Pbt Gf30: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for pbt gf30

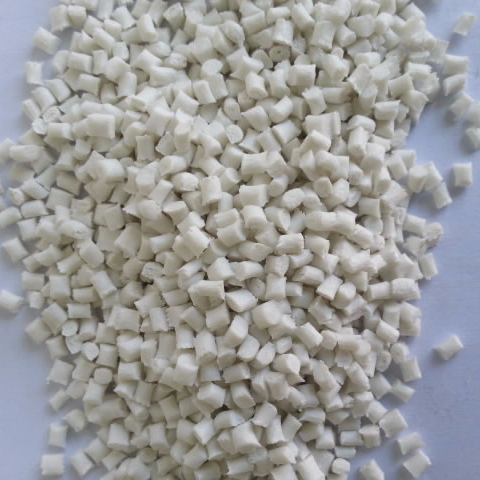

In today’s fast-paced global market, sourcing high-quality PBT GF30 (polybutylene terephthalate with 30% glass fiber reinforcement) can pose significant challenges for B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe. As industries increasingly demand materials that offer exceptional mechanical strength, thermal stability, and dimensional accuracy, navigating the complexities of material selection and supplier reliability is crucial. This guide provides a comprehensive overview of PBT GF30, addressing its various types and applications, supplier vetting processes, pricing structures, and key performance attributes.

By exploring the critical properties of PBT GF30—such as its resistance to heat and chemicals, excellent electrical insulation, and low water absorption—this guide equips international buyers with the insights needed to make informed purchasing decisions. It highlights the material’s versatility in applications ranging from automotive components and electronics to healthcare devices, ensuring that businesses can align their sourcing strategies with specific operational requirements.

Furthermore, we delve into the nuances of supplier selection, offering strategies to identify reputable manufacturers and distributors that adhere to global quality standards. As you navigate the intricacies of the global PBT GF30 market, this guide serves as your essential resource, empowering you to streamline procurement processes, optimize supply chain efficiency, and ultimately enhance your competitive edge in the marketplace.

Understanding pbt gf30 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PBT GF30 Standard | Contains 30% glass fiber, excellent mechanical strength | Automotive components, industrial machinery | Pros: High strength and durability; Cons: Limited weather resistance |

| PBT GF30 Flame Retardant | Enhanced flame resistance properties | Electrical housings, automotive safety components | Pros: Improved safety; Cons: Higher cost due to additives |

| PBT GF30 UV Stabilized | Resistance to UV degradation, suitable for outdoor use | Outdoor applications, consumer electronics | Pros: Long-lasting performance outdoors; Cons: May be less strong than standard |

| PBT GF30 Food-Grade | Compliant with food safety standards, low water absorption | Food processing equipment, packaging materials | Pros: Safe for food contact; Cons: Limited temperature range |

| PBT GF30 High-Temperature | Capable of withstanding higher temperatures, thermal stability | Aerospace, automotive high-performance parts | Pros: Suitable for extreme conditions; Cons: More expensive than standard |

What are the Characteristics of PBT GF30 Standard?

The PBT GF30 Standard is the most common variation, known for its robust mechanical properties due to the inclusion of 30% glass fiber. This variant is ideal for applications requiring high strength, such as automotive components and industrial machinery. Buyers should consider its excellent dimensional stability and low water absorption, which enhance performance in demanding environments. However, its limited weather resistance may pose challenges in outdoor applications.

How Does PBT GF30 Flame Retardant Enhance Safety?

The Flame Retardant variant of PBT GF30 is engineered with additives that improve its resistance to fire. This makes it suitable for electrical housings and automotive safety components where fire safety is paramount. While its enhanced safety features provide peace of mind, buyers should be aware of the higher costs associated with these flame-retardant properties, which may affect budget considerations.

Why Choose PBT GF30 UV Stabilized for Outdoor Applications?

PBT GF30 UV Stabilized is specifically designed to resist degradation caused by ultraviolet (UV) light, making it an excellent choice for outdoor applications such as consumer electronics and outdoor equipment. This variant ensures long-lasting performance in harsh sunlight conditions. However, it may not offer the same mechanical strength as the standard variant, so buyers should evaluate the specific requirements of their applications before purchasing.

What Makes PBT GF30 Food-Grade Ideal for the Food Industry?

The Food-Grade version of PBT GF30 complies with stringent food safety standards and features low water absorption, making it suitable for food processing equipment and packaging materials. This variant is particularly important for businesses looking to ensure compliance with health regulations. However, it has a limited temperature range compared to other variants, which may restrict its use in high-heat applications.

How Does PBT GF30 High-Temperature Perform in Extreme Conditions?

PBT GF30 High-Temperature is designed for applications that require exceptional thermal stability, making it suitable for aerospace and high-performance automotive parts. This variant can withstand extreme temperatures without compromising its mechanical properties, making it highly valuable for industries where reliability is critical. However, the advanced formulation comes at a higher cost, which buyers should factor into their purchasing decisions.

Key Industrial Applications of pbt gf30

| Industry/Sector | Specific Application of pbt gf30 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Sensor housings for engine management systems | Enhanced durability and precision in monitoring engine performance | Ensure compliance with automotive standards and regulations |

| Electronics | Position sensors for robotics and automation | Improved accuracy and reliability in operational tasks | Look for suppliers with expertise in electronic applications |

| Manufacturing | Components for predictive maintenance systems | Increased operational efficiency and reduced downtime | Evaluate the supplier’s ability to deliver consistent quality |

| Healthcare | Patient monitoring devices | Critical for patient safety and device efficacy | Verify biocompatibility and compliance with health regulations |

| Construction | Wear plates and cogs for machinery | Extended lifespan of equipment and reduced maintenance costs | Assess the material’s resistance to environmental factors |

How is pbt gf30 Used in the Automotive Industry?

In the automotive sector, pbt gf30 is primarily utilized in the production of sensor housings for engine management systems. Its excellent mechanical strength and thermal resistance ensure that these sensors can withstand harsh operating conditions, providing accurate readings that enhance vehicle performance and safety. For international buyers, particularly in regions like Brazil and Saudi Arabia, it’s essential to source materials that comply with local automotive standards and can withstand varying climatic conditions.

What Role Does pbt gf30 Play in Electronics?

Within the electronics industry, pbt gf30 is commonly employed in position sensors used for robotics and automation. The material’s high tensile strength and dimensional stability make it ideal for applications requiring precise movements and measurements. Buyers from South America and Africa should consider suppliers with a strong track record in electronics to ensure that the products meet specific performance standards and can operate reliably in diverse environments.

How is pbt gf30 Beneficial in Manufacturing?

Pbt gf30 is integrated into manufacturing equipment as components for predictive maintenance systems. By utilizing this material, businesses can improve operational efficiency and significantly reduce downtime, leading to cost savings. When sourcing for manufacturing applications, companies should prioritize suppliers that can guarantee consistent quality and timely delivery, as these factors are crucial for maintaining production schedules.

Why is pbt gf30 Important in Healthcare Devices?

In the healthcare sector, pbt gf30 is crucial for the fabrication of patient monitoring devices. Its reliability and biocompatibility ensure that these devices not only function accurately but also prioritize patient safety. B2B buyers in this field, particularly from the Middle East and Europe, must ensure that their suppliers adhere to strict health regulations and standards to avoid compliance issues.

How is pbt gf30 Applied in Construction?

In construction, pbt gf30 is used for wear plates and cogs in machinery, enhancing the durability and efficiency of construction equipment. This results in longer equipment lifespans and lower maintenance costs, which are critical for businesses operating in competitive markets. Buyers should assess the material’s resistance to environmental factors, especially in regions with extreme weather conditions, to ensure longevity and performance.

3 Common User Pain Points for ‘pbt gf30’ & Their Solutions

Scenario 1: Ensuring Material Quality and Consistency in Supply Chains

The Problem: B2B buyers often face challenges with ensuring the quality and consistency of PBT GF30 materials throughout their supply chains. Variability in material properties can lead to performance issues in end products, such as reduced mechanical strength or dimensional inaccuracies, which can result in costly production delays or product failures. This problem is particularly acute for buyers operating in industries like automotive or electronics, where precision is critical.

The Solution: To mitigate these risks, buyers should prioritize sourcing PBT GF30 from reputable suppliers who provide comprehensive material certifications and testing results. Implement a robust vendor assessment process that includes evaluating the supplier’s manufacturing practices, quality control measures, and previous customer feedback. Additionally, consider establishing long-term partnerships with suppliers who can demonstrate a consistent track record of delivering high-quality materials. Implementing regular quality checks upon receipt of materials can further ensure that the properties of PBT GF30 meet specified standards before they are integrated into production processes. This proactive approach not only enhances product reliability but also builds trust within the supply chain.

Scenario 2: Adapting PBT GF30 for Diverse Applications

The Problem: B2B buyers often struggle with adapting PBT GF30 for various applications due to its specific properties, such as temperature resistance and mechanical strength. For instance, while PBT GF30 is suitable for many automotive components, it may not perform well in applications requiring high impact resistance or exposure to harsh chemicals. This can lead to unexpected failures and increased costs for businesses that rely on this material for critical components.

The Solution: To effectively adapt PBT GF30 for diverse applications, buyers should invest time in understanding the material’s properties and limitations. Collaborating with material scientists or engineers can provide valuable insights into how PBT GF30 can be modified or combined with other materials to enhance its performance for specific applications. Additionally, conducting thorough testing in the application environment can help identify potential issues before full-scale production begins. Buyers should also stay informed about advancements in material technology that could allow for the enhancement of PBT GF30’s properties, such as incorporating additives or coatings that improve its resistance to impact or chemicals.

Scenario 3: Navigating Regulatory Compliance and Safety Standards

The Problem: Another common pain point for B2B buyers of PBT GF30 is navigating the complex landscape of regulatory compliance and safety standards, especially when the material is used in sensitive industries like healthcare or food processing. The lack of clear guidelines can lead to uncertainty regarding the safe use of PBT GF30, potentially resulting in regulatory fines or product recalls.

The Solution: To effectively navigate compliance challenges, buyers should familiarize themselves with relevant regulations and standards applicable to their industry, such as FDA regulations for healthcare or food safety standards. Engaging with legal or compliance experts can provide clarity on the specific requirements for using PBT GF30 in their products. Additionally, buyers should seek out suppliers who are well-versed in compliance matters and can provide documentation that confirms the material’s safety and suitability for intended applications. Regular training and updates for procurement and engineering teams on compliance issues can also help mitigate risks associated with non-compliance, ensuring that all stakeholders are aligned and informed.

Strategic Material Selection Guide for pbt gf30

What Are the Key Properties of PBT GF30?

PBT GF30, or polybutylene terephthalate reinforced with 30% glass fiber, is a thermoplastic polymer known for its excellent mechanical and thermal properties. This material exhibits high tensile strength, good dimensional stability, and resistance to heat and chemicals, making it suitable for demanding applications. Its operating temperature can reach up to 200°C for short periods and 110°C for continuous use, which is critical for industries such as automotive and electronics that often deal with high-temperature environments.

What Are the Advantages and Disadvantages of PBT GF30?

When considering PBT GF30 for various applications, it is essential to weigh its advantages against its limitations.

Advantages:

1. Durability: The glass fiber reinforcement significantly enhances the mechanical strength and rigidity of PBT GF30, making it highly resistant to wear and deformation.

2. Dimensional Accuracy: The material maintains its shape and size across a wide temperature range, which is crucial for applications requiring precision.

3. Chemical Resistance: PBT GF30 demonstrates good resistance to a variety of chemicals, making it suitable for industrial environments.

Disadvantages:

1. Cost: PBT GF30 tends to be on the higher end of the cost spectrum compared to other engineering plastics, which may impact budget-sensitive projects.

2. Manufacturing Complexity: The processing of PBT GF30 can require specialized equipment and techniques, potentially increasing production time and costs.

3. Limited Weather Resistance: While it performs well in controlled environments, PBT GF30 has poor weather resistance, which may limit its use in outdoor applications.

How Does PBT GF30 Impact Specific Applications?

PBT GF30 is widely utilized in various sectors, including automotive, electronics, and healthcare. In automotive applications, it is commonly used for parts that require high mechanical strength and temperature resistance, such as sensor housings and structural components. In electronics, its excellent electrical insulation properties make it ideal for components like connectors and circuit boards. However, buyers should consider the specific media compatibility, as PBT GF30 may not be suitable for all chemical environments.

What Should International B2B Buyers Consider?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several factors should be taken into account when selecting PBT GF30. Compliance with local standards such as ASTM, DIN, or JIS is crucial for ensuring product quality and safety. Additionally, understanding the regional preferences and availability of materials can help in making informed purchasing decisions. Buyers should also evaluate the supply chain logistics, considering factors like shipping costs and lead times, which can vary significantly across different regions.

Summary Table

| Material | Typical Use Case for pbt gf30 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PBT GF30 | Automotive sensors, electronic components | High mechanical strength and rigidity | Higher cost and manufacturing complexity | High |

| PET | General packaging, textiles | Cost-effective and versatile | Lower thermal stability compared to PBT GF30 | Low |

| Nylon | Mechanical parts, automotive applications | Excellent wear resistance | Water absorption can affect performance | Med |

| Polycarbonate | Optical components, safety equipment | High impact resistance and clarity | Susceptible to scratching and UV degradation | Med |

This strategic material selection guide aims to provide B2B buyers with actionable insights into PBT GF30 and its alternatives, facilitating informed decisions that align with their specific industry needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pbt gf30

What Are the Key Stages in the Manufacturing Process of PBT GF30?

The manufacturing process of PBT GF30, a fiberglass-reinforced polybutylene terephthalate, involves several critical stages that ensure the material meets stringent quality and performance standards. Understanding these stages is essential for B2B buyers looking to procure this engineering plastic for their applications.

1. Material Preparation: Sourcing and Compounding

The first step in manufacturing PBT GF30 is the careful selection and preparation of raw materials. High-quality polybutylene terephthalate and fiberglass are sourced from reputable suppliers. Compounding involves mixing the base polymer with 30% fiberglass, which enhances the material’s mechanical properties. This process is typically conducted in controlled environments to prevent contamination and ensure consistent quality.

2. Forming: Molding Techniques

Once the materials are compounded, they undergo forming processes. The most common methods for shaping PBT GF30 include injection molding and extrusion.

-

Injection Molding: This technique involves injecting the molten polymer into a mold under high pressure. It allows for the production of complex shapes and high-volume parts, making it ideal for automotive components, electrical housings, and various industrial applications.

-

Extrusion: In this process, the compounded material is pushed through a die to create sheets or rods. This method is suitable for producing large quantities of uniform cross-sectional profiles.

Both techniques require precise temperature control and timing to ensure optimal material flow and finish.

Illustrative image related to pbt gf30

3. Assembly: Integrating Components

For applications requiring multiple parts, assembly becomes a crucial step. Components made from PBT GF30 may be combined with other materials or components, such as metals and other plastics. This stage often involves mechanical fastening, adhesive bonding, or welding, depending on the design specifications.

Efficient assembly processes ensure that the final product maintains its integrity and performance characteristics, which is vital for applications like automotive sensors or electronic devices.

4. Finishing: Surface Treatment and Quality Checks

The finishing stage may involve machining, surface treatment, or coating to enhance the final product’s appearance and performance. Common finishing processes include sanding, polishing, and applying protective coatings. These treatments help improve wear resistance and aesthetic appeal, crucial for consumer-facing applications.

Illustrative image related to pbt gf30

How Is Quality Assurance Implemented in PBT GF30 Manufacturing?

Quality assurance (QA) is vital in ensuring that PBT GF30 meets international standards and customer specifications. Implementing robust QA processes not only enhances product reliability but also builds trust with B2B buyers.

International Standards Relevant to PBT GF30

Several international and industry-specific standards govern the quality of PBT GF30. Key standards include:

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is crucial for manufacturers seeking to demonstrate their commitment to consistent quality. Compliance with ISO 9001 ensures that processes are in place to enhance customer satisfaction and continually improve.

-

CE Marking: For products sold within the European Economic Area (EEA), CE marking signifies compliance with health, safety, and environmental protection standards.

-

API Standards: In industries like oil and gas, adherence to American Petroleum Institute (API) standards is crucial for materials used in critical applications.

What Are the Critical Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to monitor quality at various stages:

Illustrative image related to pbt gf30

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. This step is crucial to prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor parameters such as temperature, pressure, and material consistency. This ensures that any deviations are caught early, minimizing waste and rework.

-

Final Quality Control (FQC): Once production is complete, finished products undergo comprehensive testing to verify that they meet all specifications and standards. This may include mechanical testing, dimensional checks, and environmental resistance assessments.

What Testing Methods Are Commonly Used for PBT GF30?

Various testing methods are employed to ensure that PBT GF30 meets the required performance criteria. These include:

-

Mechanical Testing: Tensile strength, flexural strength, and impact resistance tests are conducted to assess the material’s mechanical properties.

-

Thermal Testing: The thermal stability and resistance to deformation under heat are evaluated through methods such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA).

-

Chemical Resistance Testing: PBT GF30 is tested against various chemicals to ensure its suitability for specific applications, especially in harsh environments.

-

Dimensional Inspection: Using tools such as calipers and coordinate measuring machines (CMM), manufacturers ensure that the dimensions of the final product meet the specifications outlined in the design.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical. Here are actionable steps to ensure quality:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and quality management systems. This helps identify any potential issues before placing large orders.

-

Request Quality Assurance Documentation: Suppliers should provide certifications, testing reports, and compliance documents that demonstrate adherence to relevant standards.

-

Engage Third-Party Inspection Services: Utilizing independent third-party inspectors can provide an unbiased assessment of the supplier’s quality practices and product conformity.

-

Establish Clear Communication Channels: Maintaining open lines of communication with suppliers allows for quick resolution of any quality issues and fosters a collaborative approach to quality improvement.

What Are the Quality Certification Nuances for International Buyers?

International buyers should be aware of specific nuances regarding quality certifications and standards when sourcing PBT GF30. Different regions may have varying regulatory requirements, and understanding these can facilitate smoother transactions.

Illustrative image related to pbt gf30

-

Regional Certifications: While ISO standards are globally recognized, some regions may have additional local certifications that are necessary for market entry. For instance, products entering the European market must comply with specific CE marking requirements.

-

Cultural Considerations: Understanding cultural differences in business practices can help in establishing trust and ensuring that quality expectations are met.

By focusing on the manufacturing processes and quality assurance protocols associated with PBT GF30, B2B buyers can make informed decisions, ensuring they procure high-quality materials that meet their application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pbt gf30’

In today’s competitive landscape, sourcing high-quality materials like PBT GF30 is essential for manufacturers and businesses that require durable and reliable components. This guide provides a structured approach to help B2B buyers navigate the procurement process effectively, ensuring they find the best suppliers and materials for their needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for PBT GF30 that meet your project’s needs. Consider factors such as mechanical strength, thermal stability, and chemical resistance. Providing detailed specifications will facilitate better communication with suppliers and help them understand your exact requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in PBT GF30. Look for companies with a strong reputation in engineering plastics, particularly those that can demonstrate expertise in fiberglass-reinforced materials. Use online platforms, industry directories, and trade shows to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your chosen suppliers hold relevant certifications, such as ISO 9001 or other industry-specific standards. Certifications indicate a commitment to quality management practices and can provide assurance of the supplier’s reliability and product quality. Additionally, check for compliance with regional regulations pertinent to your industry.

Step 4: Request Material Samples

Always request samples of PBT GF30 before finalizing your order. Evaluating physical samples allows you to assess the material’s properties, such as tensile strength and dimensional stability, ensuring it meets your project’s specifications. It also provides an opportunity to test the material in real-world applications to confirm its suitability.

Step 5: Discuss Pricing and Payment Terms

Engage in negotiations regarding pricing and payment terms with potential suppliers. Ensure that the pricing aligns with your budget while also reflecting the quality of the material. Discuss payment options, such as upfront payments or credit terms, to find a mutually beneficial arrangement. Be cautious of prices that seem too low, as they may indicate inferior quality.

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the supplier’s logistics and delivery capabilities to ensure they can meet your timeline. Understanding their shipping methods, lead times, and geographical coverage is vital, especially if you are sourcing internationally. Confirm that they can handle customs and any potential delays, particularly when dealing with suppliers in different regions.

Step 7: Establish a Communication Plan

Effective communication is crucial for a successful partnership. Establish a clear communication plan that outlines points of contact, frequency of updates, and preferred communication channels. This will facilitate smooth interactions throughout the sourcing process and help address any concerns or changes promptly.

By following this checklist, B2B buyers can streamline the sourcing process for PBT GF30, ensuring they select the right materials and suppliers for their needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for pbt gf30 Sourcing

When sourcing PBT GF30, a robust engineering plastic reinforced with glass fibers, understanding the comprehensive cost structure is crucial for B2B buyers. This material is favored for its mechanical strength, thermal stability, and versatility across various industries, including automotive, electronics, and manufacturing. Below is an analysis of the cost components, price influencers, and strategic buyer tips specific to international markets.

What Are the Key Cost Components of PBT GF30?

The cost structure of PBT GF30 encompasses several critical components:

-

Materials: The primary cost driver is the PBT resin itself, along with the glass fiber reinforcement. Prices can vary significantly based on the quality of the raw materials and market fluctuations.

-

Labor: Manufacturing labor costs can vary by region. Countries with lower labor costs may provide more competitive pricing, but this can impact quality and delivery times.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and maintenance. Efficient manufacturing processes can mitigate these costs, impacting overall pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom specifications. Buyers should consider whether the tooling costs are amortized over a large production run, which can reduce per-unit costs.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring product reliability, particularly for applications in sensitive industries like automotive and healthcare. Enhanced QC processes can increase costs but also minimize returns and defects.

-

Logistics: Shipping and handling costs depend on the distance, volume, and delivery terms. International buyers must consider freight costs, customs duties, and insurance when calculating total costs.

-

Margin: Suppliers typically include a margin that reflects their operational costs and profit goals. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect PBT GF30 Pricing?

Several factors influence the pricing of PBT GF30, including:

-

Volume/MOQ: Bulk purchases often lead to significant discounts. Suppliers are more inclined to offer competitive pricing to buyers who can commit to larger quantities.

-

Specifications and Customization: Custom formulations or specific grades of PBT GF30 can incur additional costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (such as ISO or RoHS compliance) can command higher prices. Buyers should weigh the cost against the benefits of enhanced performance and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their products due to perceived reliability and support.

-

Incoterms: The agreed Incoterms (International Commercial Terms) can significantly influence total costs. For instance, opting for DDP (Delivered Duty Paid) can shift the responsibility for customs and duties to the supplier, impacting the upfront price.

What Tips Can Help Buyers Negotiate Better Prices for PBT GF30?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can utilize several strategies to enhance their sourcing efforts:

-

Negotiate Wisely: Engaging in open discussions about pricing, volume discounts, and payment terms can yield favorable outcomes. Building long-term relationships with suppliers can also lead to better pricing.

-

Focus on Total Cost of Ownership (TCO): Assessing the TCO rather than just the upfront price can provide a clearer picture of the financial implications. Consider factors like durability, performance, and maintenance costs over the product lifecycle.

-

Understand Pricing Nuances: Currency fluctuations, geopolitical factors, and local market conditions can affect pricing. Staying informed about these elements can aid in making strategic purchasing decisions.

-

Leverage Local Partnerships: Collaborating with local distributors or agents can provide insights into market conditions and may facilitate better pricing due to localized negotiations.

Conclusion

Sourcing PBT GF30 requires a comprehensive understanding of its cost structure and the various factors influencing pricing. By strategically navigating these components and employing effective negotiation tactics, international buyers can optimize their sourcing decisions and achieve favorable outcomes in their procurement processes.

Alternatives Analysis: Comparing pbt gf30 With Other Solutions

Exploring Alternatives to PBT GF30: A Comparative Analysis

In the realm of engineering plastics, PBT GF30 stands out for its mechanical strength and thermal stability. However, businesses often face the challenge of selecting the most suitable material for their specific applications. This section examines PBT GF30 in comparison to two viable alternatives: Polycarbonate (PC) and Nylon 6,6 (PA 66). Each material has unique attributes that cater to different operational needs, making it essential for B2B buyers to understand these differences.

| Comparison Aspect | PBT GF30 | Polycarbonate (PC) | Nylon 6,6 (PA 66) |

|---|---|---|---|

| Performance | High mechanical strength; good thermal stability | Excellent impact resistance; good clarity | High tensile strength; good wear resistance |

| Cost | Moderate (€26–50/kg) | Moderate to high (€20–40/kg) | Moderate (€15–35/kg) |

| Ease of Implementation | Available in sheets and rods; easy to machine | Requires specific tooling; can be more complex to process | Commonly available; relatively easy to mold |

| Maintenance | Low maintenance; durable | Low maintenance; susceptible to scratching | Moderate; may require lubrication for moving parts |

| Best Use Case | Automotive, industrial applications | Electronics, safety glasses, and automotive | Textiles, gears, and automotive applications |

In-Depth Analysis of Alternatives

What are the advantages and disadvantages of Polycarbonate (PC)?

Polycarbonate is known for its exceptional impact resistance and clarity, making it a go-to choice for applications that require transparency, such as safety glasses and automotive lighting. Its ability to withstand high temperatures adds to its appeal. However, PC can be more expensive than PBT GF30 and may require specialized processing techniques. Additionally, it is more prone to scratching, which can affect its long-term appearance and functionality.

Illustrative image related to pbt gf30

How does Nylon 6,6 (PA 66) compare?

Nylon 6,6 is recognized for its high tensile strength and excellent wear resistance, making it suitable for applications like gears and bearings. It performs well in mechanical applications, especially where friction is a concern. However, PA 66 has a higher moisture absorption rate, which can lead to dimensional changes in humid environments. While it is generally easy to mold and process, its lubrication requirements may increase maintenance efforts compared to PBT GF30.

Making the Right Choice for Your Application

When selecting a material, B2B buyers should consider the specific requirements of their applications, including mechanical properties, environmental conditions, and cost constraints. PBT GF30 is ideal for applications that demand high mechanical strength and dimensional stability, particularly in automotive and industrial sectors. In contrast, Polycarbonate is preferred for applications requiring clarity and impact resistance, while Nylon 6,6 excels in wear-intensive environments.

Ultimately, understanding the unique attributes of each material will empower buyers to make informed decisions that align with their operational needs and budget considerations.

Illustrative image related to pbt gf30

Essential Technical Properties and Trade Terminology for pbt gf30

What Are the Key Technical Properties of PBT GF30 and Why Are They Important for B2B Buyers?

PBT GF30, or polybutylene terephthalate reinforced with 30% glass fiber, is a material widely used in various industries due to its exceptional properties. Understanding its technical specifications is crucial for B2B buyers looking to leverage this material in their applications.

What Are the Critical Specifications of PBT GF30?

-

Specific Gravity (1.46 g/cm³)

– This measure indicates the density of PBT GF30. A specific gravity of 1.46 suggests that the material is relatively dense, contributing to its strength and stability. For B2B buyers, understanding specific gravity is essential for calculating material costs and determining shipping logistics. -

Tensile Strength (46 MPa)

– Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before failing. PBT GF30’s tensile strength of 46 MPa makes it ideal for applications requiring robust structural integrity, such as automotive components and industrial machinery. Buyers should consider this property to ensure that the material will meet performance requirements in their applications. -

Flexural Modulus (3400 MPa)

– This property measures the material’s ability to resist deformation under load. A high flexural modulus indicates that PBT GF30 maintains its shape under stress, making it suitable for use in precision components. For B2B buyers, this translates to reduced maintenance costs and improved product longevity. -

Operating Temperature Range (up to 110 °C)

– PBT GF30 can operate continuously at temperatures up to 110 °C, with a peak instantaneous temperature of 200 °C. This thermal stability is vital for applications exposed to heat, such as automotive and electronic components. Buyers must evaluate this specification to ensure the material will perform reliably in their specific environmental conditions. -

Low Water Absorption (0.02% after 24 hours)

– The low water absorption rate indicates that PBT GF30 is resistant to moisture, which is essential for maintaining its mechanical properties over time. This characteristic is particularly important in humid environments or applications where water exposure is a concern. Buyers should factor in water absorption when selecting materials for their products. -

Impact Strength (37 kJ/m²)

– Impact strength measures a material’s ability to resist sudden forces or shocks. With an impact strength of 37 kJ/m², PBT GF30 is well-suited for applications where durability and resilience are critical. B2B buyers need to consider this property to ensure that their products can withstand operational stresses.

What Are Common Trade Terms Related to PBT GF30?

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are sold under another company’s brand. In the context of PBT GF30, OEMs often utilize this material in their products, emphasizing the need for buyers to understand which manufacturers utilize high-quality PBT GF30. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to consider, as it can affect inventory management and production costs. Understanding MOQ helps in negotiating better terms with suppliers. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific quantities of products. For buyers interested in PBT GF30, issuing an RFQ can help compare pricing and terms across multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

– These are a set of predefined international trade terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms is essential for B2B transactions involving PBT GF30, as they dictate shipping responsibilities, risk, and costs. -

Lead Time

– This term refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is vital for B2B buyers to plan their production schedules and manage inventory effectively. -

Certification Standards

– These refer to the regulations and quality benchmarks that PBT GF30 must meet to be deemed suitable for specific applications. Buyers should be aware of relevant certification standards to ensure compliance and quality assurance in their products.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed purchasing decisions regarding PBT GF30, ensuring they select the right materials for their applications.

Navigating Market Dynamics and Sourcing Trends in the pbt gf30 Sector

What Are the Key Market Drivers for PBT GF30?

The global market for PBT GF30 is witnessing robust growth driven by advancements in material science, increasing demand from the automotive and electronics industries, and the rising need for high-performance engineering plastics. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are attracted to PBT GF30 for its exceptional mechanical strength, thermal stability, and resistance to chemical degradation. These properties make it suitable for various applications, including automotive components, industrial machinery, and consumer electronics.

Emerging trends indicate a shift towards more sustainable sourcing practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical production and environmental responsibility. Additionally, the integration of advanced manufacturing technologies such as 3D printing is enhancing the customization and production efficiency of PBT GF30 components. This trend is particularly beneficial for businesses looking to reduce lead times and costs while maintaining high-quality standards.

Illustrative image related to pbt gf30

Furthermore, as industries evolve, the demand for specialized PBT GF30 formulations tailored for specific applications is on the rise. This diversification is crucial for B2B buyers seeking competitive advantages in their respective markets. Keeping an eye on these market dynamics will enable international buyers to make informed sourcing decisions that align with their operational needs and sustainability goals.

How Does Sustainability Impact Sourcing Decisions for PBT GF30?

Sustainability is becoming a pivotal factor in the sourcing strategies of international B2B buyers in the PBT GF30 sector. The environmental impact of plastic production, including energy consumption and greenhouse gas emissions, is under scrutiny. Buyers are increasingly seeking suppliers who utilize sustainable practices, such as using recycled materials or adopting energy-efficient manufacturing processes. This shift is driven by both regulatory pressures and consumer demand for environmentally responsible products.

Ethical sourcing is also gaining prominence, with buyers looking for transparent supply chains that ensure fair labor practices and minimal ecological disruption. Certifications like ISO 14001 for environmental management systems and the use of bio-based materials are becoming essential for companies aiming to enhance their corporate social responsibility (CSR) profiles.

Moreover, the growing trend towards circular economy principles encourages the development of biodegradable or recyclable PBT GF30 variants. This not only mitigates environmental concerns but also opens new market opportunities for innovative products. By aligning sourcing decisions with sustainability objectives, B2B buyers can enhance their brand reputation and meet the evolving expectations of their customers.

What Is the Historical Context of PBT GF30 Development?

The development of PBT GF30 dates back to the late 20th century when the need for high-performance engineering plastics surged across various industries. Initially, PBT was recognized for its excellent thermal and mechanical properties, but the introduction of glass fiber reinforcement (GF30) significantly enhanced its strength and durability. This evolution marked a turning point, making PBT GF30 an attractive option for applications requiring resilience and precision, particularly in automotive and electronics.

Over the years, advancements in polymer technology and manufacturing processes have further improved the performance characteristics of PBT GF30. As industries have evolved, so too have the applications for this material, leading to its integration into a wider range of products. Today, PBT GF30 is not only a staple in traditional sectors but is also paving the way for innovation in emerging technologies, reflecting its adaptability and enduring relevance in the B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of pbt gf30

-

1. How do I choose the right supplier for PBT GF30?

Selecting a reliable supplier for PBT GF30 involves assessing several key factors. Look for suppliers with a proven track record in engineering plastics, particularly those specializing in PBT materials. Evaluate their production capabilities, quality certifications (such as ISO), and adherence to international standards. It’s also beneficial to request samples to assess material quality firsthand. Additionally, consider suppliers that can provide comprehensive technical support and timely delivery, ensuring they can meet your specific project requirements. -

2. What are the typical applications of PBT GF30 in various industries?

PBT GF30 is versatile and widely used across multiple sectors. In the automotive industry, it’s utilized for components requiring high mechanical strength, such as cogs, bearing systems, and wear plates. In electronics, it serves in sensors and connectors due to its excellent electrical insulation properties. Additionally, PBT GF30 finds applications in manufacturing for wear-resistant parts and in healthcare for durable components in medical devices. Understanding these applications can help you identify suitable uses in your projects. -

3. What are the minimum order quantities (MOQs) for PBT GF30?

Minimum order quantities for PBT GF30 can vary significantly depending on the supplier and your specific requirements. Typically, suppliers may set MOQs ranging from 100 kg to several tons. When sourcing internationally, it’s essential to discuss MOQs directly with potential suppliers, as they might offer flexibility based on your needs, especially for first-time orders or sample requests. This negotiation can help you balance cost-effectiveness with your project demands. -

4. How can I ensure the quality of PBT GF30 products?

To ensure the quality of PBT GF30, request detailed product specifications and technical datasheets from suppliers. Inquire about their quality assurance processes, including testing methods and certifications. You can also ask for samples to conduct your own tests on mechanical properties and performance under different conditions. Additionally, consider suppliers that provide third-party inspection services to verify product quality before shipment, especially for international transactions. -

5. What payment terms are typically offered by suppliers of PBT GF30?

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial payments upon order confirmation, and balance payments upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. It’s advisable to negotiate clear payment terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

6. How does international shipping work for PBT GF30 materials?

International shipping for PBT GF30 involves several key steps. First, confirm the shipping methods available, such as air freight or sea freight, considering factors like cost and delivery time. Ensure that your supplier is familiar with export regulations and can provide necessary documentation, including bills of lading and customs declarations. Additionally, factor in customs duties and taxes that may apply upon importation into your country, as these can affect overall costs and delivery timelines. -

7. What customization options are available for PBT GF30 products?

Many suppliers offer customization options for PBT GF30, such as varying dimensions, colors, and formulations to meet specific performance criteria. If your project has unique requirements, discuss these with potential suppliers to explore available options. Customization may also include the addition of specific additives for enhanced properties like UV resistance or improved thermal stability. Collaborating closely with the supplier during the design phase can lead to better-tailored solutions. -

8. What are the advantages of using PBT GF30 over other materials?

PBT GF30 offers several advantages compared to other engineering plastics. Its fiberglass reinforcement enhances mechanical strength and rigidity, making it ideal for demanding applications. It exhibits excellent dimensional stability across a wide temperature range, which is crucial for precision components. Additionally, PBT GF30 has low water absorption and good chemical resistance, ensuring durability in various environments. These properties make it a preferred choice in industries requiring reliability and performance.

Top 7 Pbt Gf30 Manufacturers & Suppliers List

1. PBT – Electronic Throttle Control Cover

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: PBT-GF30 Electronic Throttle Control Cover, Mass Air Flow Sensor, Nitrogen Oxide Sensor Unit, 20 Pin Connector, various automotive parts including sensors for brands like Cummins, Opel, Renault, BMW, Mercedes-Benz, Audi, and Volvo. Prices range from $6.50 to $300.00 with options for new, open box, and pre-owned items. Delivery options vary by location.

2. AMP – PBT-GF30 Part

Domain: questcomp.com

Registered: 2003 (22 years)

Introduction: Part Number: PBT-GF30

Manufacturer: AMP

Availability: 73 parts available

Shipping Dates: September 25th – September 29th

Minimum Order Quantity: 20

Price: $4.0000 each for 20+ units, $3.7000 each for 64+ units

Export Restrictions: Cannot be shipped outside of the US; may not be available for export.

Tariff Fee: Subject to tariff fee due to international trade regulations.

Environmental Compliance:…

3. Reddit – PBT-GF30 Plastic Casing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: PBT-GF30 is a type of plastic used in the casing of a battery management system, specifically polybutylene terephthalate that is 30% glass filled. It is not related to the function of the electronics inside the unit.

4. Facet – Automotive Sensor 3319 21C

Domain: e90post.com

Registered: 2005 (20 years)

Introduction: PBT-GF30 is a fiberglass-reinforced plastic material used for housing automotive parts. The part number associated with the sensor is “3319 21C”. The sensor was made in Italy, and the user replaced it with a Facet brand sensor, which may be the OEM.

5. Rantle – PBT GF30 Sensor

Domain: rantle.com

Registered: 2005 (20 years)

Introduction: PBT GF30 Sensor is a polybutylene terephthalate (PBT) sensor reinforced with 30% glass fiber (gf30). Key features include superior temperature resistance, long lifespan, and measurement accuracy. Common applications span across various industries such as automotive (tyre pressure monitoring, airbag deployment), electronics (position sensors, temperature sensors), healthcare (patient monitoring sys…

6. Ensinger – TECADUR PBT GF30 Natural

Domain: specialchem.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “TECADUR PBT GF30 Natural”, “Supplier”: “Ensinger”, “Description”: “Polybutylene terephthalate (PBT) grade filled with 30% glass fiber.”, “Benefits”: [“High dimensional stability”, “Very high strength”, “Good chemical resistance”, “Very high stiffness”, “Weldable”, “Easily foldable”, “High rigidity”, “High mechanical strength”, “High creep strength”], “Limitations”: [“Does not wit…

7. Aikolon – PBT GF30 Polybutylene Terephthalate

Domain: aikolon.fi

Registered: 1998 (27 years)

Introduction: This company, Aikolon – PBT GF30 Polybutylene Terephthalate, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pbt gf30

In navigating the competitive landscape of engineering plastics, PBT GF30 stands out due to its exceptional mechanical strength, dimensional stability, and versatility across industries. This material is particularly suited for applications in the automotive, electronics, and healthcare sectors, where reliability and precision are paramount. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the unique properties of PBT GF30 can significantly enhance product performance and operational efficiency.

Strategic sourcing of PBT GF30 not only ensures access to high-quality materials but also fosters long-term partnerships with suppliers who can provide ongoing support and innovation. As market demands evolve, leveraging the benefits of PBT GF30 will position businesses to remain agile and competitive.

Illustrative image related to pbt gf30

Looking ahead, it is crucial for buyers to engage with suppliers who understand their specific needs and can offer tailored solutions. By investing in PBT GF30, businesses can enhance their product offerings and drive sustainable growth. Take the next step in your sourcing strategy today, and explore the possibilities that PBT GF30 can unlock for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.