Playground Merry Go Round For Sale: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for playground merry go round for sale

In the dynamic world of playground equipment, sourcing high-quality merry-go-rounds that meet safety standards and accommodate diverse needs can pose a significant challenge for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, navigating the complexities of product specifications, supplier reliability, and regional compliance requires a comprehensive understanding of the market. This guide serves as an essential resource, detailing the various types of playground merry-go-rounds available, their applications across different environments, and critical factors to consider when making a purchase.

From traditional models to innovative designs, we explore the diverse offerings in the merry-go-round category, ensuring you can find options that not only enhance play experiences but also foster inclusivity with wheelchair-accessible features. Additionally, we provide insights into supplier vetting processes, helping you identify reputable manufacturers that adhere to quality and safety standards. Cost considerations are also addressed, offering transparency on pricing structures, enabling you to make informed budgetary decisions.

By equipping yourself with the knowledge presented in this guide, you can confidently navigate the global marketplace for playground merry-go-rounds, ensuring your investment contributes positively to child development and community engagement. Whether you’re a school administrator, park planner, or distributor, this guide empowers you to make strategic purchasing decisions that benefit your organization and the children you serve.

Understanding playground merry go round for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Merry-Go-Round | Circular design, typically accommodates multiple children | Schools, parks, community centers | Pros: Encourages group play; Cons: Requires significant space |

| Wheelchair Accessible Merry-Go-Round | Designed for inclusivity, allowing wheelchair access | Inclusive playgrounds, special needs facilities | Pros: Promotes inclusivity; Cons: Higher initial investment |

| Mini Merry-Go-Round | Smaller diameter, suitable for younger children | Daycares, early childhood education centers | Pros: Space-efficient; Cons: Limited capacity for older children |

| Spinner or Rotator | Spins with a disc-like design, often with a central pivot | Adventure parks, recreational facilities | Pros: Engaging and dynamic play; Cons: May require more maintenance |

| Themed Merry-Go-Round | Custom designs based on themes (e.g., animals, space) | Themed parks, private play areas | Pros: Unique attraction; Cons: Potentially higher costs and longer lead times |

What Are the Characteristics of Traditional Merry-Go-Rounds?

Traditional merry-go-rounds are circular playground equipment designed to accommodate several children at once. They are often constructed from durable materials to withstand heavy use and come in various sizes, typically ranging from 6 to 10 feet in diameter. Suitable for schools and parks, these merry-go-rounds foster cooperative play and social interaction among children. When considering a purchase, buyers should evaluate the available space, safety surfacing requirements, and maintenance needs.

How Do Wheelchair Accessible Merry-Go-Rounds Promote Inclusivity?

Wheelchair accessible merry-go-rounds are specifically designed to allow children with mobility challenges to participate in play alongside their peers. These models feature a flat platform or ramp that accommodates wheelchairs, ensuring that all children can enjoy the spinning experience. B2B buyers should prioritize these models when creating inclusive playgrounds, particularly in schools and special needs facilities. While the initial investment may be higher, the long-term benefits of inclusivity and enhanced community engagement are substantial.

What Makes Mini Merry-Go-Rounds Ideal for Early Childhood Settings?

Mini merry-go-rounds are smaller in diameter and designed primarily for younger children, making them a perfect fit for daycares and early childhood education centers. Their compact size allows for easy integration into smaller play areas while ensuring safe play. When purchasing, B2B buyers should consider the age group of the intended users, as these units may not be suitable for older children. Their affordability and space-efficient design are key selling points for institutions with limited outdoor space.

Why Choose Spinners or Rotators for Dynamic Play Experiences?

Spinners or rotators offer a unique twist on traditional merry-go-rounds, featuring a disc-like design that spins around a central pivot. These playground elements provide children with an engaging and dynamic play experience, promoting physical activity and coordination. Ideal for adventure parks and recreational facilities, buyers should consider maintenance requirements and safety standards, as these models often require more frequent upkeep due to their moving parts. Their ability to attract and engage children makes them a valuable addition to any play area.

How Do Themed Merry-Go-Rounds Enhance Playground Appeal?

Themed merry-go-rounds are customized playground equipment that can be designed around specific motifs, such as animals, vehicles, or fantasy themes. These models serve as unique attractions that can enhance the overall appeal of a playground, particularly in themed parks and private play areas. B2B buyers should weigh the potential for increased foot traffic against the higher costs and longer lead times associated with custom designs. The investment in themed equipment can result in a distinctive play experience that sets a facility apart from competitors.

Key Industrial Applications of playground merry go round for sale

| Industry/Sector | Specific Application of playground merry go round for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Playground equipment for schools and educational institutions | Enhances physical activity and social skills among students | Compliance with safety standards; age-appropriate designs |

| Recreation & Leisure | Installation in public parks and recreational facilities | Attracts families, increases foot traffic, and promotes community engagement | Durability against weather conditions; maintenance and support services |

| Childcare & Early Education | Equipment for daycare centers and preschools | Encourages cooperative play, aiding in social development | Size and accessibility for young children; safety surfacing requirements |

| Urban Development & Planning | Integration in urban playgrounds and community spaces | Improves quality of life, promotes healthy lifestyles in communities | Local regulations and safety compliance; aesthetic considerations |

| Hospitality & Tourism | Attractions in family-oriented hotels and resorts | Enhances guest experience, encourages longer stays | Customization options; compliance with international safety standards |

How Are Playground Merry-Go-Rounds Utilized in Educational Settings?

In schools and educational institutions, playground merry-go-rounds serve as crucial tools for promoting physical activity and social interaction among students. They foster cooperation and teamwork, as children must work together to spin the equipment. For international buyers, especially from regions like Africa and South America, sourcing merry-go-rounds that comply with local safety standards is essential. Additionally, buyers should consider age-appropriate designs to cater to various student age groups, ensuring inclusivity and safety.

What Role Do Merry-Go-Rounds Play in Public Parks?

Public parks utilize playground merry-go-rounds to create engaging recreational spaces that attract families and children. These installations enhance community interaction and contribute to healthier lifestyles by encouraging physical activity. For buyers in Europe and the Middle East, durability against harsh weather conditions is a key consideration, alongside the need for regular maintenance and support services to ensure long-term usability.

Why Are Merry-Go-Rounds Important for Daycare Centers?

In daycare centers and preschools, merry-go-rounds are essential for developing social skills and physical coordination in young children. They provide a safe environment for energetic play, which is vital for early childhood development. Buyers should focus on sourcing smaller, age-appropriate models that comply with safety regulations, including requirements for safety surfacing. Accessibility options, such as wheelchair-friendly designs, are also crucial to ensure all children can participate.

How Do Merry-Go-Rounds Enhance Urban Development Projects?

In urban development and planning, merry-go-rounds are integrated into playgrounds and community spaces to enhance the overall quality of life. They contribute to the aesthetic value of neighborhoods while promoting active lifestyles among residents. Buyers should be aware of local regulations regarding safety compliance and aesthetic considerations, as these can vary widely across different regions, including Africa and Europe.

What Benefits Do Merry-Go-Rounds Offer to the Hospitality Sector?

In the hospitality and tourism industry, merry-go-rounds are valuable additions to family-oriented hotels and resorts. They enhance the guest experience by providing entertainment options for children, which can lead to longer stays and increased customer satisfaction. International buyers must consider customization options to align with their brand identity and ensure compliance with international safety standards, which can vary depending on the region.

3 Common User Pain Points for ‘playground merry go round for sale’ & Their Solutions

Scenario 1: Balancing Safety and Fun in Playground Equipment

The Problem:

B2B buyers, especially those responsible for purchasing playground equipment for schools and parks, often grapple with the challenge of ensuring that merry-go-rounds are both fun and safe for children. The fear of liability issues stemming from accidents can lead to hesitance in making a purchase. Additionally, buyers may find it difficult to assess whether the equipment meets safety standards, particularly in regions where regulations can vary significantly.

The Solution:

To address these concerns, it is crucial for buyers to thoroughly research manufacturers and suppliers who prioritize safety in their designs. Look for products that comply with local safety standards, such as the ASTM F1487 for playground equipment. Inquire about features like speed control mechanisms, which can help prevent accidents by limiting how fast the merry-go-round spins. Moreover, consider selecting equipment that includes safety features such as non-slip surfaces and rounded edges. Engaging with suppliers who offer detailed product specifications, safety certifications, and user testimonials can further bolster confidence in your purchase. Conducting site visits to existing installations can also provide insight into how the equipment performs in real-life scenarios.

Scenario 2: Navigating Budget Constraints for Playground Equipment

The Problem:

Many organizations face tight budgets when it comes to purchasing playground equipment. This can be particularly challenging in regions with limited funding for recreational infrastructure, where B2B buyers must balance the need for quality equipment with financial limitations. This often leads to a compromise on safety or durability, which can ultimately impact the user experience and maintenance costs.

The Solution:

Buyers should explore a variety of purchasing strategies to maximize their budget. Consider sourcing from manufacturers that offer a range of price points and financing options. Bulk purchasing can lead to discounts, so collaborating with other institutions or parks in your area might yield better pricing. Additionally, look for equipment that is designed for longevity and requires minimal maintenance; this can significantly reduce long-term costs. Utilizing grants or community fundraising initiatives can also help to supplement the budget. Lastly, investing in versatile equipment, such as multi-functional merry-go-rounds that can accommodate different age groups and abilities, ensures that you get the most value from your investment.

Scenario 3: Ensuring Inclusivity in Playground Design

The Problem:

As playgrounds increasingly aim to be inclusive, B2B buyers often face the challenge of ensuring that their merry-go-round selections cater to children of all abilities. The lack of accessible play equipment can alienate children with disabilities, leading to a less enriching play experience and potential backlash from the community.

The Solution:

When sourcing merry-go-rounds, prioritize suppliers who offer inclusive designs, such as wheelchair-accessible models. These merry-go-rounds should feature lower platforms and safety harnesses to accommodate children with mobility challenges. Engage with community stakeholders, including parents of children with disabilities, to gather insights on their needs and preferences. Furthermore, consider integrating educational resources or training for staff on how to facilitate inclusive play. This not only enhances the playground experience but also fosters a sense of community and belonging. By actively promoting inclusive play, buyers can create a welcoming environment that encourages social interaction among all children, enhancing the overall value of the playground.

Strategic Material Selection Guide for playground merry go round for sale

What Are the Common Materials Used in Playground Merry-Go-Rounds?

When selecting materials for playground merry-go-rounds, it’s essential to consider durability, safety, and maintenance needs. Here, we analyze four common materials: steel, aluminum, plastic, and composite materials, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform in Playground Merry-Go-Round Applications?

Steel is a widely used material in playground equipment due to its strength and durability. It has excellent temperature resistance and can withstand significant pressure, making it suitable for high-traffic playgrounds. Steel’s corrosion resistance can be enhanced through galvanization or powder coating, which is vital for outdoor applications.

Pros: Steel is highly durable and can support heavy loads, making it ideal for larger merry-go-rounds designed for older children. Its longevity reduces the need for frequent replacements.

Cons: The initial cost of steel can be high, and it may require regular maintenance to prevent rust, especially in humid or coastal environments. Additionally, manufacturing complexity can increase due to the need for welding and finishing processes.

Impact on Application: Steel merry-go-rounds are robust and can handle various environmental conditions, but buyers must ensure that the coating is appropriate for their local climate.

Considerations for International Buyers: Compliance with standards like ASTM or EN (European Norms) is crucial. Buyers from regions like Africa and the Middle East should also consider local environmental factors that may affect maintenance.

What Are the Benefits of Using Aluminum in Merry-Go-Round Construction?

Aluminum is another popular choice for playground merry-go-rounds, known for its lightweight properties and natural corrosion resistance. It performs well in various temperatures and does not rust, making it suitable for diverse climates.

Pros: The lightweight nature of aluminum allows for easier installation and relocation of playground equipment. It also requires less maintenance compared to steel.

Cons: While aluminum is resistant to corrosion, it is not as strong as steel, which may limit its use in larger installations. The cost can also be relatively high compared to other materials.

Impact on Application: Aluminum merry-go-rounds are ideal for smaller playgrounds or those intended for younger children, as they are easier to spin and manage.

Considerations for International Buyers: Compliance with safety standards is essential, and buyers should verify that the aluminum used meets specific quality certifications relevant to their region.

Why Choose Plastic for Playground Merry-Go-Round Equipment?

Plastic is increasingly used in playground equipment due to its versatility and safety features. It is often used in the construction of components such as seats and bases.

Pros: Plastic is lightweight, resistant to UV rays, and does not corrode, making it an excellent choice for outdoor use. It is also available in various colors, enhancing aesthetic appeal.

Cons: While plastic is durable, it can be less robust than metal options and may not withstand heavy loads over time. Additionally, it may become brittle in extreme temperatures.

Impact on Application: Plastic merry-go-rounds are suitable for younger children and can be designed to be more colorful and engaging.

Considerations for International Buyers: Buyers should ensure that the plastic used is compliant with safety regulations and does not contain harmful chemicals, especially in regions with strict safety standards.

What Advantages Do Composite Materials Offer for Merry-Go-Round Design?

Composite materials, which combine plastic with other materials, offer a balance between durability and weight. They are designed to mimic the qualities of wood or metal while providing enhanced resistance to environmental factors.

Pros: Composites are highly durable, resistant to rot and corrosion, and require minimal maintenance. They can also be molded into various shapes, allowing for creative designs.

Cons: The manufacturing process can be complex, leading to higher costs. Additionally, not all composites are created equal, so quality can vary significantly.

Impact on Application: Composite merry-go-rounds are suitable for innovative designs and can cater to various age groups, making them versatile for different playground settings.

Considerations for International Buyers: It’s crucial to verify that composite materials meet local safety and environmental standards, as regulations can vary widely.

Summary Table of Material Selection for Merry-Go-Rounds

| Material | Typical Use Case for playground merry go round for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Large playgrounds, high-traffic areas | Exceptional durability and strength | High cost, requires maintenance | High |

| Aluminum | Smaller playgrounds, installations for younger children | Lightweight, low maintenance | Less strength compared to steel | Medium |

| Plastic | Playgrounds for younger children | UV resistant, colorful options | Less robust, can become brittle | Low |

| Composite | Innovative designs, versatile applications | Durable, low maintenance | Higher manufacturing complexity | Medium |

This comprehensive analysis provides B2B buyers with essential insights into material selection for playground merry-go-rounds, ensuring informed purchasing decisions that meet safety, durability, and aesthetic requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for playground merry go round for sale

What Are the Key Stages in the Manufacturing Process of Playground Merry-Go-Rounds?

The manufacturing process for playground merry-go-rounds involves several critical stages, each designed to ensure that the final product is not only safe but also durable and appealing to children. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials, typically involving galvanized steel for the frame and durable plastics or rubber for components that require flexibility or cushioning. Materials must be sourced from reliable suppliers who meet international standards for safety and sustainability.

-

Forming: In this stage, raw materials are shaped into the desired components. Techniques such as CNC machining or laser cutting are often employed to ensure precision in creating parts like the base, seats, and handrails. This stage may also include bending and welding processes to create a sturdy structure.

-

Assembly: Once the individual components are formed, they are assembled into the final product. This stage involves not only the physical joining of parts but also the installation of safety features such as governors that control spinning speed. Attention to detail is critical, as improper assembly can lead to safety hazards.

-

Finishing: The final stage involves applying protective coatings and finishes. Powder coating is commonly used for metal components to prevent rust and enhance aesthetics. This process also includes the application of any decals or branding, ensuring that the merry-go-round is visually appealing and weather-resistant.

What Quality Assurance Measures Are Implemented During Manufacturing?

Quality assurance (QA) is vital in the manufacturing of playground equipment, as it ensures that products meet safety standards and are built to last. Several international and industry-specific standards guide the QA process.

-

International Standards Compliance: Manufacturers often adhere to ISO 9001, which outlines criteria for a quality management system. This certification demonstrates a commitment to continuous improvement and customer satisfaction.

-

Industry-Specific Standards: In addition to ISO standards, playground equipment must comply with safety certifications like CE marking in Europe and ASTM standards in the USA. These certifications ensure that the equipment meets specific safety and performance criteria.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before production begins.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor quality and adherence to standards.

– Final Quality Control (FQC): Once the product is fully assembled, it undergoes a final inspection to verify that it meets all design and safety standards before shipping.

How Do Manufacturers Test Playground Merry-Go-Rounds for Safety and Durability?

Testing is a crucial aspect of the quality assurance process. Manufacturers employ various testing methods to ensure that merry-go-rounds are safe for use by children.

-

Load Testing: This involves applying weight to the merry-go-round to simulate the maximum load it will encounter during use. This test helps identify any structural weaknesses that could lead to failure.

-

Spin Tests: Merry-go-rounds are subjected to rigorous spinning tests to evaluate their stability and the effectiveness of safety features like speed governors.

-

Durability Testing: This includes exposure to environmental factors such as UV light, temperature fluctuations, and moisture to ensure that materials do not degrade over time.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to ensure that the products meet safety and quality standards.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. This can include reviewing documentation of their quality management system and observing their production practices.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can help buyers understand how the manufacturing process aligns with international standards. These reports should include results from load tests, durability tests, and compliance with safety certifications.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These organizations can perform inspections at various stages of production and provide certification that the products meet required standards.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers must consider several nuances when it comes to quality control for playground equipment.

-

Regulatory Differences: Different countries have varying regulations regarding playground equipment safety. Buyers should be aware of local regulations in their respective markets to ensure compliance.

-

Cultural Expectations: In regions such as Africa and South America, there may be specific cultural considerations regarding safety and play equipment. Understanding these expectations can help buyers select products that are not only compliant but also culturally appropriate.

-

Shipping and Handling: The transportation of playground equipment can pose risks of damage. Buyers should ensure that suppliers have robust packaging and handling procedures in place to minimize potential damage during transit.

Conclusion: Why Is Quality Assurance Essential for Playground Merry-Go-Rounds?

In summary, the manufacturing process for playground merry-go-rounds encompasses a series of stages that prioritize safety, durability, and enjoyment for children. Implementing rigorous quality control measures and adhering to international standards ensures that these products are reliable and safe. For B2B buyers, understanding and verifying these processes is crucial for making informed purchasing decisions that will ultimately enhance the play experience for children worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘playground merry go round for sale’

In the competitive landscape of playground equipment procurement, specifically for merry-go-rounds, it is essential to follow a structured approach to ensure that you select the best option for your project. This guide provides a step-by-step checklist to assist B2B buyers in making informed decisions when sourcing playground merry-go-rounds.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for aligning your requirements with available products. Consider factors such as the age range of children using the equipment, weight capacity, and safety features. Additionally, specify the dimensions and design style that best fit your playground’s aesthetic and functional needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to create a list of potential suppliers. Look for companies that specialize in playground equipment and have a proven track record in your region. Pay attention to their product range, customer reviews, and industry reputation, as these factors can significantly influence the quality and reliability of your purchase.

Step 3: Evaluate Supplier Certifications and Compliance

Before proceeding with a supplier, verify their certifications and compliance with international safety standards. Ensure that the merry-go-rounds meet relevant safety regulations, such as ASTM and EN standards. This step is crucial to guarantee that the equipment is safe for children and minimizes liability risks for your organization.

Step 4: Request Product Samples and Specifications

Once you’ve shortlisted suppliers, request detailed product specifications and samples where possible. Assess the materials used, durability, and overall construction quality. This hands-on evaluation will help you determine whether the merry-go-rounds can withstand the rigors of outdoor play and remain safe over time.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing effectively. Be wary of the cheapest option, as it may compromise quality. Look for transparency in pricing, including additional costs such as shipping, installation, and warranties. Understanding payment terms can also help you manage cash flow and budget effectively.

Step 6: Check Customer Support and Warranty Policies

A reliable supplier should offer robust customer support and clear warranty policies. Inquire about post-purchase services, including maintenance, repairs, and replacement parts. A solid warranty will protect your investment and provide peace of mind, ensuring that you are covered in the event of defects or issues.

Step 7: Confirm Delivery and Installation Options

Finally, confirm the delivery timelines and installation services offered by the supplier. Efficient delivery and professional installation are essential to minimize downtime and ensure that the merry-go-rounds are set up correctly. Discuss logistics, including any site preparation requirements, to avoid unexpected delays.

By following this structured checklist, B2B buyers can navigate the procurement process for playground merry-go-rounds with confidence, ensuring that they select the best products that meet safety standards and project requirements.

Comprehensive Cost and Pricing Analysis for playground merry go round for sale Sourcing

When considering the procurement of playground merry-go-rounds, international B2B buyers must navigate a complex cost structure and pricing landscape. Understanding the various components and influencers of pricing can lead to more informed purchasing decisions.

What Are the Key Cost Components for Playground Merry-Go-Rounds?

-

Materials: The primary materials used in manufacturing merry-go-rounds include high-grade steel, plastic, and rubber for safety mats. The choice of materials affects durability and safety, with higher-quality materials typically resulting in higher costs.

-

Labor: Labor costs encompass wages for skilled workers involved in the assembly and finishing processes. In regions with higher labor costs, such as parts of Europe, the overall price may be elevated compared to regions with lower labor rates.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities and maintenance. Efficient manufacturing processes can help keep these costs down, influencing the final price offered to buyers.

-

Tooling: Custom tooling for unique designs or specifications can significantly increase initial costs. Buyers should weigh the need for customization against standard offerings to determine cost-effectiveness.

-

Quality Control (QC): Rigorous QC processes ensure that the equipment meets safety standards, especially important for playground equipment. Enhanced QC measures may add to the overall cost but provide peace of mind regarding safety and compliance.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer to the buyer, shipping methods, and any additional handling required for large, heavy items like merry-go-rounds. Buyers should also consider potential import duties and taxes.

-

Margin: Suppliers typically include a profit margin that reflects their market position and perceived value. Understanding the market can help buyers gauge whether the margin is reasonable.

How Do Price Influencers Affect the Cost of Playground Merry-Go-Rounds?

-

Volume/MOQ: Minimum Order Quantities (MOQ) can impact pricing; larger orders often lead to better per-unit pricing. Buyers should assess their needs against potential discounts for bulk purchases.

-

Specifications and Customization: Custom designs or specific color schemes can increase costs. Buyers should evaluate whether the added expense aligns with their project goals.

-

Materials and Quality Certifications: Equipment that meets international safety standards or certifications may come at a premium. This is particularly relevant for buyers in regions with strict compliance requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established brands may charge more but offer warranties and better support, which can be beneficial in the long run.

-

Incoterms: Understanding shipping terms can help buyers manage costs. For instance, “FOB” (Free on Board) shipping may require buyers to handle shipping logistics, potentially increasing overall expenses.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

-

Negotiation: Engage in open discussions with suppliers regarding pricing, especially for larger orders. Many suppliers are willing to negotiate terms and conditions to secure a deal.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, operational costs, and potential downtime. Selecting higher-quality equipment may lead to lower long-term costs.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local market conditions, and regional demand, which can affect pricing.

-

Market Research: Conduct thorough research on various suppliers and their offerings. This can provide insights into competitive pricing and help identify the best value options.

Conclusion

While indicative prices for playground merry-go-rounds can range from approximately $1,500 to over $15,000 depending on specifications, quality, and supplier, it is crucial for B2B buyers to analyze the comprehensive cost structure and pricing influencers thoroughly. By doing so, they can ensure they make informed purchasing decisions that align with their needs and budget constraints.

Alternatives Analysis: Comparing playground merry go round for sale With Other Solutions

Understanding Alternatives to Playground Merry Go Rounds for Sale

When considering playground equipment, especially merry-go-rounds, it’s crucial to explore various options that serve similar purposes. These alternatives can provide different play experiences, accommodate various age groups, and meet specific safety and budgetary requirements. This analysis will compare playground merry-go-rounds with two viable alternatives: spinning disks and climbing structures.

Comparison Table

| Comparison Aspect | Playground Merry Go Round For Sale | Spinning Disk | Climbing Structure |

|---|---|---|---|

| Performance | High engagement for cooperative play | Moderate engagement, encourages individual play | High physical engagement and skill development |

| Cost | $1,900 – $15,000 | $500 – $5,000 | $1,500 – $20,000 |

| Ease of Implementation | Moderate; requires space and safety surfacing | Easy; minimal space and surfacing needed | Moderate; requires structural installation and safety measures |

| Maintenance | Moderate; regular checks needed for wear and tear | Low; generally requires minimal upkeep | High; requires regular inspections for safety and integrity |

| Best Use Case | Ideal for group play in parks and schools | Suitable for smaller play areas or home backyards | Great for developing physical skills in school or community playgrounds |

What Are the Benefits and Drawbacks of Spinning Disks?

Spinning disks are a popular alternative to traditional merry-go-rounds. They offer a fun, spinning experience that can be enjoyed by one or more children. The primary advantage is their lower cost and simpler installation requirements, making them ideal for smaller playgrounds or residential settings. However, the engagement level is typically lower compared to merry-go-rounds, as they do not promote the same level of cooperative play. Moreover, they may not be as appealing for larger groups of children, which can limit their use in community or school settings.

How Do Climbing Structures Compare to Merry Go Rounds?

Climbing structures present another alternative, providing children with opportunities to develop physical skills such as balance, strength, and coordination. These structures can accommodate many children simultaneously, making them suitable for larger playgrounds. However, they often come with higher costs and maintenance requirements, as regular inspections are necessary to ensure safety. Climbing structures can also require more extensive space and planning to meet safety regulations. While they encourage physical activity, they do not replicate the spinning and cooperative play that merry-go-rounds offer.

Making the Right Choice for Your Playground Needs

When choosing between playground merry-go-rounds and their alternatives, B2B buyers should consider several factors, including the target age group, budget constraints, and the intended play experience. Merry-go-rounds excel in fostering cooperative play and are suited for larger groups, making them ideal for schools and parks. In contrast, spinning disks may be more appropriate for smaller spaces or budget-conscious projects, while climbing structures cater to those focused on physical development and skill-building. By carefully evaluating these options against specific project needs, buyers can make informed decisions that enhance play experiences and ensure safety for children.

Essential Technical Properties and Trade Terminology for playground merry go round for sale

What Are the Key Technical Properties of Playground Merry-Go-Rounds?

When considering playground merry-go-rounds for commercial applications, understanding their technical properties is crucial. Here are some of the critical specifications that B2B buyers should evaluate:

-

Material Grade

The materials used in the construction of merry-go-rounds often include high-grade stainless steel, galvanized steel, or heavy-duty plastic. These materials enhance durability and resistance to weather, corrosion, and wear. For B2B buyers, selecting the right material is essential for ensuring long-term use and safety, especially in outdoor environments. -

Diameter and Capacity

Merry-go-rounds are available in various diameters, typically ranging from 6 to 12 feet, with some models specifically designed for younger children or wheelchair accessibility. The capacity, usually defined by the number of children it can accommodate safely, is also a vital specification. This information helps buyers determine the suitability of the equipment for their target demographic, whether for schools, parks, or community centers. -

Safety Standards Compliance

Commercial playground equipment must adhere to specific safety standards, such as those outlined by ASTM (American Society for Testing and Materials) or EN1176 (European standards). Compliance with these regulations is critical for minimizing liability and ensuring the safety of children during play. B2B buyers should confirm that the products they consider have the necessary certifications. -

Installation Requirements

The installation process for merry-go-rounds can vary based on the design and complexity. Some models may require additional safety surfacing or specific anchoring methods. Understanding the installation requirements helps buyers budget for additional costs and ensure that the equipment is set up correctly for safe use. -

Maintenance Features

Merry-go-rounds should include features that simplify maintenance, such as grease fittings for bearings or rust-resistant coatings. Regular maintenance is essential for prolonging the life of playground equipment and ensuring safety. B2B buyers should inquire about these features to avoid future operational disruptions. -

Weight Limit

Many merry-go-rounds come with specified weight limits to ensure safety during play. This information is essential for buyers to understand how many children can play on the equipment at once and to ensure that it accommodates the intended user group.

What Are Common Trade Terms Related to Playground Merry-Go-Rounds?

Understanding industry-specific terminology can streamline the purchasing process and enhance negotiations. Here are some common trade terms relevant to playground merry-go-rounds:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the playground equipment industry, knowing the OEM can help buyers assess the quality and reputation of the merry-go-rounds they are considering. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers, especially those operating on tight budgets or looking to test a new product line without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document that potential buyers send to suppliers to request pricing, specifications, and terms for a specific product or service. Submitting an RFQ for merry-go-rounds allows buyers to compare offers from multiple suppliers, ensuring they find the best deal. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers, particularly when sourcing products from international suppliers, to ensure clarity in transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for B2B buyers to plan their projects and installations effectively, especially in areas where playground demand is high. -

Warranty and Guarantee

These terms refer to the manufacturer’s promise regarding the quality and performance of the merry-go-round. Knowing the warranty details helps buyers evaluate the long-term value and reliability of their investment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing playground merry-go-rounds, ensuring they meet the needs of their communities while adhering to safety and quality standards.

Navigating Market Dynamics and Sourcing Trends in the playground merry go round for sale Sector

What Are the Key Trends Influencing the Playground Merry-Go-Round Market?

The global playground equipment market, particularly the merry-go-round segment, is driven by increasing investments in public parks, schools, and recreational facilities. This trend is particularly prominent in developing regions like Africa and South America, where there is a growing recognition of the importance of outdoor play in child development. In Europe, especially in countries like Germany, there is a push towards modernizing existing playgrounds with innovative designs that enhance safety and inclusivity.

Emerging technologies in manufacturing are also transforming the sourcing landscape. For instance, 3D printing and advanced materials are enabling manufacturers to create custom designs and reduce lead times significantly. Moreover, the integration of smart technology in playground equipment—such as interactive merry-go-rounds that promote learning through play—is becoming increasingly popular.

International B2B buyers should also note the importance of safety standards and certifications, which vary by region. Understanding these regulations is crucial for compliance and ensuring the longevity of the equipment. Additionally, the rise of online marketplaces has simplified sourcing processes, allowing buyers from different regions to compare prices and specifications easily.

How Can Sustainability and Ethical Sourcing Impact Your Purchasing Decisions?

Sustainability has emerged as a pivotal factor in the playground equipment sector, with an increasing number of manufacturers adopting eco-friendly practices. The environmental impact of sourcing materials for playground merry-go-rounds is significant; thus, many companies are turning to recycled materials and sustainably sourced wood. This shift not only reduces the carbon footprint but also appeals to socially conscious buyers who prioritize ethical sourcing.

B2B buyers should look for certifications such as Forest Stewardship Council (FSC) for wood products or Green Seal for overall sustainability. These certifications ensure that the materials used are sourced responsibly and have a lower environmental impact. Additionally, many manufacturers are now focusing on lifecycle assessments to ensure that their products can be recycled or repurposed at the end of their life cycle.

Ethical supply chains are becoming a significant concern for international buyers, particularly in regions where labor practices may vary. Engaging with suppliers that maintain transparency in their sourcing processes and adhere to fair labor practices can mitigate risks and enhance brand reputation.

What Is the Historical Context of Playground Merry-Go-Rounds in B2B?

The merry-go-round has a rich history that dates back centuries, originally designed as a simple rotating platform for entertainment. Over the years, the design and functionality of merry-go-rounds have evolved dramatically. In the mid-20th century, they became a staple in playgrounds across the globe, often viewed as a symbol of childhood joy and community play.

As playground safety standards began to tighten in the late 20th century, the design of merry-go-rounds was modernized to include safety features such as speed governors and more stable platforms. This evolution not only enhanced safety but also expanded the target market to include inclusive designs, ensuring that children of all abilities can enjoy merry-go-rounds.

Today, the merry-go-round is not just a piece of playground equipment but a vital part of promoting physical activity and social interaction among children, making it an essential consideration for any B2B buyer in the playground equipment market.

Frequently Asked Questions (FAQs) for B2B Buyers of playground merry go round for sale

-

How do I choose the right merry-go-round for my playground project?

Choosing the right merry-go-round involves considering factors such as the age group of children who will use it, the number of users, and the available space in your playground. For younger children, smaller models are suitable, while larger models can accommodate older kids. Additionally, ensure that the merry-go-round complies with safety standards and includes features like wheelchair accessibility, if necessary. Assess color options and materials that fit your project’s aesthetic and durability requirements. -

What are the key safety features to look for in a merry-go-round?

When sourcing a merry-go-round, prioritize safety features such as a low-profile design for easy access, sturdy handrails, and a non-slip surface. Look for models with mechanical speed control devices to prevent excessive spinning. Ensure that the equipment meets local safety regulations and is made from durable, weather-resistant materials. The inclusion of safety surfacing around the merry-go-round is also crucial to minimize injury risks during play. -

What is the typical lead time for ordering playground equipment like merry-go-rounds?

Lead times can vary based on the supplier, customization options, and order volume. Generally, standard models may ship within 4-6 weeks, while custom designs could take longer, ranging from 8-12 weeks. It’s advisable to discuss timelines upfront with your supplier and factor in additional time for shipping, especially for international orders. Early planning can help ensure that your playground project meets its opening deadlines. -

What are the minimum order quantities (MOQs) for playground merry-go-rounds?

Minimum order quantities can differ significantly between manufacturers and suppliers. Many companies offer flexible MOQs, especially for larger projects, but some may require a minimum of 5-10 units for bulk pricing. When negotiating, inquire about pricing tiers, as larger orders often yield better per-unit costs. If you’re purchasing for a single location, ask if the supplier can accommodate smaller orders without compromising on pricing. -

How can I vet suppliers for playground equipment?

To vet suppliers, start by reviewing their reputation through customer testimonials and industry reviews. Check for certifications that demonstrate compliance with safety standards, such as ASTM or EN standards. Request references from previous clients and inquire about their experiences regarding product quality and customer service. Additionally, consider visiting the supplier’s facility if possible, or request a virtual tour to assess their manufacturing capabilities and quality control processes. -

What payment terms should I expect when purchasing merry-go-rounds internationally?

Payment terms can vary widely among suppliers. Common terms include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer credit terms or letters of credit, especially for larger orders. Be sure to clarify any additional costs such as shipping, taxes, and customs duties. Understanding these terms in advance can help you manage your budget effectively and avoid unexpected expenses. -

What logistics considerations should I keep in mind when importing merry-go-rounds?

Logistics can be complex when importing playground equipment. Consider factors like shipping methods (air vs. sea), customs clearance, and local regulations regarding playground installations. Work with a freight forwarder familiar with importing playground equipment to ensure compliance with safety standards and documentation requirements. Additionally, factor in potential delays caused by customs inspections or shipping disruptions, and plan accordingly to avoid project setbacks. -

Can I customize the design or colors of the merry-go-rounds?

Most manufacturers offer customization options for merry-go-rounds, including size, color, and design features. While standard models are readily available, custom orders may involve additional costs and longer lead times. Discuss your specific needs with the supplier, including any branding requirements or unique safety features. Be prepared to provide design specifications and confirm any additional charges associated with customization to ensure that your playground meets your vision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Playground Merry Go Round For Sale Manufacturers & Suppliers List

1. Willy Goat – Merry Go Rounds

Domain: willygoat.com

Registered: 2000 (25 years)

Introduction: Merry Go Rounds: Safe and Affordable! These spinning devices were initially designed to help young warriors get used to the chaos of battle, evolving into the classic and beloved ride enjoyed today. Besides being a source of fun, merry-go-rounds offer engaging play experiences.

2. Constructive Playthings – 10ft Merry-Go-Round

Domain: constructiveplaythings.com

Introduction: This company, Constructive Playthings – 10ft Merry-Go-Round, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

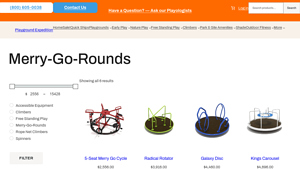

3. Playground Expedition – Merry-Go-Rounds

Domain: playgroundexpedition.com

Registered: 2020 (5 years)

Introduction: Merry-Go-Rounds for Sale: 5-Seat Merry Go Cycle ($2,556.00), Radical Rotator ($3,916.00), Galaxy Disc ($4,460.00), Kings Carousel ($4,696.00), Mauritius ($7,416.00), One Capacity Wheelchair Accessible Merry Go Round ($15,428.00). Features include accessible equipment, various designs for different age groups, emphasis on safety, durability, and inclusive design trends such as ADA-compliant feature…

4. Noah’s Park & Playgrounds – Merry-Go-Rounds

Domain: noahsplay.com

Introduction: Merry-go-rounds are a staple of playgrounds, providing exciting spinning motion for children. All products are IPEMA-tested and meet ASTM and CPSC standards for safety. Noah’s Park & Playgrounds offers a variety of models, including wheelchair accessible options and different styles such as carousels and spinners. Key models include Carrington’s Carousel, Wheelchair Accessible ADA Merry Go Round, …

5. SportsPlay – Merry Go Round Playground Equipment

Domain: rehabmart.com

Registered: 1999 (26 years)

Introduction: Product Name: SportsPlay Merry Go Round Playground Equipment

Sizes Available: 6 ft, 8 ft, 10 ft

Color Options: Red and Yellow, Tan and Green, Multi-Colored

Starting Price: $4,545.20 (with free shipping)

Key Features:

– Mechanical speed control governor for safety

– Rounded platform edges

– Encourages outdoor play and social interaction

– Grease fittings for maintenance

– Made-to-order with a 13-1…

Strategic Sourcing Conclusion and Outlook for playground merry go round for sale

Strategic sourcing for playground merry-go-rounds represents a pivotal opportunity for international buyers aiming to enhance their recreational offerings. By focusing on quality, safety, and accessibility, organizations can ensure they meet the diverse needs of children across various demographics. The extensive range of options available—from traditional designs to innovative, wheelchair-accessible models—allows for tailored solutions that foster inclusive play environments.

Investing in high-quality merry-go-rounds not only supports children’s physical development through cooperative play but also enriches community spaces, making them more attractive to families. Strategic sourcing enables buyers to leverage competitive pricing and high standards of manufacturing, ensuring long-term value and safety compliance.

As the global market evolves, staying informed about the latest trends and innovations in playground equipment is crucial. International buyers from regions like Africa, South America, the Middle East, and Europe should seize the moment to establish partnerships with reputable suppliers, ensuring they provide safe, engaging, and modern play options. Embrace this opportunity to elevate your playground offerings and contribute to the well-being of children in your communities.