Polishing Machines Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for polishing machines

In an increasingly competitive global market, sourcing high-quality polishing machines can pose significant challenges for B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the quest for efficient and reliable polishing equipment is critical to enhancing operational efficiency and product quality. This comprehensive guide delves into the diverse landscape of polishing machines, offering insights into various types, applications, and the nuances of supplier vetting processes.

Buyers will explore essential considerations such as cost structures, technological advancements, and the suitability of different machines for specific industry needs. From manual to fully automated solutions, understanding the strengths and weaknesses of each option will empower decision-makers to make informed purchasing choices tailored to their unique market requirements.

Moreover, this guide emphasizes the importance of evaluating suppliers beyond price, focusing on aspects such as customer support, warranty policies, and after-sales service, which are vital for maintaining long-term operational success. By equipping buyers with actionable insights and strategic approaches, this resource aims to streamline the sourcing process, minimize risks, and ultimately facilitate smoother transactions in the global marketplace for polishing machines.

Understanding polishing machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bench-Top Polishing Systems | Compact design, versatile for various materials | Jewelry, automotive, electronics | Pros: Space-saving, cost-effective; Cons: Limited to smaller items |

| Automatic Polishing Machines | Fully automated processes, high throughput | Laboratories, high-volume manufacturing | Pros: Consistent results, reduced labor costs; Cons: Higher initial investment |

| Manual Polishing Machines | Operator-controlled, flexible use | Small workshops, custom jobs | Pros: Versatile, lower cost; Cons: Labor-intensive, variability in results |

| Vibratory Polishers | Uses vibration to polish surfaces, ideal for bulk items | Metal finishing, plastic components | Pros: Efficient for mass production; Cons: Limited precision on fine details |

| Multi-Station Lapping Machines | Multiple workstations for simultaneous operations | Metallographic sample preparation | Pros: Increased productivity, versatile; Cons: Requires more space and maintenance |

What Are Bench-Top Polishing Systems and Who Should Use Them?

Bench-top polishing systems are compact machines designed for polishing various materials, including metals and plastics. Their space-saving design makes them ideal for small workshops and businesses with limited floor space. B2B buyers should consider these systems for operations like jewelry making or automotive detailing, where precision and versatility are essential. However, they are typically limited to smaller items, which may not suit larger-scale manufacturing needs.

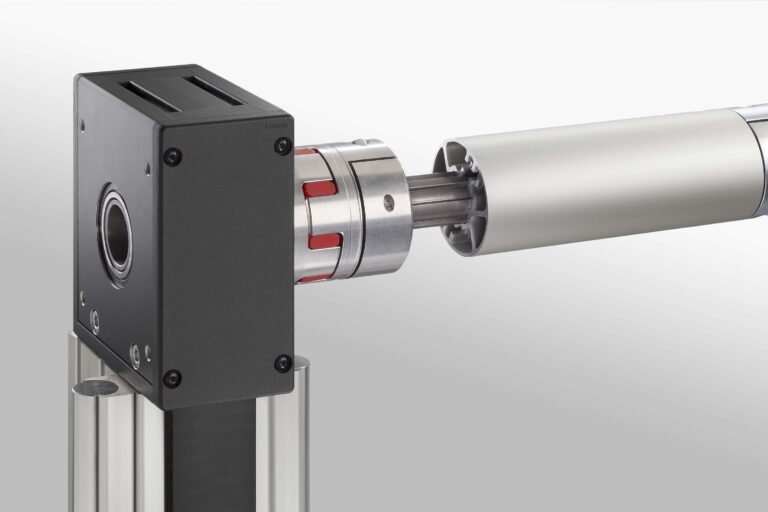

Illustrative image related to polishing machines

How Do Automatic Polishing Machines Enhance Manufacturing Efficiency?

Automatic polishing machines are engineered for high-volume production environments, offering fully automated processes that minimize human intervention. These machines are ideal for laboratories and manufacturing sectors requiring consistent quality and high throughput. While they significantly reduce labor costs and ensure uniform results, potential buyers should be aware of the higher initial investment and the need for regular maintenance to keep them operating optimally.

What Are the Advantages and Disadvantages of Manual Polishing Machines?

Manual polishing machines provide operators with the flexibility to adjust techniques based on the specific requirements of each project. They are particularly beneficial for small workshops that focus on custom jobs or intricate detailing. However, the labor-intensive nature of these machines can lead to variability in results, making them less suitable for high-volume applications. Buyers should weigh the lower costs against the need for skilled labor and time investment.

Why Choose Vibratory Polishers for Bulk Polishing Needs?

Vibratory polishers utilize vibration to achieve a polished finish on bulk items, making them particularly effective in industries like metal finishing and plastic component production. Their efficiency in mass production settings allows businesses to achieve consistent results quickly. However, buyers should consider that vibratory polishers may lack the precision required for detailed work, which could limit their application in specialized fields.

What Benefits Do Multi-Station Lapping Machines Offer?

Multi-station lapping machines are designed for simultaneous operations, significantly enhancing productivity in metallographic sample preparation. These machines are ideal for laboratories that require high throughput and versatility across various tasks. While they provide increased efficiency, potential buyers should consider the additional space requirements and maintenance needs associated with operating multiple workstations.

Key Industrial Applications of polishing machines

| Industry/Sector | Specific Application of Polishing Machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Surface finishing of metal components | Enhanced aesthetics and corrosion resistance | Machine durability, speed of operation, and maintenance support |

| Electronics | Polishing of semiconductor wafers | Improved performance and yield in electronic devices | Precision control, compatibility with various materials, and service availability |

| Automotive Manufacturing | Polishing of automotive parts and surfaces | Increased product lifespan and visual appeal | Customization options, production capacity, and safety features |

| Jewelry and Watchmaking | Finishing and polishing of intricate designs | Higher customer satisfaction and product value | Material compatibility, ease of use, and after-sales service |

| Aerospace and Defense | Surface preparation for critical components | Compliance with stringent safety and quality standards | Certification requirements, reliability, and technical support |

How Are Polishing Machines Used in Metal Fabrication?

In the metal fabrication industry, polishing machines are essential for achieving a high-quality finish on metal components. These machines help remove surface imperfections, enhance aesthetics, and improve corrosion resistance, making them crucial for both functional and decorative applications. Buyers from regions like Africa and South America should consider the durability and speed of the machines, as well as the availability of maintenance support, to ensure long-term operational efficiency.

What Role Do Polishing Machines Play in Electronics?

Polishing machines are pivotal in the electronics sector, particularly for the polishing of semiconductor wafers. This process is vital for improving the performance and yield of electronic devices. For international buyers, especially from the Middle East and Europe, key requirements include precision control features and compatibility with various materials. Additionally, the availability of reliable service and support is crucial to minimize downtime in production.

How Are Polishing Machines Utilized in Automotive Manufacturing?

In automotive manufacturing, polishing machines are used to finish parts and surfaces to enhance both durability and visual appeal. A polished surface not only improves the aesthetic quality of vehicles but also increases their lifespan by providing better resistance to wear and corrosion. Buyers should focus on customization options that suit specific production needs, as well as the machine’s production capacity and safety features, to ensure compliance with industry standards.

Why Are Polishing Machines Important in Jewelry and Watchmaking?

The jewelry and watchmaking industries rely heavily on polishing machines to finish intricate designs and enhance product value. A well-polished piece not only attracts customers but also reflects the quality of craftsmanship. Buyers in these sectors must consider the machine’s compatibility with various materials, ease of use, and the availability of after-sales service to ensure smooth operations and high-quality output.

How Do Polishing Machines Contribute to Aerospace and Defense?

In the aerospace and defense sectors, polishing machines are critical for surface preparation of components that must meet stringent safety and quality standards. These machines help eliminate surface defects that could compromise the integrity of critical parts. For international B2B buyers, understanding the certification requirements and ensuring the reliability of the equipment is essential, as is access to technical support to navigate complex compliance landscapes.

3 Common User Pain Points for ‘polishing machines’ & Their Solutions

Scenario 1: Inefficient Polishing Processes Leading to Production Delays

The Problem: B2B buyers often face significant downtime due to inefficient polishing processes. This may stem from outdated machinery, lack of automation, or improper operator training. For instance, a manufacturing facility in Brazil might rely on manual polishing methods that are time-consuming and prone to human error, resulting in inconsistent quality and slower production rates. Such inefficiencies can lead to missed deadlines and increased operational costs, ultimately affecting customer satisfaction and business reputation.

The Solution: To address these inefficiencies, businesses should consider investing in modern, automated polishing machines. Equipment that integrates advanced technology such as programmable logic controllers (PLC) can enhance precision and speed. Buyers should also prioritize machines with built-in safety features and user-friendly interfaces to minimize operator training time. Collaborating with manufacturers to provide comprehensive training on machine operation can further optimize the polishing process. Regular maintenance schedules should be established to ensure equipment runs smoothly, reducing the likelihood of unexpected downtimes.

Scenario 2: Inconsistent Quality Across Different Materials

The Problem: B2B buyers frequently encounter challenges in achieving consistent polishing quality across various materials. For instance, a company in Nigeria may process metals, plastics, and ceramics, each requiring different polishing techniques and equipment settings. Without proper adjustments, the final product may exhibit visible scratches or uneven finishes, leading to rework and wasted materials. This inconsistency not only affects product quality but also strains relationships with clients who expect uniform standards.

The Solution: To combat this issue, buyers should invest in multifunctional polishing machines capable of handling diverse materials. Machines equipped with adjustable speed settings and interchangeable polishing pads can be tailored to the specific requirements of different substrates. It is essential to develop a detailed protocol for each material type, including recommended settings and consumables. Collaborating with polishing machine suppliers to access material-specific polishing guides can further enhance quality control. Regular calibration of machines will also ensure that the polishing process remains consistent, regardless of the materials being processed.

Scenario 3: High Operating Costs Due to Consumables

The Problem: Operating costs associated with polishing machines can quickly escalate due to the frequent need for consumables such as polishing pads, compounds, and maintenance supplies. For businesses in South America, where budgets may be tight, these ongoing expenses can significantly impact profitability. Moreover, if consumables are of low quality, they can lead to premature wear on machines, resulting in increased maintenance and replacement costs.

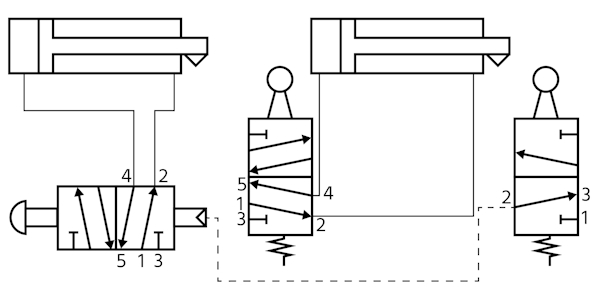

Illustrative image related to polishing machines

The Solution: To reduce operating costs, buyers should focus on sourcing high-quality, durable consumables that offer better longevity and performance. Engaging with suppliers who provide bulk purchasing options or loyalty programs can help mitigate expenses. Additionally, investing in machines designed to optimize consumable usage—such as those with advanced dosing systems—can ensure that materials are used efficiently. Conducting a cost-benefit analysis of different consumables will allow businesses to identify the most cost-effective options without compromising on quality. Training staff to properly maintain and care for polishing machines can also extend their lifespan and reduce unexpected expenditures.

Strategic Material Selection Guide for polishing machines

What Are the Key Materials Used in Polishing Machines?

When selecting polishing machines, the choice of materials significantly influences performance, durability, and cost. Below, we analyze four common materials used in polishing machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Impact Polishing Machine Performance?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating up to 150°C and can withstand moderate pressure.

Pros: Aluminum is durable and lightweight, making it easier to handle and install in various applications. Its corrosion resistance is beneficial for environments with moisture or chemicals, extending the lifespan of the machine.

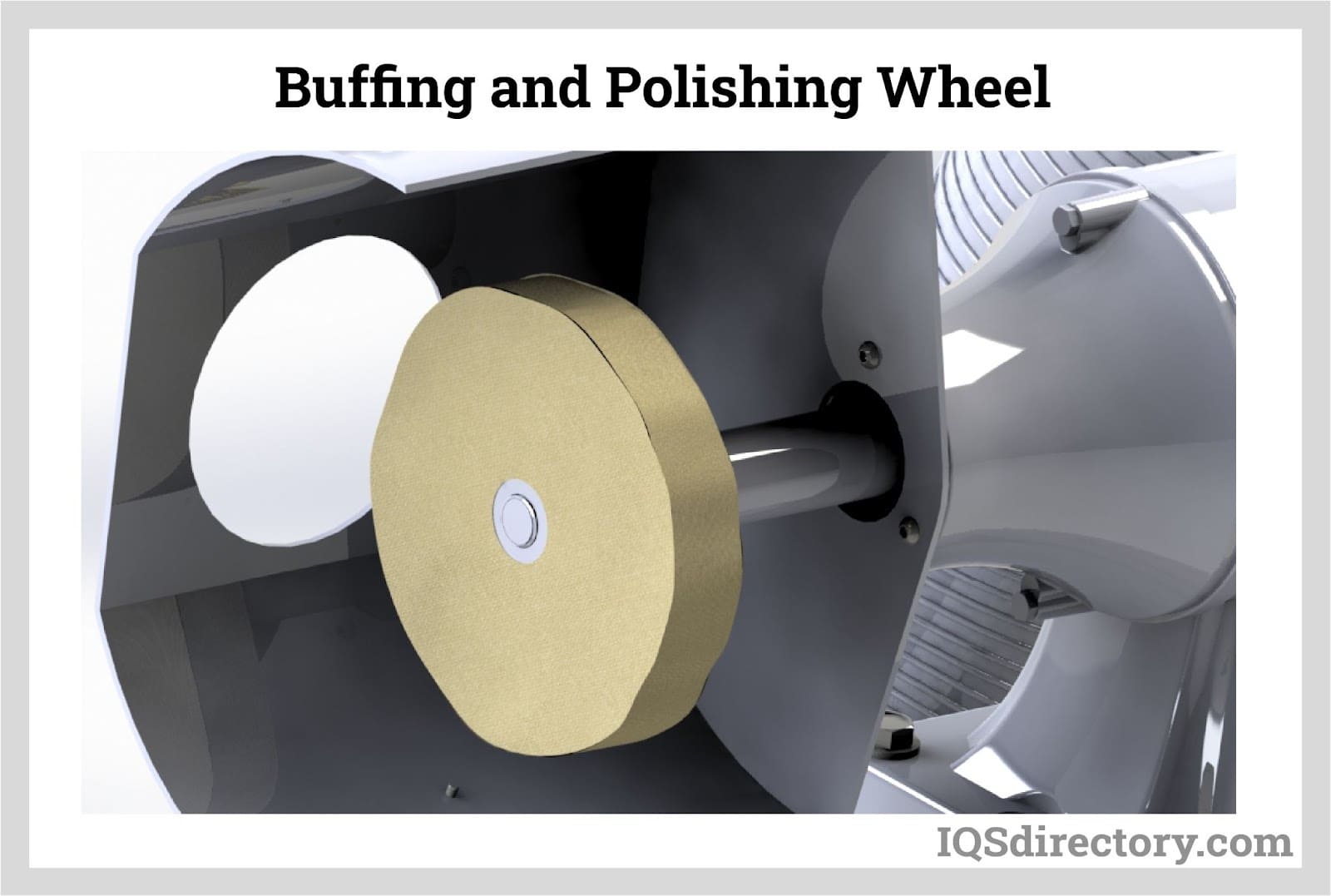

Illustrative image related to polishing machines

Cons: While aluminum is cost-effective, it may not be suitable for high-temperature applications due to its lower melting point compared to other metals. Additionally, manufacturing complexity can increase with intricate designs.

Impact on Application: Aluminum’s compatibility with various polishing media, including diamond and silicon carbide, makes it versatile for different polishing tasks.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN, particularly for safety and quality assurance.

What Role Does Stainless Steel Play in Polishing Machines?

Stainless steel is renowned for its strength and resistance to corrosion, making it a popular choice in polishing machines. It can handle high temperatures (up to 400°C) and substantial pressure.

Pros: The durability of stainless steel allows for long-term use in demanding environments. Its resistance to rust and staining is crucial for maintaining hygiene in industries like food processing and pharmaceuticals.

Illustrative image related to polishing machines

Cons: The cost of stainless steel is generally higher than aluminum, which may affect budget considerations. Additionally, its weight can complicate installation and mobility.

Impact on Application: Stainless steel is compatible with a wide range of polishing media, ensuring effective performance across various applications.

Considerations for International Buyers: Compliance with international standards is essential, especially in Europe, where regulations regarding material safety and environmental impact are stringent.

How Does Plastic Material Influence Polishing Machines?

Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in polishing machines due to their lightweight and corrosion-resistant properties.

Pros: Plastics are cost-effective and can be molded into complex shapes, allowing for innovative designs. They are resistant to many chemicals, making them suitable for various polishing applications.

Cons: Plastics generally have lower heat resistance compared to metals, limiting their use in high-temperature settings. They may also be less durable over time, especially under heavy usage.

Impact on Application: Plastics can be used in non-critical components of polishing machines, such as housing or covers, where exposure to extreme conditions is minimal.

Considerations for International Buyers: Buyers should verify that the plastic materials meet local compliance standards, particularly in regions with strict environmental regulations like the EU.

What Advantages Does Composite Material Offer for Polishing Machines?

Composite materials, which combine different substances, are gaining traction in polishing machines for their strength and lightweight properties.

Pros: Composites can be engineered for specific applications, offering tailored performance characteristics. They are often more resistant to wear and tear than traditional materials.

Cons: The manufacturing process for composites can be complex and costly, which may impact the overall price of the polishing machine. Additionally, not all composites are suitable for high-temperature environments.

Impact on Application: Composites can enhance the performance of polishing machines by providing a balance between weight and strength, making them suitable for portable or high-performance applications.

Considerations for International Buyers: Understanding the specific composite materials used and their compliance with international standards is crucial for ensuring product reliability and safety.

Summary Table of Material Properties for Polishing Machines

| Material | Typical Use Case for polishing machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight components | Excellent corrosion resistance | Limited high-temperature use | Low |

| Stainless Steel | Structural components | High durability and temperature resistance | Higher cost and weight | High |

| Plastic | Non-critical housings | Cost-effective and versatile designs | Lower heat resistance | Low |

| Composite | High-performance applications | Tailored performance and lightweight | Complex manufacturing process | Medium |

This analysis provides a comprehensive overview of material selection for polishing machines, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for polishing machines

What Are the Main Stages in the Manufacturing Process of Polishing Machines?

The manufacturing of polishing machines involves several crucial stages, each contributing to the machine’s overall performance and reliability. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality raw materials, typically metals such as aluminum, stainless steel, and various alloys. These materials are chosen for their durability and ability to withstand the rigors of polishing operations. Advanced techniques like laser cutting and water jet cutting are often employed to achieve precise dimensions and reduce waste.

What Forming Techniques Are Commonly Used in Manufacturing Polishing Machines?

Once the materials are prepared, they undergo forming processes, which can include bending, stamping, and machining. Computer Numerical Control (CNC) machines are frequently utilized to ensure accuracy in dimensions and surface finishes. This precision is critical, as it directly affects the performance of the polishing machine in terms of speed and effectiveness.

How Is Assembly Conducted in Polishing Machine Manufacturing?

The assembly stage involves integrating various components, including motors, belts, and polishing pads. Quality control measures are implemented at this stage to ensure that all parts fit correctly and function together seamlessly. Automated assembly lines may be used for efficiency, but manual assembly is also common for more complex machines, where skilled technicians can ensure quality and attention to detail.

What Finishing Processes Are Important for Polishing Machines?

Finishing processes, such as coating and surface treatment, are essential to enhance the machine’s durability and aesthetics. Techniques like anodizing and powder coating protect against corrosion and wear, ensuring longevity. Additionally, polishing the exterior surfaces not only improves appearance but also aids in maintaining hygiene in industrial settings.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is a critical aspect of the manufacturing process for polishing machines. International standards, such as ISO 9001, provide frameworks for consistent quality management across production processes. These standards emphasize customer satisfaction and continual improvement, which are vital for maintaining competitiveness in the global market.

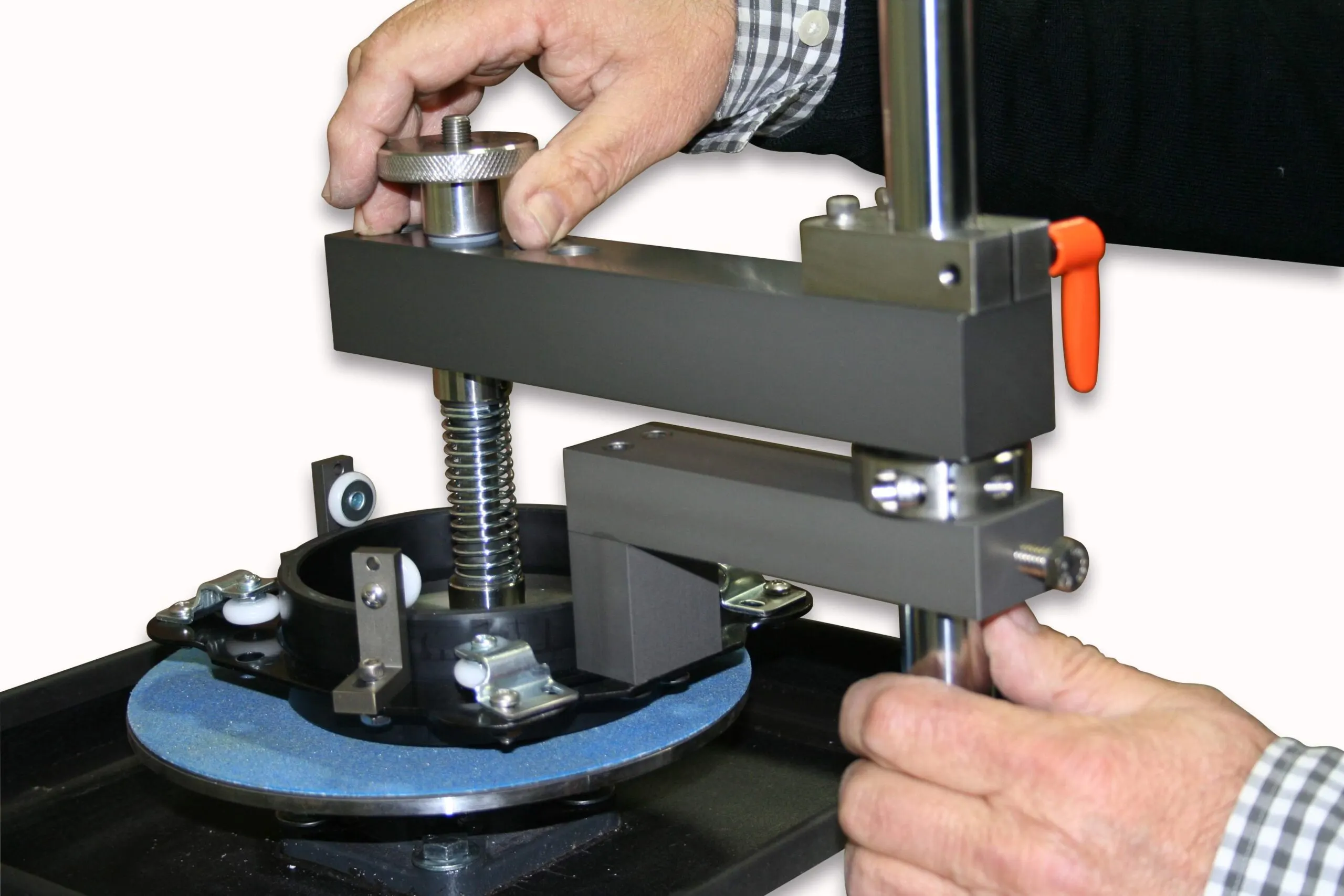

Illustrative image related to polishing machines

Are There Industry-Specific Quality Certifications for Polishing Machines?

In addition to ISO standards, industry-specific certifications such as CE marking for compliance with European safety standards or API standards for oil and gas applications may also be relevant. These certifications assure buyers that the polishing machines meet strict safety and performance requirements, which is particularly important for operations in industries with high stakes.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that every machine meets the required specifications.

What Are Incoming Quality Control (IQC) Measures?

Incoming Quality Control (IQC) assesses raw materials and components before they enter the production line. This step ensures that all inputs meet predefined quality criteria and specifications.

How Is In-Process Quality Control (IPQC) Implemented?

In-Process Quality Control (IPQC) monitors the manufacturing processes in real-time. This can include regular inspections of machining operations and assembly line processes to catch any deviations from quality standards early in the production cycle.

What Does Final Quality Control (FQC) Entail?

Final Quality Control (FQC) occurs once the polishing machine is fully assembled. At this stage, comprehensive testing is conducted to ensure that the machine operates correctly under various conditions. This may include performance tests, safety checks, and a thorough inspection of the machine’s components.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers.

What Are Effective Audit Strategies for Supplier Verification?

Conducting audits of suppliers’ facilities is one of the most effective methods. This allows buyers to assess the manufacturing processes and quality control measures firsthand. Regular audits can help identify areas for improvement and ensure compliance with international standards.

How Can Buyers Utilize Quality Reports and Certifications?

Requesting quality reports and certifications from suppliers is another essential step. These documents provide insights into the supplier’s adherence to quality standards and their history of compliance. Look for detailed reports that outline testing methods and results, as this transparency is indicative of a supplier’s commitment to quality.

What Role Do Third-Party Inspections Play in Quality Assurance?

Third-party inspections can serve as an impartial verification of a supplier’s quality control processes. Engaging a reputable third-party inspection agency can provide additional assurance that the polishing machines meet all required specifications and standards before shipment.

Illustrative image related to polishing machines

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing polishing machines from international suppliers, especially from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific quality control nuances.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations that affect quality assurance practices. For example, European suppliers may adhere to stricter environmental regulations compared to those in other regions. Buyers should familiarize themselves with these standards to ensure compliance and avoid potential legal issues.

What Are the Challenges of Language and Cultural Differences in Quality Control?

Language barriers and cultural differences can also pose challenges in understanding quality control processes. It is advisable for buyers to engage in clear communication with suppliers and, if necessary, employ translators to ensure that specifications and quality standards are fully understood and adhered to.

In summary, the manufacturing processes and quality assurance practices for polishing machines are multifaceted, involving meticulous attention to detail at every stage. By understanding these processes and implementing rigorous verification methods, B2B buyers can confidently source high-quality polishing machines that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polishing machines’

Introduction

Navigating the procurement of polishing machines can be a complex task for B2B buyers, especially when considering factors such as specifications, supplier reliability, and compliance with industry standards. This guide offers a structured checklist to streamline the sourcing process, ensuring you make informed decisions that align with your operational needs.

Illustrative image related to polishing machines

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline the technical specifications of the polishing machines you require. Consider factors like the materials you’ll be polishing, the desired finish quality, and machine capacity.

– Important Considerations: Look for machine types—manual, semi-automatic, or fully automatic—that best suit your production volume and complexity.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and technologies in polishing machines. Understanding advancements can help you identify features that enhance efficiency and reduce operational costs.

– Key Areas to Explore: Investigate innovations such as automated polishing processes, energy-efficient models, and machines equipped with advanced safety features.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and reliability standards. Request detailed company profiles, including their manufacturing capabilities, product range, and customer testimonials.

– What to Look For: Seek references from similar industries and confirm their experience with international shipping and support, especially if you are sourcing from regions like Africa or South America.

Step 4: Verify Compliance and Certifications

Ensure that the polishing machines you are considering comply with relevant international standards and certifications. This is crucial for safety, performance, and quality assurance.

– Certifications to Check: Look for ISO certifications or specific industry standards that apply to your sector, which can indicate a supplier’s commitment to quality.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that break down costs, including machine price, shipping fees, and any potential import duties.

– Considerations for Quotations: Ensure that the quotes include warranty details and after-sales support options, as these factors can significantly affect your total cost of ownership.

Step 6: Conduct a Trial Run

If possible, arrange for a trial run of the polishing machines before finalizing your purchase. This allows you to assess the machine’s performance and suitability for your specific applications.

– Benefits of a Trial: A hands-on experience can reveal operational nuances and help you gauge the machine’s ease of use and maintenance needs.

Step 7: Finalize Purchase Agreement

After evaluating all options, finalize the purchase agreement with the chosen supplier. Ensure that all terms, including delivery timelines, payment conditions, and service agreements, are clearly documented.

– Key Elements to Confirm: Pay attention to the service level agreements (SLAs) for maintenance and support, as these are critical for minimizing downtime in your operations.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing polishing machines, ensuring that they select equipment that meets their operational needs while fostering reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for polishing machines Sourcing

What Are the Key Cost Components in Polishing Machines?

When sourcing polishing machines, buyers should be aware of the various cost components that contribute to the final price. The primary factors include:

-

Materials: The quality and type of materials used in manufacturing polishing machines significantly influence costs. Higher-grade components, such as durable metals and advanced electronic systems, typically increase the machine’s price. Additionally, specialty materials for specific applications can further elevate costs.

-

Labor: Labor costs can vary based on geographic location and the complexity of the machine. Skilled labor in regions with higher wage standards can lead to increased production costs. Conversely, sourcing from countries with lower labor costs may offer savings, but it’s essential to consider the potential trade-offs in quality and service.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and administrative expenses related to production. Companies with advanced manufacturing technologies may enjoy lower overhead costs, which can be reflected in more competitive pricing.

-

Tooling: The investment in specialized tooling for production can affect the pricing structure. Custom tooling for unique specifications increases initial costs but may be justified by the machine’s performance and efficiency.

-

Quality Control (QC): Rigorous quality control processes ensure reliability and performance but add to manufacturing costs. Buyers should evaluate whether the additional QC measures are reflected in the pricing and if they align with their quality requirements.

-

Logistics: Shipping and handling costs can vary based on the distance from the supplier, the shipping method, and the volume of the order. International buyers should factor in customs duties and taxes, which can significantly impact total costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely depending on market conditions and competition.

How Do Price Influencers Affect Polishing Machines?

Several key factors influence pricing in the polishing machine market:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger volumes usually results in discounts. Buyers should negotiate terms that allow for bulk purchasing to maximize savings.

-

Specifications and Customization: Custom-built machines or those with advanced specifications generally command higher prices. Buyers should assess whether the additional features justify the cost based on their operational needs.

-

Materials: The choice of materials not only affects durability but also the price. For example, machines made with stainless steel or advanced composites may be more expensive upfront but can lead to lower maintenance costs over time.

-

Quality and Certifications: Machines that meet international quality standards or possess certifications may be priced higher. However, they can provide assurance of performance and longevity, making them a worthwhile investment.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their brand, but they often provide better support and warranty options.

-

Incoterms: Understanding the shipping terms (Incoterms) is vital for budgeting. Different terms can lead to variations in the total landed cost, influencing the decision-making process.

What Buyer Tips Can Enhance Cost-Efficiency in Polishing Machine Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, and the Middle East, the following strategies can enhance cost-efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules. Building a good relationship with suppliers can lead to better deals over time.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the machine, including maintenance, energy consumption, and potential downtime. A lower initial purchase price may not always result in overall savings.

-

Be Aware of Pricing Nuances: Prices can fluctuate based on market demand, currency exchange rates, and geopolitical factors. Staying informed about these influences can help buyers make timely purchasing decisions.

-

Research Local Suppliers: Exploring local suppliers can reduce shipping costs and import duties, making it a viable option for budget-conscious buyers.

-

Leverage Technology: Utilize online platforms and marketplaces to compare prices and features efficiently. This can help in identifying the best value propositions available in the market.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on specific supplier agreements, market conditions, and order volumes. Always request detailed quotes from suppliers to ensure accurate budgeting.

Illustrative image related to polishing machines

Alternatives Analysis: Comparing polishing machines With Other Solutions

Understanding Alternative Solutions for Polishing Needs

In the realm of surface finishing, polishing machines are a popular choice due to their efficiency and effectiveness. However, various alternatives exist that can also achieve similar results, each with its unique advantages and drawbacks. This analysis compares polishing machines against two viable alternatives: manual polishing and vibratory polishing systems, helping international B2B buyers make informed decisions based on their specific needs and operational contexts.

| Comparison Aspect | Polishing Machines | Manual Polishing | Vibratory Polishing Systems |

|---|---|---|---|

| Performance | High, consistent results | Variable, skill-dependent | Moderate, good for bulk work |

| Cost | Moderate to high investment | Low initial cost | Moderate investment |

| Ease of Implementation | Requires training and setup | Simple, low-tech | Needs setup and maintenance |

| Maintenance | Regular maintenance needed | Minimal maintenance | Regular maintenance required |

| Best Use Case | Precision tasks, high volume | Small-scale, intricate work | Bulk processing, mass production |

What Are the Pros and Cons of Manual Polishing?

Manual polishing involves using handheld tools and abrasives to achieve a polished finish. This method is often favored for its simplicity and low initial investment. However, its performance can be highly variable, depending on the skill level of the operator. While it is ideal for small-scale projects or intricate details, the process can be time-consuming and labor-intensive, making it less suitable for high-volume applications. Additionally, the lack of consistency may lead to variations in quality, which can be detrimental in sectors requiring precision.

How Do Vibratory Polishing Systems Compare?

Vibratory polishing systems utilize a combination of abrasive media and vibration to achieve a polished finish. These systems are particularly effective for bulk processing and are often used in industries such as jewelry manufacturing and metal finishing. They offer a moderate performance level and can handle large volumes of work efficiently. However, they require a significant setup and maintenance effort. While the initial investment is moderate, ongoing costs may arise from consumable media and maintenance. Vibratory systems are best suited for applications where uniformity is crucial, but they may not provide the precision required for specialized tasks.

Conclusion: How to Choose the Right Polishing Solution

Selecting the appropriate polishing solution hinges on understanding specific operational needs, budget constraints, and production goals. B2B buyers should evaluate the performance requirements of their projects, considering whether they need high precision or bulk processing capabilities. Manual polishing may be ideal for smaller, intricate tasks with a lower budget, while vibratory systems suit larger operations where uniformity is key. Polishing machines, with their advanced capabilities, are the best fit for high-volume, precision-driven applications. By carefully weighing these factors, buyers can make an informed decision that aligns with their operational objectives and maximizes efficiency.

Essential Technical Properties and Trade Terminology for polishing machines

What Are the Key Technical Properties of Polishing Machines?

Understanding the technical specifications of polishing machines is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties to consider:

Illustrative image related to polishing machines

1. Material Grade

The material grade of a polishing machine refers to the quality of the materials used in its construction, such as steel or aluminum. Higher-grade materials often translate to increased durability and longevity, which is vital for businesses looking to minimize maintenance costs and downtime. In regions like Africa and South America, where environmental conditions can vary, opting for machines made from robust materials can ensure consistent performance.

2. Power Output

Measured in horsepower or watts, power output indicates the machine’s ability to handle demanding polishing tasks. A higher power output allows for faster operation and the ability to polish harder materials. For manufacturers in the Middle East or Europe, where precision is paramount, selecting machines with adequate power can significantly enhance productivity and quality.

3. Speed Control

Speed control features enable operators to adjust the polishing speed according to the specific material and desired finish. This flexibility is essential for achieving optimal results across various applications. For B2B buyers, especially in sectors like automotive or aerospace, machines with variable speed settings can provide a competitive edge by allowing for custom polishing solutions.

4. Working Area Size

The size of the working area dictates the types and sizes of materials that can be polished. A larger working area accommodates bigger components, making it suitable for industries such as construction or heavy machinery. Buyers should assess their operational needs to ensure the machine’s specifications align with their production capabilities.

5. Automation Level

Polishing machines can range from fully manual to fully automated systems. Automated machines often enhance efficiency by reducing human error and increasing throughput. For businesses in Europe focusing on high-volume production, investing in automated polishing solutions can lead to significant cost savings and improved consistency.

Illustrative image related to polishing machines

What Are Common Trade Terms Used in the Polishing Machine Industry?

Familiarizing yourself with industry jargon is essential for navigating the purchasing process effectively. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for spare parts and accessories, ensuring that their polishing machines remain operational with compatible components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can impact budgeting and inventory management. Buyers in regions like Nigeria and Brazil should clarify MOQs to avoid over-committing to quantities that may not align with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. By submitting an RFQ, businesses can compare pricing and terms from different suppliers, which is essential for making cost-effective purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms is vital for B2B transactions, especially for international buyers, as they define who is responsible for shipping costs, insurance, and risk during transit.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for effective supply chain management, particularly for businesses that operate in fast-paced industries. Buyers should always inquire about lead times to ensure timely delivery and avoid production delays.

By grasping these technical properties and trade terms, B2B buyers can navigate the complex landscape of polishing machine procurement with greater confidence and efficiency.

Navigating Market Dynamics and Sourcing Trends in the polishing machines Sector

Global drivers shaping the polishing machines sector include technological advancements, increased demand for precision in manufacturing, and the growing trend of automation in industrial processes. As businesses across various sectors, including automotive, aerospace, and electronics, seek to enhance product quality and reduce time-to-market, the demand for high-performance polishing machines continues to rise. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for innovative solutions that offer efficiency, reliability, and scalability.

Emerging technologies such as smart manufacturing, IoT integration, and advanced automation features are influencing sourcing trends in the polishing machines market. Companies are now prioritizing equipment that can seamlessly integrate into their existing production lines while offering real-time data analytics for process optimization. Additionally, the shift towards sustainable practices is prompting manufacturers to innovate with energy-efficient models and environmentally friendly materials, thus appealing to a broader audience that includes eco-conscious buyers.

Market dynamics are also shaped by regional variations in demand. For instance, African markets are experiencing growth in the automotive sector, leading to increased investment in polishing solutions. Similarly, South America is witnessing a burgeoning demand for polishing equipment in the mining and metalworking industries. Understanding these regional trends is crucial for international buyers seeking to make informed purchasing decisions and capitalize on market opportunities.

How Does Sustainability Influence B2B Sourcing in the Polishing Machines Sector?

Environmental impact is a pivotal consideration for modern businesses, particularly in the context of polishing machines. As the global focus on sustainability intensifies, companies are increasingly held accountable for their environmental footprint. This has led to a greater emphasis on ethical sourcing practices and the use of environmentally friendly materials in manufacturing polishing machines.

Buyers are now prioritizing suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001, which highlights effective environmental management systems. Additionally, the demand for ‘green’ materials, such as biodegradable lubricants and energy-efficient components, is on the rise. These choices not only help in reducing ecological impact but also resonate with customers who are making purchasing decisions based on corporate social responsibility.

Illustrative image related to polishing machines

Furthermore, ethical supply chains are becoming a key differentiator in B2B transactions. Companies that can trace the origin of their materials and ensure fair labor practices are more likely to attract and retain clients who value transparency. For international buyers, particularly from regions with stringent environmental regulations, aligning with sustainable suppliers can also mitigate risks associated with compliance and reputational damage.

What is the Historical Context of Polishing Machines in B2B Markets?

The evolution of polishing machines can be traced back to the industrial revolution, where manual polishing methods were gradually replaced by mechanized solutions. Early polishing machines were rudimentary, relying on simple rotating discs and manual operation. Over the decades, advancements in motor technology and materials science have led to the development of more sophisticated machines capable of delivering higher precision and efficiency.

By the late 20th century, the introduction of computer numerical control (CNC) technology revolutionized the polishing industry, allowing for automated processes that significantly reduced human error. Today, the market is witnessing a shift towards fully automated and smart polishing solutions that integrate seamlessly with Industry 4.0 frameworks. This historical context not only reflects technological progress but also highlights the growing importance of efficiency and quality in the B2B landscape.

In conclusion, international B2B buyers looking for polishing machines must navigate a complex landscape characterized by technological advancements, sustainability demands, and historical evolution. Understanding these dynamics will enable them to make informed sourcing decisions that align with their business goals and market needs.

Frequently Asked Questions (FAQs) for B2B Buyers of polishing machines

-

How do I solve issues with polishing machine performance?

To address performance issues with polishing machines, first, ensure that the machine is properly calibrated according to the manufacturer’s specifications. Regular maintenance, including cleaning and replacing worn components, is crucial. If the machine is underperforming, assess the quality of the polishing materials being used, as inferior products can affect results. Additionally, consider the speed and pressure settings; these often need to be adjusted based on the specific material being polished. If problems persist, consult the manufacturer for troubleshooting advice or potential upgrades. -

What is the best polishing machine for metal surfaces?

The best polishing machine for metal surfaces typically depends on the specific application and desired finish. For large-scale operations, a high-speed automatic polisher may be ideal, as it ensures consistent results and increased efficiency. For smaller, intricate jobs, a bench-top unit or a manual polisher may provide better control. Features to look for include adjustable speed settings, compatibility with various polishing pads, and robust construction to handle metal materials effectively. Always review product specifications and user reviews to find the right fit for your needs. -

What factors should I consider when sourcing polishing machines internationally?

When sourcing polishing machines internationally, consider factors such as the supplier’s reputation, product quality, and compliance with local regulations. It’s vital to assess the supplier’s experience in the industry and their ability to provide after-sales support. Additionally, consider the total landed cost, including shipping, tariffs, and customs duties. Research the availability of spare parts and maintenance services in your region, as this can significantly affect operational efficiency. Lastly, ensure that the machine meets your specific production requirements and quality standards. -

How can I ensure the quality of polishing machines from suppliers?

To ensure the quality of polishing machines, conduct thorough supplier vetting. Start by checking certifications and compliance with international standards such as ISO or CE marks. Request product samples or demonstrations to evaluate performance firsthand. Additionally, seek references from other businesses that have purchased from the supplier. A reliable supplier should provide comprehensive warranty terms and readily available customer service. Regular audits of the supplier’s production process can also help maintain quality assurance. -

What customization options are available for polishing machines?

Customization options for polishing machines can vary widely based on the manufacturer. Common modifications include adjustments to speed control, pad size, and additional features like automated feeding systems. Some suppliers may offer tailored solutions to meet specific industry needs, such as unique polishing compounds or specialized attachments for different materials. When discussing customization, ensure you provide detailed specifications of your requirements, and inquire about the implications on pricing and lead time. -

What is the typical minimum order quantity (MOQ) for polishing machines?

The minimum order quantity (MOQ) for polishing machines can differ significantly between suppliers. Generally, manufacturers may set MOQs to ensure production efficiency and cost-effectiveness. MOQs can range from one unit for smaller suppliers to several units for larger manufacturers. When negotiating, consider discussing your specific needs and any potential flexibility in MOQs, especially if you’re looking to test a machine before committing to larger orders. -

What payment terms should I expect when purchasing polishing machines?

Payment terms for polishing machines vary by supplier and can include options such as upfront payments, payment upon delivery, or installment plans. It’s common for suppliers to request a deposit (often 30-50%) before manufacturing, with the balance due upon shipment or delivery. Always review the payment terms carefully, including any potential penalties for late payments. Discussing terms upfront can prevent misunderstandings and ensure a smoother transaction. -

What logistics considerations should I keep in mind when importing polishing machines?

When importing polishing machines, consider logistics factors such as shipping methods, freight costs, and delivery timelines. Collaborate with a reliable freight forwarder familiar with international shipping regulations to navigate customs clearance and documentation requirements. Evaluate the total landed cost, which includes shipping, insurance, and duties. Additionally, ensure that the machines are adequately packaged to prevent damage during transit. It’s advisable to track shipments closely and maintain communication with your supplier throughout the shipping process for updates.

Top 3 Polishing Machines Manufacturers & Suppliers List

1. Caswell Plating – 1/2 Collet for NotcHead Grip

Domain: caswellplating.com

Registered: 1997 (28 years)

Introduction: This company, Caswell Plating – 1/2 Collet for NotcHead Grip, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Handler Manufacturing – Bench Top Polishing Systems

Domain: handlermfg.com

Registered: 1996 (29 years)

Introduction: [{‘name’: ‘575 Bench Top Polishing System’, ‘original_price’: 2736.02, ‘current_price’: 2342.03}, {‘name’: ‘575-0 Bench-Top Polishing System’, ‘original_price’: 2251.78, ‘current_price’: 1624.0}, {‘name’: ‘600JP Multifunctional Polishing Unit’, ‘price’: 3220.66}, {‘name’: ’60FC-1-TS Polishing Unit’, ‘price’: 4604.24}, {‘name’: ’60FC-TS Polishing Unit’, ‘original_price’: 4303.7, ‘current_price’: 38…

3. MTI – Polishers

Domain: mtixtl.com

Registered: 2002 (23 years)

Introduction: Polishers – 15 products available, including Automatic Lapping and Polishing (2 products), Feeders (1 product), and Polishing Efficiency Accessories (1 product). In stock: 7 products, Out of stock: 8 products. Sort options include Featured, Best selling, Alphabetically A-Z, Alphabetically Z-A, Price low to high, Price high to low, Date old to new, Date new to old.

Strategic Sourcing Conclusion and Outlook for polishing machines

In summary, effective strategic sourcing for polishing machines is paramount for international B2B buyers seeking to enhance operational efficiency and product quality. As highlighted, the diverse range of polishing machines—from manual to fully automated systems—offers tailored solutions for various industrial applications, making it essential for buyers to assess their specific needs. Leveraging reliable suppliers who provide comprehensive support and consumables can significantly reduce operational downtime and improve overall productivity.

Moreover, understanding the regional market dynamics in Africa, South America, the Middle East, and Europe can lead to better negotiation outcomes and cost savings. Investing in advanced polishing technology not only enhances product finishes but also supports sustainability goals through improved resource management.

As the global market continues to evolve, buyers are encouraged to stay informed about emerging technologies and trends in the polishing sector. Embrace the opportunity to streamline your sourcing process and elevate your competitive edge by aligning with reputable manufacturers and distributors. Start your strategic sourcing journey today to unlock the full potential of your operations and meet the increasing demands of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.