Parts Of A Baler: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for parts of a baler

In the dynamic landscape of agricultural machinery, sourcing the right parts of a baler can pose significant challenges for B2B buyers across diverse markets, particularly in regions such as Africa, South America, the Middle East, and Europe. The complexity of selecting high-quality components that not only fit specific baler models but also adhere to regional operational standards can be daunting. This comprehensive guide is designed to demystify the process of acquiring baler parts, providing insights into the various types of components, their applications, and best practices for supplier vetting.

With a focus on critical elements such as bale chambers, knotters, and drive systems, this guide will equip international buyers with the knowledge needed to make informed purchasing decisions. We will delve into the importance of safety features, the role of aftermarket parts, and the considerations for cost efficiency in sourcing. Additionally, we’ll explore supplier reliability, ensuring that you can confidently navigate the global market while minimizing downtime and maximizing productivity.

By empowering B2B buyers with actionable insights and a clear understanding of the baler parts landscape, this guide aims to enhance operational efficiency and drive sustainable growth in your agricultural endeavors. Whether you’re in Brazil, Vietnam, or elsewhere, unlocking the potential of your baling operations starts with making informed choices about the parts that keep your machinery running smoothly.

Understanding parts of a baler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bale Chamber | Varies in shape (rectangular, round) and size; critical for compression. | Hay and straw baling, waste management. | Pros: Efficient compression; customizable sizes. Cons: Size limitations based on machine design. |

| Pickup System | Mechanism to gather material; can be fixed or floating. | Agricultural operations, recycling. | Pros: Enhanced material collection; adaptable to terrain. Cons: Requires maintenance for optimal performance. |

| Drive System | Powers the baler; can be hydraulic or mechanical. | Heavy-duty agricultural tasks. | Pros: Reliable power transfer; various configurations. Cons: Complexity can lead to higher repair costs. |

| Knotter System | Twine or netting application; ensures bales hold shape. | Hay production, waste management. | Pros: Consistent bale quality; reduces labor. Cons: Potential for jams; requires regular adjustment. |

| Control System | Digital or manual interface for operation management. | All baling applications. | Pros: User-friendly; enhances operational efficiency. Cons: Digital systems may require training. |

What Are the Key Characteristics of a Bale Chamber?

The bale chamber is the core component of any baler, designed to compress gathered materials into manageable bales. Bale chambers come in various shapes, including rectangular and round, which can significantly influence the efficiency of the baling process. The choice of chamber size is critical for B2B buyers, as it should align with the type of material being processed and the desired bale size. Understanding the specific needs of agricultural operations or waste management can guide the selection of an appropriately sized chamber.

How Does the Pickup System Impact Baling Efficiency?

The pickup system plays a vital role in the baling process by gathering loose material and feeding it into the bale chamber. Depending on the design, pickup systems can be fixed or floating, allowing them to adapt to uneven terrain. This adaptability is crucial for agricultural buyers operating in varied environments. Regular maintenance is essential to ensure optimal performance, as a well-functioning pickup system can significantly enhance productivity and reduce downtime.

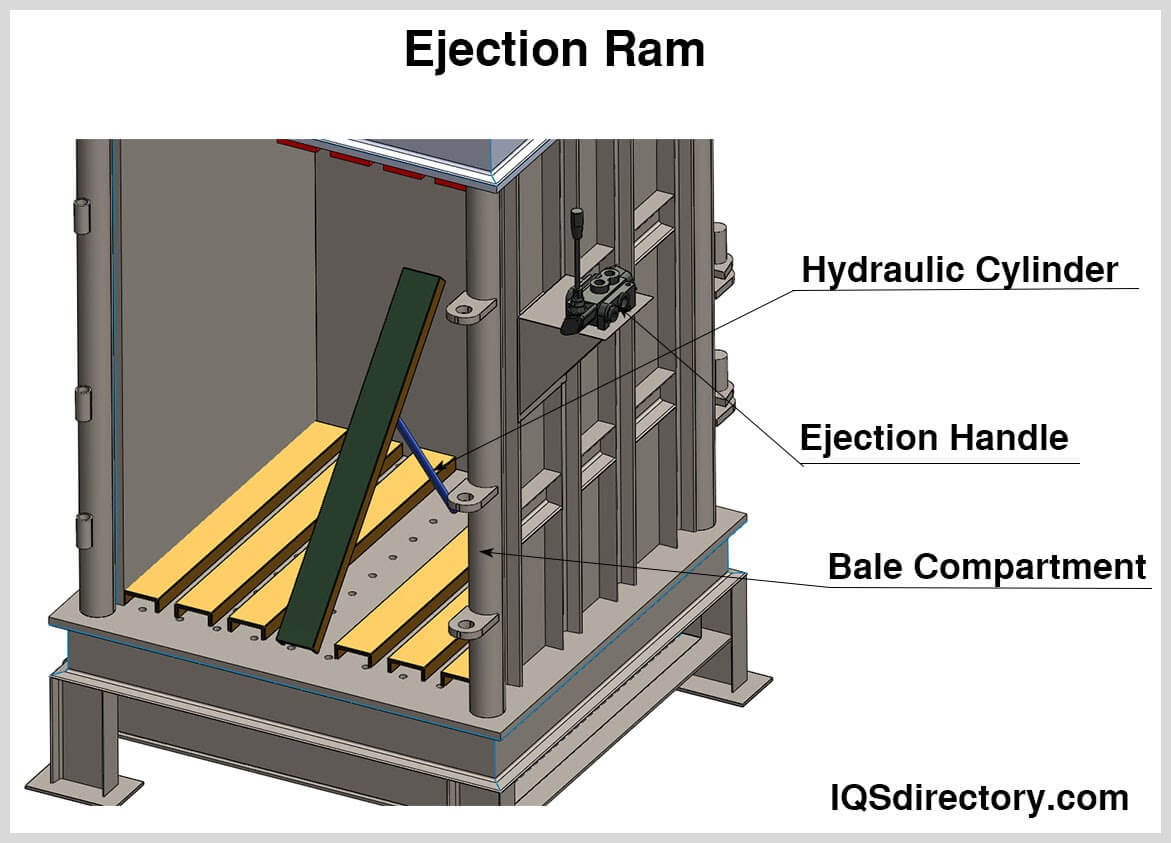

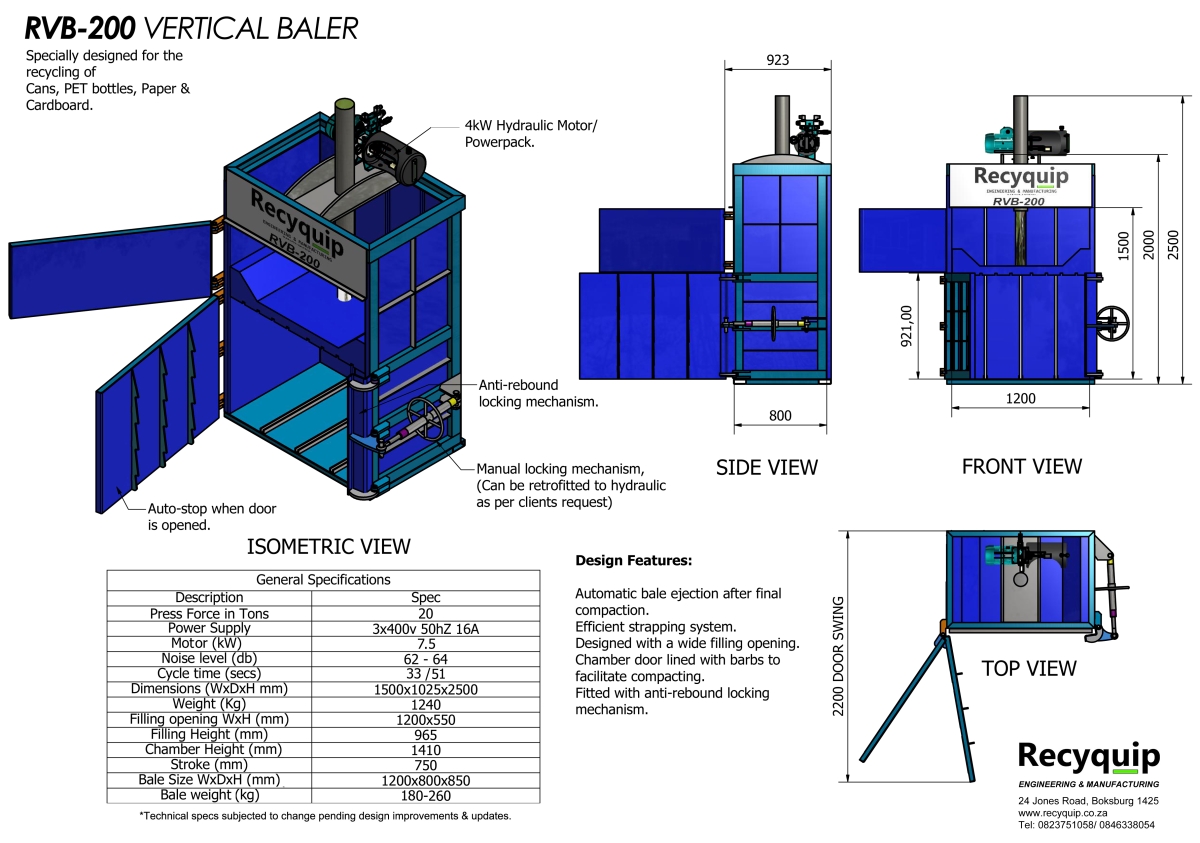

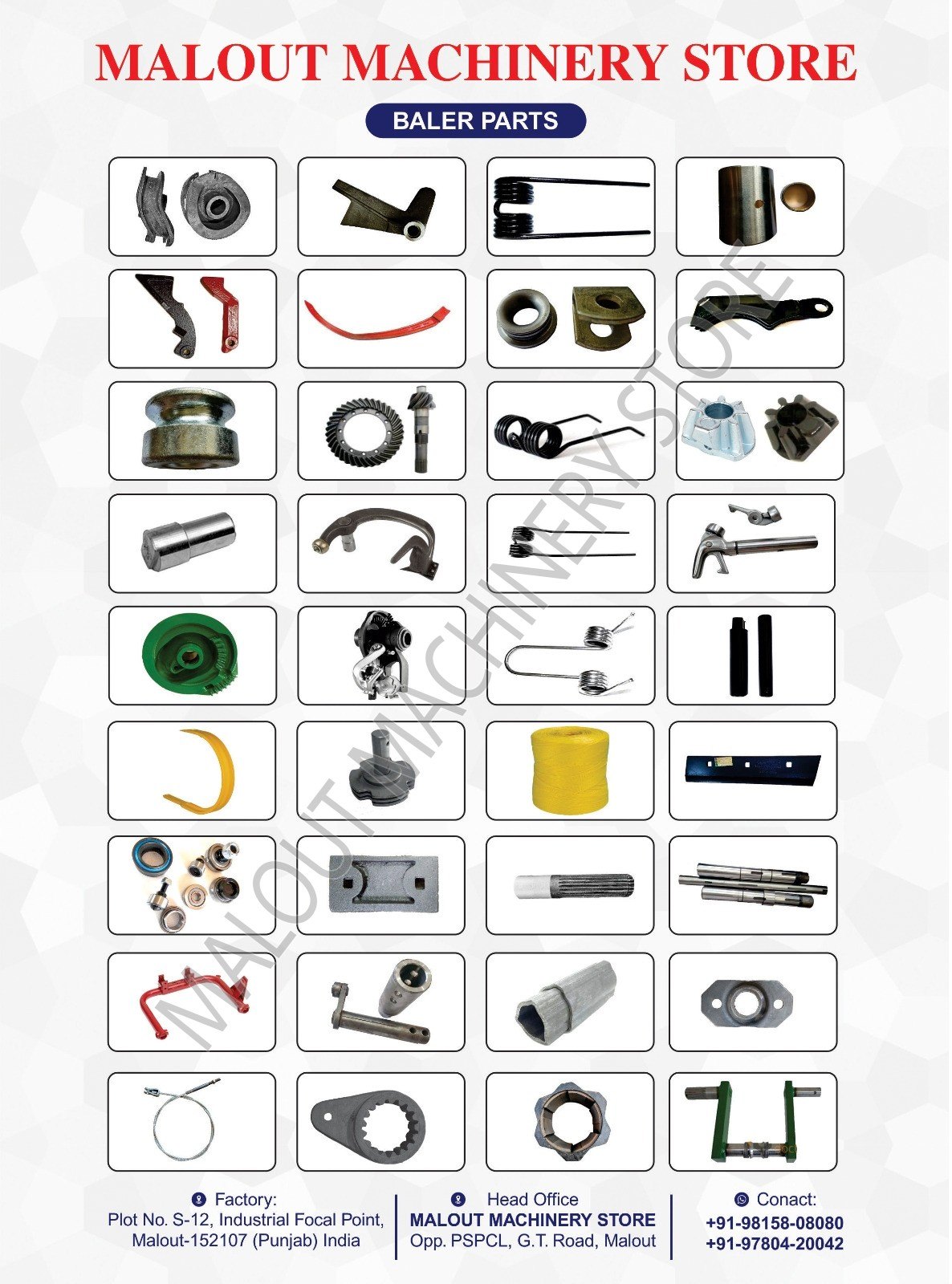

Illustrative image related to parts of a baler

What Should Buyers Know About Drive Systems?

The drive system is responsible for powering the baler’s operations, with options ranging from hydraulic to mechanical configurations. This component is particularly important for heavy-duty agricultural tasks where reliability and power transfer are paramount. Buyers should consider the complexity of the drive system, as more intricate setups may incur higher repair and maintenance costs. Understanding the operational demands of their specific applications will help buyers choose the most suitable drive system.

Why Is the Knotter System Essential for Quality Bales?

The knotter system secures bales using twine or netting, ensuring they maintain their shape during handling and storage. A reliable knotter is essential for producing high-quality bales, which is particularly important in hay production and waste management. While knotters can enhance efficiency and reduce labor needs, they also require regular adjustments and can be prone to jams. Buyers should assess the knotter’s design and reliability when selecting a baler.

What Role Does the Control System Play in Baler Operations?

The control system of a baler allows operators to manage its functions effectively, whether through a digital interface or manual levers. A user-friendly control system enhances operational efficiency, making it easier for operators to adjust settings on the fly. However, buyers should be aware that digital systems may necessitate additional training for their staff. Understanding the technology level and user interface of a baler’s control system is crucial for ensuring a smooth transition and optimal operation in various applications.

Key Industrial Applications of parts of a baler

| Industry/Sector | Specific Application of parts of a baler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Hay and forage production using balers | Efficient harvesting and storage of fodder | Quality and compatibility of parts; local availability |

| Waste Management | Recycling and waste compacting operations | Reduction of transportation costs and landfill use | Durability of parts; compliance with local regulations |

| Animal Husbandry | Production of feed bales for livestock | Ensures consistent feed quality and availability | Nutritional analysis; consistency in bale size and weight |

| Biomass Energy | Baling of biomass for energy production | Facilitates easier transport and processing | Material compatibility; energy efficiency of baling process |

| Construction and Landscaping | Baling of organic waste for landscaping use | Cost-effective disposal and recycling of materials | Environmental impact; sourcing of sustainable materials |

How Are Parts of a Baler Used in Agriculture?

In the agricultural sector, parts of a baler are crucial for the efficient production of hay and forage. The bale chamber compresses cut grass into tightly packed bales, which are easier to handle and store. By using high-quality knotters and feeder systems, farmers can ensure that the bales maintain their shape and nutritional value during storage. B2B buyers in this industry should consider sourcing parts that are durable and compatible with their existing machinery to minimize downtime and maximize productivity.

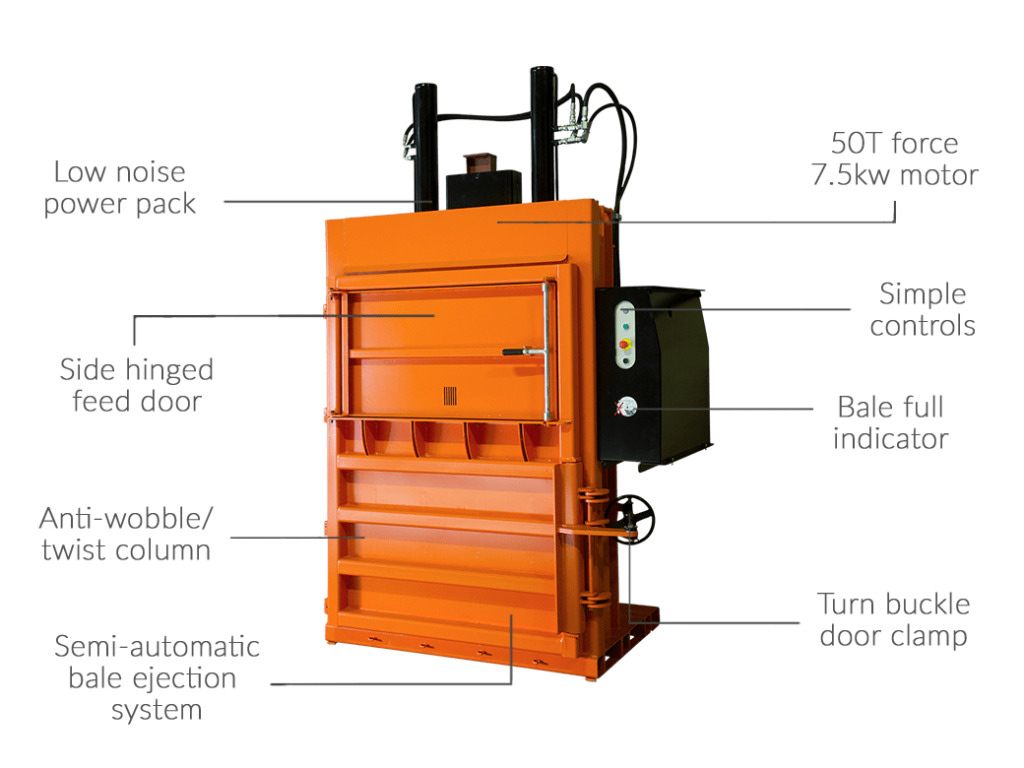

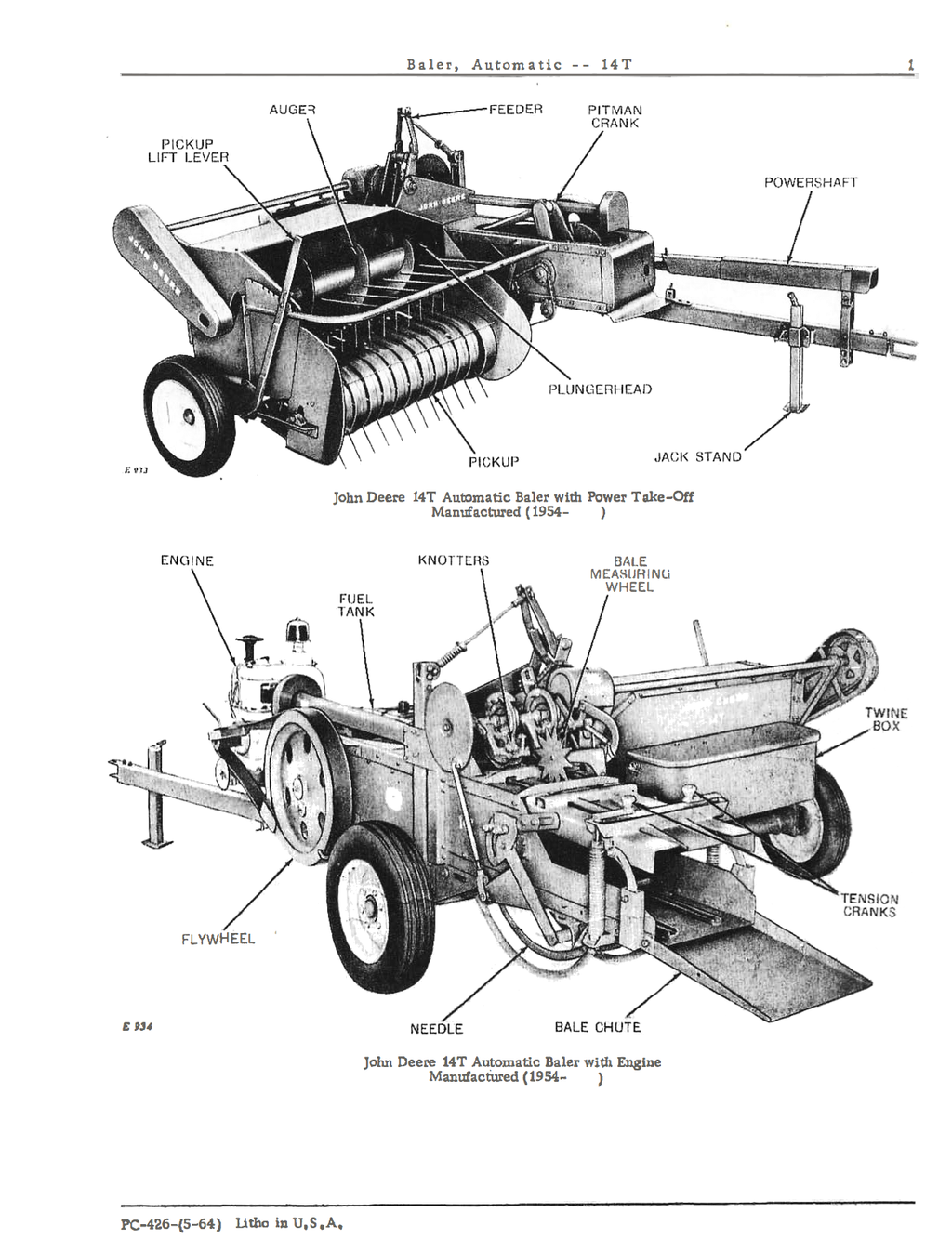

Illustrative image related to parts of a baler

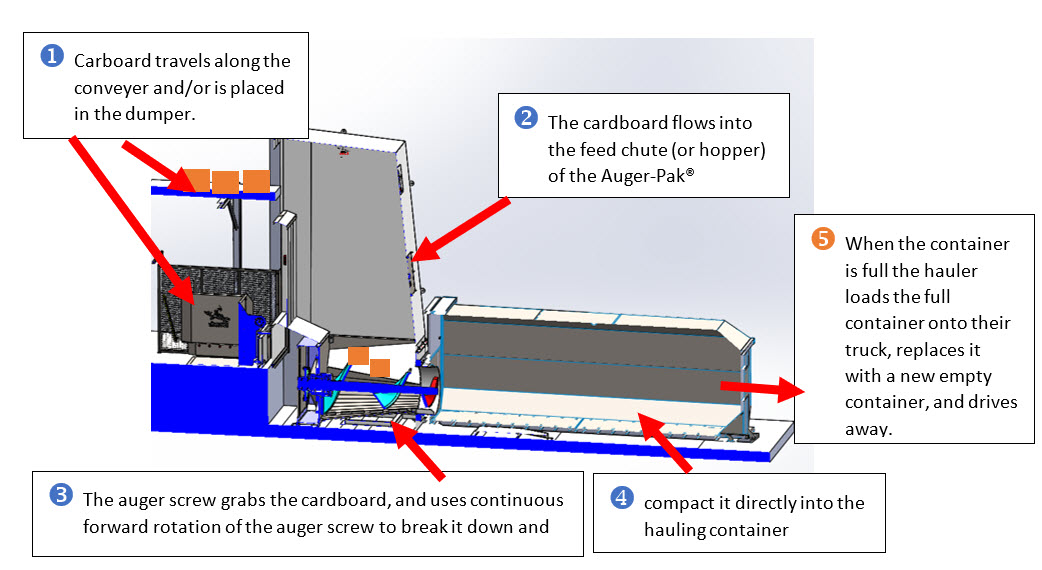

What Role Do Baler Parts Play in Waste Management?

In waste management, balers are used to compact recyclable materials, such as cardboard and plastics, into manageable bales. This significantly reduces the volume of waste, leading to lower transportation costs and more efficient use of landfill space. For international buyers, it is essential to select baler parts that meet local regulations and standards, ensuring compliance and safety during operations. Sourcing durable components can also enhance the machine’s lifespan and efficiency.

How Do Baler Parts Benefit Animal Husbandry?

For animal husbandry, balers are instrumental in producing feed bales from various forage types. The knotters and drive systems ensure that bales are tightly secured and uniform in size, which is vital for consistent feeding. This reliability helps farmers maintain livestock health and productivity. Buyers in this sector must focus on the nutritional aspects of the baled feed and ensure that the parts used in their balers do not compromise the quality of the feed.

How Are Baler Parts Utilized in Biomass Energy Production?

In the biomass energy sector, balers are used to compress organic materials, such as agricultural residues and wood chips, into bales for easier transport to energy plants. Efficient baling reduces the handling costs and optimizes the energy extraction process. International buyers should prioritize sourcing parts that enhance the energy efficiency of the baling process and ensure compatibility with various biomass materials.

What Importance Do Baler Parts Have in Construction and Landscaping?

In construction and landscaping, balers help manage organic waste by compacting it into bales for recycling or disposal. This process provides a cost-effective solution for waste management while promoting sustainability. Buyers in this sector should consider the environmental impact of the materials used in balers and prioritize sourcing parts that support eco-friendly practices, ensuring compliance with sustainability standards.

3 Common User Pain Points for ‘parts of a baler’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Replacement Parts

The Problem:

B2B buyers often face significant challenges when sourcing reliable replacement parts for balers, especially in regions like Africa and South America where parts availability can be sporadic. Many suppliers may not stock OEM (Original Equipment Manufacturer) parts, leading to the risk of using inferior quality alternatives that can compromise the baler’s performance. Additionally, the lack of local suppliers may result in extended downtime due to shipping delays, affecting operational efficiency and productivity during critical harvesting periods.

The Solution:

To mitigate this issue, buyers should establish relationships with reputable suppliers who specialize in baler parts and have a proven track record in their region. It is advisable to request a comprehensive list of available OEM parts from these suppliers to ensure authenticity and quality. Creating a proactive inventory management strategy that includes maintaining a stock of critical spare parts can significantly reduce downtime. Additionally, considering a partnership with a local distributor who can provide immediate access to essential components can enhance operational reliability. Buyers should also utilize online platforms that specialize in baler parts to compare pricing and availability, ensuring they have multiple options when sourcing replacements.

Scenario 2: Inadequate Knowledge of Baler Component Functions

The Problem:

Many B2B buyers are not fully aware of the specific functions of various baler components, which can lead to misdiagnosis of issues when malfunctions occur. For example, a faulty knotter may be mistaken for a problem in the drive system, resulting in unnecessary repairs and increased costs. This lack of understanding can also lead to improper parts selection, further complicating maintenance and repairs.

The Solution:

To overcome this knowledge gap, buyers should invest in training for their teams, focusing on understanding the baler’s core components and their functions. This can include workshops or online courses offered by equipment manufacturers or industry associations. Additionally, creating a detailed parts guide that outlines the function and importance of each component can serve as a valuable reference. This approach not only helps in accurate troubleshooting but also empowers the team to make informed decisions when ordering parts. Regular maintenance checks and keeping detailed logs of component performance can also aid in understanding which parts may need replacement before they cause more significant issues.

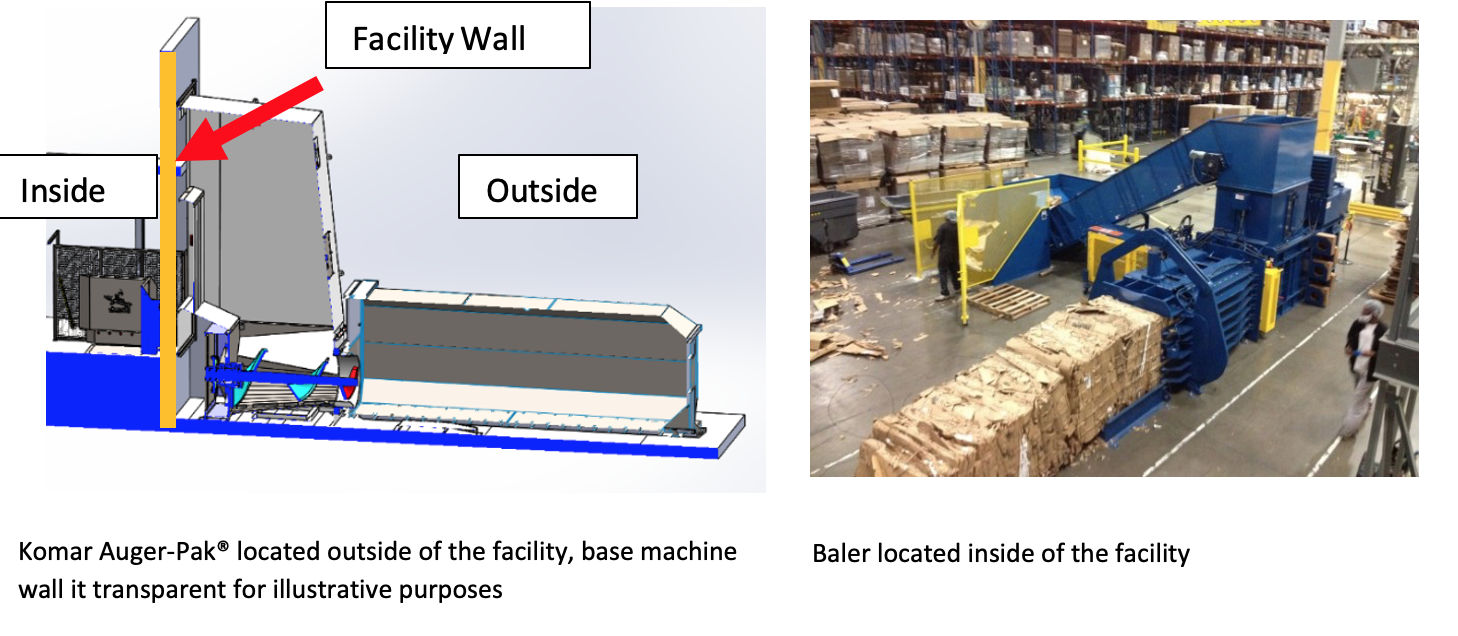

Illustrative image related to parts of a baler

Scenario 3: Performance Issues Due to Improper Installation of Parts

The Problem:

After replacing parts, some B2B buyers experience performance issues, often due to improper installation. Incorrectly installed components can lead to inefficiencies and may even cause further damage to the baler, leading to costly repairs and extended downtime. This is particularly problematic in regions where skilled labor may be limited, making it challenging to ensure that all installations meet manufacturer specifications.

The Solution:

To address installation challenges, buyers should prioritize hiring experienced technicians or seeking training for existing staff on proper installation techniques for baler parts. Many manufacturers offer installation guides or videos that provide step-by-step instructions, which can be invaluable resources. Furthermore, establishing a quality control checklist for each installation can help ensure that all parts are fitted correctly and functioning as intended. Implementing a mentorship program where more experienced technicians assist newer employees can also enhance skill development and improve installation accuracy. By focusing on proper installation practices, buyers can significantly reduce the likelihood of performance issues and extend the lifespan of their balers.

Strategic Material Selection Guide for parts of a baler

When selecting materials for parts of a baler, it is essential to consider various factors that can influence performance, durability, and overall cost-effectiveness. This analysis focuses on four common materials used in baler components: steel, aluminum, rubber, and composite materials. Each material has unique properties and implications for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to parts of a baler

What are the Key Properties of Steel in Baler Parts?

Steel is widely used in baler construction due to its high strength and durability. It typically offers excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel components can withstand significant wear and tear, which is crucial for parts like the drive system and bale chamber.

Pros: Steel is cost-effective and readily available, making it a popular choice for manufacturers. Its strength ensures longevity and reliability in demanding environments.

Cons: The primary drawback of steel is its susceptibility to corrosion, particularly in humid or wet conditions. This can lead to increased maintenance costs and potential failures if not properly treated.

Impact on Application: Steel is compatible with various media but requires protective coatings or treatments to enhance corrosion resistance, especially in regions with high moisture levels.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers should also consider local availability and the cost of corrosion-resistant treatments.

How Does Aluminum Benefit Baler Parts?

Aluminum is another common material, particularly for components that require a lightweight yet strong structure. It has excellent corrosion resistance and can perform well in various environmental conditions.

Pros: The lightweight nature of aluminum reduces the overall weight of the baler, improving fuel efficiency during transport and operation. Its resistance to corrosion means lower maintenance costs over time.

Cons: Aluminum is generally more expensive than steel and can be less durable under heavy loads. It may also require specialized manufacturing processes, which can increase production complexity.

Impact on Application: Aluminum is suitable for parts exposed to moisture and corrosive elements, such as certain housing and casing components.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM B221 for aluminum extrusions. Understanding local market preferences for lightweight materials can also influence purchasing decisions.

What Role Does Rubber Play in Baler Parts?

Rubber is primarily used in balers for components such as seals, gaskets, and tires. Its flexibility and excellent shock absorption properties make it an ideal choice for parts that experience vibration and movement.

Pros: Rubber provides excellent sealing capabilities, preventing leaks and ensuring the efficient operation of hydraulic systems. Its resilience contributes to the longevity of components subjected to constant movement.

Cons: Rubber can degrade over time when exposed to UV light and extreme temperatures, leading to potential failures. It is also less effective in high-temperature applications compared to metals.

Impact on Application: Rubber is compatible with various fluids and can withstand moderate temperature variations, making it suitable for hydraulic systems in balers.

Considerations for International Buyers: Buyers should look for rubber that meets specific standards, such as ASTM D2000, to ensure quality. The availability of rubber compounds suitable for different climates is also crucial for performance.

How Do Composite Materials Enhance Baler Performance?

Composite materials, often a combination of plastics and fibers, are increasingly used in baler parts due to their unique properties. They are lightweight, strong, and resistant to corrosion.

Illustrative image related to parts of a baler

Pros: Composites can be engineered to offer specific performance characteristics, such as enhanced strength-to-weight ratios and resistance to environmental degradation. They also reduce the overall weight of the baler, improving efficiency.

Cons: The manufacturing process for composites can be complex and costly. Additionally, they may not be as widely available as traditional materials, depending on the region.

Impact on Application: Composites are suitable for non-structural parts that require high strength and low weight, such as covers and housing.

Considerations for International Buyers: Compliance with standards like ASTM D638 for tensile properties is essential. Understanding the local market’s familiarity with composites can help in making informed purchasing decisions.

Summary Table of Material Selection for Baler Parts

| Material | Typical Use Case for parts of a baler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Drive systems, bale chamber | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Housing, casing components | Lightweight and corrosion-resistant | Higher cost, less durable under load | High |

| Rubber | Seals, gaskets, tires | Excellent sealing and shock absorption | Degrades under UV and extreme temps | Medium |

| Composite | Non-structural parts, covers | Lightweight, customizable properties | Complex manufacturing process | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a baler

What Are the Key Stages in the Manufacturing Process of Baler Parts?

The manufacturing of baler parts involves several critical stages that ensure the components meet the necessary specifications for performance and durability. Here’s a breakdown of the main stages involved in the manufacturing process:

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in the manufacturing process is material preparation, where raw materials such as high-strength steel, aluminum, and various polymers are selected based on their properties. Manufacturers often source materials from certified suppliers to ensure quality. Materials undergo processes such as cutting, shearing, and bending to create blanks that will form the basis of the baler parts. Quality checks at this stage involve verifying material certifications and conducting tensile tests to ensure they meet specific strength requirements.

Forming: What Techniques Are Used to Shape Baler Components?

Once the materials are prepared, the next step is forming, where the raw materials are transformed into the desired shapes. Common techniques include:

- Stamping and Punching: These methods are used for flat parts such as plates and covers, where precision is critical.

- Casting: For complex shapes like housings or large components, casting techniques (sand casting, die casting) may be employed to ensure uniformity and structural integrity.

- Machining: CNC (Computer Numerical Control) machining is a prevalent technique for producing high-precision parts, such as gears and shafts, ensuring tight tolerances.

Throughout the forming process, manufacturers implement in-process quality control (IPQC) measures, such as dimensional checks and visual inspections, to catch any deviations early on.

Assembly: How Are Baler Parts Assembled for Optimal Functionality?

The assembly stage is where individual components come together to create the final product. This involves the integration of various parts such as the drive system, knotters, and bale chambers.

In this phase, manufacturers often use techniques like:

- Welding: For joining metal parts, ensuring a strong bond.

- Bolting: For components that may require future disassembly or maintenance.

- Adhesives: In cases where bonding non-metallic materials is necessary.

Quality assurance during assembly includes functional testing to ensure that all components work together seamlessly. This may involve simulating operational conditions to verify performance.

Finishing: What Processes Are Applied to Enhance Durability and Appearance?

After assembly, the finishing stage enhances the durability and appearance of baler parts. Common finishing processes include:

- Painting or Coating: To prevent rust and wear, parts are often coated with protective paints or powder coatings.

- Surface Treatments: Techniques like anodizing or galvanizing may be used to improve corrosion resistance.

- Final Inspection: A thorough check ensures that all components meet aesthetic and functional requirements before they are packaged and shipped.

What Quality Assurance Standards Are Relevant for Baler Parts?

Quality assurance is paramount in the manufacturing of baler parts to ensure reliability and safety. International standards such as ISO 9001 are critical benchmarks that manufacturers must adhere to, ensuring a consistent level of quality across all processes.

In addition, industry-specific certifications, such as CE marking for compliance with European standards or API certification for oil and gas applications, may apply depending on the intended use of the baler parts. These certifications assure buyers that the products meet rigorous safety and performance standards.

How Are Quality Control Checkpoints Implemented During Manufacturing?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, critical dimensions and characteristics are monitored to catch any deviations in real-time.

- Final Quality Control (FQC): Before shipment, a final inspection is conducted to confirm that the finished parts adhere to all quality standards and specifications.

What Common Testing Methods Are Used to Ensure Product Quality?

Manufacturers employ various testing methods to validate the quality of baler parts, including:

- Dimensional Testing: Utilizing calipers and gauges to confirm that parts meet specified tolerances.

- Functional Testing: Simulating the operational environment to ensure that parts perform as intended.

- Stress Testing: Assessing the durability and strength of parts under extreme conditions to predict performance in real-world applications.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, verifying the quality assurance practices of suppliers is crucial. Here are some actionable steps:

- Supplier Audits: Conducting audits of manufacturing facilities can provide insights into the quality control processes and adherence to standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC.

- Third-party Inspections: Engaging independent inspection services can offer an unbiased assessment of the supplier’s quality assurance practices.

What Nuances Should International Buyers Consider Regarding QC Certifications?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality certifications. Different markets may have varying standards, and recognizing these can enhance the procurement process.

For instance, while ISO 9001 is globally recognized, local standards may also play a role in the acceptance of products. Buyers should ensure that suppliers are compliant with both international and regional standards to facilitate smoother transactions and reduce the risk of quality-related issues.

Conclusion

Understanding the manufacturing processes and quality assurance practices for baler parts is essential for B2B buyers seeking reliable suppliers. By familiarizing themselves with the stages of manufacturing, relevant quality standards, and verification methods, buyers can make informed decisions that align with their operational needs and quality expectations. This knowledge not only enhances procurement efficiency but also contributes to the overall success of their operations in the agricultural sector.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a baler’

To ensure a successful procurement process for baler parts, it’s essential to follow a structured approach that minimizes risks and maximizes efficiency. This checklist serves as a practical guide for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, to effectively source the components necessary for maintaining their baling operations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Identify the specific baler model and the parts required, such as the bale chamber, pickup system, or knotter. This clarity helps ensure compatibility and avoids costly mistakes.

- Considerations:

- Review the baler’s operational manual for part numbers.

- List any unique requirements based on your operational conditions.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in baler parts. This step is vital to ensure that you are sourcing from reputable companies that understand the nuances of agricultural machinery.

- Key Actions:

- Utilize online platforms and industry directories to find suppliers.

- Check for customer reviews and ratings to gauge reliability.

Step 3: Evaluate Supplier Certifications and Quality Assurance

Before making any commitments, it’s crucial to verify that your chosen suppliers adhere to industry standards and possess relevant certifications. This ensures that the parts you procure are of high quality and compliant with international safety regulations.

- What to Look For:

- ISO certifications or equivalent quality management certifications.

- Compliance with local regulations in your region.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, lead times, and shipping options. This information is essential for comparing costs and making informed decisions.

Illustrative image related to parts of a baler

- Important Details:

- Ensure that quotes specify part numbers and descriptions.

- Inquire about bulk purchase discounts or warranty options.

Step 5: Assess Aftermarket Support and Service

Consider suppliers that offer robust aftermarket support, including installation assistance and technical service. This is particularly important for complex components, where proper installation and maintenance can significantly affect performance.

- Evaluation Criteria:

- Availability of installation guides or technical support.

- Options for training your staff on new components.

Step 6: Negotiate Terms and Conditions

Before finalizing your order, engage in negotiations to establish favorable terms and conditions. This includes payment terms, return policies, and warranties, which can protect your investment in the long term.

- Negotiation Tips:

- Be clear about your budget constraints while discussing terms.

- Ensure that all agreements are documented to avoid misunderstandings.

Step 7: Place Your Order and Monitor Delivery

After finalizing the terms, place your order and closely monitor the delivery process. Timely delivery is critical to maintaining your operational schedule, especially during peak farming seasons.

- Follow-Up Actions:

- Communicate regularly with the supplier to track the order status.

- Prepare for receiving and inspecting the parts upon arrival to ensure they meet your specifications.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing parts for balers, ensuring both operational efficiency and cost-effectiveness.

Illustrative image related to parts of a baler

Comprehensive Cost and Pricing Analysis for parts of a baler Sourcing

What Are the Key Cost Components for Baler Parts?

Understanding the cost structure of baler parts is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials can vary significantly based on the type of parts being sourced. For instance, high-quality steel or specialized alloys used in critical components like the bale chamber or knotter can increase overall costs.

-

Labor: Labor costs can differ by region, particularly if parts are manufactured in countries with lower wage rates. Consider the labor force’s skill level, as specialized labor may command higher wages.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead, which is beneficial for both suppliers and buyers.

-

Tooling: The initial setup for production, including molds and fixtures, can add to costs. Custom parts often require specific tooling, increasing upfront expenses.

-

Quality Control: Investing in robust QC processes ensures that parts meet industry standards and certifications, which can influence pricing. Buyers should verify that suppliers adhere to relevant quality certifications to avoid future issues.

-

Logistics: Shipping and handling are significant factors, especially for international transactions. Costs can escalate based on distance, shipping method, and customs duties.

-

Margin: Suppliers will typically add a profit margin to cover their costs and risks. Understanding the typical margins in the industry can aid buyers in negotiating better deals.

How Do Price Influencers Affect Baler Parts Sourcing?

Several factors can influence the pricing of baler parts, particularly for international buyers.

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to discounts due to economies of scale. Buyers should evaluate their needs and negotiate MOQs to minimize costs.

-

Specifications and Customization: Customized parts tailored to specific baler models may incur higher costs. Buyers should clearly define specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications like ISO or CE can justify higher prices. Buyers should assess whether the added costs align with their operational requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge premium prices but offer better service and reliability.

-

Incoterms: Understanding shipping terms can significantly influence overall costs. Different Incoterms dictate who is responsible for shipping, insurance, and tariffs, affecting the total landed cost.

What Negotiation and Cost-Efficiency Tips Should Buyers Consider?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the upfront price. Consider maintenance, durability, and replacement costs when evaluating potential suppliers.

-

Negotiation Tactics: Be prepared to negotiate not just on price but also on payment terms, delivery schedules, and warranty conditions. Building strong relationships with suppliers can lead to better deals.

-

Understanding Pricing Nuances: Be aware of regional market trends and pricing variations. For example, parts sourced from Europe may carry different pricing structures compared to those from Asia due to labor and manufacturing costs.

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and quality standards. This knowledge empowers buyers to negotiate effectively and select suppliers that provide the best value.

In summary, a comprehensive understanding of cost components, price influencers, and effective negotiation strategies is essential for international B2B buyers sourcing baler parts. By focusing on these factors, buyers can make informed decisions that enhance their operational efficiency and profitability.

Alternatives Analysis: Comparing parts of a baler With Other Solutions

Exploring Alternative Solutions to Baler Parts

In the agricultural machinery sector, understanding the various options available for baling operations can significantly impact efficiency and profitability. While the parts of a baler play a crucial role in hay and straw management, alternative solutions also exist that may meet specific operational needs more effectively or economically. This analysis will compare the traditional baler parts with two viable alternatives: the round baler and the automated wrapping system.

| Comparison Aspect | Parts Of A Baler | Round Baler | Automated Wrapping System |

|---|---|---|---|

| Performance | High compression and consistent bale shape | Produces larger, denser bales suitable for transport | Enhances storage life and reduces spoilage |

| Cost | Moderate to high initial investment | Higher initial costs but lower operational costs | Variable costs based on system complexity |

| Ease of Implementation | Requires technical knowledge for setup | User-friendly with tractor attachment | Generally more complex; may require training |

| Maintenance | Regular maintenance needed for optimal performance | Requires less frequent maintenance due to robust design | Maintenance can be intensive; requires skilled labor |

| Best Use Case | Ideal for small to medium farms focused on hay production | Best for large-scale operations needing efficient transport | Suitable for operations prioritizing long-term storage |

What Are the Pros and Cons of Round Balers?

Round balers are designed to produce cylindrical bales that are larger and denser than those created by traditional balers. The primary advantage of round balers is their efficiency in handling large volumes of material, making them ideal for expansive farms. They also tend to require less frequent maintenance due to their robust construction. However, the initial investment can be significantly higher, which may deter smaller operators. Additionally, the size of the bales may require specialized handling equipment, adding to the operational complexity.

How Do Automated Wrapping Systems Improve Baling Operations?

Automated wrapping systems complement traditional balers by wrapping bales in plastic film immediately after formation, enhancing preservation and reducing spoilage. This method is particularly advantageous for farmers focused on maintaining the quality of silage or haylage. The primary benefit lies in the extended storage life of the bales, which can lead to cost savings over time. However, these systems can be complex and may require a higher level of training for operators. Additionally, they can incur variable costs based on the materials used for wrapping and the complexity of the machinery.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate baling solution, B2B buyers should assess their operational needs, budget, and long-term goals. For smaller farms or those focusing on hay production, traditional baler parts may provide the best balance of performance and cost. Conversely, larger operations that prioritize efficiency and transport may find that round balers are a more suitable investment. If long-term storage and preservation are critical, automated wrapping systems could offer significant advantages despite their complexity. Ultimately, understanding the unique demands of your agricultural operation will guide you in choosing the best baling solution.

Essential Technical Properties and Trade Terminology for parts of a baler

What Are the Key Technical Properties of Baler Parts?

Understanding the technical specifications of baler parts is crucial for B2B buyers seeking to optimize their equipment performance and longevity. Here are several critical specifications to consider:

-

Material Grade

The material grade of baler components, such as steel or aluminum, significantly impacts durability and wear resistance. High-grade materials like ASTM A36 steel are preferred for structural components due to their strength and corrosion resistance. Selecting the right material ensures that the baler can withstand harsh agricultural environments, minimizing the risk of breakdowns and extending service life. -

Tolerance Levels

Tolerance levels refer to the permissible limits of variation in a part’s dimensions. For baler parts, precise tolerances ensure proper fit and function, which is vital for efficient operation. Inconsistent tolerances can lead to misalignment, increased wear, and mechanical failures. Understanding these specifications helps buyers choose parts that will operate smoothly and reduce maintenance costs. -

Load Capacity

Load capacity indicates the maximum weight a baler part can handle without failure. Components such as the bale chamber and pickup system must be rated for the expected loads they will encounter during operation. Knowing the load capacity is essential for preventing equipment damage and ensuring safe operation, especially in large-scale agricultural settings. -

Wear Resistance

Wear resistance is a critical property for parts that experience friction and stress, such as rollers and knotters. Materials with high wear resistance, like hardened steel or specialized composites, can significantly enhance the lifespan of these components. Buyers should prioritize wear-resistant materials to minimize downtime and replacement costs. -

Corrosion Resistance

Corrosion resistance is vital for parts exposed to moisture and chemicals, such as those in baling operations. Coatings like galvanization or the use of stainless steel can protect parts from rust and deterioration. This property is particularly important in regions with high humidity or heavy rainfall, where equipment longevity is at risk.

Which Trade Terms Are Essential for B2B Buyers in the Baler Industry?

Familiarity with industry terminology can streamline the purchasing process and facilitate better communication with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM parts are made by the original manufacturer of the baler. These parts are designed to meet the exact specifications of the equipment, ensuring compatibility and performance. For buyers, choosing OEM parts can lead to better reliability and warranty coverage, although they may come at a premium price. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs that align with their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting detailed pricing and availability for specific parts. Submitting an RFQ allows buyers to compare offers and negotiate terms effectively. Clarity in RFQs can lead to better pricing and faster response times from suppliers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They specify who is responsible for shipping, insurance, and tariffs. Understanding these terms is vital for B2B transactions, particularly for international buyers, to avoid unexpected costs and ensure smooth logistics. -

Lead Time

Lead time is the period between placing an order and receiving the goods. Knowing the lead time helps buyers plan their operations and manage inventory effectively. Suppliers with shorter lead times can provide a competitive advantage, especially in fast-paced agricultural environments.

By grasping these essential technical properties and industry terms, B2B buyers can make informed decisions when sourcing baler parts, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the parts of a baler Sector

What Are the Current Market Dynamics and Key Trends Influencing Baler Parts Sourcing?

The global market for baler parts is witnessing significant shifts driven by technological advancements and changing agricultural practices. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their operations, they are increasingly focusing on components that enhance efficiency and productivity. Key trends include the rise of precision agriculture technologies, which integrate IoT and data analytics into baling processes. This shift allows for real-time monitoring and predictive maintenance, thereby reducing downtime and improving output.

Moreover, the demand for aftermarket parts is growing, as operators seek cost-effective solutions to maintain their machinery. Buyers are also looking for parts that are compatible across different brands, which enhances flexibility and reduces inventory costs. In markets like Brazil and Vietnam, the increasing mechanization of agriculture is propelling demand for high-quality baler parts, while European buyers are increasingly concerned about compliance with stringent safety and performance standards.

Emerging trends also highlight the importance of digital platforms for sourcing. E-commerce solutions are becoming the preferred method for international buyers to access a wider range of parts, facilitating easier comparisons and quicker procurement. This digitization is transforming the sourcing landscape, making it more efficient and transparent.

How Does Sustainability and Ethical Sourcing Impact Baler Parts Procurement?

As environmental consciousness grows, sustainability is becoming a key consideration for B2B buyers in the baler parts sector. The environmental impact of agricultural machinery, including balers, necessitates a focus on sustainable practices in sourcing. Buyers are increasingly demanding parts made from recyclable materials or those that contribute to energy efficiency. This trend is particularly pronounced in Europe, where regulations around carbon footprints and waste management are stringent.

Ethical sourcing is also critical in this context. Buyers are keen to understand the supply chains behind the parts they procure, looking for suppliers who demonstrate a commitment to fair labor practices and environmentally responsible manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications are becoming essential for suppliers aiming to capture the attention of environmentally conscious buyers.

Furthermore, as the pressure to minimize waste increases, the focus on refurbishing and recycling baler parts is gaining traction. This not only reduces environmental impact but also offers cost savings for businesses looking to extend the lifespan of their equipment.

What Is the Evolution of Baler Parts and Its Relevance to Today’s B2B Landscape?

The evolution of baler parts has been shaped significantly by technological advancements and the increasing demands of modern agriculture. Initially, balers were simple machines that relied on manual operation and basic components. Over the decades, innovation has led to the development of sophisticated systems that include automated knotters, advanced drive systems, and integrated control mechanisms.

This evolution reflects the broader trends in the agricultural sector, where efficiency and productivity are paramount. Modern balers are equipped with features that enhance their performance, such as sensors for monitoring bale density and moisture levels. As such, understanding the historical context of these advancements is crucial for B2B buyers who must navigate the complexities of sourcing modern parts that meet current operational demands.

Today, the focus is not just on the functionality of parts but also on their compatibility with advanced technologies. Buyers must ensure that the parts they procure can seamlessly integrate with existing machinery and contribute to a more sustainable agricultural practice. This historical perspective equips buyers with the insights needed to make informed decisions in a rapidly changing marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a baler

1. How do I solve common issues with baler parts?

To address common issues with baler parts, first identify the specific problem—whether it’s related to the drive system, knotter, or bale chamber. Regular maintenance, including lubrication and inspections, can prevent many issues. When a part fails, consult your machine’s manual for troubleshooting tips, and consider sourcing replacement parts from reputable suppliers who offer OEM or high-quality aftermarket options. If the problem persists, collaborating with a service technician can provide insights into underlying issues that may not be immediately visible.

2. What is the best baler part for improving efficiency?

The best baler part for improving efficiency is often the knotter mechanism. A reliable knotter ensures that bales are securely tied, reducing the risk of unravelling during handling and storage. Additionally, investing in a high-quality pickup system can enhance hay collection and minimize losses during baling. Consider parts that are compatible with your specific baler model and look for upgrades that incorporate the latest technology to improve performance and reduce downtime.

3. How can I ensure the quality of baler parts when sourcing internationally?

To ensure the quality of baler parts when sourcing internationally, conduct thorough research on potential suppliers. Look for manufacturers with a solid reputation and positive reviews from other businesses. Request samples or certifications, such as ISO standards, to verify quality. Establish clear communication regarding specifications and quality assurance processes. Additionally, consider engaging a third-party inspection service to assess the parts before shipment to ensure they meet your requirements.

4. What are the minimum order quantities (MOQs) for baler parts?

Minimum order quantities (MOQs) for baler parts can vary significantly between suppliers and regions. Generally, MOQs may range from a few units to several hundred, depending on the part and the supplier’s production capabilities. When negotiating with suppliers, clarify the MOQ and explore options for smaller orders or bulk discounts. Some suppliers may offer flexibility for first-time buyers or during promotional periods, allowing you to test the market without committing to large quantities.

5. What payment terms should I expect when purchasing baler parts?

Payment terms for purchasing baler parts typically include options such as upfront payment, net 30 or net 60 days, or a letter of credit for larger transactions. Terms may vary based on the supplier’s policies, the order size, and your relationship with the supplier. It’s essential to discuss and agree upon payment terms before finalizing your order to avoid any misunderstandings. Consider using secure payment methods to protect your transaction, especially when dealing with international suppliers.

6. How do I vet suppliers of baler parts for reliability?

Vetting suppliers for reliability involves checking their history, client testimonials, and industry certifications. Request references from other businesses that have purchased similar parts and assess their response times, customer service, and after-sales support. Additionally, review their production capabilities, quality control processes, and whether they have a return or warranty policy. Engaging in direct communication with potential suppliers can also help gauge their professionalism and willingness to meet your specific needs.

7. What logistics considerations should I keep in mind when importing baler parts?

When importing baler parts, consider logistics factors such as shipping methods, customs regulations, and delivery times. Choose a reliable freight forwarder familiar with agricultural machinery to navigate customs efficiently. Understand the import duties and taxes applicable in your region, as these can impact overall costs. Additionally, ensure that the supplier provides proper documentation, including invoices and packing lists, to streamline the customs clearance process and avoid delays.

8. Can baler parts be customized for specific applications?

Yes, many baler parts can be customized to suit specific applications or operational requirements. When discussing your needs with suppliers, provide detailed specifications regarding the intended use, dimensions, and performance characteristics you require. Customization may involve modifying existing parts or fabricating new components based on your specifications. Be prepared for potential lead times and costs associated with custom orders, and ensure that the supplier can meet your quality standards throughout the process.

Top 7 Parts Of A Baler Manufacturers & Suppliers List

1. AGCO – Baler Parts

Domain: parts.agcocorp.com

Registered: 1996 (29 years)

Introduction: AGCO Parts Baler Parts include components such as Haydogs, Knife Pivots, Knotters & Elements, Liners, Needles & Protection, Pick-up Guide Bands, Tying & Twine Guides, Baler Belts, Draper Belts, and Harvest Drive Belts.

2. Baler Parts Online – EA-0031 Limit Switch

Domain: balerpartsonline.com

Registered: 2016 (9 years)

Introduction: Aftermarket Baler Parts for Balemaster and American Balers. Key products include: 1. EA-0031 (Limit Switch) – $293.94, compatible with Balemaster part number GXA00031, fits all Balemaster Balers. 2. Lift Cart for Baling Wire – $1,180.00, features 4″ x 1″ wheels, removable platform, adjustable forks, and a hand crank for lifting. 3. Ram Reline Kit – prices range from $10,121.56 to $15,598.30 depend…

3. Farmparts4less – Quality Baler Parts

Domain: farmparts4less.com

Registered: 2010 (15 years)

Introduction: Your One-Stop Shop for Quality Baler Parts – Farmparts4less.com offers a wide range of baler parts for all types of balers, including replacement belts, bearings, gears, and sprockets. All parts are sourced from reputable manufacturers to ensure quality and durability. The company stocks a wide range of parts in their warehouse for quick shipping.

4. PTR – Balers and Compactors

Domain: parts.ptrco.com

Registered: 2004 (21 years)

Introduction: {“company_name”: “PTR Baler and Compactor Company”, “shipping_info”: “Most Orders placed before 2PM will ship same day.”, “product_types”: [“Balers”, “Compactors”, “Self-Contained”, “Stationary”, “BACE”, “Marathon”, “Wastequip”, “Cart Tippers”, “Docks and Doors”, “Baling Wire”, “Hardware”, “Labels / Manuals”, “Aftermarket / Other Brands”], “featured_products”: [{“name”: “AEROSOL SPRAY PAINT PTR ST…

5. Herschel – Baler Poly Pick Up Bands

Domain: herschelparts.com

Registered: 2008 (17 years)

Introduction: {“category”:”Baler Parts”,”subcategories”:[“Pick Up Bands”,”Teeth”],”products”:[{“name”:”JD BALER POLY PICK UP BAND”,”item_number”:”H311772″,”price”:”$43.18″},{“name”:”CNH BALER POLY PICK UP BAND”,”item_number”:”H700129658″,”price”:”$43.18″},{“name”:”CNH BALER POLY PICK UP BAND”,”item_number”:”H84801631″,”price”:”$43.18″},{“name”:”NH BALER POLY PICK UP BAND”,”item_number”:”H86637149″,”price”:”$43….

6. Anis Trend – Baler Parts Overview

Domain: anis-trend.com

Registered: 2019 (6 years)

Introduction: Baler parts include: 1. Conveyor Belts and Chains – Used for transporting waste materials to the baler; requires maintenance for wear and tension. 2. Feeders – The entry point for materials, may crush or shred them; requires maintenance for guards and tines. 3. Hydraulic Components – Provide crushing power; often need replacement due to wear. 4. Hydraulic Cylinder – Main component for crushing pow…

7. John Deere – Replacement Parts for 1-4 Series Compact Tractors

Domain: shop.deere.com

Registered: 1990 (35 years)

Introduction: This company, John Deere – Replacement Parts for 1-4 Series Compact Tractors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for parts of a baler

In the evolving landscape of agricultural equipment, effective strategic sourcing for baler parts is vital for enhancing operational efficiency and minimizing downtime. By understanding the core components of balers—such as the bale chamber, pickup systems, drive mechanisms, and knotters—buyers can make informed decisions that directly impact productivity and cost-effectiveness. The integration of safety features and modern control systems further emphasizes the importance of selecting the right parts to optimize machine performance.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, aligning with reliable suppliers who offer high-quality OEM and aftermarket parts can lead to significant long-term benefits. Consideration of local market conditions, supplier reliability, and availability of spare parts can enhance your sourcing strategy and ensure seamless operations.

Looking ahead, the demand for efficient baling solutions will continue to grow as agricultural practices modernize. Therefore, now is the time to evaluate your sourcing strategies and partner with trusted suppliers who can provide the necessary parts and support. Invest in the future of your agricultural operations by prioritizing quality and reliability in your baler parts sourcing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to parts of a baler