Nickel Steel: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for nickel steel

In an increasingly competitive global market, sourcing high-quality nickel steel can be a significant challenge for international B2B buyers. This essential alloy, renowned for its strength, toughness, and exceptional corrosion resistance, plays a critical role in various industries, from cryogenic applications to the construction of storage tanks for liquefied natural gas (LNG). However, navigating the complexities of supplier selection, pricing structures, and compliance with international standards can overwhelm even the most seasoned procurement professionals.

This comprehensive guide aims to empower B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—by providing detailed insights into the diverse types of nickel steel available, their specific applications, and the critical factors to consider when vetting suppliers. Additionally, it will address cost considerations, industry trends, and best practices for ensuring quality and reliability in your sourcing decisions.

By equipping you with the knowledge to make informed choices, this guide will not only streamline your procurement process but also enhance your competitive edge in your respective markets. Whether you are looking for high nickel content variants for cryogenic storage or standard nickel steel for structural applications, this resource will serve as your go-to reference for successful sourcing in the global nickel steel market.

Understanding nickel steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Low Nickel Steel | Contains 1-3% nickel; improved toughness and hardness. | General structural applications, automotive components. | Pros: Cost-effective, versatile. Cons: Lower corrosion resistance compared to higher nickel variants. |

| Medium Nickel Steel | Contains 4-8% nickel; enhanced toughness and ductility. | Aerospace, pressure vessels, and cryogenic storage. | Pros: Good balance of strength and weight. Cons: Higher cost than low nickel options. |

| High Nickel Steel | Contains 9-30% nickel; excellent corrosion resistance. | Cryogenic applications, LNG storage tanks. | Pros: Superior performance in extreme environments. Cons: Higher material costs and specialized fabrication requirements. |

| Nickel-Chromium Steel | Combines nickel with chromium for added strength. | Oil and gas pipelines, chemical processing equipment. | Pros: Increased resistance to oxidation and wear. Cons: More complex alloying process can increase costs. |

| Nickel-Copper Steel | Contains nickel and copper; non-magnetic and corrosion-resistant. | Marine applications, electrical components. | Pros: Excellent for harsh environments. Cons: Limited availability may affect supply chain. |

What Are the Key Characteristics of Low Nickel Steel?

Low nickel steel typically contains between 1-3% nickel, which enhances its toughness and hardness compared to standard carbon steel. This type is often used in general structural applications and automotive components due to its cost-effectiveness and versatility. For B2B buyers, the primary consideration is balancing performance with budget constraints, as it provides adequate strength for many applications without the higher costs associated with nickel-rich alloys.

How Does Medium Nickel Steel Stand Out in Applications?

Medium nickel steel, with a nickel content of 4-8%, offers improved toughness and ductility, making it suitable for demanding applications such as aerospace components and pressure vessels. This variant maintains a good balance between strength and weight, crucial for industries where both factors are critical. Buyers should consider the benefits of enhanced performance against the increased costs compared to low nickel options, especially in applications requiring reliable material performance under stress.

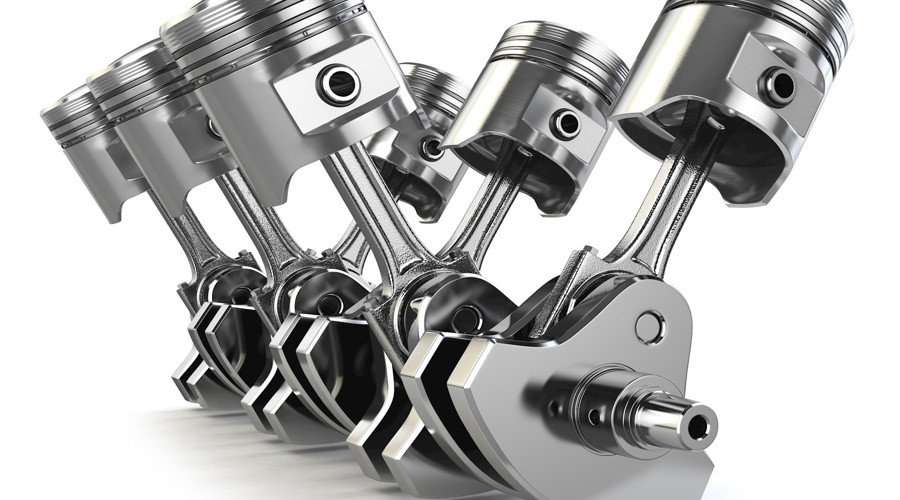

Illustrative image related to nickel steel

What Makes High Nickel Steel Essential for Cryogenic Applications?

High nickel steel, containing 9-30% nickel, is renowned for its exceptional corrosion resistance and mechanical properties at cryogenic temperatures. This makes it the preferred choice for constructing storage tanks for liquefied natural gas (LNG) and other cryogenic applications. While it offers superior performance, buyers must weigh the higher material costs and the need for specialized fabrication techniques against the long-term benefits of durability and reliability in extreme conditions.

Why Choose Nickel-Chromium Steel for Industrial Applications?

Nickel-chromium steel combines the properties of both nickel and chromium, resulting in enhanced strength and resistance to oxidation. This type is commonly used in oil and gas pipelines and chemical processing equipment, where durability and safety are paramount. B2B buyers should consider the added benefits of this alloy in terms of performance longevity and reduced maintenance costs, although the more complex alloying process may lead to higher initial pricing.

What Are the Advantages of Nickel-Copper Steel in Harsh Environments?

Nickel-copper steel is recognized for its non-magnetic properties and excellent corrosion resistance, making it ideal for marine applications and electrical components. Its ability to withstand harsh environments makes it a valuable choice for industries facing exposure to saltwater or chemicals. However, buyers should be mindful of the limited availability of this alloy, which could impact supply chains and lead times in procurement.

Key Industrial Applications of nickel steel

| Industry/Sector | Specific Application of nickel steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Storage tanks for liquefied natural gas (LNG) | High strength and toughness at cryogenic temperatures | Compliance with ASTM standards, availability of certified suppliers |

| Aerospace | Structural components in aircraft manufacturing | Enhanced durability and weight reduction | Precision specifications, sourcing from reputable manufacturers |

| Automotive | High-performance automotive parts | Improved performance and longevity | Quality assurance processes, compatibility with existing technologies |

| Construction | Reinforcement in high-stress environments | Increased safety and structural integrity | Certification for construction standards, local regulations compliance |

| Chemical Processing | Pressure vessels for chemical storage | Corrosion resistance and mechanical reliability | Material traceability, adherence to safety regulations |

How Is Nickel Steel Used in Oil & Gas Applications?

In the oil and gas sector, nickel steel is primarily utilized for the construction of storage tanks for liquefied natural gas (LNG). Its high nickel content provides exceptional strength and toughness at cryogenic temperatures, making it ideal for storing LNG safely. Buyers need to ensure compliance with ASTM standards, particularly ASTM A300 and A353, to guarantee that the materials meet the required mechanical properties. Additionally, sourcing from certified suppliers is critical to minimize risks associated with equipment failure and ensure operational efficiency.

What Role Does Nickel Steel Play in Aerospace Manufacturing?

Nickel steel serves as a vital material in the aerospace industry, particularly for manufacturing structural components of aircraft. Its lightweight yet durable properties enhance aircraft performance by reducing overall weight while maintaining structural integrity. International buyers should focus on precision specifications and seek reputable manufacturers that can provide materials that meet stringent aerospace standards. Quality assurance processes are essential to ensure that the nickel steel components can withstand the demanding conditions of flight.

Why Is Nickel Steel Important for Automotive Parts?

In the automotive industry, nickel steel is used to produce high-performance parts that require enhanced durability and longevity. Components such as crankshafts, gears, and axles benefit from the strength and toughness that nickel steel provides. For businesses in this sector, it is crucial to ensure compatibility with existing technologies and rigorous quality assurance processes to meet safety and performance standards. Sourcing from established suppliers who can provide traceability and compliance documentation is also essential.

How Does Nickel Steel Enhance Construction Safety?

In construction, nickel steel is often employed as reinforcement in high-stress environments, such as bridges and high-rise buildings. Its superior strength and resistance to cracking contribute to increased safety and structural integrity. Buyers in the construction sector must consider local regulations and certification requirements for construction materials to ensure compliance. Establishing relationships with suppliers that can provide materials with the necessary certifications and quality assurances will mitigate risks associated with structural failures.

What Are the Benefits of Nickel Steel in Chemical Processing?

Nickel steel is extensively used in the chemical processing industry for constructing pressure vessels that store various chemicals. Its corrosion resistance and mechanical reliability make it suitable for handling aggressive substances. Businesses must prioritize material traceability and adherence to safety regulations when sourcing nickel steel for chemical applications. Collaborating with suppliers who understand the specific requirements of the chemical industry can enhance operational safety and efficiency.

Illustrative image related to nickel steel

3 Common User Pain Points for ‘nickel steel’ & Their Solutions

Scenario 1: Navigating Corrosion Resistance Challenges in Harsh Environments

The Problem: B2B buyers often encounter significant difficulties when sourcing nickel steel for applications exposed to corrosive environments, such as offshore oil rigs or chemical processing plants. Traditional carbon steel may not withstand the harsh conditions, leading to premature failure, safety hazards, and costly downtime. Buyers are frequently uncertain about the specific nickel content needed to ensure optimal corrosion resistance, particularly when competing materials are available.

The Solution: To effectively address corrosion resistance, buyers should prioritize sourcing nickel steel with a higher nickel content, ideally above 9%. This percentage enhances the alloy’s resistance to corrosion and oxidation, making it suitable for extreme environments. Conduct thorough evaluations of suppliers, focusing on their ability to provide high-quality nickel steel that meets ASTM standards for corrosion resistance. Additionally, consider investing in third-party testing for the specific applications to validate the material’s performance. Proper specifications should include the desired nickel content, along with detailed requirements for mechanical properties and corrosion resistance to ensure the selected material will meet the operational demands.

Scenario 2: Managing Challenges in Cryogenic Applications

The Problem: Companies involved in the storage and transportation of liquefied natural gas (LNG) face unique challenges when selecting materials for cryogenic applications. Nickel steel’s performance at low temperatures is crucial, yet many buyers are unsure about the appropriate grades and heat treatment processes necessary to maintain structural integrity at these extreme temperatures. Missteps in material selection can lead to catastrophic failures, risking both safety and financial loss.

The Solution: To mitigate risks associated with cryogenic applications, buyers should opt for 9% nickel steel, which has been specifically developed for these conditions. Ensure that the supplier adheres to rigorous quality control processes and provides documentation of compliance with ASTM A300 or A353 standards. Engaging with metallurgists or materials scientists can provide insights into the necessary heat treatment procedures that enhance toughness and fracture resistance at cryogenic temperatures. Furthermore, conducting impact testing at -196°C can confirm the material’s suitability for LNG applications. Establishing partnerships with suppliers who specialize in cryogenic materials will facilitate more informed decisions and enhance reliability.

Scenario 3: Overcoming Welding Difficulties with Nickel Steel

The Problem: Welding nickel steel can present significant challenges, particularly due to the risk of cracking in the heat-affected zones. B2B buyers involved in manufacturing or construction often struggle with finding the right welding techniques and filler materials compatible with nickel steel. These difficulties can lead to increased production times, waste of materials, and compromised structural integrity.

Illustrative image related to nickel steel

The Solution: To effectively navigate the welding challenges associated with nickel steel, buyers should invest in training for their welding teams focused on the unique properties of nickel alloys. Selecting the appropriate filler materials that match the nickel content of the base metal is crucial. For example, using a filler with similar or higher nickel content can help minimize the risk of cracking and ensure strong joints. It is also advisable to adopt preheating techniques to reduce thermal shock and stress during welding. Collaborating with experienced welding engineers to develop standardized procedures and conducting regular inspections post-welding will further enhance the quality and durability of the welded components. Additionally, consider utilizing advanced welding technologies, such as laser or electron beam welding, which can provide better control over heat input and improve the overall weld quality.

Strategic Material Selection Guide for nickel steel

What Are the Key Properties of Nickel Steel Alloys for B2B Applications?

Nickel steel is recognized for its enhanced mechanical properties, making it a preferred choice in various industrial applications. The primary characteristic of nickel steel is its ability to maintain high strength and toughness, especially at low temperatures. Alloys typically contain between 5% to 9% nickel, which significantly improves their resistance to corrosion and fatigue. For instance, 9% nickel steel is particularly noted for its performance in cryogenic environments, maintaining structural integrity at temperatures as low as -196°C.

What Are the Advantages and Disadvantages of Nickel Steel Alloys?

When considering nickel steel alloys, it is essential to weigh their advantages against potential drawbacks.

Advantages:

– Durability: Nickel steel exhibits high resistance to wear and tear, making it suitable for demanding applications such as liquefied natural gas (LNG) storage.

– Corrosion Resistance: Higher nickel content enhances resistance to corrosive environments, which is crucial for industries operating in humid or chemically aggressive settings.

– Weldability: Nickel steels can be welded effectively, allowing for versatile construction methods in tank and vessel fabrication.

Disadvantages:

– Cost: The inclusion of nickel raises the overall cost of the material compared to standard carbon steels.

– Manufacturing Complexity: The need for specialized heat treatments and welding techniques can complicate the manufacturing process, potentially leading to longer lead times.

– Specificity of Applications: While nickel steel is robust, it may not be the best choice for all applications, particularly where lower-cost alternatives suffice.

How Does Nickel Steel Impact Specific Applications?

Nickel steel’s unique properties make it suitable for various applications, particularly in sectors requiring high-performance materials. For instance, in the oil and gas industry, 9% nickel steel is extensively used for the construction of cryogenic tanks and pipelines due to its ability to withstand extreme temperatures and pressures. Additionally, its corrosion resistance makes it ideal for offshore and marine applications where exposure to saltwater is prevalent.

What Should International B2B Buyers Consider When Selecting Nickel Steel?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several considerations are vital:

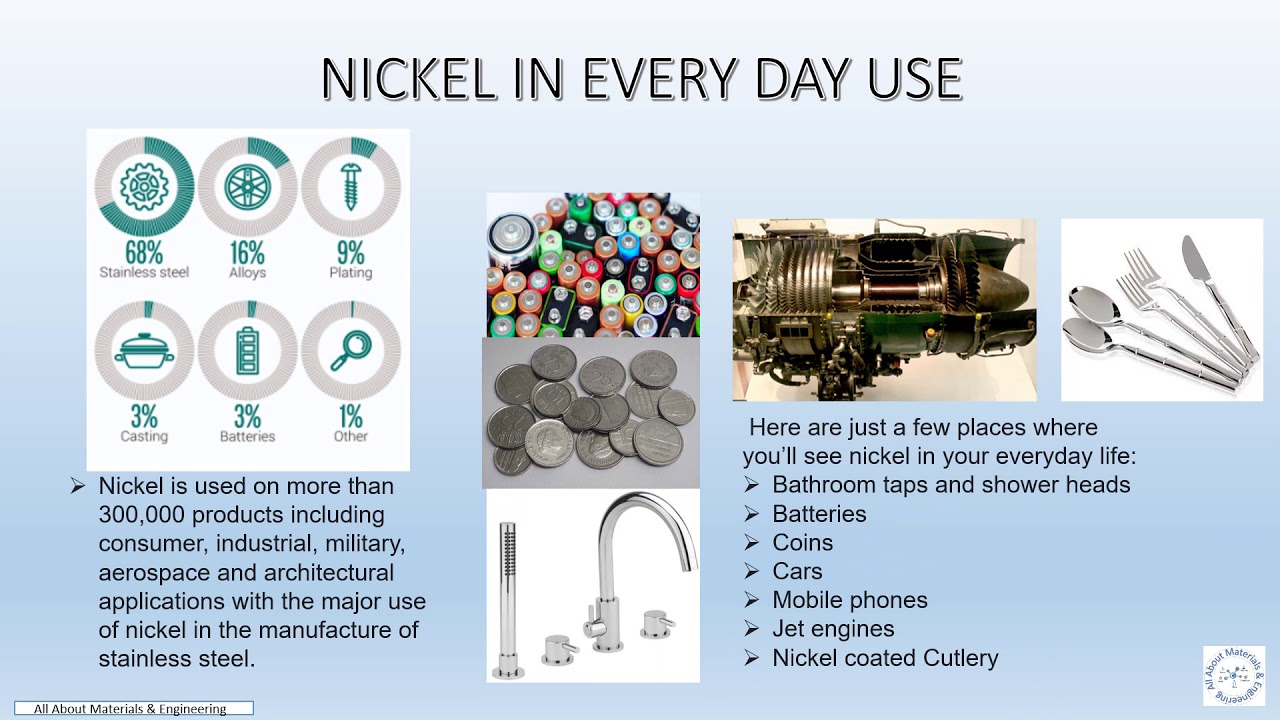

Illustrative image related to nickel steel

- Compliance with Standards: Buyers should ensure that the nickel steel alloys meet international standards such as ASTM, DIN, or JIS, which govern material specifications and performance.

- Local Availability: Sourcing nickel steel locally can reduce costs and lead times, but buyers must verify the quality and compliance of locally produced materials.

- Market Preferences: Understanding regional preferences for material grades and specifications can guide buyers in selecting the most suitable nickel steel for their applications.

Summary Table of Nickel Steel Materials

| Material | Typical Use Case for nickel steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 5% Nickel Steel | General structural applications | Good balance of strength and cost | Limited corrosion resistance at extreme temps | Medium |

| 9% Nickel Steel | Cryogenic storage tanks for LNG | Excellent toughness at low temperatures | Higher cost and complex fabrication | High |

| Nickel-Chromium Steel | Aerospace components | Superior fatigue resistance | More expensive due to alloy complexity | High |

| High-Carbon Nickel Steel | Heavy machinery and tools | Enhanced hardness and wear resistance | Prone to brittleness if not properly treated | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to leverage the unique properties of nickel steel in their applications. By understanding the advantages, disadvantages, and specific considerations, buyers can make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for nickel steel

What Are the Key Stages in the Manufacturing Process of Nickel Steel?

The production of nickel steel involves several critical stages, each requiring precision and adherence to international standards. Understanding these processes can help B2B buyers make informed decisions when sourcing nickel steel products.

Material Preparation: What Are the Initial Steps?

The first step in manufacturing nickel steel is material preparation, which includes sourcing high-quality raw materials. Nickel is added to carbon steel to enhance its mechanical properties. The nickel content typically ranges from 5% to 9%, which significantly improves the alloy’s strength, toughness, and corrosion resistance. During this phase, the materials undergo rigorous quality checks to ensure they meet the required specifications, such as ASTM standards. Suppliers should provide certifications verifying the composition of their nickel and steel materials.

How Is Nickel Steel Formed and Shaped?

Once the materials are prepared, the next step involves forming and shaping the nickel steel. This can be achieved through various techniques, including:

-

Hot and Cold Rolling: Hot rolling is commonly used to create sheets and plates, while cold rolling is utilized for precision components. Both processes help achieve the desired thickness and mechanical properties.

-

Forging: This method is particularly useful for producing complex shapes and enhancing the material’s grain structure, leading to improved strength and ductility.

-

Casting: For specific applications, nickel steel can be cast into desired shapes, especially for large components that require minimal machining.

Each of these methods requires strict adherence to operational standards to maintain the integrity of the alloy.

What Are the Final Steps in Nickel Steel Production?

Assembly: How Are Components Joined Together?

After the nickel steel is formed, the next stage is assembly, where different parts are joined together. Welding is the primary technique used in assembling nickel steel components, particularly for cryogenic applications. The welding process must be carefully controlled to prevent defects in the heat-affected zone.

Illustrative image related to nickel steel

Welders must adhere to specific procedures outlined in standards such as AWS D1.1 for structural welding. Buyers should ensure that their suppliers employ skilled welders who are certified in accordance with industry standards, as this can significantly impact the performance of the final product.

Finishing: What Techniques Enhance Performance?

Finishing processes aim to improve surface quality and enhance the material’s properties. Techniques such as:

-

Heat Treatment: Applied to improve hardness and toughness, particularly critical for cryogenic applications. Processes like quenching and tempering are commonly used.

-

Surface Treatments: Methods like shot peening or coating can be applied to enhance corrosion resistance and overall durability.

These finishing processes are essential for ensuring that the nickel steel performs reliably in demanding environments.

What Quality Assurance Practices Should Be Followed?

Quality assurance (QA) in nickel steel manufacturing is paramount for ensuring the material meets industry standards and customer specifications. Various international and industry-specific standards govern these practices.

Which International Standards Are Relevant?

ISO 9001 is a widely recognized standard for quality management systems and is essential for manufacturers aiming to ensure consistent product quality. Additionally, industry-specific certifications, such as API (American Petroleum Institute) for oil and gas applications and CE marking for European markets, are crucial for ensuring compliance with safety and performance standards.

Illustrative image related to nickel steel

What Are the Key Quality Control Checkpoints?

Quality control (QC) typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage ensures that all raw materials meet specified requirements before production begins.

-

In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify any deviations from quality standards early on.

-

Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications before it is shipped to customers.

Each of these checkpoints plays a vital role in maintaining the integrity of the final product.

How Can B2B Buyers Verify Supplier Quality Control?

Buyers looking to ensure the quality of their nickel steel products should adopt several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and QC practices. This can help verify compliance with international standards and identify any areas for improvement.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed QC reports that outline testing methods and results. These reports should include information on mechanical properties, corrosion resistance, and any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the quality and compliance of the products being sourced. This is particularly important for buyers in regions like Africa and South America, where local suppliers may not always adhere to international standards.

What Are the Specific QC Considerations for International B2B Buyers?

For buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of QC is crucial. Different regions may have varying standards and practices, so it is essential to ensure that suppliers can meet both local and international requirements.

-

Cultural and Regulatory Differences: Buyers must be aware of the regulatory environment in their region and ensure that suppliers are compliant with local laws and standards.

-

Documentation and Certification: Proper documentation is vital for international transactions. Buyers should ensure that suppliers provide all necessary certifications, including material safety data sheets (MSDS) and compliance with international standards.

-

Logistics and Shipping Considerations: The quality of nickel steel can be affected during transportation. Buyers should work with suppliers who understand the logistics involved in international shipping and can ensure that products arrive in optimal condition.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and ensure they source high-quality nickel steel products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nickel steel’

This guide serves as a practical checklist for B2B buyers looking to procure nickel steel, a crucial material known for its strength, toughness, and resistance to corrosion. By following these steps, you can ensure a well-informed and efficient sourcing process tailored to your specific needs.

Illustrative image related to nickel steel

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Determine the required nickel content, mechanical properties, and any specific standards (e.g., ASTM A300 or A353) that the nickel steel must meet. This clarity will help you communicate your needs effectively to suppliers and avoid potential misunderstandings.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in nickel steel. Look for companies with a proven track record in your industry and region. Utilize industry directories, online platforms, and trade shows to gather a list of potential vendors, ensuring they have experience with the specific grades of nickel steel you require.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold relevant certifications and comply with international quality standards. Check for ISO certifications, compliance with ASTM specifications, and any industry-specific standards. These certifications serve as a quality assurance measure, indicating that the supplier adheres to strict manufacturing and safety protocols.

Step 4: Request Material Samples and Test Reports

Obtain samples of the nickel steel along with test reports from the suppliers you are considering. This will allow you to assess the material’s quality and ensure it meets your technical specifications. Look for mechanical property test results, such as tensile strength and impact resistance, particularly if you plan to use the steel in cryogenic applications.

Illustrative image related to nickel steel

Step 5: Conduct Supplier Audits

If feasible, perform an on-site audit of potential suppliers. This step is essential for evaluating their manufacturing processes, quality control measures, and overall operational capabilities. During the audit, ask about their production methods, equipment, and any challenges they face, which can impact your supply chain.

Step 6: Negotiate Terms and Pricing

Once you have shortlisted potential suppliers, enter negotiations regarding pricing, delivery schedules, and payment terms. Ensure that you understand the total cost of procurement, including shipping and any potential tariffs, especially if dealing with international suppliers. Establishing clear terms upfront will help mitigate risks and ensure a smooth transaction.

Step 7: Establish a Long-term Relationship

After securing a supplier, focus on building a long-term relationship. Regular communication, feedback, and collaboration can enhance service quality and reliability. Consider discussing future needs and potential projects, as a strong partnership can lead to better pricing and priority treatment in times of demand.

Illustrative image related to nickel steel

By following these steps, B2B buyers can effectively navigate the complexities of sourcing nickel steel, ensuring they receive high-quality materials that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for nickel steel Sourcing

What Are the Key Cost Components in Nickel Steel Sourcing?

When sourcing nickel steel, understanding the cost structure is essential for effective budgeting and financial planning. Key cost components include:

-

Materials: The primary cost driver in nickel steel is the raw materials, particularly the nickel content. The price of nickel fluctuates based on global demand and supply dynamics, impacting the overall cost of the alloy. Additionally, the quality and grade of the steel used can further influence material costs.

-

Labor: Labor costs are incurred during the manufacturing process, including skilled labor for specialized tasks such as welding and quality control. Labor rates can vary significantly by region, with higher costs often found in developed markets compared to emerging economies.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, depreciation of equipment, and facility maintenance. Overhead costs can vary widely based on the efficiency of the manufacturing process and the scale of production.

-

Tooling: The cost of tooling is critical, particularly for custom orders. Specialized dies and molds may be required for different specifications, which can increase initial costs but may lead to savings in the long run through optimized production runs.

-

Quality Control (QC): Ensuring that nickel steel meets specific standards requires robust quality control measures. Costs associated with testing, inspections, and certifications can add a significant expense, particularly if compliance with international standards is necessary.

-

Logistics: Transportation costs are a vital consideration, especially for international buyers. Factors such as shipping methods, distance, and import tariffs can significantly impact overall costs.

-

Margin: Suppliers will typically include a margin over their costs, which can vary based on market conditions, competition, and the perceived value of the product.

What Influences Pricing in the Nickel Steel Market?

Several factors can influence the pricing of nickel steel, making it essential for buyers to understand the nuances involved:

-

Volume/MOQ: Pricing often scales with order volume. Larger orders may benefit from discounts, while smaller quantities may attract higher per-unit prices due to lack of economies of scale.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized production processes and materials. Buyers should clarify their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: High-quality nickel steel that meets stringent international standards typically commands a higher price. Certifications can also add costs but are crucial for industries where compliance is non-negotiable.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: Understanding Incoterms is vital for cost calculation. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can shift costs and responsibilities between buyers and suppliers, impacting the total cost of ownership.

What Tips Can Help Buyers Optimize Their Nickel Steel Costs?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies to optimize their nickel steel sourcing costs:

-

Negotiation: Engaging in negotiations with suppliers can yield better pricing, especially if buyers can demonstrate their potential for repeat business or larger orders.

-

Cost-Efficiency: Assessing the Total Cost of Ownership (TCO) is crucial. Consider not just the purchase price but also long-term factors such as durability, maintenance, and potential savings from lower failure rates.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices across different suppliers. This can help identify competitive pricing and establish a baseline for negotiations.

-

Understanding Regional Dynamics: Buyers should be aware of the regional market dynamics that influence pricing, such as local demand, currency fluctuations, and geopolitical factors that may affect supply chains.

Disclaimer for Indicative Prices

Prices for nickel steel can vary widely based on the aforementioned factors, and the information provided here should be considered indicative only. Buyers are encouraged to conduct their own market research and obtain quotes from multiple suppliers to ensure they secure the best possible deal for their specific needs.

Alternatives Analysis: Comparing nickel steel With Other Solutions

Understanding Alternatives to Nickel Steel in Industrial Applications

In the quest for optimal materials in industrial applications, especially for structures and components exposed to extreme conditions, businesses often consider alternatives to nickel steel. Nickel steel is renowned for its high strength, toughness, and corrosion resistance, particularly in cryogenic environments. However, various alternatives exist that can also meet specific requirements depending on the application, cost constraints, and operational conditions.

Comparison Table

| Comparison Aspect | Nickel Steel | Stainless Steel | Aluminum Alloys |

|---|---|---|---|

| Performance | High strength, excellent toughness at low temperatures | Good corrosion resistance, moderate strength | Lightweight, moderate strength, good corrosion resistance |

| Cost | Generally higher due to nickel content | Mid-range, dependent on grade | Typically lower than nickel and stainless steel |

| Ease of Implementation | Requires specialized welding and heat treatment | Easier to fabricate and weld, widely available | Simple to work with, but may require special coatings |

| Maintenance | Low maintenance, but requires careful welding | Low maintenance, good longevity | Requires protective coatings in harsh environments |

| Best Use Case | Cryogenic storage, LNG tanks | Food processing, chemical industries | Lightweight structures, aerospace applications |

Detailed Breakdown of Alternatives

Stainless Steel

Stainless steel is an alloy primarily composed of iron, chromium, and nickel, known for its excellent corrosion resistance and moderate strength. It is easier to fabricate and weld compared to nickel steel, making it a popular choice in industries such as food processing and chemical manufacturing. However, while it offers good performance in many applications, it may not withstand extreme low temperatures as effectively as nickel steel, making it less suitable for cryogenic applications.

Aluminum Alloys

Aluminum alloys are lightweight materials that exhibit good corrosion resistance and moderate strength. They are often utilized in industries where weight reduction is critical, such as aerospace and automotive sectors. The ease of fabrication and lower cost make aluminum alloys attractive for many applications. However, they may not perform as well under extreme temperatures or high-stress conditions compared to nickel steel. Additionally, aluminum may require protective coatings to enhance its performance in harsh environments.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate material for industrial applications requires a thorough analysis of the specific operational demands, budget constraints, and performance requirements. For applications involving cryogenic temperatures or high stress, nickel steel remains a top choice due to its superior strength and toughness. However, alternatives like stainless steel and aluminum alloys may provide viable solutions in scenarios where cost, ease of implementation, or weight are more critical factors. B2B buyers should evaluate their unique requirements and the specific advantages and disadvantages of each material to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for nickel steel

What Are the Key Technical Properties of Nickel Steel?

Nickel steel is a specialized alloy that offers distinct advantages in various applications, particularly in demanding environments. Understanding its technical properties is crucial for B2B buyers looking to make informed procurement decisions.

1. Material Grades

Nickel steel is categorized into various grades based on its nickel content, with 9% nickel steel being particularly notable. This grade provides high strength and excellent toughness, essential for cryogenic applications. Understanding material grades helps buyers select the appropriate type for specific applications, ensuring reliability and performance.

2. Tensile Strength

This property measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. Nickel steel typically exhibits a tensile strength ranging from 700 to 1,200 MPa, depending on its composition and treatment. High tensile strength is critical in industries like aerospace and oil and gas, where structural integrity is paramount.

3. Ductility

Ductility refers to a material’s ability to deform under tensile stress. Nickel steel is known for its excellent ductility, allowing it to be shaped and welded without cracking. This property is particularly important for manufacturers who need to fabricate complex components and structures, as it reduces the risk of failure during processing.

4. Impact Toughness

This measures a material’s ability to absorb energy during deformation, particularly at low temperatures. Nickel steel maintains high impact toughness even at cryogenic temperatures, making it suitable for applications such as liquefied natural gas (LNG) storage and transport. Buyers should prioritize this property when sourcing materials for environments that experience extreme conditions.

5. Corrosion Resistance

Nickel enhances the corrosion resistance of steel, making it suitable for environments that expose materials to harsh chemicals or moisture. Steels with higher nickel content (above 29%) can be non-magnetic and exhibit superior resistance to pitting and crevice corrosion. This property is vital for industries like chemical processing, where material degradation can lead to significant operational costs.

Illustrative image related to nickel steel

6. Hardness

Hardness is a measure of a material’s resistance to deformation, usually assessed via the Rockwell or Brinell scales. Nickel steel offers increased hardness due to the alloying process, which is beneficial in applications requiring wear resistance, such as tooling and machinery parts.

What Are Common Trade Terms Related to Nickel Steel?

Navigating the procurement process for nickel steel involves familiarity with specific industry jargon that can significantly impact negotiations and transactions.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM requirements is essential for buyers who need to ensure compatibility and quality in their supply chain.

2. MOQ (Minimum Order Quantity)

This term refers to the smallest number of units that a supplier is willing to sell. Knowing the MOQ is vital for buyers, especially in budgeting and inventory management, as it can affect the overall cost of procurement.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specified products or services. By issuing an RFQ, buyers can compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms.

Illustrative image related to nickel steel

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother transactions across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Knowing the lead time is crucial for project planning and inventory management, especially in industries where timely delivery is critical to operations.

6. Certification

Certification refers to the validation of a material’s properties and compliance with industry standards. Buyers should seek certified nickel steel products to ensure quality and performance, particularly in regulated industries like aerospace and energy.

Understanding these technical properties and trade terms will empower B2B buyers in making informed decisions regarding nickel steel procurement, optimizing their operations and ensuring compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the nickel steel Sector

What Are the Key Market Dynamics and Trends Impacting the Nickel Steel Sector?

The nickel steel market is experiencing robust growth, driven by increasing demand in sectors such as energy, automotive, and manufacturing. A significant factor propelling this growth is the global shift towards cleaner energy sources, particularly liquefied natural gas (LNG) production and storage. Nickel steel, especially variants with high nickel content, is crucial in constructing cryogenic tanks and pipelines, which are essential for LNG transport. In regions like Africa and South America, the expansion of energy infrastructure is creating new opportunities for B2B buyers to source nickel steel for projects aimed at meeting rising energy demands.

Emerging technologies are reshaping sourcing strategies, with digital platforms facilitating real-time procurement and supplier management. Buyers are increasingly utilizing data analytics to assess market trends and supplier performance, enabling more informed decision-making. Additionally, the trend towards automation in manufacturing processes is enhancing the efficiency of nickel steel production, leading to cost reductions that can benefit B2B buyers.

Moreover, geopolitical factors, including trade policies and tariffs, are influencing nickel steel pricing and availability. Buyers from the Middle East and Europe must navigate these complexities, ensuring they have reliable suppliers who can offer competitive pricing while adhering to international standards. The adoption of just-in-time inventory systems is also gaining traction, allowing companies to minimize holding costs and respond swiftly to market fluctuations.

How Important Is Sustainability and Ethical Sourcing in the Nickel Steel Industry?

Sustainability and ethical sourcing have become pivotal considerations in the nickel steel sector, as global awareness of environmental issues increases. The production of nickel steel can have a substantial environmental impact, particularly regarding mining practices and carbon emissions. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, including reducing their carbon footprint and implementing eco-friendly production processes.

Ethical supply chains are essential for maintaining brand reputation and customer trust. Buyers should seek suppliers who are transparent about their sourcing practices, ensuring that nickel is obtained responsibly and without contributing to social or environmental harm. Certifications such as ISO 14001 for environmental management systems or the ResponsibleSteel certification can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the demand for ‘green’ materials is on the rise, with buyers looking for nickel steel products that meet stringent environmental standards. This trend is driving innovation in the industry, as manufacturers explore ways to recycle nickel and utilize alternative materials with lower environmental impacts. For B2B buyers, aligning procurement strategies with sustainability goals not only supports corporate responsibility but can also lead to cost savings and improved operational efficiency.

What Is the Historical Context of Nickel Steel and Its Relevance Today?

Nickel steel has a rich history that dates back to its development in the early 20th century. Initially introduced by the International Nickel Company in 1942, it was designed to enhance the mechanical properties of steel, particularly for applications requiring high strength and toughness. The introduction of 9% nickel steel significantly advanced the capabilities of materials used in cryogenic environments, making it a preferred choice for constructing storage tanks and vessels for liquefied natural gas.

Over the decades, the evolution of nickel steel has been closely linked to advancements in manufacturing technology and the growing demand for high-performance materials. Today, the emphasis on safety and efficiency in energy infrastructure projects continues to underscore the importance of nickel steel in global supply chains. For B2B buyers, understanding the historical context of nickel steel can provide insights into its current applications and future potential in various industries, particularly as the world transitions towards more sustainable energy solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of nickel steel

-

How do I ensure the quality of nickel steel before purchase?

To ensure the quality of nickel steel, request material test reports (MTRs) or certificates of compliance from suppliers. These documents confirm that the steel meets specific industry standards, such as ASTM specifications. Conducting third-party inspections can further verify the steel’s properties, including tensile strength, corrosion resistance, and ductility. Additionally, consider supplier reputation and reviews from other customers to gauge reliability and product quality. -

What specifications should I look for in nickel steel?

When sourcing nickel steel, focus on the nickel content, which typically ranges from 5% to 9% for cryogenic applications. Check compliance with industry standards such as ASTM A300 and A353 for low-carbon nickel steels. It’s essential to evaluate the steel’s mechanical properties, including yield strength, ultimate tensile strength, and impact toughness, particularly at low temperatures. Understanding the intended application will guide you in selecting the appropriate specifications. -

What are the typical applications of nickel steel in industry?

Nickel steel is widely used in applications requiring high strength and resistance to extreme conditions, such as cryogenic storage and transportation of liquefied natural gas (LNG). Its excellent toughness at low temperatures makes it ideal for manufacturing tanks and vessels. Additionally, it is utilized in aerospace, automotive, and military applications where durability and reliability are critical. -

How can I vet suppliers of nickel steel effectively?

To vet suppliers, begin by researching their market presence and customer testimonials. Verify their certifications and compliance with international standards. Request samples for quality testing and assess their production capabilities, including lead times and minimum order quantities (MOQs). Engaging in direct communication about your requirements can provide insights into their responsiveness and customer service quality. -

What are the common payment terms when sourcing nickel steel internationally?

Payment terms can vary by supplier and region, but common practices include letters of credit, advance payments, and net 30 or 60 days after delivery. It’s advisable to negotiate terms that provide security for both parties. Consider using escrow services for larger orders to ensure that funds are released only upon satisfactory delivery of the product. -

What logistics considerations should I keep in mind when importing nickel steel?

When importing nickel steel, consider shipping methods (air, sea, or land) based on cost and urgency. Evaluate customs regulations and import duties in your country, as they can significantly impact overall costs. Ensure the supplier provides adequate packaging and documentation to facilitate smooth customs clearance. Additionally, working with a reputable freight forwarder can help navigate logistics complexities. -

Can nickel steel be customized for specific projects?

Yes, many suppliers offer customization options for nickel steel, including specific dimensions, alloy compositions, and surface treatments. Clearly communicate your project requirements, including any unique conditions or standards to be met. Customization may involve additional lead times, so it’s essential to discuss timelines and potential costs upfront with your supplier. -

What are the implications of nickel steel’s corrosion resistance for my project?

Nickel steel’s enhanced corrosion resistance is particularly beneficial in harsh environments, such as marine or chemical applications. This property can lead to lower maintenance costs and longer service life for structures and equipment. However, understanding the specific environmental conditions your product will face is crucial. Discuss with your supplier the appropriate nickel content and any necessary coatings or treatments to maximize corrosion resistance for your intended application.

Top 4 Nickel Steel Manufacturers & Suppliers List

1. Nickel Steel Federal Credit Union – Home Banking

Domain: amimembernet.com

Registered: 2015 (10 years)

Introduction: Nickel Steel Federal Credit Union Home Banking, user registration required, username and password recovery options, contact number for assistance: 419-224-7861.

2. Nickel Steel – Key Properties

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Nickel steel is a steel alloy predominantly containing nickel, enhancing properties such as ultimate strength, toughness, hardness, and corrosion resistance. It is particularly effective in cryogenic applications due to its strength and ductility at low temperatures. Nickel content affects the steel’s properties; for instance, steels with 5-9% nickel maintain satisfactory properties down to -260°F…

3. Niobelcon – Nickel Alloy Solutions

Domain: niobelcon.com

Registered: 2010 (15 years)

Introduction: Nickel in carbon steel is a crucial alloying element that acts as a solid solution strengthener, mild hardenability agent, and promoter of high toughness, especially at low temperatures. Nickel improves hardenability, retards the formation of polygonal ferrite grains, and enhances low-temperature toughness. It allows for finer grain sizes and a more homogeneous distribution in heavier gaged produc…

4. MDPI – Nickel in Carbon Steels

Domain: mdpi.com

Registered: 2003 (22 years)

Introduction: This company, MDPI – Nickel in Carbon Steels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for nickel steel

How Can Strategic Sourcing Enhance Your Nickel Steel Procurement?

In today’s competitive landscape, strategic sourcing of nickel steel is vital for businesses aiming to enhance their operational efficiency and product quality. By partnering with reliable suppliers, companies can ensure a steady supply of high-quality nickel steel, which is essential for industries like cryogenics and LNG storage. The unique properties of nickel steel, including its strength, toughness, and corrosion resistance, make it a critical material for construction and manufacturing applications.

B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who demonstrate a commitment to quality and innovation. Engaging with suppliers who invest in advanced manufacturing techniques and adhere to international standards will not only mitigate risks but also foster long-term relationships that can drive mutual growth.

Looking ahead, the demand for nickel steel is poised to increase, driven by its essential role in sustainable energy solutions and advanced manufacturing processes. Now is the time to reassess your sourcing strategies, align with forward-thinking partners, and position your business for success in the evolving global market. Take action today to secure your competitive edge in the nickel steel supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.