Plastic Extrusion Line: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for plastic extrusion line

In today’s competitive landscape, sourcing an efficient plastic extrusion line presents a significant challenge for manufacturers aiming to enhance productivity while maintaining product quality. With a multitude of options available globally, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Brazil—must navigate a complex market to identify the right equipment that meets their specific needs. This guide provides an in-depth exploration of the plastic extrusion line sector, covering essential types of extrusion systems, their diverse applications across industries, and the critical factors to consider when vetting suppliers.

Understanding the intricacies of plastic extrusion technology is vital for making informed purchasing decisions. This comprehensive resource delves into the various components that comprise extrusion lines, including extruders, die heads, and cooling systems, as well as the latest advancements that enhance operational efficiency. Additionally, we address cost considerations, ensuring that buyers can assess potential return on investment effectively. By equipping B2B buyers with actionable insights and expert guidance, this guide empowers manufacturers to navigate the global market confidently, ultimately leading to successful procurement strategies and improved production outcomes. Whether you are a seasoned industry player or new to the field, this resource is designed to facilitate informed decisions that align with your business objectives.

Understanding plastic extrusion line Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

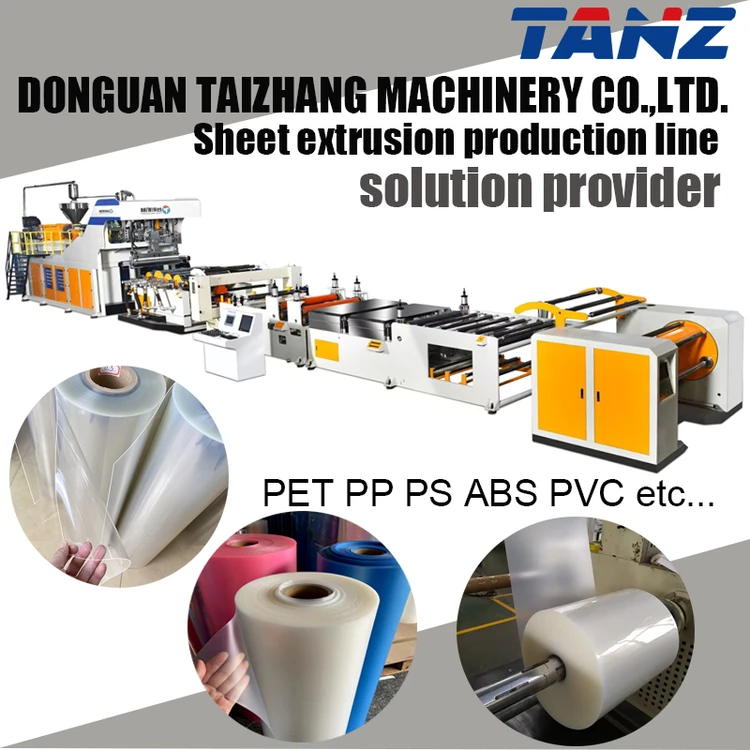

| Sheet Extrusion Line | Produces flat plastic sheets, customizable thickness, high-speed | Packaging, construction, automotive parts | Pros: High output, energy-efficient. Cons: High initial investment. |

| Pipe Extrusion Line | Specialized for creating pipes/tubing, continuous profiles | Plumbing, irrigation, industrial applications | Pros: Continuous production, consistent quality. Cons: Limited to specific shapes. |

| Film Extrusion Line | Focuses on thin plastic films, co-extrusion capabilities | Food packaging, agricultural films | Pros: Versatile applications, lightweight. Cons: Requires precise control for quality. |

| Profile Extrusion Line | Creates complex shapes and profiles, high customization | Window frames, weather stripping | Pros: Flexibility in design, efficient production. Cons: More complex machinery setup. |

| Blown Film Extrusion Line | Produces tubular films, utilizes air for shaping | Flexible packaging, industrial wraps | Pros: High strength films, cost-effective. Cons: Potential for material waste. |

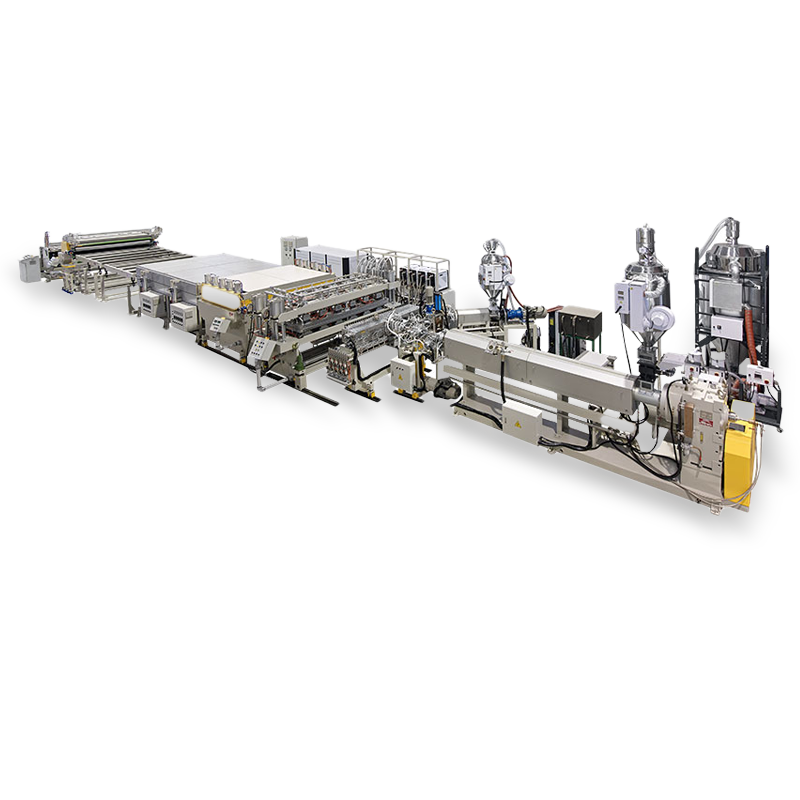

What Are the Characteristics of a Sheet Extrusion Line?

Sheet extrusion lines are designed to produce flat plastic sheets in various thicknesses, catering to industries like packaging and construction. Their key features include advanced screw designs for efficient melting and customizable configurations to handle multiple plastic types. Buyers should consider the initial investment against the high output and energy efficiency these lines offer, making them suitable for high-volume production environments.

How Does a Pipe Extrusion Line Differ from Other Types?

Pipe extrusion lines are specialized for creating continuous profiles, primarily pipes and tubing. They are characterized by their ability to produce uniform dimensions and high-quality finishes, making them ideal for plumbing and industrial applications. When purchasing, businesses should weigh the benefits of consistent quality and continuous production against the limitations in shape versatility.

What Are the Unique Features of a Film Extrusion Line?

Film extrusion lines focus on producing thin plastic films, often incorporating co-extrusion capabilities for multi-layered products. These lines are widely used in food packaging and agricultural applications. B2B buyers should prioritize precision control features to ensure high-quality output, while also considering the versatility these lines provide across various applications.

Why Choose a Profile Extrusion Line for Custom Shapes?

Profile extrusion lines are adept at creating complex shapes and profiles, allowing for high customization. They are commonly used in manufacturing window frames and weather stripping. Buyers should consider the flexibility in design and efficient production capabilities, although the complexity of the machinery setup may require additional investment in operator training.

What Makes Blown Film Extrusion Lines Cost-Effective?

Blown film extrusion lines produce tubular films by utilizing air for shaping, making them particularly popular in flexible packaging. These lines are known for creating high-strength films at a lower cost. However, potential material waste should be a consideration for buyers looking to optimize their production processes while maintaining cost-effectiveness.

Key Industrial Applications of plastic extrusion line

| Industry/Sector | Specific Application of Plastic Extrusion Line | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Production of PVC pipes and window frames | Durable and cost-effective building materials | Quality of raw materials, compliance with local standards, and energy efficiency of the extrusion line. |

| Automotive | Manufacturing of interior trim and components | Lightweight parts that enhance fuel efficiency | Precision in dimensions, customization options, and supplier reliability for just-in-time manufacturing. |

| Packaging | Creation of flexible packaging films | Reduced material costs and enhanced product shelf life | Material compatibility, production speed, and the ability to integrate with existing packaging lines. |

| Consumer Goods | Production of plastic containers and household items | Versatile designs and cost-effective production | Custom mold capabilities, energy efficiency, and after-sales support for maintenance and upgrades. |

| Medical Devices | Fabrication of medical tubing and bags | High-quality standards and regulatory compliance | Cleanroom capabilities, material certifications, and precision in production processes. |

How is Plastic Extrusion Used in Construction?

In the construction industry, plastic extrusion lines are primarily utilized to manufacture durable products such as PVC pipes and window frames. These materials are essential for plumbing and structural applications due to their resistance to corrosion and ease of installation. International buyers should prioritize sourcing from manufacturers who offer high-quality raw materials that meet local building codes and standards. Additionally, energy-efficient extrusion lines can reduce operational costs, making it essential to evaluate the energy consumption of machinery before procurement.

What Role Does Plastic Extrusion Play in the Automotive Sector?

The automotive industry relies heavily on plastic extrusion lines for producing lightweight interior trim and various components. These extruded parts contribute to overall vehicle weight reduction, enhancing fuel efficiency and performance. Buyers from regions like Africa and South America should consider suppliers that provide precision in dimensions and customization options to meet specific design needs. Additionally, a reliable supply chain is crucial for just-in-time manufacturing processes, ensuring that parts are available when needed without excess inventory costs.

How is Plastic Extrusion Beneficial in Packaging?

In the packaging sector, plastic extrusion lines are key for creating flexible packaging films that protect products while extending their shelf life. This application is particularly advantageous for businesses looking to reduce material costs without compromising quality. International buyers should focus on sourcing extrusion lines that offer compatibility with various materials and high production speeds to meet market demands. Integration capabilities with existing packaging systems can also streamline operations, making it a vital consideration during the procurement process.

How Does Plastic Extrusion Support Consumer Goods Manufacturing?

Plastic extrusion plays a significant role in the production of various consumer goods, including plastic containers and household items. This process allows for versatile designs and efficient mass production, enabling businesses to respond quickly to market trends. Buyers should evaluate suppliers based on their ability to provide custom mold capabilities and energy-efficient machinery. Moreover, after-sales support for maintenance and upgrades is crucial to ensure long-term operational efficiency.

What are the Applications of Plastic Extrusion in Medical Devices?

In the medical field, plastic extrusion lines are instrumental in fabricating high-quality medical tubing and bags that meet stringent regulatory standards. This application requires precision in production processes and adherence to cleanroom conditions to ensure product safety. International buyers must consider sourcing from manufacturers that offer material certifications and demonstrate compliance with medical industry regulations. The ability to maintain high-quality standards throughout the production process is critical for success in this highly regulated sector.

3 Common User Pain Points for ‘plastic extrusion line’ & Their Solutions

Scenario 1: Frequent Production Downtime Due to Equipment Failures

The Problem: Many B2B buyers of plastic extrusion lines face the challenge of unexpected equipment failures that lead to significant production downtimes. This situation not only hampers production efficiency but can also strain relationships with clients due to delays in order fulfillment. For instance, a manufacturer in Nigeria may find that a critical component like the extruder screw or die head has worn down, necessitating immediate repairs or replacements. This not only incurs additional costs but can also disrupt the entire production schedule, leading to financial losses and operational stress.

The Solution: To mitigate the risk of downtime, it is essential to invest in high-quality equipment and establish a proactive maintenance schedule. Buyers should prioritize sourcing machinery from reputable manufacturers known for reliability and durability, such as Davis-Standard or KraussMaffei. Additionally, implementing a predictive maintenance program using IoT sensors can help monitor the condition of the extrusion line in real-time, allowing for early detection of wear and tear. Regular training for operators on maintenance practices can also ensure that minor issues are addressed before they escalate, ultimately leading to increased uptime and a more efficient production process.

Scenario 2: Inconsistent Product Quality Leading to Waste

The Problem: A common pain point for manufacturers using plastic extrusion lines is the inconsistency in product quality, which can lead to excessive waste and increased production costs. For example, a company in Brazil may experience variations in thickness or density of the extruded sheets, resulting in products that do not meet customer specifications. This inconsistency can stem from fluctuating material temperatures, improper calibration of the extrusion equipment, or inadequate quality control measures, thereby impacting the bottom line.

The Solution: To enhance product quality, it is crucial to invest in advanced extrusion lines equipped with precise temperature control and automated thickness monitoring systems. Implementing real-time quality control measures, such as inline measurement tools, can provide immediate feedback and allow operators to make necessary adjustments during production. Additionally, conducting regular audits of raw materials and ensuring they meet quality standards can prevent inconsistencies from the outset. Collaborating closely with suppliers to understand material properties and potential variations can also lead to better quality outcomes.

Scenario 3: Challenges in Sourcing Suitable Raw Materials

The Problem: Sourcing the right raw materials for plastic extrusion can be a significant hurdle for manufacturers, especially in regions like the Middle East and Africa where supply chains may be less developed. B2B buyers often struggle with identifying reliable suppliers who can provide high-quality resins suitable for their specific extrusion processes. For instance, a manufacturer may require specific grades of polypropylene or polyethylene but find that local suppliers offer limited options or inconsistent quality, leading to production delays and compromised product performance.

The Solution: To navigate these challenges, buyers should actively seek out partnerships with established suppliers who have a proven track record of delivering quality materials. Engaging in networking within industry associations or attending trade shows can help identify reputable suppliers. Furthermore, buyers should consider diversifying their supplier base to mitigate risks associated with relying on a single source. Utilizing online platforms that specialize in B2B transactions can also facilitate access to a broader range of materials and suppliers. Additionally, establishing long-term contracts with suppliers can ensure a steady supply of quality materials while potentially securing better pricing and terms.

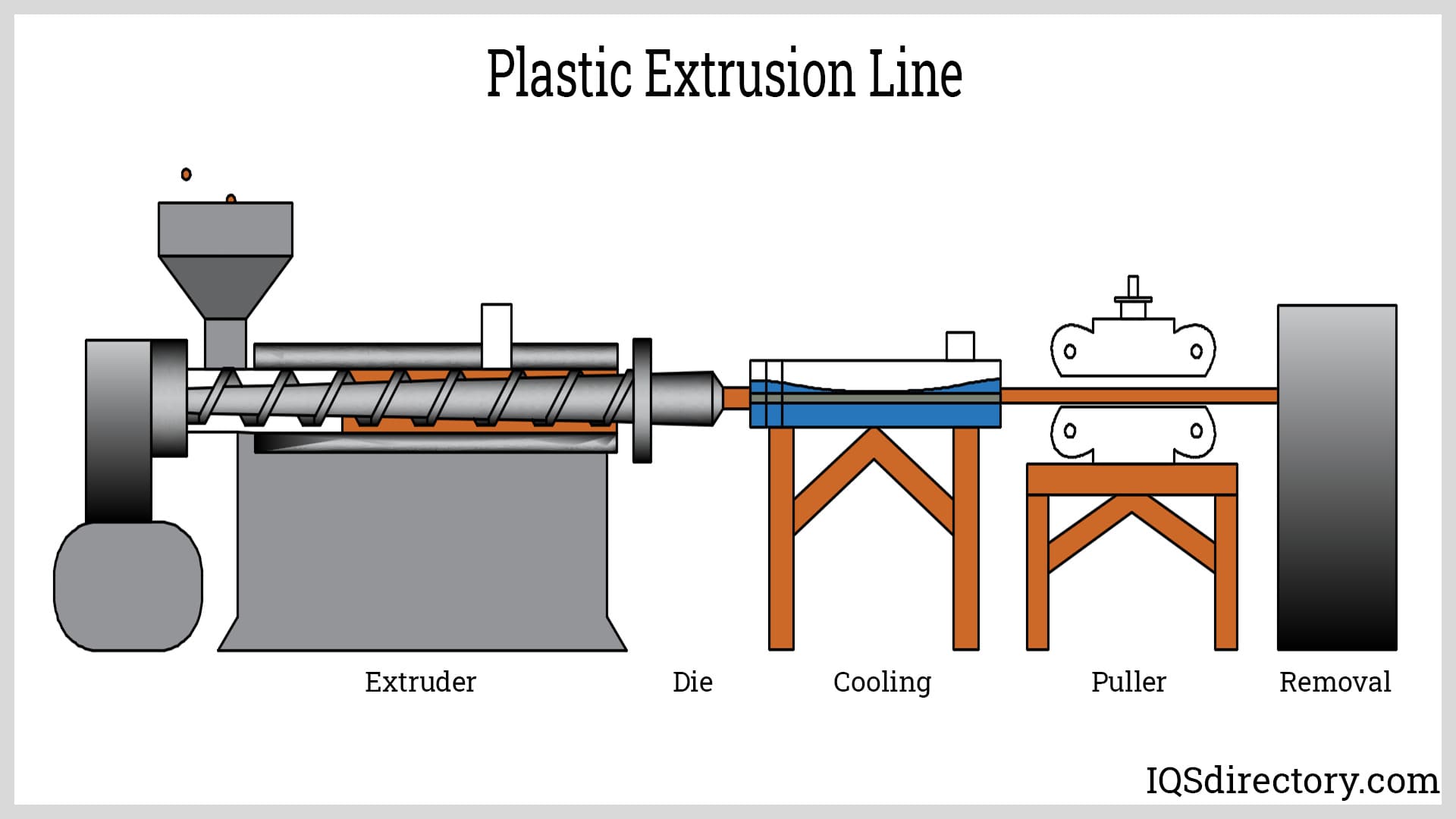

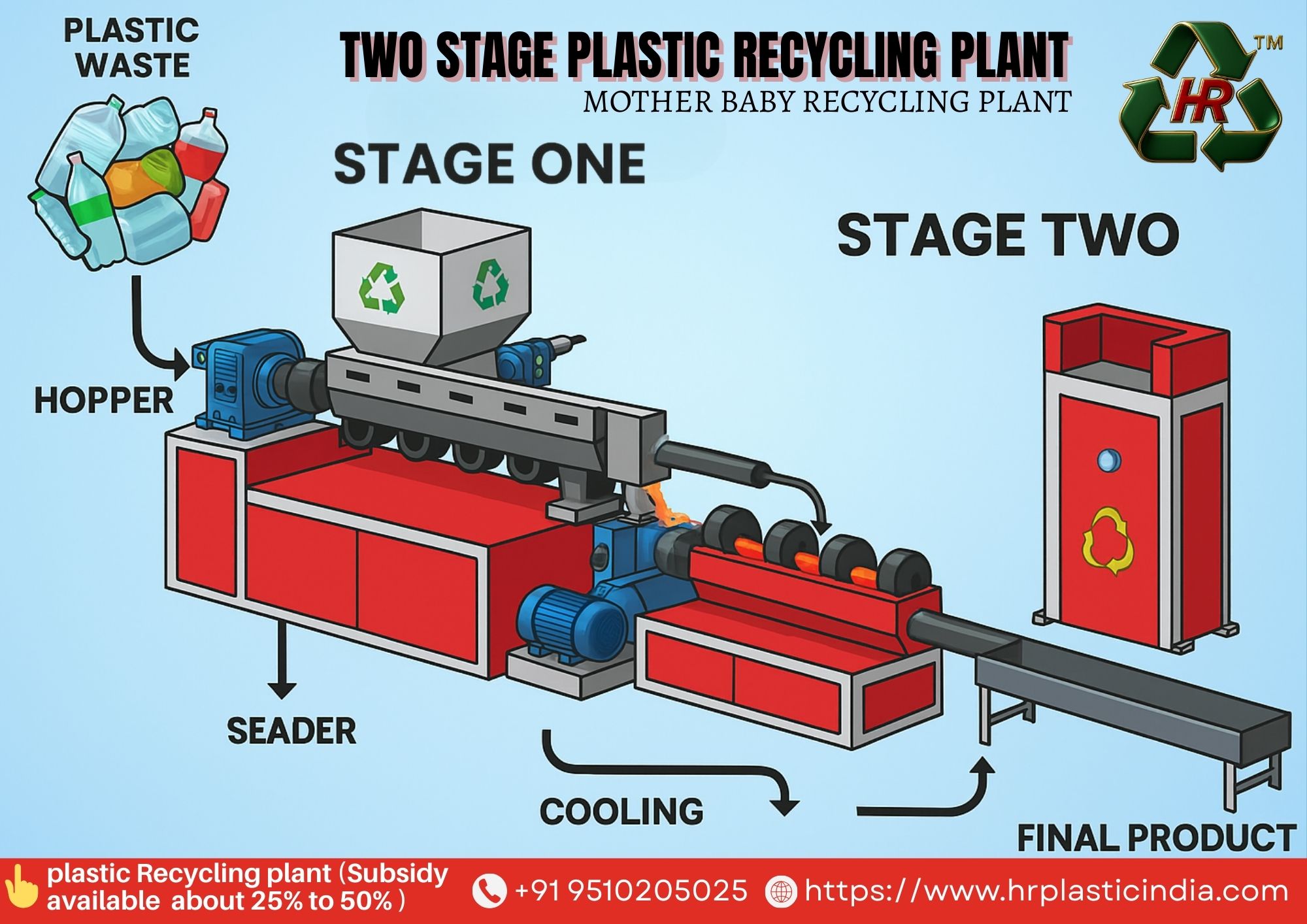

Illustrative image related to plastic extrusion line

Strategic Material Selection Guide for plastic extrusion line

What Are the Key Materials for Plastic Extrusion Lines?

When selecting materials for a plastic extrusion line, it’s crucial to consider the specific properties and applications of each type. Here, we analyze four common materials used in plastic extrusion, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polypropylene (PP) Perform in Plastic Extrusion?

Polypropylene (PP) is a widely used thermoplastic known for its versatility and cost-effectiveness. It boasts a high melting point (around 160-170°C) and excellent chemical resistance, making it suitable for various applications, including packaging and automotive parts.

Pros: PP is lightweight, has good fatigue resistance, and is relatively inexpensive. Its ability to be molded into complex shapes without compromising strength is a significant advantage.

Cons: However, PP can be sensitive to UV light, leading to degradation over time unless stabilized with additives. Additionally, its lower impact resistance compared to other materials may limit its use in high-stress applications.

Impact on Application: PP is compatible with a wide range of media, making it ideal for packaging and containers. However, buyers should ensure compliance with local regulations regarding food safety and environmental standards.

What Advantages Does Polyethylene (PE) Offer for Extrusion?

Polyethylene (PE) is another popular choice for extrusion, particularly in the production of films, containers, and pipes. With a melting point ranging from 120°C to 130°C, PE is known for its excellent flexibility and toughness.

Pros: PE is resistant to moisture and chemicals, making it suitable for outdoor applications. Its low density contributes to lower transportation costs.

Cons: On the downside, PE has a lower tensile strength compared to other materials, which can limit its application in structural components. It is also more susceptible to environmental stress cracking.

Illustrative image related to plastic extrusion line

Impact on Application: PE’s compatibility with various substances makes it ideal for packaging, but international buyers should be aware of local recycling and disposal regulations, especially in regions with stringent environmental laws.

Why Choose Polyvinyl Chloride (PVC) for Extrusion?

Polyvinyl Chloride (PVC) is a robust thermoplastic that is often used in construction, plumbing, and electrical applications. It has a higher melting point (around 75-105°C) and excellent resistance to corrosion and chemicals.

Pros: PVC is durable and can withstand harsh environmental conditions, making it suitable for long-term applications. It also offers good insulation properties for electrical applications.

Cons: However, PVC can be more expensive than PP and PE, and its processing can be complex due to the need for stabilizers and plasticizers. Additionally, it can emit harmful fumes when burned.

Impact on Application: PVC’s durability makes it ideal for pipes and fittings. Buyers should consider compliance with industry standards like ASTM and DIN, particularly in construction applications.

What Role Does Polystyrene (PS) Play in Plastic Extrusion?

Polystyrene (PS) is a versatile plastic that is often used in packaging, insulation, and consumer goods. It has a melting point of around 240°C and is known for its rigidity and ease of processing.

Pros: PS is lightweight and can be easily molded into intricate designs, making it ideal for packaging and disposable products. It also has good clarity, which is beneficial for certain applications.

Illustrative image related to plastic extrusion line

Cons: The main drawback of PS is its brittleness, which can lead to cracking under stress. Additionally, it has poor chemical resistance, limiting its use in applications involving solvents.

Impact on Application: PS is commonly used in food packaging, but international buyers should ensure compliance with food safety standards and consider the environmental impact of using polystyrene, especially in regions where single-use plastics are being phased out.

Summary Table of Material Selection for Plastic Extrusion Lines

| Material | Typical Use Case for plastic extrusion line | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Packaging, automotive parts | Lightweight and cost-effective | Sensitive to UV light | Low |

| Polyethylene (PE) | Films, containers, pipes | Excellent flexibility and toughness | Lower tensile strength | Low |

| Polyvinyl Chloride (PVC) | Construction, plumbing, electrical | High durability and corrosion resistance | More expensive and complex processing | Med |

| Polystyrene (PS) | Packaging, insulation | Lightweight and easy to mold | Brittleness and poor chemical resistance | Med |

This guide provides a comprehensive overview of key materials used in plastic extrusion lines, helping international B2B buyers make informed decisions based on application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic extrusion line

What are the Main Stages of the Manufacturing Process for Plastic Extrusion Lines?

The manufacturing process of a plastic extrusion line is a multi-stage operation that transforms raw plastic materials into finished products. Understanding these stages is crucial for B2B buyers looking to invest in reliable and efficient extrusion lines.

Material Preparation: What is Involved Before Extrusion?

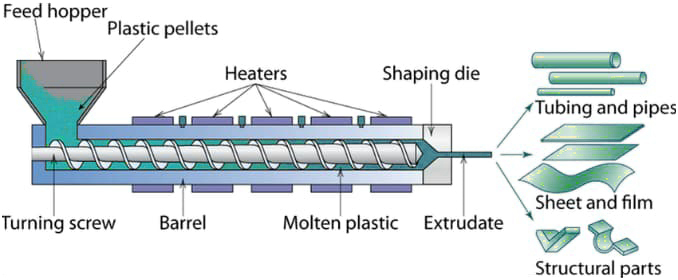

The first stage involves the preparation of raw materials, typically in the form of pellets or granulates. These materials are often mixed with additives such as colorants, UV stabilizers, or flame retardants to enhance their properties. The preparation phase requires careful consideration of material compatibility and uniformity to ensure optimal extrusion performance. High-quality feeding systems ensure consistent material flow into the extruder, which is essential for maintaining quality throughout the process.

Illustrative image related to plastic extrusion line

How is the Forming Process Executed in Extrusion?

Once the materials are prepared, they are fed into the extruder. The extruder melts the plastic through a combination of heat and mechanical shear, forcing it through a die to form a continuous profile. Key techniques in this stage include:

- Temperature Control: Precise temperature management is vital for achieving the desired viscosity of the melted material, which directly impacts the quality of the extrudate.

- Screw Design: Advanced screw designs are employed to facilitate efficient melting and mixing of the material, ensuring a homogeneous output.

- Die Design: The die defines the shape and dimensions of the final product, and its engineering plays a significant role in ensuring uniform flow and thickness of the extruded material.

What Steps are Taken During Assembly and Finishing?

Following the forming process, the extruded material is cooled and solidified. This is typically achieved through air or water cooling systems that stabilize the dimensions of the product. After cooling, the product undergoes several finishing steps, including:

- Cutting: The extruded material is cut to the specified lengths.

- Stacking: Finished products are stacked for packaging or further processing, ensuring they are ready for shipment or integration into downstream manufacturing processes.

What Quality Assurance Measures are Commonly Implemented in Plastic Extrusion?

Quality assurance (QA) is a critical component of the plastic extrusion manufacturing process. B2B buyers must be aware of the various quality control measures that ensure product consistency and compliance with international standards.

Which International Standards Should Buyers Consider?

For B2B buyers, understanding relevant international and industry-specific standards is essential for ensuring product quality. Some of the most pertinent standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is widely recognized globally. It ensures that organizations consistently meet customer and regulatory requirements.

- CE Marking: Products sold in the European Economic Area must comply with CE marking directives, ensuring they meet safety and environmental protection standards.

- API Certification: For manufacturers producing plastic components for the oil and gas industry, API certification is critical for compliance with industry-specific safety and quality standards.

What are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in plastic extrusion typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. It ensures that only materials meeting specified standards are used.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor parameters such as temperature, pressure, and extrudate dimensions. This helps identify any deviations from quality standards in real-time.

- Final Quality Control (FQC): Once production is complete, the finished products undergo rigorous testing to ensure they meet all specifications and regulatory requirements. Common testing methods include tensile strength tests, dimensional inspections, and surface quality assessments.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is vital for B2B buyers, especially when sourcing from international markets. Here are some effective strategies:

What are the Best Practices for Conducting Supplier Audits?

Conducting thorough supplier audits can provide insights into the operational processes and quality management systems in place. Key aspects to evaluate during an audit include:

- Documentation Review: Assessing quality manuals, procedures, and records can reveal how a supplier adheres to standards like ISO 9001.

- Facility Inspection: A physical inspection of the manufacturing facility allows buyers to observe production practices and equipment condition.

- Employee Interviews: Engaging with staff can provide insights into the company culture surrounding quality assurance and their understanding of quality processes.

How Important are Quality Reports and Third-Party Inspections?

Requesting quality reports and certifications from suppliers is essential for validating their claims of compliance with international standards. Additionally, third-party inspections can serve as an unbiased assessment of a supplier’s quality practices. Third-party certifications can enhance credibility, particularly when sourcing from regions where quality assurance practices may vary.

What Nuances Should International Buyers Consider in Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional nuances in quality control is crucial:

- Regulatory Differences: Be aware of varying regulatory requirements in different regions, which may influence quality standards and certifications.

- Supply Chain Considerations: Geopolitical factors can impact supply chain reliability and the ability to maintain consistent quality.

- Cultural Factors: Understanding cultural attitudes towards quality and compliance can facilitate better communication and collaboration with suppliers.

By being informed about the manufacturing processes and quality assurance measures related to plastic extrusion lines, B2B buyers can make more informed decisions, ensuring that they partner with suppliers who prioritize product quality and compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic extrusion line’

To assist B2B buyers in procuring a plastic extrusion line, this guide outlines a systematic approach to ensure informed decision-making. By following these steps, you can streamline the sourcing process, mitigate risks, and enhance your operational efficiency.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to clearly outline your technical needs. Consider the types of plastics you will be processing, the desired output capacity, and the specific applications of the extruded products. This clarity will guide you in selecting the right equipment that aligns with your production goals and ensures compatibility with your existing systems.

Step 2: Conduct Market Research for Suppliers

Engage in thorough market research to identify potential suppliers. Look for manufacturers that specialize in plastic extrusion lines and have a proven track record. Utilize industry directories, trade shows, and online platforms to compile a list of suppliers, focusing on those with positive reviews and customer testimonials.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key factors to assess include:

– Experience and Expertise: Ensure the supplier has extensive experience in manufacturing the specific type of extrusion line you require.

– Technical Support: Check if they offer after-sales support, training, and maintenance services.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers comply with international standards and certifications relevant to the plastic extrusion industry. Look for certifications such as ISO 9001 for quality management systems and CE marking for safety compliance. This step is vital to guarantee that the equipment meets safety and operational standards, particularly in regions with strict regulations.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, delivery timelines, warranty terms, and payment conditions. Analyze the quotations carefully to understand the total cost of ownership, including installation and maintenance costs. This transparency will help you make a more informed financial decision.

Step 6: Assess Technological Features and Customization Options

Evaluate the technological features of the plastic extrusion lines offered by suppliers. Look for advanced capabilities such as:

– Energy Efficiency: Modern machines should have energy-saving features to reduce operational costs.

– Customizability: Ensure the equipment can be tailored to your production needs, allowing for flexibility in processing various materials and product specifications.

Illustrative image related to plastic extrusion line

Step 7: Plan for Installation and Training

Finally, consider the logistics of installation and the training required for your staff. Discuss with the supplier how they will support the setup process and what training resources are available. Proper training is crucial to maximize the efficiency of your new extrusion line and to ensure that your team can operate the equipment safely and effectively.

By following this comprehensive checklist, B2B buyers can confidently navigate the procurement process for a plastic extrusion line, ultimately leading to enhanced production capabilities and business growth.

Comprehensive Cost and Pricing Analysis for plastic extrusion line Sourcing

What Are the Key Cost Components of Sourcing a Plastic Extrusion Line?

When sourcing a plastic extrusion line, it’s crucial to understand the multifaceted cost structure involved. The primary components include:

-

Materials: The cost of raw materials, such as thermoplastics (e.g., polypropylene, polyethylene), significantly influences the total expenditure. Prices can fluctuate based on market conditions and supplier contracts.

-

Labor: Skilled labor is necessary for operating and maintaining extrusion lines. Labor costs will vary by region, with higher rates in developed countries compared to emerging markets.

-

Manufacturing Overhead: This includes utilities, rent, and indirect labor costs. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Custom dies and molds are essential for producing specific shapes and sizes. The complexity of the tooling will affect both initial costs and lead times.

-

Quality Control (QC): Ensuring product quality through inspections and testing adds to the cost. Investing in advanced QC systems can lead to long-term savings by reducing waste and rework.

-

Logistics: Shipping and handling costs, including customs duties for international buyers, can add a significant amount to the final price. Proximity to suppliers can help mitigate these costs.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding market rates can help buyers negotiate better deals.

What Influences the Pricing of Plastic Extrusion Lines?

Several factors can impact the pricing of plastic extrusion lines, making it essential for buyers to consider these elements when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower unit prices. Negotiating MOQs can provide substantial savings, particularly for larger companies.

-

Specifications and Customization: Customized machines tailored to specific production needs may incur higher costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., ISO, CE) can drive up prices. However, they often result in better performance and durability.

-

Supplier Reputation and Reliability: Established suppliers may charge a premium due to their track record. Assessing supplier capabilities and past performance can help justify the costs.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers in shipping costs and risks. Different terms can significantly affect total costs.

How Can Buyers Negotiate Effectively for Plastic Extrusion Lines?

Effective negotiation strategies can lead to better pricing and terms:

-

Do Your Research: Understand market prices and compare multiple suppliers to establish a baseline for negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront cost but the long-term operational costs, including maintenance, energy consumption, and downtime.

-

Build Relationships: Long-term relationships with suppliers can lead to better terms and preferential pricing. Regular communication fosters trust and collaboration.

-

Leverage Volume Discounts: If your business anticipates future needs, negotiate for volume discounts that can apply to multiple purchases over time.

-

Explore Financing Options: Some suppliers offer financing plans or leasing options, which can help manage cash flow while acquiring essential machinery.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, and the Middle East, should consider:

-

Currency Fluctuations: Exchange rate volatility can impact overall costs. Consider locking in prices or using hedging strategies to mitigate risks.

-

Import Duties and Taxes: Understanding local regulations regarding import duties can affect the total cost. Engage with customs brokers for clarity.

-

Cultural Differences: Negotiation styles may vary across cultures. Being aware of local practices can facilitate smoother discussions.

-

Logistical Challenges: International shipping may involve delays or additional costs. Planning for these factors can prevent unexpected expenses.

Disclaimer on Indicative Prices

Pricing for plastic extrusion lines can vary widely based on specifications, supplier agreements, and market conditions. The information provided is intended for guidance and should not be viewed as definitive. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure a comprehensive understanding of potential costs.

Alternatives Analysis: Comparing plastic extrusion line With Other Solutions

Exploring Alternative Solutions to Plastic Extrusion Lines

In the quest for efficient manufacturing processes, businesses often explore alternatives to plastic extrusion lines. While extrusion is renowned for its ability to produce continuous profiles and complex shapes, several other methods can also fulfill similar needs in the plastic processing industry. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific operational requirements.

| Comparison Aspect | Plastic Extrusion Line | Injection Molding | Blow Molding |

|---|---|---|---|

| Performance | High throughput, ideal for continuous production of uniform profiles. | Excellent for complex shapes and high precision; slower cycle times. | Best for hollow objects; efficient for mass production. |

| Cost | Higher initial investment, cost-effective for large volumes. | Moderate initial costs; more economical for smaller batches. | Lower capital costs; ideal for large volume production. |

| Ease of Implementation | Requires specialized setup and training; more complex integration. | Relatively easy to implement with standard equipment; versatile. | Simple setup; requires specific equipment for different shapes. |

| Maintenance | Requires regular maintenance; can be complex due to multiple components. | Generally lower maintenance; easier to service. | Low maintenance; fewer moving parts simplify servicing. |

| Best Use Case | Ideal for producing sheets, pipes, and profiles in bulk. | Best for intricate components like automotive parts and consumer goods. | Optimal for bottles, containers, and large hollow items. |

Understanding Injection Molding as an Alternative

Injection molding is a widely adopted manufacturing process that involves injecting molten plastic into a mold to create specific shapes. This method excels in producing high-precision components and intricate designs. The primary advantage of injection molding is its ability to produce high-quality parts in large quantities with minimal waste. However, it requires a significant upfront investment in molds, which can be cost-prohibitive for smaller production runs. Additionally, the cycle times can be longer compared to extrusion, making it less suitable for continuous production.

Evaluating Blow Molding as a Viable Option

Blow molding is another alternative that is particularly effective for creating hollow plastic products, such as bottles and containers. This process involves inflating hot plastic within a mold, allowing for rapid production at lower costs. Blow molding is ideal for high-volume production and offers great flexibility in terms of design and size. However, it is limited to hollow shapes and cannot achieve the complexity of solid parts that injection molding can. Maintenance is generally low, making it an appealing choice for manufacturers focused on efficiency.

Illustrative image related to plastic extrusion line

Making an Informed Choice: Which Solution Suits Your Needs?

When considering the right manufacturing method, B2B buyers should assess their specific production needs, including the type of products they aim to create, volume requirements, and budget constraints. Plastic extrusion lines are unparalleled for continuous and bulk production of profiles, while injection molding shines with precision and complexity. Conversely, blow molding provides an efficient, cost-effective option for hollow products. By analyzing these factors, buyers can select the solution that aligns best with their operational goals and market demands, ensuring a strategic investment that drives profitability.

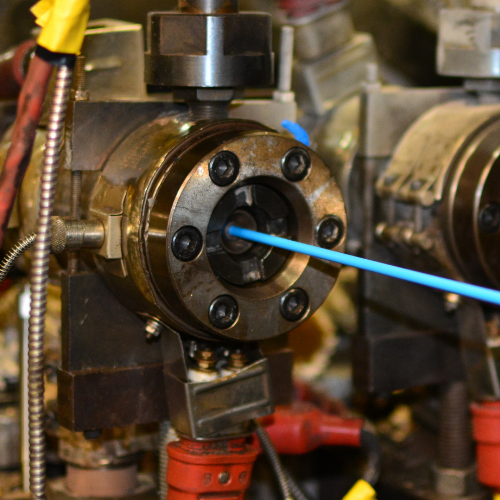

Essential Technical Properties and Trade Terminology for plastic extrusion line

What Are the Key Technical Properties of a Plastic Extrusion Line?

Understanding the essential specifications of a plastic extrusion line is critical for B2B buyers, especially when making significant investments in machinery. Here are several key properties that should be considered:

1. Material Grade

The material grade refers to the type of plastic resin used in the extrusion process, such as polyethylene (PE), polypropylene (PP), or polystyrene (PS). Each material has unique properties, including temperature resistance, flexibility, and durability. Selecting the appropriate material grade is crucial for ensuring the final product meets required standards and performance criteria.

Illustrative image related to plastic extrusion line

2. Tolerance

Tolerance indicates the allowable deviation from specified dimensions in the final product. For instance, tight tolerances are essential in applications like medical tubing or automotive parts, where precision is critical. Understanding tolerance levels helps businesses ensure that their products fit seamlessly into larger assemblies, reducing the risk of defects and returns.

3. Output Rate

The output rate, measured in kilograms per hour (kg/h), defines how much product can be produced within a given time frame. This specification directly affects production efficiency and costs. B2B buyers must evaluate their production needs against the output capabilities of the extrusion line to ensure it aligns with their operational goals.

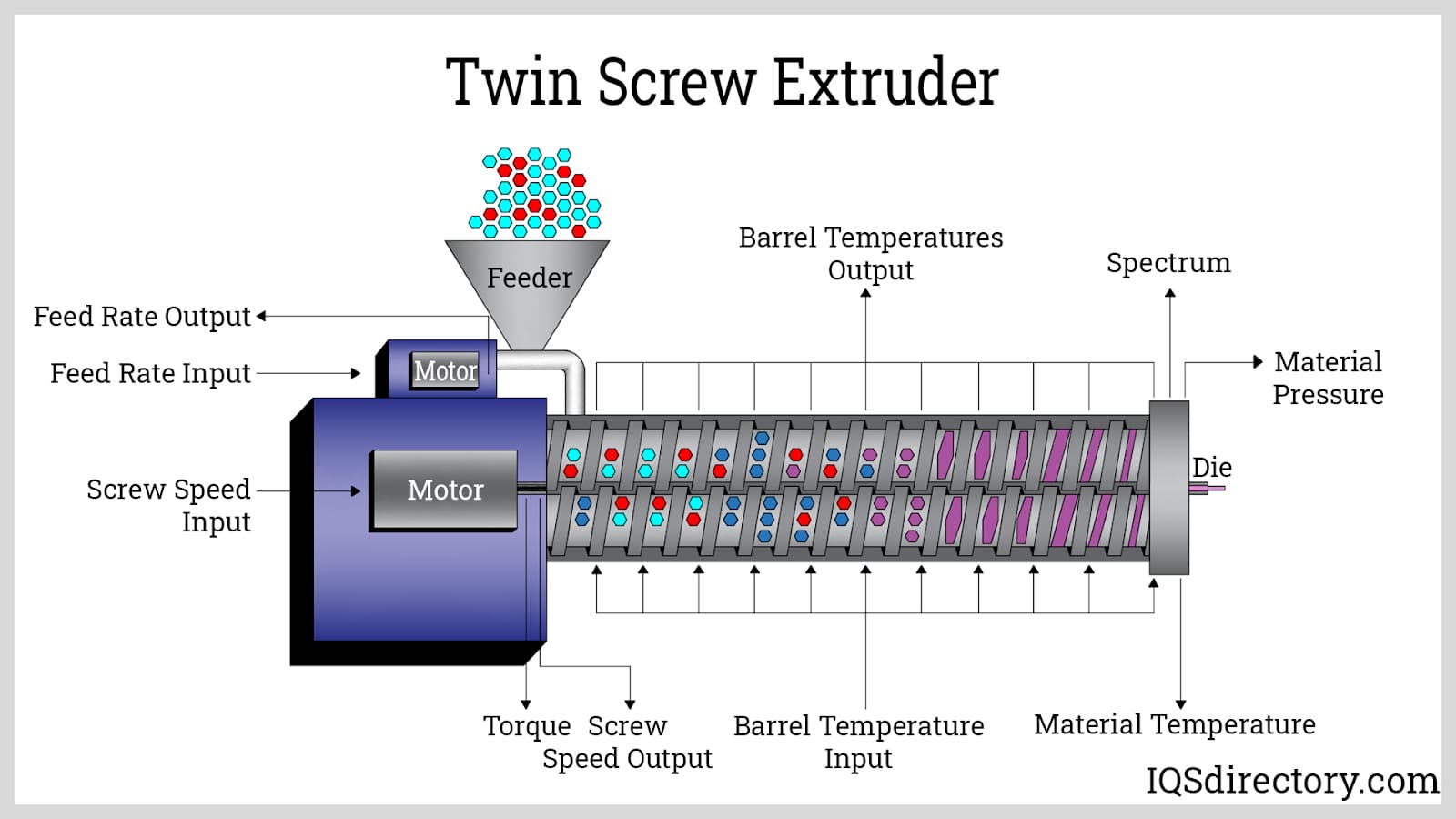

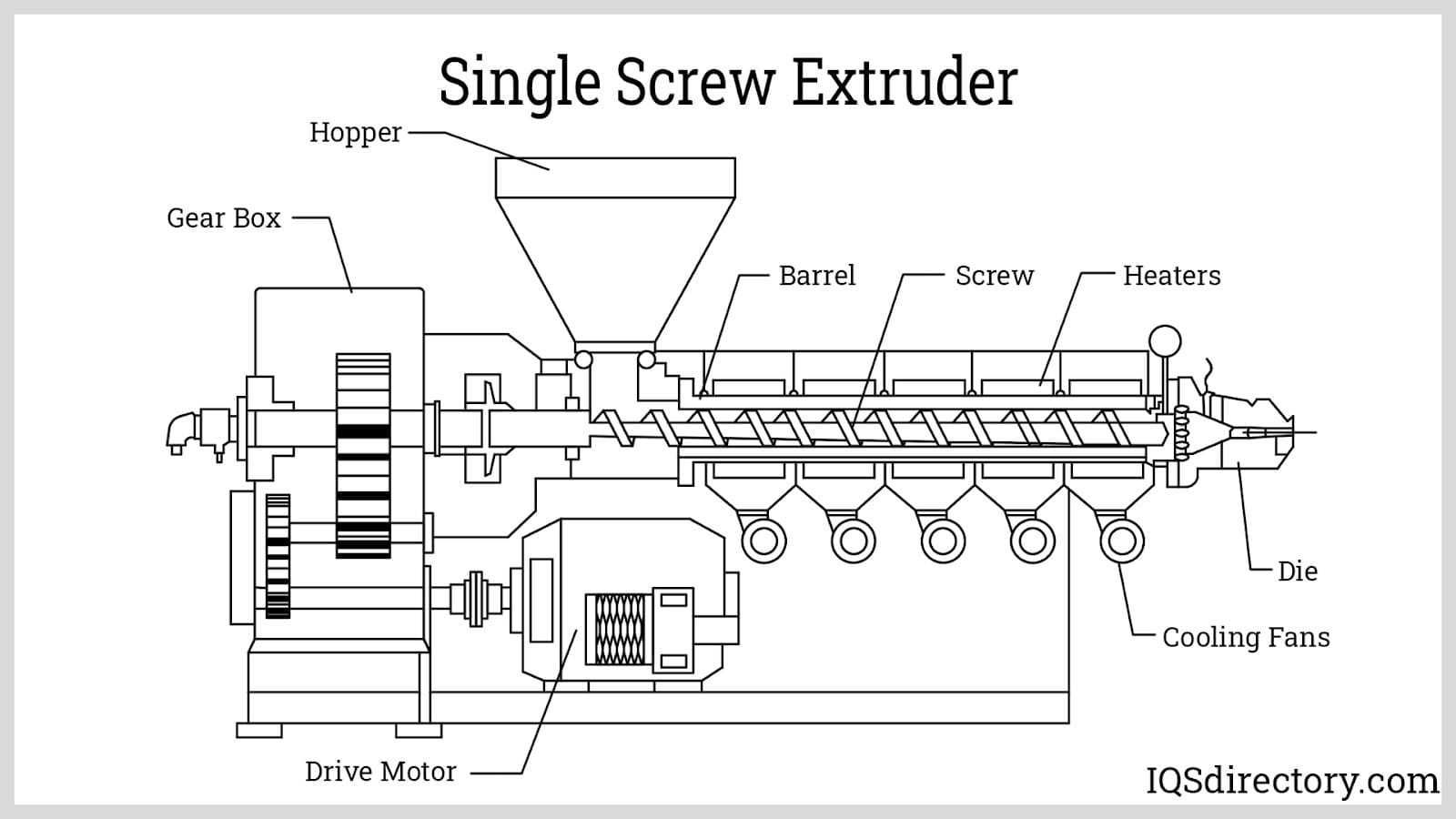

4. Screw Design

The design of the extruder screw impacts material processing, including melting, mixing, and conveying. Different screw designs can optimize the processing of various materials and enhance product quality. Understanding screw design is vital for buyers looking to maximize efficiency and product consistency.

5. Heating/Cooling Systems

Effective heating and cooling systems are essential for maintaining the proper temperature throughout the extrusion process. This ensures the plastic is uniformly melted and prevents defects in the final product. Buyers should evaluate the efficiency and reliability of these systems to minimize production downtime and enhance product quality.

6. Control Systems

Modern extrusion lines come equipped with advanced control systems that allow for real-time monitoring and adjustments. These systems enhance operational efficiency by enabling precise control over temperature, pressure, and speed. For B2B buyers, investing in a machine with a robust control system can lead to improved product quality and reduced operational costs.

Illustrative image related to plastic extrusion line

What Are Common Trade Terms in the Plastic Extrusion Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are several common trade terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of plastic extrusion, an OEM may provide specific components of the extrusion line. Understanding OEM relationships helps buyers identify reliable suppliers and ensure product compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for B2B buyers to manage inventory levels and production schedules effectively. It also influences purchasing decisions, especially for companies with limited budgets or those entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is crucial for ensuring competitive pricing and informed decision-making. B2B buyers should prepare detailed RFQs to receive accurate quotes that meet their specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. They specify aspects such as shipping costs, risk of loss, and delivery points. Familiarity with Incoterms helps B2B buyers navigate international transactions and mitigate risks associated with cross-border logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is essential for effective supply chain management. Buyers should consider lead times when planning production schedules to ensure timely delivery of materials and components.

6. Customization

Customization refers to the ability to tailor products or services to meet specific client requirements. In the context of plastic extrusion, it may involve altering machine settings or selecting specialized materials. Buyers should seek suppliers that offer customization options to ensure the final products align with their unique needs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when investing in plastic extrusion lines, ultimately enhancing their operational efficiencies and product quality.

Navigating Market Dynamics and Sourcing Trends in the plastic extrusion line Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Extrusion Line Sector?

The global plastic extrusion line market is undergoing significant transformation driven by technological advancements, increasing demand for customized solutions, and sustainability concerns. Key growth drivers include the rising consumption of plastic products across various industries, such as construction, automotive, and packaging. In regions like Africa, South America, the Middle East, and Europe, the demand for efficient and high-capacity extrusion lines is surging as manufacturers seek to enhance production efficiency and reduce operational costs.

Emerging trends indicate a shift towards automation and Industry 4.0 technologies, where smart extrusion systems with integrated IoT capabilities are becoming commonplace. These innovations allow manufacturers to monitor production processes in real-time, thus optimizing performance and minimizing waste. Furthermore, the increasing adoption of additive manufacturing techniques is reshaping the plastic extrusion landscape, enabling the production of complex geometries and bespoke products that meet specific customer requirements.

For international B2B buyers, particularly in emerging markets, understanding these dynamics is crucial. The ability to source advanced machinery that aligns with local regulations and market needs can provide a competitive edge. Buyers should focus on suppliers that offer comprehensive support, including training and after-sales service, to ensure seamless integration of new technologies into existing operations.

How Is Sustainability Influencing Sourcing Decisions in the Plastic Extrusion Line Industry?

Sustainability is at the forefront of sourcing decisions within the plastic extrusion line sector. The environmental impact of plastic production has prompted a growing emphasis on ethical supply chains and sustainable practices. B2B buyers are increasingly seeking suppliers who prioritize eco-friendly materials and manufacturing processes, which not only comply with regulatory standards but also enhance brand reputation.

Illustrative image related to plastic extrusion line

The importance of utilizing recycled materials in extrusion processes cannot be overstated. Many manufacturers are now investing in technology that allows for the use of post-consumer recycled plastics, which helps reduce dependence on virgin materials and lowers carbon footprints. Buyers should look for suppliers that provide transparent information regarding the sourcing of their materials and their commitment to sustainability.

Additionally, various green certifications, such as ISO 14001 and LEED, are becoming essential criteria in supplier evaluation. These certifications not only signify compliance with environmental standards but also reflect a commitment to continuous improvement in sustainability practices. By prioritizing suppliers with these credentials, B2B buyers can strengthen their sustainability initiatives while ensuring the quality and reliability of the plastic extrusion lines they procure.

What Historical Developments Have Shaped the Plastic Extrusion Line Market?

The evolution of the plastic extrusion line market dates back to the early 20th century when the process was first developed for manufacturing simple plastic profiles. Over the decades, advancements in materials science and engineering have led to the creation of more sophisticated extrusion technologies. The introduction of computer numerically controlled (CNC) systems in the late 20th century revolutionized the industry by enhancing precision and enabling complex designs.

As the demand for plastic products grew, so did the focus on efficiency and scalability. The 1990s saw the rise of co-extrusion techniques, allowing manufacturers to produce multi-layered products that meet diverse market needs. Today, the industry is witnessing a significant shift towards automation and digitalization, reflecting broader trends in manufacturing.

This historical context is essential for B2B buyers, as it highlights the importance of investing in advanced technologies that can deliver higher efficiency and adaptability in an ever-evolving market. Understanding these developments can inform sourcing strategies, guiding buyers to select machinery that not only meets current demands but is also future-proof against emerging trends.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic extrusion line

1. How do I select the right plastic extrusion line for my business needs?

Choosing the right plastic extrusion line involves several key considerations. Start by evaluating the specific products you intend to manufacture, as different lines are optimized for various materials and shapes. Assess the production capacity required to meet your demand, and consider the level of automation you need for efficiency. Additionally, prioritize suppliers with a strong track record in your industry and inquire about customization options to ensure the machinery fits seamlessly into your existing processes.

2. What is the best material for plastic extrusion lines?

The best material for your plastic extrusion line largely depends on the end products you aim to produce. Commonly used materials include polypropylene (PP), polyethylene (PE), polystyrene (PS), and polyethylene terephthalate (PET). Each material has distinct properties that affect processing temperatures, flow characteristics, and end-product performance. Consult with suppliers to determine which material aligns with your production goals and product specifications, ensuring optimal performance and quality.

3. How can I ensure quality assurance during the extrusion process?

Quality assurance in the plastic extrusion process can be maintained through several strategies. Implement real-time monitoring systems to track key parameters such as temperature, pressure, and material flow. Regular calibration of machinery and periodic quality checks of the extrudate are essential. Additionally, work with suppliers who offer comprehensive training for your operators and detailed documentation of quality control processes, which can help minimize defects and improve overall product consistency.

4. What are the typical payment terms for purchasing a plastic extrusion line?

Payment terms for purchasing a plastic extrusion line can vary widely based on the supplier and the scale of the transaction. Common arrangements include a deposit upfront, followed by milestone payments as production progresses, and a final payment upon delivery. For international transactions, consider discussing flexible terms that accommodate shipping timelines and customs clearance. Always ensure that the terms are documented clearly in a contract to avoid misunderstandings.

5. What are the minimum order quantities (MOQ) for plastic extrusion lines?

Minimum order quantities (MOQ) for plastic extrusion lines can vary by supplier and the specific equipment you are purchasing. Some suppliers may offer single machine sales, while others may require a minimum purchase of multiple units, especially for customized setups. It’s crucial to communicate your production needs clearly to the supplier and negotiate terms that align with your business capacity, ensuring you do not overcommit or underinvest in equipment.

6. How do I vet suppliers for plastic extrusion lines?

Vetting suppliers for plastic extrusion lines involves several steps. Start by researching their reputation in the industry through online reviews and testimonials. Request references from past clients to gauge their satisfaction with the equipment and after-sales service. Assess the supplier’s experience, especially in your specific market region, and inquire about their quality certifications. Finally, consider visiting their facilities or attending trade shows to observe their operations and product offerings firsthand.

7. What logistics considerations should I keep in mind when importing a plastic extrusion line?

When importing a plastic extrusion line, logistics play a crucial role in the successful delivery and installation of your equipment. Factor in shipping times, customs regulations, and potential tariffs specific to your country. Collaborate with a logistics partner experienced in handling industrial machinery to ensure that all documentation is in order. Additionally, plan for on-site installation and training, which may require coordination with the supplier to ensure that technical support is available upon arrival.

8. Can I customize my plastic extrusion line to meet specific production requirements?

Yes, many suppliers offer customization options for plastic extrusion lines to better suit your production requirements. Customization can include adjustments to the extruder design, die head configurations, and additional components such as cooling systems and cutting equipment. When discussing your needs with potential suppliers, provide detailed specifications of your desired output, materials, and production processes to ensure that the customization aligns with your operational goals, enhancing efficiency and product quality.

Top 5 Plastic Extrusion Line Manufacturers & Suppliers List

1. Arlington Machinery – Key Components of Plastic Sheet Extrusion Lines

Domain: arlingtonmachinery.com

Registered: 1997 (28 years)

Introduction: Key Components of Plastic Sheet Extrusion Lines: 1. Extruder: Advanced screw design, precision temperature control, customizable configurations. 2. Die Head: Defines sheet width and thickness, ensures uniform material flow. 3. Calendering and Cooling Section: Automated thickness control, integrated cooling system. 4. Pull Rollers: Ensure steady tension and constant drawing of the sheet. 5. Cutting…

2. Bausano – Plastic Extrusion Solutions

Domain: bausano.com

Registered: 2000 (25 years)

Introduction: Bausano offers a variety of plastic extrusion solutions including:

1. **Complete Lines**:

– Pipe Extrusion Lines: For standard and special pipe applications.

– Profile Extrusion Lines: For the production of plastic profiles.

– Pelletizing Extrusion Lines: Customized for granulation.

– WPC Extrusion Lines: New generation high-level WPC extruders.

– Medical Extrusion Lines: For…

3. Paul Murphy Plastics – Extrusion Lines for Plastic Processing

Domain: paulmurphyplastics.com

Registered: 1999 (26 years)

Introduction: Extrusion lines for plastic processing are used to melt and mix polymer resins available in various colors, thicknesses, and types. Key types of extruders mentioned include: 1. Single Screw Extruders – Least expensive, commonly used for manufacturing plastics, suitable for producing high-quality plastic products with minimal effort. 2. Twin Screw Extruders – Used to melt and combine plastic resins…

4. Conair – Auxiliary Equipment for Extrusion Processing

Domain: conairgroup.com

Registered: 1996 (29 years)

Introduction: Conair offers a range of auxiliary equipment for extrusion processing, including: 1. **Blending**: Gravimetric Batch Blenders, Feeders, and Blending Accessories. 2. **Conveying**: Self-Contained Vacuum Loaders, Compressed Air Material Loaders, Vacuum Pumps/Dust Collectors. 3. **Drying**: Desiccant Dryers, Drying Monitors. 4. **Process Heating**: Process Heaters. 5. **Extrusion Equipment**: Vacuum …

5. Diamat – Plastic Extrusion Components

Domain: diamat.com

Registered: 1999 (26 years)

Introduction: Components for plastic extrusion lines include: 1. Material handling – Complete equipment for flexibility in mixing materials. 2. Crystallization and drying – Optimized material conveyed via screw conveyor. 3. Plastic extruders – Single-screw technology capable of processing up to 100% recycled plastic. 4. Calendering and polishing – Robust construction with pneumatic gap adjustment for film thick…

Strategic Sourcing Conclusion and Outlook for plastic extrusion line

In the rapidly evolving landscape of the plastics industry, effective strategic sourcing of plastic extrusion lines stands as a critical factor for success. International buyers, particularly those from emerging markets in Africa, South America, the Middle East, and Europe, must prioritize partnerships with reputable suppliers who offer advanced machinery that enhances efficiency and quality. Key considerations include evaluating the extruder’s design, temperature control capabilities, and the overall energy efficiency of the system.

Investing in high-performance extrusion lines not only leads to significant operational cost savings but also ensures consistent product quality, which is paramount in a competitive global market. The ability to customize configurations for diverse materials further enhances the versatility of your production capabilities, allowing for innovation and adaptation to market demands.

Looking ahead, the future of plastic extrusion is poised for innovation, driven by advancements in technology and sustainability practices. Now is the time for B2B buyers to engage with experienced suppliers and explore cutting-edge solutions that align with their operational goals. By embracing strategic sourcing, companies can secure a competitive edge and position themselves favorably for growth in the dynamic plastics sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to plastic extrusion line

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.