Oil And Gas Testing Chambers Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for oil and gas testing chambers

In the rapidly evolving oil and gas sector, sourcing reliable testing chambers is a pivotal challenge for international B2B buyers. These specialized environmental chambers are crucial for ensuring compliance with stringent industry standards, validating product performance, and enhancing operational safety. This guide serves as a comprehensive resource, detailing various types of oil and gas testing chambers, their applications, and the critical factors to consider when selecting a supplier. From temperature and humidity testing to vibration and thermal shock simulations, we explore the diverse functionalities that these chambers provide to optimize product reliability in demanding environments.

Navigating the global market for oil and gas testing chambers can be daunting, especially for buyers in regions such as Africa, South America, the Middle East, and Europe, including key players like Saudi Arabia and Nigeria. This guide empowers decision-makers by offering actionable insights on supplier vetting, cost considerations, and the latest technological advancements in testing equipment. By understanding the intricacies of environmental testing, buyers can make informed purchasing decisions that not only enhance product quality but also align with regulatory compliance and sustainability goals. Join us as we delve into the essential components of selecting the right oil and gas testing chambers for your operational needs.

Understanding oil and gas testing chambers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pressure Testing Chambers | Simulates high-pressure environments; robust construction | Oil drilling equipment, pipelines | Pros: Ensures safety and compliance; Cons: High initial cost |

| Temperature & Humidity Chambers | Controls temperature and humidity levels | Material testing, equipment reliability | Pros: Versatile for various tests; Cons: May require calibration |

| Corrosion Testing Chambers | Simulates corrosive environments | Material durability, pipeline integrity | Pros: Identifies weaknesses in materials; Cons: Longer testing cycles |

| Vibration Testing Chambers | Simulates mechanical vibrations | Equipment testing, seismic analysis | Pros: Validates structural integrity; Cons: Requires specific setups |

| Thermal Shock Chambers | Rapid temperature fluctuations | Electronics, automotive parts | Pros: Tests extreme conditions; Cons: Complex operational requirements |

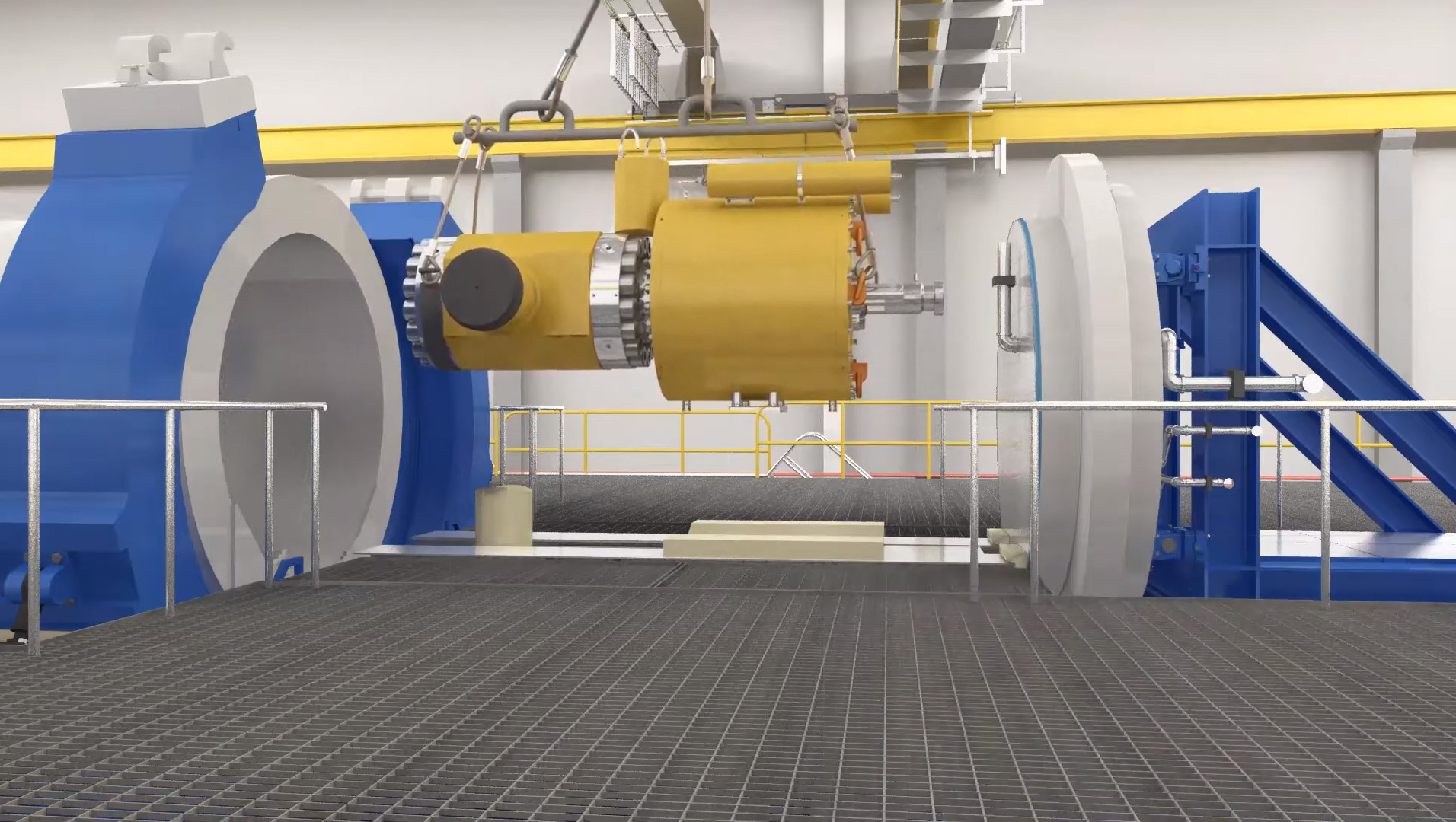

What Are the Key Characteristics of Pressure Testing Chambers?

Pressure testing chambers are designed to simulate high-pressure conditions that oil and gas equipment may encounter during operation. These chambers are constructed with robust materials to withstand extreme pressures, ensuring accurate testing of components like pipelines and drilling equipment. When considering a purchase, buyers should evaluate the chamber’s pressure range, safety features, and compliance with industry standards, as these factors directly impact testing efficacy and regulatory adherence.

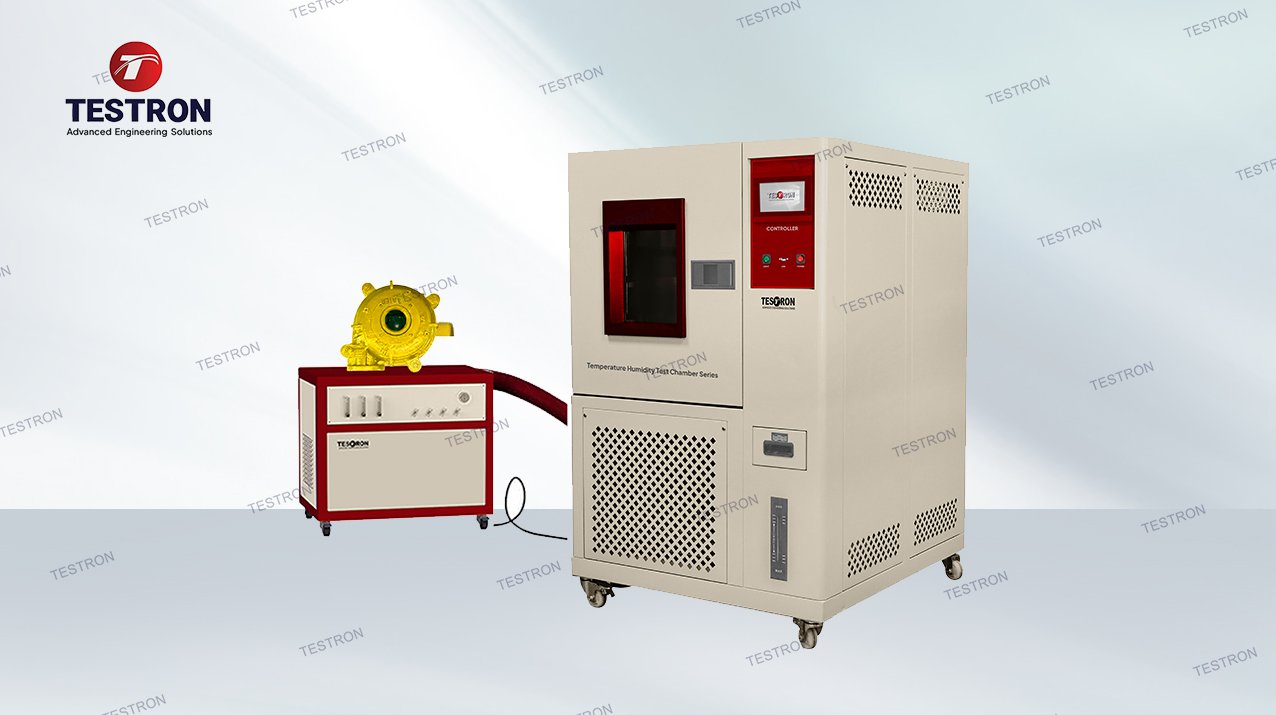

How Do Temperature & Humidity Chambers Enhance Product Reliability?

Temperature and humidity chambers control environmental factors to assess how materials and components perform under varying conditions. They are essential for testing the reliability of equipment used in oil and gas applications, where fluctuations in temperature and humidity can impact performance. Buyers should consider the chamber’s range of temperature and humidity settings, as well as its ability to conduct simultaneous tests, to ensure it meets their specific testing requirements.

Why Invest in Corrosion Testing Chambers?

Corrosion testing chambers are pivotal in evaluating the durability of materials against corrosive agents commonly found in oil and gas environments. By simulating conditions that lead to corrosion, these chambers help identify vulnerabilities in materials and coatings. When purchasing, buyers should focus on the chamber’s ability to replicate real-world corrosive conditions, the speed of testing, and the versatility of materials that can be tested, which are crucial for ensuring long-lasting equipment performance.

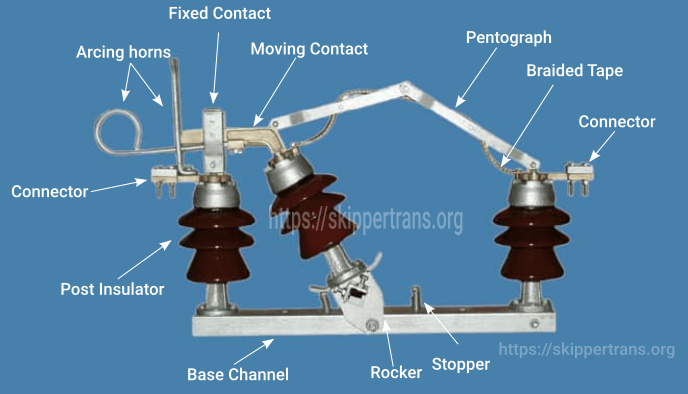

What Benefits Do Vibration Testing Chambers Offer?

Vibration testing chambers are designed to simulate mechanical vibrations that equipment may experience during operation, such as seismic activity or transportation stresses. They are particularly beneficial for validating the structural integrity of components in the oil and gas sector. Buyers should assess the chamber’s vibration frequency range, compatibility with other testing systems, and ease of use, as these factors influence the reliability of the test results.

How Do Thermal Shock Chambers Test Extreme Conditions?

Thermal shock chambers rapidly alternate between extreme temperatures to evaluate how materials react to sudden changes. This is critical for components in the oil and gas industry, where equipment may be exposed to rapid temperature variations. When considering a thermal shock chamber, buyers should look for features such as the speed of temperature transitions and the range of temperatures achievable, as these will determine the chamber’s effectiveness in simulating realistic operating conditions.

Key Industrial Applications of oil and gas testing chambers

| Industry/Sector | Specific Application of oil and gas testing chambers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil Exploration | Simulating extreme pressure and temperature conditions | Validates equipment reliability in harsh environments | Look for chambers with high-pressure capabilities and robust insulation. |

| Refining | Testing materials for corrosion and thermal stability | Ensures safety and longevity of materials in processing | Consider chambers with customizable settings for various corrosive environments. |

| Transportation | Evaluating fuel systems under varying conditions | Enhances fuel efficiency and compliance with regulations | Seek chambers that can replicate altitude and temperature fluctuations. |

| Equipment Manufacturing | Testing components for vibration and shock resistance | Reduces risk of failure during operations | Ensure the chambers are compatible with specific vibration testing protocols. |

| Environmental Compliance | Assessing emissions and environmental impact of products | Supports regulatory compliance and enhances corporate reputation | Prioritize chambers equipped for VOC and emissions testing. |

How Are Oil and Gas Testing Chambers Used in Oil Exploration?

In oil exploration, testing chambers simulate extreme pressure and temperature conditions found deep within the earth. This is crucial for validating the reliability of drilling equipment and other components exposed to harsh environments. By ensuring that equipment can withstand these conditions, companies can prevent costly failures and downtime. Buyers should prioritize sourcing chambers with high-pressure capabilities and robust insulation to meet their specific testing needs.

What Role Do Oil and Gas Testing Chambers Play in Refining Processes?

In the refining industry, oil and gas testing chambers are essential for testing materials for corrosion and thermal stability. Given the aggressive chemicals and high temperatures involved in refining processes, it is vital to ensure that materials maintain integrity over time. Chambers designed for corrosive environments can help refine companies select suitable materials, ultimately ensuring safety and longevity. Buyers should consider chambers with customizable settings that can accommodate various corrosive substances.

How Do Oil and Gas Testing Chambers Enhance Transportation Safety?

Transportation of oil and gas products requires rigorous testing of fuel systems under varying environmental conditions. Testing chambers can replicate altitude changes and temperature fluctuations to evaluate how fuel systems perform in different scenarios. This not only enhances fuel efficiency but also ensures compliance with international regulations. When sourcing, buyers should look for chambers that can simulate a broad range of conditions to meet specific testing requirements.

Why Are Oil and Gas Testing Chambers Important for Equipment Manufacturing?

For equipment manufacturers in the oil and gas sector, testing components for vibration and shock resistance is critical. This ensures that equipment can withstand the rigors of operation in the field. Using specialized testing chambers can significantly reduce the risk of failure during operations, thereby protecting investments and enhancing operational efficiency. Buyers should ensure that the chambers they select are compatible with specific vibration testing protocols to meet industry standards.

How Do Oil and Gas Testing Chambers Support Environmental Compliance?

Environmental compliance is a growing concern in the oil and gas industry, and testing chambers play a pivotal role in assessing emissions and the environmental impact of products. These chambers help companies adhere to regulatory standards, ultimately enhancing their corporate reputation. When sourcing testing chambers, it is essential to prioritize those equipped for volatile organic compounds (VOC) and emissions testing to ensure compliance with local and international regulations.

3 Common User Pain Points for ‘oil and gas testing chambers’ & Their Solutions

Scenario 1: Ensuring Compliance with Industry Standards in Testing

The Problem: B2B buyers in the oil and gas sector often struggle to ensure that their testing procedures meet stringent industry regulations and safety standards. The complexity of these regulations can lead to significant challenges in product validation. For instance, a company might invest in advanced testing chambers only to find that their results do not comply with local or international standards, resulting in potential penalties, product recalls, or reputational damage.

The Solution: To navigate compliance effectively, buyers should prioritize sourcing testing chambers designed specifically for the oil and gas industry. Look for chambers that can simulate the unique environmental conditions encountered in this sector, such as extreme temperatures, humidity, and pressure variations. When specifying a chamber, ensure it meets relevant certifications, such as API or ISO standards, and consider manufacturers who offer customizable options tailored to your specific testing protocols. Additionally, investing in training for your staff on regulatory requirements and proper testing methodologies can significantly enhance compliance and reliability in your testing processes.

Scenario 2: Addressing Equipment Downtime and Maintenance Costs

The Problem: Equipment downtime due to chamber failures or insufficient maintenance can severely impact operational efficiency and lead to increased costs. B2B buyers often face the challenge of maintaining the reliability of their testing chambers, which can be exacerbated by the harsh conditions typical in the oil and gas industry. This situation can lead to delays in testing timelines, ultimately affecting product launch schedules.

The Solution: To mitigate downtime, buyers should consider investing in high-quality, durable testing chambers that are specifically engineered for resilience in challenging environments. Opt for chambers with advanced monitoring systems that provide real-time feedback on performance metrics, allowing for proactive maintenance before issues escalate. Establishing a routine maintenance schedule with the manufacturer or a certified technician can also help identify potential problems early. Furthermore, buyers should explore warranty and service agreements that offer support and parts replacement to minimize unexpected costs and ensure continuous operation.

Scenario 3: Adapting to Diverse Testing Requirements

The Problem: B2B buyers in the oil and gas sector often face diverse testing requirements due to the variety of products being tested, from drilling equipment to safety gear. This variability can complicate the selection of appropriate testing chambers, leading to either over-investment in unnecessary features or under-performance in testing capabilities. As a result, companies may find themselves unable to adequately evaluate their products’ performance in real-world conditions.

The Solution: Buyers should adopt a flexible approach by selecting testing chambers that offer a broad range of customizable features to accommodate diverse testing needs. When sourcing chambers, look for options that allow for multi-environmental testing, such as simultaneous temperature and humidity control or altitude simulation. Collaborate closely with manufacturers to understand your specific testing requirements and ensure that the chamber can adapt to future needs. Furthermore, consider implementing a modular testing setup that allows for easy reconfiguration as testing requirements evolve, providing long-term value and efficiency in your testing processes.

Strategic Material Selection Guide for oil and gas testing chambers

When selecting materials for oil and gas testing chambers, it is crucial to consider the unique requirements of the industry, including exposure to extreme temperatures, high pressures, and corrosive environments. Here, we analyze four common materials used in the construction of these chambers, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Stainless Steel for Oil and Gas Testing Chambers?

Stainless steel is widely regarded for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. Its typical temperature rating can exceed 800°C, making it suitable for high-heat applications. Additionally, stainless steel’s non-reactive nature ensures that it does not contaminate the testing environment, which is critical for accurate results.

Pros: Stainless steel offers durability and longevity, requiring minimal maintenance over time. Its inherent strength allows for the construction of robust chambers capable of withstanding high pressures, making it suitable for various testing scenarios.

Cons: The primary drawback of stainless steel is its cost, which can be significantly higher than other materials. Additionally, manufacturing complexities can arise due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including hydrocarbons and corrosive fluids, making it ideal for oil and gas applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, particularly in regions like the Middle East and Europe, where strict regulations govern material selection.

How Does Carbon Steel Compare for Oil and Gas Testing Chambers?

Carbon steel is another common material used in the construction of testing chambers. It is known for its high strength and ability to withstand mechanical stress. However, it typically has a lower temperature rating compared to stainless steel, usually around 400°C.

Pros: The primary advantage of carbon steel is its lower cost, making it an attractive option for budget-conscious projects. It is also relatively easy to fabricate, allowing for quicker production times.

Illustrative image related to oil and gas testing chambers

Cons: Carbon steel is prone to rust and corrosion, especially in humid or corrosive environments, which may necessitate additional protective coatings or treatments.

Impact on Application: While carbon steel can be used for certain testing applications, its susceptibility to corrosion makes it less suitable for environments involving aggressive chemicals or high moisture levels.

Considerations for International Buyers: Buyers should consider the need for protective coatings and ensure that the material meets local compliance standards, particularly in regions like Africa and South America, where environmental conditions can vary significantly.

What Are the Benefits of Aluminum in Oil and Gas Testing Chambers?

Aluminum is often chosen for its lightweight properties and excellent corrosion resistance. It can withstand temperatures up to 600°C, making it suitable for moderate-temperature applications.

Pros: The lightweight nature of aluminum facilitates easier handling and installation. It also provides good thermal conductivity, which can be beneficial for temperature-controlled testing environments.

Illustrative image related to oil and gas testing chambers

Cons: Aluminum has a lower strength-to-weight ratio compared to stainless steel, which may limit its use in high-pressure applications. Additionally, it is more expensive than carbon steel.

Impact on Application: Aluminum is suitable for testing applications where weight is a critical factor, such as in portable or mobile testing chambers.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant industry standards and consider the potential need for additional treatments to enhance durability in harsh environments.

How Do Composite Materials Perform in Oil and Gas Testing Chambers?

Composite materials, often made from a combination of resins and fibers, are increasingly used in specialized testing chambers. They offer unique properties such as high strength-to-weight ratios and excellent resistance to corrosion and chemicals.

Illustrative image related to oil and gas testing chambers

Pros: Composites can be tailored to specific testing requirements, providing flexibility in design. They are also lightweight and can significantly reduce the overall weight of testing chambers.

Cons: The primary limitation of composite materials is their cost, which can be higher than traditional metals. Additionally, they may require specialized manufacturing techniques, increasing production complexity.

Impact on Application: Composites are particularly effective in applications requiring resistance to aggressive chemicals and extreme temperatures.

Illustrative image related to oil and gas testing chambers

Considerations for International Buyers: Buyers should be aware of the need for compliance with specific industry standards and certifications, particularly in regions with stringent regulations, such as Europe.

| Material | Typical Use Case for oil and gas testing chambers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure, high-temperature testing | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Carbon Steel | General testing applications | Lower cost, easy to fabricate | Prone to corrosion | Low |

| Aluminum | Lightweight, portable testing setups | Lightweight, good thermal conductivity | Lower strength for high-pressure | Medium |

| Composite Materials | Specialized, chemical-resistant applications | Tailored properties, lightweight | Higher cost, complex manufacturing | High |

In summary, selecting the right material for oil and gas testing chambers involves balancing performance requirements with cost and manufacturing considerations. International buyers must also navigate compliance with local standards to ensure safety and efficacy in their testing operations.

In-depth Look: Manufacturing Processes and Quality Assurance for oil and gas testing chambers

What Are the Key Stages in the Manufacturing Process of Oil and Gas Testing Chambers?

The manufacturing process for oil and gas testing chambers involves several critical stages that ensure the final product meets the rigorous demands of the industry. Each stage is designed to optimize performance, durability, and compliance with international standards.

Material Preparation: What Materials Are Used in Oil and Gas Testing Chambers?

The first step in the manufacturing process is material preparation. Manufacturers typically use high-grade stainless steel, aluminum, and specialized alloys that withstand extreme temperatures and corrosive environments. The choice of materials is crucial for ensuring longevity and reliability in the field. Additionally, manufacturers may treat materials to enhance their resistance to corrosion and wear, which is particularly vital in oil and gas applications.

How Are Oil and Gas Testing Chambers Formed?

Once the materials are prepared, the next stage is forming. This involves cutting, bending, and welding the components into the desired shapes and sizes. Advanced techniques such as laser cutting and CNC machining are commonly employed to achieve precise dimensions and tolerances. The use of automated processes not only enhances accuracy but also improves production efficiency, allowing for quicker turnaround times on orders.

What Does the Assembly Process Entail?

After forming, the components are assembled. This stage may involve both manual and automated processes, depending on the complexity of the chamber design. Skilled technicians typically oversee assembly to ensure that all parts fit together correctly and that the chamber meets design specifications. This stage also includes integrating systems for temperature control, humidity regulation, and pressure monitoring, which are essential for oil and gas testing operations.

What Finishing Techniques Are Applied to Testing Chambers?

The final stage in manufacturing is finishing, which enhances both the aesthetic and functional qualities of the chambers. This may include surface treatments such as powder coating or anodizing to improve corrosion resistance. Additionally, manufacturers often perform rigorous cleaning processes to remove any contaminants from the assembly process, ensuring that the chambers are ready for testing and certification.

Illustrative image related to oil and gas testing chambers

How Is Quality Assurance Implemented in Oil and Gas Testing Chambers Manufacturing?

Quality assurance (QA) is a fundamental aspect of manufacturing oil and gas testing chambers, involving multiple checkpoints throughout the production process. Effective QA not only ensures compliance with industry standards but also enhances the reliability and performance of the final product.

What International Standards Are Relevant for Quality Assurance?

For manufacturers targeting international markets, compliance with standards such as ISO 9001 is essential. This standard outlines the criteria for a quality management system and emphasizes continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for demonstrating adherence to safety and performance standards relevant to oil and gas applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints during the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials and components before they enter the production line. Ensuring high-quality inputs is vital for maintaining the integrity of the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor compliance with specifications. This may involve checking weld integrity, dimensional accuracy, and system functionality during assembly.

-

Final Quality Control (FQC): Before the chambers are shipped, a final inspection is performed to ensure that all aspects of the chamber meet design and regulatory requirements. This often includes testing for leaks, performance under simulated conditions, and compliance with safety standards.

What Common Testing Methods Are Used in Quality Assurance?

To ensure the chambers meet industry specifications, manufacturers employ various testing methods, including:

-

Performance Testing: This involves subjecting the chambers to extreme conditions to assess their operational capabilities. Tests may include simulating high pressures, temperature extremes, and environmental factors.

-

Leak Testing: Essential for ensuring the integrity of the chambers, this testing method checks for any potential leaks that could compromise performance.

-

Calibration Checks: Regular calibration of measurement instruments is critical to guarantee accurate performance data. This process ensures that the chambers provide reliable and consistent results during testing.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality assurance processes of potential suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing capabilities and quality control measures firsthand. This includes evaluating production processes, equipment, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports and certificates from suppliers can provide insights into their QA processes. Look for documentation that outlines compliance with ISO standards and other relevant certifications.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can add an additional layer of assurance. These organizations can conduct unbiased evaluations of the manufacturing processes and final products.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, understanding regional compliance requirements is crucial. Different markets may have specific regulations regarding materials, safety standards, and environmental considerations. Buyers should be aware of:

Illustrative image related to oil and gas testing chambers

-

Regional Certifications: Ensure that suppliers possess the necessary certifications for the specific markets they intend to serve. For instance, chambers intended for the European market must comply with CE regulations.

-

Cultural and Regulatory Differences: Familiarize yourself with the local regulatory landscape in your target markets. This knowledge will help in negotiating terms and ensuring compliance with both local and international standards.

In conclusion, the manufacturing processes and quality assurance practices for oil and gas testing chambers are intricate and vital for ensuring the reliability and safety of these critical components. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with manufacturers who uphold the highest standards of quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oil and gas testing chambers’

In the dynamic and demanding field of oil and gas, selecting the right testing chambers is crucial for ensuring product reliability and compliance with industry standards. This practical sourcing guide provides a checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing oil and gas testing chambers. Consider factors such as the types of tests required (e.g., temperature, humidity, pressure) and the specific environmental conditions you need to simulate. This clarity will help you shortlist suppliers that can meet your exact needs.

Illustrative image related to oil and gas testing chambers

- Testing Requirements: Identify the specific tests your products must undergo, such as thermal shock, altitude simulation, or vibration testing.

- Size and Capacity: Determine the dimensions and weight of the items you will be testing to ensure the chamber can accommodate them.

Step 2: Research Industry Standards and Compliance

Understanding the relevant industry standards is essential for ensuring that the testing chambers you select will meet necessary regulatory requirements. Familiarize yourself with standards such as ISO, ASTM, or specific regional regulations pertinent to oil and gas testing.

- Compliance Certification: Check if the chambers are certified for compliance with industry standards, which is crucial for ensuring the reliability of test results.

- Documentation: Ensure that suppliers can provide documentation demonstrating compliance with relevant safety and environmental regulations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; seek out testimonials and independent reviews to gauge their reputation.

- Experience and Expertise: Look for suppliers with a proven track record in producing oil and gas testing chambers, particularly those that understand the unique challenges of your industry.

- Support Services: Assess whether suppliers offer ongoing support, including maintenance and calibration services, which can significantly affect long-term performance.

Step 4: Request Customization Options

Every oil and gas operation has unique testing needs, so inquire about customization options. Suppliers that offer tailored solutions can help you optimize testing processes and improve efficiency.

Illustrative image related to oil and gas testing chambers

- Modular Designs: Consider suppliers that provide modular chambers, allowing for future upgrades or modifications based on evolving testing requirements.

- Integration with Existing Systems: Ensure that the testing chamber can seamlessly integrate with your current laboratory equipment and software systems.

Step 5: Assess Energy Efficiency and Sustainability

In today’s environmentally conscious marketplace, energy-efficient testing chambers are not just beneficial for operational costs but also align with sustainability goals. Look for features that promote energy savings and reduced environmental impact.

- Eco-Friendly Technologies: Investigate whether the chambers utilize low-GWP refrigerants or other sustainable technologies that minimize their carbon footprint.

- Operational Costs: Evaluate the long-term operational costs associated with energy consumption, as this can significantly impact your budget.

Step 6: Negotiate Pricing and Terms

Once you have narrowed down potential suppliers, it’s time to discuss pricing and terms. Be prepared to negotiate not just on the purchase price but also on warranties, service agreements, and delivery timelines.

- Bulk Purchase Discounts: If you plan to purchase multiple chambers, inquire about bulk purchase discounts or financing options.

- Warranty and Support: Ensure that warranty terms are clear and that you understand what is covered, especially regarding potential maintenance and service needs.

By following this checklist, B2B buyers can make informed decisions when procuring oil and gas testing chambers, ensuring they select solutions that meet their operational requirements and contribute to product reliability.

Comprehensive Cost and Pricing Analysis for oil and gas testing chambers Sourcing

What Are the Key Cost Components in Sourcing Oil and Gas Testing Chambers?

When sourcing oil and gas testing chambers, understanding the cost structure is essential for international B2B buyers. The total cost comprises several components:

-

Materials: The quality and type of materials used significantly impact pricing. High-grade materials that withstand extreme conditions, such as corrosion-resistant metals and advanced insulation, typically raise costs but enhance durability and performance.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor for assembly, calibration, and quality control is essential, especially for chambers requiring custom specifications.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Custom tooling may be necessary for specialized testing chambers. This upfront investment can be significant, but it is often amortized over large production volumes, reducing per-unit costs.

-

Quality Control (QC): Rigorous QC processes ensure reliability and compliance with industry standards, which can add to the overall cost. However, investing in QC can mitigate risks associated with product failures in the field.

-

Logistics: Shipping costs, especially for international buyers, can vary widely based on distance, shipping methods, and customs duties. Understanding Incoterms can help buyers anticipate these costs.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market positioning. This margin can vary based on the supplier’s reputation, market demand, and competition.

How Do Price Influencers Affect the Cost of Oil and Gas Testing Chambers?

Several factors influence the pricing of oil and gas testing chambers, which buyers should consider:

Illustrative image related to oil and gas testing chambers

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Suppliers may offer discounts for bulk orders, making it advantageous for larger projects.

-

Specifications and Customization: Customized chambers tailored to specific testing protocols generally come at a premium. Standard models are more cost-effective but may not meet all testing requirements.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO compliance) can increase initial costs but may lead to savings in the long run through reduced maintenance and failure rates.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can impact pricing. Local suppliers may offer lower shipping costs, while established brands may command higher prices due to their reliability.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is crucial for budgeting the total cost of ownership. Different Incoterms can significantly affect final expenses.

What Tips Can Buyers Use for Cost-Efficiency in Sourcing Testing Chambers?

B2B buyers can implement several strategies to enhance cost-efficiency:

-

Negotiate: Engage suppliers in discussions to negotiate better pricing, especially when committing to larger orders or long-term contracts. Suppliers may be willing to offer discounts or favorable terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the operational costs, maintenance, and potential downtime. Investing in higher-quality chambers may yield lower TCO over their lifespan.

-

Research and Compare: Evaluate multiple suppliers and their offerings. Request quotes, review specifications, and assess after-sales support to ensure that you’re receiving the best value.

-

Leverage Regional Insights: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences and any tariffs or import duties that may apply. Local suppliers may provide advantages in cost and logistics.

-

Stay Updated on Market Trends: Keep abreast of advancements in testing technology and materials, as these can impact pricing structures and offer opportunities for cost savings.

Disclaimer on Pricing

Please note that prices for oil and gas testing chambers can vary significantly based on the factors outlined above. The information provided serves as a general guideline and should be validated with specific suppliers to obtain accurate quotations tailored to your requirements.

Alternatives Analysis: Comparing oil and gas testing chambers With Other Solutions

In the competitive landscape of oil and gas testing, buyers are often faced with a range of solutions that can meet their testing needs. While oil and gas testing chambers are designed specifically for the rigorous requirements of this sector, several alternative solutions exist that may offer unique benefits. This section explores these alternatives, providing a comparative analysis that can aid in decision-making for B2B buyers.

| Comparison Aspect | Oil And Gas Testing Chambers | Environmental Test Chambers | Portable Testing Solutions |

|---|---|---|---|

| Performance | High accuracy for specific oil and gas parameters | Versatile; can simulate various environmental conditions | Limited accuracy; best for field conditions |

| Cost | Higher initial investment; long-term savings through reliability | Mid-range cost; customizable options can increase expenses | Lower upfront cost; potential for higher ongoing costs |

| Ease of Implementation | Requires specialized installation and training | Generally straightforward installation; some customization needed | Quick setup; user-friendly |

| Maintenance | Regular maintenance required; specialized service providers | Routine maintenance; parts readily available | Minimal maintenance; often user-serviceable |

| Best Use Case | Ideal for laboratory settings requiring precise measurements | Suitable for a variety of industries needing environmental simulations | Best for on-site testing in remote locations |

What Are Environmental Test Chambers and Their Advantages?

Environmental test chambers offer a versatile alternative to oil and gas testing chambers. They are capable of simulating various environmental conditions such as temperature, humidity, and altitude, making them suitable for multiple industries, including aerospace, automotive, and electronics. The primary advantage of these chambers is their adaptability; they can be customized to meet specific testing requirements. However, this versatility can come at a higher cost, especially when customized features are added. Additionally, while they provide reliable performance, they may not deliver the same level of precision for oil and gas-specific tests compared to dedicated testing chambers.

Illustrative image related to oil and gas testing chambers

How Do Portable Testing Solutions Compare in the Oil and Gas Sector?

Portable testing solutions are designed for on-site applications, making them an appealing option for oil and gas companies that operate in remote locations. These solutions are typically easier to set up and require minimal training, allowing for quick assessments in the field. However, the trade-off is in the accuracy and comprehensiveness of the tests conducted. While portable solutions can be effective for initial screenings or assessments, they often lack the precision required for in-depth analysis and may not cover the full spectrum of oil and gas testing parameters. Their lower initial cost is attractive, but ongoing operational costs can accumulate, particularly if frequent recalibrations or replacements are necessary.

How Can B2B Buyers Choose the Right Testing Solution?

When selecting the appropriate testing solution, B2B buyers should carefully evaluate their specific needs, including the types of tests required, the environment in which they operate, and budget constraints. Oil and gas testing chambers are ideal for organizations that prioritize accuracy and reliability in controlled environments. On the other hand, environmental test chambers may be more suitable for companies that require flexibility across various testing scenarios. Lastly, portable testing solutions are best for those needing immediate, on-site results without the overhead of complex installations. By understanding these options and their respective advantages, buyers can make informed decisions that align with their operational goals and testing requirements.

Essential Technical Properties and Trade Terminology for oil and gas testing chambers

What Are the Key Technical Properties of Oil and Gas Testing Chambers?

When selecting oil and gas testing chambers, understanding their technical specifications is crucial for ensuring compliance with industry standards and optimizing testing outcomes. Here are some essential properties to consider:

1. Material Grade

The materials used in constructing testing chambers are vital for durability and safety. Common materials include stainless steel and carbon steel, chosen for their resistance to corrosion and temperature extremes. Selecting the appropriate material grade ensures that the chamber can withstand harsh testing conditions and maintain structural integrity over time, which is critical for reliability in oil and gas applications.

2. Temperature Tolerance

Temperature tolerance specifies the range of temperatures a chamber can maintain during testing, often spanning from -70°C to +180°C. This range is essential for simulating real-world conditions that oil and gas equipment might face, such as extreme cold in offshore environments or high temperatures in processing facilities. Understanding temperature tolerance helps B2B buyers ensure that their testing protocols align with operational requirements.

Illustrative image related to oil and gas testing chambers

3. Pressure Ratings

Testing chambers must be equipped to handle the pressure levels relevant to oil and gas applications, often reaching up to 1500 psi or more. This property is crucial for simulating the conditions found in deep-sea drilling or high-pressure pipelines. Buyers should verify that chambers meet the necessary pressure ratings to avoid equipment failure and ensure accurate test results.

4. Humidity Control

Humidity control capabilities define the range of moisture levels the chamber can simulate, typically from 10% to 98% relative humidity. This feature is significant for testing the resilience of materials and components against corrosion and other moisture-related failures. For oil and gas companies, ensuring proper humidity control can lead to better product reliability and longevity.

5. Vibration Resistance

Vibration resistance is a key property that evaluates how well a chamber can maintain testing conditions while subjected to external vibrations. This is particularly important in the oil and gas sector, where equipment is often exposed to significant vibrations during operation. A chamber with high vibration resistance ensures that testing results are reliable and reflective of real-world conditions.

6. Cycle Time Efficiency

Cycle time efficiency refers to the time it takes for a chamber to complete a testing cycle, including heating, cooling, and stabilization. Shorter cycle times can accelerate product development and validation processes, allowing companies to bring safer and more reliable products to market faster. For B2B buyers, understanding cycle time can lead to better resource allocation and improved project timelines.

What Are Common Trade Terms in the Oil and Gas Testing Chamber Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of testing chambers, understanding OEM relationships can help buyers ensure they are sourcing high-quality, compliant equipment.

Illustrative image related to oil and gas testing chambers

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory and budget effectively, especially when ordering specialized testing chambers that may require significant investment.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specified products or services. When procuring testing chambers, issuing an RFQ helps buyers compare options, negotiate pricing, and ensure they receive competitive bids.

4. Incoterms (International Commercial Terms)

Incoterms are a set of pre-defined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping responsibilities, costs, and risks associated with their purchases.

5. Calibration

Calibration refers to the process of adjusting and verifying the accuracy of testing equipment. For oil and gas testing chambers, ensuring proper calibration is vital for obtaining reliable and repeatable test results, ultimately impacting product quality and safety.

Illustrative image related to oil and gas testing chambers

By understanding these technical properties and trade terms, B2B buyers in the oil and gas sector can make informed decisions when selecting testing chambers that meet their operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the oil and gas testing chambers Sector

What Are the Key Trends Influencing the Oil and Gas Testing Chambers Market?

The global oil and gas testing chambers market is witnessing significant transformation driven by technological advancements, regulatory changes, and increasing demand for product reliability. As countries in Africa, South America, the Middle East, and Europe ramp up exploration and production activities, the need for precise testing solutions has intensified. Emerging technologies such as automation and IoT integration are reshaping how testing chambers operate, enabling remote monitoring and control, which enhances efficiency and reduces downtime. Moreover, the growing emphasis on safety and compliance with international standards is pushing companies to adopt more sophisticated testing protocols.

Another key trend is the customization of testing chambers to cater to specific environmental conditions encountered in various regions. For instance, testing chambers that can simulate extreme temperatures and pressures are essential for oil and gas operations in Saudi Arabia and Nigeria. Additionally, as the industry moves towards more sustainable practices, there is a rising demand for environmentally friendly testing solutions that minimize waste and energy consumption. Buyers from diverse markets are increasingly looking for suppliers that can offer both high-performance and eco-conscious products.

How Are Sustainability and Ethical Sourcing Impacting the Oil and Gas Testing Chambers Market?

Sustainability has become a core consideration for B2B buyers in the oil and gas testing chambers sector. The environmental impact of manufacturing and operating testing equipment is under scrutiny, prompting companies to seek out suppliers that prioritize sustainable practices. Buyers are now evaluating the lifecycle of testing chambers, focusing on materials and processes that reduce carbon footprints and environmental degradation.

Ethical sourcing is equally critical, particularly in regions where supply chain transparency is often challenged. Buyers are increasingly favoring suppliers who adhere to strict ethical standards, ensuring that the materials used in testing chambers are responsibly sourced and produced. Certifications such as ISO 14001 for environmental management and LEED for energy efficiency are becoming essential for suppliers aiming to establish credibility in the market. These certifications not only enhance brand reputation but also align with the growing demand for corporate social responsibility among stakeholders.

Illustrative image related to oil and gas testing chambers

How Has the Oil and Gas Testing Chambers Market Evolved Over Time?

The evolution of oil and gas testing chambers can be traced back to the industry’s need for rigorous quality assurance and safety standards. Initially, testing chambers were rudimentary, primarily focusing on basic temperature and pressure simulations. However, as the industry expanded and technology advanced, so did the complexity of testing requirements.

Today’s testing chambers are equipped with advanced features that allow for multifaceted environmental simulations, including thermal shock, altitude changes, and vibration tests. This evolution is largely driven by the need for enhanced product reliability and compliance with stringent regulatory frameworks. As exploration activities continue to expand in challenging environments, the demand for sophisticated testing solutions is expected to grow, further shaping the market dynamics for years to come.

In summary, international B2B buyers in the oil and gas testing chambers sector must remain vigilant about market trends, sustainability, and ethical sourcing to make informed purchasing decisions that align with their operational and strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of oil and gas testing chambers

-

How do I solve challenges related to environmental conditions in oil and gas testing?

To effectively address environmental challenges in oil and gas testing, consider investing in advanced environmental test chambers. These chambers can simulate extreme conditions, such as temperature variations, humidity levels, and pressure fluctuations, allowing for thorough product validation and reliability assessment. Collaborate with suppliers who offer customized solutions tailored to your specific testing protocols. Additionally, ensure that the chambers meet international standards to facilitate compliance and enhance product quality. -

What is the best testing chamber for oil and gas applications?

The best testing chamber for oil and gas applications is typically one that can simulate a wide range of environmental conditions, including extreme temperatures, humidity, and pressure changes. Look for chambers equipped with features like thermal shock capabilities and combined environmental testing functions. Custom-engineered solutions are often ideal, as they can be tailored to meet the specific requirements of your oil and gas products, ensuring accurate and reliable testing outcomes. -

What are the key factors to consider when sourcing oil and gas testing chambers?

When sourcing oil and gas testing chambers, focus on the manufacturer’s reputation, product durability, and compliance with international standards. Evaluate the technical specifications to ensure the chambers can simulate the necessary environmental conditions for your products. Consider customization options, after-sales support, and the availability of spare parts. Additionally, assess the supplier’s experience with similar applications within the oil and gas sector to ensure they understand your unique testing needs. -

How can I vet suppliers of oil and gas testing chambers?

To vet suppliers effectively, conduct thorough background research, including reviewing their industry experience and client testimonials. Request references from other oil and gas companies that have utilized their chambers. Assess their certifications, compliance with international standards, and manufacturing capabilities. Additionally, consider visiting their facilities if possible, and inquire about their quality assurance processes and customer support services to ensure a reliable partnership. -

What customization options are available for oil and gas testing chambers?

Customization options for oil and gas testing chambers can include specific temperature ranges, humidity controls, and pressure simulations tailored to your testing requirements. Many manufacturers offer bespoke solutions, enabling you to modify chamber dimensions, control systems, and testing protocols. Be sure to discuss your unique needs with potential suppliers to identify the best options that align with your operational goals and compliance standards. -

What are the typical minimum order quantities (MOQ) for testing chambers?

Minimum order quantities for oil and gas testing chambers can vary significantly based on the supplier and the complexity of the chamber. Generally, standard models may have lower MOQs, while custom-engineered solutions may require larger orders. It’s advisable to discuss your specific needs with suppliers to determine their MOQ policies and explore options for smaller initial orders or rental agreements, especially if you’re testing new products or technologies. -

What payment terms should I expect when purchasing testing chambers internationally?

Payment terms for international purchases of testing chambers typically include options such as upfront payment, partial payment upon order confirmation, and the balance upon delivery or installation. Some suppliers may offer financing or leasing options, particularly for high-value equipment. Always clarify payment terms upfront and ensure that they align with your budget and cash flow requirements. Consider using letters of credit or escrow services for added security in international transactions. -

What logistics considerations should I keep in mind for importing testing chambers?

When importing oil and gas testing chambers, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Coordinate with your supplier to ensure proper packaging and labeling to facilitate smooth transportation. Familiarize yourself with import regulations in your country, including tariffs and duties. It may also be beneficial to partner with a reliable freight forwarder who can assist with logistics planning and ensure timely delivery of your equipment.

Top 7 Oil And Gas Testing Chambers Manufacturers & Suppliers List

1. Weiss Technik – Environmental Test Chambers

Domain: weiss-na.com

Registered: 2013 (12 years)

Introduction: Weiss Technik offers a comprehensive range of environmental test chambers, including Temperature Test Chambers, Humidity Test Chambers, Walk-In & Drive-In Environmental Test Chambers, Thermal Shock Chambers, Battery Test Chambers, HALT/HASS/AGREE & Vibration Test Chambers, Altitude & Space Simulation Test Chambers, Life Science, Stability Test Chambers, and Containment Systems. Their chambers can …

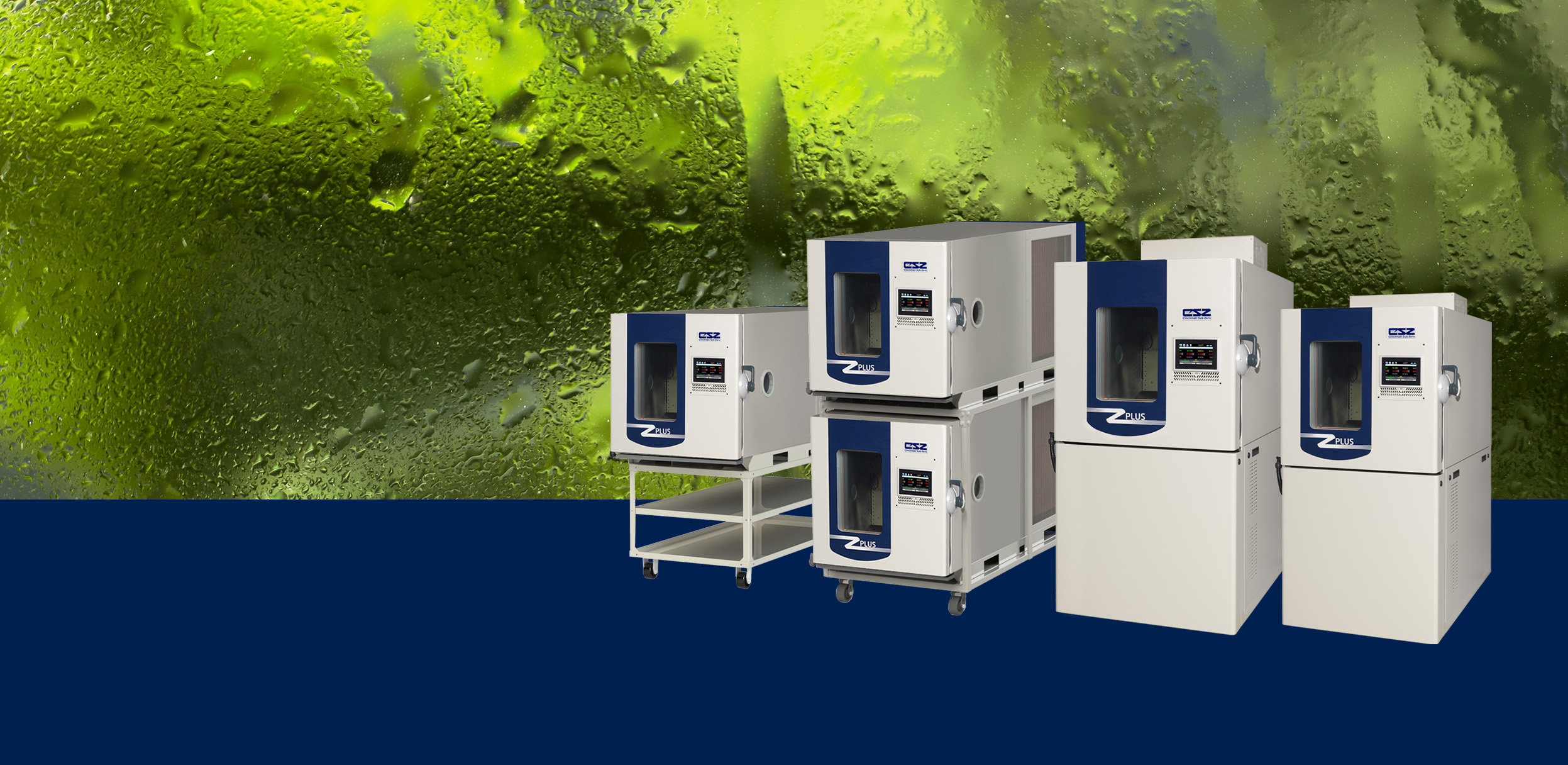

2. CSZ – Environmental Test Chambers

Domain: cszindustrial.com

Registered: 2002 (23 years)

Introduction: CSZ Environmental Test Chambers include a wide range of products such as Temperature Humidity Chambers (Z Plus, MicroClimate, Benchtop MicroClimate 3), Constant Climate Chambers, Thermal Shock Chambers (VTS Compact, VTS Large, TSB Liquid Horizontal), Stability Chambers (PharmaEvent, Photostability), Walk-In and Drive-In Chambers (Modular, Welded), Vibration Test Chambers (Benchtop Vibration Table,…

3. Russells – Environmental Test Chambers

Domain: russells-tech.com

Registered: 1996 (29 years)

Introduction: Environmental Test Chambers by Russells Technical Products include a comprehensive lineup for testing temperature, humidity, altitude, and vibration. Key products include: 1. Temperature & Humidity Chambers: Available in pre-engineered and custom sizes for product reliability testing. 2. Altitude Test Chambers: Designed for military, industrial, aviation, and consumer applications, simulating low-…

4. Environmental Test Chambers – Climate Control Solutions

Domain: environmentaltestchambers.com

Registered: 2000 (25 years)

Introduction: Environmental test chambers, also known as climate chambers or climatic chambers, are controlled enclosures designed to simulate various environmental conditions for testing products, components, or assemblies. They can replicate temperature extremes, humidity fluctuations, pressure variations, and other physical variables. Key types of environmental test chambers include: AGREE Chamber, Altitude …

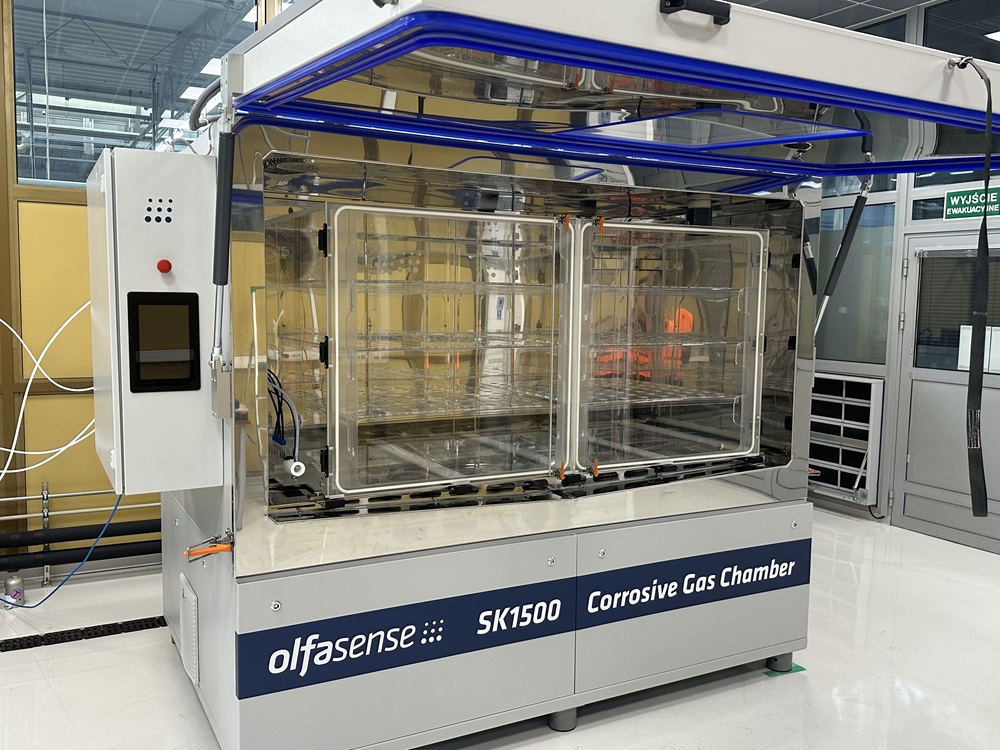

5. Olfasense – Corrosive Gas Test Chamber SK400B

Domain: olfasense.com

Registered: 2002 (23 years)

Introduction: Product Name: Corrosive Gas Test Chamber SK400B

Manufacturer: Olfasense GmbH

Volume/External Dimensions of Climate Chamber: approx. 1000 Liters

Test Space Volume/External Dimensions: approx. 400 Liters (618 mm x 606 mm x 1070 mm)

Possible Floors within Test Room: up to 4

Material of Test Space and Premixing Chamber: PMMA (transparent, corrosion-resistant plastic)

Gas Dosing: High-precision mass fl…

6. Weiss Technik – Specialty Test Chambers

Domain: weiss-technik.mx

Registered: 2021 (4 years)

Introduction: Weiss Technik offers a complete portfolio of specialty and custom test chambers for unique testing requirements, including battery applications, explosion resistance, and spray/splash applications. Key features include advanced technology, reliability, and superior quality. The chambers utilize LEEF and LOW GWP technologies for up to 40% energy savings and use R-449A refrigerant. Types of specialt…

7. IQS Directory – Environmental Test Chambers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Environmental test chambers are sophisticated devices designed to replicate various atmospheric conditions for assessing product performance and reliability. They simulate conditions such as high humidity, temperature swings, and differing pressure levels. Key features include:

– Types: Steady-state testing chambers, thermal cycling chambers, thermal vacuum chambers, altitude test chambers, and cr…

Strategic Sourcing Conclusion and Outlook for oil and gas testing chambers

The landscape of oil and gas testing chambers is evolving rapidly, driven by the need for enhanced product reliability and compliance with stringent industry standards. Strategic sourcing plays a pivotal role in this evolution, enabling businesses to select high-quality testing solutions tailored to their specific operational requirements. By investing in advanced environmental test chambers, companies can significantly reduce warranty costs, accelerate product development, and mitigate risks associated with environmental testing.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the opportunity to leverage innovative testing technologies is immense. As these markets continue to expand, the demand for reliable and efficient testing solutions will grow. It is imperative for organizations to engage with reputable manufacturers who offer customizable, high-performance chambers capable of simulating diverse environmental conditions.

Illustrative image related to oil and gas testing chambers

Looking ahead, the emphasis on sustainability and eco-conscious operations will further shape sourcing strategies. Buyers are encouraged to prioritize suppliers committed to innovative technologies that enhance energy efficiency and reduce carbon footprints. Embrace this strategic approach to sourcing and ensure your operations are not only compliant but also positioned for future growth in the dynamic oil and gas sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to oil and gas testing chambers

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.