Plastic Channel: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for plastic channel

In the rapidly evolving global marketplace, sourcing the right plastic channel can present significant challenges for international B2B buyers. Whether you’re seeking durable edge protection for retail displays or reliable components for electrical insulation, understanding the myriad options available is crucial. This comprehensive guide delves into the diverse types of plastic channels, including U-channels, C-channels, and H-channel connectors, while also exploring their various applications across industries such as visual merchandising, office furniture manufacturing, and mobile electrification solutions.

As you navigate this complex landscape, this guide equips you with essential insights into supplier vetting processes, material specifications, and cost considerations. By addressing the unique needs of buyers from Africa, South America, the Middle East, and Europe—such as Germany and Brazil—we aim to empower you to make informed purchasing decisions. With a focus on practical applications and expert recommendations, this resource will help you streamline your sourcing process, ensuring that you select the right plastic channel products to enhance your business operations.

Leverage the information provided here to not only meet your immediate needs but also to foster long-term partnerships with reliable suppliers, ultimately driving your success in the competitive global market.

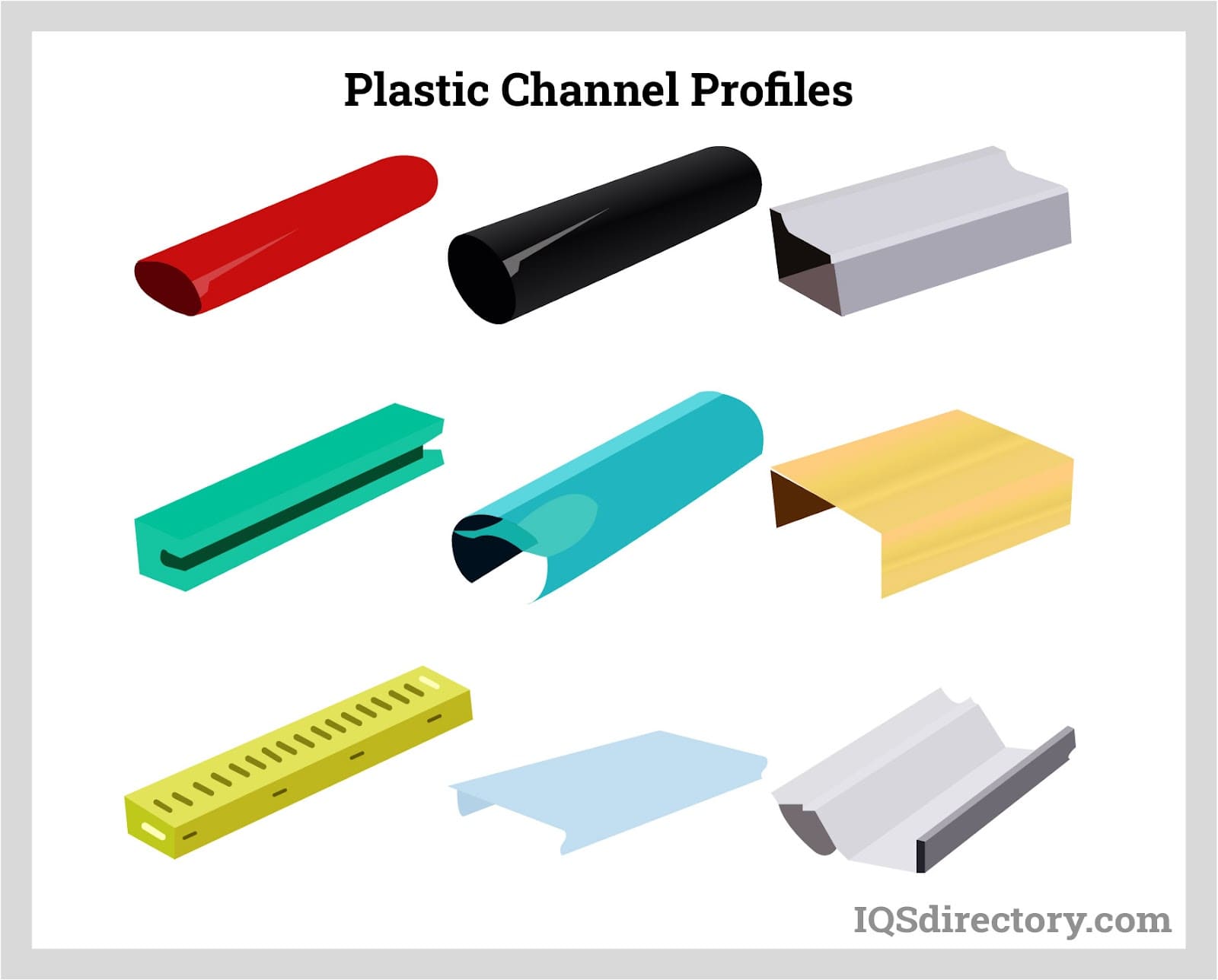

Understanding plastic channel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| U-Channel | A U-shaped profile with open ends for easy insertion. | Display framing, edge trim, signage. | Pros: Versatile, easy to install. Cons: Limited load-bearing capacity. |

| C-Channel | A C-shaped profile with shorter outer walls. | Structural support, framing, and edging. | Pros: Stronger than U-channels. Cons: More complex installation. |

| H-Channel | A double-sided channel ideal for connecting two surfaces. | Mobile electrification, data transfer systems. | Pros: Excellent for securing items. Cons: Requires precise alignment. |

| Sliding Channel | Features a groove for sliding components or inserts. | Label holders, card displays, shelving. | Pros: Facilitates easy access and reconfiguration. Cons: May require custom lengths. |

| PVC Channel | Made from PVC, offering chemical resistance and durability. | Construction, plumbing, and electrical insulation. | Pros: Cost-effective and durable. Cons: Can be less flexible than other materials. |

What are U-Channels and Their Key Features for B2B Buyers?

U-channels are versatile plastic profiles characterized by their U-shaped design, which allows for easy insertion of materials. Commonly used in display framing and edge trimming, they are particularly beneficial for signage applications. When purchasing U-channels, buyers should consider factors such as material strength, color options, and compatibility with adhesives for effective installation. While U-channels are easy to install and adaptable for various applications, they have limitations in load-bearing capacity, which may affect their suitability for certain structural uses.

How Do C-Channels Compare in Terms of Strength and Application?

C-channels, distinguished by their C-shaped profile with shorter outer walls, provide greater structural integrity than U-channels. They are widely used in applications requiring strong support, such as framing and edging. B2B buyers should focus on the channel’s thickness, material type, and overall dimensions when making a purchase. Although C-channels offer enhanced strength, their installation can be more complex, necessitating precise measurements and alignment to ensure optimal performance.

What Are the Advantages of H-Channels for Mobile Electrification?

H-channels are specifically designed for applications that require a secure connection between two surfaces, making them ideal for mobile electrification and data transfer systems. Buyers should evaluate factors such as compatibility with existing systems and ease of installation when considering H-channels. They provide excellent security for components but require careful alignment during installation to ensure functionality. This makes them suitable for specialized industries where precision is critical.

Why Choose Sliding Channels for Display and Shelving Solutions?

Sliding channels are designed with grooves that facilitate the sliding of components or inserts, making them perfect for applications such as label holders and shelving systems. They enable easy access and reconfiguration of display items, which is essential for retail environments. B2B buyers should consider the dimensions, material options, and potential need for custom lengths when selecting sliding channels. While they offer significant flexibility, the need for specific lengths may lead to additional costs.

What Makes PVC Channels a Cost-Effective Choice for Various Industries?

PVC channels are popular due to their chemical resistance and durability, making them suitable for a wide range of applications, including construction and electrical insulation. Buyers should assess the specific chemical exposure and environmental conditions the channels will face. While PVC channels are often cost-effective and robust, they may lack the flexibility of other materials, which could limit their use in certain dynamic applications. Understanding these aspects is crucial for making informed purchasing decisions.

Key Industrial Applications of plastic channel

| Industry/Sector | Specific Application of Plastic Channel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and Display | Point-of-Purchase Displays | Enhances product visibility and customer engagement | Customizable sizes and colors to match branding |

| Furniture Manufacturing | Edge Protection and Trim | Provides a professional finish while ensuring safety | Material durability and aesthetic compatibility |

| Electrical and Electronics | Cable Management and Insulation | Improves safety and organization of electrical systems | Compliance with international safety standards |

| Construction and Architecture | Decorative Molding and Framing | Adds aesthetic value and structural integrity | Resistance to environmental factors and long-term durability |

| Automotive | Protective Trim for Interior Components | Increases product lifespan and enhances user experience | Lightweight yet strong materials to meet performance standards |

How is Plastic Channel Used in Retail and Display Applications?

In the retail sector, plastic channels are extensively utilized for point-of-purchase displays. They serve as holders for signage and product information, enhancing visibility and attracting customers. These channels can be customized in various colors and sizes to align with a brand’s identity, making them essential for visual merchandising strategies. International buyers should consider sourcing options that allow for customization and quick turnaround times, as the retail landscape often demands rapid changes in display setups.

What Role Does Plastic Channel Play in Furniture Manufacturing?

In furniture manufacturing, plastic channels provide edge protection and trim, ensuring a polished and professional finish. These channels help to smooth out uneven edges, enhancing safety by reducing sharp points. Buyers in this sector should prioritize materials that are not only durable but also aesthetically pleasing to maintain the furniture’s overall design appeal. Additionally, understanding local regulations regarding material safety and sustainability can be crucial for international sourcing.

How is Plastic Channel Essential for Electrical and Electronics?

Plastic channels are critical in the electrical and electronics industry for cable management and insulation. They help organize wires, reducing clutter and the risk of electrical hazards. Proper cable management enhances operational efficiency and safety, which is particularly important in regions with stringent electrical safety regulations. B2B buyers should ensure that the plastic channels comply with international standards for fire resistance and electrical insulation to mitigate risks.

Why is Plastic Channel Important in Construction and Architecture?

In construction and architecture, plastic channels are used for decorative molding and framing, adding both aesthetic and structural value. They are favored for their lightweight yet sturdy properties, which can withstand various environmental conditions. Buyers should consider sourcing channels that offer UV resistance and weatherproofing features, especially in regions with extreme climates. This ensures that the products maintain their appearance and functionality over time.

How Does Plastic Channel Enhance Automotive Interior Components?

In the automotive industry, plastic channels are employed as protective trim for interior components, providing a clean finish and enhancing user experience. They help to prevent wear and tear on surfaces, prolonging the lifespan of interior fittings. For international buyers, it is essential to consider the weight-to-strength ratio of the materials used, as automotive applications often require components that are both lightweight and robust to improve fuel efficiency and performance.

3 Common User Pain Points for ‘plastic channel’ & Their Solutions

Scenario 1: Difficulty in Custom Sizing and Shape Requirements

The Problem:

B2B buyers often face challenges when their projects require custom sizes or unique shapes for plastic channels. This can arise in industries like retail display or furniture manufacturing, where standard dimensions do not fit specific design needs. The frustration stems from the lengthy lead times and potential additional costs associated with sourcing custom solutions, which can delay project timelines and impact overall operational efficiency.

The Solution:

To overcome this issue, buyers should partner with manufacturers that offer in-house tooling and custom extrusion capabilities. Before placing an order, it’s essential to communicate precise specifications, including dimensions, shapes, and any specific material requirements. A proactive approach involves requesting samples or prototypes to test fit and functionality before full production. Additionally, leveraging a supplier’s expertise in materials—such as HDPE or Rigid PVC—can ensure that the chosen plastic channel meets not just the aesthetic needs but also the durability required for the intended application. Establishing a long-term relationship with a reliable supplier can also streamline future custom orders, reducing lead times and costs.

Scenario 2: Inconsistent Quality and Performance Across Suppliers

The Problem:

Quality inconsistency can be a major concern for B2B buyers, especially when sourcing plastic channels from multiple suppliers. Variations in material quality, manufacturing processes, or even environmental factors can lead to products that do not meet specifications or perform reliably in applications such as signage, edge protection, or cable management. This can result in increased costs due to returns, replacements, or project delays.

The Solution:

To mitigate quality issues, buyers should focus on establishing relationships with ISO-certified manufacturers who adhere to strict quality control standards. Conducting thorough supplier evaluations, including reviewing certifications and past performance, can help ensure product reliability. Additionally, implementing a consistent testing protocol for incoming materials can catch discrepancies early. Buyers should also consider negotiating service-level agreements that outline quality expectations, delivery timelines, and recourse for non-compliance, creating accountability and ensuring a consistent supply of high-quality plastic channels.

Scenario 3: Complexity in Application Versatility

The Problem:

Many B2B buyers struggle with the versatility of plastic channels, particularly when integrating them into various applications. For instance, in visual merchandising, the same channel type may need to serve as a protective edge, a graphic holder, or even a cable management solution. This complexity can lead to confusion in selecting the right product, resulting in suboptimal performance and increased costs due to trial and error.

The Solution:

To navigate this challenge, buyers should invest time in understanding the full range of applications for plastic channels and the materials best suited for each. Engaging with suppliers who provide comprehensive product guides or technical support can aid in making informed decisions. It’s also beneficial to conduct workshops or training sessions with supplier representatives to explore practical applications and best practices. By identifying multi-functional products that can serve various roles, buyers can streamline their inventory and reduce costs. Additionally, adopting a consultative approach with suppliers can lead to tailored solutions that maximize the utility of plastic channels across different projects.

Strategic Material Selection Guide for plastic channel

What Are the Key Properties of Common Materials Used in Plastic Channels?

When selecting materials for plastic channels, understanding their properties is crucial for ensuring optimal performance in various applications. Here, we analyze four commonly used materials: PVC, Polycarbonate, HDPE, and ABS.

How Does PVC Perform as a Material for Plastic Channels?

Polyvinyl Chloride (PVC) is one of the most widely used materials for plastic channels due to its excellent balance of properties. It has a temperature rating of up to 60°C and is resistant to many chemicals, making it suitable for a variety of environments.

Pros: PVC is durable, cost-effective, and easy to fabricate. It offers good impact resistance and can be easily extruded into complex shapes.

Cons: However, PVC can become brittle over time when exposed to UV light unless treated. Additionally, it has a lower temperature resistance compared to some other materials.

Impact on Application: PVC channels are commonly used in electrical insulation and as trim in furniture. They are compatible with various media, including water and mild chemicals, but may not be suitable for high-temperature applications.

Considerations for International Buyers: Compliance with local regulations regarding PVC usage is essential, especially in regions like Europe, where RoHS and REACH directives apply. Buyers should also be aware of ASTM standards for construction materials.

What Are the Advantages of Using Polycarbonate for Plastic Channels?

Polycarbonate is known for its exceptional strength and high impact resistance, making it a preferred choice for applications requiring durability. It has a temperature rating of up to 120°C.

Pros: Its transparency allows for aesthetic applications, such as display systems. Polycarbonate also has excellent UV resistance, making it suitable for outdoor use.

Cons: The main drawback is its higher cost compared to PVC and its susceptibility to scratching.

Impact on Application: Polycarbonate channels are ideal for signage and display cases, where visibility and durability are paramount. They can handle exposure to UV light and various environmental conditions.

Considerations for International Buyers: Buyers in regions with strict safety regulations should ensure that polycarbonate products meet local standards, such as DIN or JIS.

Why Choose HDPE for Plastic Channels?

High-Density Polyethylene (HDPE) is known for its high strength-to-density ratio, making it suitable for heavy-duty applications. It can withstand temperatures up to 80°C and has excellent resistance to chemicals and moisture.

Pros: HDPE is lightweight, durable, and has a high resistance to impact and corrosion. It is also recyclable, which can be a significant advantage for environmentally conscious companies.

Cons: The main limitation is its lower rigidity compared to PVC and polycarbonate, which may not be suitable for all structural applications.

Impact on Application: HDPE channels are often used in agricultural and industrial applications, particularly for chemical handling and storage.

Considerations for International Buyers: Compliance with food safety standards is critical when using HDPE in food-related applications. Buyers should also consider local recycling regulations.

What Are the Key Features of ABS in Plastic Channels?

Acrylonitrile Butadiene Styrene (ABS) is a versatile thermoplastic known for its toughness and impact resistance, with a temperature rating up to 80°C.

Pros: ABS is easy to machine and has excellent dimensional stability, making it suitable for precision applications. Its ability to be painted or glued adds to its versatility.

Cons: However, ABS is less resistant to UV light and may degrade over time when exposed to sunlight.

Impact on Application: ABS channels are commonly used in automotive and electronic applications, where durability and aesthetic appeal are essential.

Considerations for International Buyers: Buyers should be aware of the need for compliance with automotive standards in regions like Europe and North America.

Summary Table of Material Selection for Plastic Channels

| Material | Typical Use Case for Plastic Channel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Electrical insulation, furniture trim | Cost-effective, easy to fabricate | Brittle with UV exposure | Low |

| Polycarbonate | Signage, display cases | High impact resistance, UV stable | Higher cost, prone to scratching | High |

| HDPE | Chemical handling, agricultural use | Lightweight, corrosion resistant | Lower rigidity compared to others | Medium |

| ABS | Automotive, electronic applications | Tough, easy to machine | Poor UV resistance | Medium |

This guide provides actionable insights for international B2B buyers looking to select the appropriate materials for plastic channels, ensuring that they meet both performance requirements and compliance standards in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic channel

What Are the Main Stages in the Manufacturing Process of Plastic Channels?

The manufacturing of plastic channels involves several critical stages, ensuring that the final product meets the desired specifications and quality standards. Understanding these stages can help B2B buyers assess potential suppliers more effectively.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing plastic channels is material preparation. Manufacturers typically use various thermoplastics, including HDPE, PVC, and polycarbonate, chosen for their durability and application suitability. The raw materials are often supplied in pellet form and must be dried to eliminate moisture, which can compromise the extrusion process.

Once dried, the pellets are fed into an extruder, where they are heated to their melting point. The selection of material can significantly affect the channel’s performance, such as flexibility, strength, and resistance to environmental factors.

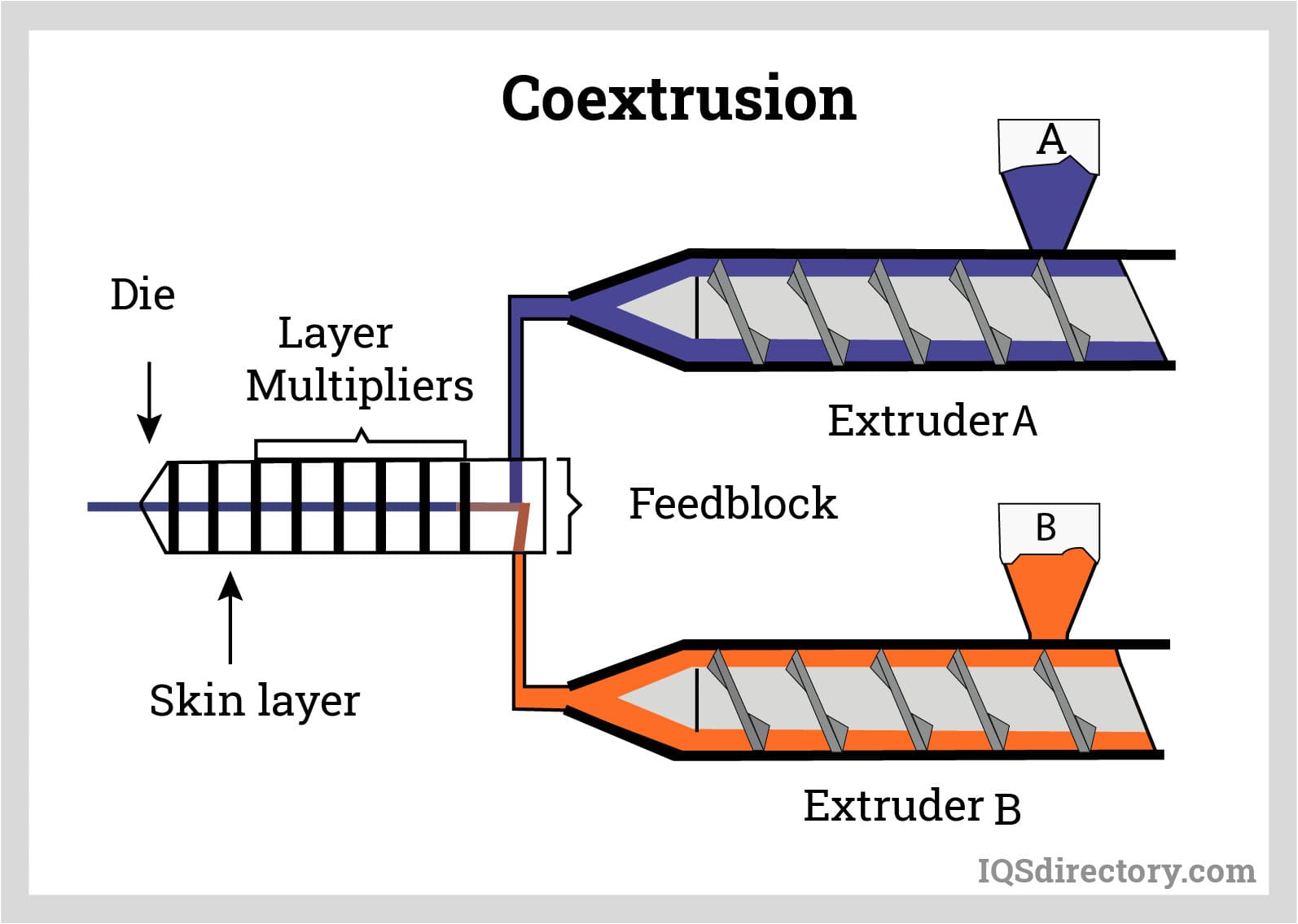

How Is the Forming Process Conducted for Plastic Channels?

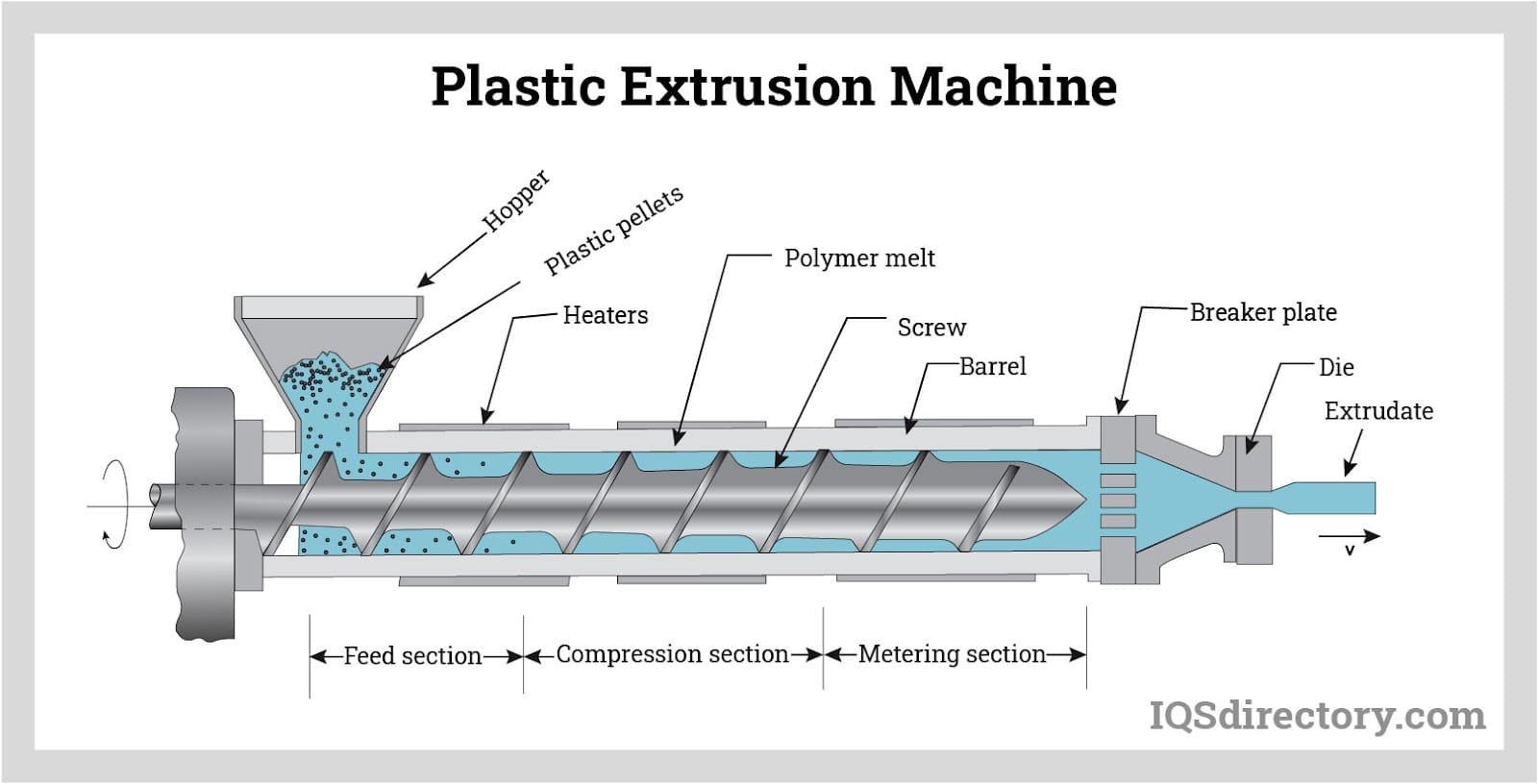

The core of the manufacturing process is the forming stage, typically accomplished through extrusion. In this continuous process, the molten plastic is forced through a die that shapes it into the desired profile.

Illustrative image related to plastic channel

Extrusion allows for a high volume of production with consistent quality. Variations like co-extrusion can also be employed, where two or more materials are combined to create channels with unique properties, such as enhanced strength or improved aesthetics. The extrusion process is closely monitored to ensure that the material flows evenly and maintains the required dimensions throughout.

What Finishing Techniques Are Used to Enhance Plastic Channels?

After extrusion, the channels undergo several finishing processes to enhance their functionality and appearance. Common finishing techniques include cutting to specific lengths, surface treatments, and the application of coatings or adhesives.

For instance, channels may be polished for a smoother finish or painted in custom colors to meet client specifications. Additionally, some manufacturers offer custom fabrication services, such as adding holes or notches for specific applications, which can provide added value for B2B buyers looking for tailored solutions.

What Quality Assurance Practices Are Essential for Plastic Channel Production?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets industry standards and customer expectations. Effective QA practices can significantly reduce the risk of defects and enhance customer satisfaction.

Illustrative image related to plastic channel

Which International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding the international quality standards applicable to plastic channels is vital. ISO 9001 is one of the most recognized standards, focusing on quality management systems and continuous improvement. Compliance with ISO 9001 indicates that a manufacturer has established effective processes to ensure consistent quality.

In addition to ISO standards, industry-specific certifications such as CE marking in Europe or API standards for specific applications may also apply. These certifications can reassure buyers that the products are safe and reliable for use in various applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to catch defects early and ensure compliance with specifications. Common QC checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During production, samples are regularly taken to monitor parameters such as thickness, dimensions, and material properties. This ensures that the extrusion process remains within tolerances.

-

Final Quality Control (FQC): Once production is complete, final inspections are conducted on the finished channels. This may involve dimensional checks, visual inspections for defects, and functional tests to ensure the channels meet all specifications.

What Common Testing Methods Are Used to Validate the Quality of Plastic Channels?

Various testing methods are employed to validate the quality of plastic channels. These may include:

-

Mechanical Testing: Evaluates properties such as tensile strength, impact resistance, and flexibility, ensuring the product can withstand its intended use.

-

Dimensional Verification: Uses tools like calipers and gauges to confirm that the channels meet specified dimensions and tolerances.

-

Environmental Testing: Assesses the performance of plastic channels under various environmental conditions, such as UV exposure, temperature fluctuations, and chemical exposure.

These testing methods help ensure that the final product is reliable and performs as expected in its application.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are several strategies to assess supplier quality:

-

Conduct Supplier Audits: Regular audits of suppliers can help verify their adherence to quality standards and manufacturing processes. These audits can focus on their quality management systems, production capabilities, and compliance with international standards.

-

Request Quality Assurance Documentation: Suppliers should provide documentation related to their quality assurance processes, including certifications, test reports, and inspection records. This documentation can provide insights into their commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspectors can conduct on-site evaluations and perform tests to ensure compliance with specifications.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of certain nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulations regarding the use of plastics, particularly in industries such as food, healthcare, and construction. Buyers should ensure that suppliers comply with local regulations.

-

Cultural Differences in Quality Expectations: Different markets may have varying expectations regarding product quality and customer service. Understanding these differences can help buyers set appropriate criteria when evaluating suppliers.

-

Logistical Considerations: Quality control can be affected by shipping and handling, particularly for international shipments. Buyers should consider how products are packaged and transported to minimize damage and maintain quality.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for plastic channels, ultimately enhancing their supply chain reliability and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic channel’

In the ever-evolving market of plastic channels, ensuring a successful procurement process requires a systematic approach. This guide serves as a practical checklist for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to navigate the complexities of sourcing plastic channels effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the plastic channels meet your project’s requirements. Consider factors such as dimensions, material type (e.g., HDPE, PVC, or polycarbonate), and application (e.g., edge trim, signage, or insulation). This foundational step helps in narrowing down your options and communicating effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in plastic channels. Look for companies with a strong track record in your target markets, and consider their production capabilities and product offerings. Utilize platforms like industry directories, trade shows, and online reviews to gather insights on potential partners.

Illustrative image related to plastic channel

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with relevant industry standards. Certifications such as ISO 9001 indicate a commitment to quality management, which can significantly impact the reliability of your materials. Additionally, check for environmental certifications, especially if sustainability is a priority for your business.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the plastic channels to evaluate their quality and suitability for your application. Testing the samples can reveal important characteristics such as durability, flexibility, and ease of installation. This step is crucial to ensure that the products will perform well in your specific use case.

Step 5: Analyze Pricing and Terms

Compare the pricing structures and payment terms offered by different suppliers. Ensure that the pricing reflects the quality of the product and includes all associated costs, such as shipping and handling. Look for favorable payment terms that align with your cash flow requirements, but remain cautious of deals that seem too good to be true.

Step 6: Review the Supplier’s Production Capacity

Understanding the production capacity of your selected supplier is essential, especially for large-scale projects. Inquire about their lead times, minimum order quantities, and ability to scale production if needed. This information will help you plan your inventory and ensure timely project completion.

Step 7: Establish Communication and Support Channels

Effective communication is key to a successful partnership. Ensure that the supplier has clear channels for customer support and that they can promptly address any inquiries or issues that arise. Establishing a good rapport with your supplier can lead to better service and responsiveness in the long run.

By following this checklist, B2B buyers can streamline the procurement process for plastic channels, ensuring that they select the right materials and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for plastic channel Sourcing

What Are the Key Cost Components in Plastic Channel Sourcing?

When sourcing plastic channels, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of plastic significantly impacts the price. Common materials like HDPE, Rigid PVC, and Polycarbonate vary in cost. For instance, high-density polyethylene (HDPE) may be more economical than polycarbonate due to its widespread availability and lower processing costs.

-

Labor: Labor costs can fluctuate based on the region and the complexity of the extrusion process. Skilled labor may demand higher wages, particularly in regions with stringent quality standards.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment depreciation. These costs are typically fixed and should be factored into the overall pricing.

-

Tooling: Custom tooling for specialized channel designs can incur significant upfront costs. Buyers should inquire about any one-time tooling charges that may affect initial pricing.

-

Quality Control (QC): Ensuring that products meet specific quality standards incurs additional costs. Manufacturers often implement rigorous testing protocols, which can influence the final price.

-

Logistics: Transportation and handling fees are crucial, especially for international buyers. These costs can vary significantly depending on the shipping method and distance, impacting overall pricing.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. This margin can vary widely based on market conditions and competitive landscape.

How Do Price Influencers Affect the Sourcing of Plastic Channels?

Several factors can influence the pricing of plastic channels, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger quantities typically leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or unique specifications can drive up costs due to the need for specialized tooling and production processes. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., compliance with environmental standards) often come at a premium. Buyers should assess the necessity of such certifications relative to their end-use.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer better warranties and support, justifying higher prices. Conversely, new or less experienced suppliers might provide lower prices but with added risk.

-

Incoterms: Understanding the agreed-upon Incoterms is crucial for determining the responsibilities of buyers and sellers regarding shipping and delivery. This can significantly affect the total landed cost.

What Tips Should B2B Buyers Consider for Cost-Efficiency in Plastic Channel Sourcing?

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing and terms. Leverage your purchasing volume to negotiate better rates or favorable payment terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not just the purchase price but also shipping, handling, and potential downtime due to quality issues. A lower upfront cost may lead to higher overall expenses if quality is compromised.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should account for currency fluctuations, tariffs, and import duties, which can affect overall costs.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends in the plastic channel industry. This knowledge can empower buyers during negotiations and decision-making.

Disclaimer on Indicative Prices

Prices for plastic channels can vary widely based on the aforementioned factors. Therefore, it is advisable for buyers to seek quotes from multiple suppliers and conduct due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing plastic channel With Other Solutions

When considering solutions for applications that require channeling, edge protection, or display framing, evaluating alternatives to plastic channels is essential for making informed purchasing decisions. Below, we explore how plastic channels compare with two viable alternatives: aluminum channels and wood trim. Each option presents unique benefits and drawbacks, making it crucial for buyers to understand the distinctions to choose the best fit for their specific needs.

| Comparison Aspect | Plastic Channel | Aluminum Channel | Wood Trim |

|---|---|---|---|

| Performance | Durable, lightweight, and resistant to moisture and chemicals. Suitable for a variety of applications, including edge trim and framing. | Highly durable and strong; excellent for structural applications but can be prone to corrosion without proper treatment. | Aesthetic appeal and good for interior applications; can warp or rot in humid conditions. |

| Cost | Generally cost-effective, especially for bulk purchases. | Higher initial cost but offers longevity, potentially reducing long-term replacement costs. | Moderate cost; can vary significantly based on type and finish. |

| Ease of Implementation | Easy to cut and install; lightweight nature simplifies handling and installation. | Requires specialized tools for cutting and may need additional finishing work. | Installation can be labor-intensive; requires tools for cutting and finishing. |

| Maintenance | Minimal maintenance required; resistant to fading and wear. | Low maintenance if properly treated; may need periodic inspections for corrosion. | Requires regular maintenance (e.g., sealing, staining) to prevent damage. |

| Best Use Case | Ideal for display systems, signage, and moisture-prone areas. | Best for structural applications, outdoor environments, and areas requiring high strength. | Suitable for decorative applications, furniture, and interior finishes. |

What are the Pros and Cons of Aluminum Channels Compared to Plastic Channels?

Aluminum channels are favored for their strength and durability, making them suitable for structural applications where high load-bearing capacity is essential. Their resistance to corrosion, especially when treated, allows for longevity in outdoor settings. However, the initial cost is higher than that of plastic channels, and the installation process may require specialized tools, which can complicate project timelines. Additionally, while aluminum is recyclable, the energy involved in its production can be a drawback for eco-conscious buyers.

How Does Wood Trim Stack Up Against Plastic Channels?

Wood trim offers a classic aesthetic that is hard to replicate with synthetic materials. It’s ideal for interior applications where design and appearance are paramount. However, wood can be susceptible to warping, rotting, and insect damage, especially in humid environments, which necessitates regular maintenance. The installation process can be labor-intensive, requiring precision cutting and finishing. While wood may be moderately priced, the ongoing maintenance can add to the overall cost over time.

How Can B2B Buyers Choose the Right Solution?

In selecting the appropriate channeling solution, B2B buyers should assess their specific needs, including the environment in which the product will be used, aesthetic requirements, and budget constraints. For applications requiring moisture resistance and lightweight properties, plastic channels are often the most suitable choice. Conversely, for projects demanding structural integrity or a premium finish, aluminum channels or wood trim might be more appropriate. Understanding the trade-offs associated with each alternative will enable buyers to make informed decisions that align with their operational and financial goals.

Essential Technical Properties and Trade Terminology for plastic channel

Understanding the technical properties and terminology associated with plastic channels is crucial for B2B buyers, especially those involved in sectors like retail displays, furniture manufacturing, and electrical insulation. Here, we explore key specifications and trade terms that will enhance your decision-making process when sourcing plastic channels.

What Are the Key Technical Properties of Plastic Channels?

1. Material Grade

Plastic channels are available in various materials such as HDPE (High-Density Polyethylene), Rigid PVC (Polyvinyl Chloride), and Polycarbonate. The choice of material affects the channel’s durability, flexibility, and resistance to chemicals and UV light. For instance, HDPE is known for its strength and resistance to impact, making it ideal for outdoor applications. Selecting the right material grade is essential for ensuring that the channel meets the specific demands of your application, thereby reducing the risk of failure and costly replacements.

Illustrative image related to plastic channel

2. Wall Thickness

Wall thickness is a critical specification that influences the channel’s strength and load-bearing capacity. Thicker walls generally provide better durability and resistance to deformation under stress. For example, a channel with a wall thickness of 0.08 inches may be preferred for heavy-duty applications, while thinner profiles may suffice for decorative or lightweight uses. B2B buyers should assess the required wall thickness based on the intended use to ensure longevity and effectiveness.

3. Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the extrusion process. Tight tolerances are crucial for applications requiring precise fit and alignment, such as in electrical installations or display systems. Understanding the tolerance levels ensures that the plastic channel can be integrated seamlessly into existing structures or systems, minimizing installation challenges.

4. Color and Finish Options

Plastic channels are often available in various colors and finishes, which can enhance aesthetic appeal or functionality. For instance, channels with a matte finish may be preferable for reducing glare in display systems, while bright colors may be used for safety markings. Choosing the right color and finish is not only about visual appeal but also impacts brand representation and the overall user experience.

5. Customization Capabilities

Many manufacturers offer customization options for plastic channels, allowing for specific lengths, shapes, or features tailored to unique requirements. This flexibility can be vital for businesses needing specialized solutions that standard products cannot provide. Understanding customization capabilities can significantly influence project timelines and costs, enabling buyers to align product specifications with their operational needs.

Illustrative image related to plastic channel

What Are Common Trade Terms Related to Plastic Channels?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of plastic channels, it’s important to identify OEMs that can provide high-quality components tailored to specific applications, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budget management and inventory planning. For international buyers, aligning MOQ with project needs can help optimize supply chain efficiency.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers. It typically includes detailed specifications and quantities. Submitting an RFQ can help businesses compare prices and terms from multiple suppliers, ensuring they secure the best deal for their plastic channel needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in transactions. Familiarity with Incoterms is vital for understanding shipping costs, risk management, and delivery timelines, which are crucial for international buyers sourcing plastic channels.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Knowing the lead time is critical for planning project timelines and ensuring that materials arrive when needed, preventing delays in production.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance overall operational efficiency when sourcing plastic channels.

Navigating Market Dynamics and Sourcing Trends in the plastic channel Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Channel Sector?

The global plastic channel market is witnessing significant growth, driven by increased demand across various industries, including retail, construction, and automotive. In regions such as Africa, South America, the Middle East, and Europe, B2B buyers are particularly focused on sourcing high-quality, durable plastic channels that can withstand diverse environmental conditions. The rise of e-commerce and online retail has also spurred demand for innovative display solutions, further propelling the growth of plastic channels in point-of-purchase displays and visual merchandising.

Emerging trends in the B2B landscape include the adoption of advanced manufacturing technologies such as 3D printing and automation, which enhance customization capabilities and reduce lead times. Additionally, the shift towards digital procurement platforms is transforming how buyers interact with suppliers, making it easier to compare products, request quotes, and manage orders efficiently. Sustainability is increasingly becoming a key consideration for international buyers, with a growing preference for suppliers that offer eco-friendly materials and practices.

In terms of market dynamics, fluctuating raw material prices, particularly for polymers like PVC and polycarbonate, pose challenges for manufacturers and buyers alike. This volatility necessitates strategic sourcing decisions and long-term partnerships with reliable suppliers. Furthermore, regulatory changes related to plastic use and waste management are shaping sourcing strategies, pushing companies to adopt more sustainable practices while ensuring compliance with local and international standards.

How Is Sustainability and Ethical Sourcing Impacting the Plastic Channel Industry?

Sustainability is at the forefront of global business practices, and the plastic channel sector is no exception. The environmental impact of plastic production and disposal has prompted B2B buyers to prioritize ethical sourcing and sustainable materials. Buyers are increasingly seeking suppliers who demonstrate a commitment to reducing their carbon footprint, such as using recycled materials or biodegradable alternatives in their products.

The importance of ethical supply chains cannot be overstated. Companies are now expected to maintain transparency regarding their sourcing practices, ensuring that materials are acquired responsibly and without harming communities or ecosystems. This shift is reflected in the growing demand for certifications such as ISO 14001 (Environmental Management) and those related to sustainable sourcing.

In response to this demand, manufacturers are innovating by developing ‘green’ plastic channels made from recyclable or bio-based materials. These products not only meet the functional requirements of B2B buyers but also align with their sustainability goals. As a result, organizations that prioritize sustainability in their sourcing strategies are likely to enhance their brand reputation and appeal to environmentally-conscious customers.

What Is the Evolution of the Plastic Channel Industry?

The evolution of the plastic channel industry is marked by significant technological advancements and shifts in market demand. Originally, plastic channels were primarily used for functional applications such as insulation and protection in electrical systems. However, as industries evolved, so did the applications of plastic channels. The introduction of advanced extrusion techniques has allowed for a wider variety of shapes, sizes, and materials, catering to diverse market needs.

In recent years, the focus has shifted towards aesthetic applications, particularly in retail and commercial environments where visual merchandising plays a crucial role. Today, plastic channels are not only functional but also serve as essential components in design and branding strategies. The ongoing emphasis on sustainability is further driving innovation, leading to the development of eco-friendly alternatives that meet both consumer and regulatory demands.

As the market continues to evolve, B2B buyers must stay informed about the latest trends and advancements in the plastic channel sector to make informed sourcing decisions that align with their strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic channel

-

How do I select the right plastic channel for my application?

Choosing the right plastic channel involves understanding the specific requirements of your project, including material type, dimensions, and intended use. Consider factors such as environmental conditions (e.g., exposure to UV light or chemicals), the load the channel will bear, and aesthetic preferences. Common materials include PVC, HDPE, and polycarbonate, each offering unique durability and flexibility. Consulting with suppliers about your application can also yield insights into the best options for your needs. -

What are the key applications of plastic channels in various industries?

Plastic channels serve diverse functions across multiple industries, including retail display systems, office furniture manufacturing, and signage. They are often used for edge trim, graphic holders, and protective edging. In sectors like mobile electrification and data transfer systems, they provide effective cable management and insulation. Understanding your industry’s specific applications can help you identify the most suitable plastic channel profiles for your projects. -

What customization options are available for plastic channels?

Most manufacturers offer various customization options for plastic channels, including different lengths, shapes, colors, and materials. You can request specific wall thicknesses and profiles to meet your project’s requirements. Additionally, some suppliers provide custom tooling at no extra cost, allowing you to create unique designs tailored to your needs. Engaging in discussions with suppliers about your project specifications can lead to tailored solutions that enhance functionality and aesthetics. -

What are the minimum order quantities (MOQs) for plastic channels?

Minimum order quantities for plastic channels vary by supplier and can depend on factors such as material type and complexity of the order. Typically, MOQs may range from a few hundred to several thousand units. When sourcing internationally, it’s crucial to clarify MOQs upfront to ensure they align with your project budget and timelines. Suppliers may offer flexibility on MOQs for repeat customers or bulk orders, so it’s worth negotiating based on your needs. -

What payment terms should I expect when sourcing plastic channels internationally?

Payment terms for international orders of plastic channels can vary widely among suppliers. Common terms include upfront payments, letter of credit, or payment upon delivery. It’s essential to discuss and agree on payment methods that ensure security for both parties. Additionally, consider factors like currency exchange rates and transaction fees. Establishing clear payment terms in the contract can help avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance (QA) for plastic channels?

Quality assurance for plastic channels begins with selecting reputable suppliers who adhere to industry standards. Request certifications such as ISO 9001 or specific material quality certifications. Additionally, you may want to conduct pre-production samples or audits to assess material quality and manufacturing processes. Implementing a quality control process upon receipt of goods, including visual inspections and measurements, can further ensure that the products meet your specifications. -

What logistical considerations should I keep in mind when importing plastic channels?

Logistical considerations for importing plastic channels include shipping costs, delivery times, and customs regulations. Ensure that your supplier provides clear shipping options, including freight costs and expected delivery timelines. Familiarize yourself with import duties and customs procedures in your country to avoid unexpected delays. Working with a freight forwarder can help streamline the logistics process and ensure compliance with international trade regulations. -

How can I vet potential suppliers of plastic channels effectively?

Vetting suppliers of plastic channels involves assessing their experience, reputation, and production capabilities. Start by reviewing their website, customer testimonials, and case studies. Request references and verify their business licenses and certifications. Additionally, consider visiting their facility if possible or arranging virtual tours. Engaging in direct communication can help gauge their responsiveness and willingness to meet your specific needs, ensuring you select a reliable partner for your sourcing requirements.

Top 3 Plastic Channel Manufacturers & Suppliers List

1. Tap Plastics – Plastic Rods, Tubes & Shapes

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Plastic rods, tubes, and shapes for joining applications. Suitable for various projects and industries. Available in different sizes and materials. Ideal for custom fabrication and repairs.

2. IQS Directory – Plastic Channels

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Plastic channels are linear, extruded plastic products with a uniform cross-section, commonly used for trim edging, connectors, sealants, insulators, panels, guides, and structural elements. They are manufactured from various thermoplastic materials, including: 1. Polyvinyl Chloride (PVC): High-strength, rigid, durable, cost-effective, with excellent chemical resistance, electrical insulation, and…

3. Interstate Plastics – PVC Gray U Channel Profiles

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: Product Name: PVC Gray U Channel Plastic Profile

Material: PVC Type I resins

Dimensions: Various sizes available, including:

– .51″ x 0.59″ x .060″ (Length: 118″, Box Quantity: 45)

– .944″ x .787″ x .066″ (Length: 118″, Box Quantity: 29)

– .944″ x 1.57″ x .080″ (Length: 118″, Box Quantity: 17)

– 1.14″ x 1.65″ x .080″ (Length: 118″, Box Quantity: 15)

– 1.87″ x .787″ x .137″ (Length: 118″, Box Quant…

Strategic Sourcing Conclusion and Outlook for plastic channel

In conclusion, strategic sourcing of plastic channels presents a significant opportunity for international B2B buyers to enhance product offerings across various industries, including retail displays, furniture manufacturing, and electrical solutions. By leveraging durable materials such as HDPE, PVC, and polycarbonate, companies can meet diverse application requirements while ensuring high-quality performance and aesthetics.

Investing in customized solutions, such as tailored lengths and profiles, enables businesses to differentiate themselves in competitive markets. Furthermore, understanding the intricacies of plastic extrusion and the specific benefits of different materials can lead to informed sourcing decisions that optimize both cost and functionality.

Illustrative image related to plastic channel

As we look ahead, it is vital for buyers from Africa, South America, the Middle East, and Europe to engage with reliable suppliers who can provide innovative solutions and sustainable practices. By fostering partnerships with experienced manufacturers, businesses can not only streamline their procurement processes but also position themselves for future growth in an evolving marketplace. Take the next step in enhancing your supply chain—explore the diverse options available in plastic channels and discover how they can elevate your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.