Osmium Cube: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for osmium cube

In an increasingly competitive landscape, international B2B buyers face the challenge of sourcing osmium cubes, a rare and highly valuable material. With its unique properties—such as being the densest naturally occurring element and one of the hardest metals—osmium holds significant potential across various industries, from aerospace to electronics. However, navigating the complexities of the global market for osmium cubes requires a strategic approach to ensure quality, authenticity, and value.

This comprehensive guide delves into the nuances of osmium cubes, covering the different types available, their myriad applications, and essential supplier vetting processes. We will also provide insights into pricing structures and market trends, empowering buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—to make informed purchasing decisions.

By equipping B2B buyers with the knowledge needed to identify reliable suppliers and evaluate product quality, this guide aims to streamline the procurement process for osmium cubes. Whether you are seeking to enhance your product offerings or invest in this exceptional metal for its unique properties, understanding the global market landscape will be crucial to your success.

Understanding osmium cube Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 99.95% Pure Osmium Cube | Highest purity, standard size (10mm) | Research, luxury goods, investment | Pros: High value, recognized purity. Cons: Limited availability, high cost. |

| 99.999% Ultra-Pure Cube | Exceptional purity, customized dimensions available | Specialized industrial applications, electronics | Pros: Ideal for high-tech applications. Cons: Requires significant investment. |

| Osmium Alloy Cube | Composed of osmium with other metals | Aerospace, automotive, and heavy machinery | Pros: Enhanced properties, cost-effective. Cons: Lower value than pure osmium. |

| Osmium Nanoparticles | Nano-sized particles for advanced applications | Catalysis, biomedical research | Pros: Versatile use in cutting-edge technology. Cons: Handling precautions needed due to toxicity. |

| Custom-Made Osmium Cubes | Tailored to client specifications | High-end jewelry, art pieces | Pros: Unique offerings, potential for high margins. Cons: Longer lead times, higher production costs. |

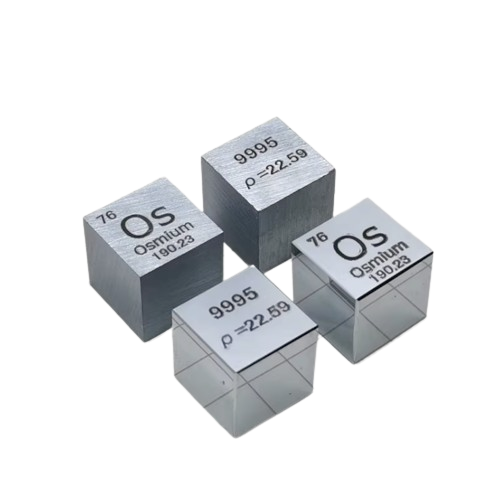

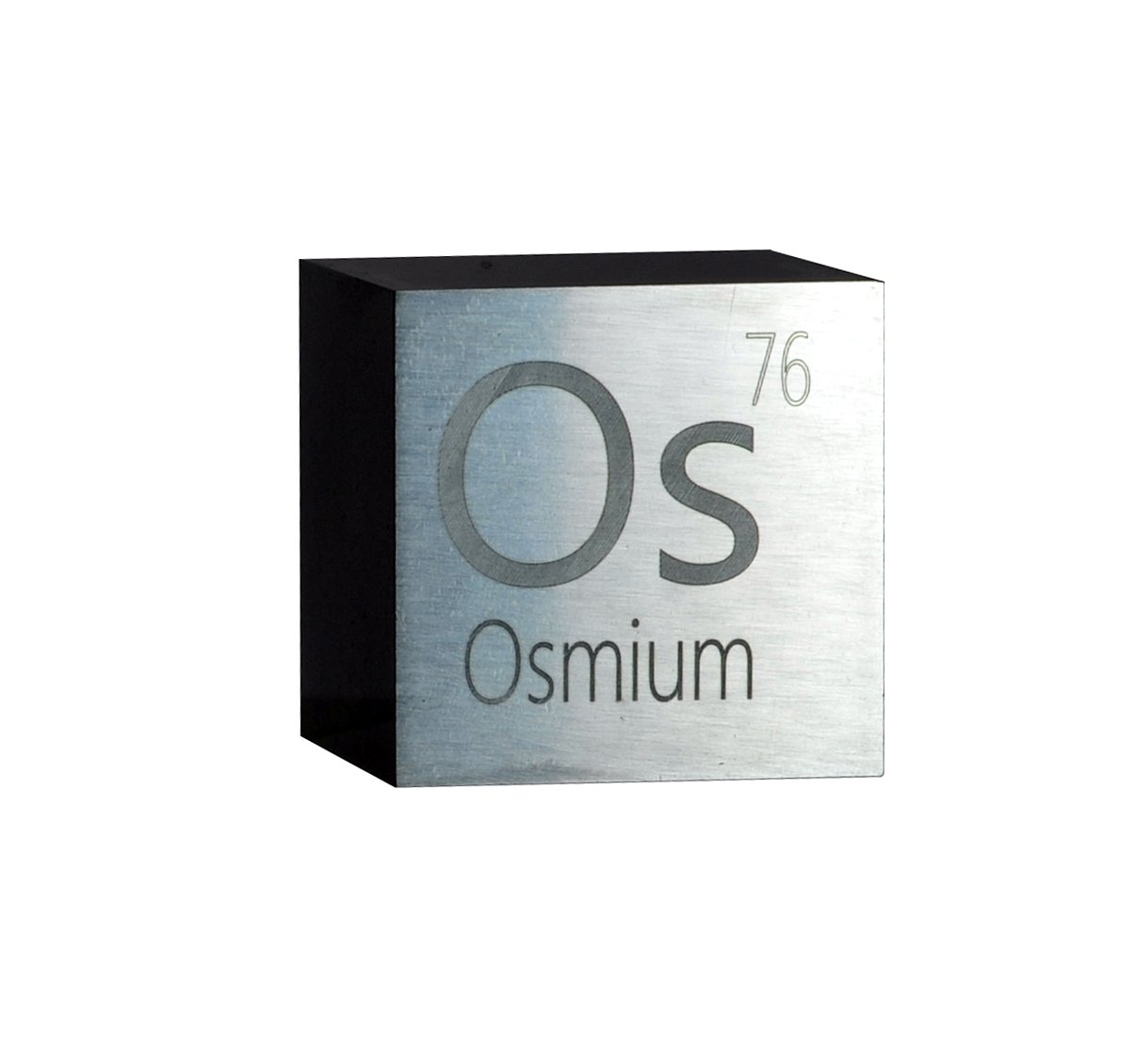

What Are the Key Characteristics of 99.95% Pure Osmium Cubes?

99.95% pure osmium cubes are the industry standard for various applications, particularly in research and investment. These cubes typically measure 10mm and are highly valued for their purity and density, making them suitable for luxury goods and collectibles. Buyers should consider that while they represent a significant investment, their limited availability and high cost can be challenging. However, their recognition in the market can assure buyers of their inherent value.

Illustrative image related to osmium cube

How Do 99.999% Ultra-Pure Osmium Cubes Differ from Standard Options?

99.999% ultra-pure osmium cubes are distinguished by their exceptional purity and the availability of custom dimensions. These cubes are essential for specialized industrial applications, particularly in electronics and high-tech sectors where purity is critical for performance. While they offer unmatched quality, buyers must be prepared for a significant investment, as the costs associated with ultra-pure materials can be substantial. The return on investment can be high for businesses requiring precise specifications.

Why Would Buyers Consider Osmium Alloy Cubes?

Osmium alloy cubes combine osmium with other metals to enhance specific properties, making them suitable for applications in aerospace, automotive, and heavy machinery. These alloys can provide a more cost-effective solution while still leveraging the unique attributes of osmium. Buyers may find these cubes appealing due to their improved mechanical properties and lower price point compared to pure osmium. However, they must weigh the trade-offs, as these alloys do not hold the same intrinsic value as pure osmium.

What Are the Advantages of Using Osmium Nanoparticles in Industry?

Osmium nanoparticles are revolutionizing industries such as catalysis and biomedical research due to their unique properties at the nanoscale. These particles are versatile and can be utilized in various cutting-edge technologies. However, buyers should be cautious about handling these materials, as osmium in nanoparticle form can pose health risks. The potential applications are vast, but companies must ensure they have the appropriate safety measures in place.

How Do Custom-Made Osmium Cubes Benefit Niche Markets?

Custom-made osmium cubes cater to niche markets such as high-end jewelry and unique art pieces. These cubes can be tailored to meet specific client requirements, allowing businesses to create exclusive products that can command high margins. While the uniqueness and potential for premium pricing are significant advantages, buyers should also consider longer lead times and higher production costs associated with custom orders. This option is ideal for businesses looking to differentiate themselves in a competitive market.

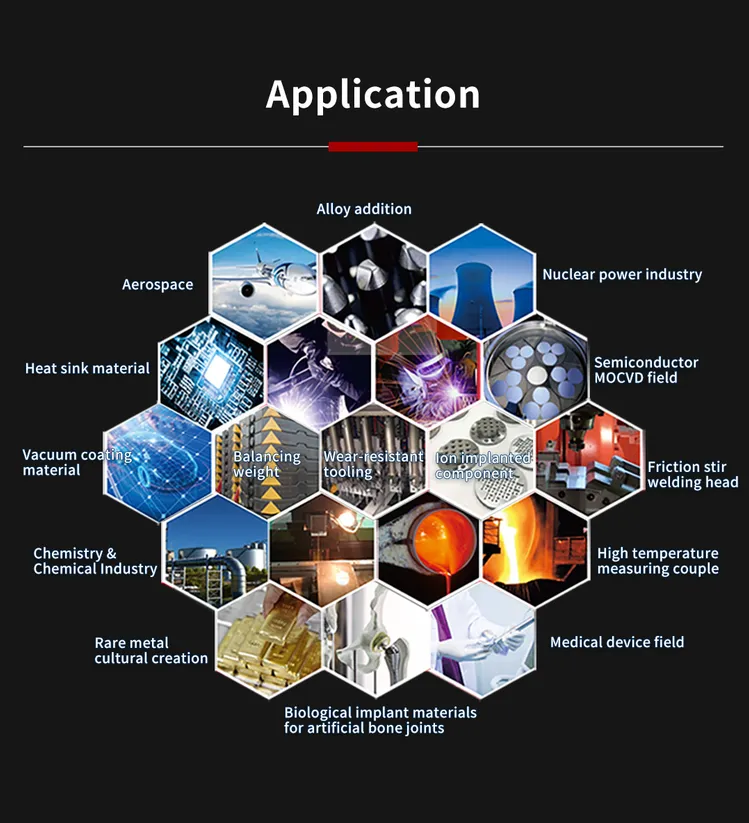

Key Industrial Applications of osmium cube

| Industry/Sector | Specific Application of osmium cube | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components in aircraft engines | Enhances durability and performance under extreme conditions | Ensure compliance with aerospace material standards and certifications |

| Electronics | High-density contacts and connectors | Improves electrical conductivity and reduces size | Focus on purity levels and specific dimensions to meet design requirements |

| Medical Devices | Diagnostic and imaging equipment | Increases the effectiveness and reliability of medical tools | Verify biocompatibility and adherence to medical regulations |

| Jewelry and Luxury Goods | Exclusive luxury items | Offers unique value propositions due to rarity and prestige | Source from reputable suppliers to ensure authenticity and quality |

| Research and Development | Experimental applications in materials science | Enables innovative research in high-performance materials | Consider custom dimensions and specialized packaging for sensitive applications |

How is Osmium Cube Used in Aerospace Applications?

In the aerospace industry, osmium cubes are utilized to manufacture precision components for aircraft engines. Due to osmium’s exceptional hardness and density, parts made from this metal can withstand extreme temperatures and pressures, which is critical for engine performance and safety. International buyers, particularly from regions like Africa and the Middle East, should prioritize suppliers who adhere to aerospace material standards to ensure reliability and compliance with safety regulations.

What Role Does Osmium Cube Play in Electronics?

Osmium cubes find applications in the electronics sector, specifically in the production of high-density contacts and connectors. Their superior electrical conductivity allows for the creation of smaller, more efficient components, which is essential in modern electronics. Buyers from Europe and South America should focus on sourcing osmium that meets specific purity levels and dimensions to ensure compatibility with their design requirements and performance expectations.

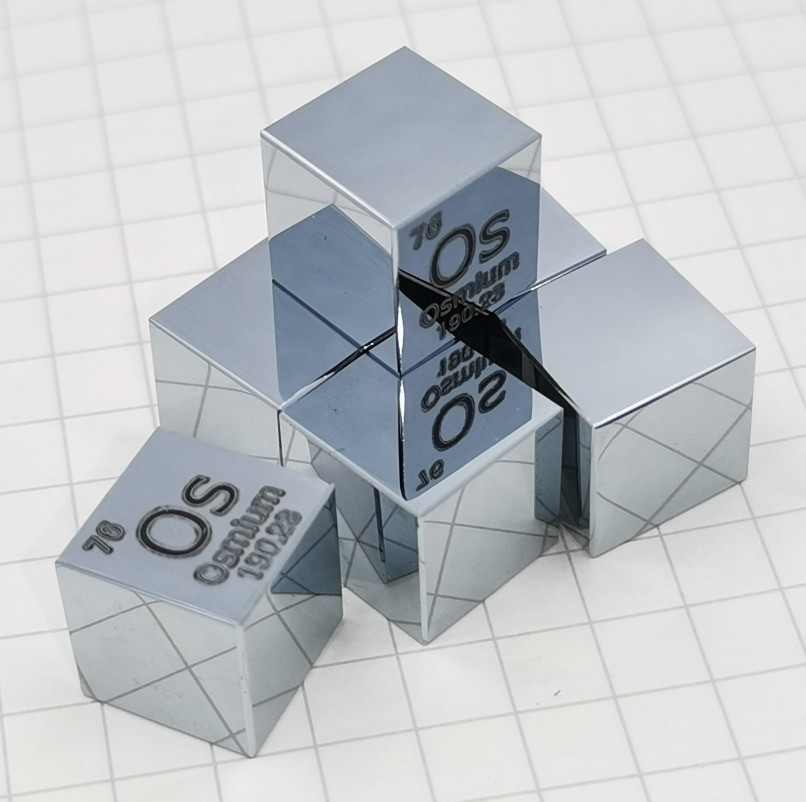

Illustrative image related to osmium cube

Why is Osmium Cube Important for Medical Devices?

In the medical device industry, osmium cubes are employed in diagnostic and imaging equipment, enhancing the effectiveness and reliability of these critical tools. The unique properties of osmium contribute to improved imaging resolution and durability. B2B buyers in this sector, particularly from regions like Nigeria and Saudi Arabia, must ensure that the osmium sourced meets stringent biocompatibility standards and complies with relevant medical regulations to guarantee patient safety.

How Does Osmium Cube Enhance Luxury Goods?

Osmium cubes are increasingly used in the jewelry and luxury goods market, serving as exclusive components in high-end items. The rarity and unique characteristics of osmium create significant value propositions for luxury brands looking to differentiate themselves. Buyers in this sector should prioritize sourcing from reputable suppliers to ensure authenticity and quality, as the market for luxury goods is heavily reliant on brand trust and product integrity.

What is the Research Potential of Osmium Cube?

In research and development, osmium cubes are critical for experimental applications in materials science. Their unique properties enable researchers to explore high-performance materials, contributing to innovations across various fields. Buyers from international research institutions should consider sourcing custom dimensions and specialized packaging to protect the integrity of osmium during shipping and handling, as these factors can significantly impact research outcomes.

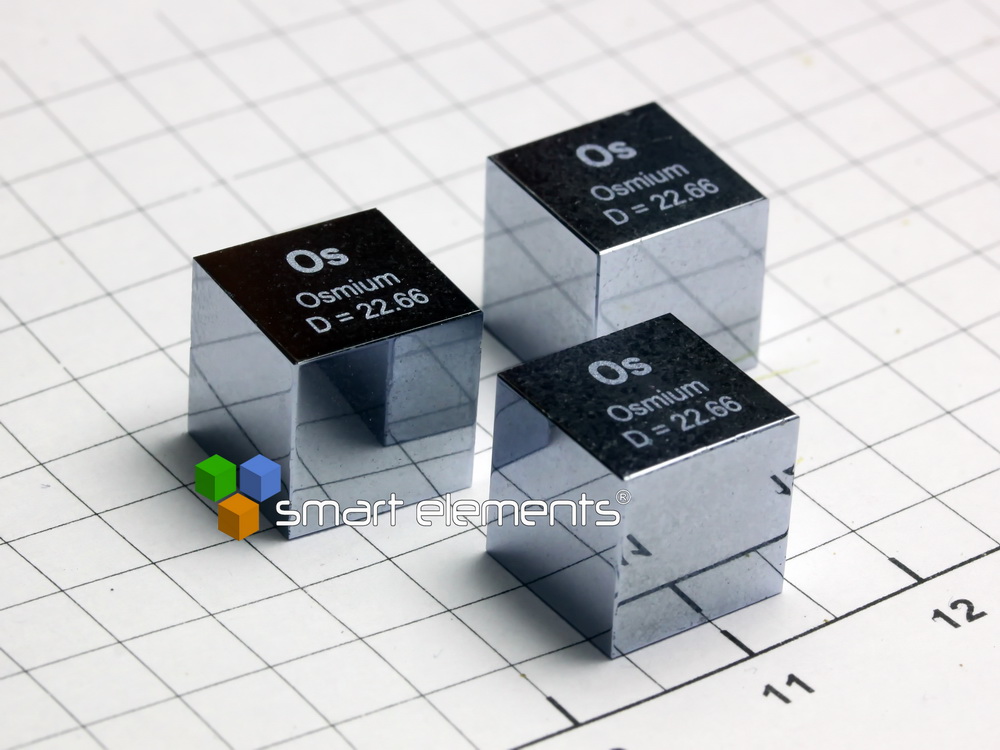

Illustrative image related to osmium cube

3 Common User Pain Points for ‘osmium cube’ & Their Solutions

Scenario 1: Sourcing High-Quality Osmium Cubes for Specialized Applications

The Problem: B2B buyers often face challenges when sourcing osmium cubes due to the rarity and high demand for this precious metal. Many suppliers may not provide the necessary quality assurance or technical specifications, leading to concerns about the reliability of the product for specialized applications such as research, aerospace, or high-precision manufacturing. Buyers may also encounter difficulties in finding suppliers that can meet stringent quality requirements, which is critical for ensuring safety and compliance in their operations.

The Solution: To effectively source high-quality osmium cubes, buyers should focus on identifying reputable suppliers with a proven track record in handling rare metals. They should request detailed specifications, including purity levels (preferably 99.99% or higher), dimensional accuracy, and certifications such as ISO or ASTM compliance. Establishing a direct line of communication with suppliers can help clarify any technical queries and ensure that the osmium cubes meet the intended application requirements. Additionally, buyers can consider visiting manufacturing facilities or arranging for third-party testing to validate the quality before committing to large orders.

Scenario 2: Understanding the Safe Handling and Storage of Osmium Cubes

The Problem: Due to osmium’s unique properties and its potential toxicity in certain forms (e.g., osmium tetroxide), B2B buyers often struggle with understanding the safety protocols for handling and storing osmium cubes. Mismanagement in this area can lead to safety hazards, regulatory compliance issues, and financial losses from accidents or contamination.

The Solution: It is essential for buyers to implement comprehensive safety protocols when working with osmium cubes. First, they should familiarize themselves with the safety data sheets (SDS) provided by suppliers, which detail handling, storage, and emergency measures. Buyers should also invest in appropriate personal protective equipment (PPE) for their staff, including gloves and safety goggles, to minimize exposure risks. For storage, osmium cubes should be kept in a cool, dry place, preferably in sealed containers to prevent contamination. Regular training sessions for employees on safe handling practices will further enhance workplace safety and compliance.

Scenario 3: Navigating the High Costs of Osmium Cubes

The Problem: The high cost associated with osmium cubes can be a significant barrier for B2B buyers, particularly in regions with fluctuating market prices or limited access to suppliers. This financial strain can hinder project budgets and affect overall profitability, making it crucial for buyers to find cost-effective solutions without compromising on quality.

The Solution: To navigate the high costs of osmium cubes, buyers should explore bulk purchasing options or long-term contracts with suppliers to secure more favorable pricing. Conducting market research to identify suppliers in different regions can also uncover more competitive pricing. Additionally, buyers can consider alternative materials or alloys that may offer similar properties at a lower cost for certain applications. Engaging in collaborative purchasing with other companies or industry partners can further reduce expenses while ensuring access to high-quality osmium cubes when needed. By strategically managing procurement processes, buyers can optimize their budgets while maintaining the integrity of their projects.

Strategic Material Selection Guide for osmium cube

What Are the Key Properties of Osmium for B2B Applications?

Osmium is a unique metal known for its exceptional density, hardness, and rarity. With a density of approximately 22.59 grams per cubic centimeter, it stands as the densest naturally occurring element. This property makes osmium cubes highly suitable for applications requiring compactness and weight. Additionally, osmium has a high melting point (3045 °C) and low compressibility, making it ideal for high-temperature environments. However, its rarity and the complexity of manufacturing processes can pose challenges for international buyers.

What Are the Pros and Cons of Using Osmium for Manufacturing Cubes?

The advantages of osmium cubes include their unparalleled hardness and resistance to wear, making them suitable for precision instruments and high-stress applications. Their exceptional durability ensures a long lifespan, reducing the need for frequent replacements. However, the primary drawback is the high cost associated with osmium, which is significantly more expensive than more common metals. The manufacturing complexity also poses challenges, as specialized equipment and expertise are required to work with osmium, limiting the number of suppliers capable of producing high-quality osmium cubes.

How Does Osmium Impact Specific Applications?

In applications such as precision engineering and high-performance components, osmium’s unique properties allow for the creation of parts that can withstand extreme conditions. Its low compressibility and high melting point make it suitable for use in environments where other materials might fail. However, the rarity of osmium means that supply may be limited, which can impact production timelines and costs. For international buyers, understanding the specific applications and ensuring compatibility with existing systems is crucial.

Illustrative image related to osmium cube

What Should International B2B Buyers Consider When Sourcing Osmium Cubes?

For buyers from regions such as Africa, South America, the Middle East, and Europe, compliance with international standards like ASTM, DIN, and JIS is essential. Buyers should ensure that suppliers can provide documentation, including Certificates of Analysis and Safety Data Sheets. Additionally, considering the logistics of sourcing such a rare material is vital; potential buyers must account for shipping costs, import regulations, and possible tariffs. Establishing relationships with reliable suppliers who understand the nuances of the osmium market can facilitate smoother transactions.

Summary Table of Material Considerations for Osmium Cube

| Material | Typical Use Case for osmium cube | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Osmium | Precision engineering, high-performance components | Exceptional hardness and durability | High cost and manufacturing complexity | High |

| Rhenium | Aerospace and electronics | High melting point and excellent corrosion resistance | Less dense than osmium, potentially lower performance | Med |

| Iridium | High-temperature applications, spark plugs | Good corrosion resistance and high density | More abundant but still expensive | Med |

| Platinum | Jewelry, electronics, and catalysts | Excellent corrosion resistance and malleability | Less dense than osmium, lower hardness | High |

This analysis provides B2B buyers with a comprehensive understanding of osmium cubes, highlighting key properties, advantages, and considerations for sourcing in international markets. By evaluating these factors, buyers can make informed decisions that align with their specific needs and applications.

In-depth Look: Manufacturing Processes and Quality Assurance for osmium cube

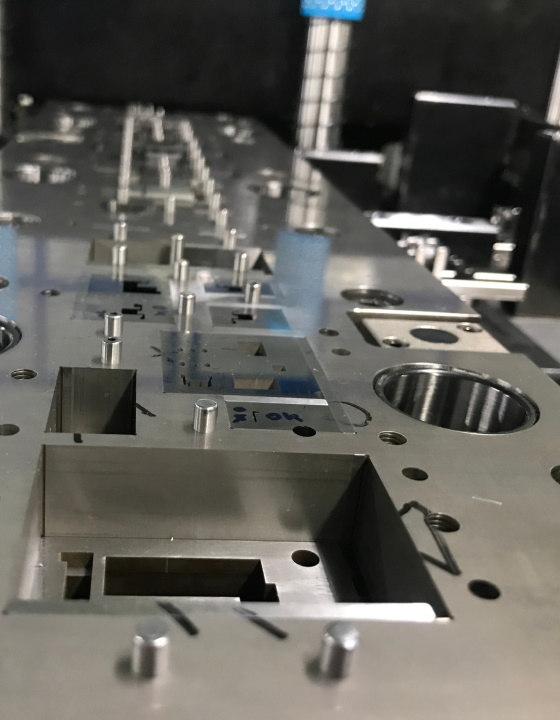

What Are the Key Stages in the Manufacturing Process of Osmium Cubes?

The manufacturing of osmium cubes involves several critical stages, each of which requires precision and expertise due to the unique properties of osmium. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to osmium cube

Material Preparation: How Is Osmium Processed for Cube Production?

The process begins with sourcing high-purity osmium, which is typically obtained from specialized suppliers. Given its rarity, the procurement of osmium requires strict adherence to quality standards. Suppliers often provide osmium in various forms, including powder or granules. The material is then subjected to rigorous purification processes to ensure it meets the necessary specifications, often aiming for purity levels of 99.9% or higher.

Once the osmium is purified, it undergoes an evaluation to determine its physical properties. This includes assessments of density, melting point, and other metallurgical characteristics essential for the subsequent manufacturing stages. Proper documentation of these properties is critical, especially for international buyers who may require certifications.

Forming: What Techniques Are Used to Create Osmium Cubes?

The forming stage involves converting the prepared osmium into the desired cube shape. This is achieved through precision engineering techniques, often utilizing methods like arc melting or powder metallurgy.

-

Arc Melting: This technique involves melting osmium in a vacuum or inert gas atmosphere, which helps to prevent oxidation. The molten osmium is poured into a cube-shaped mold, allowing it to solidify into a precise shape.

-

Powder Metallurgy: This method involves compacting osmium powder into a mold and then sintering it at high temperatures to form a solid piece. This technique is particularly useful for achieving uniform density and microstructure.

Quality control begins at this stage, with manufacturers checking dimensional tolerances and ensuring the integrity of the formed pieces.

Assembly: How Are Osmium Cubes Finalized?

While osmium cubes typically do not require assembly in the traditional sense, any additional features or branding (such as engraving) must be carefully integrated. This stage focuses on ensuring that all aesthetic and functional specifications are met.

In cases where osmium is combined with other materials (for example, in jewelry or commemorative pieces), meticulous attention to detail is necessary to maintain the quality and appearance of the final product.

Finishing: What Processes Ensure the Quality of Osmium Cubes?

The finishing stage involves polishing the cubes to achieve the desired surface quality. This can include multiple polishing techniques to enhance the natural luster of osmium. The goal is to create a smooth, aesthetically pleasing finish that meets high standards.

Additional testing at this stage might include checks for surface defects and dimensional accuracy. This ensures that the final product not only meets visual standards but also complies with technical specifications.

What Quality Assurance Standards Are Relevant for Osmium Cube Manufacturing?

Quality assurance is paramount in the production of osmium cubes, particularly given the material’s high value and unique characteristics. Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system.

Illustrative image related to osmium cube

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that each stage meets the required standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt. For osmium, this means verifying purity and quality documentation from suppliers.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to ensure that the forming and finishing processes adhere to specifications.

-

Final Quality Control (FQC): Once the osmium cubes are completed, they undergo final inspections. This includes dimensional checks, surface quality assessments, and tests for physical properties.

Which Testing Methods Are Commonly Used for Quality Assurance?

A variety of testing methods are employed in the QC process, including:

-

Spectroscopy: Used to verify the purity of osmium by analyzing its elemental composition.

-

Dimensional Measurement: Tools like calipers and coordinate measuring machines (CMM) ensure that the dimensions of the cubes meet specified tolerances.

-

Hardness Testing: This assesses the hardness of the osmium cubes, ensuring they meet industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies to ensure compliance:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes and quality control systems firsthand.

-

Requesting Quality Reports: Buyers should ask for detailed QC reports that include results from various tests conducted during the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices.

What Are the Nuances of Quality Certification for International Buyers?

International buyers should be aware of the specific certifications that may apply to osmium cubes. Different regions may have varying regulations and standards. For instance:

-

CE Marking: For products sold within the European Economic Area, ensuring compliance with CE marking standards can be essential.

-

API Certification: If the osmium cubes are intended for use in medical or pharmaceutical applications, API certification may be necessary.

Buyers should also consider the implications of import/export regulations, particularly concerning the transport of precious metals like osmium. Understanding these nuances can greatly assist in ensuring compliance and maintaining quality throughout the supply chain.

Conclusion

In summary, the manufacturing and quality assurance processes for osmium cubes are complex and necessitate a high degree of precision and quality control. By understanding the key stages of manufacturing, relevant quality standards, and verification methods, B2B buyers can make informed decisions when sourcing osmium cubes from global suppliers. This diligence not only ensures product quality but also fosters trust and reliability in international trade relationships.

Illustrative image related to osmium cube

Practical Sourcing Guide: A Step-by-Step Checklist for ‘osmium cube’

Introduction

Navigating the procurement of osmium cubes requires careful planning and attention to detail due to the metal’s rarity and high value. This guide provides a comprehensive checklist to help B2B buyers streamline their sourcing process. By following these steps, you can ensure that you select a reliable supplier and secure high-quality products that meet your specific requirements.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical specifications for the osmium cubes you require. Consider factors such as purity levels (e.g., 99.95% or higher), dimensions, and any specific certifications needed for your industry. Precise specifications will help you communicate effectively with suppliers and avoid misunderstandings later in the process.

Step 2: Research Potential Suppliers

Invest time in researching potential suppliers who specialize in high-purity osmium products. Look for companies with a proven track record and experience in handling rare materials. Utilize online resources, trade shows, and industry forums to gather information and reviews about suppliers’ reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 for quality management and compliance with environmental regulations are essential indicators of a supplier’s credibility. Additionally, request documentation like Safety Data Sheets (SDS) to ensure that the products meet safety and handling requirements.

Illustrative image related to osmium cube

Step 4: Request Quotes and Compare Pricing

Once you have identified a shortlist of suppliers, request detailed quotes that include pricing, delivery timelines, and payment terms. Compare these quotes not just on price but also on the value offered, including service levels, shipping options, and after-sales support. Be cautious of significantly lower prices, as they may indicate inferior quality or hidden costs.

Step 5: Conduct Due Diligence on Suppliers

Before finalizing your order, conduct thorough due diligence on your chosen suppliers. This may include checking references from other clients, examining case studies, and assessing their production capabilities. A supplier’s ability to meet your specifications consistently is critical, especially for rare materials like osmium.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to finalize terms and conditions that protect your interests. Discuss factors such as payment methods, delivery schedules, and return policies. Clear agreements can prevent disputes and ensure a smooth transaction, particularly given the high value of osmium cubes.

Step 7: Plan for Logistics and Handling

Once the procurement process is underway, plan for the logistics of transporting and handling osmium cubes. Due to their density and value, special handling may be required. Ensure that your team is familiar with the necessary safety protocols and packaging requirements to maintain the integrity of the product during transit.

By following this checklist, you can streamline your procurement process for osmium cubes, minimizing risks and maximizing the value of your investment.

Comprehensive Cost and Pricing Analysis for osmium cube Sourcing

What Are the Key Cost Components for Sourcing Osmium Cubes?

When sourcing osmium cubes, several cost components contribute to the overall price. The primary elements include:

-

Materials: Osmium is one of the rarest elements, with a market price significantly influenced by its scarcity. The cost of raw osmium can fluctuate based on global supply and demand dynamics, making it a critical factor in the pricing structure.

-

Labor: The production of osmium cubes involves specialized labor, as the material requires precise handling and machining to ensure quality. Skilled labor is often necessary for tasks such as cutting, polishing, and quality assurance, which adds to the labor costs.

-

Manufacturing Overhead: This includes the expenses associated with running a manufacturing facility, such as utilities, equipment maintenance, and administrative costs. Given the niche nature of osmium production, these overheads can represent a significant portion of the total cost.

-

Tooling: The production of osmium cubes necessitates specialized tooling and equipment, which can be expensive. Tooling costs can vary based on the complexity of the cube designs and the precision required.

-

Quality Control (QC): Rigorous quality control is essential to ensure that the osmium cubes meet the required specifications. The costs associated with QC processes, including testing and certification, must be factored into the pricing.

-

Logistics: Given the high value and density of osmium, logistics costs can be substantial. This includes transportation fees, insurance, and customs duties, particularly for international shipments.

-

Margin: Suppliers typically incorporate a profit margin that reflects their operational risks and market positioning. This margin can vary widely based on the supplier’s business model and market conditions.

How Do Price Influencers Affect Osmium Cube Costs?

Several factors influence the pricing of osmium cubes, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should consider negotiating for bulk pricing, especially if they anticipate ongoing needs.

-

Specifications and Customization: Custom designs or specific purity levels can significantly impact the price. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher purity osmium (e.g., 99.95% vs. 99.999%) generally commands a premium. Additionally, certifications such as ISO or ASTM can add to the cost due to the rigorous testing and compliance required.

-

Supplier Factors: The reputation and location of suppliers can affect pricing. Established suppliers with a track record of reliability may charge more, but they often provide better quality assurance.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) can influence the total landed cost. Buyers should understand these terms to fully grasp the cost implications of logistics.

What Are the Best Practices for Negotiating Osmium Cube Prices?

To effectively negotiate prices for osmium cubes, buyers should consider the following strategies:

-

Conduct Market Research: Understanding the market landscape and current pricing trends can empower buyers during negotiations. This includes researching different suppliers and their offerings.

-

Leverage Volume Discounts: If possible, consolidate orders to meet minimum order quantities, which can lead to more favorable pricing.

-

Request Multiple Quotes: Obtaining quotes from various suppliers allows buyers to compare prices and negotiate better terms based on competitive offers.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the total cost over the lifecycle of the product, including maintenance, logistics, and potential resale value.

-

Be Aware of Pricing Nuances in International Trade: For buyers from regions like Africa, South America, the Middle East, and Europe, fluctuations in currency exchange rates, local tariffs, and import regulations can affect overall costs. Being informed about these factors can aid in negotiating better deals.

Conclusion: What Should Buyers Keep in Mind Regarding Osmium Cube Pricing?

While osmium cubes represent a niche market with high-value components, understanding the cost structure and pricing influencers can help buyers make informed decisions. It is advisable to approach sourcing with a strategic mindset, focusing on long-term partnerships with reliable suppliers and considering all elements of the total cost of ownership. Given the variability in prices and the unique nature of osmium, potential buyers should be prepared for fluctuations and engage in thorough negotiations to secure the best possible terms.

Alternatives Analysis: Comparing osmium cube With Other Solutions

Understanding Alternatives for Osmium Cube in B2B Applications

In the realm of specialized metals, osmium cube stands out due to its unique properties such as extreme density, rarity, and hardness. However, buyers often seek alternatives that may offer similar functionalities at different costs or with varied implementation requirements. This analysis compares osmium cubes with other viable alternatives, providing B2B buyers with insights to make informed decisions.

Comparison Table

| Comparison Aspect | Osmium Cube | Alternative 1: Iridium Cube | Alternative 2: Tungsten Cube |

|---|---|---|---|

| Performance | Highest density, hardness | High corrosion resistance, good hardness | Excellent thermal and electrical conductivity |

| Cost | Extremely high (gold-level pricing) | High, but generally lower than osmium | Moderate, significantly lower than osmium |

| Ease of Implementation | Requires specialized suppliers, limited availability | More readily available, easier sourcing | Widely available, common in industrial applications |

| Maintenance | Minimal, but requires careful handling due to toxicity | Minimal, stable under normal conditions | Low, robust against wear and tear |

| Best Use Case | Niche applications requiring extreme density and hardness | High-performance electronics, aerospace | General manufacturing, tooling, and electrical applications |

Detailed Breakdown of Alternatives

Iridium Cube

Iridium is another member of the platinum group metals and is known for its high corrosion resistance and durability. While it offers comparable hardness and density to osmium, it is more readily available and slightly less expensive. Iridium cubes are ideal for applications in high-performance electronics and aerospace, where corrosion resistance is critical. However, iridium’s performance may not match osmium’s in applications requiring the utmost density, making it a less suitable choice for specific niche markets.

Tungsten Cube

Tungsten is renowned for its high melting point, strength, and excellent thermal and electrical conductivity. It is significantly more affordable than osmium and iridium, making it a popular choice in various industrial applications. Tungsten cubes are widely used in manufacturing, tooling, and electrical applications due to their robustness and durability. However, they do not match osmium’s density and hardness, which may limit their effectiveness in specialized applications that require those specific attributes.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between osmium cubes and their alternatives, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and availability. Osmium cubes offer unparalleled density and hardness but come at a premium cost and require specialized sourcing. In contrast, alternatives like iridium and tungsten provide viable options with unique benefits, such as lower costs and easier availability, though they may not fully replicate osmium’s superior attributes. Ultimately, the right choice will depend on balancing performance needs with financial considerations and supply chain logistics.

Essential Technical Properties and Trade Terminology for osmium cube

Osmium cubes, a rare and valuable form of osmium metal, possess unique technical properties and trade terminology that are essential for B2B buyers, particularly in industries such as jewelry, electronics, and scientific research. Understanding these aspects can significantly enhance purchasing decisions and strategic sourcing.

What Are the Key Technical Properties of Osmium Cubes?

1. Material Grade

Osmium cubes are typically available in various purity grades, ranging from 99% to 99.999%. Higher grades indicate fewer impurities, which is crucial for applications requiring high-performance materials, such as aerospace and medical devices. Buyers must assess the purity levels needed for their specific applications to ensure optimal performance and compliance with industry standards.

2. Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For osmium cubes, a standard tolerance is ±0.1 mm for precision machining. Tight tolerances are vital for applications that demand exact specifications, such as in precision engineering or as calibration standards in laboratories. Buyers should specify their tolerance requirements in their orders to avoid discrepancies that could affect project outcomes.

3. Density

With a density of approximately 22.59 g/cm³, osmium is the densest naturally occurring element. This property is significant for applications requiring weight and durability, such as counterweights in machinery or as a component in high-density alloys. Understanding density helps buyers evaluate the material’s suitability for their specific needs and informs shipping and handling logistics.

4. Melting and Boiling Points

Osmium has a melting point of around 3045 °C and a boiling point of 5027 °C. These high thermal thresholds make it suitable for applications exposed to extreme temperatures, such as in high-performance electronics or specialized industrial processes. Buyers should consider these thermal properties when assessing the material for use in high-temperature environments.

5. Vickers Hardness

Osmium ranks among the hardest metals, with a Vickers hardness of approximately 3920 MPa. This hardness makes osmium cubes resistant to wear and scratching, which is valuable in applications such as jewelry and high-wear industrial components. Buyers should consider hardness when selecting materials for durability and longevity.

What Trade Terminology Should Buyers Understand When Purchasing Osmium Cubes?

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers sourcing osmium cubes for integration into larger systems or products.

Illustrative image related to osmium cube

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers should inquire about MOQs to ensure they can meet purchasing requirements without overcommitting to excess inventory, especially given the high cost and rarity of osmium.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities and specifications. Issuing an RFQ is a standard practice in B2B transactions, enabling buyers to compare offers and negotiate better terms for osmium purchases.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in shipping and logistics. Understanding Incoterms is essential for buyers to clarify shipping costs, risk, and delivery responsibilities associated with osmium cube transactions.

5. SDS (Safety Data Sheet)

SDS provides detailed information about the properties, handling, and hazards of a material. Buyers should request SDS for osmium cubes to ensure compliance with safety regulations and to implement appropriate handling procedures.

By understanding these critical technical properties and trade terms, B2B buyers can make informed decisions when sourcing osmium cubes, ultimately ensuring the success of their projects and operations.

Navigating Market Dynamics and Sourcing Trends in the osmium cube Sector

What Are the Current Market Dynamics and Key Trends in the Osmium Cube Sector?

The osmium cube market is characterized by its rarity and high demand among niche industries. Global drivers for osmium’s appeal include its unique physical properties, such as exceptional density and hardness, making it valuable for applications in high-performance materials and electronics. The limited availability, with osmium being the least abundant stable element, contributes to its premium pricing, often exceeding that of gold.

Emerging B2B sourcing trends indicate a shift towards digital platforms for procurement, enabling buyers from regions like Africa, South America, the Middle East, and Europe to access global suppliers more efficiently. E-commerce platforms and specialized marketplaces are gaining traction, allowing businesses to compare offerings and secure competitive pricing. Additionally, as technology advances, manufacturers are exploring innovative methods of production, such as precision machining and advanced metallurgy, to create customized osmium products. This trend is particularly relevant for buyers looking for specific dimensions or purity levels, enhancing the market’s responsiveness to customer needs.

How Does Sustainability and Ethical Sourcing Impact the Osmium Cube Supply Chain?

Sustainability and ethical sourcing are increasingly critical in the osmium cube sector. The environmental impact of mining and refining osmium—primarily sourced as a byproduct of platinum—requires careful management to minimize ecological damage. Responsible sourcing practices include ensuring that suppliers adhere to environmental regulations and support local communities affected by mining activities.

Illustrative image related to osmium cube

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for suppliers who can provide transparency in their sourcing methods, including certifications that demonstrate adherence to environmental and social governance (ESG) standards. This demand for accountability has led to the emergence of ‘green’ certifications that can enhance the marketability of osmium products. Suppliers who can demonstrate a commitment to sustainability not only attract environmentally conscious buyers but also differentiate themselves in a competitive landscape.

What Is the Brief Evolution and History of Osmium in the B2B Market?

Osmium’s history dates back to its discovery in 1803 by Smithson Tennant. Initially recognized for its unique properties, osmium remained a curiosity for many years due to its scarcity and the challenges associated with its extraction and processing. The use of osmium in industrial applications began to gain traction in the early 20th century, primarily in niche markets such as electronics and high-precision instruments.

As global demand for high-performance materials grew, osmium found a place in various specialized applications, from fountain pen nibs to electrical contacts. The introduction of osmium cubes as a product line has further broadened the market, appealing to collectors and industries seeking premium materials. The evolution of osmium from a little-known element to a highly sought-after commodity illustrates the changing dynamics of material sourcing in the B2B sector, driven by technological advancements and increasing awareness of its unique attributes.

Frequently Asked Questions (FAQs) for B2B Buyers of osmium cube

-

1. What are the key properties of osmium cubes that make them unique?

Osmium cubes are renowned for their exceptional density, being the densest naturally occurring element at approximately 22.59 grams per cubic centimeter. Their rarity is another significant factor; osmium is one of the rarest elements, found at about 1 part per billion in the Earth’s crust. Additionally, osmium exhibits impressive hardness, ranking just behind diamond and chromium. These properties make osmium cubes not only valuable for collectors but also suitable for specialized industrial applications, including electronics and high-performance materials. -

2. What should I consider when sourcing osmium cubes internationally?

When sourcing osmium cubes, it’s crucial to evaluate the supplier’s reputation and reliability. Look for suppliers who provide certifications of authenticity and quality assurance, such as Certificates of Analysis. Additionally, verify their compliance with international standards and regulations, especially if you’re importing into regions with stringent import laws. Understanding the supplier’s logistics capabilities, including shipping times and costs, is also vital to ensure timely delivery. -

3. Are there customization options available for osmium cubes?

Yes, many suppliers offer customization options for osmium cubes, such as varying dimensions and purity levels. You can request specific sizes or finishes to meet your project requirements. Customization may also include branding or engraving, particularly for promotional purposes. However, be prepared for longer lead times for custom orders, as they may require special manufacturing processes. -

4. What are the minimum order quantities (MOQ) for osmium cubes?

Minimum order quantities for osmium cubes can vary significantly between suppliers. While some may allow orders as low as one cube, others might require larger quantities to justify production and shipping costs. It’s advisable to discuss your specific needs with suppliers to understand their MOQ policies. Additionally, negotiating terms may be possible, especially if you are considering long-term partnerships. -

5. What payment terms are typically offered for osmium cube purchases?

Payment terms for osmium cube purchases can differ based on supplier policies and the buyer’s creditworthiness. Common terms include upfront payments, partial payments upon order confirmation, or payment upon delivery. Some suppliers may also offer net payment terms, allowing a set period post-delivery for payment. Always clarify payment terms in advance to avoid misunderstandings and ensure a smooth transaction. -

6. How can I ensure quality assurance when purchasing osmium cubes?

To ensure quality assurance when purchasing osmium cubes, request detailed documentation from your supplier, including Certificates of Analysis and compliance with international standards. Conduct due diligence by checking customer reviews and testimonials. If possible, request sample products before placing a larger order. Establishing a clear communication channel with the supplier will also help address any concerns regarding quality and specifications. -

7. What logistics considerations should I keep in mind when importing osmium cubes?

When importing osmium cubes, consider logistics factors such as shipping methods, costs, and customs regulations. Choose a reliable freight forwarder experienced in handling precious metals to ensure smooth transportation. Be aware of the import duties and taxes applicable in your country, as these can significantly impact the overall cost. Additionally, ensure that proper documentation, including a Bill of Lading and customs declarations, is prepared to avoid delays. -

8. What industries commonly utilize osmium cubes, and for what applications?

Osmium cubes are utilized across various industries, particularly in electronics, medical devices, and high-performance engineering applications. Their high density and durability make them suitable for components requiring extreme hardness and resistance to wear. In the luxury goods sector, osmium is also gaining traction for use in high-end jewelry and collectible items. Understanding these applications can help B2B buyers identify potential markets for resale or incorporation into their products.

Top 7 Osmium Cube Manufacturers & Suppliers List

1. Luciteria – Osmium Metal Cube 99.95%

Domain: luciteria.com

Registered: 2014 (11 years)

Introduction: Osmium Metal Cube 99.95% – Price: from $1.00 – Density: 22.59 grams per cubic centimeter (densest naturally occurring element) – Rarity: Estimated concentration of 1 part per billion in Earth’s crust (one of the rarest stable elements) – Cost: Most expensive metal on the market for any given designed shape – Compressibility: Least compressible solid matter (except neutron stars and black holes) – …

2. Reddit – 1.5 Osmium Cube

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1.5″ cube of osmium, weighs more than 1.1kg, largest piece made, technical exploration for future 50mm osmium cubes.

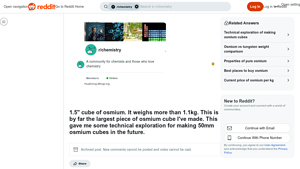

3. American Elements – Osmium Cubes

Domain: americanelements.com

Registered: 1998 (27 years)

Introduction: {‘product_name’: ‘Osmium Cubes’, ‘CAS_number’: ‘7440-04-2’, ‘linear_formula’: ‘Os’, ‘MDL_number’: ‘MFCD00011147’, ‘EC_number’: ‘231-114-0’, ‘product_code’: ‘OS-M-02-CB, OS-M-03-CB, OS-M-04-CB, OS-M-05-CB’, ‘purity_levels’: [‘99%’, ‘99.9%’, ‘99.99%’, ‘99.999%’], ‘molecular_weight’: ‘190.23’, ‘appearance’: ‘solid cubes’, ‘melting_point’: ‘3045 °C’, ‘boiling_point’: ‘5027 °C’, ‘density’: ‘22.57 g/cm³…

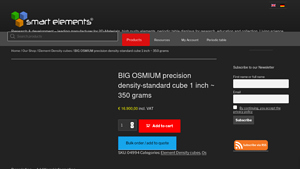

4. Smart Elements – BIG OSMIUM Precision Density-Standard Cube

Domain: smart-elements.com

Registered: 2004 (21 years)

Introduction: {“name”: “BIG OSMIUM precision density-standard cube”, “dimensions”: “1 x 1 x 1 inch”, “weight”: “~ 350 grams (344-350 grams)”, “price”: “US$ 16,513”, “production_time”: “about 2 – 4 weeks”, “material”: “osmium”, “features”: [“precision density standard”, “perfect surface”, “sharp edges”, “exact size”, “handcrafted in Austria”], “category”: “density cubes”, “item_number”: “04994”, “note”: “exclude…

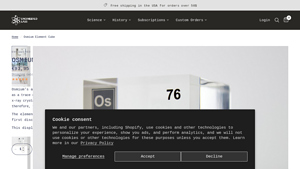

5. Engineered Labs – Osmium Element Cube

Domain: engineeredlabs.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Osmium Element Cube”, “price”: “$107.83”, “original_price”: “$134.79”, “shipping_info”: “Free shipping in the USA for orders over $50”, “atomic_number”: 76, “symbol”: “Os”, “description”: “A hard, brittle, bluish-white transition metal in the platinum group, found as a trace element in alloys, mostly in platinum ores. It is the densest naturally occurring element with a density o…

6. NovaElements® – Osmium Metal

Domain: novaelements.com

Registered: 2015 (10 years)

Introduction: Osmium Metal – NovaElements®

– Element: Osmium (Os 76)

– Characteristics: Blue platinum group metal, most heavy element of the periodic table, very hard, rare, and expensive.

– Uses: Durable and small applications, such as in high-end ballpoint pens (in alloy with iridium).

– Rarity: More rare than gold and rhodium; 100 grams of pure osmium requires extraction from 10 tons of platinum ores.

– Inve…

7. GVAesthetics – 99.95% High Purity Osmium Small Pieces

Domain: gvaesthetics.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “99.95% High Purity Os Small Pieces for Lab”, “purity”: “99.95%”, “form”: “small pieces”, “usage”: “laboratory applications”, “element”: “Osmium”, “item_code”: “C-d-499077”}

Strategic Sourcing Conclusion and Outlook for osmium cube

In the rapidly evolving landscape of precious metals, osmium cubes represent a unique opportunity for strategic sourcing. As one of the rarest and densest metals known, osmium not only holds exceptional physical properties but also offers substantial value for industries ranging from high-tech manufacturing to luxury goods. The scarcity of osmium ensures that international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage this asset for both investment and innovative applications.

Strategic sourcing of osmium cubes involves meticulous supplier evaluation and a clear understanding of market dynamics. Given the limited availability and high demand, establishing relationships with reputable suppliers can unlock competitive advantages and secure better pricing. As the market for osmium continues to mature, buyers are encouraged to remain proactive in their sourcing strategies, considering factors such as purity grades, customization options, and compliance with international standards.

Looking ahead, the osmium market is poised for growth, driven by emerging technologies and new applications. International buyers are urged to explore partnerships that can facilitate access to this rare metal and capitalize on its potential. Embrace the opportunity to differentiate your offerings and drive value through strategic sourcing of osmium cubes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to osmium cube