Nylon Cleaning Brush: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for nylon cleaning brush

Navigating the complexities of sourcing nylon cleaning brushes for various industrial applications can present significant challenges for international B2B buyers. With a diverse array of products available, understanding the right type of brush for specific cleaning tasks is crucial for maintaining operational efficiency and achieving optimal results. This guide provides a comprehensive overview of nylon cleaning brushes, detailing the various types available—including soft and stiff bristle options—and their applications across different industries, from automotive to hospitality.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam, will benefit from insights into supplier vetting processes, pricing structures, and quality standards. By exploring these critical factors, buyers can make informed decisions that align with their specific needs and budgets. The guide also addresses the importance of selecting the right nylon cleaning brush based on surface compatibility and cleaning requirements, enabling businesses to enhance their cleaning protocols effectively.

By equipping B2B buyers with the necessary knowledge and tools, this guide empowers them to navigate the global market confidently. Whether you are seeking cost-effective solutions or premium-grade products, understanding the nuances of nylon cleaning brushes will ensure your purchasing decisions contribute to improved operational outcomes and customer satisfaction.

Understanding nylon cleaning brush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hard Bristle Nylon Brush | Stiff bristles for aggressive scrubbing | Industrial cleaning, floor maintenance | Pros: Effective on tough stains; durable. Cons: May scratch softer surfaces. |

| Soft Bristle Nylon Brush | Gentle bristles suitable for delicate surfaces | Carpet cleaning, automotive detailing | Pros: Safe for sensitive surfaces; versatile. Cons: Less effective on heavy grime. |

| Bottle Brush | Long, narrow design for cleaning inside bottles and tubes | Food and beverage industry, laboratories | Pros: Reaches tight spaces; effective cleaning. Cons: Limited to specific applications. |

| Tile and Grout Brush | Angled bristles designed for grout lines and tile surfaces | Residential and commercial cleaning | Pros: Specialized for difficult areas; effective on grout. Cons: May not be versatile for other uses. |

| Tube Cleaning Brush | Dual diameter for cleaning various tube sizes | HVAC systems, industrial equipment | Pros: Customizable for different tube sizes; efficient cleaning. Cons: Requires precise sizing for effectiveness. |

What Are the Key Characteristics of Hard Bristle Nylon Brushes?

Hard bristle nylon brushes are designed with stiff bristles that provide aggressive scrubbing action. They are ideal for industrial cleaning tasks, particularly in environments that require the removal of tough stains and grime from hard surfaces. When considering a purchase, B2B buyers should assess the surface materials to avoid potential scratches. Their durability makes them a cost-effective option for high-frequency cleaning applications, although they may not be suitable for delicate surfaces.

How Do Soft Bristle Nylon Brushes Differ in Use?

Soft bristle nylon brushes feature gentler bristles that are safe for use on delicate surfaces such as carpets and painted finishes. These brushes are commonly used in carpet cleaning and automotive detailing, where a softer touch is essential. B2B buyers should consider the specific cleaning requirements when choosing this type, as soft bristles may not effectively tackle heavy-duty grime. However, their versatility and safety make them a popular choice across various industries.

Why Are Bottle Brushes Important for Certain Industries?

Bottle brushes are uniquely designed with a long and narrow shape, allowing them to clean the interiors of bottles, tubes, and other confined spaces. This type of brush is particularly valuable in the food and beverage industry, as well as laboratories, where cleanliness is paramount. When purchasing, businesses should evaluate the size and flexibility of the brush to ensure it meets their specific cleaning needs. While bottle brushes are highly effective, their specialized design limits their use to specific applications.

What Makes Tile and Grout Brushes Essential for Cleaning?

Tile and grout brushes are characterized by their angled bristles, which are specifically designed to clean grout lines and tile surfaces effectively. They are widely used in both residential and commercial cleaning settings, particularly in bathrooms and kitchens where grime buildup is common. B2B buyers should prioritize the brush’s size and bristle stiffness based on the cleaning tasks at hand. While these brushes excel in their intended use, they may not be suitable for general cleaning tasks.

How Do Tube Cleaning Brushes Enhance Equipment Maintenance?

Tube cleaning brushes are designed with dual diameters to accommodate various tube sizes, making them essential for maintaining HVAC systems and industrial equipment. Their ability to clean both soft deposits and harder scale makes them versatile tools in maintenance operations. When purchasing, companies should ensure they select the correct size for their specific applications, as improper sizing can hinder cleaning effectiveness. While tube brushes can be highly efficient, they require careful consideration of compatibility with existing equipment.

Illustrative image related to nylon cleaning brush

Key Industrial Applications of nylon cleaning brush

| Industry/Sector | Specific Application of Nylon Cleaning Brush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Cleaning food processing equipment and surfaces | Ensures hygiene and compliance with safety standards | Durable and resistant to chemicals; soft bristles for delicate surfaces |

| Automotive | Cleaning engine parts and machinery | Enhances maintenance efficiency and equipment lifespan | Variety of stiffness options; compatibility with different machinery |

| Textile and Carpet Cleaning | Carpet and upholstery cleaning using encapsulation methods | Improves cleaning effectiveness and extends fabric life | Soft and stiff bristle options; compatibility with various cleaning machines |

| Manufacturing and Heavy Industry | Tube and pipe cleaning in manufacturing processes | Increases operational efficiency and reduces downtime | Specific sizes for different applications; durability for tough environments |

| Janitorial Services | General-purpose cleaning in commercial spaces | Provides thorough cleaning for improved sanitation | Multi-surface compatibility; ease of handling and storage options |

How is Nylon Cleaning Brush Used in the Food and Beverage Industry?

In the food and beverage sector, nylon cleaning brushes are essential for maintaining hygiene standards in processing equipment and surfaces. They effectively remove residues without scratching delicate materials, ensuring compliance with safety regulations. Buyers in this industry should prioritize brushes that are durable, chemical-resistant, and designed for easy cleaning. Sourcing considerations include the brush’s bristle stiffness, which should be soft enough to avoid damage to sensitive surfaces but firm enough to remove stubborn grime.

What Role Does the Nylon Cleaning Brush Play in Automotive Applications?

Nylon cleaning brushes are vital in the automotive industry for cleaning engine parts and machinery. Their versatility allows them to tackle a range of contaminants, from oil to dirt, enhancing maintenance efficiency and prolonging equipment lifespan. B2B buyers should look for brushes that offer a variety of bristle stiffness to suit different cleaning needs, ensuring compatibility with various machinery. Additionally, sourcing options should include brushes that can withstand exposure to harsh chemicals and high temperatures.

How are Nylon Cleaning Brushes Utilized in Textile and Carpet Cleaning?

In textile and carpet cleaning, nylon brushes are specifically designed for use with encapsulation cleaning methods. These brushes effectively lift dirt and stains from carpets and upholstery, improving cleaning results and extending the life of fabrics. Buyers in this sector must consider the brush’s bristle type and stiffness, as different applications may require soft bristles for delicate fabrics or stiff bristles for tougher surfaces. Compatibility with various cleaning machines and ease of replacement are also critical factors in sourcing.

Illustrative image related to nylon cleaning brush

Why are Nylon Cleaning Brushes Important in Manufacturing and Heavy Industry?

In manufacturing and heavy industry, nylon cleaning brushes are crucial for cleaning tubes and pipes during production processes. They help remove soft deposits like mud and algae, which can hinder equipment performance and lead to costly downtime. B2B buyers should focus on sourcing brushes that are durable and available in specific sizes to fit various tube diameters. Additionally, the brushes should be designed for heavy-duty applications, ensuring they can withstand rigorous cleaning tasks.

How do Janitorial Services Benefit from Using Nylon Cleaning Brushes?

Janitorial services rely on nylon cleaning brushes for general-purpose cleaning in commercial spaces. These brushes are effective for various surfaces, ensuring thorough cleaning and sanitation, which is vital in maintaining a healthy environment. Buyers should consider brushes that offer multi-surface compatibility and ease of handling, as well as options for storage. The ability to choose between different bristle types will also enhance their cleaning capabilities, allowing for tailored solutions based on specific cleaning tasks.

3 Common User Pain Points for ‘nylon cleaning brush’ & Their Solutions

Scenario 1: The Challenge of Finding the Right Brush for Specific Applications

The Problem:

B2B buyers often struggle to identify the appropriate nylon cleaning brush for their specific cleaning applications. Different tasks, such as cleaning carpets, tiles, or delicate machinery, require brushes with varying bristle stiffness and shapes. A buyer in the industrial cleaning sector may find themselves overwhelmed by the diverse options available, risking the selection of an unsuitable brush that could lead to ineffective cleaning or even damage to surfaces. This challenge is particularly pronounced in regions where access to specialized cleaning tools is limited, making it essential to make the right choice from the outset.

The Solution:

To address this issue, buyers should conduct a thorough assessment of the surfaces and materials they need to clean. Understanding the specific requirements—like the type of debris to be removed, surface texture, and whether the brush will be used in a manual or machine application—is crucial. Buyers can benefit from consulting with manufacturers or distributors who can provide detailed product specifications, including bristle stiffness (soft, medium, or hard) and size options. Additionally, leveraging resources such as product catalogs and online guides can help buyers make informed decisions. If possible, requesting samples for trials can also help ensure the chosen brush performs effectively before committing to larger orders.

Scenario 2: Managing Inventory and Reducing Costs

The Problem:

Another common pain point for B2B buyers is the challenge of managing inventory levels while keeping costs under control. Many businesses find themselves overstocking cleaning supplies, including nylon brushes, which can lead to cash flow issues and wasted resources. Conversely, running out of essential cleaning tools can disrupt operations and impact service delivery. This balancing act is especially challenging for companies operating in multiple regions with varying demands and supply chain dynamics.

Illustrative image related to nylon cleaning brush

The Solution:

To optimize inventory management and reduce costs, buyers should implement a systematic approach to tracking usage patterns and forecasting demand. Utilizing inventory management software can help in monitoring stock levels and predicting when to reorder based on historical usage data. Establishing relationships with reliable suppliers who offer flexible ordering options, such as bulk discounts or just-in-time delivery, can also mitigate the risk of overstocking. Additionally, considering a subscription model for essential cleaning tools can provide a steady supply while minimizing upfront costs, thereby improving overall cash flow.

Scenario 3: Ensuring Compliance with Health and Safety Standards

The Problem:

Compliance with health and safety standards is a critical concern for many businesses, particularly those in industries such as food processing, healthcare, or manufacturing. B2B buyers must ensure that the nylon cleaning brushes they procure meet specific regulatory requirements regarding materials, performance, and sanitation. Failure to comply can result in serious repercussions, including fines and damage to reputation.

The Solution:

Buyers should prioritize sourcing nylon cleaning brushes that are certified for safety and compliance. This can be achieved by working closely with suppliers who can provide documentation regarding the materials used and any certifications obtained, such as FDA compliance for food-grade brushes or ISO certifications. Additionally, conducting regular audits of cleaning supplies to ensure they meet industry standards is advisable. Training staff on the proper use and care of cleaning tools can further enhance compliance efforts, as it ensures that brushes are used effectively and maintained in a sanitary condition. By implementing these practices, buyers can not only safeguard their operations but also enhance their credibility in the marketplace.

Strategic Material Selection Guide for nylon cleaning brush

What are the Key Materials Used in Nylon Cleaning Brushes?

When selecting nylon cleaning brushes for various applications, understanding the materials used is critical for ensuring optimal performance and compatibility with specific cleaning tasks. Below, we analyze four common materials used in nylon cleaning brushes, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to nylon cleaning brush

1. Nylon

Key Properties: Nylon is a synthetic polymer known for its excellent strength and durability. It can withstand temperatures up to 180°C (356°F) and offers good resistance to abrasion and chemicals.

Pros & Cons: Nylon brushes are highly durable and maintain their shape under stress, making them suitable for heavy-duty cleaning tasks. However, they can be more expensive than other materials, and their manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Nylon brushes are compatible with a wide range of cleaning media, including water, detergents, and solvents. They are particularly effective for cleaning delicate surfaces without scratching.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local regulations regarding synthetic materials. Understanding ASTM and ISO standards can also help in selecting high-quality nylon brushes.

Illustrative image related to nylon cleaning brush

2. Polypropylene

Key Properties: Polypropylene is a thermoplastic polymer that is lightweight and resistant to moisture and chemicals. It has a lower temperature tolerance than nylon, typically around 100°C (212°F).

Pros & Cons: Polypropylene brushes are generally less expensive than nylon and are highly resistant to chemical corrosion, making them ideal for cleaning applications involving harsh chemicals. However, they may not be as durable as nylon, leading to a shorter lifespan.

Impact on Application: These brushes are suitable for cleaning tasks in environments where moisture and chemicals are prevalent, such as food processing or chemical industries. However, they may not perform well on high-temperature surfaces.

Considerations for International Buyers: Buyers in South America and Europe should be aware of the environmental impact of polypropylene and seek suppliers that adhere to sustainability practices. Compliance with local regulations regarding plastic materials is also essential.

3. Stainless Steel

Key Properties: Stainless steel bristles offer high corrosion resistance and can withstand extreme temperatures, making them suitable for a variety of industrial applications.

Pros & Cons: Stainless steel brushes are incredibly durable and effective for tough cleaning tasks, such as removing rust or heavy debris. However, they can scratch softer surfaces and are typically more expensive than nylon or polypropylene options.

Impact on Application: These brushes are ideal for heavy-duty applications, including industrial cleaning and maintenance. They are effective on metal surfaces but should be avoided on delicate materials.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure that stainless steel brushes meet relevant standards for corrosion resistance and safety, such as DIN or JIS standards.

4. Brass

Key Properties: Brass bristles are softer than stainless steel and provide a balance of durability and gentleness. They are resistant to corrosion and can withstand moderate temperatures.

Pros & Cons: Brass brushes are effective for cleaning softer metals and delicate surfaces without causing damage. However, they are less durable than stainless steel and may wear out more quickly.

Illustrative image related to nylon cleaning brush

Impact on Application: Brass brushes are particularly useful in applications where scratching is a concern, such as cleaning brass or copper surfaces. They are less suitable for heavy-duty cleaning tasks.

Considerations for International Buyers: Buyers in regions like Africa and Saudi Arabia should consider the specific applications and ensure compliance with local standards for metal materials.

Summary Table of Material Selection for Nylon Cleaning Brushes

| Material | Typical Use Case for Nylon Cleaning Brush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General-purpose cleaning | High durability and abrasion resistance | Higher manufacturing complexity | Medium |

| Polypropylene | Chemical and moisture-prone environments | Cost-effective and moisture-resistant | Lower durability than nylon | Low |

| Stainless Steel | Heavy-duty industrial cleaning | Exceptional durability and heat resistance | Can scratch softer surfaces | High |

| Brass | Cleaning delicate metal surfaces | Gentle on surfaces, corrosion-resistant | Less durable than stainless steel | Medium |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for nylon cleaning brushes, ensuring informed decisions that align with specific cleaning needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for nylon cleaning brush

What Are the Key Stages in the Manufacturing Process of Nylon Cleaning Brushes?

The manufacturing of nylon cleaning brushes typically involves several critical stages, each ensuring that the final product meets high-quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality nylon filaments, which are chosen based on their stiffness and durability. Manufacturers often conduct a thorough analysis of the raw materials to ensure they meet specific performance criteria. This step may involve testing the nylon for tensile strength and resistance to wear, which are crucial for the brush’s longevity.

-

Forming: In this stage, the nylon filaments are cut to the desired lengths and shaped into bristles. Various techniques are used, such as extrusion and molding. Extrusion allows for the creation of uniform bristle lengths and diameters, while molding can be employed to create custom shapes or configurations for specialized brushes.

-

Assembly: Once the bristles are formed, they are attached to the brush head, which can be made of plastic, metal, or other materials. This assembly can be done manually or via automated processes, depending on the production scale. The attachment must be secure to ensure the bristles do not shed during use, which is a critical quality aspect.

-

Finishing: The final stage involves inspecting the brushes for defects, applying any necessary coatings, and packaging. Finishing processes may include adding ergonomic handles or anti-slip grips to enhance usability. Quality checks during this phase ensure that the brushes are aesthetically pleasing and functionally sound.

How Is Quality Assurance Integrated into the Manufacturing of Nylon Cleaning Brushes?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that nylon cleaning brushes meet international and industry-specific standards. This encompasses various checkpoints and testing methods.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which outline requirements for a quality management system. This ensures that the production process is consistent and that the final products meet customer and regulatory requirements. Compliance with CE marking may also be necessary for products sold in Europe, indicating that they meet EU safety and environmental protection requirements.

-

Quality Control Checkpoints: Effective QA involves several checkpoints:

– Incoming Quality Control (IQC): This is where raw materials are inspected upon arrival at the manufacturing facility. Testing might include checking for material specifications and physical properties.

– In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor processes and ensure that production is on track and within quality parameters.

– Final Quality Control (FQC): After assembly and finishing, a final inspection is carried out to verify that each brush meets the established standards before packaging and shipping. -

Common Testing Methods: Various testing methods are employed to assess the performance of nylon cleaning brushes. These may include:

– Durability Testing: Assessing how well the brushes withstand repeated use over time.

– Bristle Retention Tests: Ensuring that bristles remain securely attached during normal use.

– Chemical Resistance Testing: Verifying that the brushes can withstand exposure to cleaning agents without degrading.

What Should B2B Buyers Consider When Verifying Supplier Quality Control?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are key considerations:

-

Supplier Audits: Conducting regular audits of suppliers can help ensure that they adhere to the required quality standards. Buyers should request documentation of past audits and certifications to assess the reliability of the supplier’s quality management system.

-

Quality Assurance Reports: Suppliers should provide detailed QA reports that outline their testing methods, results, and compliance with international standards. These reports serve as evidence of the supplier’s commitment to quality.

-

Third-Party Inspections: Utilizing third-party inspection services can add an extra layer of confidence in the quality of products. These independent inspectors can verify compliance with quality standards and conduct their own tests on samples.

-

Understanding QC Nuances in Different Regions: Different regions may have unique quality expectations and regulatory requirements. For example, buyers in Europe may prioritize CE compliance, while those in the Middle East might focus on local safety standards. Understanding these nuances is vital for successful procurement.

-

Building Relationships: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations. Regular discussions about quality issues can help address concerns before they escalate.

How Do International Standards Impact the Quality of Nylon Cleaning Brushes?

International standards play a significant role in the quality assurance of nylon cleaning brushes. Compliance with these standards not only ensures product reliability but also enhances marketability across different regions.

-

Global Market Access: Adhering to internationally recognized standards such as ISO 9001 and CE marking allows manufacturers to access global markets. This compliance reassures buyers about the quality and safety of the products they are purchasing.

-

Consumer Trust: Products that meet international standards often enjoy higher consumer trust. For B2B buyers, sourcing from compliant suppliers can enhance their own credibility in the market.

-

Continuous Improvement: Many quality standards emphasize continuous improvement processes. This encourages manufacturers to regularly evaluate and enhance their production methods, leading to better product quality over time.

-

Risk Mitigation: Compliance with quality standards helps mitigate risks associated with product failures. This is particularly important in industries where cleaning brushes are used in sensitive environments, such as food processing or healthcare.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for nylon cleaning brushes is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions that ensure they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon cleaning brush’

To ensure a successful procurement process for nylon cleaning brushes, it is essential to follow a structured approach. This guide provides a step-by-step checklist to help international B2B buyers make informed decisions, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to nylon cleaning brush

Step 1: Define Your Technical Specifications

Clearly outline the requirements for the nylon cleaning brushes you need. Consider factors such as bristle stiffness (soft, medium, hard), brush size, and compatibility with specific cleaning applications (e.g., tile, grout, or delicate surfaces). Precise specifications will help streamline the sourcing process and ensure you obtain products that meet your operational needs.

Step 2: Research and Identify Potential Suppliers

Begin by conducting thorough research to identify suppliers who specialize in nylon cleaning brushes. Utilize online directories, trade shows, and industry-specific platforms to compile a list of potential vendors. Focus on suppliers with a proven track record in your target regions, as local knowledge can enhance reliability and customer service.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who have experience with international shipping and understand the logistics involved in your specific market. Their ability to meet delivery timelines and quality standards is paramount.

Step 4: Verify Product Quality and Compliance

Ensure that the nylon cleaning brushes meet international quality standards and any specific regulations relevant to your industry. Request samples to assess the brush performance, durability, and suitability for your intended applications. Additionally, check for certifications that demonstrate compliance with safety and environmental regulations.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted potential suppliers, initiate negotiations to establish pricing, payment terms, and delivery schedules. Be transparent about your budget constraints and expectations, while also considering the total cost of ownership, including shipping and customs fees. Aim for a mutually beneficial agreement that fosters a long-term partnership.

Step 6: Establish Communication Channels

Effective communication is vital throughout the sourcing process. Set up clear lines of communication with your chosen supplier to facilitate updates on order status, shipping details, and any potential issues. Regular interactions can help build trust and ensure that both parties are aligned on expectations.

Step 7: Plan for Inventory Management

Develop a strategy for managing inventory once the nylon cleaning brushes are procured. Consider factors such as storage requirements, shelf life, and reorder points to avoid stockouts or excess inventory. Implementing an efficient inventory management system will help optimize your operations and reduce costs.

By following this checklist, B2B buyers can navigate the complexities of sourcing nylon cleaning brushes and make informed decisions that contribute to their business success. Each step is designed to ensure that the procurement process is efficient, cost-effective, and aligned with the buyer’s specific needs.

Comprehensive Cost and Pricing Analysis for nylon cleaning brush Sourcing

What Are the Key Cost Components in Sourcing Nylon Cleaning Brushes?

When sourcing nylon cleaning brushes, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The type of nylon and bristle stiffness significantly impact the cost. High-quality nylon, which offers durability and resistance to wear, may be more expensive but will enhance the product’s lifespan.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower wage rates may offer competitive pricing but could compromise quality or lead times.

-

Manufacturing Overhead: This includes utilities, rent, and equipment costs. Efficient manufacturing practices can help reduce overhead, leading to lower overall pricing.

-

Tooling: The initial investment in tooling for custom brushes can be substantial. However, this cost is amortized over large production runs, making it more economical for high-volume orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability. While this adds to the cost, it is crucial for maintaining quality standards, particularly for buyers in regulated industries.

-

Logistics: Transportation costs can vary widely depending on the origin and destination of the brushes. International shipping, customs duties, and tariffs must be factored into the total cost.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. This margin can vary based on supplier reputation, market demand, and competition.

What Influences Pricing for Nylon Cleaning Brushes?

Several factors influence the pricing of nylon cleaning brushes, which can affect negotiations and purchasing decisions:

-

Volume/MOQ: Minimum order quantities (MOQ) often apply. Larger orders typically reduce the per-unit cost, making it vital for buyers to assess their needs accurately.

-

Specifications and Customization: Customized brushes with specific dimensions or features may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials: The choice between soft and stiff bristles, as well as the quality of nylon used, will affect pricing. Higher-end materials may justify a higher price due to better performance.

-

Quality Certifications: Brushes that meet specific quality standards or certifications may be priced higher. However, these certifications can be essential for certain applications, such as food safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is critical for international transactions. Different terms can affect who bears the cost and risk during shipping, impacting overall pricing.

What Negotiation Tips Can Help B2B Buyers Secure Better Prices?

B2B buyers looking to optimize their sourcing of nylon cleaning brushes should consider the following negotiation strategies:

-

Leverage Volume Discounts: If you anticipate a steady demand, negotiate for lower prices based on volume commitments. Suppliers may be willing to reduce prices for larger contracts.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, replacement, and performance. A higher initial investment may lead to cost savings over time.

-

Be Aware of Pricing Nuances: Factors such as currency fluctuations, regional market trends, and local economic conditions can affect pricing. Stay informed about these dynamics to strengthen your negotiating position.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing, terms, and service. Regular communication and prompt payments can enhance trust and cooperation.

What Should International Buyers Consider When Sourcing?

For buyers in Africa, South America, the Middle East, and Europe, additional considerations may include:

-

Import Regulations: Understanding local import regulations and tariffs is crucial. This knowledge can prevent unexpected costs and delays.

-

Cultural Sensitivity: Different regions may have varying expectations regarding communication and negotiation styles. Tailoring your approach can lead to more successful outcomes.

-

Logistics Infrastructure: Assessing the logistics capabilities in your region is important. Ensure that your supplier can meet your delivery timelines and shipping requirements.

By keeping these cost components and pricing influencers in mind, B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices can vary significantly based on market conditions and specific supplier offerings.

Alternatives Analysis: Comparing nylon cleaning brush With Other Solutions

Understanding Alternatives for Cleaning Solutions

In the realm of industrial and commercial cleaning, selecting the right tool is crucial for efficiency and effectiveness. While nylon cleaning brushes are popular due to their versatility and durability, there are several alternative solutions worth considering. This analysis will compare nylon cleaning brushes with other viable options, helping B2B buyers make informed decisions based on their specific cleaning needs.

Comparison Table

| Comparison Aspect | Nylon Cleaning Brush | Rotary Scrubber | Steam Cleaning Machine |

|---|---|---|---|

| Performance | Effective on various surfaces; gentle on delicate materials | High efficiency for large areas; aggressive cleaning power | Sanitizes and cleans without chemicals; effective for grease and grime |

| Cost | Low to moderate ($5 – $50) | Moderate to high ($100 – $500) | High ($200 – $1,500) |

| Ease of Implementation | Simple to use; no setup required | Requires training for optimal use | Requires setup and potential technical training |

| Maintenance | Low; replace bristles as needed | Moderate; brushes and pads need replacement | Moderate to high; requires regular descaling and maintenance |

| Best Use Case | General cleaning, detailed scrubbing | Large-scale cleaning in commercial spaces | Deep cleaning, sanitization, and tough stains |

Detailed Breakdown of Alternatives

Rotary Scrubber

Rotary scrubbers are powerful machines designed for cleaning large areas quickly and effectively. They are particularly useful in commercial settings such as warehouses and large retail spaces. Their aggressive cleaning action makes them ideal for tough stains and heavy-duty tasks. However, the cost can be significantly higher than nylon brushes, and they require some level of training to operate efficiently. Maintenance is also necessary, as brushes and pads will wear out over time.

Steam Cleaning Machine

Steam cleaning machines utilize high-temperature steam to sanitize and clean surfaces without the need for harsh chemicals. They are excellent for deep cleaning and can effectively remove grease, grime, and bacteria, making them suitable for environments requiring high hygiene standards. While steam cleaners can be highly effective, they come with a steeper price tag and may require more maintenance, including regular descaling to ensure longevity. Additionally, they often need some level of technical understanding for optimal use.

Illustrative image related to nylon cleaning brush

Conclusion: How to Choose the Right Cleaning Solution

When choosing between a nylon cleaning brush and its alternatives, B2B buyers should consider their specific cleaning requirements, budget constraints, and operational capabilities. For routine cleaning tasks with a focus on versatility and cost-effectiveness, nylon brushes are an excellent choice. Conversely, for larger-scale operations that demand more aggressive cleaning or sanitization, rotary scrubbers or steam cleaning machines may provide superior results. By carefully assessing these factors, businesses can select the most appropriate cleaning solution that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for nylon cleaning brush

What Are the Key Technical Properties of Nylon Cleaning Brushes?

When considering nylon cleaning brushes for B2B purchasing, understanding the critical specifications is essential for making informed decisions. Here are several key technical properties that buyers should evaluate:

1. Bristle Material and Grade

The primary component of nylon cleaning brushes is the bristle material, typically nylon, which is known for its durability and resistance to wear. Nylon brushes can be formulated in various grades, influencing their stiffness and cleaning effectiveness. A higher grade nylon offers enhanced longevity and performance, particularly in industrial applications where brushes are subjected to frequent use.

2. Bristle Stiffness

Bristle stiffness is a crucial property that affects the brush’s cleaning capability. Brushes are available in soft, medium, and hard bristle options. Soft bristles are ideal for delicate surfaces, while hard bristles are suited for heavy-duty scrubbing of resilient surfaces like tile or concrete. Selecting the appropriate stiffness is vital for achieving optimal cleaning results without damaging surfaces.

3. Size and Shape Variability

Nylon cleaning brushes come in various sizes and shapes, including standard scrub brushes, bottle brushes, and specialized designs for specific applications (e.g., tube cleaning brushes). Understanding the dimensions required for your cleaning tasks ensures compatibility with cleaning equipment and maximizes efficiency. Custom sizes may also be available, allowing for tailored solutions to meet unique business needs.

4. Heat and Chemical Resistance

The ability of nylon brushes to withstand high temperatures and exposure to chemicals is an important factor, especially in industrial settings. Certain nylon grades are engineered to resist degradation from harsh cleaning agents and extreme conditions, prolonging the brush’s lifespan. This property is particularly relevant for sectors like food processing or automotive cleaning, where compliance with safety standards is crucial.

5. Replaceable Components

Many nylon cleaning brushes feature replaceable parts, such as bristles or grommets, which can significantly enhance the product’s lifecycle. This capability allows businesses to maintain performance without the need for complete brush replacement, offering cost savings and reduced waste. Understanding the availability of replacement components can influence purchasing decisions, especially for high-use environments.

What Common Trade Terms Should B2B Buyers Know When Purchasing Nylon Cleaning Brushes?

Navigating the procurement process for nylon cleaning brushes requires familiarity with industry jargon. Here are several common terms that B2B buyers should understand:

Illustrative image related to nylon cleaning brush

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of cleaning brushes, buyers may seek brushes that are OEM-compatible with their existing cleaning equipment, ensuring seamless integration and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier requires a buyer to purchase in a single order. Understanding the MOQ is crucial for inventory management and cash flow planning. Businesses must assess their cleaning needs against the MOQ to avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. B2B buyers should utilize RFQs when sourcing nylon cleaning brushes to obtain competitive pricing and ensure they receive accurate information regarding product specifications.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international transactions to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and rights, facilitating smoother international transactions.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. In the context of nylon cleaning brushes, each variation (size, bristle type, etc.) will have its own SKU, allowing for efficient inventory management and tracking.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions when sourcing nylon cleaning brushes, ensuring they meet their operational needs effectively and efficiently.

Navigating Market Dynamics and Sourcing Trends in the nylon cleaning brush Sector

What Are the Key Trends Shaping the Global Nylon Cleaning Brush Market?

The nylon cleaning brush market is experiencing significant growth, driven by several global factors. Increased industrialization and urbanization, particularly in emerging economies in Africa and South America, are leading to heightened demand for efficient cleaning solutions across various sectors, including automotive, healthcare, and food processing. Furthermore, the rising awareness of hygiene standards is prompting businesses to invest in high-quality cleaning tools, including nylon brushes, that offer durability and versatility.

Technological advancements are also influencing sourcing trends. The integration of digital platforms for procurement is making it easier for international buyers to access suppliers, compare products, and manage orders efficiently. This shift toward e-commerce is particularly relevant for B2B buyers in regions like the Middle East and Europe, where convenience and speed are paramount. Additionally, the use of automation in manufacturing processes is enhancing product consistency and reducing lead times, making it more feasible for businesses to source nylon cleaning brushes on-demand.

Moreover, the market is witnessing a trend towards customization. Buyers are increasingly seeking brushes tailored to specific applications, such as specialized brushes for cleaning industrial machinery or brushes designed for delicate surfaces. This demand for tailored solutions is prompting manufacturers to adopt flexible production techniques, allowing for shorter production runs and quicker turnaround times.

How Are Sustainability and Ethical Sourcing Influencing the Nylon Cleaning Brush Sector?

Sustainability is becoming a critical consideration for B2B buyers in the nylon cleaning brush market. The environmental impact of plastic waste, particularly from synthetic materials like nylon, has led many companies to reevaluate their sourcing strategies. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through the use of recycled materials, eco-friendly manufacturing processes, and responsible end-of-life disposal options.

Ethical sourcing is another crucial aspect, as businesses strive to create transparent supply chains that minimize harm to the environment and ensure fair labor practices. Buyers are advised to seek out manufacturers with certifications that verify their commitment to sustainable practices, such as ISO 14001 for environmental management or certifications from recognized organizations focused on social responsibility.

In response to consumer demand for greener products, many manufacturers are innovating by developing nylon brushes made from bio-based or recycled materials. This not only reduces the carbon footprint associated with production but also appeals to eco-conscious buyers looking to enhance their corporate social responsibility (CSR) initiatives. As sustainability becomes a key differentiator in the market, B2B buyers should actively seek partnerships with suppliers who align with their values and goals.

How Has the Nylon Cleaning Brush Market Evolved Over Time?

The nylon cleaning brush has evolved significantly since its inception, transitioning from basic utility tools to specialized equipment tailored for diverse applications. Initially, brushes were primarily used in domestic settings; however, as industries expanded, the need for more robust and versatile cleaning tools became apparent. The introduction of nylon bristles revolutionized the cleaning brush market due to their durability, resistance to wear, and ability to maintain effectiveness across various surfaces.

Illustrative image related to nylon cleaning brush

In recent decades, the nylon cleaning brush has further diversified, with advancements in manufacturing technologies allowing for the production of specialized brushes designed for specific tasks, such as heavy-duty industrial cleaning or delicate applications in healthcare. This evolution reflects broader trends in material science and an increasing focus on efficiency and effectiveness in cleaning operations. Today, B2B buyers can access an extensive range of nylon cleaning brushes that cater to their unique operational needs, enhancing productivity and maintaining high standards of cleanliness in their environments.

Frequently Asked Questions (FAQs) for B2B Buyers of nylon cleaning brush

-

How do I choose the right nylon cleaning brush for my business needs?

Selecting the appropriate nylon cleaning brush involves assessing the specific cleaning tasks and surfaces you’ll be working with. Consider factors such as bristle stiffness (soft, medium, or hard), brush size, and the surface material (e.g., tile, grout, metal). Additionally, evaluate whether you need specialty brushes for particular applications, such as tube cleaning or carpet maintenance. Engaging with your suppliers for samples can also provide insight into the performance and suitability of different brushes for your needs. -

What is the best nylon cleaning brush for heavy-duty industrial applications?

For heavy-duty industrial cleaning, brushes with stiff bristles made of durable nylon are often the best choice. These brushes are designed to handle aggressive scrubbing on hard surfaces like concrete and tile. Look for options that are resistant to wear and have features like ergonomic handles for ease of use. Brands specializing in industrial cleaning tools often offer a range of sizes and stiffness levels to meet various cleaning demands, so it’s beneficial to consult with suppliers about their recommendations based on your specific industry. -

How can I vet suppliers of nylon cleaning brushes in international markets?

To vet suppliers effectively, start by researching their reputation through online reviews, industry forums, and trade associations. Request references from other businesses that have purchased from them. Ensure they comply with international quality standards, such as ISO certifications. It’s also advisable to conduct a factory visit if possible or use third-party inspection services to evaluate their manufacturing capabilities and quality control processes before placing an order. -

What are the common minimum order quantities (MOQs) for nylon cleaning brushes?

Minimum order quantities (MOQs) for nylon cleaning brushes can vary significantly based on the supplier and the specific product. Typically, MOQs range from 100 to 500 units. Some suppliers may allow lower MOQs for standard items or offer discounts for larger orders. It’s essential to discuss your requirements directly with suppliers to negotiate favorable terms that suit your purchasing strategy while ensuring you meet their production thresholds. -

What payment terms should I expect when sourcing nylon cleaning brushes internationally?

Payment terms can differ based on the supplier’s policies and the nature of your business relationship. Common terms include 30% upfront payment with the balance due before shipment or upon delivery. Some suppliers may offer letter of credit options for larger orders. Be sure to clarify payment methods accepted (e.g., wire transfer, PayPal) and inquire about any discounts for early payments or bulk orders to optimize your cash flow. -

What quality assurance measures should I consider for nylon cleaning brushes?

Quality assurance is critical in ensuring that the nylon cleaning brushes meet your performance expectations. Inquire about the supplier’s quality control processes, including material sourcing, manufacturing standards, and testing protocols. Request certifications that demonstrate compliance with relevant safety and quality standards. Additionally, consider establishing a quality inspection process before shipment to confirm that the brushes meet your specifications and are free from defects. -

How can I customize nylon cleaning brushes to fit my specific requirements?

Many suppliers offer customization options for nylon cleaning brushes, allowing you to specify dimensions, bristle stiffness, and handle designs. To initiate customization, provide detailed specifications and discuss your needs with the supplier. Be prepared to engage in a prototype phase where you can assess sample brushes before finalizing your order. This ensures that the final product aligns with your operational requirements and enhances your cleaning efficiency. -

What logistics considerations should I keep in mind when importing nylon cleaning brushes?

When importing nylon cleaning brushes, consider factors like shipping costs, lead times, and customs regulations in your country. Work with reliable freight forwarders who understand the import process and can assist with documentation. Ensure that your order is consolidated efficiently to minimize shipping expenses. Additionally, account for potential delays in customs clearance and plan your inventory accordingly to maintain consistent supply levels for your business.

Top 2 Nylon Cleaning Brush Manufacturers & Suppliers List

1. Cimex – White Nylon Brushes (3 Pack)

Domain: cimex.us

Registered: 2016 (9 years)

Introduction: {“product_name”: “White Nylon Brushes (3 Pack)”, “price_range”: “$196.01 – $407.77”, “description”: “Pack of 3 economical white nylon brushes. Safe for use on most surfaces. Available in both soft and stiff bristles.”, “soft_bristles”: “Gentle enough for encapsulation carpet cleaning with Cimex Carpet Machines.”, “stiff_bristles”: “Offers aggressive cleaning on hard floors with Cimex Scrubbers.”, …

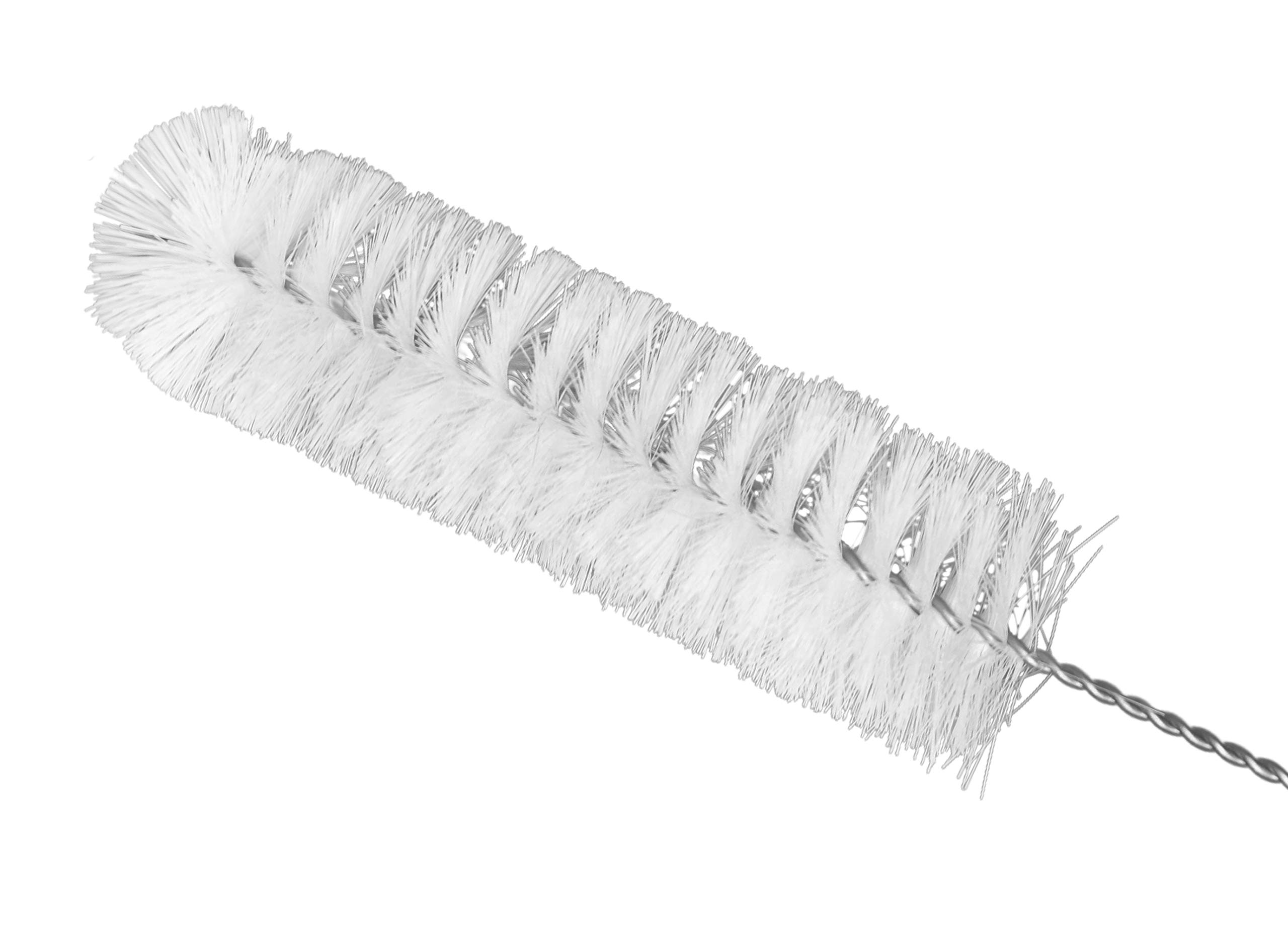

2. Goodway – Tube Cleaning Brush, Nylon ‘Patriot’ Dual Diameter

Domain: goodway.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Tube Cleaning Brush, Nylon, ‘Patriot’ Dual Diameter”, “sku”: “ENN-062-Q”, “price”: “$7.75”, “brush_fitting_type”: [“Quick Connect”, “Standard Threading”], “tube_inner_diameter”: [“5/8″ (15.9mm)”, “15/16″ (23.8mm)”], “features”: [“High quality dual diameter nylon brush”, “Recommended for removing soft deposits (mud, algae, etc.)”, “Durable and long lasting”, “Available in two size…

Strategic Sourcing Conclusion and Outlook for nylon cleaning brush

How Can Strategic Sourcing Enhance Your Nylon Cleaning Brush Procurement?

In today’s competitive landscape, the strategic sourcing of nylon cleaning brushes is essential for international B2B buyers aiming to optimize their cleaning operations. By understanding the diverse applications of nylon brushes—from soft bristle options for delicate surfaces to stiff bristles for heavy-duty cleaning—companies can make informed decisions that align with their specific needs.

Furthermore, leveraging local suppliers in regions like Africa, South America, the Middle East, and Europe can lead to cost efficiencies and reduced lead times. Engaging with manufacturers who offer tailored solutions and flexible ordering options ensures that businesses are equipped with the right tools for their cleaning tasks, enhancing overall productivity.

As we look to the future, the nylon cleaning brush market is poised for growth, driven by innovations in material technology and sustainable practices. International buyers are encouraged to explore partnerships that not only meet their current needs but also adapt to evolving market demands. Embrace strategic sourcing as a pathway to streamline your procurement processes and elevate your operational effectiveness. Act now to position your business advantageously in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.