Mu Metal Suppliers Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for mu metal suppliers

In today’s global marketplace, sourcing high-quality mu metal suppliers can be a daunting challenge for international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe. The need for effective magnetic shielding solutions spans a variety of industries, including aerospace, healthcare, and electronics, where precision and reliability are paramount. This guide serves as a comprehensive resource, providing insight into the diverse types of mu metal, their specific applications, and the critical factors to consider when vetting suppliers.

By exploring the intricacies of mu metal characteristics, production capabilities, and cost considerations, this guide empowers B2B buyers to make informed purchasing decisions. It highlights the importance of collaboration with suppliers who possess the technical expertise and flexibility to meet unique project requirements. Additionally, we will delve into the nuances of supplier evaluation, ensuring that you can identify partners who not only deliver quality but also understand the complexities of your industry needs. Whether you are based in Germany or Nigeria, this guide aims to equip you with the knowledge necessary to navigate the global market for mu metal suppliers confidently, ensuring you secure the best solutions for your magnetic shielding applications.

Understanding mu metal suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Mu Metal Suppliers | Offer generic mu metal products with standard specifications. | Electronics, Industrial Equipment | Pros: Cost-effective, widely available. Cons: Limited customization options. |

| Custom Mu Metal Fabricators | Provide tailored solutions based on specific client needs. | Aerospace, Medical Devices | Pros: Highly specialized, designed for unique applications. Cons: Higher costs and longer lead times. |

| High-Performance Mu Metal Suppliers | Focus on advanced formulations for extreme conditions. | Defense, High-Tech Research | Pros: Enhanced performance under challenging environments. Cons: Premium pricing, often requires extensive testing. |

| Value-Added Service Providers | Include additional services like consulting and heat treatment. | Research Institutions, High-End Manufacturing | Pros: Comprehensive solutions, improved product lifecycle. Cons: Potentially complex procurement process. |

| International Mu Metal Suppliers | Operate on a global scale, catering to diverse markets. | Global Supply Chains, International Projects | Pros: Access to a wide range of products, competitive pricing. Cons: Logistics challenges, potential communication barriers. |

What Are the Characteristics of Standard Mu Metal Suppliers?

Standard mu metal suppliers typically offer a range of pre-manufactured products that meet common industry specifications. They are ideal for businesses that require reliable shielding solutions without the need for extensive customization. These suppliers generally provide products at competitive prices, making them suitable for cost-sensitive applications in electronics and industrial equipment. When purchasing, buyers should consider the supplier’s reputation for quality and delivery timelines.

How Do Custom Mu Metal Fabricators Operate?

Custom mu metal fabricators focus on creating bespoke solutions tailored to the specific needs of their clients. They work closely with customers to develop shielding solutions that address unique challenges, especially in complex sectors like aerospace and medical devices. While these suppliers offer high levels of customization, buyers should be prepared for longer lead times and potentially higher costs. It’s essential to assess the fabricator’s expertise and past performance in similar projects.

Illustrative image related to mu metal suppliers

What Sets High-Performance Mu Metal Suppliers Apart?

High-performance mu metal suppliers specialize in advanced alloys designed to withstand extreme environments and conditions. These products are often used in defense and high-tech research applications, where superior magnetic shielding is crucial. While they deliver enhanced performance, the associated costs can be significantly higher than standard options. Buyers must weigh the benefits of advanced shielding against their budget constraints and project requirements.

What Additional Services Do Value-Added Service Providers Offer?

Value-added service providers go beyond merely supplying mu metal products; they also offer services such as consulting, design assistance, and heat treatment. This comprehensive approach can significantly enhance the effectiveness and longevity of the shielding products. Organizations in research and high-end manufacturing may find these services particularly beneficial. However, the procurement process can be more complex, requiring careful coordination between multiple service aspects.

How Do International Mu Metal Suppliers Cater to Global Markets?

International mu metal suppliers operate on a global scale, providing products to diverse markets across various continents. They often leverage economies of scale to offer competitive pricing and a broad selection of products. While this can be advantageous for companies with global supply chains, buyers should be aware of potential logistics challenges and communication barriers that may arise. Establishing clear lines of communication and understanding shipping timelines is crucial for successful procurement.

Key Industrial Applications of mu metal suppliers

| Industry/Sector | Specific Application of mu metal suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Magnetic shielding for navigation and communication systems | Enhanced signal integrity and accuracy in navigation systems | Compliance with aerospace standards and certifications |

| Medical/Healthcare | MRI machine shielding to reduce interference | Improved imaging quality and patient safety | Supplier’s experience with medical-grade materials |

| Defense | Shielding for sensitive military equipment | Protection against electromagnetic interference | Capability to provide custom solutions and rapid prototyping |

| High Technology/Electronics | Shielding for sensitive electronic devices (e.g., SQUIDs) | Increased performance and reliability of devices | Expertise in precision fabrication and design support |

| Industrial/Manufacturing | Shielding for transformers and motors | Reduced operational noise and improved efficiency | Availability of bulk production and cost-effective solutions |

How Are mu metal Suppliers Used in Aerospace Applications?

In the aerospace sector, mu metal suppliers provide magnetic shielding for navigation and communication systems, which are critical for flight safety. The shielding minimizes interference from external magnetic fields, ensuring the accuracy of instruments. International buyers, particularly from regions like Europe and the Middle East, must consider suppliers that meet stringent aerospace standards and certifications to ensure compliance and reliability.

What Role Do mu metal Suppliers Play in Medical/Healthcare Applications?

In the medical field, mu metal suppliers are pivotal in manufacturing shielding for MRI machines. This shielding reduces electromagnetic interference, leading to clearer imaging and enhanced patient safety. For B2B buyers in Africa and South America, it is essential to partner with suppliers that have experience in medical-grade materials and can ensure adherence to health regulations and quality standards.

How Do mu metal Suppliers Support Defense Applications?

For defense applications, mu metal suppliers create shielding for sensitive military equipment to protect against electromagnetic interference. This is vital for the operational integrity of communication systems and radar technologies. Buyers in emerging markets should prioritize suppliers that offer custom solutions and rapid prototyping capabilities to address unique defense requirements effectively.

Why Are mu metal Suppliers Important for High Technology and Electronics?

In the high technology and electronics sectors, mu metal suppliers are essential for shielding sensitive devices like superconducting quantum interference devices (SQUIDs). This shielding enhances performance by eliminating interference from the Earth’s magnetic field. International buyers must look for suppliers with expertise in precision fabrication and design support to ensure optimal results for their high-tech applications.

How Do mu metal Suppliers Benefit Industrial and Manufacturing Operations?

In industrial and manufacturing settings, mu metal suppliers provide shielding for transformers and motors to reduce operational noise and enhance efficiency. This is crucial for maintaining a productive work environment. Buyers from regions such as Nigeria and Germany should seek suppliers that can deliver bulk production capabilities and cost-effective solutions while ensuring high-quality standards.

3 Common User Pain Points for ‘mu metal suppliers’ & Their Solutions

Scenario 1: Navigating Complex Specifications for High-Performance Applications

The Problem: B2B buyers often face challenges when selecting the right mu metal specifications for high-performance applications, such as aerospace or medical equipment. The complexity of the required properties—like permeability, hysteresis loss, and mechanical integrity—can lead to confusion. Buyers may struggle to communicate their needs effectively, resulting in mismatched expectations and costly delays in production.

The Solution: To overcome this issue, it’s essential to collaborate closely with mu metal suppliers from the outset. Begin by conducting thorough research on your application’s specific requirements. Prepare a detailed specification sheet that includes desired permeability levels, the intended operational environment, and any relevant industry standards. Engage with suppliers who have proven expertise in your field, and request samples for testing in your actual operating conditions. Establishing a dialogue with the supplier’s engineering team can facilitate the development of a tailored solution that meets your exact needs, minimizing the risk of errors and ensuring timely project completion.

Scenario 2: Managing Supply Chain Disruptions and Lead Times

The Problem: Buyers often encounter disruptions in the supply chain that affect lead times for mu metal products. Global events, changes in demand, or unexpected production issues can lead to delays, which can severely impact project timelines and budgets. Such uncertainties can be particularly problematic for industries that require just-in-time manufacturing or have tight deadlines.

The Solution: To mitigate supply chain risks, it is advisable to establish strategic partnerships with multiple mu metal suppliers. Diversifying your supplier base can provide alternative options in case of disruptions. Additionally, work with suppliers who offer real-time tracking of your orders and transparent communication about lead times. Incorporating buffer stock for critical components can also help maintain operational continuity. Lastly, consider discussing long-term contracts with suppliers that can provide assurances on pricing and availability, thus creating a more stable supply chain.

Scenario 3: Achieving Cost-Effective Solutions Without Compromising Quality

The Problem: Many B2B buyers are under pressure to reduce costs while still delivering high-quality products. This can lead to the temptation to opt for cheaper materials or suppliers who may not meet industry standards, ultimately compromising product performance and reliability. Such decisions can result in increased long-term costs due to failures or the need for replacements.

The Solution: To achieve a balance between cost and quality, buyers should engage in a thorough cost-benefit analysis. Evaluate the total cost of ownership (TCO) rather than just the upfront price. Consider the performance characteristics of different mu metal grades and how they will affect your product’s reliability and lifecycle. Collaborate with suppliers who can offer value-added services, such as design assistance or prototype testing, which can identify potential issues before full-scale production. Additionally, foster a long-term relationship with suppliers who understand your needs and can offer competitive pricing based on volume, thus ensuring both quality and cost-effectiveness in your sourcing strategy.

Strategic Material Selection Guide for mu metal suppliers

What Are the Key Properties of Mu Metal and Its Alternatives?

Mu metal is primarily known for its exceptional magnetic shielding properties, but understanding the various materials available is crucial for B2B buyers. Below, we analyze several common materials relevant to mu metal suppliers, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

1. Mu Metal (Nickel-Iron-Molybdenum Alloy)

Key Properties: Mu metal typically consists of approximately 80% nickel, 20% iron, and a small percentage of molybdenum. It offers high permeability, low hysteresis loss, and excellent magnetic shielding capabilities, particularly for low-frequency applications.

Pros & Cons: The primary advantage of mu metal is its effectiveness in shielding against magnetic interference, making it ideal for sensitive applications like MRI machines and scientific instruments. However, it is relatively expensive and can be challenging to fabricate due to its sensitivity to mechanical stress and heat treatment requirements.

Impact on Application: Mu metal is particularly effective in environments where magnetic interference is prevalent, such as in medical imaging and aerospace applications. Its performance can be significantly affected by temperature and mechanical handling.

Considerations for International Buyers: Compliance with standards such as ASTM A753 is crucial. Buyers from regions like Europe and the Middle East often prioritize suppliers who can provide certifications and detailed specifications.

2. Permalloy (Nickel-Iron Alloy)

Key Properties: Permalloy is another soft magnetic material, typically composed of 80% nickel and 20% iron. It has high magnetic permeability and low coercivity, making it suitable for various electromagnetic applications.

Pros & Cons: The key advantage of permalloy is its cost-effectiveness compared to mu metal while still offering good shielding performance. However, it may not perform as well in extreme conditions and can be less effective at higher frequencies.

Impact on Application: Permalloy is often used in transformers, inductors, and magnetic sensors. It is particularly effective in applications where cost is a critical factor, but it may require additional measures for high-frequency performance.

Considerations for International Buyers: Buyers should ensure that suppliers adhere to international standards, such as JIS and DIN, particularly in regions like Germany, where precision and compliance are paramount.

3. Silicon Steel

Key Properties: Silicon steel is a ferromagnetic material that contains silicon to improve its electrical resistivity and magnetic properties. It is commonly used in electrical applications, such as transformers and electric motors.

Pros & Cons: The main advantage of silicon steel is its availability and lower cost compared to specialized alloys like mu metal. However, its magnetic properties are not as favorable for shielding applications, and it can be less effective in high-frequency scenarios.

Impact on Application: Silicon steel is suitable for applications requiring magnetic cores but may not be ideal for environments with significant magnetic interference. It is often used in industrial settings where cost efficiency is essential.

Considerations for International Buyers: Buyers should be aware of the different grades of silicon steel and their respective standards, especially in regions like Africa, where material quality can vary significantly.

4. Ferrite Materials

Key Properties: Ferrites are ceramic compounds composed of iron oxide mixed with other metals. They exhibit high magnetic permeability and are often used in high-frequency applications.

Pros & Cons: Ferrites are lightweight and cost-effective, making them ideal for mass production. However, they are brittle and can be less effective in applications requiring high mechanical strength.

Impact on Application: Ferrites are commonly used in applications like RF transformers and inductors. Their effectiveness in high-frequency environments makes them suitable for telecommunications but may limit their use in low-frequency applications.

Considerations for International Buyers: Buyers should consider the specific type of ferrite material and its compatibility with their applications, especially in regions like South America, where access to quality materials may vary.

Summary Table of Material Selection for Mu Metal Suppliers

| Material | Typical Use Case for mu metal suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mu Metal | MRI machines, scientific instruments | Exceptional magnetic shielding | High cost, fabrication complexity | High |

| Permalloy | Transformers, magnetic sensors | Cost-effective, good shielding | Less effective in extreme conditions | Medium |

| Silicon Steel | Electrical transformers, motors | Widely available, lower cost | Poor shielding performance | Low |

| Ferrite Materials | RF transformers, inductors | Lightweight, cost-effective | Brittle, limited low-frequency effectiveness | Medium |

This guide provides a comprehensive overview of the materials available for mu metal suppliers, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mu metal suppliers

What Are the Main Stages in the Manufacturing Process of Mu Metal?

The manufacturing process of mu metal, a high-permeability magnetic shielding material, involves several critical stages that ensure the final product meets stringent performance standards. These stages typically include material preparation, forming, assembly, and finishing.

How is Material Prepared for Mu Metal Production?

Material preparation begins with sourcing high-quality nickel, iron, and molybdenum alloys. Suppliers must adhere to strict specifications, such as ASTM A753 and military standards like MIL-N-14411. The raw materials are then analyzed for purity and composition to ensure they meet the required metallurgical properties. This initial phase is crucial as the quality of the raw materials directly influences the performance of the final product.

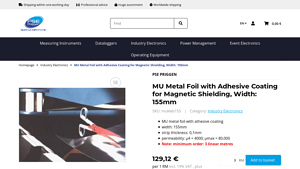

Illustrative image related to mu metal suppliers

What Forming Techniques Are Commonly Used in Mu Metal Manufacturing?

Once the material is prepared, the forming process begins. Common techniques include bending, stamping, and hydroforming, which shape the mu metal into the desired forms while maintaining its magnetic properties. Hydroforming, in particular, is favored for its ability to create complex geometries without compromising material integrity. During this stage, operators must carefully monitor the stress levels in the material to prevent work hardening, which can adversely affect permeability.

How is Assembly Conducted for Mu Metal Components?

The assembly stage involves the integration of various mu metal components into a cohesive unit. This may include welding, which requires careful control to avoid introducing contaminants like oxygen that can degrade performance. Advanced techniques such as laser welding may be employed to achieve precision and minimize heat distortion. At this point, the focus is on ensuring that the assembled units are structurally sound and ready for testing.

What Finishing Processes Are Essential for Mu Metal Products?

Finishing processes play a vital role in enhancing the functional and aesthetic qualities of mu metal products. Techniques such as machining, surface treatment, and heat treatment are commonly applied. Heat treating, particularly in a hydrogen atmosphere, is critical for maximizing permeability and removing impurities. This process helps achieve the desired grain structure, which is essential for optimal magnetic performance.

What Quality Control Measures Are Implemented by Mu Metal Suppliers?

Quality assurance is paramount in the manufacturing of mu metal, given its applications in sensitive industries such as aerospace, medical, and defense. Suppliers typically adhere to international standards like ISO 9001, which establishes a framework for quality management systems.

How Do Quality Control Checkpoints Function?

Quality control is typically structured around several checkpoints, including:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various parameters are monitored to identify any deviations from quality standards.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to verify that they meet all specifications and performance criteria.

What Testing Methods Are Commonly Used in Mu Metal Quality Assurance?

Several testing methods are employed to evaluate the performance characteristics of mu metal, including:

- Permeability Testing: Measures the material’s ability to absorb magnetic flux.

- Mechanical Testing: Assesses strength and durability under various stress conditions.

- Dimensional Inspection: Ensures that components meet specified tolerances and dimensions.

These tests help confirm that the mu metal products will perform reliably in their intended applications.

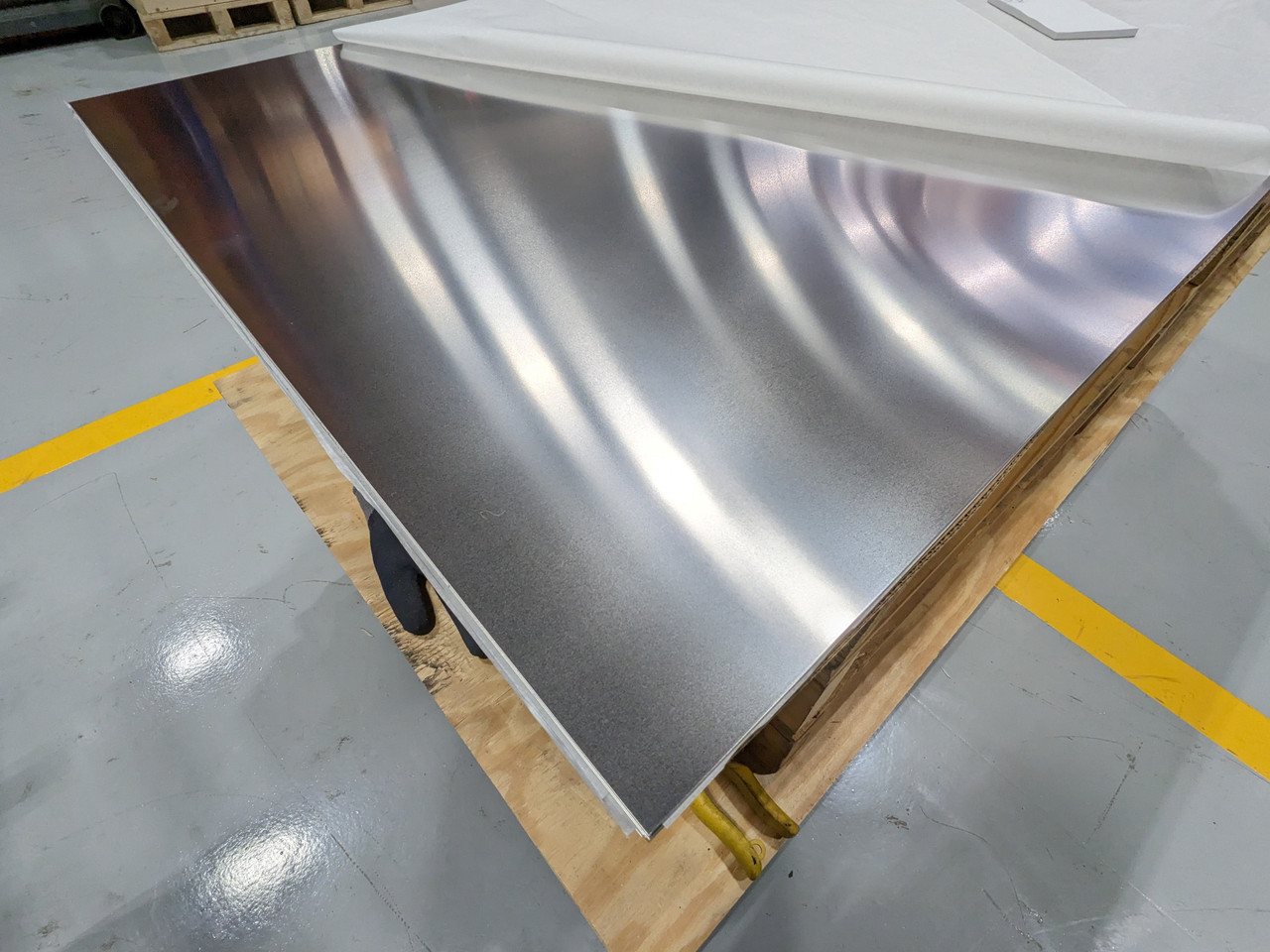

Illustrative image related to mu metal suppliers

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps to ensure the reliability of mu metal suppliers:

What Steps Can Buyers Take for Supplier Audits and Assessments?

- Conduct Supplier Audits: Periodic audits of the manufacturing facilities can provide insights into their quality control processes and adherence to standards.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality assurance processes, including inspection reports and testing results.

- Engage Third-Party Inspectors: Utilizing independent inspection agencies can offer an unbiased assessment of the supplier’s quality practices.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must also consider nuances in quality certification and compliance. Different regions may have specific regulations and standards that must be met. For instance, European suppliers may need to comply with CE marking, while those catering to the oil and gas sector might require API certification. Understanding these requirements is crucial for ensuring that the mu metal products are suitable for the intended markets.

Conclusion

The manufacturing processes and quality assurance measures adopted by mu metal suppliers are intricate and essential for producing high-performance magnetic shielding products. By understanding these processes and implementing rigorous quality verification methods, B2B buyers can confidently source mu metal components that meet their specific needs and standards. This comprehensive approach not only enhances product reliability but also fosters long-term partnerships in the global supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mu metal suppliers’

In the quest to procure high-quality mu metal for your business needs, a systematic approach is essential. This guide provides a clear checklist for B2B buyers, helping you navigate the complexities of sourcing mu metal suppliers effectively.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, it’s crucial to establish your specific requirements for mu metal. This includes determining the alloy composition, dimensions, and any unique properties needed for your application. Having precise specifications will streamline the selection process and ensure that suppliers can meet your technical needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in mu metal. Look for companies with a strong reputation in your industry, as well as experience working with clients in your geographical region. Utilize online directories, industry forums, and trade associations to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

Once you have a list of potential suppliers, verify their certifications and quality standards. Look for compliance with relevant industry standards such as ASTM A753 and military specifications like MIL-N-14411. Certifications indicate that the supplier adheres to stringent quality controls, which is critical for ensuring the reliability of your mu metal products.

Step 4: Request Samples and Technical Data Sheets

Before making a commitment, request samples of the mu metal along with technical data sheets. Analyzing these samples will allow you to assess their quality, permeability, and suitability for your applications. Additionally, the technical data sheets provide essential information on the material properties, helping you make informed decisions.

Step 5: Assess Manufacturing Capabilities

Investigate the manufacturing capabilities of your shortlisted suppliers. Evaluate their production processes, machinery, and technologies used in fabricating mu metal products. Suppliers who invest in advanced manufacturing techniques, such as CNC machining and laser cutting, are more likely to deliver precise and high-quality components.

Step 6: Inquire About Lead Times and Delivery Options

Understanding the lead times and delivery options is crucial for planning your projects effectively. Communicate your timelines and assess whether the suppliers can meet your deadlines. Reliable suppliers should provide clear information on their production schedules and shipping processes to avoid any disruptions.

Step 7: Evaluate Customer Support and Communication

Strong customer support and effective communication are essential when dealing with complex materials like mu metal. Evaluate how responsive the suppliers are to your inquiries and their willingness to provide assistance throughout the sourcing process. A supplier that values communication can help resolve issues quickly and ensure a smoother procurement experience.

Illustrative image related to mu metal suppliers

By following this checklist, you can streamline your sourcing process for mu metal suppliers, ensuring that you select a partner who meets your technical, quality, and logistical needs.

Comprehensive Cost and Pricing Analysis for mu metal suppliers Sourcing

When sourcing mu metal, understanding the comprehensive cost structure is crucial for international B2B buyers. This material, primarily used for high permeability magnetic shielding, involves multiple cost components that can influence pricing.

What Are the Key Cost Components in Mu Metal Procurement?

-

Material Costs: The primary component of mu metal pricing is the raw material itself, which consists of approximately 80% nickel and 20% iron, along with small amounts of molybdenum. Fluctuations in the prices of these metals, influenced by global market trends, can significantly impact overall costs. Buyers should monitor commodity prices to anticipate changes in their procurement budgets.

-

Labor Costs: Skilled labor is essential for the fabrication of mu metal products. Labor costs can vary based on geographic location and the complexity of the manufacturing processes involved. In regions like Europe, where labor is often more expensive, buyers may find higher overall costs compared to sourcing from regions with lower labor rates, such as parts of Africa or South America.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility operations. Suppliers with advanced manufacturing capabilities, such as CNC machining or laser cutting, may have higher overhead costs, which can be reflected in their pricing.

-

Tooling Costs: Custom tooling may be required for specific mu metal applications, adding to the initial setup costs. Buyers should consider these expenses when requesting quotes, particularly if they need unique specifications.

-

Quality Control (QC): Ensuring that mu metal meets specific standards often involves rigorous testing and quality assurance processes. Certifications (e.g., ASTM A753) that validate the material’s properties can contribute to higher costs but are essential for applications in industries like aerospace and defense.

-

Logistics: Shipping and handling costs can vary significantly, especially for international buyers. Factors such as distance, shipping methods, and freight charges will influence overall costs. Understanding Incoterms is vital for buyers to clarify who bears responsibility for these expenses.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary widely between suppliers, depending on their market positioning and the level of service they provide.

What Price Influencers Should Buyers Consider?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to cost savings due to economies of scale. Buyers should negotiate MOQs that align with their production needs to optimize their cost structure.

-

Specifications and Customization: Customized mu metal solutions tailored to specific applications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Quality and Certifications: Higher quality and certified materials typically command premium pricing. Buyers must balance the need for quality with budget constraints, particularly in price-sensitive markets.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers with a proven track record may charge more, but they often provide better service and product quality.

What Are the Best Buyer Tips for Cost-Efficiency?

-

Negotiation Strategies: Effective negotiation can lead to better pricing. Buyers should be prepared to discuss their needs in detail and explore flexible payment terms or bulk discounts.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with mu metal procurement, including maintenance, durability, and performance. Lower initial prices may not always yield the best value over time.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import tariffs that could impact total costs. Leveraging local suppliers or those familiar with regional regulations can mitigate some of these risks.

-

Disclaimer for Indicative Prices: It’s essential to note that pricing for mu metal can vary widely based on the aforementioned factors. Buyers should seek tailored quotes from multiple suppliers to get an accurate understanding of the market landscape.

In conclusion, a comprehensive understanding of the cost structure and pricing dynamics of mu metal will empower international B2B buyers to make informed decisions, ensuring they achieve the best value for their investment.

Illustrative image related to mu metal suppliers

Alternatives Analysis: Comparing mu metal suppliers With Other Solutions

Understanding Alternative Solutions to Mu Metal Suppliers

In the realm of magnetic shielding, mu metal suppliers offer specialized materials and expertise for high-performance applications. However, various alternatives exist that can also provide effective solutions for magnetic interference challenges. Understanding these options allows B2B buyers to make informed decisions based on specific project requirements, performance needs, and budget constraints.

Comparison of Magnetic Shielding Solutions

| Comparison Aspect | Mu Metal Suppliers | Soft Ferrite Cores | Conductive Foams |

|---|---|---|---|

| Performance | High permeability, effective for low frequencies | Moderate permeability, good for RF applications | Limited shielding effectiveness, depends on conductivity |

| Cost | Generally higher due to material and processing | Moderate, often lower than mu metal | Low, especially for bulk purchases |

| Ease of Implementation | Requires precise design and fabrication | Easy to integrate in various designs | Simple to use, can be cut to size easily |

| Maintenance | Low, but may require specialized handling | Low, durable under normal conditions | Moderate, can degrade over time |

| Best Use Case | Aerospace, medical imaging, sensitive electronics | RF applications, transformers, inductors | General shielding in consumer electronics |

Alternative 1: Soft Ferrite Cores

Soft ferrite cores are ceramic materials made from iron oxide mixed with other metal oxides. They are commonly used in inductors and transformers due to their moderate permeability and high electrical resistivity. The primary advantage of soft ferrite cores is their cost-effectiveness compared to mu metal, making them a popular choice for RF applications. However, their performance may not match mu metal in low-frequency magnetic shielding, as they are less effective in environments with strong static magnetic fields.

Alternative 2: Conductive Foams

Conductive foams are lightweight materials infused with conductive particles, providing a flexible option for electromagnetic interference (EMI) shielding. They are simple to implement, as they can be easily cut and shaped to fit various components. While conductive foams are cost-effective and suitable for general shielding applications, they typically offer limited performance compared to mu metal. Their effectiveness diminishes in high-frequency environments, making them less ideal for critical applications requiring robust shielding.

Conclusion: How to Choose the Right Magnetic Shielding Solution

When selecting a magnetic shielding solution, B2B buyers should evaluate their specific needs, including performance requirements, budget, and application context. Mu metal suppliers excel in providing tailored solutions for high-performance scenarios, particularly in industries like aerospace and medical technology. However, alternatives like soft ferrite cores and conductive foams may be more appropriate for cost-sensitive projects or less demanding applications. By carefully assessing the advantages and limitations of each option, buyers can ensure they select the most suitable solution for their unique challenges.

Illustrative image related to mu metal suppliers

Essential Technical Properties and Trade Terminology for mu metal suppliers

When navigating the realm of mu metal suppliers, understanding the essential technical properties and industry terminology is crucial for making informed purchasing decisions. This section outlines key specifications and trade terms that will empower B2B buyers to engage effectively with suppliers.

What Are the Key Technical Properties of Mu Metal?

1. Material Grade

Mu metal is primarily characterized as an 80% nickel-iron-molybdenum alloy. This specific grade is known for its high permeability, making it ideal for magnetic shielding applications. For buyers, knowing the material grade is essential as it directly influences the performance of the shielding in various environments, such as aerospace or medical applications.

2. Permeability

Permeability refers to the ability of mu metal to absorb magnetic fields. Higher permeability indicates greater effectiveness in shielding against magnetic interference. Understanding the permeability ratings can help buyers select materials that will meet their specific shielding requirements, particularly in sensitive technological applications.

3. Hysteresis Loss

Hysteresis loss is the energy lost due to the lag between the magnetization and demagnetization of the material. In mu metal, minimizing hysteresis loss is critical for efficiency. Suppliers often provide this specification to help buyers understand how energy-efficient their shielding solution will be over time, especially in high-frequency applications.

4. Tensile Strength

Tensile strength measures how much pulling force a material can withstand before failing. For mu metal, this property is vital in applications where mechanical stress is a factor. Buyers should consider tensile strength when evaluating the durability of the shielding in their specific use cases, ensuring it can withstand operational conditions.

Illustrative image related to mu metal suppliers

5. Heat Treatment Process

The heat treatment process significantly affects the properties of mu metal, enhancing its permeability and structural integrity. Understanding the specifics of heat treatment—such as temperature and duration—can help buyers ensure they are receiving the highest quality shielding materials tailored to their needs.

6. Dimensions and Tolerances

Dimensions and tolerances define the acceptable size and variability in manufacturing mu metal components. Accurate specifications are crucial for ensuring that parts fit properly in their intended applications. Buyers should prioritize suppliers who provide clear tolerances, as this will affect assembly and overall performance.

What Are Common Trade Terms Used in Mu Metal Supply?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end product. In the context of mu metal, an OEM may require specific shielding components that meet stringent performance criteria. Understanding this term helps buyers identify suppliers who can meet their unique specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers who may be budgeting for larger projects. Knowing the MOQ helps in planning purchases and negotiating with suppliers to align with project timelines.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. This term is crucial for initiating discussions with mu metal suppliers and ensuring that buyers receive competitive pricing based on their specific requirements.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery processes. Familiarity with these terms is essential for B2B transactions, as they clarify who is responsible for costs and risks at various stages of shipping mu metal products.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for planning and project management, especially in industries where time-sensitive applications are common.

6. Certification Standards

Certification standards, such as ASTM A753 or military specifications, indicate compliance with specific performance and quality benchmarks. Buyers should ensure that their suppliers adhere to relevant certification standards to guarantee the reliability and safety of mu metal products.

By grasping these essential technical properties and trade terminology, B2B buyers can navigate the mu metal supply landscape more effectively, ensuring they select the right materials and suppliers for their unique applications.

Navigating Market Dynamics and Sourcing Trends in the mu metal suppliers Sector

What Are the Current Market Dynamics and Key Trends Affecting Mu Metal Suppliers?

The mu metal suppliers sector is experiencing significant shifts driven by advancements in technology and the increasing need for effective magnetic shielding solutions across various industries. Global demand for high-performance magnetic shielding materials is rising, particularly in sectors such as aerospace, defense, healthcare, and electronics. These industries require mu metal’s unique properties, such as high permeability and minimal hysteresis loss, to protect sensitive equipment from magnetic interference.

Emerging trends in B2B sourcing include a growing focus on customization and rapid prototyping. Suppliers are increasingly expected to collaborate closely with clients to develop tailored solutions that meet specific application requirements. This trend is particularly pertinent for international buyers in regions like Africa, South America, the Middle East, and Europe, where diverse industrial needs necessitate flexible and innovative approaches. Digital transformation is also reshaping the sector, with suppliers adopting advanced manufacturing technologies like CNC machining and laser cutting to enhance efficiency and precision in production.

Additionally, global supply chain dynamics are influencing sourcing strategies. The ongoing shifts in trade policies and regional market conditions necessitate that buyers remain agile, leveraging local suppliers when possible to mitigate risks associated with international shipping and tariffs. As such, international buyers should prioritize suppliers that demonstrate robust capabilities in both production and logistical flexibility.

How Important Is Sustainability and Ethical Sourcing for Mu Metal Suppliers?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the mu metal sector. The environmental impact of material extraction and manufacturing processes is under scrutiny, prompting suppliers to adopt more sustainable practices. This includes reducing waste, minimizing energy consumption, and utilizing recycled materials whenever feasible.

Buyers are increasingly looking for suppliers who possess ‘green’ certifications, which validate their commitment to environmentally responsible practices. These certifications can include ISO 14001 for environmental management systems or adherence to the Responsible Steel standard, which promotes sustainable steel production.

Moreover, ethical supply chains are becoming a priority, particularly for companies operating in regions where labor practices may not always meet international standards. By partnering with suppliers that prioritize ethical sourcing, buyers can ensure that their supply chains are not only compliant but also socially responsible. This consideration can enhance brand reputation and align with the values of environmentally and socially conscious consumers.

Illustrative image related to mu metal suppliers

What Is the Brief Evolution and History of Mu Metal Suppliers?

The evolution of mu metal suppliers can be traced back to the mid-20th century, coinciding with the rapid advancements in technology and the increasing demand for effective magnetic shielding solutions. Initially developed for specialized applications in the aerospace and defense industries, mu metal quickly gained recognition for its exceptional magnetic properties.

As electronic devices became more complex and sensitive, the need for high-performance magnetic shielding expanded into various sectors, including healthcare and industrial manufacturing. Over the decades, suppliers have adapted to these changing demands, investing in research and development to enhance material properties and production techniques. Today, the mu metal supply chain is characterized by a blend of traditional craftsmanship and modern manufacturing technologies, ensuring that suppliers can meet the diverse needs of a global market.

This historical context highlights the importance of innovation and adaptability in the mu metal sector, underscoring the value of collaborating with suppliers who are not only knowledgeable but also responsive to emerging market trends and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of mu metal suppliers

-

How do I select the right mu metal supplier for my business needs?

Choosing the right mu metal supplier involves assessing their industry experience, production capabilities, and certifications. Look for suppliers with a proven track record in your specific industry, whether it’s aerospace, healthcare, or electronics. It’s also essential to inquire about their quality assurance processes, lead times, and flexibility in customization. Request samples and references to evaluate their product quality and customer service. Finally, ensure they can meet your logistical needs, especially if you are importing from international markets. -

What is the best application of mu metal in shielding technology?

Mu metal is widely used for magnetic shielding in applications requiring high permeability, such as MRI machines, scientific instruments, and electronic devices. Its unique properties allow it to absorb and redirect magnetic flux, minimizing interference. The best application depends on your specific requirements, such as the frequency of interference and environmental conditions. Consulting with a supplier can help you determine the most effective design and configuration for your application. -

What customization options are available for mu metal products?

Most mu metal suppliers offer a range of customization options, including varying thicknesses, shapes, and sizes to meet your specific shielding requirements. You can also request design modifications to fit unique applications or environments. Discuss your needs with the supplier’s engineering team to ensure that the final product aligns with your technical specifications. Additionally, inquire about their ability to produce prototypes for testing before full-scale production. -

What is the minimum order quantity (MOQ) for mu metal products?

Minimum order quantities can vary significantly between suppliers and depend on factors such as product type and complexity. Some suppliers may have a low MOQ for standard products, while custom designs may require larger orders to justify production costs. Always clarify the MOQ upfront during negotiations, especially if you are a smaller business or startup. Understanding these terms can help you manage inventory and budget effectively. -

What payment terms should I expect when sourcing mu metal?

Payment terms for mu metal suppliers can vary, often ranging from upfront payments to net 30 or 60 days after delivery. Discussing payment options early in the negotiation process is crucial. Some suppliers may require a deposit for custom orders or larger quantities. Ensure that you understand any additional fees, such as shipping or handling, and consider using secure payment methods to protect your investment. -

How do I ensure quality assurance when sourcing mu metal?

To ensure quality assurance, request detailed specifications, certifications, and testing reports from your mu metal supplier. Look for compliance with international standards such as ASTM A753 or military specifications. Some suppliers may offer third-party testing services to validate material performance. Establish clear communication regarding quality expectations and consider visiting the supplier’s facility if feasible, to observe their production and quality control processes firsthand. -

What logistics considerations should I keep in mind when importing mu metal?

Logistics play a critical role in the importation of mu metal, particularly regarding shipping methods, customs clearance, and delivery timelines. Choose a supplier with experience in international shipping to ensure compliance with import regulations in your country. Additionally, factor in potential delays and costs associated with customs duties and taxes. Establishing a reliable logistics partner can help streamline the process and minimize risks related to transportation and delivery. -

How do I handle potential challenges in international sourcing of mu metal?

Challenges in international sourcing of mu metal may include language barriers, cultural differences, and varying regulatory standards. To mitigate these risks, conduct thorough research on potential suppliers and consider using local agents or intermediaries who understand the regional market. Establish clear communication channels and document all agreements to avoid misunderstandings. Additionally, consider starting with smaller orders to test the supplier’s reliability before committing to larger contracts.

Top 8 Mu Metal Suppliers Manufacturers & Suppliers List

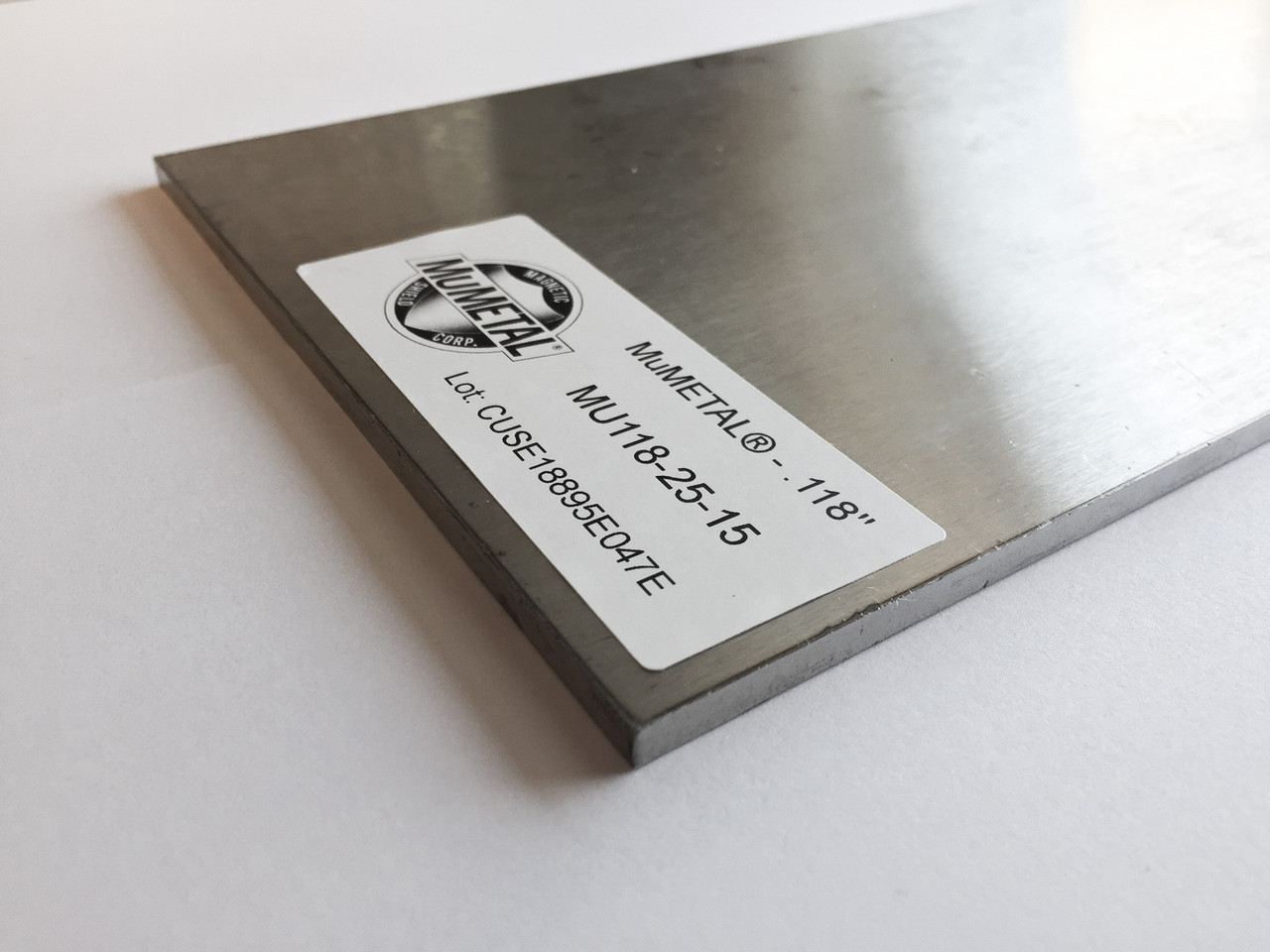

1. MuMetal® – Shielding Solutions

Domain: magnetic-shield.com

Registered: 1996 (29 years)

Introduction: MuMetal® brand products include a variety of raw material types, shapes, and sizes such as shielding sheets, plates, foils, toroidal cores, and custom scientific chambers. The products are designed for shielding applications in wiring and cabling. The brand is a registered trade name owned by Magnetic Shield Corporation, which has over 80 years of experience in manufacturing precision shielding al…

2. Mumetal – High Permeability Magnetic Shielding Material

Domain: mumetal.com

Registered: 1999 (26 years)

Introduction: Mumetal is a high permeability magnetic shielding material made from a non-oriented 80% nickel-iron-molybdenum alloy, primarily composed of approximately 80% Nickel (Ni), 20% Iron (Fe), and small amounts of Molybdenum (Mo). It is designed for low frequency and static magnetic shielding applications. MuShield offers design and production services for various industries including aerospace, defense,…

3. Holland Shielding – Mu-Metal Magnetic Shielding Solutions

Domain: hollandshielding.com

Registered: 1998 (27 years)

Introduction: Mu-Metal – Magnetic shielding materials used for shielding transformers and sensitive sensors. Key products include: MFHD ‘ Mu-ferro HD for low frequency magnetic shielding for sensors, PCs, and electronic devices; 3208 ‘ Mu-ferro foil & tape for low-frequency magnetic field shielding; MFSD ‘ Mu-ferro shielding foil, thin and flexible with high permeability; ZGC ‘ Mu-metal zero gauss chamber for l…

4. HongerTech – Mu Metal Core Manufacturer

Domain: hongertech.com

Registered: 2016 (9 years)

Introduction: Mu Metal Core Manufacturer and Shielding Suppliers. Key products include: 1. Raw Materials: Mu Metal (Nickel-Iron-Molybdenum alloy) with high magnetic permeabilities and minimal core losses. 2. Transformer Laminations: Made from nickel-based alloy (Permalloy), used in high-end audio transformers and sensors. 3. Shielding Series: Mu Metal shielding parts for protecting devices from magnetic interfe…

5. Mu-Metal – Magnetic Shielding

Domain: aircraftspruce.com

Registered: 1999 (26 years)

Introduction: Mu-Metal Magnetic Shielding

– Price: $6.50 per inch

– Part Number: 11-04483

– Manufacturer Model: MUT004-4

– Dimensions: 4″ width x 4 mil thickness

– Sold by the inch (e.g., qty 1 = 1″ x 4″)

– Adhesive backing for easy application

– Composition: ~80% Nickel, ~15% Iron, <5% Molybdenum, Manganese, Silicon

– Free shipping on eligible orders

– 30 Day Risk Free Purchase with free outbound and return sh…

6. EMI Shielding – Mu Metal Solutions

Domain: emi-shielding.net

Registered: 2002 (23 years)

Introduction: Mu Metal is a high-permeability alloy known for its exceptional magnetic shielding capabilities in sensitive electronic applications. It is used in various forms including thin foils, annealed sheets, shielding cans, toroidal cores, and custom-built chambers. Applications include scientific instruments, aerospace electronics, magnetic sensors, and MRI shielding environments. Industries served incl…

7. Priggen – MU Metal Foil with Adhesive Coating

Domain: priggen.com

Registered: 2005 (20 years)

Introduction: MU Metal Foil with Adhesive Coating for Magnetic Shielding, Width: 155mm, Strip Thickness: 0.1mm, Permeability: µ4 = 4000; µmax = 80,000, Minimum Order: 3 linear metres, Price: 129.12 € per 1 RM (incl. 19% VAT), Shipping Costs: 8 – 10 Workdays (DE – international shipments may differ).

8. Salomons Metalen – Mu-Metal Shielding Solutions

Domain: salomons-metalen.com

Registered: 2015 (10 years)

Introduction: Material: Mu-Metal; Composition: Nickel (77%), Iron (15%), Molybdenum, Copper; Applications: Shielding against magnetic fields (e.g., cassette tapes); Available Forms: Sheets, Plates; Processing: Extensive range of advanced machinery; Quality Assurance: ISO 9001 certified; Company Background: Family business with over a century in metal wholesale, trading as Salomon’s Metalen for 45 years.

Strategic Sourcing Conclusion and Outlook for mu metal suppliers

As the demand for high-performance magnetic shielding solutions continues to rise across various sectors, strategic sourcing of mu metal is vital for businesses aiming to enhance their product quality and operational efficiency. Key takeaways for international B2B buyers include the importance of partnering with suppliers who possess deep expertise in magnetic shielding applications and can offer tailored solutions to meet specific needs. Furthermore, leveraging suppliers with robust manufacturing capabilities, such as precision machining and heat treatment processes, can significantly improve the reliability of magnetic components.

In regions like Africa, South America, the Middle East, and Europe, the right sourcing strategy can open doors to innovative technologies and competitive pricing. By prioritizing suppliers who focus on collaboration and customer engagement, businesses can not only reduce their design cycles but also ensure they receive high-quality products that align with their project timelines.

Looking ahead, the landscape of mu metal supply is poised for growth, driven by advancements in technology and increased demand in industries such as aerospace, healthcare, and electronics. B2B buyers are encouraged to take proactive steps in identifying and forming strategic partnerships with reputable mu metal suppliers to stay ahead in this competitive market. Investing in strong supplier relationships today will pave the way for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to mu metal suppliers