Plug Tip: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for plug tip

Navigating the complexities of the global market for plug tips can be a daunting task for B2B buyers, especially when sourcing reliable components that ensure optimal performance in various applications. Whether you are seeking spark plug tip inserts to prevent engine malfunctions or specialized plug tips for agricultural equipment, understanding the nuances of product specifications, supplier credibility, and pricing is crucial. This guide provides a comprehensive overview of plug tips, covering diverse types and their specific applications, as well as vital insights into supplier vetting processes, cost considerations, and logistical challenges.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Vietnam and Nigeria—this resource is tailored to empower you in making informed purchasing decisions. By detailing key factors such as performance metrics, compatibility with existing systems, and industry standards, the guide ensures you can confidently select the right plug tips that meet your operational needs. Additionally, we highlight strategic sourcing techniques and negotiation tactics to help you secure the best deals in a competitive landscape. With this guide, you will be equipped to navigate the global market effectively, mitigating risks and enhancing your procurement strategy.

Understanding plug tip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spark Plug Tip Insert | Reusable, designed for specific plug models | Automotive, motorsport | Pros: Cost-effective, reduces waste. Cons: Limited compatibility with specific models. |

| TeeJet Plug Tips | Prevents spray from exiting nozzles, replaces nozzles | Agriculture, pest control | Pros: Easy to install, enhances spray control. Cons: May require additional nozzles for versatility. |

| Tip Plugs & Jacks | Available in various sizes, voltage ratings, and colors | Electronics testing, industrial applications | Pros: Versatile, suitable for different testing needs. Cons: Compatibility issues may arise with non-standard equipment. |

| Banana Plug Tips | Standardized connection, widely used for test equipment | Educational, electronics prototyping | Pros: Easy to connect/disconnect, widely available. Cons: Limited to low-voltage applications. |

| Standard Tip Plugs | Common sizes for various applications, durable materials | General testing, industrial machinery | Pros: Durable, extensive range of options. Cons: May not be suitable for high-voltage applications. |

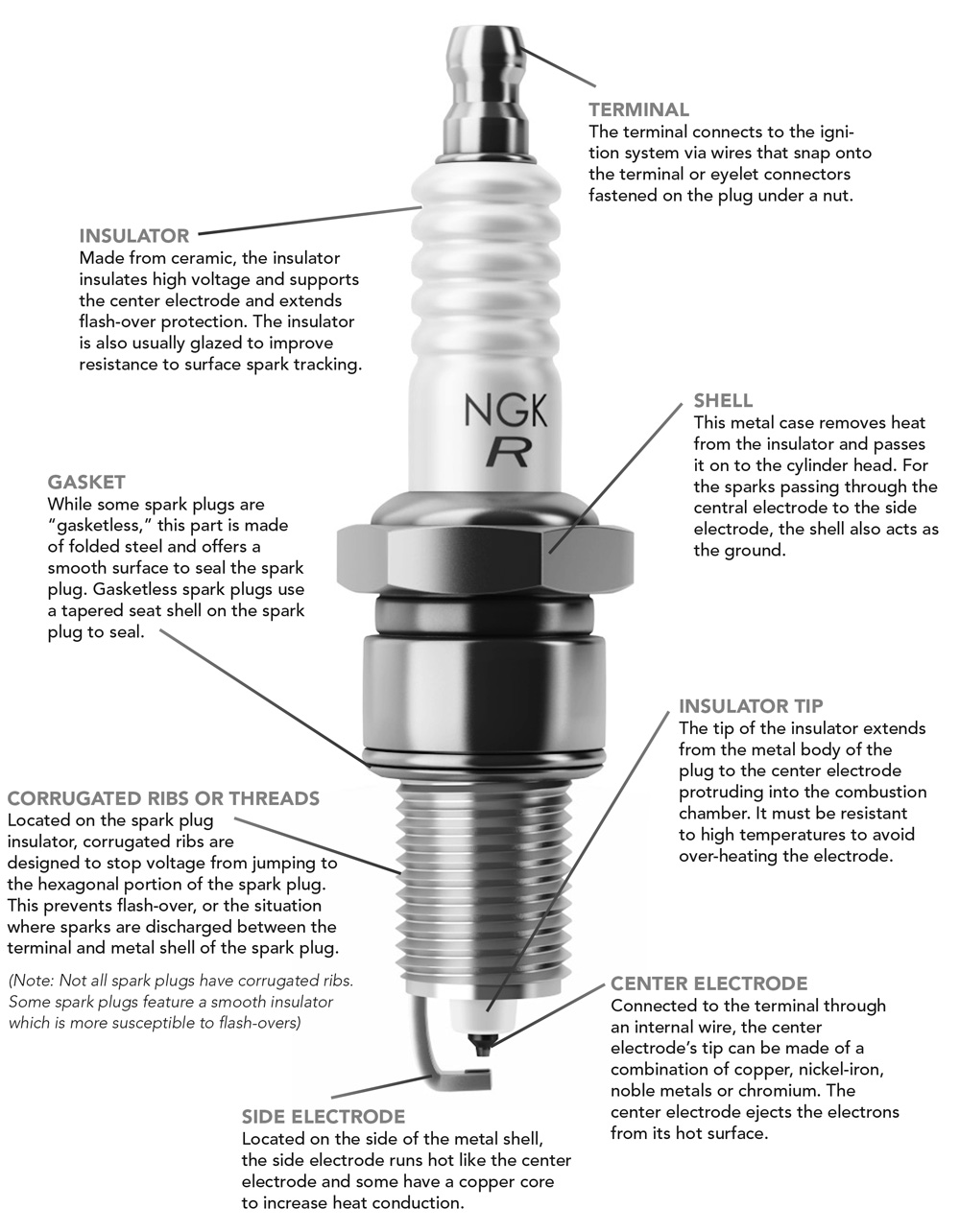

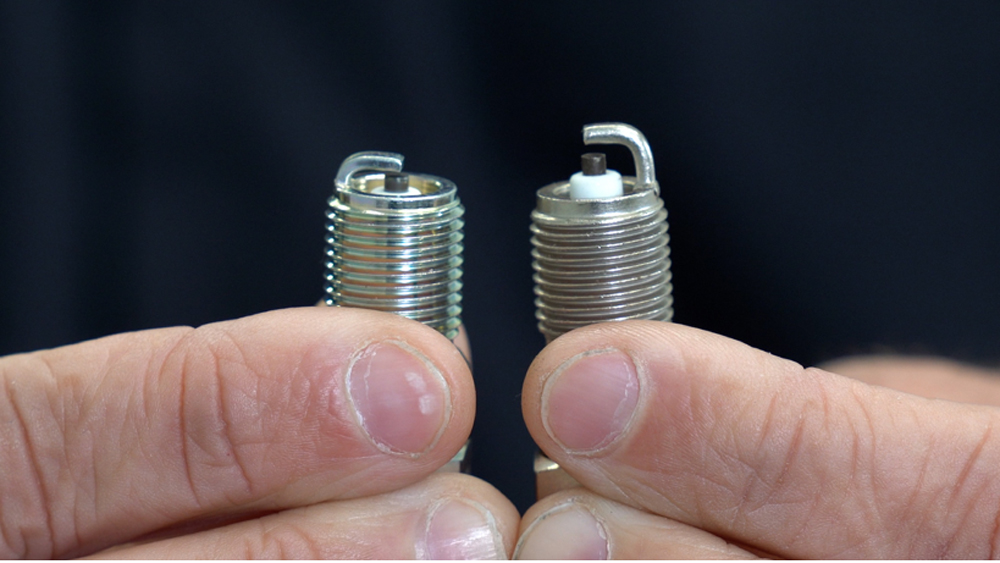

What are Spark Plug Tip Inserts and Their Applications?

Spark Plug Tip Inserts are reusable components designed to enhance the reliability of spark plugs, specifically addressing issues like dislodged electrodes. They are particularly beneficial in automotive and motorsport applications where engine performance is critical. When considering Spark Plug Tip Inserts for B2B purchases, buyers should assess compatibility with existing plug models, as these inserts typically cater to specific designs, such as the NGK R6061. The ability to reuse these inserts offers a cost-effective solution, reducing waste and maintenance costs.

How Do TeeJet Plug Tips Improve Agricultural Efficiency?

TeeJet Plug Tips are designed to replace nozzles on spray equipment, effectively stopping spray from exiting a nozzle when not in use. This feature is particularly useful in agricultural settings, where precise application of chemicals is crucial for crop health and pest control. B2B buyers in the agriculture sector should consider the ease of installation and the potential for improved spray control. However, to maximize versatility, they may need to invest in additional nozzles, which could increase initial costs.

What Should B2B Buyers Know About Tip Plugs and Jacks?

Tip Plugs and Jacks are essential components in electronics testing, offering a wide range of sizes, voltage ratings, and colors. Their versatility makes them suitable for various industrial applications, from testing circuits to connecting equipment. When purchasing these components, businesses should evaluate the compatibility with their existing testing setups. Although they provide flexibility, buyers must be aware of potential compatibility issues with non-standard equipment, which could lead to operational inefficiencies.

Why Are Banana Plug Tips Popular in Educational Settings?

Banana Plug Tips are widely recognized for their standardized connection, making them a staple in educational and electronics prototyping environments. Their ease of use allows for quick connections and disconnections, facilitating hands-on learning experiences. For B2B buyers in educational sectors, the availability and affordability of Banana Plug Tips are significant advantages. However, their application is generally limited to low-voltage scenarios, which may restrict their use in more demanding industrial environments.

What Are the Benefits of Standard Tip Plugs?

Standard Tip Plugs are characterized by their durability and availability in common sizes, making them suitable for a wide array of applications, including general testing and industrial machinery. For B2B buyers, the extensive range of options allows for tailored solutions to meet specific operational needs. However, businesses should consider the voltage ratings when selecting these plugs, as they may not be appropriate for high-voltage applications, which could pose safety risks.

Key Industrial Applications of plug tip

| Industry/Sector | Specific Application of plug tip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Spark plug tips for high-performance engines | Enhances engine efficiency and reduces maintenance costs | Compatibility with specific engine types and performance standards |

| Agriculture | TeeJet plug tips in agricultural spraying systems | Prevents leaks, ensuring precise chemical application | Chemical compatibility and nozzle integration |

| Electronics | Tip plugs for testing and measurement equipment | Ensures accurate readings and reliable connectivity | Voltage ratings and material durability under various conditions |

| Industrial Manufacturing | Tip plugs in assembly line machinery | Increases operational efficiency and reduces downtime | Sourcing from reputable manufacturers to ensure quality and reliability |

| Telecommunications | Plug tips for connecting test and measurement devices | Supports accurate data transmission and system diagnostics | Compliance with international standards and specifications |

How Are Plug Tips Used in the Automotive Industry?

In the automotive sector, plug tips are essential for high-performance engines, particularly in racing and modified vehicles. These tips enhance the reliability of spark plugs, preventing malfunctions that could lead to engine damage. By ensuring optimal ignition performance, businesses can reduce maintenance costs and improve fuel efficiency. International buyers should focus on compatibility with specific engine types and the performance standards required for their applications, ensuring they source plug tips that meet rigorous quality checks.

What Role Do Plug Tips Play in Agriculture?

Agricultural operations utilize TeeJet plug tips in their spraying systems to ensure precision in chemical applications. By replacing standard nozzles with plug tips, farmers can effectively control spray patterns and prevent leaks, which is crucial for maintaining crop health and optimizing resource use. Buyers in regions like Africa and South America should consider the chemical compatibility of plug tips with various pesticides and fertilizers, as well as their integration with existing spraying equipment to maximize efficiency.

How Are Plug Tips Utilized in Electronics Testing?

In the electronics industry, tip plugs are vital for connecting testing and measurement devices. They ensure accurate readings by providing reliable electrical connections in various testing scenarios. This is particularly important in quality control processes where precise measurements are critical. Buyers should prioritize sourcing tip plugs that meet specific voltage ratings and durability requirements, especially in regions with varying environmental conditions, to ensure long-term performance.

What Benefits Do Plug Tips Offer in Industrial Manufacturing?

In industrial manufacturing, plug tips are commonly used in assembly line machinery to facilitate connections between various components. Their role in increasing operational efficiency is significant, as they help to minimize downtime caused by connection failures. Businesses should focus on sourcing plug tips from reputable manufacturers to ensure quality and reliability, particularly in high-demand environments where machinery uptime is critical for productivity.

How Are Plug Tips Essential in Telecommunications?

In telecommunications, plug tips are crucial for connecting test and measurement devices that monitor system performance. They support accurate data transmission and diagnostics, which are essential for maintaining network integrity. Buyers must ensure that the plug tips comply with international standards and specifications to guarantee compatibility with global telecommunications equipment, thereby facilitating smoother operations across diverse markets.

3 Common User Pain Points for ‘plug tip’ & Their Solutions

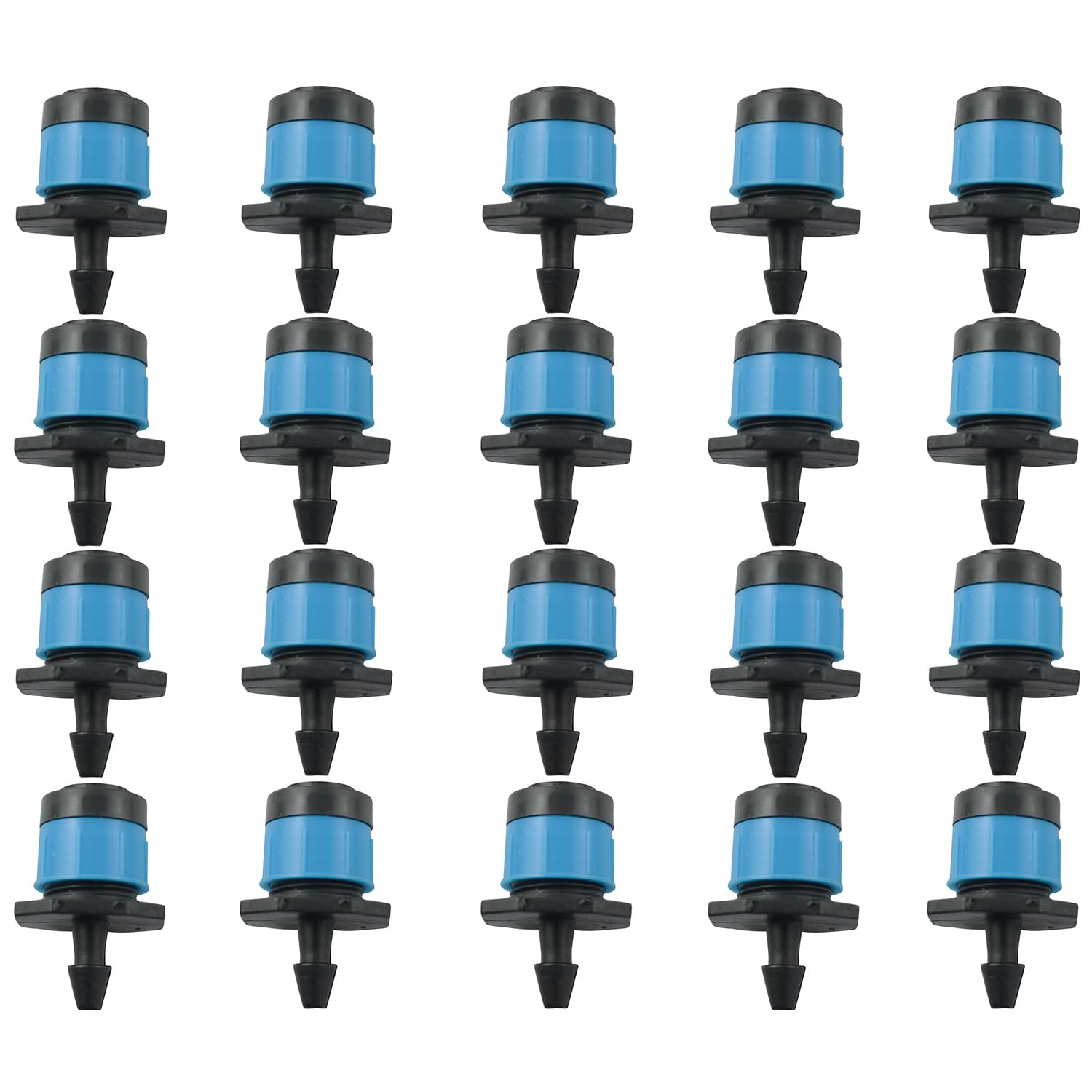

Scenario 1: Inconsistent Spray Patterns in Agricultural Equipment

The Problem: B2B buyers in the agriculture sector often face challenges with inconsistent spray patterns from their equipment, which can lead to uneven coverage of pesticides or fertilizers. This inconsistency can result from worn or damaged plug tips in nozzles, impacting crop yield and leading to increased operational costs. Such issues can be especially pronounced in regions where precision is critical, like parts of South America and Africa, where agricultural output directly affects local economies.

Illustrative image related to plug tip

The Solution: To address this issue, it is crucial for buyers to regularly inspect and replace plug tips in their spray nozzles. When sourcing replacement parts, opt for high-quality, durable plug tips specifically designed for your equipment model, such as those from reputable manufacturers like TeeJet. Additionally, consider investing in adjustable plug tips that allow for fine-tuning of spray patterns according to specific crop requirements. Implementing a scheduled maintenance routine can help mitigate problems before they affect productivity, ensuring consistent application and optimal crop performance.

Scenario 2: Electrical Connectivity Issues in Testing Equipment

The Problem: In industries relying on testing equipment, such as electronics manufacturing or quality assurance, unreliable electrical connections can lead to erroneous test results and wasted resources. B2B buyers may encounter issues with tip plugs that do not fit securely into jacks, resulting in intermittent connections and increased downtime. This problem is particularly frustrating when operating in fast-paced environments where precision and reliability are paramount.

The Solution: Buyers should focus on sourcing tip plugs that meet specific voltage and current ratings compatible with their testing equipment. When selecting connectors, consult with the manufacturers for compatibility specifications to avoid mismatches. Additionally, consider investing in higher-quality connectors that offer enhanced durability and resistance to wear. Regularly auditing and maintaining testing equipment, including cleaning contacts and checking for wear, can help ensure reliable performance and reduce the risk of connectivity issues during critical testing phases.

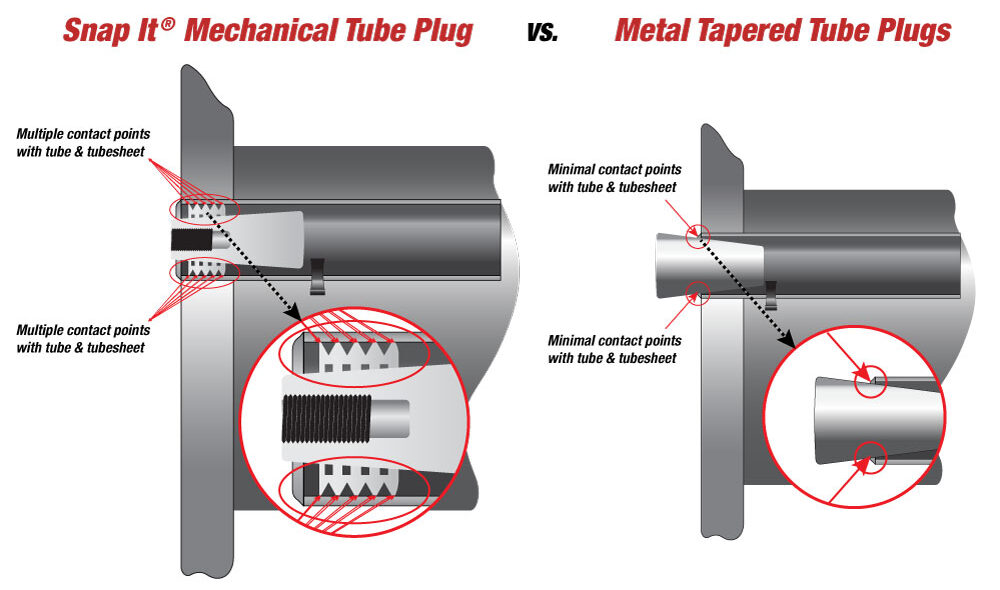

Scenario 3: High Replacement Costs Due to Non-Reusable Plug Tips

The Problem: Many businesses face escalating costs associated with frequently replacing plug tips that are not designed for reuse. This is particularly relevant in industries such as automotive and manufacturing, where plug tips are often used in high-volume applications. Non-reusable tips can lead to increased inventory management challenges and contribute to higher operational costs, which can significantly affect the bottom line.

The Solution: Transitioning to reusable plug tips can significantly cut costs and improve sustainability efforts. Buyers should look for products like the PLR spark plug tip insert, which allows for easy installation and removal, making it possible to transfer tips from old plugs to new ones. Additionally, consider bulk purchasing options to reduce unit costs. Establishing a standard operating procedure for the inspection and maintenance of plug tips can also help extend their lifespan, ensuring that businesses do not incur unnecessary expenses while also supporting eco-friendly practices.

Strategic Material Selection Guide for plug tip

What Are the Key Properties of Common Materials Used for Plug Tips?

When selecting materials for plug tips, several factors come into play, including performance characteristics, manufacturing complexity, and suitability for specific applications. Here, we analyze four common materials used in the production of plug tips: brass, stainless steel, plastic, and aluminum.

How Does Brass Perform as a Material for Plug Tips?

Brass is an alloy of copper and zinc, known for its excellent electrical conductivity and resistance to corrosion. It typically performs well at moderate temperatures and pressures, making it suitable for a variety of applications.

Pros and Cons: The durability of brass is a significant advantage, as it can withstand mechanical stress and resist wear. However, brass can be more costly than some alternatives and may not be suitable for high-temperature applications due to its lower melting point compared to other metals.

Illustrative image related to plug tip

Impact on Application: Brass is compatible with various media, including water and air, but may not be suitable for highly corrosive environments. International buyers should ensure compliance with standards such as ASTM B16 for brass fittings.

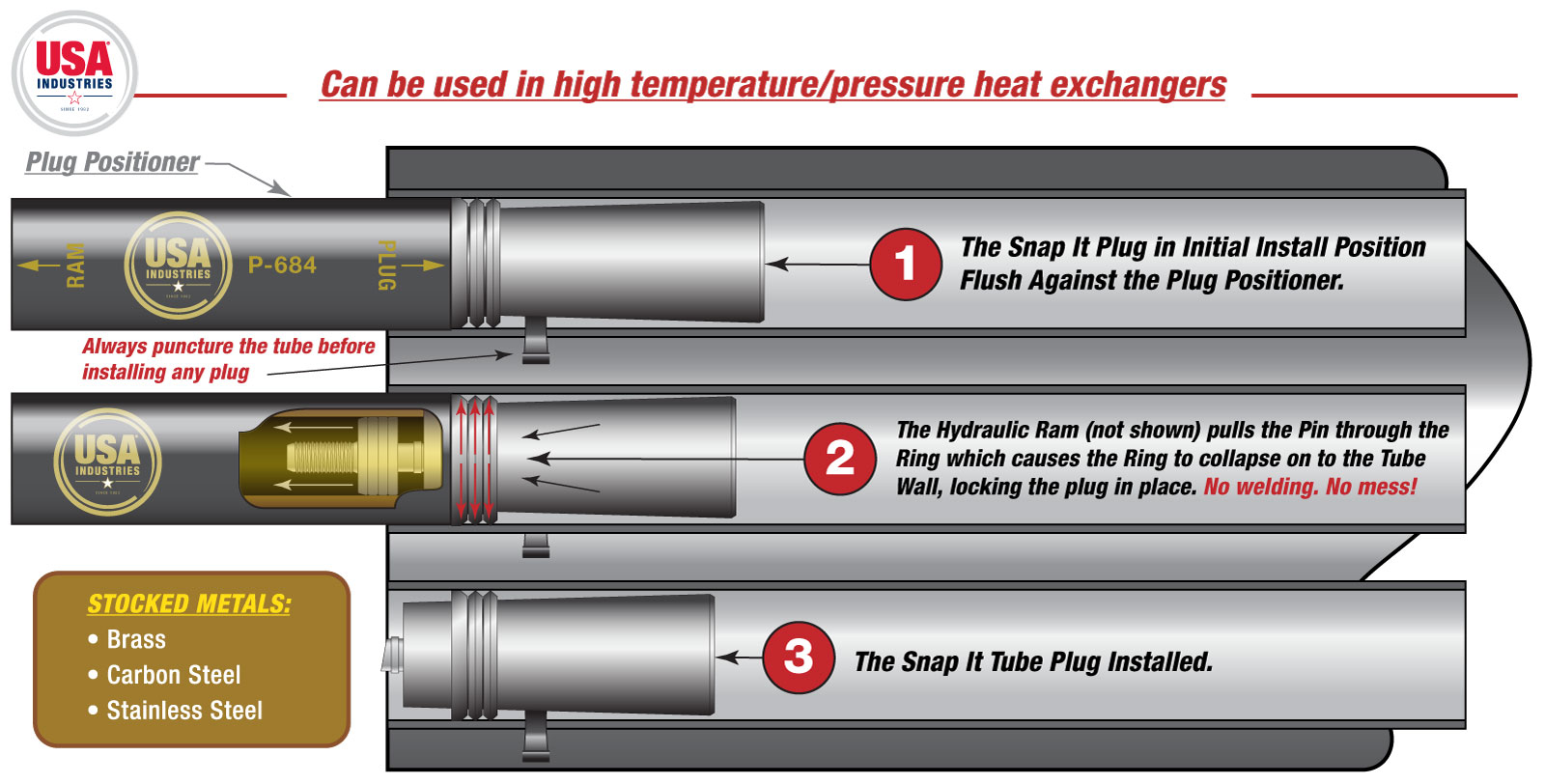

What Are the Benefits of Using Stainless Steel for Plug Tips?

Stainless steel is renowned for its exceptional corrosion resistance and high-temperature tolerance, making it a preferred choice for demanding environments.

Pros and Cons: The primary advantage of stainless steel is its longevity and ability to maintain structural integrity under extreme conditions. However, it can be more expensive and may require specialized manufacturing techniques, increasing production complexity.

Impact on Application: Stainless steel is compatible with a wide range of chemicals and is often used in industries such as oil and gas, food processing, and pharmaceuticals. Buyers from regions with stringent regulations, such as Europe, should consider compliance with standards like ISO 9001.

Why Choose Plastic for Plug Tips?

Plastic plug tips are lightweight and offer good resistance to corrosion and chemicals, making them a versatile option for various applications.

Pros and Cons: The cost-effectiveness of plastic is a significant advantage, particularly for high-volume applications. However, plastics generally have lower temperature and pressure ratings compared to metals, which may limit their use in certain environments.

Impact on Application: Plastic is suitable for non-aggressive media, such as water and air, but may not hold up well in high-temperature or high-pressure situations. International buyers must check for compliance with standards like ASTM D638 for plastic materials.

What Are the Advantages of Aluminum as a Plug Tip Material?

Aluminum is lightweight and has good corrosion resistance, making it a popular choice for plug tips in various applications.

Pros and Cons: The main advantage of aluminum is its balance of strength and weight, which can reduce shipping costs and ease installation. However, aluminum may not be as durable as stainless steel or brass, particularly in high-stress applications.

Impact on Application: Aluminum is generally compatible with a range of media but may not be suitable for highly corrosive environments. Buyers should ensure compliance with standards such as ASTM B211 for aluminum products.

Summary Table of Material Selection for Plug Tips

| Material | Typical Use Case for plug tip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Electrical connectors, automotive | Excellent conductivity and durability | Higher cost and lower temperature tolerance | Medium |

| Stainless Steel | Oil and gas, food processing | Exceptional corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Water and air applications | Cost-effective and lightweight | Limited temperature and pressure ratings | Low |

| Aluminum | General-purpose applications | Lightweight and good corrosion resistance | Less durable under stress | Medium |

This guide provides a comprehensive overview of the materials commonly used for plug tips, helping international B2B buyers make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for plug tip

What Are the Key Stages in the Manufacturing Process of Plug Tips?

The manufacturing of plug tips is a complex process that involves several critical stages to ensure quality and functionality. Each stage is designed to prepare materials, shape the components, assemble them, and finish the product to meet rigorous standards.

Material Preparation: What Materials Are Used for Plug Tips?

The first step in manufacturing plug tips is material selection and preparation. Commonly used materials include high-grade metals, plastics, and ceramics, each chosen for their durability, conductivity, and resistance to wear. For example, metals like copper are often used for their excellent electrical conductivity, while high-temperature resistant plastics may be utilized in specific applications.

Once selected, raw materials undergo a series of treatments, such as annealing or heat treatment, to enhance their properties. This process helps to achieve the desired strength and flexibility, making the plug tips more resilient under operational stress.

How Are Plug Tips Formed and Shaped?

Following material preparation, the next phase is forming. This typically involves various techniques such as machining, molding, or stamping, depending on the design and material used. For instance, precision machining may be employed for metal components to achieve tight tolerances, while injection molding is common for plastic parts.

Advanced technologies, such as CNC machining, allow for high precision and repeatability in the production of plug tips. This is crucial in ensuring that each component meets the specifications required for optimal performance.

What Does the Assembly Process Look Like?

Once the individual components are formed, they are assembled into plug tips. This process may involve several methods, including soldering, welding, or mechanical fastening. The choice of assembly technique depends on the materials and the intended application of the plug tip.

Quality during assembly is paramount, as improper assembly can lead to malfunctions or failures in the field. Manufacturers often employ jigs and fixtures to ensure precise alignment and secure fastening of parts during this stage.

How Are Plug Tips Finished for Optimal Performance?

The final stage of manufacturing involves finishing processes that enhance the aesthetic and functional characteristics of the plug tips. This may include surface treatments like anodizing, plating, or coating to improve corrosion resistance and durability.

Finishing also encompasses quality checks to ensure that the surface meets specifications, which can include testing for surface roughness and coating adhesion. The goal is to produce a plug tip that not only functions well but also withstands environmental factors and mechanical wear over time.

Illustrative image related to plug tip

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is critical in the manufacturing of plug tips, particularly for B2B buyers who need reliable and durable products. Understanding the relevant international and industry-specific standards is essential for ensuring compliance and product integrity.

Which International Standards Are Relevant for Plug Tips?

ISO 9001 is a widely recognized standard for quality management systems applicable across industries, including manufacturing. Compliance with this standard indicates that a manufacturer follows established quality management principles, such as a strong customer focus, process approach, and continuous improvement.

Additionally, specific industries may require adherence to standards such as CE marking in Europe, which signifies conformity with health, safety, and environmental protection standards. For industries like oil and gas, compliance with API (American Petroleum Institute) standards is critical, especially for plug tips used in high-pressure environments.

What Are the Key Quality Control Checkpoints?

Quality control (QC) during the manufacturing process typically involves several checkpoints to ensure that products meet specified standards. The primary checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter production. Suppliers must provide certificates of compliance to ensure materials meet specified standards.

-

In-Process Quality Control (IPQC): Conducted during various stages of manufacturing, IPQC involves monitoring processes to identify defects early. Statistical process control (SPC) methods are often employed to track variations.

-

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing and inspection to confirm they meet design specifications. Common testing methods include dimensional checks, functional tests, and stress testing.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are some strategies to effectively assess supplier QC:

What Steps Can Buyers Take to Audit Suppliers?

Conducting audits is an effective way to evaluate a supplier’s quality management system. Buyers can request an audit of the supplier’s facilities to assess compliance with relevant standards and internal QC processes.

Additionally, buyers should seek detailed QC reports that outline inspection results, non-conformances, and corrective actions taken. This documentation provides insight into the supplier’s commitment to quality and their ability to address issues proactively.

Why Is Third-Party Inspection Important?

Engaging a third-party inspection service can provide an unbiased assessment of a supplier’s quality control processes. These inspections typically include checking production processes, verifying compliance with standards, and conducting random sampling of finished products for testing.

Third-party inspectors can also provide certification that may be required for specific markets, adding an extra layer of assurance for B2B buyers. This is particularly important for international transactions, where compliance with local regulations and standards is mandatory.

What Unique QC Considerations Are There for International Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying regulatory requirements and industry standards. Buyers should familiarize themselves with the local standards applicable to plug tips in their market. This includes understanding any additional certifications required for importation or use within specific industries.

What Are the Challenges of Sourcing from International Suppliers?

Sourcing from international suppliers can pose challenges related to language barriers, cultural differences, and varying expectations regarding quality. Buyers should establish clear communication channels and set expectations early in the relationship to minimize misunderstandings.

Additionally, buyers should consider local partnerships or agents who can help navigate the complexities of international sourcing and ensure adherence to quality standards.

By understanding the manufacturing processes, quality assurance standards, and verification strategies, B2B buyers can make informed decisions when sourcing plug tips, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plug tip’

Introduction

This guide serves as a practical checklist for B2B buyers looking to source plug tips effectively. Plug tips play a critical role in various applications, from automotive to electronic testing, and ensuring you procure the right type can prevent operational inefficiencies and costly errors. By following this step-by-step guide, you will be equipped to make informed decisions in your purchasing process.

1. Define Your Technical Specifications

Begin by clearly outlining the specifications required for the plug tips. Consider the application, voltage ratings, current ratings, and compatibility with existing systems.

– Voltage and Current Requirements: Ensure that the plug tips can handle the necessary electrical specifications to avoid malfunctions.

– Compatibility Considerations: Verify that the plug tips match with connectors or devices you currently use.

2. Research Potential Suppliers

Identify potential suppliers that specialize in plug tips. Conduct thorough research to ensure they have a solid reputation in the industry.

– Supplier Background Checks: Look for suppliers with a history of reliability and quality. Investigate their market presence and customer reviews.

– Local vs. International Suppliers: Consider the advantages and disadvantages of sourcing locally versus internationally, including shipping costs and lead times.

3. Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with industry standards. This ensures you are dealing with reputable manufacturers.

– Quality Assurance Standards: Look for certifications like ISO 9001, which demonstrate commitment to quality management.

– Product Compliance: Ensure that products meet regional standards, especially if you are sourcing from different countries.

4. Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the plug tips you intend to purchase. Testing samples allows you to evaluate quality and compatibility.

– Compatibility Testing: Ensure that the samples work with your existing equipment and meet your specifications.

– Quality Assessment: Check for durability, performance, and any defects. This will help you gauge the supplier’s manufacturing quality.

5. Negotiate Pricing and Terms

Discuss pricing, payment terms, and delivery schedules with your chosen suppliers. Negotiation is key to achieving favorable terms that align with your budget.

– Bulk Purchase Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

– Payment Flexibility: Discuss payment options that work for both parties, ensuring you maintain cash flow.

Illustrative image related to plug tip

6. Finalize Purchase Agreements

Once you are satisfied with the supplier and the terms, proceed to finalize the purchase agreement. Ensure all details are documented to avoid misunderstandings.

– Contract Clarity: Clearly outline all terms, including delivery dates, warranties, and return policies.

– Legal Considerations: Consult legal counsel if necessary to ensure that the agreement protects your interests.

7. Establish a Relationship for Future Purchases

After completing the transaction, consider building a long-term relationship with the supplier. A strong partnership can lead to better terms and priority service in the future.

– Feedback Loop: Provide feedback on their products and service to foster a collaborative relationship.

– Future Needs Assessment: Keep the supplier informed about your future needs to ensure they can meet your growing demands.

By following these steps, B2B buyers can navigate the complexities of sourcing plug tips effectively, ensuring that they make informed decisions that benefit their operations.

Comprehensive Cost and Pricing Analysis for plug tip Sourcing

What Are the Key Cost Components in Plug Tip Sourcing?

When sourcing plug tips, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of materials used significantly impacts the cost. For example, high-quality metals and polymers for plug tips may cost more but offer better performance and longevity.

-

Labor: Labor costs encompass the wages paid to workers involved in manufacturing, assembly, and quality control. Regions with higher labor costs, such as Europe, may lead to increased overall pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs, making them less significant per unit when purchasing in bulk.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can add to the overall cost. Certifications such as ISO can also influence pricing.

-

Logistics: Shipping costs, including freight and customs duties, vary based on the origin and destination of the goods. Understanding Incoterms is essential for predicting these costs accurately.

-

Margin: Suppliers will add their profit margin to the base cost, which varies by market dynamics and competition.

How Do Price Influencers Affect Plug Tip Costs?

Several factors can influence the pricing of plug tips beyond the basic cost structure:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract better pricing due to economies of scale. Buyers should assess their needs carefully to avoid excess inventory while still benefiting from bulk pricing.

-

Specifications and Customization: Custom designs or specific performance characteristics can significantly increase costs. Buyers should evaluate whether the added specifications justify the additional expense.

-

Materials and Quality Certifications: Higher-grade materials and certifications can lead to increased costs but may be essential for specific applications, particularly in regulated industries.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can all impact pricing. Local suppliers may offer lower logistics costs but might not always provide the best material quality or price.

-

Incoterms: Understanding shipping terms can help buyers manage logistics costs effectively. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine responsibility for shipping costs and risks.

What Tips Can Help Buyers Negotiate Better Pricing for Plug Tips?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating favorable pricing can be pivotal:

-

Conduct Market Research: Understanding the market rates for plug tips in different regions can empower buyers to negotiate better deals.

-

Negotiate Based on Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with durability, maintenance, and potential replacements.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Trust can also facilitate smoother negotiations.

-

Flexibility in Specifications: If possible, be open to alternative materials or designs that can lower costs without compromising quality.

-

Timing and Currency Considerations: Be aware of seasonal fluctuations in pricing and currency exchange rates, which can affect costs, especially in international transactions.

Conclusion: Understanding Pricing Nuances for Plug Tip Sourcing

Navigating the complexities of plug tip sourcing requires a comprehensive understanding of cost components, price influencers, and effective negotiation strategies. By being informed and strategic, buyers can optimize their sourcing decisions, ensuring they achieve both quality and cost-efficiency. As prices can vary significantly based on multiple factors, it’s advisable to seek quotes from various suppliers and consider all aspects of the purchasing process before making decisions.

Illustrative image related to plug tip

Alternatives Analysis: Comparing plug tip With Other Solutions

Exploring Alternatives to Plug Tips in Industrial Applications

In the realm of industrial applications, particularly those involving engine performance and electrical connectivity, businesses often seek efficient solutions to common challenges. Plug tips, while effective, are not the only option available. This section will compare plug tips with two viable alternatives: TeeJet Plug Tips and Tip Plugs & Jacks. Understanding these options can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Plug Tip | TeeJet Plug Tips | Tip Plugs & Jacks |

|---|---|---|---|

| Performance | High reliability for spark plugs; prevents malfunctions. | Effective for controlling spray from nozzles; versatile. | Suitable for test and measurement; high voltage ratings. |

| Cost | Approximately $8 per unit. | Varies, generally affordable. | Ranges from $0.94 to $11.79 based on specifications. |

| Ease of Implementation | Simple to install; reusable. | Easy to use; requires minimal setup. | Installation can vary; generally straightforward. |

| Maintenance | Low maintenance; durable materials. | Minimal upkeep; replace when damaged. | Regular checks recommended for optimal performance. |

| Best Use Case | Ideal for automotive and racing applications. | Best for agricultural and spraying applications. | Effective for electronic testing and diagnostics. |

What Are the Advantages and Disadvantages of TeeJet Plug Tips?

TeeJet Plug Tips are primarily designed for agricultural equipment, allowing operators to stop spray from exiting specific nozzles. The major advantage of this alternative is its simplicity and effectiveness in managing liquid flow, which is crucial for precision spraying. The cost is generally low, making it an attractive option for farmers or agricultural companies. However, its application is limited to specific contexts, primarily in agriculture, which may not be suitable for all industrial needs.

How Do Tip Plugs & Jacks Compare to Plug Tips?

Tip Plugs & Jacks serve as connectors for test and measurement equipment, providing high voltage capabilities and reliable connections. Their versatility makes them suitable for a wide range of electronic applications, from laboratories to field testing. They are available at various price points, catering to different budget constraints. However, the need for regular maintenance and checks can make them less appealing for users seeking a low-maintenance solution compared to plug tips.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When evaluating the right solution, B2B buyers should consider their specific application requirements, including performance, cost, ease of implementation, and maintenance. For those in automotive or racing contexts, plug tips provide a robust solution to spark plug issues. Conversely, agricultural businesses may benefit more from TeeJet Plug Tips, while electronics and testing labs could find Tip Plugs & Jacks more aligned with their operational needs. Ultimately, understanding the unique demands of your industry will guide the decision-making process, ensuring that the chosen solution delivers optimal results and value.

Essential Technical Properties and Trade Terminology for plug tip

Understanding the technical properties and terminology associated with plug tips is crucial for B2B buyers in various sectors, including automotive, electronics, and agriculture. This knowledge can enhance purchasing decisions, facilitate smoother transactions, and ensure the right products are selected for specific applications.

What Are the Key Technical Properties of Plug Tips?

1. Material Composition

Plug tips are commonly made from materials such as thermoplastic elastomers, rubber, or metals. The choice of material affects durability, flexibility, and resistance to environmental factors. For example, thermoplastic elastomers provide excellent weather resistance, making them suitable for outdoor applications. Buyers should assess the application requirements to select the appropriate material that will ensure longevity and performance.

2. Electrical Ratings

This specification includes voltage and current ratings, crucial for ensuring safe and effective performance in electrical applications. For instance, a plug tip rated for 10A and 250V is suitable for specific electrical loads. Understanding these ratings helps prevent electrical failures and enhances safety in operational environments.

Illustrative image related to plug tip

3. Connector Size and Compatibility

Plug tips come in various sizes, typically defined by their diameter (e.g., 2mm, 4mm). The size must match the corresponding socket or connector to ensure proper fit and functionality. Buyers should verify compatibility with existing systems to avoid costly misfits, especially in bulk orders.

4. Breakdown Voltage

This property indicates the maximum voltage a plug tip can withstand before failing. A higher breakdown voltage is essential for applications involving high voltage systems. Understanding this parameter helps buyers select products that can safely operate under specific electrical conditions without risking failure.

5. Tolerance Specifications

Tolerance refers to the allowable deviation from a specified measurement, which is critical for ensuring compatibility and performance. For example, a tolerance of ±0.1mm on a plug tip can significantly impact its fit in a connector. Ensuring tight tolerances is vital in precision applications, particularly in electronics and automotive sectors.

6. RoHS Compliance

RoHS (Restriction of Hazardous Substances) compliance indicates that a product meets environmental safety standards by limiting hazardous materials. This specification is increasingly important for B2B buyers focused on sustainability and regulatory compliance. Ensuring that plug tips are RoHS compliant can enhance a company’s reputation and reduce liability.

What Are Common Trade Terms Associated with Plug Tips?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s products. Understanding OEM relationships can be beneficial for buyers seeking reliable sources for plug tips that meet specific design requirements.

Illustrative image related to plug tip

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management. Buyers should consider their consumption rates when negotiating MOQs to avoid excess stock or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is an essential tool for buyers to obtain competitive pricing for plug tips and to clarify specifications before making purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is critical for buyers to manage shipping costs and risks effectively.

5. Lead Time

Lead time refers to the period from placing an order to receiving the goods. Knowing the lead time for plug tips can help buyers plan their inventory and production schedules more effectively, ensuring they have the necessary components on hand when needed.

6. Certification

Certification indicates that a product meets certain industry standards or regulations. For plug tips, certifications such as UL (Underwriters Laboratories) can assure buyers of product safety and reliability, making it a key consideration in purchasing decisions.

By understanding these properties and terms, B2B buyers can navigate the complexities of sourcing plug tips more effectively, ensuring they select the right products for their specific needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the plug tip Sector

Market Overview & Key Trends: What Are the Current Dynamics Influencing the Plug Tip Sector?

The plug tip sector is experiencing notable transformations driven by various global market dynamics. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable sources, they are influenced by factors like technological advancements and evolving consumer demands. One major trend is the increasing demand for reusable and efficient plug tips, which minimize waste and enhance performance. Products like the reusable spark plug tip insert exemplify this trend, allowing users to replace only the necessary components rather than the entire plug, thereby reducing costs and material usage.

Furthermore, the integration of digital technologies in sourcing processes is reshaping market dynamics. E-commerce platforms and digital supply chain management systems are facilitating smoother transactions and enhancing supplier visibility. Buyers are increasingly relying on data analytics to assess supplier performance, optimize procurement strategies, and mitigate risks associated with supply chain disruptions. Additionally, as global trade regulations evolve, international buyers must stay informed about tariffs, compliance requirements, and regional standards, particularly when sourcing from emerging markets.

Emerging markets in Africa and South America are becoming significant players in the plug tip industry. Countries like Nigeria and Brazil are witnessing increased investments in manufacturing capabilities, which can lead to cost-effective sourcing options for international buyers. As these regions enhance their production capabilities, there is a growing opportunity for buyers to capitalize on local suppliers who can offer competitive pricing and quicker turnaround times.

Illustrative image related to plug tip

Sustainability & Ethical Sourcing in B2B: How Are Environmental Concerns Shaping Plug Tip Procurement?

Sustainability is becoming a crucial consideration for B2B buyers in the plug tip sector. The environmental impact of manufacturing processes, coupled with increasing regulatory pressures, is prompting companies to seek ethically sourced materials. Buyers are now evaluating suppliers based on their sustainability practices, including the use of eco-friendly materials and adherence to ethical labor practices.

Green certifications and materials are gaining traction in the plug tip industry. Suppliers that offer products with certifications such as ISO 14001 (Environmental Management) or those that utilize recycled materials are more likely to attract conscientious buyers. For instance, plug tips made from sustainable plastics or those that have a lower carbon footprint during production are increasingly favored. By prioritizing suppliers who demonstrate a commitment to sustainability, businesses can not only enhance their brand reputation but also contribute to a more sustainable supply chain.

Moreover, the demand for transparency in supply chains is rising. Buyers are increasingly interested in understanding the sourcing and manufacturing processes behind the products they purchase. This shift is driving suppliers to provide detailed information about their operations, materials used, and the environmental impact of their products, fostering trust and loyalty among B2B partners.

Illustrative image related to plug tip

Brief Evolution/History of the Plug Tip Sector: What Key Developments Have Shaped Its Current Landscape?

The plug tip sector has evolved significantly over the years, driven by advancements in technology and changing consumer needs. Initially, plug tips were primarily designed for specific applications, such as automotive and agricultural machinery. However, with the rise of precision engineering and increased performance expectations, manufacturers began to innovate, leading to the development of specialized plug tips that cater to diverse industries.

In recent decades, the focus has shifted toward enhancing efficiency and sustainability. The introduction of reusable plug tips, like those used in spark plugs and TeeJet nozzles, reflects this trend. As industries face mounting pressure to reduce waste and improve operational efficiency, the evolution of plug tips continues to be influenced by the demand for innovative solutions that align with sustainability goals and operational requirements. This historical context is crucial for B2B buyers looking to understand the product landscape and make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of plug tip

-

How do I solve spark plug malfunctions caused by dislodged electrodes?

To address spark plug malfunctions, consider using reusable spark plug tip inserts. These inserts can replace existing terminals on spark plugs, preventing dislodged electrodes that lead to engine damage. They are specifically designed for certain plug models, such as the NGK R6061. Ensure compatibility by confirming the specific plug model you use before purchase. If your plugs are compatible, simply remove the insert from the old plugs and install it in the new ones, providing a reliable solution for your engine’s performance. -

What is the best type of plug tip for agricultural spray nozzles?

For agricultural applications, TeeJet plug tips are ideal as they can effectively stop spray from exiting a nozzle. These plug tips are versatile and can be used in place of standard TeeJet nozzles, making them a valuable addition to your agricultural equipment. When selecting a plug tip, consider the specific requirements of your spraying application, such as flow rate and nozzle compatibility, to ensure optimal performance. -

How can I ensure the quality of plug tips when sourcing internationally?

To ensure quality, it is crucial to vet potential suppliers rigorously. Look for suppliers who provide certifications such as ISO or RoHS compliance, which indicate adherence to international quality standards. Request product samples before placing large orders to assess their quality firsthand. Additionally, leverage platforms that offer buyer protection and reviews to gauge supplier reliability. Establish clear quality assurance protocols and communicate your standards to suppliers to maintain consistent product quality. -

What are common minimum order quantities (MOQs) for plug tips?

Minimum order quantities for plug tips vary significantly by supplier and product type. Generally, MOQs can range from as low as 10 units to several hundred, depending on the manufacturer and the specific type of plug tip. When negotiating with suppliers, inquire about bulk pricing options, as larger orders often lead to better pricing and terms. It’s also advisable to confirm whether the MOQ includes various types of plug tips or if it must be a single product type. -

What payment terms should I expect when purchasing plug tips from international suppliers?

Payment terms can vary widely based on the supplier’s policies and the nature of the transaction. Common terms include payment in advance, a 30-50% deposit with the balance due upon shipment, or net 30 days after delivery. It is essential to clarify these terms before finalizing your order. Consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially when dealing with new suppliers. -

How do logistics impact the delivery of plug tips?

Logistics play a critical role in the timely delivery of plug tips, especially for international shipments. Factors such as shipping method, customs clearance, and local transportation can affect delivery times. Work with suppliers who have experience in international shipping to navigate customs regulations effectively. Additionally, consider using freight forwarders to streamline the logistics process and mitigate potential delays caused by unforeseen circumstances. -

Can I customize plug tips to meet specific requirements?

Yes, many suppliers offer customization options for plug tips, allowing you to tailor products to your specific needs. This may include alterations in size, material, or functionality to better suit your applications. When discussing customization, provide detailed specifications and requirements to your supplier. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly. -

What should I consider when evaluating potential suppliers for plug tips?

When evaluating suppliers, consider their industry experience, product range, and customer service. Look for suppliers who have a proven track record in manufacturing plug tips and can provide references or case studies. Additionally, assess their responsiveness to inquiries, willingness to provide samples, and flexibility in terms of customization and MOQs. Establishing a good relationship with your supplier can lead to better communication and more favorable terms in future transactions.

Top 3 Plug Tip Manufacturers & Suppliers List

1. Proline Racing – PLR Spark Plug Tip Insert

Domain: prolineracing.net

Registered: 2009 (16 years)

Introduction: PLR Spark Plug Tip Insert – Reusable; Price: $8.00; Provides a reliable solution for avoiding spark plug malfunctions and engine damage caused by dislodged electrodes; Easily replaces existing terminals on plugs and can be reused; Designed for NGK R6061 plug; Sold individually, services one spark plug; Instructions available for download.

2. Newark – Tip Plugs & Jacks

Domain: newark.com

Registered: 1994 (31 years)

Introduction: This company, Newark – Tip Plugs & Jacks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Iridium Spark Plugs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Iridium Spark Plugs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for plug tip

How Can Strategic Sourcing Enhance Your Plug Tip Procurement?

In conclusion, strategic sourcing plays a pivotal role in ensuring that businesses effectively procure plug tips, catering to diverse operational needs while minimizing risks associated with product quality and supply chain disruptions. By understanding the specific requirements of different applications—from automotive to electronic testing—buyers can identify the most reliable suppliers and negotiate better terms.

Moreover, leveraging reusable solutions, such as the PLR Spark Plug Tip Insert, can lead to significant cost savings and sustainability benefits. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe engage in strategic sourcing, it is essential to evaluate suppliers not only on price but also on their ability to deliver consistent quality and support.

Illustrative image related to plug tip

Looking ahead, the demand for high-performance and reliable plug tips is expected to rise, driven by advancements in technology and increasing industrial applications. To remain competitive, businesses should proactively seek partnerships with suppliers who are committed to innovation and quality assurance. Embrace strategic sourcing today to secure a resilient supply chain and drive your business forward in a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.