production or assembly.

By understanding these essential technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing polyurethane bushings, ensuring they select the right components for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the polyurethane bushing material Sector

What are the Current Market Dynamics and Key Trends for Polyurethane Bushing Material?

The polyurethane bushing material market is witnessing a transformative phase driven by increased demand across various industries, including automotive, construction, and machinery. Global factors such as the push for lightweight materials, enhanced durability, and improved performance in mechanical applications are propelling market growth. Emerging economies in Africa, South America, and the Middle East are particularly focused on infrastructure development and automotive expansion, leading to a surge in the need for high-quality polyurethane bushings.

Illustrative image related to polyurethane bushing material

Technological advancements in manufacturing processes, such as 3D printing and automation, are reshaping sourcing strategies. International B2B buyers are increasingly leaning towards suppliers who can offer rapid prototyping and customization options. Additionally, the integration of IoT in manufacturing is fostering transparency in supply chains, allowing buyers to track production processes and materials used, thus enhancing decision-making.

Moreover, the growing trend towards e-commerce in B2B transactions is simplifying the procurement process. Buyers can now access a wider range of suppliers and products, enabling competitive pricing and better quality assurance. In regions like Nigeria and Vietnam, where industrial growth is accelerating, the emphasis on quality and reliability in sourcing polyurethane bushings is paramount, making it crucial for suppliers to align with local regulations and standards.

How is Sustainability and Ethical Sourcing Influencing the Polyurethane Bushing Material Sector?

As environmental concerns escalate, sustainability and ethical sourcing are becoming integral to the polyurethane bushing material sector. The production of polyurethane can have significant environmental impacts, primarily due to the chemicals used and energy consumed during manufacturing. B2B buyers are increasingly prioritizing suppliers who adopt environmentally friendly practices, such as minimizing waste and using renewable energy sources.

Moreover, the demand for ‘green’ certifications is on the rise. Certifications such as ISO 14001 for environmental management and other eco-labels are becoming critical criteria for suppliers. Buyers from regions with stringent environmental regulations, like Europe, are particularly vigilant about sourcing materials that are compliant with such standards.

Illustrative image related to polyurethane bushing material

Ethical supply chains that ensure fair labor practices and transparency are also gaining importance. Buyers are encouraged to conduct thorough due diligence on suppliers to ensure their operations align with ethical standards. This not only mitigates risks associated with reputational damage but also appeals to an increasingly socially conscious consumer base.

How has the Polyurethane Bushing Material Market Evolved Over Time?

The evolution of polyurethane bushing material can be traced back to the mid-20th century when polyurethane was first developed as a versatile alternative to rubber. Initially, its applications were limited, but as industries sought materials that offered better performance characteristics, polyurethane gained traction.

By the 1980s, the automotive sector recognized polyurethane’s advantages in durability and flexibility, leading to its widespread adoption in suspension systems. Over the years, advances in chemical formulation and processing techniques have enhanced the material’s properties, allowing for greater customization in hardness and resilience.

Today, polyurethane bushings are not only prevalent in automotive applications but have also found their way into industrial machinery and consumer products, reflecting a broader trend towards high-performance materials in various sectors. As global demand continues to grow, the polyurethane bushing material market remains dynamic, adapting to technological innovations and changing market needs.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane bushing material

-

How do I ensure the quality of polyurethane bushing material from suppliers?

To ensure quality, start by requesting product samples and certifications from potential suppliers. Look for compliance with international standards such as ISO or ASTM. Conduct factory visits if possible, or arrange for third-party inspections. Additionally, review customer testimonials and case studies to assess the supplier’s reliability. Establish a clear Quality Assurance (QA) process that includes regular testing of materials upon arrival to confirm they meet your specifications. -

What is the best polyurethane hardness for automotive applications?

The ideal hardness of polyurethane bushings for automotive applications typically ranges from Shore A 70 to Shore D 80. Softer formulations provide better vibration dampening, making them suitable for passenger vehicles, while harder formulations offer increased durability and performance in high-load conditions, such as racing or off-road vehicles. Always consider the specific application and environment when selecting hardness to ensure optimal performance and longevity. -

What should I consider when vetting international suppliers of polyurethane bushing material?

When vetting international suppliers, assess their manufacturing capabilities, certifications, and experience in the industry. Check for their compliance with international trade regulations and quality standards. It’s also essential to examine their supply chain reliability, lead times, and flexibility in meeting your demands. Engage in direct communication to evaluate their customer service and responsiveness, which can be crucial for long-term partnerships. -

What are the typical minimum order quantities (MOQs) for polyurethane bushing materials?

Minimum order quantities for polyurethane bushing materials can vary significantly based on the supplier and the complexity of the design. Generally, MOQs can range from 100 to 1,000 units for standard products, while custom formulations may require larger orders. Discuss your specific needs with suppliers to determine if they can accommodate smaller quantities, especially for initial orders or prototypes, without compromising pricing or lead times. -

What payment terms are common for international transactions involving polyurethane materials?

Common payment terms for international transactions include Letters of Credit (LC), wire transfers, and PayPal. Many suppliers may require an upfront deposit (typically 30%) with the balance payable before shipment or upon delivery. It is advisable to negotiate terms that ensure security and cash flow management, such as staggered payments based on production milestones. Always ensure that the payment terms align with your financial strategy and risk tolerance. -

How can I customize polyurethane bushings for specific applications?

Customization of polyurethane bushings can involve altering their hardness, size, shape, or even adding specific chemical properties to enhance performance. Engage with your supplier early in the design process to discuss your application requirements. They may offer prototyping services to test different formulations and designs. Ensure that you provide detailed specifications and any relevant performance criteria to achieve the desired results. -

What logistics considerations should I keep in mind when importing polyurethane bushings?

When importing polyurethane bushings, consider lead times for production and shipping. Understand the customs regulations in your destination country to avoid delays. Work with experienced freight forwarders who can handle the complexities of international shipping, including duties and tariffs. Additionally, ensure that your supplier can provide necessary documentation, such as Certificates of Origin and Quality Assurance certificates, to facilitate smooth customs clearance. -

What are the potential challenges in sourcing polyurethane bushing materials from international suppliers?

Challenges in sourcing polyurethane bushing materials internationally may include fluctuating raw material costs, language barriers, and time zone differences that can affect communication. Quality assurance can also be a concern if suppliers do not adhere to agreed-upon specifications. To mitigate these risks, establish strong relationships with suppliers, utilize contracts that outline performance expectations, and implement regular quality checks throughout the production process.

Top 4 Polyurethane Bushing Material Manufacturers & Suppliers List

1. Delrin – Thermoplastic for Bushings

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: Delrin (polyoxymethylene) – thermoplastic sold by DuPont; available from other companies as Celcon, Ramtal, and Kepital; 4-foot stick purchased from Grainger for less than $50; sufficient for four bushings plus experiments. Urethane – bushing-grade urethane is typically molded; a 16-ounce kit purchased for under $20; two-part mixture that thickens in about 10 minutes and cures in 24 hours; hardnes…

2. Energy Suspension – Universal Polyurethane Bushings

Domain: energysuspensionparts.com

Registered: 2004 (21 years)

Introduction: Energy Suspension Universal Polyurethane Bushings are designed for exact measurements and longer-lasting performance compared to original equipment rubber replacements. Made from Hyperflex Polyurethane, these bushings are suitable for various applications including control arms, track rods, 4 bar links, push/nerf bars, tire carrier racks, and engine & transmission mounts. They fit many common 4 Ba…

3. Polyurethane – Suspension Bush Rod

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: polyurethane bar rod suspension bush material; available diameters: 19mm, 25mm, 37mm, 43mm, 50mm, 61mm; available lengths: 100MM, 200MM, 300MM; condition: New; packaging: original packaging; estimated delivery: Wed, Sep 24 – Wed, Oct 15; shipping cost: $20.40; price: approx. $8.15 GBP 5.99; quantity options: 1 to 12.

4. Prothane – Universal Polyurethane Pivot Bushings

Domain: prothanesuspensionparts.com

Registered: 2009 (16 years)

Introduction: {“Part Number”:”19604″,”Product Name”:”Universal Polyurethane Pivot Bushings”,”Outer Diameter (OD)”:”1.25 in (31.75 mm)”,”Inner Diameter (ID)”:”.747 in (19 mm)”,”Tube Length”:”1.25 in (31.75 mm)”,”Manufacturer”:”Prothane”,”Price”:”$10.09″,”Color Options”:[“Black”,”Red”],”In Stock”:”Yes”,”Ships Immediately”:”Yes”,”Warranty”:”Lifetime Warranty”,”Included Items”:”4 Hat Bushings, 2 Metal Sleeves”,”Dur…

Strategic Sourcing Conclusion and Outlook for polyurethane bushing material

In summary, strategic sourcing of polyurethane bushing materials presents a significant opportunity for international B2B buyers. By leveraging the unique properties of polyurethane—such as durability, elasticity, and resistance to wear—businesses can enhance product performance and customer satisfaction. Buyers should prioritize partnerships with reliable suppliers who offer high-quality materials that meet industry standards, ensuring compliance and optimizing supply chain efficiency.

Moreover, understanding the manufacturing processes, such as molding and machining, can provide additional insights into cost-effective sourcing strategies. Engaging with local manufacturers in regions like Africa, South America, the Middle East, and Europe can also foster innovation and reduce lead times, ultimately benefiting your bottom line.

As the market for polyurethane bushings continues to evolve, it is crucial for B2B buyers to stay informed about emerging technologies and material advancements. By proactively adapting to these trends, businesses can position themselves for long-term success. We encourage you to explore new sourcing avenues and collaborate with key industry players to unlock the full potential of polyurethane bushing materials in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.