Northeast Laser Monroe Ct: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for northeast laser monroe ct

In an increasingly competitive global landscape, sourcing advanced laser systems from Northeast Laser in Monroe, CT, presents unique challenges for international B2B buyers. As industries evolve, the demand for precision laser solutions—ranging from cutting and welding to engraving—grows, creating a pressing need for reliable suppliers who can deliver quality and innovation. This comprehensive guide aims to equip buyers, particularly those from Africa, South America, the Middle East, and Europe, with actionable insights into sourcing laser technology effectively.

Navigating the complexities of the global market for laser systems involves understanding various types of lasers, their applications, and the nuances of supplier vetting. This guide delves into the specifications of CO2, fiber, and Nd:YAG lasers, and explores their suitability for diverse industrial, medical, and scientific applications. Additionally, we will discuss the importance of evaluating supplier capabilities, including installation, maintenance, and customization services.

By providing a detailed overview of costs, quality standards, and the competitive landscape, this resource empowers buyers to make informed purchasing decisions. Whether you are seeking standard laser products or custom solutions, this guide will help you identify trusted suppliers like Northeast Laser and optimize your procurement strategies for success in your respective markets.

Understanding northeast laser monroe ct Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Lasers | Utilizes carbon dioxide as a gain medium; ideal for cutting and engraving non-metal materials. | Woodworking, textiles, packaging, and signage. | Pros: Versatile for various materials; high precision. Cons: Limited metal cutting capabilities. |

| Fiber Lasers | Employs optical fibers for high efficiency; excellent for metal cutting and welding. | Aerospace, automotive, and metal fabrication. | Pros: High speed and precision; low maintenance. Cons: Higher initial investment. |

| Nd:YAG Lasers | Uses neodymium-doped yttrium aluminum garnet; suitable for deep penetration cutting and welding. | Medical devices, aerospace components. | Pros: High power output; effective for thick materials. Cons: More complex operation and setup. |

| Diode Lasers | Compact and energy-efficient; ideal for marking and engraving. | Electronics, jewelry, and promotional items. | Pros: Cost-effective; compact design. Cons: Limited cutting capabilities compared to CO2 and fiber lasers. |

| Custom Laser Solutions | Tailored systems designed to meet specific industry needs and applications. | Specialized manufacturing, unique product designs. | Pros: Meets specific requirements; enhances operational efficiency. Cons: Longer development time and higher costs. |

What are the Key Characteristics of CO2 Lasers and Their B2B Applications?

CO2 lasers are a popular choice in industries requiring precision cutting and engraving of non-metal materials such as wood, textiles, and plastics. These lasers utilize carbon dioxide as a gain medium, allowing for high-quality results at relatively lower operational costs. B2B buyers should consider the versatility of CO2 lasers, which can be adapted for various applications, but note their limitations in cutting metals. These systems are particularly suited for businesses in woodworking, signage, and packaging industries.

How Do Fiber Lasers Stand Out in Industrial Applications?

Fiber lasers are recognized for their efficiency and speed, making them ideal for metal cutting and welding applications. They utilize optical fibers to generate the laser beam, which enhances energy efficiency and reduces maintenance needs. Industries such as aerospace and automotive benefit from the precision and high power output of fiber lasers, although buyers should be prepared for a higher initial investment. The long-term savings in energy and maintenance, however, often justify this cost.

What Makes Nd:YAG Lasers Suitable for Specialized Industries?

Nd:YAG lasers are distinguished by their ability to produce high power output, making them effective for deep penetration cutting and welding of thick materials. They find applications in the medical device and aerospace sectors, where precision and reliability are paramount. Buyers should consider the complexity of operation and setup associated with Nd:YAG lasers, which may require specialized training. Nonetheless, their capability to handle demanding applications makes them a valuable investment for businesses focused on high-quality production.

Why Choose Diode Lasers for Cost-Effective Marking Solutions?

Diode lasers are compact, energy-efficient, and particularly well-suited for marking and engraving applications. They are commonly used in the electronics and jewelry industries, where precision and cost-effectiveness are critical. While diode lasers offer excellent value, buyers should be aware of their limitations in cutting capabilities compared to CO2 and fiber lasers. For businesses focused on engraving and marking, diode lasers represent a practical and efficient solution.

What Are the Benefits of Custom Laser Solutions for B2B Buyers?

Custom laser solutions offer tailored systems designed to meet the specific needs of various industries. These solutions are particularly beneficial for specialized manufacturing processes or unique product designs that standard systems may not accommodate. While they can involve longer development times and potentially higher costs, the ability to enhance operational efficiency and meet precise requirements makes them an attractive option for businesses seeking competitive advantages in their markets.

Key Industrial Applications of northeast laser monroe ct

| Industry/Sector | Specific Application of northeast laser monroe ct | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Precision laser marking for surgical instruments | Enhances traceability and compliance with regulations | Ensure ISO certifications and experience in medical applications. |

| Aerospace | Laser cutting and welding for components | Improves structural integrity and reduces weight | Look for advanced materials handling and rapid prototyping capabilities. |

| Automotive | Laser engraving of identification codes on parts | Increases product authenticity and reduces counterfeiting | Consider turnaround times and customization options for unique parts. |

| Electronics | Laser marking for circuit boards and components | Ensures precision and reliability in electronic assemblies | Verify compatibility with various substrates and adherence to industry standards. |

| Packaging | Laser cutting and engraving for custom packaging | Enhances branding and customer engagement | Assess capabilities for both small runs and mass production needs. |

How Does Northeast Laser Serve the Medical Device Industry?

In the medical device sector, Northeast Laser specializes in precision laser marking of surgical instruments and medical assemblies. This application is crucial for enhancing traceability, as it allows for clear identification and compliance with stringent regulatory standards. International buyers should prioritize suppliers that demonstrate ISO certifications and a proven track record in medical applications to ensure quality and safety.

What Role Does Northeast Laser Play in Aerospace Manufacturing?

The aerospace industry benefits significantly from Northeast Laser’s advanced laser cutting and welding services, which are essential for manufacturing lightweight yet strong components. This capability not only improves structural integrity but also contributes to fuel efficiency in aircraft. Buyers from regions such as Africa and South America should consider suppliers that offer rapid prototyping and advanced materials handling to meet industry-specific demands.

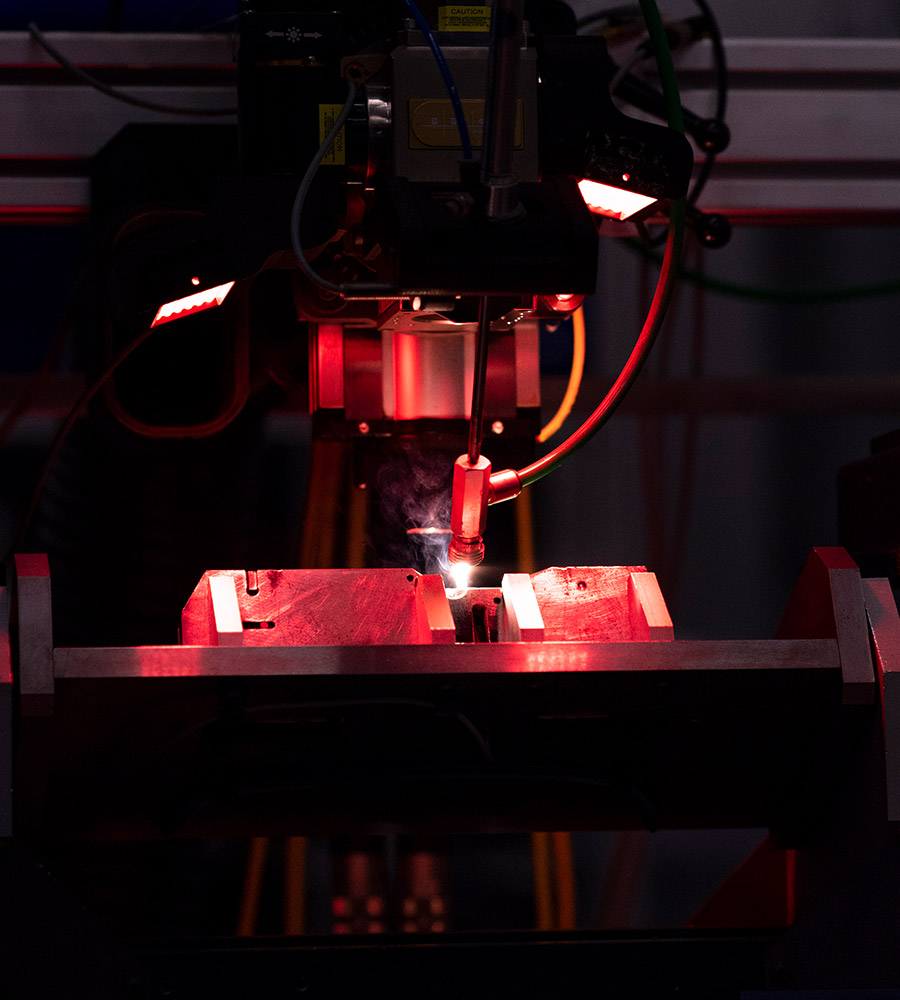

Illustrative image related to northeast laser monroe ct

How Can Automotive Companies Leverage Laser Technology?

Automotive manufacturers utilize Northeast Laser’s laser engraving services to mark identification codes on various parts, enhancing product authenticity and reducing counterfeiting risks. This application is vital for maintaining brand integrity in a competitive market. When sourcing from Northeast Laser, international automotive firms should evaluate the company’s turnaround times and customization options to align with their production schedules.

Why is Laser Marking Important for Electronics?

In the electronics sector, Northeast Laser provides laser marking for circuit boards and components, ensuring precision and reliability in electronic assemblies. This application is critical for meeting industry standards and enhancing product quality. Buyers should verify the supplier’s compatibility with various substrates, as well as adherence to relevant standards, to ensure optimal performance.

How Does Northeast Laser Improve Packaging Solutions?

Northeast Laser’s laser cutting and engraving services for custom packaging enhance branding and customer engagement through unique design elements. This application is particularly valuable in industries where packaging plays a significant role in product differentiation. Companies looking for these services should assess Northeast Laser’s capabilities for both small runs and mass production to ensure they can meet diverse packaging needs effectively.

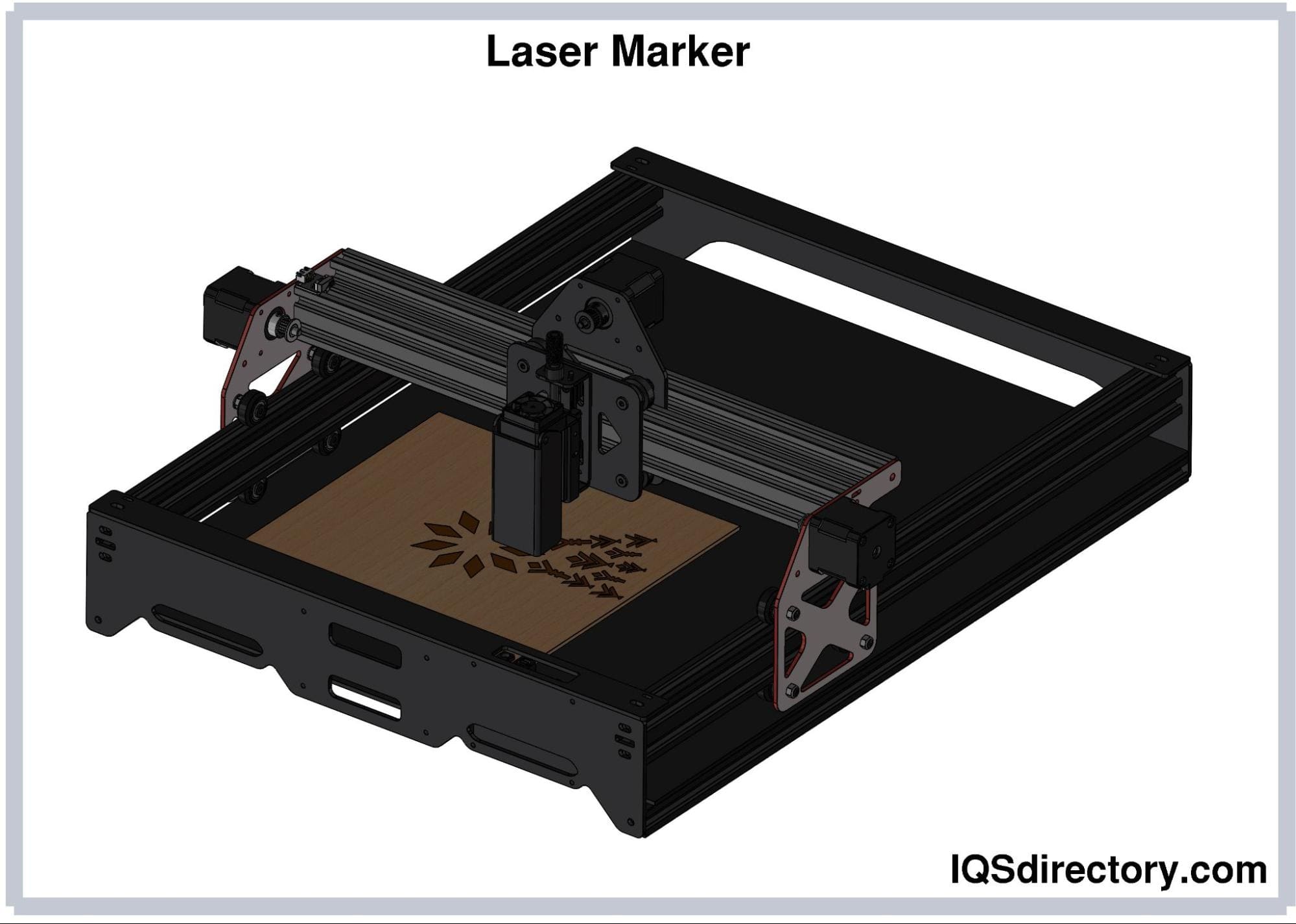

Illustrative image related to northeast laser monroe ct

3 Common User Pain Points for ‘northeast laser monroe ct’ & Their Solutions

Scenario 1: Difficulty in Finding Custom Laser Solutions for Unique Applications

The Problem: B2B buyers often face challenges when sourcing laser systems that cater to specific operational needs. Many industries require customized solutions for unique applications, such as specialized medical devices or intricate industrial components. The lack of readily available products that meet precise specifications can lead to project delays, increased costs, and frustration, particularly for companies operating in sectors like healthcare or aerospace, where precision is paramount.

The Solution: To overcome this hurdle, it’s vital to engage with Northeast Laser & Electropolish early in your project development. Start by articulating your specific requirements, including the type of materials involved, the desired outcomes, and any regulatory standards that must be met. Utilize their expertise in custom laser solutions by requesting a comprehensive consultation. This collaboration can lead to the design of bespoke laser systems tailored to your operational needs, ultimately minimizing lead times and ensuring compliance with industry standards. Additionally, consider leveraging their capability for rapid prototyping to test solutions before full-scale implementation, which can significantly reduce the risk of costly errors.

Scenario 2: Concerns About Quality Control and Service Reliability

The Problem: Quality control is a major concern for B2B buyers, especially when it comes to investing in advanced laser technologies. Buyers often worry about the reliability of the laser systems and the consistency of service provided by vendors. Inconsistent performance can lead to defective products, increased waste, and customer dissatisfaction, making it crucial for companies to partner with a supplier that emphasizes quality and reliability.

The Solution: Northeast Laser’s commitment to quality assurance can serve as a critical advantage. Before finalizing a partnership, conduct thorough due diligence by requesting information on their quality control processes, including certifications and compliance with industry standards. Inquire about their maintenance and support services, as these are essential for ensuring the longevity and reliability of your laser systems. Establishing a service level agreement (SLA) can also ensure that you receive timely maintenance and support, thus minimizing downtime. By prioritizing quality and reliability in your sourcing strategy, you can maintain operational efficiency and enhance your product quality.

Scenario 3: Navigating Rapid Technological Changes and Upgrades

The Problem: The pace of technological advancement in laser systems can be overwhelming for B2B buyers. Companies often struggle to keep their equipment updated, which can lead to obsolescence and a competitive disadvantage. The need for regular upgrades or retrofitting of existing systems can also complicate budgeting and planning, especially for businesses operating with tight margins.

The Solution: To effectively navigate these challenges, develop a proactive technology strategy in collaboration with Northeast Laser. Start by assessing your current laser systems and identifying areas where upgrades could enhance performance. Engage with their team to explore the latest laser technologies, including fiber and CO2 lasers, and their applications across different industries. Additionally, consider integrating a phased upgrade plan that allows you to allocate budget resources over time rather than facing a large, unexpected expense all at once. This approach not only keeps your operations competitive but also allows you to adapt to technological advancements seamlessly. Regularly review your technology needs with Northeast Laser to ensure that your systems remain aligned with industry trends and operational demands.

Strategic Material Selection Guide for northeast laser monroe ct

What Are the Key Materials Commonly Used in Laser Applications?

When considering laser applications offered by Northeast Laser in Monroe, CT, several materials stand out due to their unique properties and suitability for various industrial, medical, and scientific applications. Below, we analyze four common materials: metals, plastics, ceramics, and wood, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

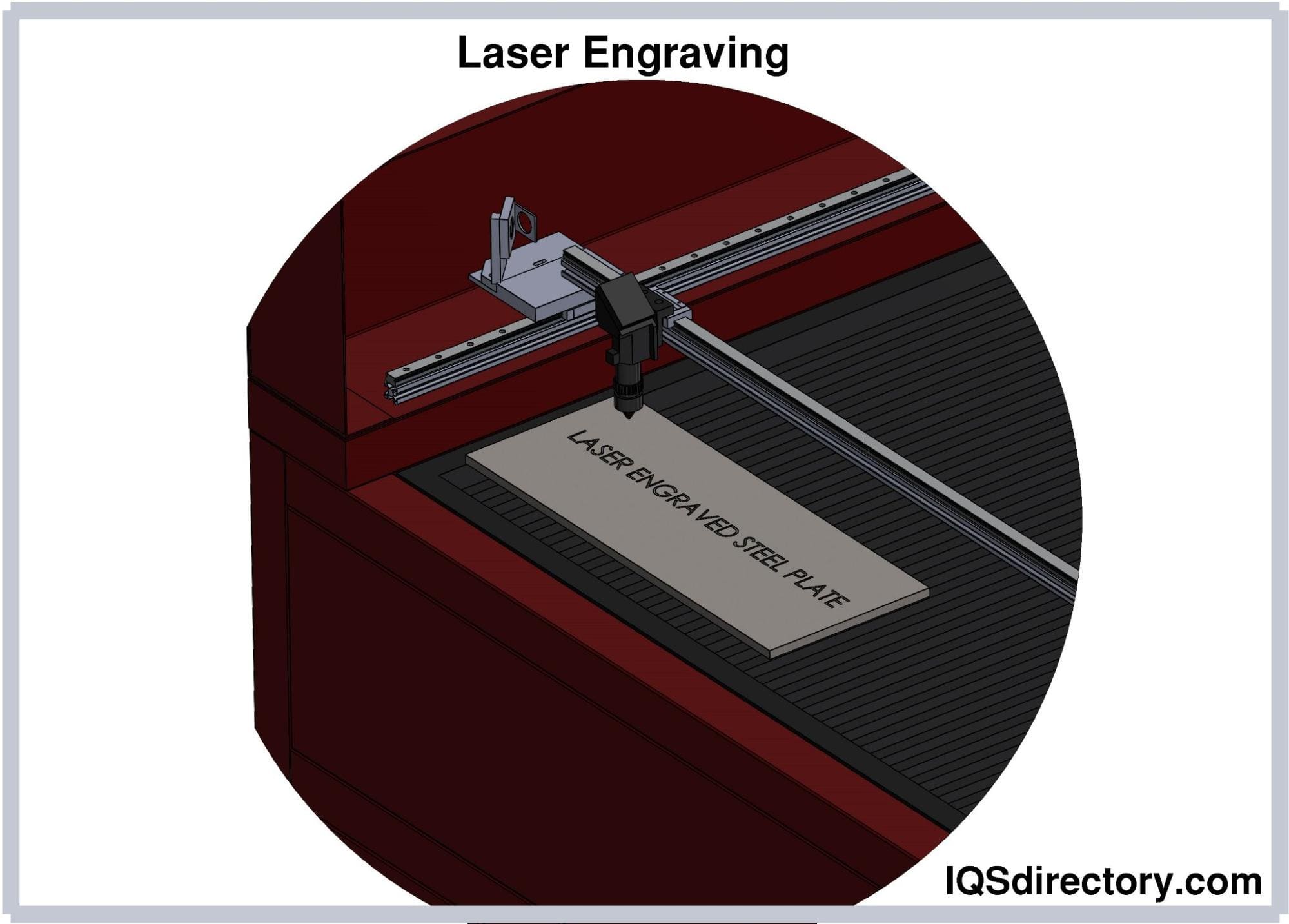

How Do Metals Perform in Laser Applications?

Metals, such as stainless steel, aluminum, and titanium, are widely used in laser cutting, engraving, and welding due to their excellent thermal conductivity and strength. Key properties include high melting points, corrosion resistance (especially in stainless steel), and the ability to withstand high-pressure environments.

Pros: Metals offer durability and are suitable for heavy-duty applications. They can be precisely cut and welded, making them ideal for components in automotive, aerospace, and medical industries.

Cons: The cost of metals can be high, especially for specialized alloys. Additionally, the manufacturing complexity increases with the need for precise control of laser parameters to avoid warping or damaging the material.

Illustrative image related to northeast laser monroe ct

Impact on Application: Metals are compatible with various media, including gases and liquids, making them versatile for different applications. However, their weight can be a consideration in design.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is crucial. Buyers from regions like Africa or South America should ensure that materials meet local regulations for safety and quality.

What Role Do Plastics Play in Laser Cutting and Engraving?

Plastics, including acrylic, polycarbonate, and PVC, are popular for laser applications due to their lightweight nature and ease of processing. Key properties include low melting points and a wide range of colors and finishes.

Pros: Plastics are generally more cost-effective than metals and can be produced in various shapes and sizes. They are also resistant to corrosion and chemicals, making them suitable for many applications.

Cons: Plastics can be less durable than metals and may not withstand high temperatures or pressures. They can also emit harmful fumes when cut or engraved, necessitating proper ventilation.

Impact on Application: Plastics are ideal for applications such as signage, packaging, and decorative items. Their compatibility with various media is excellent, but they may not be suitable for high-stress environments.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of plastics, especially in food and medical applications. Compliance with standards like DIN or JIS may be necessary.

How Do Ceramics Enhance Laser Applications?

Ceramics are increasingly utilized in laser applications due to their high hardness and thermal stability. Key properties include excellent wear resistance and the ability to withstand high temperatures.

Pros: Ceramics are highly durable and resistant to corrosion and wear, making them suitable for applications in harsh environments, such as aerospace and electronics.

Cons: The brittleness of ceramics can be a limitation, as they are prone to cracking under stress. The cost of ceramic materials can also be higher compared to metals and plastics.

Impact on Application: Ceramics are often used in specialized applications where high precision is required, such as in medical devices or electronic components. Their compatibility with various media is generally high.

Considerations for International Buyers: Buyers should ensure that ceramics meet specific international standards for quality and safety, particularly in medical applications.

Why Is Wood a Considered Material for Laser Applications?

Wood is commonly used in laser engraving and cutting due to its natural aesthetic and workability. Key properties include varying densities and the ability to be treated for durability.

Illustrative image related to northeast laser monroe ct

Pros: Wood is relatively inexpensive and easy to work with, offering a wide range of design possibilities. It is also biodegradable, making it an environmentally friendly option.

Cons: Wood can be less durable than metals and may not perform well under high-stress conditions. Additionally, it can warp or crack if not properly treated.

Impact on Application: Wood is ideal for decorative items, furniture, and signage. Its compatibility with various media is good, but moisture can affect its performance.

Considerations for International Buyers: Buyers should consider local sourcing of wood to comply with environmental regulations and sustainability practices. Standards for wood treatment and safety may also vary by region.

Summary Table of Material Selection for Laser Applications

| Material | Typical Use Case for northeast laser monroe ct | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metals | Automotive, aerospace, medical components | High durability and strength | Higher cost and manufacturing complexity | High |

| Plastics | Signage, packaging, decorative items | Cost-effective and versatile | Less durable, can emit fumes | Medium |

| Ceramics | Medical devices, electronics | Excellent wear resistance | Brittle, higher cost | High |

| Wood | Decorative items, furniture, signage | Environmentally friendly | Less durable, moisture sensitivity | Low |

This guide offers insights into material selection for laser applications, providing B2B buyers with essential information to make informed decisions. Understanding these materials’ properties and implications will help in sourcing the right solutions for various industrial needs.

Illustrative image related to northeast laser monroe ct

In-depth Look: Manufacturing Processes and Quality Assurance for northeast laser monroe ct

What Are the Key Stages of Manufacturing Processes at Northeast Laser in Monroe, CT?

Northeast Laser & Electropolish, LLC employs a systematic manufacturing process tailored to its laser systems and services. The process comprises several crucial stages: material preparation, forming, assembly, and finishing. Each phase is meticulously designed to ensure precision and high-quality output.

How Is Material Prepared for Laser Manufacturing?

The manufacturing journey begins with material selection and preparation. Northeast Laser sources high-grade materials, including metals, plastics, and ceramics, ensuring they meet specific requirements for each application. The materials undergo rigorous inspection to verify their integrity and suitability. This initial step is vital, as the quality of raw materials directly impacts the final product’s performance and reliability.

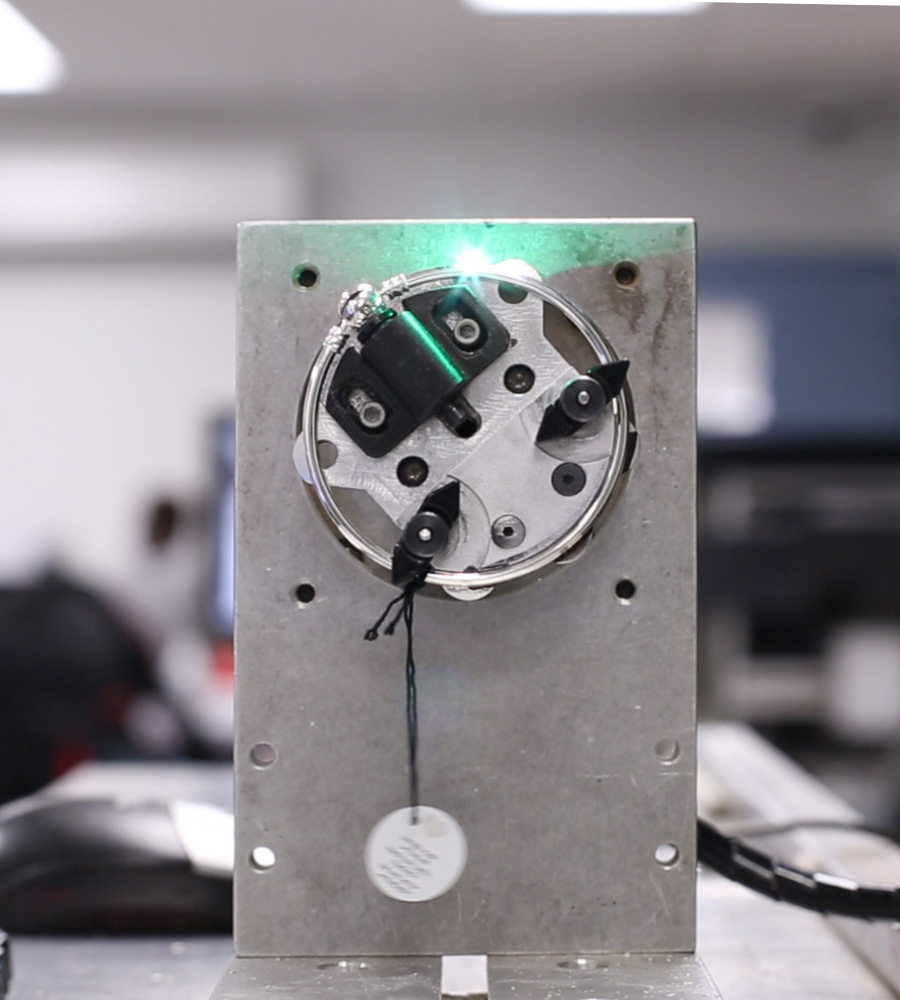

What Forming Techniques Are Utilized in Laser Manufacturing?

Once the materials are prepared, the forming stage commences. Northeast Laser employs advanced laser cutting and engraving techniques that leverage CO2, fiber, Nd:YAG, and diode lasers. These technologies allow for precise cutting, welding, and marking, accommodating various thicknesses and complexities of materials. The automated nature of these systems enhances efficiency while minimizing waste, thus offering competitive pricing for B2B buyers.

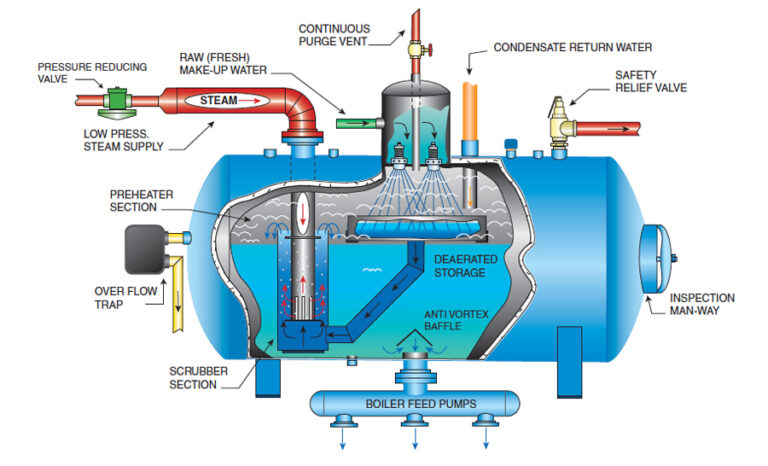

How Does Assembly Work at Northeast Laser?

Following the forming phase, the assembly of laser systems takes place. This stage involves integrating various components, including laser heads, control systems, and cooling mechanisms, into a cohesive unit. Skilled technicians ensure that each assembly meets the specified design parameters. The assembly process is often supported by modular design principles, allowing for easy upgrades and customization based on client requirements.

What Finishing Processes Are Applied to Laser Products?

The final stage in the manufacturing process involves finishing techniques such as electropolishing and surface treatment. These processes enhance the aesthetic and functional properties of the laser systems. Electropolishing, in particular, improves corrosion resistance, which is crucial for applications in medical and industrial sectors. The finishing stage also includes thorough cleaning and inspection to ensure that each product is free from defects before it reaches the customer.

How Is Quality Assurance Ensured in Manufacturing at Northeast Laser?

Quality assurance is integral to the operational ethos at Northeast Laser. The company adheres to international standards, including ISO 9001, which governs quality management systems. This commitment to quality not only enhances customer satisfaction but also fosters trust among B2B buyers.

What International Standards Are Relevant to Quality Assurance?

Northeast Laser’s adherence to ISO 9001 ensures that its processes are consistently monitored and improved. Additionally, industry-specific certifications such as CE and API are crucial for products destined for medical or aerospace applications. These certifications verify compliance with safety and performance standards, which are particularly important for international buyers.

What Are the Key Quality Control Checkpoints?

Quality control at Northeast Laser is structured around several critical checkpoints, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials before they enter the production line, ensuring they meet predefined specifications.

- IPQC monitors the manufacturing process in real-time, allowing for immediate corrections if deviations are detected.

- FQC entails a thorough examination of the finished products, verifying that they conform to all technical and aesthetic requirements.

These checkpoints create a comprehensive quality framework that minimizes the risk of defects and ensures that every product meets the high standards set by Northeast Laser.

What Common Testing Methods Are Employed?

Testing methods at Northeast Laser include dimensional inspections, functional tests, and performance evaluations. Dimensional inspections utilize advanced measuring tools to confirm that products meet specified tolerances. Functional tests evaluate the operational capabilities of the laser systems, ensuring they perform as intended under various conditions. Performance evaluations often involve stress testing to simulate real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can take several steps to verify the quality control processes of Northeast Laser.

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is an effective way to assess the manufacturing capabilities and quality assurance processes of Northeast Laser. Buyers can request access to quality documentation, including inspection reports and compliance certificates. This transparency fosters confidence and allows buyers to make informed decisions.

How Can Buyers Access Quality Reports and Third-Party Inspections?

In addition to audits, buyers should inquire about the availability of quality reports and third-party inspections. Independent assessments can provide an unbiased evaluation of the manufacturing processes and product quality. Northeast Laser’s commitment to transparency and quality assurance can be further confirmed through these third-party validations.

What Quality Certification Nuances Should International Buyers Consider?

International buyers must consider regional regulatory requirements and standards when engaging with suppliers like Northeast Laser. Certifications that are recognized in one region may not hold the same weight in another. Therefore, it’s essential for buyers to communicate their specific quality assurance needs upfront, ensuring that the products they receive are compliant with their local regulations.

Conclusion

Northeast Laser & Electropolish, LLC exemplifies a robust approach to manufacturing and quality assurance in the laser systems industry. By understanding the intricacies of their manufacturing processes and quality control measures, international B2B buyers can make informed purchasing decisions that align with their operational needs. The commitment to quality, transparency, and customer collaboration positions Northeast Laser as a valuable partner in delivering advanced laser solutions.

Illustrative image related to northeast laser monroe ct

Practical Sourcing Guide: A Step-by-Step Checklist for ‘northeast laser monroe ct’

In this practical sourcing guide, we aim to equip B2B buyers with a comprehensive checklist for procuring laser solutions from Northeast Laser in Monroe, CT. This guide is tailored for international buyers seeking high-quality laser systems and services, ensuring you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly outline your project requirements, including the type of laser technology needed—be it CO2, fiber, or Nd:YAG. Each laser type has specific capabilities suited to various applications such as cutting, engraving, or welding. Defining these specifications upfront helps streamline communication with potential suppliers and ensures that you receive solutions that meet your precise needs.

Step 2: Research Supplier Capabilities

Investigate Northeast Laser’s product offerings and service capabilities. This includes their experience in customizing laser systems for specific applications. Look for details on their range of services, such as installation, maintenance, and repair, to ensure they can support your needs beyond the initial purchase.

Illustrative image related to northeast laser monroe ct

Step 3: Evaluate Quality Assurance Processes

Understanding the quality control measures in place is crucial for ensuring reliability and safety. Request documentation on their quality assurance programs and any relevant certifications, such as ISO standards. A strong commitment to quality signifies a supplier that prioritizes performance and customer satisfaction.

Step 4: Assess Delivery and Turnaround Times

Inquire about the typical lead times for product delivery and service execution. Northeast Laser has a reputation for rapid turnaround, often offering 2-3 day service, with options for same-day service. Knowing these timelines helps align your project schedule and manage expectations effectively.

Step 5: Request Case Studies and References

Ask for case studies or testimonials from previous clients, particularly those in similar industries or applications. This not only demonstrates the supplier’s expertise but also provides insights into their customer service and reliability. Engaging with references can give you a clearer picture of what to expect.

Step 6: Verify Post-Purchase Support and Maintenance Services

Discuss the support options available after the purchase, including maintenance and repair services. Northeast Laser offers comprehensive after-sales support, which is essential for minimizing downtime and ensuring the longevity of your laser systems. Understanding the scope of their support can greatly influence your satisfaction and operational efficiency.

Step 7: Negotiate Terms and Pricing

Once you have selected a potential supplier, engage in discussions regarding pricing and payment terms. Ensure that all costs, including potential hidden fees for installation or maintenance, are clearly outlined. This step is vital to avoid budget overruns and to establish a mutually beneficial agreement.

By following this checklist, B2B buyers can navigate the procurement process for laser solutions with confidence, ensuring they select a supplier that meets their technical needs while providing exceptional service and support.

Comprehensive Cost and Pricing Analysis for northeast laser monroe ct Sourcing

What Are the Key Cost Components in Sourcing from Northeast Laser in Monroe, CT?

When considering sourcing laser products and services from Northeast Laser in Monroe, CT, it’s essential to understand the various cost components that contribute to the overall pricing structure. The primary cost elements include:

-

Materials: The type and quality of materials used in laser systems significantly impact costs. High-performance materials may elevate the price but enhance product longevity and functionality.

-

Labor: Skilled labor is crucial in the design, manufacturing, and servicing of laser systems. Labor costs can vary based on the complexity of the project and the expertise required.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment depreciation, and facility maintenance. A well-managed overhead can help keep pricing competitive.

-

Tooling: Custom tooling may be necessary for specialized laser applications, which can add to the initial setup costs. However, investing in the right tooling can lead to greater efficiency and precision in production.

-

Quality Control (QC): Rigorous QC processes ensure that all products meet high standards, which can influence pricing. A strong QC program not only ensures reliability but can reduce long-term costs by minimizing defects.

-

Logistics: Shipping costs can vary based on the destination, volume, and mode of transport. For international buyers, understanding Incoterms can help clarify responsibilities regarding shipping and customs.

-

Margin: Finally, the profit margin included in the pricing is influenced by market competition, perceived value, and the supplier’s business model.

How Do Price Influencers Affect Costs for International Buyers?

Several factors can influence pricing for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe:

-

Volume and Minimum Order Quantities (MOQ): Larger orders may qualify for discounts, reducing the per-unit cost. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customized solutions often come with additional costs. It’s crucial for buyers to clearly define their requirements to avoid unexpected expenses.

-

Materials and Certifications: Higher quality materials or specific certifications (e.g., ISO, CE) may increase costs. Buyers should evaluate the necessity of these factors in relation to their application.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more for their expertise and reliability but can offer better support and quality assurance.

-

Incoterms: Familiarity with Incoterms is essential for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect total costs.

What Negotiation Tips Can Help Achieve Cost-Efficiency?

To ensure a cost-effective sourcing experience, international buyers should consider the following negotiation tips:

-

Research Market Prices: Understanding the average market pricing for similar products can empower buyers during negotiations. This knowledge helps in assessing the competitiveness of the supplier’s pricing.

-

Leverage Long-Term Relationships: Building a relationship with suppliers can lead to better terms, including pricing and service levels. Suppliers are often more willing to negotiate with reliable, repeat customers.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term operational costs, including maintenance, training, and potential downtime. A higher upfront cost may lead to lower TCO if the product is more reliable.

-

Be Open to Compromise: Flexibility in terms of order quantities or timelines can lead to better pricing. Suppliers often appreciate buyers who are willing to work collaboratively.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers should also be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact costs. It’s wise to consider hedging options or negotiating prices in a stable currency.

-

Import Duties and Taxes: Understanding the local regulations regarding import duties and taxes is crucial. These can add to the total cost and should be factored into the overall budget.

-

Shipping Times and Costs: Longer shipping times can lead to additional inventory holding costs. Buyers should assess the trade-off between shipping costs and lead times to optimize their supply chain.

In conclusion, sourcing from Northeast Laser in Monroe, CT, requires careful consideration of various cost components and price influencers. By understanding these elements and employing effective negotiation strategies, international buyers can achieve a more favorable outcome in their procurement processes.

Alternatives Analysis: Comparing northeast laser monroe ct With Other Solutions

Exploring Alternatives to Northeast Laser Monroe CT: A Comparative Analysis

In the rapidly evolving landscape of industrial laser solutions, businesses often face the challenge of selecting the right provider. Northeast Laser Monroe CT is a well-established option, but it is prudent to consider other viable alternatives. This analysis compares Northeast Laser with two noteworthy alternatives—Isotech, Inc. and Boss Laser, LLC—across several key performance metrics.

Comparison Table

| Comparison Aspect | Northeast Laser Monroe CT | Isotech, Inc. | Boss Laser, LLC |

|---|---|---|---|

| Performance | High precision and diverse laser types (CO2, fiber, Nd:YAG) for multiple applications. | Specialized in high-power laser systems for industrial applications. | Offers a range of affordable, entry-level laser systems for small businesses. |

| Cost | Moderate to high, reflecting advanced technology and custom solutions. | Competitive pricing with a focus on industrial-grade systems. | Budget-friendly options available, especially for startups and smaller enterprises. |

| Ease of Implementation | Custom solutions may require longer lead times for design and installation. | Streamlined installation process with professional support. | User-friendly systems designed for quick setup and operation. |

| Maintenance | Comprehensive maintenance and repair services available. | Standard maintenance plans offered, but less comprehensive than Northeast. | Limited maintenance support; primarily focused on initial sales. |

| Best Use Case | Ideal for complex applications requiring precision, such as medical and military uses. | Best for large-scale industrial applications needing high-power lasers. | Perfect for small businesses and hobbyists looking for cost-effective solutions. |

In-Depth Analysis of Alternatives

Isotech, Inc.

Isotech, Inc. specializes in high-power laser systems tailored for demanding industrial applications, making it a strong alternative to Northeast Laser. The company’s focus on performance ensures that clients receive robust solutions capable of handling intensive workloads. However, while Isotech offers competitive pricing, its systems may not provide the same level of customization or flexibility as Northeast Laser’s offerings. Businesses requiring specific laser configurations might find Isotech’s products somewhat limiting, despite their reliability.

Boss Laser, LLC

Boss Laser is known for its affordability and user-friendly systems, making it an attractive choice for startups and smaller enterprises. Their laser systems are designed for quick setup, allowing businesses to get up and running efficiently. However, while Boss Laser’s products are cost-effective, they may lack the advanced technology and precision found in Northeast Laser’s offerings. This makes them less suitable for industries that demand high precision and complex applications, such as medical or military sectors.

Conclusion: Choosing the Right Laser Solution for Your Business

Selecting the appropriate laser solution depends on your specific business needs, budget, and application requirements. If precision and customization are paramount, Northeast Laser Monroe CT stands out as a leading choice. On the other hand, if cost is a significant concern, Boss Laser provides an accessible entry point for smaller businesses. Isotech, Inc. serves as a robust option for companies focused on industrial applications requiring high power. Ultimately, understanding your operational goals and evaluating the strengths of each alternative will guide you in making an informed decision that aligns with your strategic objectives.

Essential Technical Properties and Trade Terminology for northeast laser monroe ct

What Are the Essential Technical Properties for Laser Systems?

When considering laser systems from Northeast Laser in Monroe, CT, several critical technical specifications should be understood:

Illustrative image related to northeast laser monroe ct

-

Wavelength: The wavelength of a laser determines its interaction with different materials. For instance, CO2 lasers typically operate at a wavelength of 10.6 micrometers, making them ideal for cutting and engraving organic materials like wood and plastics. Understanding the appropriate wavelength for a specific application can enhance efficiency and effectiveness.

-

Power Rating: Measured in watts (W), the power rating of a laser system directly influences its cutting or marking speed and depth. Higher power ratings allow for faster processing of thicker materials, which is crucial for industries requiring high throughput, such as automotive and aerospace. Selecting the right power rating is essential for meeting production deadlines and maintaining quality.

-

Tolerance: This refers to the allowable deviation from a specified dimension in the manufacturing process. In laser cutting and engraving, a typical tolerance might range from ±0.1 mm to ±0.5 mm, depending on the material and application. Precise tolerances are critical in industries like medical device manufacturing, where even minor discrepancies can lead to product failure.

-

Material Compatibility: Not all laser systems can effectively work with every material. For example, fiber lasers excel with metals, while CO2 lasers are better suited for non-metals. Knowing the material compatibility ensures that buyers select a laser system that can handle their specific production requirements, reducing the risk of damage or subpar results.

-

Cooling Mechanism: Laser systems can generate significant heat during operation, necessitating effective cooling solutions to maintain performance and longevity. Common cooling methods include water cooling or air cooling. Understanding the cooling requirements can prevent overheating, which may lead to costly downtime or equipment failure.

-

Cycle Time: This refers to the total time taken to complete a specific task, such as cutting or engraving a part. Cycle time is critical in high-volume production environments, where efficiency translates directly to cost savings. Buyers should consider the cycle time of different laser systems to optimize their operations.

What Are Common Trade Terms in the Laser Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of laser systems, OEMs provide essential components that ensure compatibility and performance.

-

MOQ (Minimum Order Quantity): This is the smallest amount of a product that a supplier is willing to sell. For international buyers, understanding MOQ is crucial as it can affect inventory management and cash flow, especially in bulk orders.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to invite them to submit price quotes for specific products or services. This process is essential for buyers to compare pricing and services from different vendors, ensuring they receive the best value.

-

Incoterms (International Commercial Terms): These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps in mitigating risks during international shipments.

-

Lead Time: This term refers to the time taken from placing an order until the goods are delivered. Understanding lead times is essential for planning and inventory management, particularly for international buyers who may face longer shipping durations.

-

Customization: This refers to the ability to modify laser systems to meet specific customer requirements. Custom solutions are particularly important in sectors like medical devices or aerospace, where unique specifications are often necessary. Recognizing the potential for customization can help buyers align laser technology with their operational needs.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing laser systems from Northeast Laser in Monroe, CT, ensuring optimal solutions for their manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the northeast laser monroe ct Sector

What Are the Current Market Dynamics and Key Trends in the Northeast Laser Sector?

The Northeast laser sector, particularly in Monroe, CT, is experiencing significant growth driven by advancements in technology and an increase in demand across multiple industries, including medical, aerospace, and automotive. Global buyers are increasingly turning to laser solutions for precision manufacturing due to their efficiency and ability to produce intricate designs. The rise of Industry 4.0 has led to a push for automation, which is influencing sourcing trends as companies seek integrated laser systems that can easily connect with existing production lines.

Emerging technologies such as fiber lasers and ultrafast lasers are becoming prominent in the marketplace. These systems offer higher efficiency and lower operational costs, making them attractive to international buyers looking for competitive advantages. The demand for customization is also on the rise, as businesses seek tailored solutions that meet specific operational needs. This trend is particularly relevant for B2B buyers from regions like Africa, South America, and the Middle East, where diverse applications—from medical device manufacturing to decorative engraving—demand unique laser configurations.

Furthermore, the focus on rapid prototyping and short turnaround times is reshaping the supply chain dynamics. Companies like Northeast Laser & Electropolish are adapting to these demands by offering streamlined processes and quick service options, often reducing lead times to just a few days. This responsiveness is critical for international clients who require agility in their supply chains to remain competitive in their respective markets.

How Is Sustainability Influencing Sourcing in the Northeast Laser Sector?

Sustainability has become a cornerstone of B2B procurement strategies in the Northeast laser sector. As global awareness of environmental issues grows, companies are under increasing pressure to adopt ethical sourcing practices. The environmental impact of laser manufacturing—ranging from energy consumption to waste generation—has prompted many organizations to seek out suppliers who prioritize sustainability.

For buyers from Africa, South America, and Europe, understanding the sustainability credentials of their suppliers is critical. Northeast Laser, for instance, has made strides in implementing eco-friendly practices, including energy-efficient laser systems and waste reduction initiatives. Suppliers that can demonstrate commitment to sustainability through certifications such as ISO 14001 or adherence to green manufacturing standards are likely to gain a competitive edge.

In addition, the use of recyclable materials and sustainable packaging is becoming increasingly important in the sourcing decisions of international buyers. This shift not only helps in reducing the carbon footprint but also aligns with the growing consumer preference for environmentally responsible products. As a result, B2B buyers are encouraged to engage with suppliers that are transparent about their sustainability efforts and can provide certifications and documentation to support their claims.

What Is the Evolution of the Northeast Laser Sector Relevant for B2B Buyers?

The Northeast laser sector has evolved significantly over the past three decades. Initially, laser technology was primarily used for basic cutting and engraving tasks. However, advancements in laser systems have transformed the industry, expanding applications to include precision welding, marking, and even intricate medical device manufacturing.

Illustrative image related to northeast laser monroe ct

Companies like Northeast Laser & Electropolish have been at the forefront of this evolution, adapting their offerings to meet the changing needs of diverse industries. Their commitment to innovation has positioned them as leaders in custom laser solutions, catering specifically to the demands of modern manufacturing processes. This historical context is crucial for international B2B buyers, as it highlights the depth of expertise and the breadth of services available in the Monroe, CT area, making it a strategic hub for sourcing laser technologies.

Understanding this evolution not only informs buyers about the capabilities of current laser technologies but also emphasizes the importance of partnering with experienced suppliers who can offer insights and solutions tailored to their unique business challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of northeast laser monroe ct

-

1. How can I determine if Northeast Laser in Monroe, CT is the right supplier for my business needs?

To evaluate if Northeast Laser is the right supplier, consider their expertise in laser technology and the specific applications relevant to your industry, such as medical, military, or industrial. Review their portfolio of past projects, customer testimonials, and case studies to gauge their capabilities. Additionally, inquire about their customization options and whether they can meet your production volume requirements. Engaging in a preliminary consultation can also help clarify any specific needs and establish a rapport. -

2. What types of laser systems does Northeast Laser provide for industrial applications?

Northeast Laser offers a diverse range of laser systems including CO2, fiber, Nd:YAG, and diode lasers. These systems are suitable for various applications such as cutting, welding, marking, and engraving. Each laser type comes in different wavelengths and power levels, allowing for versatility in application. For tailored solutions, the company also specializes in custom laser systems designed to meet specific operational requirements. -

3. What is the minimum order quantity (MOQ) for laser cutting or engraving services?

The minimum order quantity for services at Northeast Laser can vary based on the specific project requirements and the complexity of the design. Generally, they accommodate both small batch orders and larger production runs. It’s advisable to discuss your project needs directly with their sales team, who can provide guidance on MOQ based on your specifications and budget constraints. -

4. How does Northeast Laser handle international shipping and logistics for B2B orders?

Northeast Laser has experience in managing international logistics and shipping for B2B orders. They can provide guidance on shipping options, customs documentation, and delivery timelines. To ensure timely and efficient delivery, it’s essential to communicate your specific requirements, including preferred shipping methods and delivery schedules, during the order placement process. -

5. What payment terms does Northeast Laser offer for international buyers?

Payment terms for international buyers may vary based on the order size and relationship established with Northeast Laser. Typically, they may offer flexible payment options such as wire transfers, letters of credit, or payment upon delivery. It’s recommended to discuss payment terms in detail during the negotiation phase to align expectations and facilitate a smooth transaction. -

6. How does Northeast Laser ensure quality control in their laser products and services?

Northeast Laser has a robust quality control program in place that adheres to industry standards. This includes regular inspections and testing of laser systems and services to ensure they meet performance, reliability, and safety benchmarks. Their commitment to quality is reflected in their reputation as a trusted provider, and they are open to providing certification and compliance documentation upon request. -

7. Can I request custom laser solutions tailored to my specific industry needs?

Yes, Northeast Laser specializes in providing custom laser solutions tailored to meet the unique requirements of various industries. Their team works closely with clients to understand their specific applications and develop solutions that enhance efficiency and effectiveness. Whether it’s for specialized cutting, marking, or engraving, they can design systems that align with your operational goals. -

8. What types of industries does Northeast Laser serve, and can they cater to specialized applications?

Northeast Laser serves a wide range of industries, including medical, industrial, scientific, and military sectors. They are equipped to handle specialized applications, from precision laser welding of medical components to marking and engraving for promotional items. Their expertise allows them to adapt their services to meet the unique demands of different industries effectively.

Top 2 Northeast Laser Monroe Ct Manufacturers & Suppliers List

1. Northeast Laser & Electropolish – Advanced Laser Systems

Domain: industriallasers.net

Registered: 2002 (23 years)

Introduction: Northeast Laser & Electropolish, LLC specializes in the design, manufacturing, and servicing of advanced laser systems for industrial, medical, scientific, and military applications. Key products include CO2 lasers, fiber lasers, Nd:YAG lasers, and diode lasers, available in various wavelengths and power levels suitable for cutting, welding, drilling, marking, engraving, and more. The company also…

2. Northeast Laser & Electropolish – Contract Laser Services

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Northeast Laser & Electropolish – Contract Laser Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for northeast laser monroe ct

As international B2B buyers explore the advanced solutions offered by Northeast Laser in Monroe, CT, several key takeaways emerge that underline the importance of strategic sourcing. With over 30 years of experience, Northeast Laser stands out for its comprehensive range of laser systems—including CO2, fiber, Nd:YAG, and diode lasers—tailored to diverse industrial applications. Their commitment to quality, innovation, and customer satisfaction positions them as a reliable partner for businesses looking to enhance operational efficiency through precision laser cutting, marking, and welding.

For buyers from Africa, South America, the Middle East, and Europe, leveraging the capabilities of Northeast Laser can lead to significant competitive advantages. The company’s ability to provide custom solutions ensures that specific project needs are met with precision, while their rapid turnaround times facilitate agile production processes.

Looking ahead, the demand for advanced laser technology is expected to grow across various sectors. This presents an opportunity for international buyers to engage with Northeast Laser, tapping into their expertise and state-of-the-art facilities to drive innovation and quality in their operations. Connect with Northeast Laser today to explore how their laser solutions can meet your unique business challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.