Pipe Bolt: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for pipe bolt

In today’s competitive global market, sourcing high-quality pipe bolts can pose a significant challenge for B2B buyers. With the vast array of materials, sizes, and finishes available, making the right choice is crucial for ensuring structural integrity and operational efficiency in various applications, from construction to manufacturing. This guide is designed to navigate the complexities of the pipe bolt market, offering insights into different types, applications, and the importance of selecting reliable suppliers.

Buyers will benefit from a comprehensive overview that covers essential topics such as the diverse material options—including stainless steel, galvanized, and plain steel—along with their respective advantages and disadvantages. We also delve into the critical aspects of supplier vetting, providing strategies to assess quality and reliability, which is particularly vital for international buyers from regions like Africa, South America, the Middle East, and Europe, including countries like Germany and Vietnam.

Furthermore, this guide will address cost considerations, helping you to balance quality with budget constraints. By empowering you with actionable insights and expert recommendations, this resource aims to facilitate informed purchasing decisions, ultimately enhancing your supply chain efficiency and product performance. Whether you are a seasoned buyer or new to the industry, understanding the nuances of pipe bolts will position you to make strategic choices that drive success in your operations.

Understanding pipe bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U-Bolts | Available in various sizes; made from different materials (e.g., stainless steel, galvanized) | Construction, plumbing, and automotive | Pros: Versatile, widely available; Cons: May require custom orders for specific sizes. |

| Heavy Duty U-Bolts | Thicker gauge steel; designed for high-stress applications | Heavy machinery, industrial equipment | Pros: High strength and durability; Cons: Heavier, may be overkill for lighter applications. |

| Lightweight U-Bolts | Thinner gauge steel; suitable for lighter loads | Residential plumbing, HVAC systems | Pros: Cost-effective, easy to install; Cons: Limited load capacity. |

| Ductile U-Bolts | Made from ductile iron; provides flexibility and strength | Oil and gas pipelines, infrastructure | Pros: Excellent resistance to impact; Cons: Higher cost than standard options. |

| Specialty U-Bolts | Custom sizes and finishes available; designed for specific applications | Custom machinery, specialized equipment | Pros: Tailored solutions; Cons: Longer lead times for production. |

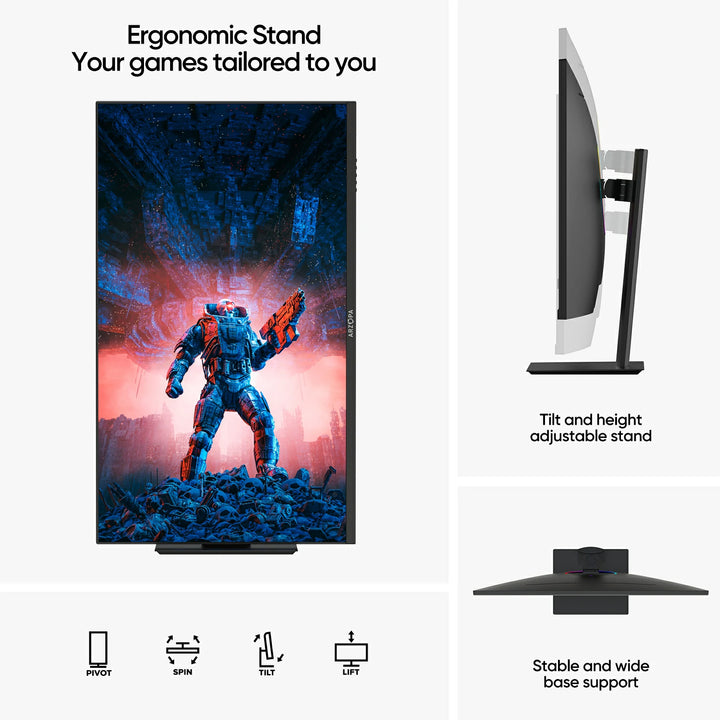

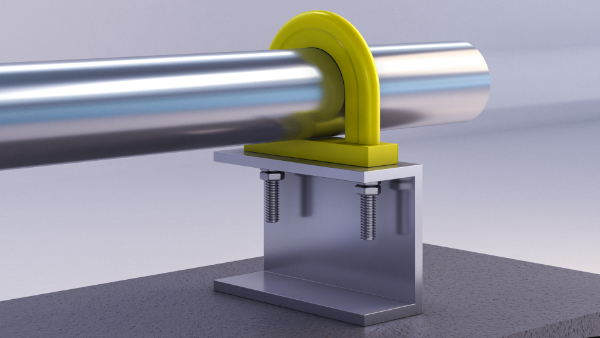

What Are the Characteristics of Standard U-Bolts?

Standard U-Bolts are a fundamental type of pipe bolt, characterized by their availability in numerous sizes and materials, including stainless steel and galvanized options. These bolts are essential in various sectors, particularly in construction and plumbing, where they secure pipes and other components. When considering a purchase, buyers should evaluate the specific size and material required for their applications, as this can significantly affect performance and longevity.

How Do Heavy Duty U-Bolts Differ from Standard Variants?

Heavy Duty U-Bolts are designed for applications that demand higher strength and durability, such as in heavy machinery and industrial equipment. Constructed from thicker gauge steel, they can withstand significant stress and harsh conditions. Buyers should consider the weight and load requirements of their projects when opting for heavy-duty variants, as these bolts may be heavier and more expensive than standard options.

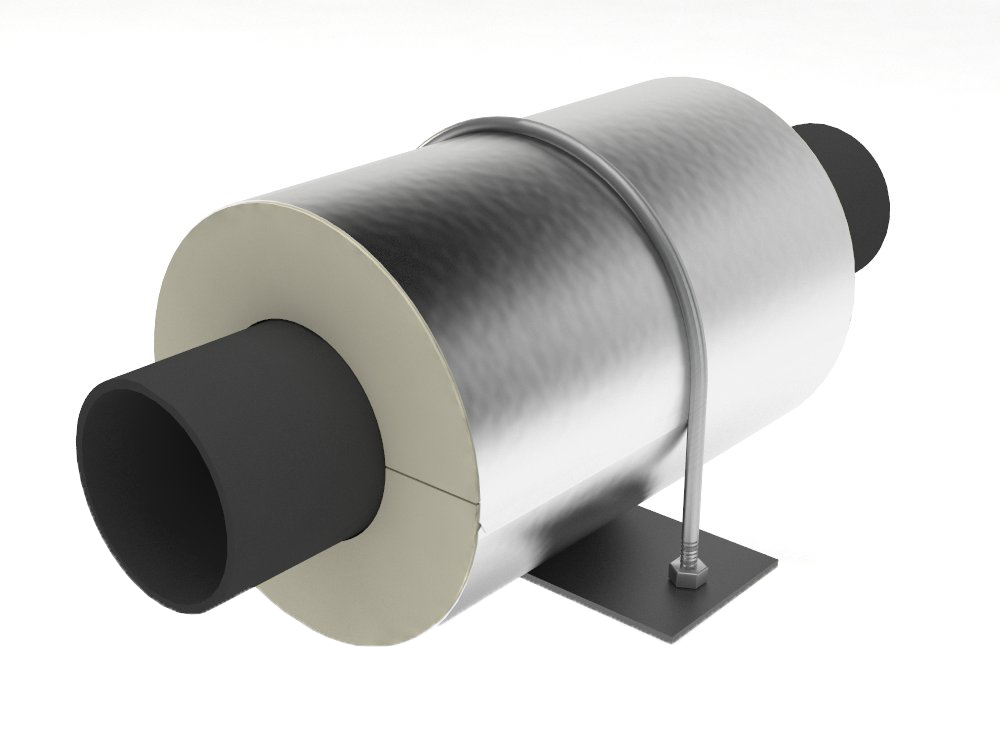

Illustrative image related to pipe bolt

What Advantages Do Lightweight U-Bolts Offer?

Lightweight U-Bolts provide an economical solution for applications that do not require heavy-duty support, such as residential plumbing and HVAC systems. Made from thinner gauge steel, they are easy to install and cost-effective. However, buyers should be mindful of their limited load capacity, ensuring that the chosen U-Bolts are suitable for the intended application to avoid potential failures.

Why Choose Ductile U-Bolts for Specific Applications?

Ductile U-Bolts are crafted from ductile iron, offering a unique combination of flexibility and strength, making them ideal for demanding environments like oil and gas pipelines. Their ability to absorb impact without breaking is a significant advantage in high-stress situations. Buyers should weigh the higher cost against the benefits of durability and impact resistance when considering these U-Bolts for critical applications.

What Are the Benefits of Specialty U-Bolts?

Specialty U-Bolts are tailored to meet specific requirements, including custom sizes and finishes for unique applications. These bolts are particularly useful in custom machinery or specialized equipment where standard options may not suffice. While they provide a precise fit and function, buyers should be prepared for longer lead times and potentially higher costs associated with custom manufacturing.

Key Industrial Applications of pipe bolt

| Industry/Sector | Specific Application of pipe bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Securing pipelines and equipment in drilling sites | Enhances safety and operational efficiency | Material durability, corrosion resistance, and size specifications are crucial. |

| Construction | Supporting structural frameworks and installations | Provides stability and strength to constructions | Compliance with local building codes and load-bearing requirements must be verified. |

| Agriculture | Connecting irrigation systems and water transport pipes | Ensures efficient water distribution for crops | Need for weather-resistant materials and size adaptability for various pipe diameters. |

| Manufacturing | Mounting machinery and equipment in production lines | Improves workflow and reduces equipment downtime | Consideration for load capacity and compatibility with existing machinery is essential. |

| Automotive | Holding exhaust systems and frames in vehicles | Enhances vehicle durability and performance | Sourcing must focus on high-temperature resistance and vibration dampening properties. |

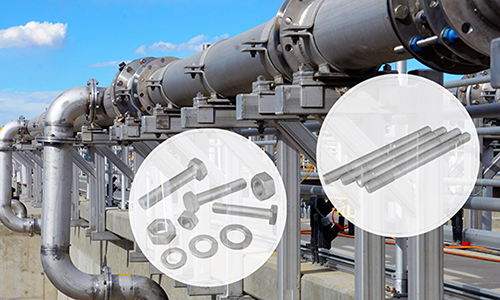

How is pipe bolt utilized in the oil and gas industry?

In the oil and gas sector, pipe bolts are vital for securing pipelines and equipment at drilling sites. These bolts help maintain the integrity of the infrastructure by preventing leaks and ensuring safety during operations. Buyers from regions like Africa and the Middle East should prioritize materials with high corrosion resistance, such as stainless steel or hot-dip galvanized options, to withstand harsh environmental conditions. Additionally, they must consider the specific sizes and grades required for their projects to ensure compliance with industry standards.

What role does pipe bolt play in construction projects?

In construction, pipe bolts are often used to support structural frameworks and various installations, including HVAC systems and plumbing. They provide the necessary strength and stability to ensure that buildings and structures can withstand environmental stresses. B2B buyers in Europe, particularly in Germany, need to ensure that their sourced pipe bolts meet local building codes and load-bearing requirements. This includes verifying the quality of materials and the specifications needed for different applications to avoid structural failures.

How does pipe bolt enhance agricultural operations?

In agriculture, pipe bolts are crucial for connecting irrigation systems and water transport pipes. Properly secured irrigation systems ensure efficient water distribution, which is vital for crop health and yield. Buyers from South America should focus on sourcing weather-resistant materials that can withstand varying climates, as well as ensuring that the bolts can adapt to different pipe diameters. This adaptability is essential to maintain operational efficiency and reduce maintenance costs.

What benefits does pipe bolt offer in manufacturing?

In manufacturing, pipe bolts are used to mount machinery and equipment on production lines. This application enhances workflow by providing a secure setup that minimizes downtime due to equipment failure. International buyers must consider load capacity and compatibility with existing machinery when sourcing pipe bolts. Additionally, understanding the specific requirements of their production processes will help them select the right materials and sizes, optimizing their operations.

How is pipe bolt important in the automotive industry?

In the automotive sector, pipe bolts are used to hold exhaust systems and frames in vehicles. The durability of these bolts is crucial for vehicle performance and longevity. Buyers should focus on sourcing pipe bolts that offer high-temperature resistance and vibration dampening properties to ensure they can withstand the rigors of automotive applications. This is particularly important for manufacturers in regions with stringent automotive standards, such as Europe and North America.

Illustrative image related to pipe bolt

3 Common User Pain Points for ‘pipe bolt’ & Their Solutions

Scenario 1: Sizing Confusion Leading to Project Delays

The Problem: Many B2B buyers struggle with selecting the correct size of pipe bolts for their specific applications. Misjudging the dimensions can lead to incompatible fittings, resulting in costly delays and project disruptions. For instance, a construction firm in South America might order bolts that are either too large or too small, causing a halt in assembly or necessitating last-minute reorders. This not only affects project timelines but can also escalate costs significantly due to expedited shipping or wasted materials.

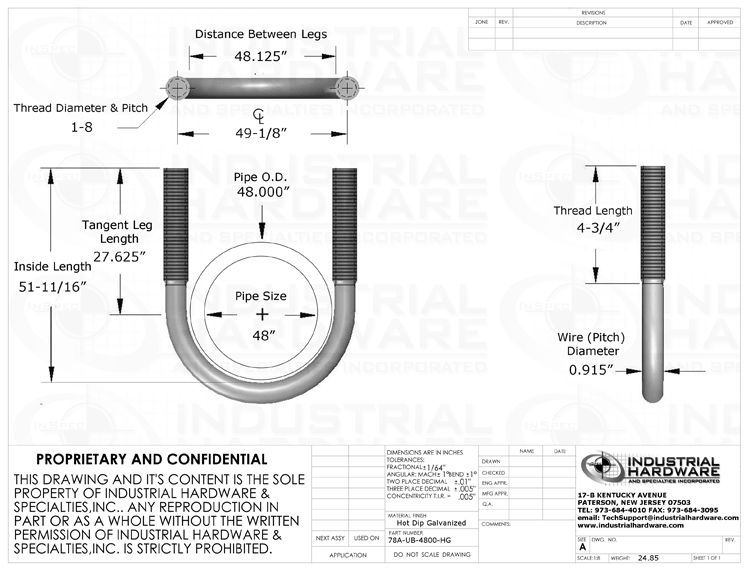

The Solution: To avoid sizing issues, it is crucial to implement a detailed measurement process before placing orders. Buyers should familiarize themselves with the pipe’s outside diameter (OD), required bolt lengths, and thread specifications. Utilizing digital tools, such as CAD software, can help visualize the assembly and verify dimensions accurately. When in doubt, suppliers can often provide guidance based on application needs. Additionally, keeping a standard size chart for common pipe diameters and bolt specifications can streamline the ordering process, ensuring that all future purchases align with the project requirements.

Scenario 2: Material Selection Missteps

The Problem: Selecting the wrong material for pipe bolts can have dire consequences, particularly in regions where environmental conditions vary significantly. For example, a buyer from the Middle East might choose plain steel bolts for an outdoor application without considering corrosion risks, leading to premature failure. This oversight not only compromises the structural integrity of installations but also demands costly repairs and replacements, affecting the overall project budget and reputation.

The Solution: To mitigate material selection issues, buyers should conduct a thorough analysis of the environmental conditions where the pipe bolts will be used. For instance, in humid or coastal regions, stainless steel (Type 304 or 316) or hot-dip galvanized options are preferable due to their corrosion-resistant properties. Additionally, engaging in discussions with suppliers about the specific application can provide insights into the best materials. Requesting samples or conducting small-scale tests can also help confirm that the selected material meets the project’s durability requirements.

Illustrative image related to pipe bolt

Scenario 3: Compatibility Challenges with Existing Infrastructure

The Problem: Compatibility between new pipe bolts and existing infrastructure is a common concern for B2B buyers, especially in industries like oil and gas or construction. An engineer in Europe might find that the bolts ordered for a new pipeline installation do not fit the existing fixtures or brackets, leading to compatibility issues that can stall the project and inflate costs due to retrofitting or redesigning.

The Solution: To ensure compatibility, it is essential to maintain comprehensive documentation of existing infrastructure specifications. Buyers should collect data on previous installations, including bolt sizes, thread types, and material specifications. Engaging with suppliers who offer customization options can also alleviate compatibility issues. When placing orders, specifying the exact requirements based on existing infrastructure will help in procuring the right products. Collaboration with engineering teams to create a compatibility checklist can further streamline the process, ensuring that all components fit seamlessly into the existing framework.

By addressing these common pain points proactively, B2B buyers can enhance their procurement processes, minimize delays, and ensure the successful execution of their projects involving pipe bolts.

Strategic Material Selection Guide for pipe bolt

What Are the Key Properties of Common Materials Used for Pipe Bolts?

When selecting materials for pipe bolts, understanding the properties of each material is crucial for ensuring optimal performance in various applications. The following analysis covers four common materials used in pipe bolt manufacturing: stainless steel, carbon steel, hot-dip galvanized steel, and alloy steel.

How Does Stainless Steel Perform in Pipe Bolt Applications?

Stainless steel, particularly types 304 and 316, is renowned for its excellent corrosion resistance and high-temperature tolerance. Type 304 is suitable for moderate corrosion environments, while Type 316 offers superior resistance to chlorides and is ideal for marine applications. Stainless steel bolts can withstand high pressures and temperatures, making them suitable for critical applications in industries such as oil and gas.

Pros: The durability and resistance to rust and corrosion make stainless steel a preferred choice for long-lasting applications. It also requires less maintenance over time.

Cons: The primary drawback is the higher cost compared to other materials. Additionally, stainless steel can be more challenging to machine, potentially increasing manufacturing complexity.

Impact on Application: Stainless steel bolts are compatible with various media, including water, oil, and chemicals, making them versatile in different environments.

Illustrative image related to pipe bolt

Considerations for International Buyers: Compliance with standards such as ASTM A193 and DIN 931 is essential. Buyers from Europe may prefer Type 316 for coastal applications due to its enhanced corrosion resistance.

What Role Does Carbon Steel Play in Pipe Bolt Manufacturing?

Carbon steel is a widely used material for pipe bolts due to its strength and affordability. It is particularly effective in applications where high tensile strength is required. However, carbon steel lacks inherent corrosion resistance, which can limit its use in harsh environments.

Pros: The cost-effectiveness of carbon steel makes it an attractive option for large-scale projects. It also has good mechanical properties, allowing for high load-bearing capacity.

Cons: The primary limitation is its susceptibility to rust and corrosion, necessitating protective coatings or treatments in corrosive environments.

Impact on Application: Carbon steel bolts are suitable for applications involving dry environments or where regular maintenance is feasible. They are not recommended for exposure to moisture or aggressive chemicals.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A307. In regions with high humidity, additional protective measures may be necessary.

Why Choose Hot-Dip Galvanized Steel for Pipe Bolts?

Hot-dip galvanized steel is carbon steel that has been coated with zinc to enhance corrosion resistance. This treatment provides a protective layer that can withstand outdoor exposure and moisture.

Pros: The zinc coating significantly improves the lifespan of the bolts in corrosive environments. It is also relatively inexpensive compared to stainless steel.

Cons: While the zinc coating provides good protection, it can wear off over time, especially in abrasive environments. Additionally, hot-dip galvanized bolts may not be suitable for high-temperature applications.

Impact on Application: Hot-dip galvanized bolts are ideal for outdoor applications, such as in construction or infrastructure projects, where exposure to the elements is a concern.

Illustrative image related to pipe bolt

Considerations for International Buyers: Compliance with ASTM A153 is crucial. Buyers should also consider local environmental conditions when selecting this material.

What Advantages Does Alloy Steel Offer for Pipe Bolts?

Alloy steel, which includes various elements to enhance its properties, is used for high-strength applications. It can withstand extreme conditions, making it suitable for heavy-duty applications in industries like mining and construction.

Pros: Alloy steel bolts offer exceptional strength and toughness, making them ideal for high-load applications. They can also be heat-treated to further enhance their properties.

Cons: The cost of alloy steel can be higher than carbon steel, and the manufacturing process can be more complex due to the need for specific heat treatments.

Impact on Application: Alloy steel bolts are suitable for applications involving heavy machinery and equipment, where high strength is critical.

Considerations for International Buyers: Compliance with standards such as ASTM A574 is essential. Buyers should also be aware of the specific alloy composition required for their applications.

Summary Table of Material Selection for Pipe Bolts

| Material | Typical Use Case for pipe bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine applications, chemical processing | Excellent corrosion resistance | Higher cost, complex machining | High |

| Carbon Steel | General construction, automotive | Cost-effective, high tensile strength | Susceptible to corrosion | Low |

| Hot-Dip Galvanized Steel | Outdoor construction, infrastructure | Good corrosion resistance | Coating can wear off, not for high temps | Medium |

| Alloy Steel | Heavy machinery, mining | Exceptional strength and toughness | Higher cost, complex manufacturing | High |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for pipe bolt

What Are the Key Stages in the Manufacturing Process of Pipe Bolts?

The manufacturing of pipe bolts involves several critical stages, each designed to ensure that the final product meets the specific needs of various industries. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used for Pipe Bolts?

The first step in the manufacturing process is material preparation, where raw materials are selected based on the intended application of the pipe bolts. Common materials include:

- Stainless Steel (Types 304 and 316): Known for their corrosion resistance, these materials are ideal for applications in harsh environments, such as marine or chemical industries.

- Hot-Dip Galvanized Steel: Provides a protective zinc coating, making it suitable for outdoor applications.

- Plain (Unfinished) Steel: Often used in applications where aesthetic finish is not a concern but strength is critical.

The choice of material directly impacts the durability, strength, and overall performance of the pipe bolts.

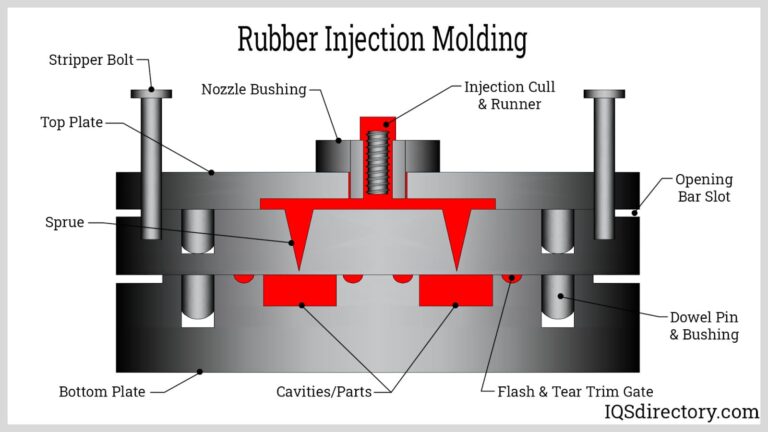

How Are Pipe Bolts Formed?

Once the material is selected, the next stage is forming. This typically involves processes such as:

- Cold Heading: This technique involves shaping the metal at room temperature, which increases its strength and hardness without compromising ductility. It’s particularly effective for creating the head of the bolt.

- Thread Rolling: After forming, threads are rolled onto the bolt using dies, which enhances the strength of the threads compared to cut threads.

- Bending: For U-bolts, the material is bent into the desired shape to accommodate specific pipe sizes.

These processes ensure that the pipe bolts are not only strong but also precisely shaped for their intended uses.

What Does the Assembly Process Involve?

In some cases, pipe bolts may require assembly with other components such as nuts and washers. This stage involves:

- Quality Checks on Components: Ensuring that all parts meet specified dimensions and tolerances.

- Final Assembly: Components are assembled either manually or through automated processes, depending on the production scale.

Efficient assembly practices minimize errors and ensure that the final product performs as intended.

What Finishing Techniques Are Commonly Used for Pipe Bolts?

Finishing is the final stage of manufacturing, where the surface of the pipe bolts is treated to enhance durability and aesthetics. Common finishing techniques include:

- Plating: Zinc or chrome plating is used to provide additional corrosion resistance.

- Passivation: For stainless steel bolts, passivation removes free iron and enhances corrosion resistance.

- Coating: Powder coating can be applied for aesthetic purposes and added protection.

These finishing processes not only improve the longevity of the pipe bolts but also make them more appealing to buyers.

What Quality Assurance Measures Are Essential for Pipe Bolt Production?

Quality assurance is crucial in ensuring that pipe bolts meet industry standards and customer specifications. Here’s how it typically unfolds.

What International Standards Apply to Pipe Bolt Manufacturing?

International standards, such as ISO 9001, provide frameworks for quality management systems that manufacturers must adhere to. Additionally, industry-specific certifications may include:

- CE Marking: Indicates compliance with European safety and health requirements.

- API Standards: Relevant for bolts used in the oil and gas industry, ensuring they can withstand extreme conditions.

These standards assure buyers that the products they purchase are reliable and safe.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected for compliance with specifications before processing begins.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to catch defects early. This may include dimensional checks and visual inspections.

- Final Quality Control (FQC): The finished products undergo rigorous testing, including mechanical and corrosion resistance tests, before they are shipped.

These checkpoints help maintain high-quality standards throughout production.

What Testing Methods Are Commonly Used for Pipe Bolts?

Common testing methods include:

- Tensile Testing: Measures the strength and ductility of the material.

- Hardness Testing: Assesses resistance to deformation.

- Corrosion Resistance Testing: Evaluates how well the materials withstand environmental factors.

Testing results provide essential data that can be shared with buyers, ensuring transparency.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential for ensuring product reliability. Here are several ways to do this:

Illustrative image related to pipe bolt

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance reports, including:

- Audit Reports: These should outline the supplier’s adherence to international standards and any certifications obtained.

- Test Reports: Documentation of testing results, including methods used and outcomes.

Regular audits can help ensure that suppliers maintain compliance with quality standards.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing and quality control processes. These inspections can be particularly beneficial for buyers from regions like Africa and South America, where local compliance may vary.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, buyers should be aware of certain nuances:

- Cultural Differences: Understanding local manufacturing practices and quality perceptions can improve communication and expectations.

- Logistics and Shipping Considerations: Ensure that quality standards are maintained throughout the shipping process, including proper handling to prevent damage.

- Regulatory Compliance: Familiarize yourself with the regulatory requirements in your region to ensure that the products meet local standards.

By understanding these aspects, B2B buyers can better navigate the complexities of sourcing pipe bolts internationally.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipe bolt’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring pipe bolts efficiently and effectively. Pipe bolts are critical components in various industrial applications, and understanding how to source them properly can save time, reduce costs, and ensure quality. This step-by-step checklist will guide you through the essential actions needed to secure the right pipe bolts for your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the procurement process. Specifications should include the type of material (e.g., stainless steel, galvanized steel), size, and intended application.

– Material Considerations: Different materials have varying properties such as corrosion resistance and load-bearing capabilities.

– Size and Dimensions: Be specific about the pipe size, bolt diameter, and thread pitch to ensure compatibility with existing systems.

Illustrative image related to pipe bolt

Step 2: Research Potential Suppliers

Finding reliable suppliers is crucial to ensure quality and timely delivery. Start by compiling a list of potential vendors specializing in pipe bolts.

– Industry Reputation: Look for suppliers with a strong track record and positive reviews from other businesses in your industry.

– Geographic Considerations: Focus on suppliers in regions that can efficiently meet your shipping and logistical needs, especially if you are sourcing from Africa, South America, or Europe.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s essential to assess the capabilities of your shortlisted suppliers. Request detailed company profiles, including their production capacity and quality control measures.

– Certifications: Verify if the suppliers hold relevant certifications (e.g., ISO, ASTM) that ensure compliance with international standards.

– Experience with Custom Orders: If you require non-standard sizes or materials, ensure the supplier has experience in fulfilling such requests.

Step 4: Request and Compare Quotes

Once you have identified potential suppliers, request detailed quotes that outline pricing, lead times, and payment terms.

– Cost Breakdown: Ensure the quote includes all costs associated with the order, including shipping and handling.

– Lead Times: Compare delivery schedules to find a supplier that can meet your project timelines without compromising quality.

Step 5: Check References and Reviews

Conduct due diligence by reaching out to previous clients of the suppliers you are considering.

– Client Feedback: Ask about their experiences regarding product quality, service responsiveness, and after-sales support.

– Case Studies: Request case studies that demonstrate the supplier’s ability to handle similar projects effectively.

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations to finalize the terms of the agreement.

– Payment Terms: Discuss flexible payment options that align with your cash flow needs.

– Warranties and Return Policies: Clarify any warranties offered on the pipe bolts and the return policy in case of defects or discrepancies.

Step 7: Place Your Order and Monitor Delivery

After agreeing on terms, place your order and establish a communication plan to monitor the shipment.

– Tracking Information: Ensure you receive tracking details to stay updated on the delivery progress.

– Quality Assurance: Upon receipt, inspect the pipe bolts for compliance with your specifications before accepting the delivery.

By following these steps, B2B buyers can streamline the procurement of pipe bolts, ensuring they acquire quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for pipe bolt Sourcing

Understanding the cost structure and pricing dynamics of pipe bolts is essential for international B2B buyers aiming for cost-effective sourcing solutions. The total cost of pipe bolts is influenced by multiple components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

What Are the Key Cost Components for Pipe Bolt Manufacturing?

Materials: The choice of materials significantly affects the pricing of pipe bolts. Common options include stainless steel (304 and 316 grades), galvanized steel, and plain unfinished steel. Stainless steel tends to be more expensive due to its corrosion resistance and durability, making it ideal for demanding environments. Buyers should assess the material requirements based on their specific applications to ensure optimal performance and cost.

Labor and Manufacturing Overhead: Labor costs vary by region and the complexity of the manufacturing process. In countries with lower labor costs, like some regions in Africa and South America, you may find more competitive pricing. Manufacturing overhead includes expenses related to facility operations, utilities, and equipment maintenance, which can fluctuate based on local economic conditions.

Tooling Costs: Customization often requires specialized tooling, which can add to the upfront cost. For buyers looking for non-standard sizes or unique specifications, the investment in tooling must be considered in the overall pricing strategy.

Illustrative image related to pipe bolt

Quality Control (QC): Ensuring the quality of pipe bolts is crucial, particularly in industries like construction and manufacturing where safety is paramount. Rigorous QC processes can increase manufacturing costs, but they also protect against costly failures and liability issues.

Logistics: Transportation and shipping costs are significant components of the overall cost structure. Factors such as distance, shipping mode, and Incoterms (International Commercial Terms) can influence logistics expenses. Buyers should evaluate the total landed cost, which includes freight, insurance, and customs duties.

Margin: Suppliers typically apply a profit margin to cover their costs and ensure sustainability. This margin can vary based on the competitive landscape and the supplier’s positioning in the market.

How Do Pricing Influencers Impact Pipe Bolt Costs?

Several factors can influence the pricing of pipe bolts, including:

-

Volume and Minimum Order Quantities (MOQs): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better terms and lower per-unit costs.

-

Specifications and Customization: Unique specifications may necessitate additional costs for tooling and QC. Buyers should clarify their requirements upfront to avoid unexpected charges later.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as ISO standards) can drive up costs. Buyers should weigh the benefits of certification against their budget and application needs.

-

Supplier Factors: The reliability, reputation, and geographic location of the supplier can affect pricing. Local suppliers may offer lower logistics costs but might have limited options compared to international suppliers.

What Negotiation Strategies Can Buyers Use for Cost-Efficiency?

To optimize costs, buyers should consider the following strategies:

-

Engage in Transparent Communication: Clearly articulate your requirements and expectations to suppliers. Transparency can lead to better pricing and service.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can help identify competitive pricing. Don’t hesitate to leverage offers from different suppliers during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price, but also the long-term costs associated with maintenance, potential downtime, and replacement. This holistic view can guide better decision-making.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and trade agreements can impact pricing for international buyers, particularly those from regions like Africa, South America, and the Middle East. Staying informed about these factors can enhance negotiation leverage.

Conclusion

While indicative prices for pipe bolts can vary significantly based on the factors discussed, understanding the underlying cost structure and pricing influencers can empower buyers to make informed sourcing decisions. Always remember to request detailed quotes that break down costs, allowing for clearer comparisons and better negotiation outcomes.

Alternatives Analysis: Comparing pipe bolt With Other Solutions

When considering fastening solutions for pipe installations, it is essential for B2B buyers to evaluate the options available in the market. While pipe bolts are a popular choice, various alternative solutions can offer different advantages based on specific project requirements. This section explores these alternatives, highlighting key aspects that can guide international buyers in making informed decisions.

| Comparison Aspect | Pipe Bolt | U-Bolt | Clamp |

|---|---|---|---|

| Performance | High tensile strength, reliable for heavy loads. | Good for securing pipes in place but may not handle extreme loads as effectively. | Versatile for various applications; however, load capacity may vary by design. |

| Cost | Moderate pricing; varies by material and size. | Generally lower cost; widely available in multiple materials. | Cost-effective, especially for simpler applications, but can vary with complexity. |

| Ease of Implementation | Requires careful installation, especially in tight spaces. | Easy to install and adjust; offers flexibility in positioning. | Simple installation with no special tools needed, quick to deploy. |

| Maintenance | Minimal maintenance; durability depends on material used. | Generally low maintenance; may require periodic checks for corrosion. | Low maintenance; depends on environment and material choice. |

| Best Use Case | Ideal for high-stress applications in industrial settings. | Suitable for securing pipes in construction and automotive applications. | Best for non-load-bearing applications or temporary installations. |

What Are the Advantages and Disadvantages of U-Bolts as an Alternative to Pipe Bolts?

U-bolts provide a reliable alternative to pipe bolts, particularly for securing pipes in place. Their design allows for quick adjustments and easy installation, making them suitable for various applications. However, while they are cost-effective and readily available in different materials, they may not handle extreme loads as well as pipe bolts. U-bolts are ideal for construction projects where flexibility and ease of use are priorities, but they may not be the best choice for high-stress applications.

How Do Clamps Compare to Pipe Bolts in Terms of Flexibility and Cost?

Clamps are another alternative that can offer significant cost savings, especially for less demanding applications. They are simple to install, requiring no special tools, which makes them an attractive option for temporary setups or less critical installations. However, their load capacity can vary significantly based on design and material, and they may not be suitable for heavy-duty applications. Clamps excel in versatility but lack the robust performance characteristics of pipe bolts, making them more appropriate for non-load-bearing situations.

Illustrative image related to pipe bolt

Conclusion: Which Fastening Solution Should You Choose?

When selecting the appropriate fastening solution, it is crucial to assess the specific needs of your project. Pipe bolts are well-suited for high-stress environments and heavy-duty applications, while U-bolts and clamps provide cost-effective and flexible options for less demanding tasks. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make an informed decision that aligns with their operational requirements and budget constraints. Understanding these alternatives allows for a tailored approach to securing pipe installations, ensuring both efficiency and reliability in diverse applications.

Essential Technical Properties and Trade Terminology for pipe bolt

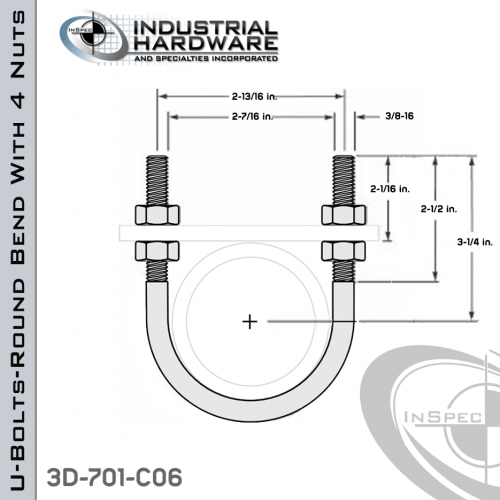

What Are the Key Technical Properties of Pipe Bolts?

When selecting pipe bolts for industrial applications, understanding their technical properties is crucial for ensuring compatibility and performance. Here are some essential specifications:

1. Material Grade

The material grade of a pipe bolt significantly influences its strength, corrosion resistance, and overall durability. Common materials include:

- Stainless Steel (Type 304 and 316): Known for excellent corrosion resistance, making it suitable for harsh environments, including chemical processing.

- Hot Dip Galvanized Steel: Provides a protective zinc coating, ideal for outdoor applications where exposure to moisture is a concern.

- Plain (Unfinished) Steel: Economical but requires further treatment to prevent rusting.

Choosing the right material grade ensures that the pipe bolts will withstand the specific conditions of your application, thereby reducing maintenance costs and increasing service life.

Illustrative image related to pipe bolt

2. Bolt Diameter and Thread Pitch

Bolt diameter and thread pitch are critical for load-bearing capacity and compatibility with existing equipment. The diameter is measured in inches and can range from 1/4″ to 36″. The thread pitch, which refers to the distance between threads, is also specified (e.g., 1/2-13).

These specifications affect how well the bolt will fit into the corresponding nuts and holes. Proper sizing ensures a secure fit, minimizing the risk of failure due to loosening or stripping.

3. Pipe Outside Diameter (OD)

The outside diameter of the pipe is essential for determining the correct size of the pipe bolt. It ensures that the bolt fits snugly around the pipe, which is critical for maintaining structural integrity. For instance, a bolt designed for a 10″ OD pipe will not be suitable for a 12″ OD pipe.

In B2B transactions, providing accurate OD measurements helps streamline the ordering process and reduces the chances of returns or rework.

4. Thread Length

Thread length refers to the portion of the bolt that is threaded, which allows for secure attachment to nuts or other components. It varies across different bolt sizes and applications. A longer thread length may be necessary for applications requiring deeper engagement, while shorter lengths may suffice for lighter loads.

Understanding thread length helps buyers ensure that they have the appropriate hardware for their assembly needs, enhancing the overall reliability of the installation.

5. Tolerance

Tolerance indicates the allowable deviation from specified dimensions. In the context of pipe bolts, it is crucial for ensuring that components fit together correctly. Tight tolerances are often required in high-precision applications, while looser tolerances may be acceptable in less critical environments.

Accurate tolerances are vital for maintaining quality control in manufacturing processes, ultimately affecting product reliability and performance.

What Are Common Trade Terms Used in the Pipe Bolt Industry?

Familiarity with industry jargon can streamline communication and improve negotiations. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand name. In the context of pipe bolts, understanding OEM specifications can help buyers identify quality standards and compatibility with existing equipment.

Illustrative image related to pipe bolt

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory levels and budget constraints effectively. It’s crucial for maintaining supply chain efficiency, especially in B2B transactions.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. This process is essential for comparing costs and terms, ensuring that buyers receive competitive pricing and suitable conditions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, thus reducing misunderstandings in global trade.

Illustrative image related to pipe bolt

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times helps buyers plan their projects more effectively and manage expectations regarding delivery schedules.

Conclusion

By grasping the technical properties and trade terminology related to pipe bolts, B2B buyers can make more informed purchasing decisions. This knowledge not only enhances the efficiency of procurement processes but also ensures that the right components are selected for specific applications.

Navigating Market Dynamics and Sourcing Trends in the pipe bolt Sector

What Are the Current Market Dynamics and Key Trends in the Pipe Bolt Sector?

The global pipe bolt market is being shaped by several pivotal factors that international B2B buyers must consider. One primary driver is the surge in infrastructure development across emerging economies in Africa, South America, and the Middle East. This growth is fueled by urbanization and industrialization, leading to increased demand for robust fastening solutions in construction and manufacturing. Additionally, advancements in manufacturing technology are making it easier for suppliers to offer customized solutions, enabling buyers to find specific sizes and materials that meet their project requirements.

Emerging technologies, such as 3D printing and digital procurement platforms, are transforming sourcing practices. Buyers can now leverage these technologies to streamline their supply chains, reduce lead times, and lower costs. For instance, digital marketplaces facilitate quick access to a wide variety of pipe bolt options, allowing companies to compare prices and specifications effortlessly. Furthermore, sustainability is becoming a critical consideration, influencing sourcing decisions. Companies are increasingly looking for suppliers that offer eco-friendly materials and practices, aligning with global trends towards greener construction methods.

How Can Sustainability and Ethical Sourcing Impact the Pipe Bolt Sector?

The environmental impact of the pipe bolt industry is significant, given the raw materials and energy consumption involved in production. As businesses and consumers become more environmentally conscious, the demand for sustainable products is on the rise. For B2B buyers, understanding the implications of sourcing decisions is essential. Companies that prioritize sustainability can reduce their carbon footprint, enhance their brand reputation, and attract a growing segment of environmentally-conscious clients.

Illustrative image related to pipe bolt

Ethical sourcing practices are also gaining traction. Buyers are now more inclined to work with suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical standards. By collaborating with responsible manufacturers, businesses can ensure that their pipe bolts are sourced from environmentally friendly materials, such as recycled steel or sustainably sourced alloys, thereby contributing to a more sustainable future.

What Is the Evolution of the Pipe Bolt Industry and Its Relevance to B2B Buyers?

The pipe bolt industry has evolved significantly over the past few decades, transitioning from basic metal fasteners to sophisticated products designed for specific applications. Initially, pipe bolts were primarily made from plain steel, but advancements in metallurgy have introduced a variety of materials, including stainless steel and galvanized options, which offer enhanced durability and corrosion resistance.

This evolution is crucial for B2B buyers, as it underscores the importance of selecting the right materials based on application needs. For example, stainless steel bolts are increasingly preferred in environments exposed to moisture or corrosive substances, while galvanized options remain popular for general construction purposes. Understanding this evolution allows buyers to make informed decisions that align with their project requirements and longevity expectations, ultimately enhancing the performance and reliability of their installations.

Frequently Asked Questions (FAQs) for B2B Buyers of pipe bolt

-

How do I choose the right pipe bolt for my application?

Selecting the right pipe bolt involves considering several factors, including the pipe’s diameter, the material of the bolt, and the environmental conditions it will face. Common materials include stainless steel, which offers corrosion resistance, and hot-dip galvanized steel for outdoor applications. Additionally, assess the load requirements and whether the bolt needs to accommodate specific pressure ratings. Consulting with suppliers about your specific application can also provide insights into the best choices. -

What materials are commonly used for pipe bolts, and how do I select the best one?

Pipe bolts are typically made from materials like stainless steel (Types 304 and 316), hot-dip galvanized steel, and plain or zinc-plated steel. For environments prone to corrosion or high temperatures, stainless steel is preferred due to its durability. In contrast, galvanized steel offers good protection against rust for general outdoor applications. Evaluating the specific conditions your bolts will face—such as exposure to chemicals or extreme temperatures—will guide you in selecting the most suitable material. -

What is the minimum order quantity (MOQ) for pipe bolts?

Minimum order quantities for pipe bolts can vary significantly by supplier and material type. Typically, MOQs range from 100 to 1,000 units, depending on the bolt specifications and the manufacturer’s production capabilities. It’s important to communicate your needs with suppliers early in the process to determine if they can accommodate smaller orders or if they offer tiered pricing for larger quantities. -

How can I ensure the quality of pipe bolts before purchasing?

To ensure quality, request certifications and test reports from suppliers that demonstrate compliance with industry standards, such as ASTM or ISO certifications. Consider conducting third-party inspections or audits if sourcing from overseas manufacturers. Additionally, review customer testimonials and case studies to gauge the supplier’s reliability and product performance in similar applications. -

What payment terms are typically offered by suppliers for international orders?

Payment terms can vary widely among suppliers, but common practices include advance payment, letter of credit, or 30-60 days net after invoice. For larger orders, some suppliers may negotiate partial payments upfront with the balance upon delivery. It’s crucial to discuss and agree on payment terms upfront to avoid misunderstandings and ensure smooth transactions. -

What should I consider regarding logistics when sourcing pipe bolts internationally?

When sourcing internationally, consider shipping methods, customs regulations, and delivery timelines. Evaluate whether you need air freight for faster delivery or sea freight for cost-effectiveness. Additionally, familiarize yourself with import duties and tariffs applicable to your region. Working with logistics providers who have experience in international shipping can streamline the process and help mitigate potential delays. -

Can I customize pipe bolts to meet specific project requirements?

Yes, many suppliers offer customization options for pipe bolts, including variations in size, material, and threading specifications. When requesting customization, provide detailed specifications and project requirements to the supplier. Be aware that custom orders may have longer lead times and potentially higher costs, so plan accordingly to meet your project deadlines. -

How do I vet suppliers for pipe bolts in different regions?

Vetting suppliers involves researching their reputation, experience, and production capabilities. Check for certifications and quality assurance processes, and request samples to evaluate product quality. Utilize platforms like trade associations, industry forums, and trade shows to find reliable suppliers. Additionally, consider reaching out to previous customers for references to gain insights into their experience with the supplier.

Top 8 Pipe Bolt Manufacturers & Suppliers List

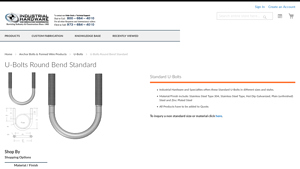

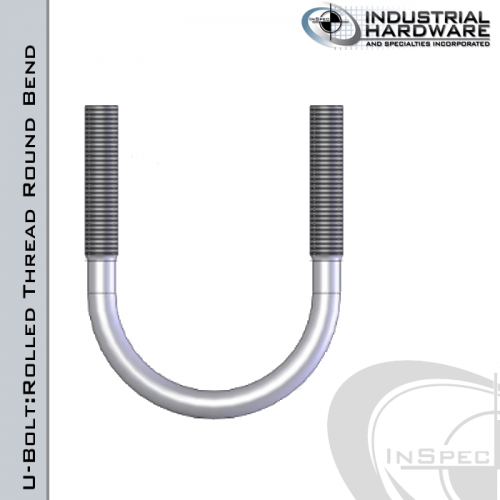

1. Industrial Hardware – U-Bolts Round Bend Standard

Domain: industrialhardware.com

Registered: 1997 (28 years)

Introduction: U-Bolts Round Bend Standard: Light Weight, Heavy Duty, Ductile

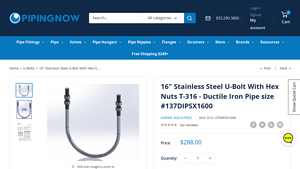

2. Empire Industries – 16 Stainless Steel U-Bolt

Domain: pipingnow.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “16” Stainless Steel U-Bolt With Hex Nuts T-316 – Ductile Iron Pipe size”, “SKU”: “012-137DIPSX1600”, “Price”: “$288.00”, “Material”: “316 Stainless Steel”, “Ductile Iron Pipe Size”: “16” , “Bolt Size”: “7/8” , “Max Recommended Load (lbs.)”: “7540”, “Manufacturer”: “Empire Industries”, “Category”: “U-Bolts”}

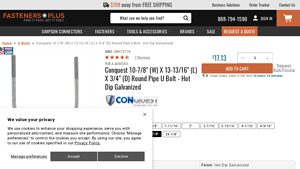

3. Fasteners Plus – 10 Galvanized U-Bolt

Domain: fastenersplus.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “10” Galvanized U-Bolt Round Pipe U-Bolt”, “Material”: “Galvanized Steel”, “Size”: “10 inch”, “Type”: “U-Bolt”, “Shape”: “Round”, “Finish”: “Galvanized”, “Usage”: “For securing pipes or other cylindrical objects”, “Load Capacity”: “Varies based on application”, “Includes”: “2 nuts and 2 washers”, “Applications”: “Plumbing, construction, and other industrial uses”}

4. LHDottie – U400 Hex Nut

Domain: lhdottie.com

Registered: 1998 (27 years)

Introduction: {‘part_number’: ‘U400’, ‘size’: “1/2”-13 x 4””, ‘pipe_size’: “4””, ‘material’: ‘Low Carbon Steel’, ‘finish’: ‘Zinc Plated’, ‘nut_type’: ‘Hex’, ‘thread_diameter’: “1/2””, ‘inside_diameter’: “4-1/2””, ‘inside_length’: “6-1/2””, ‘thread_length’: “2-1/4””, ‘standard_qty’: ’10’, ‘master_qty’: ’80’, ‘special_features’: ‘NC Rolled Machine Threads’, ‘certifications’: ‘UNSPSC 31161616, RoHS Complian…

5. Empire Industries – Fig. 137DIP Standard U-Bolt

Domain: empireindustries.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Fig. 137DIP Standard U-Bolt For Ductile Iron Pipe With 4 Hex Nuts”, “Part Number”: “137dip”, “Category”: “U-Bolts”, “Finish Options”: [“Hot Dipped Galvanized”, “Plain”, “T-304 Stainless Steel”, “T-316 Stainless Steel”], “Size Options”: [“3”, “4”, “6”, “8”, “10”, “12”, “14”, “16”, “18”, “20”, “24”, “30”], “Competitor Part Numbers”: [“137”, “283”, “B3188”, “1500”, “1600”, “15,0”, “…

6. Remington – .50 Hunting Rifle

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The .50 pipe bolt sniper rifle has a base damage of 34 points, with a .50 receiver adding 25 points for a total of 59 damage. The .50 hunting rifle has a base damage of 37 points, with a .50 receiver adding 47 points for a total of 84 damage. The hunting rifle is based on the Remington Model 700 and is considered to be of higher quality compared to the pipe rifle, which is made from scrap material…

7. McMaster – Pipe Flange Bolts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Pipe Flange Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Slash2Gash – Nut N Bolt Convertible Screw Pipe

Domain: slash2gash.com

Registered: 2016 (9 years)

Introduction: Nut N Bolt Convertible Screw Pipe – Metal Tobacco Smoking Pipe

– Style: Version 1 (Smoking Pipe), Version 2 (Hidden Stash)

– Price: Version 1 – $7.95 USD, Version 2 – $7.95 USD

– Features: Portable screw design, looks like a common nut and bolt, discreet bowl for storage

– Material: Metal

– Color: Silver

– Length: 2.5 inches

– Intended Use: Tobacco only, must read disclaimer before purchasing, no …

Strategic Sourcing Conclusion and Outlook for pipe bolt

In the evolving landscape of industrial procurement, the strategic sourcing of pipe bolts emerges as a critical factor for businesses aiming to enhance operational efficiency and reduce costs. Understanding the diverse materials available, such as stainless steel and galvanized options, allows buyers to make informed decisions that align with their specific project requirements. Moreover, recognizing the importance of standard and non-standard sizing can significantly impact the reliability and longevity of installations, leading to reduced maintenance and replacement costs.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate this complex market, leveraging strategic sourcing practices is essential. Establishing strong supplier relationships and prioritizing quality assurance not only ensures compliance with local regulations but also fosters innovation and adaptability in supply chains.

Looking ahead, businesses should be proactive in seeking out partnerships with reliable manufacturers and distributors to secure a competitive edge. By staying informed about market trends and emerging technologies in bolt manufacturing, companies can position themselves for success. Engage with trusted suppliers today to explore how strategic sourcing can unlock new opportunities and drive sustainable growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.