Parts Of A Lockset: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for parts of a lockset

In the complex landscape of global commerce, sourcing high-quality parts of a lockset poses a significant challenge for international B2B buyers. With the increasing demand for security solutions across various sectors, understanding the intricate components that make up locksets—such as cylinders, deadbolts, and strike plates—becomes crucial. This guide serves as a comprehensive resource, delving into the diverse types of lockset components, their applications in different industries, and the critical aspects of supplier vetting.

By equipping buyers with knowledge about the latest trends in door hardware, pricing structures, and quality standards, this guide empowers decision-makers from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany. In an era where security is paramount, having the right information can streamline procurement processes and ensure that investments meet specific operational needs.

As you navigate this guide, you’ll gain insights that not only enhance your understanding of lockset parts but also facilitate informed purchasing decisions that align with your business objectives. Whether you’re seeking to upgrade existing systems or explore innovative security solutions, this resource will be invaluable in optimizing your sourcing strategy.

Understanding parts of a lockset Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deadbolt | Offers superior security with a robust locking mechanism. | Commercial buildings, residential doors | Pros: High security; Cons: Requires key for operation. |

| Cylindrical Lockset | Commonly used in residential and light commercial settings. | Offices, apartments | Pros: Easy to install; Cons: Less secure than deadbolts. |

| Smart Lock | Features electronic access and remote management capabilities. | Hotels, high-security facilities | Pros: Convenience and monitoring; Cons: Battery dependency. |

| Mortise Lockset | Integrated into the door for a sleek appearance and durability. | High-end residential, commercial doors | Pros: Stronger security; Cons: More complex installation. |

| Keypad Lock | Allows entry via a numerical code instead of a physical key. | Schools, gyms, office buildings | Pros: No key required; Cons: Code can be forgotten or shared. |

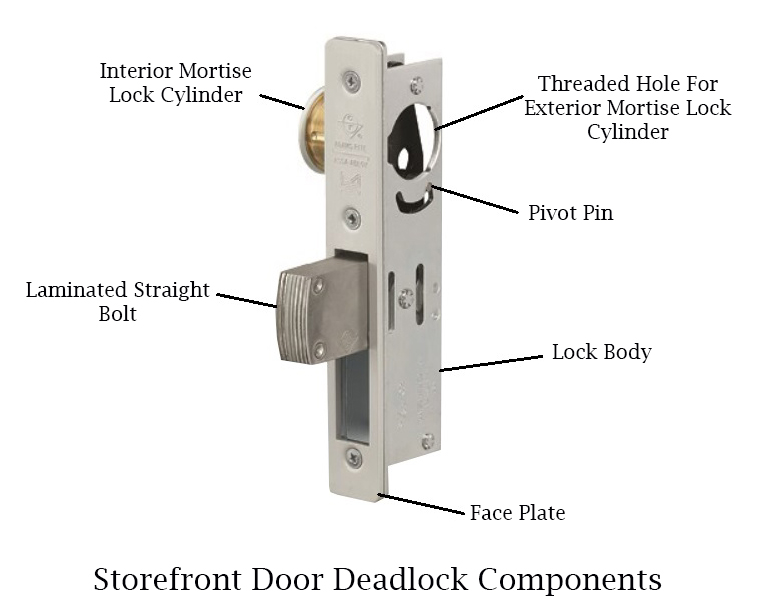

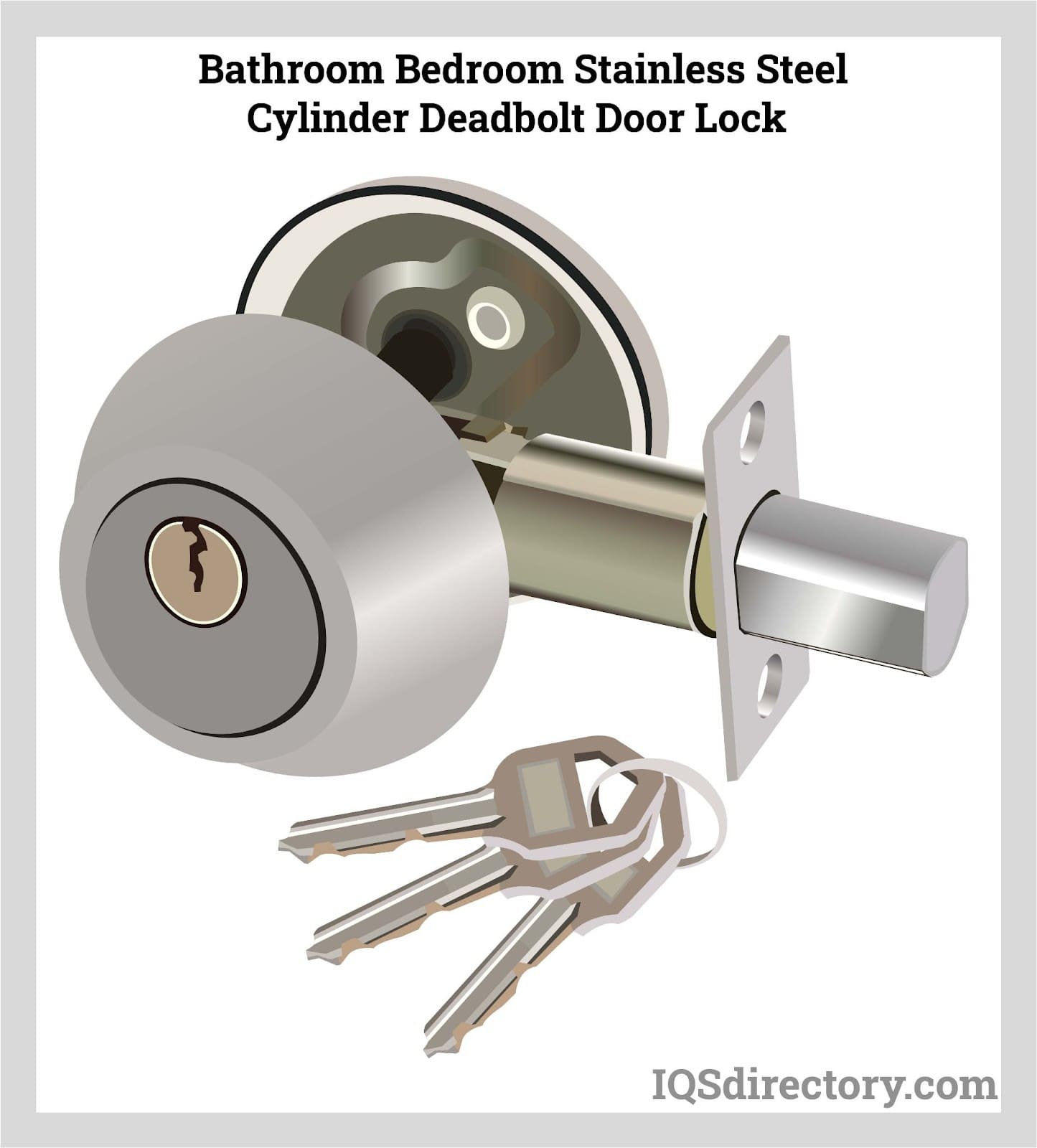

What Are the Key Characteristics of Deadbolts and Their B2B Suitability?

Deadbolts are recognized for their robust construction, providing an exceptional level of security for various door types. Typically used in both commercial buildings and residential properties, they are particularly effective in high-risk areas. B2B buyers should consider the installation requirements and whether their doors can accommodate the deadbolt’s design. While deadbolts enhance security, they require a key for access, which may not be ideal for all applications.

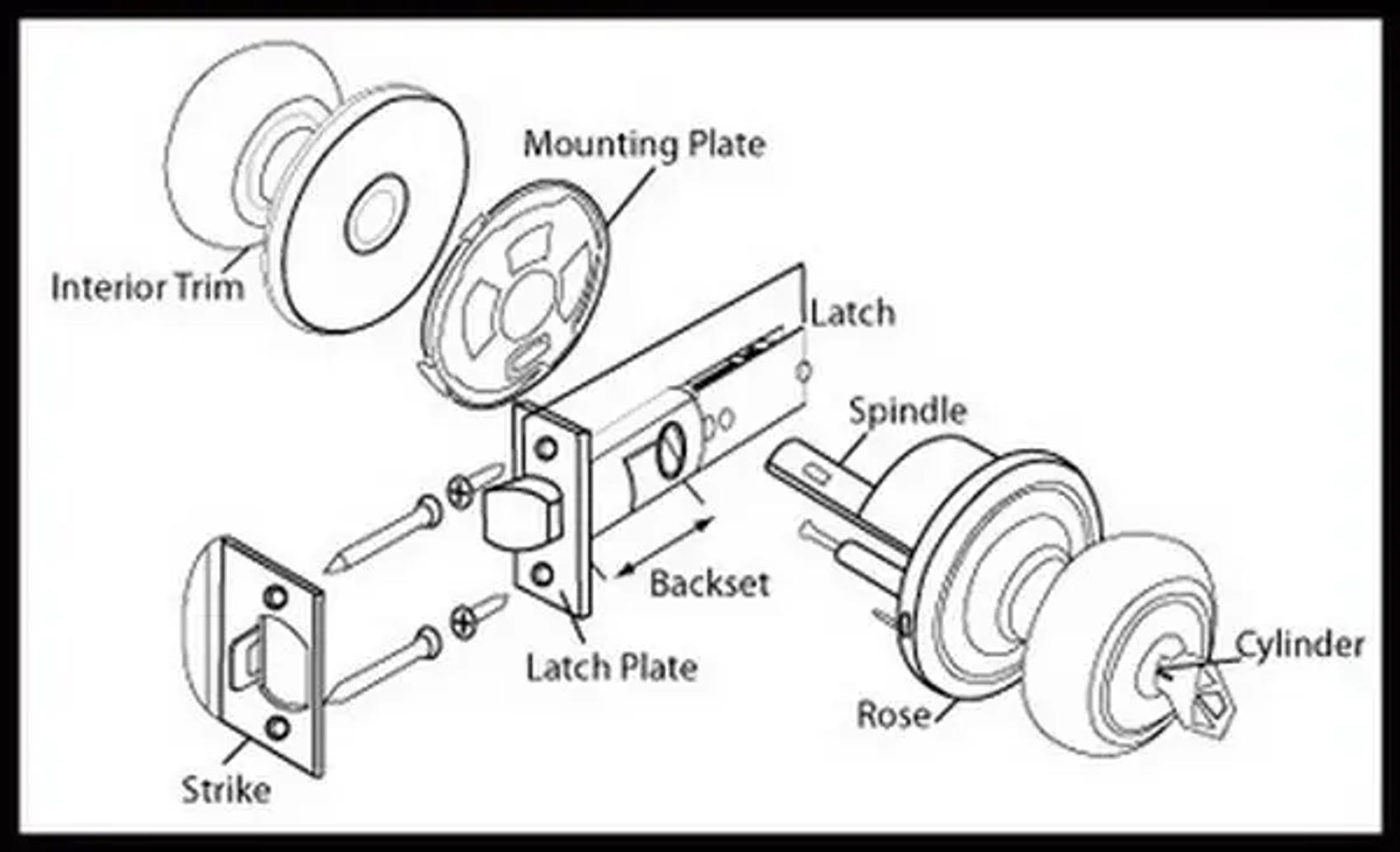

Illustrative image related to parts of a lockset

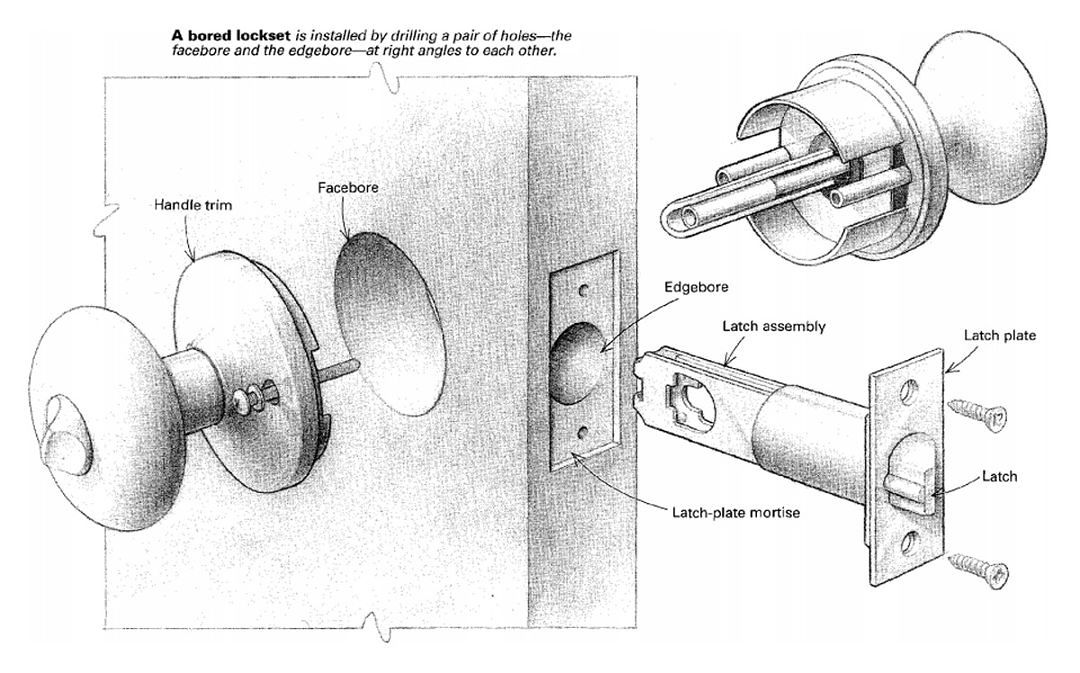

Why Choose Cylindrical Locksets for Your Business Needs?

Cylindrical locksets are among the most widely used locking mechanisms, favored for their straightforward design and ease of installation. They are suitable for offices and apartments, making them an excellent choice for property management companies. However, while they offer a reasonable level of security, they are generally less secure than deadbolts. Buyers should assess the security needs of their environment before opting for this type of lock.

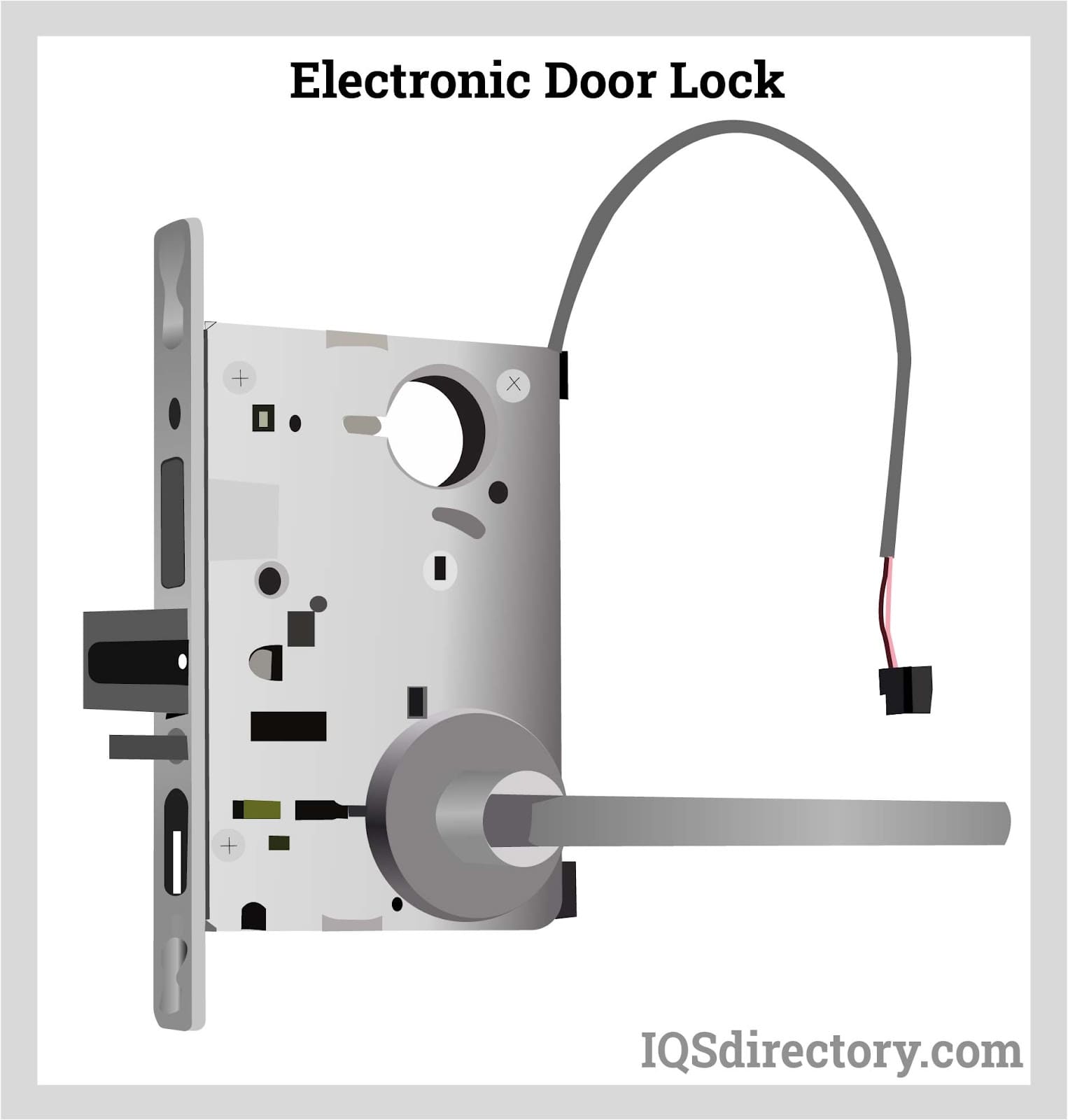

How Do Smart Locks Enhance Security and Convenience?

Smart locks represent the forefront of locking technology, integrating electronic access with features like remote management and monitoring. These locks are particularly advantageous for hotels and high-security facilities, where tracking access is crucial. However, they do rely on battery power, which can be a concern in areas with frequent power outages. B2B buyers should evaluate the technological infrastructure of their premises to ensure compatibility with smart locks.

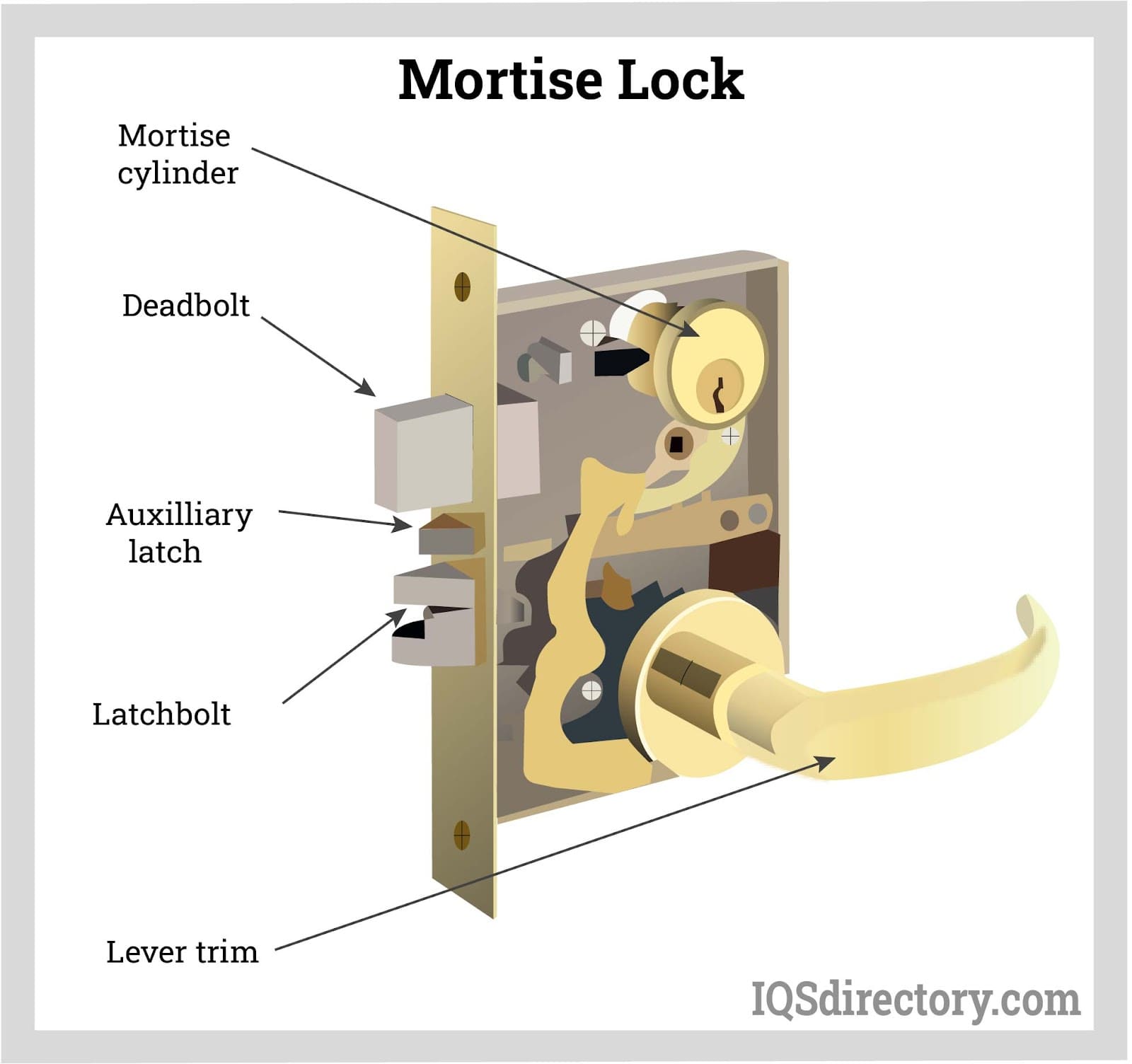

What Makes Mortise Locksets a Preferred Choice in Commercial Settings?

Mortise locksets are designed to fit into a pocket cut into the edge of the door, providing a secure and aesthetically pleasing option. They are commonly used in high-end residential properties and commercial buildings, where durability and security are paramount. While the installation process can be more complex compared to other locks, the enhanced security features make them a worthwhile investment for businesses looking to protect their assets.

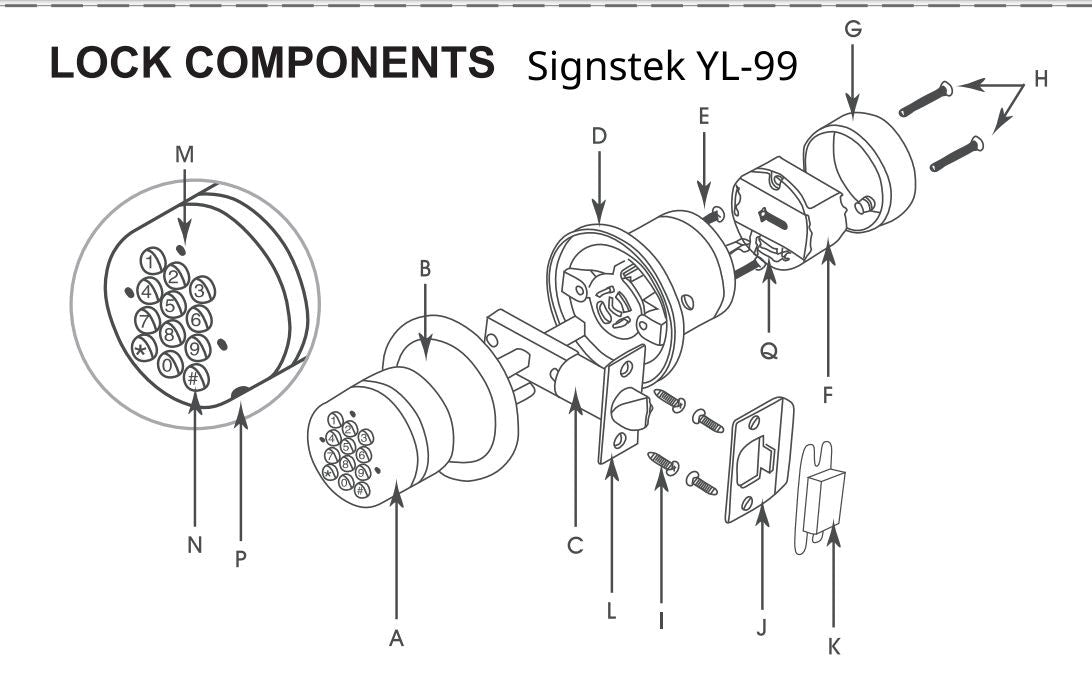

What Are the Advantages and Disadvantages of Keypad Locks?

Keypad locks offer a modern solution by allowing access through a numerical code, eliminating the need for physical keys. They are ideal for environments such as schools and gyms, where multiple users require entry. However, the potential for users to forget the code or share it can compromise security. B2B buyers should consider the user base and frequency of access when deciding if a keypad lock is the right choice for their facility.

Key Industrial Applications of parts of a lockset

| Industry/Sector | Specific Application of parts of a lockset | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel room locks and access control systems | Enhances guest security, reduces unauthorized access, and ensures compliance with safety regulations. | Consider durability, ease of installation, and compatibility with existing systems. |

| Healthcare | Patient room locks and secure medication cabinets | Protects sensitive patient information and medications, ensuring safety and compliance with health regulations. | Look for high-security features, ease of use, and maintenance requirements. |

| Retail | Storefront locks and inventory security systems | Deters theft, protects merchandise, and enhances customer trust through visible security measures. | Assess the lock’s durability, weather resistance, and compatibility with existing storefront designs. |

| Education | Classroom and administrative office locks | Provides security for students and staff, while allowing controlled access to sensitive areas. | Evaluate ease of use, durability, and compliance with safety codes. |

| Industrial Facilities | Warehouse and equipment locks | Protects valuable assets and ensures that only authorized personnel have access to sensitive areas. | Focus on heavy-duty materials, resistance to tampering, and scalability for various applications. |

How are parts of a lockset utilized in the hospitality industry?

In the hospitality sector, parts of a lockset are crucial for hotel room locks and access control systems. These components, such as deadbolts, latch assemblies, and electronic access systems, enhance guest security by preventing unauthorized access. Hotels require high durability and ease of use, particularly for electronic systems that may need integration with existing property management systems. Buyers from regions like Africa and South America should prioritize locks that comply with local safety regulations and offer features like remote access and monitoring for efficient management.

What is the role of locksets in healthcare applications?

In healthcare facilities, locksets are essential for securing patient rooms and medication cabinets. Components like high-security cylinders and deadbolts protect sensitive information and medications, ensuring compliance with regulations such as HIPAA. Buyers in this sector must consider the ease of operation for staff, the durability of components against frequent use, and any necessary certifications for healthcare environments. International buyers should also evaluate the availability of local support and maintenance services to minimize downtime.

How do locksets enhance security in the retail sector?

For retail businesses, parts of a lockset, including storefront locks and security systems, play a vital role in protecting merchandise and deterring theft. The combination of latch bolts and strike plates provides a robust barrier against unauthorized access. Retailers must consider the aesthetic appeal of locks alongside their security features to maintain a welcoming environment. Buyers should also evaluate the weather resistance of outdoor locks, especially in regions with varying climates, ensuring long-term functionality and minimal maintenance.

Why are locksets critical in educational institutions?

In educational settings, locksets are used in classrooms and administrative offices to ensure the safety of students and staff. Components like electronic locks and traditional deadbolts facilitate controlled access while enhancing security. Buyers in the education sector should prioritize ease of use, as well as compliance with safety codes and regulations. For international buyers, understanding local security requirements and the potential need for multilingual support in lock systems can be critical for successful implementation.

What benefits do industrial facilities gain from using locksets?

Industrial facilities rely on parts of a lockset, such as heavy-duty locks and padlocks, to secure warehouses and equipment. These components protect valuable assets and ensure that only authorized personnel can access sensitive areas. Buyers in this sector should focus on selecting locks made from durable materials that resist tampering and weather conditions. Additionally, scalability is important, as industrial operations may require different types of locks for various applications, necessitating a comprehensive sourcing strategy.

3 Common User Pain Points for ‘parts of a lockset’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Lockset Components for Specific Applications

The Problem: B2B buyers often struggle with choosing the correct parts of a lockset for their unique applications, whether for commercial buildings, residential complexes, or security-sensitive environments. Misunderstanding the specifications can lead to purchasing components that are incompatible with existing doors, resulting in wasted resources and delays. For example, a buyer might select a standard latch but realize it cannot support the weight of a heavy-duty door, compromising security and functionality.

The Solution: To address this challenge, buyers should conduct thorough assessments of their locking needs based on the specific door types and their operational requirements. They should familiarize themselves with key specifications, such as backset measurements, bore hole sizes, and the appropriate grade of lock for their application. Partnering with suppliers who offer detailed technical support can be invaluable. Additionally, utilizing standardized lock specifications and consulting installation guides can ensure that the selected parts will function correctly and securely. A proactive approach involves drafting a comprehensive lockset specification sheet that outlines all required dimensions and performance ratings before placing an order.

Scenario 2: Ensuring Consistent Security Across Multiple Locations

The Problem: Companies managing multiple facilities face the challenge of maintaining consistent security standards across various locations. This often leads to discrepancies in the types of locksets used, which can create vulnerabilities. For instance, a corporation might find that some branches use outdated lock technologies while others have upgraded to smart locks, complicating the security management landscape and increasing the risk of unauthorized access.

The Solution: To achieve uniform security measures, organizations should establish a centralized procurement policy that specifies the types of locksets to be used across all facilities. This policy should include criteria for selecting locksets, such as durability ratings, compatibility with smart technologies, and ease of maintenance. Engaging with a trusted supplier who can provide a range of lockset solutions tailored to the company’s needs will help ensure that all locations are equipped with the same level of security. Additionally, conducting regular audits and updates of lock technologies will ensure that all facilities remain secure and compliant with industry standards.

Scenario 3: Managing Maintenance and Repair of Lockset Parts

The Problem: Over time, wear and tear can cause significant issues with locksets, such as jamming or key misalignment. B2B buyers often overlook the importance of regular maintenance, which can lead to increased downtime and repair costs. For example, a hotel chain may experience guest dissatisfaction due to malfunctioning locks, adversely impacting their reputation and revenue.

The Solution: Implementing a proactive maintenance plan is essential for prolonging the lifespan of lockset components. Buyers should establish a routine inspection schedule that includes checking for signs of wear on parts such as latches, cylinders, and strike plates. Training staff on basic maintenance practices, such as lubricating locks and tightening loose screws, can significantly reduce the likelihood of malfunction. Additionally, maintaining a stock of commonly needed replacement parts can expedite repairs and minimize disruptions. Suppliers that offer comprehensive maintenance kits or replacement part bundles can also aid in effectively managing lockset upkeep, ensuring that facilities remain secure and operational.

Strategic Material Selection Guide for parts of a lockset

When selecting materials for parts of a lockset, it is essential to consider various factors that affect performance, durability, and cost. Here, we analyze four common materials used in lockset components: brass, stainless steel, zinc alloy, and plastic. Each material has unique properties and implications for B2B buyers, especially those operating in diverse international markets.

What Are the Key Properties of Brass for Locksets?

Brass is a traditional choice for lockset components, particularly for cylinders and knobs. It boasts excellent corrosion resistance, especially in humid environments, making it suitable for various climates. Brass can withstand moderate temperatures and pressures, ensuring reliable performance in typical door applications.

Pros and Cons:

Brass is highly durable and has a pleasing aesthetic appeal, making it popular for decorative applications. However, it can be more expensive than alternative materials and may require more complex manufacturing processes due to its malleability. Additionally, brass can tarnish over time, necessitating regular maintenance.

Impact on Application:

Brass’s compatibility with various locking mechanisms makes it a versatile choice. However, buyers must consider its susceptibility to wear in high-traffic areas.

How Does Stainless Steel Perform in Lockset Applications?

Stainless steel is renowned for its strength and resistance to corrosion, making it ideal for exterior applications or areas exposed to harsh weather. It can endure high temperatures and is less prone to rust compared to other metals.

Pros and Cons:

The durability and low maintenance requirements of stainless steel make it a preferred choice for commercial applications. However, it can be more costly than brass and may not offer the same aesthetic appeal for residential applications. The manufacturing process can also be complex, requiring specialized equipment.

Impact on Application:

Stainless steel’s robust nature is particularly beneficial in high-security environments. International buyers should ensure compliance with standards like ASTM for quality assurance.

What Are the Benefits of Using Zinc Alloy in Locksets?

Zinc alloy is often used in the production of lockset components due to its cost-effectiveness and lightweight properties. It is commonly found in lower-end locksets and decorative trims.

Pros and Cons:

Zinc alloy is relatively inexpensive and easy to mold, allowing for intricate designs. However, it has lower corrosion resistance compared to brass and stainless steel, which can limit its lifespan in outdoor applications. Its strength is also less than that of brass or stainless steel.

Impact on Application:

Zinc alloy is suitable for applications where cost is a primary concern. Buyers from regions with high humidity or salt exposure should carefully evaluate its suitability.

Illustrative image related to parts of a lockset

Why Consider Plastic for Certain Lockset Parts?

Plastic is increasingly used in lockset components, particularly for internal mechanisms and housing. It is lightweight, resistant to corrosion, and can be manufactured in various colors.

Pros and Cons:

The primary advantage of plastic is its low cost and ease of production. However, it may not provide the same level of security and durability as metal options, making it less suitable for high-security applications. Additionally, plastic can degrade under extreme temperatures or UV exposure.

Impact on Application:

Plastic components are often used in residential settings or where aesthetics are less critical. International buyers should be cautious of material quality and compliance with local standards.

Summary Table of Material Selection for Locksets

| Material | Typical Use Case for parts of a lockset | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Cylinders, knobs, decorative trims | Excellent corrosion resistance | Higher cost, requires maintenance | High |

| Stainless Steel | High-security locks, exterior applications | Strong and durable, low maintenance | Higher cost, less aesthetic appeal | High |

| Zinc Alloy | Budget locksets, decorative trims | Cost-effective, easy to mold | Lower corrosion resistance | Low |

| Plastic | Internal mechanisms, housing | Lightweight, resistant to corrosion | Less durable, potential UV degradation | Low |

In conclusion, understanding the properties, advantages, and limitations of different materials is crucial for B2B buyers in making informed decisions about lockset components. By considering regional standards and application-specific requirements, buyers can select materials that align with their operational needs and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a lockset

What Are the Main Stages of the Manufacturing Process for Lockset Parts?

The manufacturing of lockset parts is a detailed process that involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets quality and security standards.

Illustrative image related to parts of a lockset

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing lockset parts is the selection and preparation of raw materials. Common materials include brass, stainless steel, and zinc alloys, each chosen for their durability and corrosion resistance. The materials undergo rigorous testing for strength and quality before being processed.

Once selected, the materials are cut into specific dimensions using techniques such as laser cutting or water jet cutting. This ensures precision in the final components. Quality checks are conducted at this stage to ensure that the materials meet the required specifications, which is crucial for the integrity of the lockset.

How Are Lockset Parts Formed During Manufacturing?

Following material preparation, the forming stage involves shaping the components through various techniques. Common methods include die casting, forging, and machining.

-

Die Casting: This method is used for creating complex shapes and is ideal for producing parts like the chassis and knobs. It involves injecting molten metal into a mold, which is then cooled and solidified.

-

Forging: This technique is often used for creating the latch and bolt components. It involves shaping the metal using compressive forces, which enhances the material’s strength.

-

Machining: Precision machining is employed for components that require tight tolerances, such as the cylinder and spindle. This process removes material from a solid block to achieve the desired shape and dimensions.

Each forming method comes with its own set of quality control measures to ensure that the parts meet stringent specifications.

What Is Involved in the Assembly Process of Lockset Parts?

The assembly stage is where individual components come together to form a complete lockset. This stage requires precision to ensure that all parts fit and function correctly.

During assembly, components such as the cylinder, latch, and strike plate are combined. Automated assembly lines are often utilized to increase efficiency and reduce human error. Quality control checkpoints are established to inspect the assembly process, ensuring that components are correctly aligned and secured.

What Finishing Techniques Are Commonly Used for Lockset Parts?

Finishing is the final stage in the manufacturing process and involves applying protective coatings and aesthetic finishes. Common techniques include electroplating, powder coating, and polishing.

-

Electroplating: This process applies a thin layer of metal to enhance corrosion resistance and improve appearance. It is often used for decorative trim and knobs.

-

Powder Coating: This method provides a durable finish that is resistant to chipping and fading. It is commonly used for locksets that will be exposed to harsh environments.

-

Polishing: For parts that require a high shine, polishing techniques are employed to achieve a smooth surface finish.

Quality checks at this stage ensure that the finish meets both aesthetic and functional requirements.

How Is Quality Assurance Implemented in Lockset Manufacturing?

Quality assurance is a critical component of lockset manufacturing, ensuring that every product meets international standards and customer expectations. Manufacturers typically adhere to various standards, including ISO 9001, which outlines requirements for a quality management system.

Illustrative image related to parts of a lockset

What International Standards Are Relevant to Lockset Manufacturing?

ISO 9001 is a widely recognized standard for quality management systems that helps organizations ensure consistent quality in their products and services. Compliance with this standard involves regular audits, documentation of processes, and continuous improvement efforts.

In addition to ISO standards, industry-specific certifications such as CE marking in Europe and API standards for certain industrial applications may also apply. These certifications indicate that products meet specific safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Lockset Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, random inspections are performed to monitor processes and identify any deviations from quality standards.

-

Final Quality Control (FQC): After assembly and finishing, the final product undergoes thorough testing, including functional tests, durability assessments, and visual inspections.

Each of these checkpoints is essential for maintaining high-quality standards and ensuring that products are reliable and secure.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in international markets, verifying a supplier’s quality control processes is crucial. Here are effective methods to ensure quality assurance:

Illustrative image related to parts of a lockset

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes, quality control measures, and adherence to industry standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the testing and inspection processes used by the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices and product quality.

-

Certification Verification: Buyers should verify the authenticity of any certifications claimed by the supplier, ensuring they meet the necessary industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various challenges when assessing quality control practices. Different regions may have varying standards and regulations that can affect product quality. For instance:

-

Regional Standards: Buyers from Europe may prioritize CE marking, while those in the Middle East may focus on local compliance standards.

-

Cultural Differences: Understanding cultural approaches to quality and manufacturing can help buyers better navigate supplier relationships and expectations.

-

Logistics and Supply Chain Considerations: The complexity of international logistics can impact the quality of products received. Buyers should consider the entire supply chain when evaluating quality.

By understanding these nuances, international B2B buyers can make informed decisions when selecting suppliers for lockset parts.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a lockset’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring parts of a lockset efficiently and effectively. Understanding the various components involved, as well as the necessary steps to evaluate suppliers and products, is critical to ensuring quality, security, and compliance with international standards.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications for the lockset parts you need. This includes dimensions, materials, and security features.

– Key Considerations: Identify the type of lock (e.g., deadbolt, cylindrical) and any specific security requirements, such as anti-pick or anti-drill features.

– Documentation: Prepare a detailed list or blueprint that specifies your needs, which will facilitate clearer communication with potential suppliers.

Step 2: Research Market Trends and Standards

Understanding current market trends and industry standards is crucial for making informed purchasing decisions.

– Regulatory Compliance: Research relevant regulations such as the Builders Hardware Manufacturers Association (BHMA) standards to ensure that your products meet safety and performance requirements.

– Market Insights: Keep an eye on innovations, such as smart lock technology, which may enhance security and operational efficiency.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers specializing in lockset parts.

– Supplier Network: Leverage online directories, industry trade shows, and recommendations from industry peers to find reputable suppliers.

– Geographical Considerations: Consider the location of suppliers for shipping logistics, especially if sourcing from regions like Europe or South America.

Step 4: Evaluate Supplier Certifications

Ensure that the suppliers you consider have the necessary certifications and quality assurances.

– Quality Standards: Look for certifications such as ISO 9001 or BHMA grading that validate the supplier’s commitment to quality and durability.

– Supplier Verification: Request documentation of certifications and assess their relevance to your specific requirements.

Step 5: Request Samples and Prototypes

Before making a bulk purchase, request samples or prototypes of the lockset parts.

– Testing for Quality: This allows you to evaluate the quality, functionality, and compatibility of the components with your existing systems.

– Feedback Loop: Use the samples to gather feedback from your team or end users to ensure the product meets their needs.

Step 6: Negotiate Terms and Conditions

Engage in discussions with potential suppliers to negotiate pricing, delivery timelines, and payment terms.

– Cost Analysis: Analyze the pricing structure to ensure it aligns with your budget and compare it against quality and service levels.

– Contract Clarity: Ensure all terms are clearly documented to avoid misunderstandings regarding delivery schedules and warranties.

Step 7: Plan for Long-Term Relationships

Consider establishing long-term relationships with reliable suppliers for consistent quality and support.

– Partnership Benefits: A strong supplier relationship can lead to better pricing, priority service, and access to new product innovations.

– Regular Reviews: Schedule periodic reviews to assess performance and explore opportunities for collaboration on future projects.

By following these steps, B2B buyers can navigate the complexities of sourcing lockset parts, ensuring they acquire high-quality components that meet their operational and security needs.

Comprehensive Cost and Pricing Analysis for parts of a lockset Sourcing

What Are the Key Cost Components in Lockset Parts Sourcing?

When sourcing parts of a lockset, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to parts of a lockset

-

Materials: The choice of materials significantly influences the cost. For example, high-security components like hardened steel or brass tend to be more expensive than standard materials. Buyers should evaluate the durability and security features offered by different materials, as they impact long-term performance.

-

Labor: Labor costs vary depending on the location of manufacturing. Countries with lower labor costs may offer cheaper products, but this can sometimes compromise quality. Buyers should consider the balance between cost and quality, ensuring that labor practices meet ethical standards.

-

Manufacturing Overhead: This includes expenses related to facility operation, utilities, and administrative costs. Efficient manufacturing processes can lower these costs, making it essential to assess the supplier’s operational efficiency.

-

Tooling: Initial tooling costs for custom parts can be significant. However, these costs can be amortized over larger production runs, making it essential to discuss minimum order quantities (MOQs) with suppliers.

-

Quality Control: Investing in robust QC processes can prevent costly defects and returns. Suppliers with established QC protocols may charge higher prices but can save buyers money in the long run by reducing failure rates.

-

Logistics: Transportation and shipping costs can vary widely based on the supplier’s location and the delivery terms. Buyers should consider Incoterms that specify who bears the costs and risks associated with shipping.

-

Margin: Understanding a supplier’s margin can provide insight into their pricing strategy. A higher margin may indicate premium quality or service levels, while a lower margin might suggest cost-cutting that could affect product quality.

How Do Price Influencers Affect Lockset Parts?

Several factors can influence the pricing of lockset parts. These include volume or minimum order quantities (MOQs), specifications and customization, material quality and certifications, supplier reputation, and Incoterms.

-

Volume/MOQ: Ordering larger quantities often results in lower per-unit costs. B2B buyers should negotiate MOQs that align with their inventory needs while securing favorable pricing.

-

Specifications/Customization: Custom parts tailored to specific requirements typically incur higher costs due to additional engineering and tooling efforts. Buyers should weigh the necessity of customization against potential cost increases.

-

Materials and Quality: The choice of materials not only impacts the cost but also the quality certifications that might be required. High-quality certifications can add to the price but may be necessary for specific markets, especially in Europe.

-

Supplier Factors: Supplier reliability, reputation, and production capabilities can significantly affect pricing. Buyers are encouraged to conduct thorough due diligence on potential suppliers to ensure they meet both cost and quality expectations.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can influence the total landed cost of the products.

What Buyer Tips Can Enhance Cost-Efficiency in Lockset Parts Sourcing?

B2B buyers can adopt several strategies to enhance cost-efficiency in their sourcing efforts.

-

Negotiation: Engaging in transparent negotiations with suppliers can lead to better pricing. Buyers should be prepared to discuss their needs clearly and leverage their purchasing power, especially for bulk orders.

-

Total Cost of Ownership (TCO): Buyers should consider TCO beyond the initial purchase price. This includes maintenance, potential failures, and replacement costs over the product’s lifespan. A higher upfront cost may be justified if the product offers longer-term savings.

-

Pricing Nuances for International Buyers: Different regions may have unique pricing structures due to local market conditions, tariffs, and economic factors. Buyers from Africa, South America, the Middle East, and Europe should be aware of these nuances and factor them into their purchasing decisions.

Disclaimer on Indicative Prices

Prices for lockset parts can vary widely based on numerous factors, including market conditions, supplier pricing strategies, and specific buyer requirements. Therefore, it is advisable for buyers to obtain current quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing parts of a lockset With Other Solutions

Understanding Alternatives to Parts of a Lockset

In the realm of security solutions, the parts of a lockset represent a traditional approach to safeguarding doors and entries. However, with advancements in technology and changing security needs, alternative solutions have emerged. This analysis compares the components of a lockset with two viable alternatives: smart locks and access control systems. Each solution offers unique features and benefits that can cater to different business requirements, especially for international B2B buyers.

Comparison Table

| Comparison Aspect | Parts Of A Lockset | Smart Locks | Access Control Systems |

|---|---|---|---|

| Performance | Reliable for standard security | Enhanced security with features like remote access | High-level security with monitoring and control |

| Cost | Generally low to moderate | Moderate to high, depending on features | High initial investment, but scalable over time |

| Ease of Implementation | Simple installation process | Requires Wi-Fi or Bluetooth setup | Complex installation needing professional help |

| Maintenance | Low maintenance required | Requires battery changes and updates | Regular software updates and maintenance needed |

| Best Use Case | Residential and small businesses | Modern residences, hotels, and offices | Large enterprises needing controlled access |

What Are the Pros and Cons of Smart Locks?

Smart locks utilize technology to offer enhanced security features such as remote access, keyless entry, and activity logs. One of the main advantages is convenience; users can unlock doors via smartphones, reducing the need for physical keys. Additionally, smart locks often integrate with other smart home devices, creating a cohesive security system. However, they come with a higher cost compared to traditional locksets and can be vulnerable to hacking if not properly secured. They also require a stable internet connection and regular maintenance, such as battery replacements.

How Do Access Control Systems Work?

Access control systems represent a sophisticated security solution that allows businesses to manage who can enter specific areas. These systems can include card readers, biometric scanners, and keypads, providing a high level of security and flexibility. The primary advantage is that they allow for detailed tracking and control of access, which is invaluable for larger organizations. However, the complexity and cost of installation can be significant, often requiring specialized personnel. Regular maintenance and updates are also necessary to ensure optimal performance.

How Should B2B Buyers Choose the Right Solution?

When selecting a security solution, B2B buyers must assess their specific needs, budget, and operational context. For businesses with standard security needs, traditional locksets may suffice. However, those seeking advanced features and remote access capabilities might find smart locks to be more suitable. Conversely, large enterprises that require strict access control and monitoring should consider investing in access control systems. Ultimately, understanding the unique benefits and limitations of each option will enable buyers to make informed decisions that align with their security requirements and operational workflows.

Essential Technical Properties and Trade Terminology for parts of a lockset

What Are the Key Technical Properties to Consider for Lockset Parts?

When sourcing locksets, understanding the technical properties of their components is crucial for ensuring quality, security, and durability. Here are some essential specifications to consider:

-

Material Grade

The material grade determines the strength and longevity of lockset components. Common materials include brass, stainless steel, and zinc alloys. Brass offers corrosion resistance and aesthetic appeal, while stainless steel is favored for its strength and durability. For B2B buyers, selecting high-grade materials is vital as it impacts the lock’s lifespan and reliability, directly influencing customer satisfaction and repeat business. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during manufacturing. Precise tolerances ensure that parts fit together seamlessly, preventing operational issues such as jamming or improper locking. In high-security applications, tighter tolerances are critical. Understanding tolerance requirements helps buyers avoid costly returns and ensure compatibility with existing door hardware. -

Finish Quality

The finish of lockset components not only affects aesthetics but also plays a significant role in corrosion resistance and wear. Finishes like chrome, satin nickel, or powder coating can enhance durability. For international buyers, being aware of finish standards is essential, as environmental factors can vary significantly across regions, affecting product performance. -

Security Rating

Many locksets are graded according to security standards set by organizations like the Builders Hardware Manufacturers Association (BHMA). Ratings range from A to AAA, with AAA indicating the highest level of security. This is critical for B2B buyers in sectors such as commercial real estate and government contracts, where security is paramount. Knowing the security rating helps in making informed purchasing decisions. -

Operational Life Cycle

This specification indicates the number of cycles (lock/unlock actions) a lockset can withstand before failure. A high operational life cycle is essential for high-traffic environments such as schools and offices. Buyers should prioritize products with a robust life cycle to minimize maintenance and replacement costs over time.

What Are the Common Trade Terms Used in the Lockset Industry?

Familiarizing yourself with industry jargon can facilitate smoother negotiations and procurement processes. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts that are used in another company’s end products. For locksets, understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This is crucial for B2B transactions, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing needs to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers for specific products. When dealing with locksets, an RFQ can help buyers gather competitive pricing and terms, aiding in budget planning and supplier selection. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers, as they outline who bears shipping costs, insurance, and risks, ensuring clarity in logistics and cost management. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving it. In the lockset industry, understanding lead times is essential for project planning and inventory management. Buyers should factor lead times into their procurement strategies to ensure timely project completion.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing lockset components, ensuring they meet their operational needs and quality standards.

Navigating Market Dynamics and Sourcing Trends in the parts of a lockset Sector

What Are the Current Market Dynamics Influencing the Parts of a Lockset Sector?

The global lockset market is undergoing significant transformation, driven by several key factors. The increasing demand for enhanced security solutions across residential, commercial, and industrial sectors is a primary driver. In regions such as Africa and South America, urbanization and rising crime rates are propelling the need for robust locking mechanisms. Meanwhile, European markets like Germany are experiencing a shift toward smart locks, integrating technology to improve security and convenience.

Emerging B2B technology trends are reshaping sourcing strategies. The adoption of e-commerce platforms has made it easier for international buyers to access a diverse range of suppliers, fostering competition and innovation. Additionally, the rise of Industry 4.0 is influencing manufacturing processes, with automation and data analytics enhancing production efficiency and product quality. This trend is particularly relevant for B2B buyers looking for customizable solutions that meet specific security requirements.

Market dynamics also reflect a growing emphasis on product certification and compliance with international standards. This is crucial for buyers in regions with stringent regulations, as they seek suppliers who can guarantee quality, durability, and security. As the market evolves, understanding these dynamics will empower B2B buyers to make informed decisions, ensuring they source the most reliable and innovative lockset components.

How Is Sustainability and Ethical Sourcing Impacting the Parts of a Lockset Sector?

Sustainability is becoming a critical consideration in the lockset industry, with environmental impacts prompting a shift toward ethical sourcing practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials. This trend is particularly pronounced in Europe, where consumers and businesses alike are advocating for greener products.

The importance of ethical supply chains cannot be overstated. Buyers are looking for manufacturers that adhere to responsible sourcing practices, ensuring that materials are sourced from sustainable suppliers and that labor conditions are fair. Certifications such as ISO 14001 for environmental management and Fair Trade designation can serve as indicators of a supplier’s commitment to ethical practices.

Incorporating ‘green’ materials, such as recycled metals or sustainably sourced wood, into lockset components not only aligns with environmental goals but can also enhance brand reputation. This focus on sustainability and ethics is not just a trend but a growing expectation from buyers around the globe, impacting purchasing decisions significantly.

What Is the Historical Context of the Parts of a Lockset Sector That Matters for B2B Buyers?

The evolution of locksets dates back thousands of years, with early designs made from wood and simple mechanisms. The industrial revolution marked a significant turning point, introducing mass production techniques that made locks more affordable and accessible. By the late 19th century, the invention of the pin tumbler lock revolutionized security, providing a more secure and reliable locking mechanism.

In recent decades, the advent of electronic and smart locks has transformed the landscape. These innovations offer enhanced security features, such as remote access and integration with home automation systems. For B2B buyers, understanding this historical context is crucial, as it informs current trends and the technological advancements that can influence their purchasing decisions.

As the industry continues to innovate, buyers can benefit from a deeper understanding of the historical developments that have shaped modern locksets, enabling them to identify opportunities for sourcing cutting-edge solutions that meet contemporary security needs.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a lockset

-

How do I select the right parts for a lockset?

Choosing the right parts for a lockset involves understanding the specific requirements of your project, including security needs, door specifications, and aesthetic preferences. Start by evaluating the type of lock—deadbolts, knob locks, or smart locks—and ensure compatibility with your door’s backset and bore holes. Additionally, consider the finish and style of the trim to match your overall design. Consulting with suppliers about the performance ratings and material quality can further guide your decision, ensuring you source durable and reliable components. -

What is the best lockset for high-security applications?

For high-security applications, consider locksets that feature heavy-duty deadbolts, anti-drill cylinders, and reinforced strike plates. Look for products that meet BHMA Grade 1 standards, indicating superior durability and security performance. Smart locks that offer keyless entry and remote monitoring can also enhance security. Ensure that the chosen lockset is resistant to picking, bumping, and other common attack methods. Consulting with security experts or suppliers can provide insights into the best options tailored to your specific security needs. -

How can I verify the quality of lockset parts from suppliers?

To verify the quality of lockset parts, request product certifications and compliance documents from suppliers, such as BHMA or ISO certifications. Conduct background checks on suppliers, including reviews and ratings from previous customers. If possible, ask for samples to assess the material quality and craftsmanship firsthand. Establishing a clear quality assurance process, including inspections and testing procedures, will further ensure that the products meet your standards before making a bulk purchase. -

What are the typical minimum order quantities (MOQ) for lockset parts?

Minimum order quantities (MOQ) for lockset parts can vary widely among suppliers, typically ranging from 50 to 1,000 units depending on the manufacturer and specific components. For customized or specialized parts, MOQs may be higher due to the setup costs involved. It’s advisable to discuss your needs directly with suppliers to negotiate favorable terms, especially if you’re a smaller business or testing a new market. Understanding the MOQ can help you manage inventory costs effectively. -

What payment terms should I expect when sourcing lockset parts internationally?

Payment terms for international sourcing can vary based on the supplier’s policies and your negotiation. Common terms include partial payment upfront (usually 30-50%) with the balance due before shipment or upon delivery. Consider using secure payment methods like letters of credit or escrow services to mitigate risks. Ensure you clarify the currency, payment method, and any applicable taxes or duties beforehand to avoid misunderstandings that could delay your order. -

How can I ensure timely delivery of lockset parts?

To ensure timely delivery of lockset parts, establish clear communication with your supplier regarding lead times and shipping methods. Choose suppliers with a proven track record of reliability and punctuality. Consider using freight forwarders who specialize in international logistics to navigate customs and reduce delays. It’s also beneficial to account for potential disruptions by placing orders well in advance, especially for large projects or during peak seasons. -

What are the customization options available for lockset parts?

Customization options for lockset parts often include variations in size, finish, and functionality. Many manufacturers can provide tailored solutions such as branding on handles or unique keying systems. Discuss your specific requirements with suppliers early in the sourcing process to understand their capabilities and any associated costs. Customization can enhance your product offering and ensure that the locksets meet the specific needs of your customers or projects. -

How can I navigate international trade regulations for sourcing lockset parts?

Navigating international trade regulations requires familiarity with both your home country’s and the supplier’s regulations. Start by researching import/export restrictions, tariffs, and customs documentation required for your specific products. Engage with trade compliance experts or legal advisors to ensure adherence to all regulations. Utilizing freight forwarders can also help manage logistics and compliance, ensuring that all necessary paperwork is in order to facilitate smooth transactions and deliveries.

Top 6 Parts Of A Lockset Manufacturers & Suppliers List

1. Hardware Hut – Door Lock Parts

Domain: hardwarehut.com

Registered: 1998 (27 years)

Introduction: Door Lock Parts & Latchbolts – 110 items available for purchase. Includes various types of door hardware such as door locks, deadbolts, electronic locks, and accessories. The product range covers commercial hardware, sliding door track systems, key blanks, and keying accessories. Additional categories include cabinet hardware, bath hardware, kitchen organizers, and furniture components. Customer s…

2. US Hardware Supply – Locksets

Domain: ushardwaresupply.com

Registered: 2008 (17 years)

Introduction: {“Locksets”: {“Free Shipping”: “on any Order Over $450”, “Contact”: “Call Us (877) 379-8747”, “Categories”: [“air fresheners”, “carriage bolts”, “deadbolts”, “dehumidifiers”, “door locks, keys, & parts”, “lockboxes”, “padlocks”, “pipe caps & plugs”, “pool covers & hardware”, “sump pumps”, “torque jack”, “trash bags”, “winterization”, “zip ties”], “Door Locks, Keys, & Parts”: {“Satin Nickel Finish …

3. Trudoor – Lock Parts and Accessories

Domain: trudoor.com

Registered: 2010 (15 years)

Introduction: Key product details include a variety of lock parts and accessories from brands such as Schlage, Accentra, Alarm Lock, and Trudoor. The product types include deadlatch assemblies, springlatches, strike plates, rekeying kits, and boring jigs. Specific products listed are: 1) Schlage – 40-104 Key Gauge ($13.87), 2) Schlage – 40-119 Rekeying Pin Kit with Master Pins ($379.05), 3) Trudoor – 2-3/8″ Bac…

4. Pinterest – Key Door Knob Parts Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Complete guide on 12 key Door Knob/lock Parts: Names & Diagram, covers names, functions, and diagrams. Improve house safety & security.

5. Lock Component – Key Products

Domain: lockcomponent.com

Registered: 2019 (6 years)

Introduction: Key components of a lock set include: 1. Cylinder: The core part where pins and springs align with the correct key. 2. Deadbolt: Provides security by extending deep into the door frame; available in single-cylinder and double-cylinder types. 3. Latchbolt: Keeps the door closed and retracts when the knob or lever is turned. 4. Strike Plate: Mounted on the door frame, it reinforces the lock and abso…

6. HOSOM – Secure Satin-Nickel Entry Lock Set

Domain: locksmithsnearyou.com.au

Introduction: Secure Satin‑Nickel Entry Lock Set – HOSOM Grade 3 Heavy‑duty zinc alloy knob and deadbolt combo, ANSI Grade 3 certified, fits standard door sizes, easy DIY installation, features dual‑side locking for enhanced entry security. Secure Double‑Cylinder Deadbolt, Polished Stainless Grade‑3 ANSI security, tough steel guard and full 1″ throw bolt in polished stainless. Copper Creek DB2420PS delivers rob…

Strategic Sourcing Conclusion and Outlook for parts of a lockset

In navigating the complexities of lockset components, strategic sourcing emerges as a vital approach for international buyers seeking quality, reliability, and competitive pricing. Understanding the intricacies of each part—from the cylinder and latch to the strike plate—enables buyers to make informed decisions that enhance security and functionality. By prioritizing relationships with reputable suppliers, especially those who adhere to stringent quality standards like those set by the Builders Hardware Manufacturers Association (BHMA), companies can ensure they are investing in products that meet their specific needs.

As the demand for advanced locking mechanisms, including smart locks, continues to rise globally, it is crucial for businesses in Africa, South America, the Middle East, and Europe to stay ahead of the curve. Emphasizing innovation and security in procurement processes will not only address current market needs but also anticipate future trends.

Illustrative image related to parts of a lockset

Now is the time for buyers to leverage strategic sourcing to fortify their supply chains, ensuring access to high-quality lockset parts that enhance security and operational efficiency. By doing so, they will position themselves for success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.