Pipework Expansion Joints: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for pipework expansion joints

In the ever-evolving landscape of global manufacturing and construction, sourcing high-quality pipework expansion joints poses a significant challenge for international B2B buyers. These critical components play a vital role in maintaining system integrity, accommodating thermal expansions, and preventing mechanical failures in piping systems. However, navigating the complexities of various types, materials, and applications can be daunting, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe, including markets like Brazil and Vietnam.

This comprehensive guide is designed to equip procurement professionals with the knowledge and insights needed to make informed purchasing decisions regarding pipework expansion joints. It delves into the various types of expansion joints available, including metal, rubber, and fabric options, and explores their specific applications across diverse industries such as oil and gas, chemical processing, and power generation. Additionally, the guide addresses critical aspects of supplier vetting, ensuring buyers can identify reputable manufacturers and distributors who meet their quality and compliance standards.

By outlining essential cost considerations and offering practical tips for effective sourcing, this guide empowers B2B buyers to navigate the global market confidently. With a focus on actionable insights and strategic decision-making, it serves as a valuable resource for those seeking to optimize their procurement processes while ensuring the reliability and performance of their piping systems.

Understanding pipework expansion joints Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Expansion Joints | Made from stainless steel or other metals; high temperature resistance; durable design. | Oil and gas, chemical processing, power generation | Pros: High durability, suitable for extreme conditions. Cons: Higher initial cost, potential for corrosion. |

| Rubber Expansion Joints | Flexible rubber construction; good for vibration absorption; cost-effective. | HVAC systems, water treatment, food and beverage | Pros: Cost-effective, good flexibility. Cons: Limited temperature range, shorter lifespan. |

| Fabric Expansion Joints | Lightweight and flexible; made from reinforced fabrics; customizable shapes. | Aerospace, industrial applications, piping systems | Pros: Lightweight, easy to install. Cons: Not suitable for high pressure, may require frequent replacement. |

| Externally Pressurized Joints | Designed to handle larger movements; protects bellows from external pressure. | Seismic applications, building joints | Pros: Accommodates large movements, robust design. Cons: More complex installation, higher maintenance. |

| Gimbal Expansion Joints | Allows movement in multiple directions; often used in complex piping systems. | Marine, industrial processes, power plants | Pros: Versatile movement capabilities, effective in multi-directional applications. Cons: Higher cost, requires precise installation. |

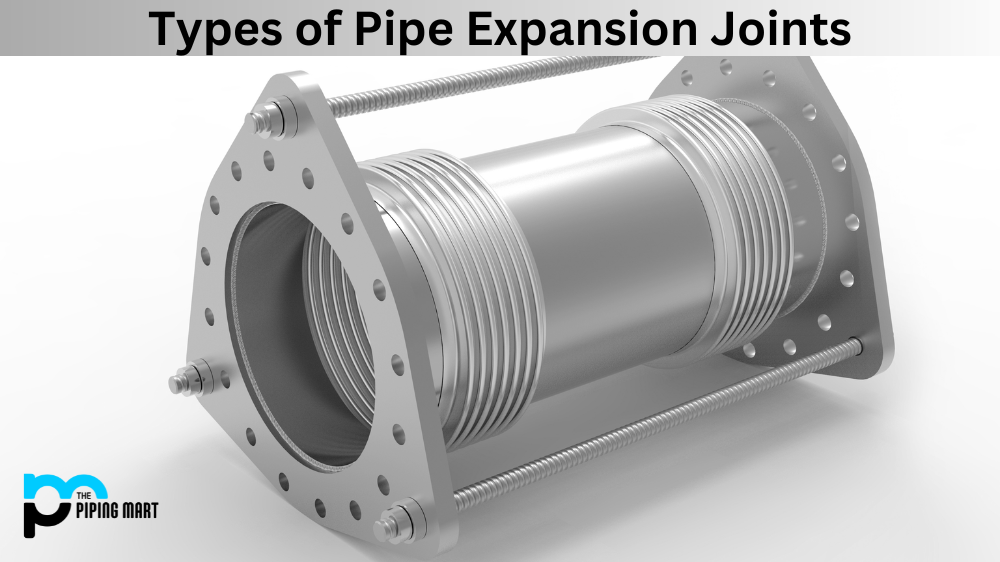

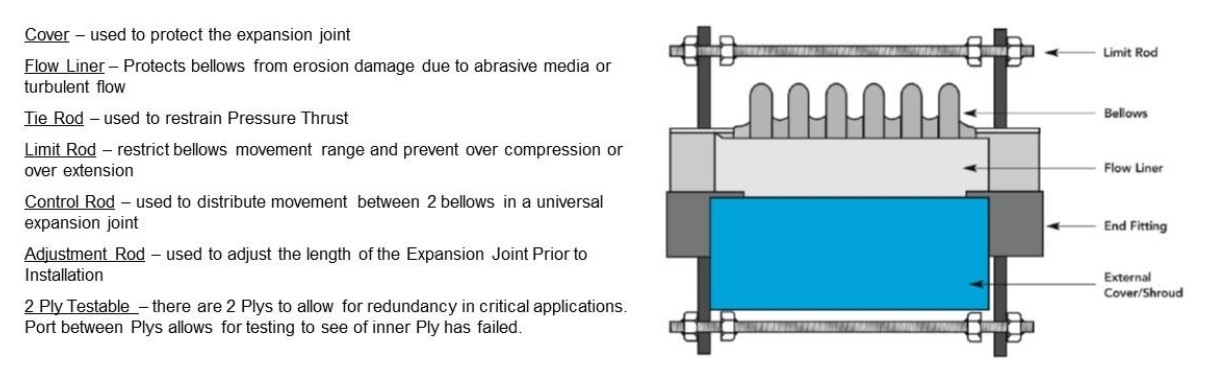

What are the Characteristics of Metal Expansion Joints and Their Suitability for B2B Applications?

Metal expansion joints are constructed from durable materials like stainless steel, enabling them to withstand extreme temperatures and pressures. They are ideal for industries such as oil and gas, chemical processing, and power generation, where robustness is crucial. Buyers should consider the initial investment versus long-term durability, especially in environments prone to corrosion. Proper installation and maintenance can significantly extend their lifespan.

Illustrative image related to pipework expansion joints

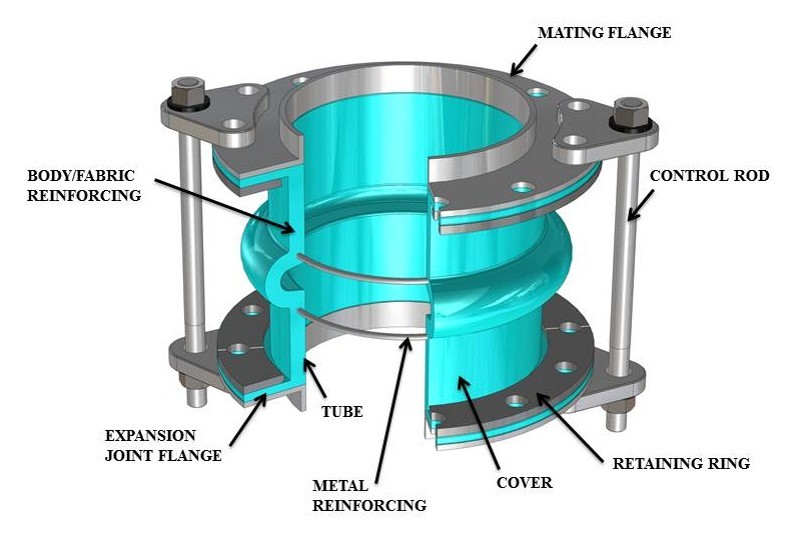

How Do Rubber Expansion Joints Benefit Various Industries?

Rubber expansion joints offer flexibility and vibration absorption, making them a cost-effective solution for HVAC systems, water treatment facilities, and food and beverage applications. Their lightweight nature allows for easier installation, but buyers should be mindful of their temperature limitations and shorter lifespan compared to metal joints. Evaluating the specific operational conditions will help determine their suitability.

What Makes Fabric Expansion Joints a Unique Option for B2B Buyers?

Fabric expansion joints are lightweight and customizable, making them suitable for aerospace and various industrial applications. Their flexibility allows for easy installation in complex piping systems. However, they are not designed for high-pressure applications and may require more frequent replacements. Buyers should assess the operational environment to determine the best use case for fabric joints.

Why Choose Externally Pressurized Joints for Seismic Applications?

Externally pressurized joints are engineered to handle significant movements and protect bellows from external pressures, making them ideal for seismic applications or building joints. While they provide robust performance, their installation can be complex, requiring skilled labor and higher maintenance. Businesses in earthquake-prone regions should prioritize these joints for enhanced safety and reliability.

Illustrative image related to pipework expansion joints

How Do Gimbal Expansion Joints Enhance Multi-Directional Movement?

Gimbal expansion joints are designed to accommodate movement in multiple directions, making them suitable for marine applications and complex industrial processes. Their versatility allows them to handle varying stresses, but buyers should be prepared for a higher upfront cost and the need for precise installation. Evaluating the specific movement requirements of the piping system will ensure optimal performance.

Key Industrial Applications of pipework expansion joints

| Industry/Sector | Specific Application of pipework expansion joints | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Used in pipelines to accommodate thermal expansion and vibration | Reduces risk of leaks and system failures | Material compatibility with oil, pressure ratings, and local regulations |

| Chemical Processing | Integration in chemical reactors and storage tanks | Enhances safety by preventing leaks and ruptures | Corrosion resistance, temperature tolerance, and compliance with safety standards |

| Power Generation | Installed in steam and gas turbines to manage thermal shifts | Increases operational efficiency and longevity | Ability to handle high temperatures and pressures, along with vibration damping capabilities |

| Water and Wastewater | Applied in municipal water treatment plants | Ensures system integrity and reduces maintenance costs | Resistance to chemicals, ease of installation, and compatibility with existing piping systems |

| Food and Beverage | Utilized in processing lines to accommodate pipe movement | Maintains hygiene standards and operational efficiency | Compliance with food safety regulations, ease of cleaning, and material safety |

How Are Pipework Expansion Joints Used in the Oil and Gas Industry?

In the oil and gas sector, pipework expansion joints are critical for managing the thermal expansion and contraction of pipelines. They allow for movement due to temperature fluctuations, which can otherwise lead to leaks or ruptures. Buyers in this sector must consider materials that can withstand corrosive substances, high pressure, and harsh environmental conditions, ensuring compliance with local regulations to maintain safety and operational efficiency.

What Role Do Pipework Expansion Joints Play in Chemical Processing?

In chemical processing, expansion joints are essential for connecting reactors and storage tanks. They accommodate movement caused by temperature changes, preventing leaks that could pose safety hazards. Buyers should prioritize materials that offer excellent corrosion resistance and can handle high temperatures, as well as ensure compliance with stringent safety standards, particularly in regions with rigorous regulatory environments.

Why Are Pipework Expansion Joints Important in Power Generation?

For power generation, especially in steam and gas turbines, pipework expansion joints manage the thermal shifts that occur during operation. They help in reducing stress on piping systems, leading to increased efficiency and longevity of equipment. Buyers need to focus on joints that can endure high temperatures and pressures, along with those that provide effective vibration damping to minimize wear and tear on the system.

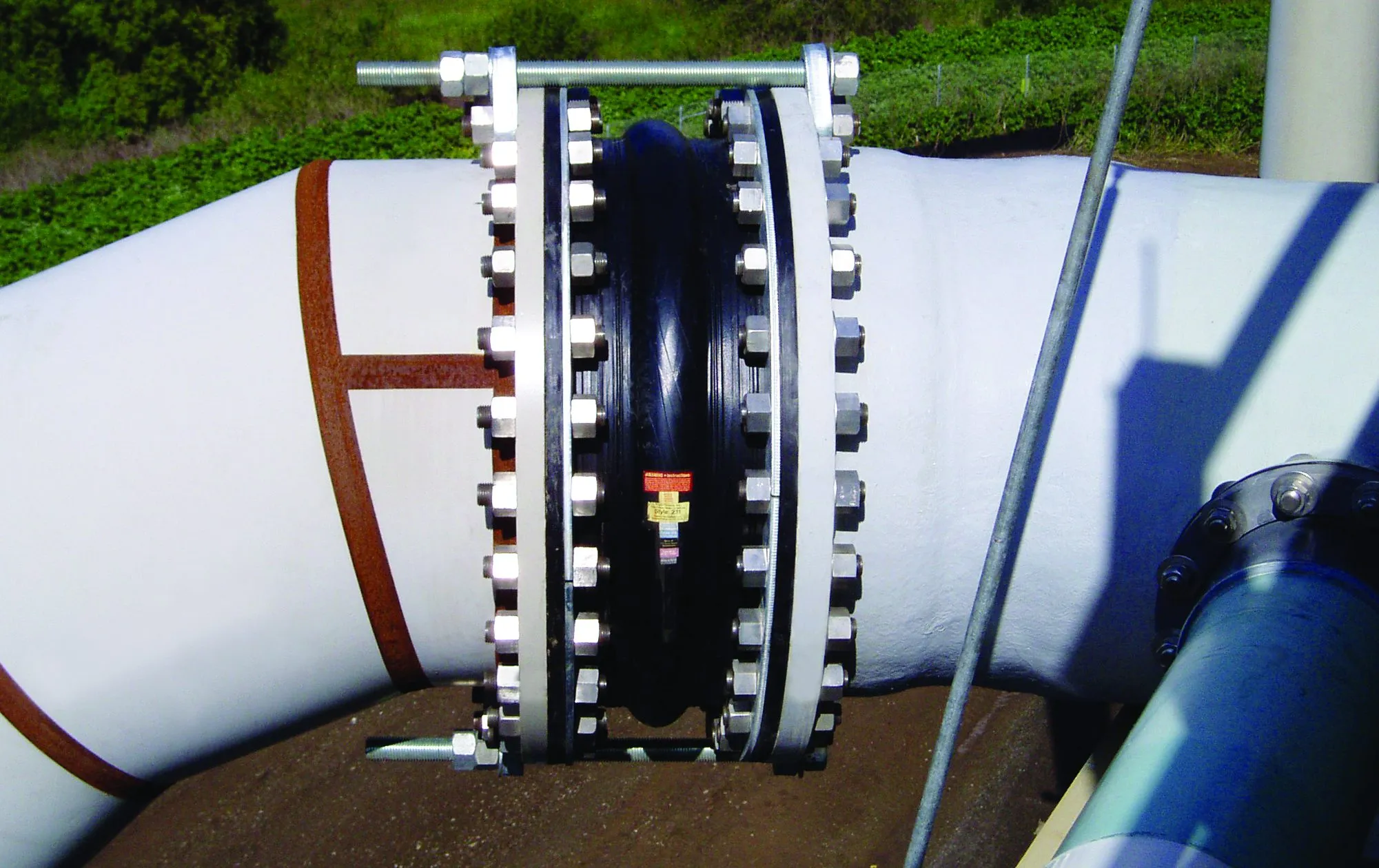

How Do Pipework Expansion Joints Benefit Water and Wastewater Management?

In municipal water treatment facilities, pipework expansion joints ensure the integrity of piping systems by accommodating movement and thermal expansion. This is crucial in preventing leaks that can lead to costly maintenance and environmental issues. Buyers should consider joints that are resistant to various chemicals found in water treatment processes, ensuring ease of installation and compatibility with existing systems to enhance operational reliability.

What Are the Considerations for Using Pipework Expansion Joints in Food and Beverage Processing?

In the food and beverage industry, pipework expansion joints are used to accommodate movement in processing lines while maintaining hygiene standards. They help prevent contamination and ensure consistent product quality. Buyers must ensure that the materials used comply with food safety regulations, are easy to clean, and can withstand the specific temperatures and pressures associated with food processing applications, particularly in international markets with varying standards.

3 Common User Pain Points for ‘pipework expansion joints’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Expansion Joint Type

The Problem: B2B buyers often struggle to choose the correct type of pipework expansion joint due to the variety of materials and designs available. With options ranging from metal to rubber and varying configurations, buyers may feel overwhelmed, leading to the selection of inappropriate joints that do not suit their specific applications. This can result in operational inefficiencies, increased maintenance costs, and premature failure of the joint, ultimately affecting the entire piping system.

The Solution: To effectively select the right expansion joint, buyers should first conduct a thorough assessment of their piping system’s operating conditions, including temperature, pressure, and the types of fluids being transported. Consulting with manufacturers or suppliers who offer technical support can be invaluable; they can provide insights into the best materials and designs for specific applications. Additionally, utilizing tools like selection calculators or technical datasheets can aid in making informed choices. For example, if dealing with high-temperature steam applications, a metal expansion joint might be more suitable than a rubber variant. Establishing a clear communication channel with the supplier can also facilitate obtaining custom solutions tailored to unique requirements.

Scenario 2: Concerns About Joint Durability and Maintenance

The Problem: Many B2B buyers are apprehensive about the durability of pipework expansion joints, particularly in demanding environments such as chemical processing or oil and gas operations. The potential for wear and tear due to vibration, thermal expansion, and corrosive media can lead to unexpected downtime and costly repairs, making the longevity of these components a critical concern.

The Solution: To mitigate durability issues, buyers should prioritize sourcing high-quality expansion joints from reputable manufacturers known for their rigorous testing and quality assurance processes. It’s essential to evaluate the joint’s material properties, such as corrosion resistance and fatigue strength, to ensure they match the operational environment. Implementing a proactive maintenance schedule that includes regular inspections can also help identify early signs of wear. Additionally, training maintenance staff on the specific requirements and limitations of the expansion joints can enhance their lifespan. Leveraging warranties and service agreements offered by manufacturers can further safeguard against premature failures.

Scenario 3: Managing Installation Challenges and Costs

The Problem: Installation of pipework expansion joints can pose significant challenges, particularly for businesses operating in remote locations or those with limited access to skilled labor. Incorrect installation can lead to functional issues, including misalignment and stress on the piping system, which can compromise the integrity of the entire network. This situation often leads to costly delays and increased expenses related to rework.

The Solution: To streamline the installation process, buyers should invest in comprehensive training for their installation teams or consider partnering with specialized contractors familiar with expansion joint systems. Providing detailed installation guides and ensuring that all necessary tools and equipment are readily available can facilitate a smoother installation process. Furthermore, pre-installation meetings with the supplier can clarify installation requirements and potential pitfalls. Engaging in a thorough planning phase that includes identifying the best practices for joint alignment and securing proper anchoring points can significantly reduce the risk of installation-related issues. By ensuring that installation is executed correctly from the start, businesses can avoid unnecessary costs and ensure optimal performance of their pipework expansion joints.

Strategic Material Selection Guide for pipework expansion joints

What Are the Key Properties of Common Materials Used in Pipework Expansion Joints?

When selecting materials for pipework expansion joints, it is crucial to consider various factors that influence performance, durability, and cost. Below are analyses of four common materials used in the manufacturing of expansion joints, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its high strength and excellent corrosion resistance. It typically has a temperature rating of up to 1,600°F (870°C) and can withstand high pressures, making it suitable for various industrial applications.

Pros & Cons:

The durability of stainless steel is one of its primary advantages, as it resists rust and pitting. However, it can be more expensive than other materials and may require specialized manufacturing techniques, which can increase lead times.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive fluids, steam, and gases. This versatility makes it a preferred choice in industries such as oil and gas, chemical processing, and food and beverage.

Illustrative image related to pipework expansion joints

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN. The availability of stainless steel grades may vary, so it’s essential to confirm specifications with suppliers.

2. Rubber

Key Properties:

Rubber expansion joints offer flexibility and can accommodate significant movement. They typically operate effectively at temperatures ranging from -20°F to 200°F (-29°C to 93°C) and have moderate pressure ratings.

Pros & Cons:

The key advantage of rubber is its ability to absorb vibrations and noise, making it ideal for dynamic applications. However, rubber is less durable than metal and can degrade over time when exposed to certain chemicals and extreme temperatures.

Illustrative image related to pipework expansion joints

Impact on Application:

Rubber joints are suitable for water, wastewater, and various non-corrosive fluids. They are often used in HVAC systems and plumbing applications.

Considerations for International Buyers:

Buyers should be aware of the specific rubber compounds used, as compatibility with media can vary. Compliance with local standards is essential, especially in regions with stringent environmental regulations.

3. PTFE (Polytetrafluoroethylene)

Key Properties:

PTFE is known for its exceptional chemical resistance and can withstand temperatures up to 500°F (260°C). It is also non-stick, which helps in preventing the buildup of deposits.

Pros & Cons:

The primary advantage of PTFE is its ability to handle aggressive chemicals, making it ideal for the pharmaceutical and chemical industries. However, it is less robust than metal options and can be more expensive.

Illustrative image related to pipework expansion joints

Impact on Application:

PTFE is particularly suitable for applications involving strong acids, bases, and solvents. Its unique properties make it a go-to material for high-purity applications.

Considerations for International Buyers:

Buyers should check for compliance with international standards such as FDA regulations for food applications. Sourcing PTFE from reputable suppliers is crucial to ensure quality.

4. Composite Materials

Key Properties:

Composite materials combine the benefits of different materials, such as rubber and fiberglass, to offer high flexibility and strength. They can operate effectively at temperatures up to 300°F (149°C) and moderate pressures.

Pros & Cons:

The advantage of composites lies in their lightweight nature and resistance to corrosion and wear. However, they may not be suitable for all applications, particularly those requiring high-temperature resistance.

Impact on Application:

Composite joints are often used in water treatment and industrial applications where weight reduction is beneficial. Their versatility allows for customization based on specific needs.

Considerations for International Buyers:

Buyers should ensure that composite materials meet local standards and certifications. Understanding the manufacturing process is essential, as it can affect the performance and longevity of the joints.

Summary Table of Material Selection for Pipework Expansion Joints

| Material | Typical Use Case for pipework expansion joints | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, chemical processing | High strength and corrosion resistance | Higher cost and manufacturing complexity | High |

| Rubber | HVAC systems, plumbing | Flexibility and vibration absorption | Less durable, chemical sensitivity | Medium |

| PTFE | Pharmaceutical, chemical industries | Exceptional chemical resistance | Less robust and higher cost | High |

| Composite | Water treatment, industrial applications | Lightweight and customizable | Limited high-temperature suitability | Medium |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding pipework expansion joints, ensuring compatibility with their specific applications and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pipework expansion joints

What Are the Key Stages in the Manufacturing Process of Pipework Expansion Joints?

The manufacturing process for pipework expansion joints consists of several critical stages that ensure the final product meets both functional and regulatory standards. These stages include material preparation, forming, assembly, and finishing. Each step is designed to optimize the quality and performance of the expansion joints, which are crucial for managing thermal expansion, vibration, and movement in piping systems.

Material Preparation: How Is Raw Material Selected and Processed?

The first step in manufacturing pipework expansion joints involves selecting the appropriate materials, typically metals such as stainless steel, carbon steel, or specialized alloys, depending on the application requirements. The chosen material undergoes rigorous quality checks to ensure it meets relevant specifications and standards.

Once selected, the raw materials are cut to size using advanced cutting techniques such as laser cutting or water jet cutting. This precision ensures that the subsequent forming process can be executed with minimal waste and maximum accuracy. Additionally, surface treatments may be applied to enhance corrosion resistance or improve adhesion for further processing.

What Forming Techniques Are Used in Pipework Expansion Joint Manufacturing?

The forming stage is where the raw material is shaped into the required bellows and components. Techniques such as deep drawing, hydroforming, and roll forming are commonly employed.

- Deep Drawing: This method is particularly effective for creating complex shapes in metal bellows, allowing for high levels of flexibility and movement.

- Hydroforming: Using high-pressure fluids, this technique shapes metal into desired forms while preserving material integrity, making it ideal for high-performance applications.

- Roll Forming: This is used for producing long lengths of uniform sections, such as flanges or supports, that are integral to the assembly of expansion joints.

The choice of forming technique often depends on the specific design and performance criteria, including factors such as pressure ratings and temperature tolerances.

How Are Pipework Expansion Joints Assembled?

Assembly is a critical phase where various components, including bellows, flanges, and supports, are joined to create a complete expansion joint. This process can involve welding, bolting, or using adhesive bonding, depending on the design specifications and material compatibility.

During assembly, precision alignment is crucial to ensure that the expansion joint functions correctly under operational conditions. Automated assembly lines may be employed for consistency and efficiency, particularly for high-volume production.

What Finishing Processes Are Commonly Applied to Pipework Expansion Joints?

Finishing processes enhance the durability and performance of pipework expansion joints. These may include:

- Surface Treatments: Techniques such as galvanizing, painting, or applying protective coatings help mitigate corrosion and wear, extending the lifespan of the joints.

- Heat Treatment: This process is applied to improve the mechanical properties of the material, ensuring it can withstand high temperatures and pressures.

- Quality Inspection: After finishing, each joint undergoes a thorough inspection to verify that it meets the specified standards and tolerances.

What Quality Assurance Practices Are Essential for Pipework Expansion Joints?

Quality assurance (QA) is fundamental to ensuring that pipework expansion joints are safe, reliable, and compliant with international standards. Various checkpoints and testing methods are integral to the QA process, which is crucial for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

Illustrative image related to pipework expansion joints

What International Standards Govern Pipework Expansion Joint Quality?

Manufacturers of pipework expansion joints must adhere to several international standards, including ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications such as CE marking for European markets, and API standards for oil and gas applications, are critical for demonstrating compliance and quality assurance.

B2B buyers should ensure that their suppliers are certified and maintain these standards, as this not only enhances product reliability but also mitigates risks associated with non-compliance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is typically organized into three main checkpoints:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor production quality and adherence to design specifications. This may include dimensional checks, visual inspections, and material property tests.

- Final Quality Control (FQC): The final stage involves comprehensive testing of the completed expansion joints, including pressure testing, leak testing, and performance evaluations. Only products that pass these stringent tests are approved for shipment.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those in emerging markets, verifying a supplier’s quality control processes is crucial. Buyers can take several proactive steps:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational standards of potential suppliers.

- Reviewing Quality Reports: Requesting detailed quality reports and documentation, including test results and compliance certificates, helps verify that the supplier meets required standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality, offering additional assurance.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must be aware of specific nuances that may affect quality control. Variations in regional standards, language barriers, and cultural differences in manufacturing practices can pose challenges.

To navigate these complexities, buyers should establish clear communication channels with suppliers and consider local regulations that may impact product certification. Additionally, understanding the specific requirements of their target markets can help in selecting suppliers that align with those standards.

By focusing on these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing pipework expansion joints, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipework expansion joints’

To assist B2B buyers in the procurement of pipework expansion joints, this practical sourcing guide outlines essential steps to ensure a successful purchasing process. By following this checklist, you can make informed decisions that align with your project requirements and operational goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right pipework expansion joints. Consider factors such as the type of media being transported, temperature ranges, pressure ratings, and the specific movements the joint must accommodate (e.g., axial, lateral, angular). This clarity will guide your supplier discussions and help avoid compatibility issues later.

Illustrative image related to pipework expansion joints

Step 2: Identify Application Requirements

Different applications may necessitate specific joint types, such as metal, rubber, or fabric expansion joints. Assess the operational environment, including factors like vibration levels, chemical exposure, and space constraints. Understanding these requirements will help you narrow down your choices to joints that can withstand the operational demands.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request company profiles, product catalogs, and case studies that demonstrate their experience in your industry. Check for references from similar projects to gauge their reliability and performance. This due diligence will help ensure you partner with a reputable manufacturer.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant industry certifications, such as ISO 9001 or compliance with local standards. Certifications can indicate a commitment to quality and safety, which is critical in sectors like oil and gas, chemical processing, or food and beverage. Additionally, inquire about their quality control processes to understand how they maintain product integrity.

Step 5: Request Samples and Test Data

Before finalizing your order, request samples of the expansion joints you are considering. Testing these samples in real-world conditions or reviewing third-party test data can provide insight into their performance and durability. Look for data on parameters such as pressure tolerance, thermal expansion capabilities, and lifespan to make a more informed decision.

Illustrative image related to pipework expansion joints

Step 6: Discuss Pricing and Terms

Engage in detailed discussions about pricing structures, payment terms, and lead times. Understand the total cost of ownership, including installation, maintenance, and potential warranty claims. Transparent pricing discussions will help you budget effectively and avoid unexpected costs down the line.

Step 7: Plan for Installation and Maintenance

Finally, consider the installation and maintenance aspects of the expansion joints. Assess whether your team has the expertise to install the joints or if you need to hire external contractors. Additionally, inquire about maintenance recommendations from the supplier to ensure long-term reliability and performance of the joints.

By following this checklist, you can streamline the sourcing process for pipework expansion joints and make informed decisions that enhance the efficiency and reliability of your piping systems.

Comprehensive Cost and Pricing Analysis for pipework expansion joints Sourcing

What Are the Key Cost Components of Pipework Expansion Joints?

When sourcing pipework expansion joints, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of materials used, such as rubber, metal, or composite materials, significantly impacts the overall cost. High-quality materials that withstand extreme temperatures or corrosive environments may command a premium.

-

Labor: Labor costs encompass not only the manufacturing workforce but also skilled technicians involved in design and customization. Labor rates can vary widely based on geographic location and skill levels.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment maintenance, which contribute to the overall production cost. Efficient manufacturing processes can help reduce overhead.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized designs. These costs are typically amortized over the production run, affecting pricing.

-

Quality Control (QC): Implementing stringent QC measures to ensure product reliability adds to the cost. Certifications (e.g., ISO, ASTM) for quality assurance can further influence pricing.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, are significant, especially for international transactions. The choice of shipping methods and Incoterms can also alter the total landed cost.

-

Margin: Suppliers will include a margin to cover risks and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Pricing Influencers Affect the Cost of Pipework Expansion Joints?

Several factors influence the pricing of pipework expansion joints, making it essential for buyers to consider these elements when negotiating.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better pricing due to economies of scale. Understanding a supplier’s MOQ can help buyers negotiate more favorable terms.

-

Specifications and Customization: Custom designs tailored to specific applications can lead to higher costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher-grade materials and certified products tend to cost more. Buyers must balance the need for quality with budget constraints, especially in competitive markets.

-

Supplier Factors: Supplier reputation, reliability, and geographical location can affect pricing. Local suppliers might offer lower logistics costs, while established brands may charge more due to perceived quality.

-

Incoterms: The chosen Incoterms determine the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms can help buyers avoid unexpected costs.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing Pipework Expansion Joints?

To maximize cost-efficiency when sourcing pipework expansion joints, buyers should implement several strategic approaches:

-

Negotiation Tactics: Engage in thorough negotiations to secure the best pricing. Leverage competitive quotes from multiple suppliers to strengthen your bargaining position.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and lifespan of the product, which can significantly affect long-term costs.

-

Understand Pricing Nuances for International Transactions: For buyers in regions like Africa, South America, the Middle East, and Europe, fluctuations in currency exchange rates and local tariffs can impact pricing. It is vital to factor these elements into cost assessments.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes associated with poor-quality products.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into market trends that may affect costs.

Conclusion

Sourcing pipework expansion joints requires a comprehensive understanding of the cost structure, pricing influencers, and strategic negotiation techniques. By carefully evaluating these elements, international B2B buyers can make informed decisions that enhance their procurement processes and overall operational efficiency. Always remember that indicative prices may vary based on market conditions, supplier relationships, and specific project requirements.

Alternatives Analysis: Comparing pipework expansion joints With Other Solutions

Understanding Alternative Solutions to Pipework Expansion Joints

When it comes to managing thermal expansion and contraction in piping systems, pipework expansion joints are a popular choice. However, several alternative solutions can also address these challenges effectively. This section will explore some of these alternatives, providing a comprehensive comparison to help international B2B buyers make informed decisions.

| Comparison Aspect | Pipework Expansion Joints | Metal Bellows Expansion Joints | Rubber Expansion Joints |

|---|---|---|---|

| Performance | High flexibility and durability, capable of handling large movements and vibrations. | Excellent for high-temperature applications, allowing significant axial movement. | Good flexibility, but limited temperature range; effective for lower pressure systems. |

| Cost | Mid-range pricing; initial investment can be offset by longevity. | Typically higher due to material costs and manufacturing complexity. | Generally lower cost, making it attractive for budget-conscious projects. |

| Ease of Implementation | Moderate; requires skilled labor for installation and alignment. | More complex installation due to custom fittings and specific alignment requirements. | Easier to install, often requiring less specialized labor. |

| Maintenance | Low; periodic inspections recommended but minimal upkeep needed. | Moderate; may require more frequent checks due to wear in high-stress environments. | Low; rubber components may degrade faster but are easy to replace. |

| Best Use Case | Ideal for dynamic systems with significant movement, such as in chemical processing. | Best for high-temperature and high-pressure applications, like steam lines. | Suitable for low-pressure, non-critical applications, such as drainage systems. |

In-Depth Analysis of Alternative Solutions

Metal Bellows Expansion Joints

Metal bellows expansion joints are designed to accommodate high levels of thermal expansion and contraction, particularly in high-pressure and high-temperature environments. Their robust construction allows them to handle significant movements and vibrations, making them suitable for applications like steam piping in power plants. However, they come with a higher initial cost and can require more complex installation procedures. Regular maintenance checks are advisable to ensure their longevity in demanding conditions.

Rubber Expansion Joints

Rubber expansion joints offer a more cost-effective solution for systems with lower pressure and temperature requirements. They provide good flexibility and vibration dampening, making them suitable for applications such as drainage and HVAC systems. While their lower cost and ease of installation are significant advantages, they do have limitations in terms of temperature tolerance and may need to be replaced more frequently than other options. This makes them ideal for non-critical applications where budget constraints are a primary concern.

Making the Right Choice for Your Piping System

When selecting between pipework expansion joints and their alternatives, B2B buyers should consider specific project requirements, including operating conditions, budget constraints, and installation capabilities. For applications that demand high performance under extreme conditions, metal bellows expansion joints may be the best fit. Conversely, for less demanding environments where cost is a priority, rubber expansion joints could provide sufficient performance.

Ultimately, the decision should align with the operational goals of the business, the expected lifecycle of the system, and the potential for future expansions or modifications. Thoroughly assessing these factors will ensure that the chosen solution not only meets current needs but also supports long-term efficiency and reliability.

Essential Technical Properties and Trade Terminology for pipework expansion joints

What Are the Key Technical Properties of Pipework Expansion Joints?

Understanding the essential technical properties of pipework expansion joints is crucial for B2B buyers, as these specifications directly impact performance, longevity, and compatibility with existing systems. Here are some critical properties to consider:

-

Material Grade

The choice of material affects durability, flexibility, and resistance to environmental factors. Common materials include stainless steel, rubber, and PTFE (polytetrafluoroethylene). For instance, stainless steel is often used for high-temperature applications due to its corrosion resistance and strength. Buyers should select the material based on the fluid type, operating temperature, and pressure conditions. -

Pressure Rating

This specification indicates the maximum pressure the expansion joint can withstand without failure. Pressure ratings are typically expressed in pounds per square inch (PSI) or bar. Understanding the pressure requirements of the system is essential for ensuring safety and preventing leaks, as exceeding this rating can lead to catastrophic failures. -

Movement Capability

Expansion joints are designed to accommodate various types of movement, including axial, lateral, and angular movements. This capability is quantified in terms of the maximum allowable movement in each direction. Selecting an expansion joint with the right movement characteristics is vital for maintaining system integrity, particularly in dynamic environments. -

Temperature Tolerance

The ability of an expansion joint to operate effectively within a specified temperature range is critical. High-temperature applications may require specialized materials or designs to maintain flexibility and performance without degrading. Buyers must ensure that the selected expansion joint can handle the thermal conditions of their specific application. -

Installation Dimensions

This includes the overall length, diameter, and flange dimensions of the expansion joint. Accurate measurements are essential for ensuring compatibility with existing pipework systems. Incorrect dimensions can lead to installation challenges and potential operational issues. -

Life Cycle and Maintenance Requirements

Understanding the expected lifespan of an expansion joint and any required maintenance is essential for long-term cost management. Some materials may require more frequent inspections or replacements than others, influencing the total cost of ownership.

What Are the Common Trade Terms in the Pipework Expansion Joint Industry?

Familiarizing yourself with industry jargon can enhance communication and streamline purchasing processes. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end product. Understanding whether a supplier is an OEM can help buyers gauge the quality and reliability of the expansion joints. -

MOQ (Minimum Order Quantity)

This specifies the smallest order size a supplier is willing to accept. Knowing the MOQ is crucial for budgeting and inventory management, especially for smaller projects that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. It helps buyers compare costs and terms from different vendors, enabling informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international transactions to avoid misunderstandings about costs and responsibilities. -

FBE (Fusion Bonded Epoxy)

This is a coating process used to enhance the corrosion resistance of steel pipes and fittings. Understanding FBE is important for buyers looking for durable solutions in corrosive environments. -

Seismic Design

This term refers to the design considerations for expansion joints in areas prone to earthquakes. Buyers in regions with seismic activity must ensure that their expansion joints comply with relevant seismic standards to mitigate risks.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing pipework expansion joints, ultimately enhancing the efficiency and safety of their piping systems.

Navigating Market Dynamics and Sourcing Trends in the pipework expansion joints Sector

What Are the Current Market Dynamics and Key Trends in the Pipework Expansion Joints Sector?

The global pipework expansion joints market is experiencing robust growth, driven by increasing infrastructure development, particularly in emerging economies across Africa, South America, and the Middle East. Key sectors such as oil and gas, chemical processing, and power generation are expanding, necessitating advanced piping solutions that can accommodate thermal expansion and contraction. Technological advancements in materials, such as high-performance alloys and composite materials, are enhancing the durability and efficiency of expansion joints. Additionally, the integration of Industry 4.0 technologies, including IoT and predictive maintenance tools, is reshaping sourcing strategies, allowing for real-time monitoring and improved supply chain efficiencies.

International B2B buyers are increasingly focused on sourcing high-quality products that offer a competitive edge in performance and longevity. In markets like Brazil and Vietnam, local manufacturers are gaining traction, but there is still a significant demand for established global brands known for reliability and innovation. Furthermore, the drive towards digital transformation is leading buyers to prioritize suppliers that provide comprehensive digital tools, such as online catalogs and advanced configuration options, to streamline the procurement process.

How Are Sustainability and Ethical Sourcing Influencing B2B Purchases in the Pipework Expansion Joints Sector?

Sustainability has become a critical factor in the procurement process for pipework expansion joints. B2B buyers are increasingly aware of the environmental impact of their sourcing decisions, pushing manufacturers to adopt sustainable practices. This includes the use of recyclable materials and processes that minimize waste. Suppliers that can demonstrate a commitment to sustainability through certifications, such as ISO 14001 or LEED, are more likely to attract discerning buyers looking to enhance their own sustainability credentials.

Ethical sourcing is equally important, with buyers seeking suppliers that maintain transparent supply chains and adhere to fair labor practices. This focus on ethical sourcing not only helps mitigate risks associated with supply chain disruptions but also aligns with the corporate social responsibility goals of many organizations. As a result, suppliers that offer ‘green’ certifications or utilize environmentally friendly materials in their pipework expansion joints are becoming increasingly desirable in the global market.

Illustrative image related to pipework expansion joints

How Has the Pipework Expansion Joints Sector Evolved Over Time?

The evolution of pipework expansion joints can be traced back to the industrial revolution, where the need for flexible piping systems became apparent due to the expansion and contraction of materials under varying temperatures. Initially, simple rubber and metal joints were employed, but advancements in material science and engineering have led to the development of more complex designs, including multi-layered bellows and high-temperature resistant materials.

In recent decades, the industry has seen a significant shift towards customization, with manufacturers offering tailored solutions to meet specific project requirements. The introduction of computer-aided design (CAD) and simulation technologies has enabled more precise and efficient manufacturing processes. As industries continue to grow and evolve, the demand for innovative and reliable expansion joints that can withstand rigorous operational conditions remains a top priority for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of pipework expansion joints

1. How do I choose the right expansion joint for my piping system?

Selecting the appropriate expansion joint involves considering several factors, including the type of pipe material, operating temperature, pressure conditions, and the specific movements (axial, lateral, or angular) that need to be accommodated. For critical applications, consult with manufacturers who can provide insights based on your specific system requirements. Additionally, ensure that the joint meets industry standards and certifications relevant to your region to guarantee reliability and safety.

2. What is the best type of expansion joint for high-temperature applications?

For high-temperature applications, metal expansion joints are typically the best choice due to their ability to withstand extreme temperatures and pressures. These joints are made from materials such as stainless steel, which offers durability and resistance to thermal fatigue. If your application involves significant movement, consider using bellows expansion joints designed specifically for high-temperature environments to ensure optimal performance and longevity.

Illustrative image related to pipework expansion joints

3. What customization options are available for pipework expansion joints?

Most manufacturers offer customization options to meet specific project needs. Customizations can include variations in size, materials, pressure ratings, and movement capabilities. Some suppliers also provide bespoke designs for unique applications, such as seismic or vibration-damping joints. When discussing custom options, be prepared to provide detailed specifications about your piping system to facilitate accurate design and manufacturing.

4. What are the minimum order quantities (MOQs) for pipework expansion joints?

Minimum order quantities for expansion joints can vary significantly among suppliers, often depending on the type and complexity of the joint. Standard models may have lower MOQs, while custom designs typically require larger orders. Always inquire about MOQs before placing an order to ensure that it aligns with your project needs and budget. Some suppliers may also offer flexibility on MOQs for long-term partnerships or bulk orders.

5. How can I verify the quality of expansion joints from suppliers?

To ensure quality, request certifications and test reports from potential suppliers. Look for compliance with international standards such as ISO, ASTM, or ASME, which indicate adherence to quality and safety protocols. Additionally, consider suppliers with a strong reputation and positive customer feedback. Engaging in a factory visit or requesting samples for testing can further validate the quality of the products before making a large investment.

6. What payment terms should I expect when sourcing expansion joints internationally?

Payment terms for international orders can vary widely based on the supplier’s policies and your business relationship. Common terms include upfront payment, net 30, or net 60 days. Some suppliers may require a deposit followed by the remaining balance upon shipment. It is advisable to negotiate terms that protect your interests, such as partial payments tied to milestones or delivery schedules, especially when dealing with large orders or custom products.

7. What logistics considerations should I keep in mind when importing expansion joints?

When importing expansion joints, consider shipping methods, delivery times, and customs regulations in your country. Choose a reliable logistics partner experienced in handling industrial equipment to ensure timely and safe delivery. Additionally, be aware of potential tariffs and taxes that may apply to your import, and ensure that all documentation is complete to avoid delays during customs clearance.

8. How do I handle after-sales support for expansion joints?

After-sales support is crucial for ensuring the long-term performance of expansion joints. Verify that your supplier offers adequate technical support, warranty services, and a clear return policy. Establishing a direct line of communication with the supplier for troubleshooting and maintenance advice can also be beneficial. Regular follow-ups and performance evaluations can help you address any issues promptly and maintain the integrity of your piping system.

Top 3 Pipework Expansion Joints Manufacturers & Suppliers List

1. Flexonics – Piping Expansion Joints

Domain: flexonics.com

Registered: 1996 (29 years)

Introduction: Flexonics offers a range of piping expansion joints designed to accommodate thermal expansion and contraction in piping systems. Key product details include:

– Sizes available: 2″ to 144″ in various increments (e.g., 2″, 2.5″, 3″, 3.5″, 4″, 5″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 22″, 24″, 26″, 28″, 30″, 32″, 34″, 36″, 38″, 40″, 42″ to 48″, 50″ to 60″, 66″ to 96″, 108″ to 144″).

– Types of exp…

2. PDBlowers – Pipe Expansion Joints

Domain: pdblowers.com

Registered: 1998 (27 years)

Introduction: Pipe Expansion Joints isolate the blower or vacuum pump from other system components to allow for thermal expansion and misalignment of the piping. Common flanged rubber expansion joints feature single or double arched bellows constructed of molded elastomers. Standard single arch models are made of EPDM elastomer. Functions include reducing flange loading on the blower, allowing thermal expansion…

3. Proco Products – Expansion Joints

Domain: procoproducts.com

Registered: 1998 (27 years)

Introduction: Proco Products is a leading manufacturer of expansion joints for piping and ducting systems. They offer a variety of expansion joints designed to protect equipment from thermal expansion, vibration, and ground movement. Key features include:

– **Materials**: Expansion joints are available in rubber, stainless steel, and polytetrafluoroethylene (PTFE).

– **Applications**: Suitable for industrial a…

Strategic Sourcing Conclusion and Outlook for pipework expansion joints

In the evolving landscape of industrial applications, the strategic sourcing of pipework expansion joints is paramount for ensuring operational efficiency and long-term reliability. By understanding the diverse types of expansion joints available, including metal and rubber variants, buyers can select products that best meet their specific needs, whether they are in the chemical processing, oil and gas, or water treatment sectors.

Key takeaways emphasize the importance of choosing high-quality materials that withstand environmental challenges while also considering the cost-effectiveness of sourcing from reputable suppliers. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer comprehensive support, including technical assistance and customization options.

As we look ahead, the demand for innovative solutions in pipework expansion joints is set to rise, driven by advancements in manufacturing technologies and the increasing complexity of industrial systems. To stay competitive, businesses must adopt a proactive approach to sourcing, leveraging strategic partnerships that enhance their supply chains. Engage with your suppliers today to explore tailored solutions that will drive your operations forward and ensure the longevity of your systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.