Motorbike Helmet Skull: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for motorbike helmet skull

In the competitive landscape of motorbike helmet skull procurement, international B2B buyers face the challenge of sourcing helmets that not only meet safety standards but also resonate with diverse consumer preferences across regions such as Africa, South America, the Middle East, and Europe. With an increasing demand for stylish yet functional designs, understanding the various types of skull helmets available—including half-shell models, those with inner shields, and options featuring unique graphics—becomes crucial for making informed purchasing decisions.

This comprehensive guide serves as a vital resource for B2B buyers, outlining essential considerations such as helmet types, applications, and the nuances of supplier vetting. It also addresses cost implications, helping businesses navigate the complexities of international trade and ensure compliance with safety regulations. By providing insights into market trends and consumer behavior, this guide empowers buyers from regions like Brazil and Nigeria to identify reliable suppliers and select products that align with local market demands.

Whether you are looking to enhance your product portfolio or establish partnerships with reputable manufacturers, this guide equips you with the knowledge needed to make strategic purchasing decisions. Engage with the global market for motorbike helmet skulls confidently, knowing you have the tools to succeed in a dynamic and evolving industry.

Understanding motorbike helmet skull Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Half Shell Skull Cap | Lightweight, minimalistic design, DOT approved | Urban commuting, recreational riding | Pros: Stylish, comfortable, low-profile. Cons: Limited protection compared to full helmets. |

| Full Face Skull Cap | Complete coverage, integrated face shield | Long-distance touring, off-road biking | Pros: Maximum protection, wind and noise reduction. Cons: Heavier, can be less ventilated. |

| Carbon Fiber Skull Cap | High strength-to-weight ratio, modern aesthetic | Performance riding, racing | Pros: Lightweight, durable, advanced materials. Cons: Higher price point, may not suit all budgets. |

| Modular Skull Cap | Convertible design, allows for open-face or full-face | Versatile riding conditions | Pros: Flexibility, suitable for various environments. Cons: Complexity may lead to mechanical issues. |

| Graphic Skull Cap | Customizable designs, artistic expressions | Youth market, fashion-conscious riders | Pros: Unique styles, attracts younger demographics. Cons: Less focus on safety features in some models. |

What are the Key Characteristics of Half Shell Skull Caps?

Half shell skull caps are characterized by their lightweight and minimalistic design, which offers a stylish look while ensuring compliance with DOT safety standards. They are particularly suitable for urban commuting and recreational riding, appealing to riders who prioritize comfort and aesthetics over maximum protection. When purchasing, B2B buyers should consider factors such as material quality, size range, and pricing, as these helmets typically offer limited coverage compared to full-face options.

How Do Full Face Skull Caps Provide Enhanced Safety?

Full face skull caps provide complete head and face coverage, often featuring an integrated face shield to protect against wind, debris, and weather elements. They are ideal for long-distance touring and off-road biking, where maximum protection is crucial. B2B buyers should focus on the helmet’s ventilation system, weight, and comfort level, as these factors can significantly affect the riding experience. While they offer superior safety, they tend to be heavier and may compromise airflow compared to half-shell designs.

Why Choose Carbon Fiber Skull Caps for Performance Riding?

Carbon fiber skull caps are known for their high strength-to-weight ratio, making them a popular choice among performance riders and racers. These helmets not only provide advanced protection but also feature a modern aesthetic that appeals to a performance-oriented market. When considering B2B purchases, it is important to evaluate the cost-effectiveness of these helmets, as they typically come at a higher price point. Buyers should also assess the availability of different styles and sizes to meet diverse customer needs.

What Makes Modular Skull Caps Versatile for Different Riding Conditions?

Modular skull caps are designed with a convertible feature that allows riders to switch between an open-face and full-face configuration. This versatility makes them suitable for various riding conditions, from casual rides to more demanding terrains. B2B buyers should consider the helmet’s locking mechanism, weight distribution, and ease of use when selecting modular options. While they offer flexibility, the complexity of their design may lead to potential mechanical issues over time.

How Do Graphic Skull Caps Appeal to Younger Riders?

Graphic skull caps are distinguished by their customizable designs, allowing riders to express their individuality through unique artwork and styles. These helmets are particularly popular in the youth market and among fashion-conscious riders. B2B buyers should focus on the balance between aesthetics and safety features when sourcing these products, as some models may prioritize style over protective qualities. Understanding market trends and consumer preferences can help buyers effectively target this demographic.

Key Industrial Applications of motorbike helmet skull

| Industry/Sector | Specific Application of motorbike helmet skull | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Use in delivery services for riders | Enhances safety and compliance with regulations | Ensure helmets meet local safety standards and comfort levels |

| Recreational Vehicle Rentals | Helmets for motorcycle and scooter rentals | Increases customer safety and satisfaction | Consider variety in designs and sizes to cater to diverse clientele |

| Event Management | Helmets for motorcycle events and rallies | Promotes safety while enhancing brand visibility | Look for customizable options for branding and visibility |

| Security Services | Helmets for security personnel on motorbikes | Provides protection during patrols and enhances professional image | Focus on durability and comfort for long hours of use |

| Sports & Entertainment | Helmets for stunt performers and motorcycle shows | Ensures safety while showcasing talent | Prioritize lightweight designs that do not compromise safety |

How Are Motorbike Helmet Skulls Used in Transportation & Logistics?

In the transportation and logistics sector, motorbike helmet skulls are essential for delivery riders who often navigate urban environments. These helmets not only enhance the safety of riders but also ensure compliance with local regulations regarding personal protective equipment. For international B2B buyers, particularly in regions like Africa and South America, it is crucial to source helmets that meet both local safety standards and provide comfort for extended wear, thereby reducing the likelihood of accidents and improving operational efficiency.

What Role Do Motorbike Helmet Skulls Play in Recreational Vehicle Rentals?

In the recreational vehicle rental industry, motorbike helmet skulls are crucial for ensuring the safety of customers who rent motorcycles or scooters. Providing high-quality helmets enhances customer satisfaction and can be a differentiating factor in a competitive market. Buyers should consider sourcing helmets that come in various styles and sizes to cater to a diverse clientele, particularly in markets like Brazil and Nigeria, where riding culture is prevalent and safety is a growing concern.

Illustrative image related to motorbike helmet skull

How Are Motorbike Helmet Skulls Beneficial for Event Management?

Event management companies utilize motorbike helmet skulls during motorcycle events and rallies to ensure participant safety while simultaneously promoting their brand. Helmets can be customized with logos and graphics, enhancing visibility and brand recognition. When sourcing helmets for such applications, businesses should focus on options that allow for customization and meet safety standards to ensure both compliance and brand promotion at high-profile events.

Why Are Motorbike Helmet Skulls Important for Security Services?

Security personnel often rely on motorbike helmet skulls while patrolling areas on motorcycles. These helmets offer crucial protection and contribute to a professional appearance, which is essential for maintaining authority and trust in security operations. For B2B buyers in the Middle East and Europe, sourcing helmets that provide durability and comfort for long hours of use is vital, as it directly impacts the effectiveness of security personnel on duty.

How Do Motorbike Helmet Skulls Enhance Safety in Sports & Entertainment?

In the sports and entertainment industry, particularly for stunt performers and motorcycle shows, motorbike helmet skulls are indispensable for ensuring safety during performances. These helmets need to be lightweight yet robust enough to withstand potential impacts. Buyers should prioritize sourcing helmets that do not compromise on safety while allowing performers to showcase their skills effectively, especially in markets where entertainment events attract large audiences.

3 Common User Pain Points for ‘motorbike helmet skull’ & Their Solutions

Scenario 1: Sourcing Quality Helmets for Diverse Markets

The Problem: B2B buyers often struggle to find motorbike helmets that meet local safety standards while also appealing to diverse consumer preferences. In markets like Africa and South America, where riding culture varies significantly, helmets must not only comply with regional regulations but also resonate with local aesthetics. Buyers may face challenges in sourcing products that are both compliant and culturally relevant, leading to potential losses in sales and customer dissatisfaction.

The Solution: To effectively source motorbike helmets, establish relationships with reputable manufacturers who have a proven track record of compliance with international safety standards, such as DOT or ECE. Conduct thorough market research to understand local preferences, including popular colors, designs, and branding elements. Consider offering customization options to appeal to regional tastes. For instance, collaborating with local artists or designers can help create unique helmet graphics that resonate with the target audience. Utilize trade shows and industry expos in target regions to connect with manufacturers and gather insights on emerging trends.

Scenario 2: Managing Inventory and Supply Chain Challenges

The Problem: B2B buyers often face inventory management issues, particularly when dealing with seasonal demand fluctuations or unexpected supply chain disruptions. In regions where motorbike riding is seasonal, such as in parts of Europe, maintaining the right stock levels of motorbike helmet skulls can be challenging. Over-ordering can lead to excess inventory and increased holding costs, while under-ordering may result in missed sales opportunities.

The Solution: Implement a robust inventory management system that allows for real-time tracking of stock levels and sales trends. Use data analytics to forecast demand based on historical sales data, taking into account seasonal variations and local events that may drive demand. Establish flexible supply agreements with manufacturers that allow for quick adjustments in order quantities based on changing market conditions. Additionally, consider diversifying your supplier base to mitigate risks associated with supply chain disruptions. This approach not only ensures consistent product availability but also fosters competitive pricing.

Scenario 3: Ensuring Customer Satisfaction and Compliance

The Problem: Customer satisfaction can be severely impacted if the motorbike helmets do not meet safety standards or are uncomfortable to wear. Buyers must ensure that the helmets they source are not only compliant with safety regulations but also comfortable for long-term use. Inconsistent quality can lead to negative reviews, returns, and loss of repeat business, which is especially critical in markets where brand loyalty is vital.

The Solution: Prioritize quality control by implementing strict testing protocols for the helmets you source. Require manufacturers to provide certification that their products meet relevant safety standards, such as the DOT or ECE certifications. Conduct wear tests to evaluate the comfort and fit of helmets, possibly involving focus groups from your target demographic to gather feedback on design and functionality. Additionally, offer a satisfaction guarantee or warranty on the helmets to reassure customers about their purchase. Providing educational content on the importance of helmet safety and proper usage can also enhance customer trust and satisfaction, leading to higher retention rates.

Strategic Material Selection Guide for motorbike helmet skull

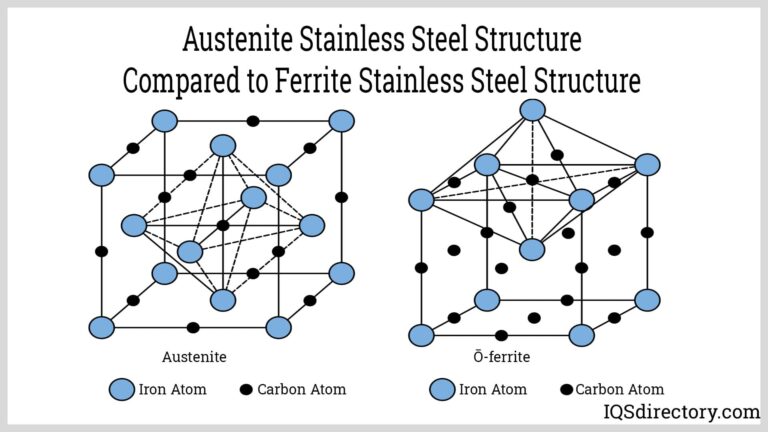

What Are the Key Materials Used in Motorbike Helmet Skulls?

When selecting materials for motorbike helmet skulls, manufacturers often consider various factors such as safety, performance, cost, and compliance with international standards. Here, we analyze four common materials used in the production of motorbike helmet skulls, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polycarbonate Perform as a Material for Helmet Skulls?

Polycarbonate is a popular choice for helmet shells due to its excellent impact resistance and lightweight nature. It typically has a temperature tolerance of -40°C to 120°C, making it suitable for diverse climates. Polycarbonate helmets are often designed to meet safety standards such as DOT and ECE.

Illustrative image related to motorbike helmet skull

Pros: The primary advantage of polycarbonate is its high impact resistance, which enhances rider safety. Additionally, it is relatively low-cost, making it an attractive option for manufacturers targeting budget-conscious markets.

Cons: However, polycarbonate can be prone to scratching and may not offer the same level of rigidity as other materials like fiberglass or carbon fiber. This may affect long-term durability.

Impact on Application: Polycarbonate helmets are well-suited for everyday use and are compatible with various environmental conditions, making them ideal for regions with varying climates, such as Africa and South America.

What Are the Benefits of Using Fiberglass in Motorbike Helmets?

Fiberglass is another widely used material for helmet shells, known for its strength and durability. It can withstand high temperatures and has good resistance to corrosion, making it suitable for long-term use in various environments.

Pros: The key advantage of fiberglass is its excellent structural integrity, providing superior protection in the event of an impact. It also allows for a more aesthetically pleasing finish, which can be important for brand differentiation.

Cons: On the downside, fiberglass helmets tend to be heavier than those made from polycarbonate, which may lead to discomfort during long rides. Additionally, the manufacturing process can be more complex and costly.

Impact on Application: Fiberglass helmets are suitable for high-performance applications and are often preferred in markets where premium products are in demand, such as Europe and parts of the Middle East.

How Does Carbon Fiber Compare as a Material for Helmet Skulls?

Carbon fiber is increasingly becoming a favored material for high-end motorbike helmets due to its exceptional strength-to-weight ratio. It can withstand extreme temperatures and is highly resistant to impact and abrasion.

Pros: The primary advantage of carbon fiber is its lightweight nature, which enhances comfort during extended use. It also offers superior protection, making it ideal for professional riders and enthusiasts.

Illustrative image related to motorbike helmet skull

Cons: However, carbon fiber helmets are typically more expensive to manufacture, which can limit their accessibility in price-sensitive markets. The production process is also complex, requiring specialized techniques.

Impact on Application: Carbon fiber helmets are particularly appealing in regions with a growing motorcycle culture, such as Brazil and Nigeria, where premium products are increasingly sought after.

What Role Does EPS Foam Play in Helmet Safety?

Expanded Polystyrene (EPS) foam is commonly used as an inner lining in helmet designs. While not a shell material, its properties are crucial for impact absorption and overall safety.

Pros: EPS foam is lightweight, cost-effective, and highly effective at absorbing shock during an impact, significantly enhancing rider safety.

Cons: The main limitation of EPS is its susceptibility to degradation over time, particularly when exposed to UV light or extreme temperatures. This necessitates regular replacement.

Impact on Application: EPS foam helmets are widely accepted across various markets due to their affordability and safety features, making them suitable for entry-level products in Africa and South America.

Summary Table of Material Properties

| Material | Typical Use Case for motorbike helmet skull | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Everyday use helmets | High impact resistance | Prone to scratching | Low |

| Fiberglass | Premium helmets for performance riders | Superior structural integrity | Heavier and more complex to manufacture | Medium |

| Carbon Fiber | High-end racing and premium helmets | Lightweight with excellent protection | Higher manufacturing cost | High |

| EPS Foam | Inner lining for all helmet types | Effective shock absorption | Degrades over time | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in motorbike helmet skulls, facilitating informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for motorbike helmet skull

What Are the Key Stages in the Manufacturing Process of Motorbike Helmet Skulls?

The manufacturing of motorbike helmet skulls involves several critical stages, each designed to ensure the final product meets stringent safety and quality standards. The primary stages of production are material preparation, forming, assembly, and finishing.

How Is Material Prepared for Motorbike Helmets?

The process begins with material selection, which is crucial for ensuring both safety and comfort. Common materials used include polycarbonate, fiberglass, and carbon fiber. Each material offers different benefits, such as weight reduction or enhanced impact resistance. After selecting the appropriate materials, they undergo preparation processes like cutting and shaping into manageable pieces. This step is essential as it sets the foundation for the subsequent forming process.

What Techniques Are Employed in Forming the Helmet Shell?

Forming is the next step, where the prepared materials are molded into the desired shape of the helmet. Techniques such as injection molding and vacuum forming are widely used. Injection molding allows for the creation of complex shapes while maintaining material integrity, which is crucial for safety. Vacuum forming, on the other hand, is ideal for producing lighter helmets with a sleek finish. During this stage, attention to detail is paramount, as any defects can compromise safety.

How Are Helmet Components Assembled?

Once the helmet shell is formed, it proceeds to the assembly stage. This involves integrating various components such as the inner foam lining, straps, and visors. The inner foam is typically made from expanded polystyrene (EPS), which absorbs impact energy. The assembly process is often automated to ensure precision and consistency, although some parts may still require manual assembly for quality assurance. Each component is carefully inspected before final assembly to mitigate any potential issues.

What Finishing Touches Are Applied to Motorbike Helmets?

The final stage, finishing, involves applying coatings, graphics, and any additional features such as ventilation systems. This not only enhances the helmet’s aesthetic appeal but also adds protective layers against environmental factors. Paints and coatings used in this stage must be durable and resistant to fading, especially for helmets sold in tropical climates common in regions like Africa and South America.

What Quality Assurance Processes Are Essential for Motorbike Helmets?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that each helmet meets international safety standards. Manufacturers often adhere to ISO 9001, which provides a framework for maintaining quality in production processes. Additionally, specific industry standards such as DOT (Department of Transportation) in the U.S. and ECE (Economic Commission for Europe) in Europe dictate safety requirements for helmets.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding the international standards applicable to motorbike helmets is crucial. Compliance with standards such as CE marking in Europe and DOT certification in the U.S. signifies that the helmets have passed rigorous safety tests. Buyers from regions such as Africa and South America should also be aware of local regulations that may influence helmet certification and safety requirements.

How Are Quality Control Checkpoints Structured?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure compliance with safety standards. These include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): This occurs during the manufacturing stages, where ongoing inspections are conducted to identify defects early in the process.

- Final Quality Control (FQC): At this stage, the completed helmets are rigorously tested for safety, fit, and durability before they are packaged for distribution.

What Testing Methods Are Commonly Used for Helmet Quality Assurance?

Testing methods for motorbike helmets can include impact tests, penetration tests, and retention tests. Each method assesses different aspects of helmet performance. For instance, impact tests measure how well the helmet absorbs shock, while retention tests ensure that the straps hold the helmet securely during an accident. These tests are crucial for verifying compliance with safety standards and can vary based on regional regulations.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, verifying a supplier’s quality control measures is essential to ensure the safety and reliability of the helmets. Here are some strategies:

Illustrative image related to motorbike helmet skull

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and QC practices. Buyers should request access to audit reports and certifications.

- Review Quality Control Reports: Suppliers should provide detailed QC reports that outline the testing methods used and the results achieved. These reports can help buyers assess the reliability of the products.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s compliance with international standards. This is particularly useful for buyers unfamiliar with local manufacturing practices.

What Are the Nuances of Quality Control for International Buyers?

International buyers must navigate various nuances in quality control when sourcing motorbike helmets. Different regions may have distinct safety standards, which can affect the certification process. For instance, helmets that meet U.S. DOT standards may not necessarily comply with European ECE regulations. Buyers should ensure that their suppliers are knowledgeable about these differences and can provide helmets certified for their specific markets.

Additionally, factors such as local climate and cultural preferences can influence helmet design and materials. Buyers from regions like Africa and South America may prioritize lightweight materials and ventilation features due to warmer climates, while European buyers might focus more on aesthetic details and compliance with stringent safety regulations.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing motorbike helmets, ensuring they meet safety standards while catering to market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorbike helmet skull’

Introduction

This practical sourcing guide provides a comprehensive checklist for B2B buyers seeking to procure motorbike helmet skulls. As the demand for stylish yet safe motorcycle helmets increases, it’s essential to approach the procurement process methodically. This checklist will help you navigate the complexities of sourcing, ensuring you select the right products and suppliers to meet your business needs.

1. Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the motorbike helmet skulls. This includes determining the type of helmets (e.g., half-shell, full-face) and safety standards (e.g., DOT, ECE) they must meet.

– Consider factors such as:

– Materials (e.g., carbon fiber, polycarbonate)

– Weight and comfort

– Design features (e.g., graphics, inner shields)

2. Step 2: Research Market Trends and Demands

Understanding current market trends is crucial for making informed purchasing decisions. Analyze consumer preferences in your target regions, such as Africa, South America, the Middle East, and Europe.

– Focus on:

– Popular styles and designs

– Price ranges and average market costs

– Seasonal demands or promotional opportunities

3. Step 3: Identify and Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they align with your business requirements. Look for manufacturers with a proven track record in producing high-quality motorbike helmets.

– Key evaluation criteria include:

– Company history and reputation

– Certifications and compliance with safety standards (e.g., DOT, ECE)

– Customer reviews and case studies from similar markets

Illustrative image related to motorbike helmet skull

4. Step 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of their motorbike helmet skulls. Testing samples allows you to assess quality, fit, and comfort firsthand.

– Assess the following:

– Durability and material quality

– Comfort during wear

– Compliance with the specified safety standards

5. Step 5: Negotiate Pricing and Terms

After evaluating suppliers and samples, engage in negotiations to secure the best pricing and terms. Consider factors such as order volume, payment terms, and delivery timelines.

– Ensure clarity on:

– Discounts for bulk orders

– Return policies for defective items

– Shipping and handling costs

6. Step 6: Finalize Contracts and Agreements

Once negotiations are complete, draft and finalize contracts with your chosen supplier. Ensure that all terms are clearly articulated to avoid misunderstandings in the future.

– Include essential elements such as:

– Payment schedules

– Delivery timelines

– Warranty and support agreements

7. Step 7: Monitor Supplier Performance

After procurement, continuously monitor the performance of your suppliers. Regular assessments will help ensure compliance with quality and delivery expectations.

– Track metrics like:

– Timeliness of shipments

– Quality of products received

– Responsiveness to queries and issues

By following this checklist, B2B buyers can make informed decisions when sourcing motorbike helmet skulls, ensuring they meet both safety standards and market demands.

Comprehensive Cost and Pricing Analysis for motorbike helmet skull Sourcing

What Are the Key Cost Components in Sourcing Motorbike Helmet Skulls?

When sourcing motorbike helmet skulls, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: High-quality materials are essential for ensuring safety and compliance with standards such as DOT or ECE. Common materials used include fiberglass, carbon fiber, and thermoplastic. The choice of materials significantly impacts both cost and performance.

-

Labor: Labor costs can vary based on the region of production and the complexity of the helmet design. Skilled labor is often required for quality assurance and assembly, particularly for custom designs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. The investment in molds and production tools should be factored into the overall pricing structure.

-

Quality Control (QC): Ensuring helmets meet safety standards requires robust QC processes. This involves testing and inspection, which adds to the overall cost but is essential for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary significantly depending on the origin and destination of the helmets. International shipments may incur additional tariffs and customs fees, which should be considered in the total cost.

-

Margin: Suppliers will typically add a profit margin on top of their costs. Understanding the expected margins in different regions can help buyers gauge the fairness of pricing.

How Do Price Influencers Affect the Cost of Motorbike Helmet Skulls?

Several factors influence pricing, making it essential for buyers to consider:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Larger orders often lead to discounts, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Custom designs or specific safety certifications can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Helmets that meet higher safety standards or use premium materials typically come at a higher price. Certifications like DOT or ECE can also influence costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for accurate cost estimation.

What Tips Can Help Buyers Negotiate Better Prices for Motorbike Helmet Skulls?

To achieve cost efficiency and favorable pricing, B2B buyers can employ several strategies:

-

Negotiate Effectively: Establish clear communication with suppliers and be prepared to negotiate terms. Leverage volume discounts and long-term partnerships to secure better pricing.

-

Consider Total Cost of Ownership (TCO): Assess not just the initial purchase price but also long-term costs, including maintenance, warranty, and potential replacements. A lower upfront cost may lead to higher TCO if the quality is compromised.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of regional market dynamics and currency fluctuations. These factors can influence pricing and should be factored into negotiations.

-

Stay Informed on Market Trends: Regularly review market trends and competitor pricing to ensure you are receiving a competitive rate.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better terms and priority during production or shipping delays. Trust is a significant factor in international B2B transactions.

Conclusion: A Disclaimer on Indicative Prices

While indicative pricing can provide a benchmark, it is essential to conduct thorough research and engage with multiple suppliers to obtain accurate quotes tailored to specific needs. The costs associated with motorbike helmet skulls can vary widely based on numerous factors, and understanding these intricacies will enable buyers to make informed decisions.

Alternatives Analysis: Comparing motorbike helmet skull With Other Solutions

Understanding Alternatives for Motorbike Helmet Skull Solutions

In the realm of motorcycle safety, the motorbike helmet skull serves as a popular choice among riders seeking a blend of style and protection. However, exploring alternative solutions can help buyers make informed decisions that align with their specific needs and preferences. This analysis compares the motorbike helmet skull with two other viable alternatives: full-face helmets and open-face helmets. Each option presents unique advantages and challenges that can significantly impact a rider’s experience.

| Comparison Aspect | Motorbike Helmet Skull | Full-Face Helmet | Open-Face Helmet |

|---|---|---|---|

| Performance | DOT-approved, good impact protection; lower coverage | Superior protection, covers entire head and face | Moderate protection; good airflow but less coverage |

| Cost | Typically ranges from $50 to $100 | Usually priced between $150 to $600 | Generally ranges from $70 to $200 |

| Ease of Implementation | Easy to wear and remove; lightweight | Slightly bulkier; may take longer to adjust | Simple to wear; quick to remove |

| Maintenance | Low maintenance; easy to clean | Requires regular cleaning; more parts to maintain | Moderate maintenance; easier to clean than full-face |

| Best Use Case | Ideal for short rides, cruising, and urban commuting | Best for long-distance riding and high-speed travel | Suitable for leisurely rides and warm weather |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of Full-Face Helmets?

Full-face helmets provide comprehensive protection for the head and face, making them the safest option for motorcyclists. They are designed to absorb impact across the entire helmet, minimizing injury during accidents. However, they tend to be bulkier and can be less comfortable in hot weather due to reduced airflow. Their cost is also significantly higher, which may deter budget-conscious buyers. For B2B buyers in regions with stringent safety regulations, the full-face helmet could be an essential offering in their product line.

How Do Open-Face Helmets Compare to Motorbike Helmet Skulls?

Open-face helmets offer a good balance between protection and comfort, featuring a design that allows for greater airflow and visibility. They are lightweight and easy to wear, making them ideal for casual riders and urban commuting. However, they provide less protection than both motorbike helmet skulls and full-face helmets, especially in terms of facial injuries. The pricing of open-face helmets makes them accessible, but buyers must consider the trade-off between comfort and safety.

Making an Informed Decision: How to Choose the Right Helmet Solution?

When selecting the appropriate helmet solution, B2B buyers should consider the target market’s specific needs, riding conditions, and safety regulations. For businesses catering to casual riders or urban commuters, motorbike helmet skulls may present a compelling choice due to their stylish design and lightweight nature. Conversely, businesses focused on long-distance or high-speed riders might find full-face helmets to be a necessary investment. Open-face helmets can serve as a versatile option for those seeking comfort without sacrificing too much safety. Ultimately, aligning product offerings with customer preferences and safety standards will enhance market competitiveness and consumer satisfaction.

Illustrative image related to motorbike helmet skull

Essential Technical Properties and Trade Terminology for motorbike helmet skull

What Are the Essential Technical Properties of Motorbike Helmet Skulls?

Motorbike helmet skulls, often referred to as skull caps, are crucial for ensuring rider safety while maintaining comfort and style. Understanding the technical properties of these helmets is vital for B2B buyers seeking reliable products. Here are some critical specifications:

-

Material Grade

The material used in helmet construction significantly impacts both weight and safety. Common materials include polycarbonate, fiberglass, and carbon fiber. Polycarbonate helmets are lightweight and durable, making them popular for everyday use. In contrast, carbon fiber helmets offer superior strength and are favored in high-performance scenarios. For B2B buyers, knowing the material grade helps in assessing product quality and suitability for specific markets. -

Safety Certifications

Helmets must meet specific safety standards to ensure rider protection. The most recognized certifications include DOT (Department of Transportation), ECE (Economic Commission for Europe), and Snell. These certifications indicate that the helmet has undergone rigorous testing to withstand impacts and protect the rider’s head. For B2B transactions, ensuring that products are certified can prevent liability issues and enhance brand reputation. -

Shell Size and Fit

The size and fit of the helmet are crucial for comfort and effectiveness. Helmets are available in various shell sizes to accommodate different head shapes. A proper fit ensures that the helmet stays securely in place during rides, reducing the risk of injury. B2B buyers should consider the sizing options available to cater to diverse customer preferences in different regions. -

Weight Tolerance

The weight of a helmet can affect rider comfort, especially during long rides. Lighter helmets reduce fatigue but must still meet safety standards. Manufacturers often provide weight specifications that can help buyers gauge the helmet’s suitability for various riding conditions. Understanding weight tolerance is essential for B2B buyers looking to provide optimal products to their customers. -

Ventilation System

A well-designed ventilation system enhances comfort by allowing airflow, reducing heat buildup inside the helmet. Features may include adjustable vents and internal airflow channels. For B2B buyers, understanding the ventilation properties can aid in selecting helmets that cater to different climates and riding styles.

What Are Common Trade Terminologies Associated with Motorbike Helmets?

Familiarity with industry jargon can streamline communication and enhance purchasing efficiency. Here are key terms relevant to motorbike helmet skulls:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the helmet industry, understanding OEM relationships helps buyers identify quality sources and potential partnerships for custom branding or private labeling. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers, as it affects inventory management and cost efficiency. Negotiating favorable MOQs can lead to better pricing and stock levels. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers. Buyers submit RFQs to gauge pricing and terms from multiple vendors before making purchasing decisions. Understanding how to formulate an RFQ can lead to more competitive pricing and better supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers, familiarity with Incoterms is crucial for understanding shipping costs and risks associated with international purchases. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the products. This period can significantly impact inventory planning and customer satisfaction. Buyers should discuss lead times with suppliers to ensure timely deliveries aligned with market demand. -

Customs Compliance

This term refers to the adherence to laws and regulations governing the import and export of goods. For B2B buyers, understanding customs compliance is vital to avoid delays and penalties during international shipments, ensuring a smooth supply chain process.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, optimize procurement processes, and strengthen their market positioning in the motorbike helmet industry.

Navigating Market Dynamics and Sourcing Trends in the motorbike helmet skull Sector

What Are the Current Market Dynamics and Key Trends in the Motorbike Helmet Skull Sector?

The global market for motorbike helmets, particularly skull caps, is witnessing significant growth, driven by increasing awareness of safety and regulations mandating the use of protective gear. In regions like Africa, South America, the Middle East, and Europe, the burgeoning motorcycle culture is amplifying demand for helmets that combine safety, comfort, and style. Key trends include the rising popularity of lightweight materials, such as carbon fiber, which enhance comfort without compromising safety. Furthermore, customizable designs and graphics are appealing to younger riders who seek personalization in their gear.

Illustrative image related to motorbike helmet skull

Emerging technologies such as 3D printing and advanced manufacturing processes are reshaping sourcing strategies. These technologies allow for rapid prototyping and a more agile production process, enabling manufacturers to respond swiftly to market demands. For international B2B buyers, particularly in emerging markets like Brazil and Nigeria, understanding local preferences and regulatory requirements is crucial. Additionally, leveraging digital platforms for sourcing can streamline procurement processes, allowing for better price comparisons and supplier evaluations.

How Can Sustainability and Ethical Sourcing Impact the Motorbike Helmet Skull Sector?

Sustainability is becoming a core consideration in the motorbike helmet skull sector, driven by both consumer demand and regulatory pressures. Buyers are increasingly aware of the environmental impact of their purchases, prompting manufacturers to adopt sustainable practices. This includes using eco-friendly materials, such as recycled plastics and bio-based composites, which not only reduce environmental footprints but also appeal to environmentally conscious consumers.

Ethical sourcing is equally important, as buyers seek suppliers that adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a brand’s reputation and marketability. For B2B buyers, partnering with manufacturers that prioritize sustainability and ethical practices can lead to enhanced brand loyalty and customer trust, particularly in regions where consumers are increasingly valuing corporate responsibility.

What Is the Brief Evolution and History of the Motorbike Helmet Skull Sector?

The motorbike helmet skull sector has evolved significantly since the early days of motorcycle safety gear. Initially, helmets were bulky and offered limited protection, primarily focusing on basic head coverage. Over the decades, advancements in materials science led to the development of lighter, more durable helmets that provide superior protection. The introduction of regulatory standards, such as the DOT (Department of Transportation) certification in the U.S., has further shaped the market, ensuring that helmets meet rigorous safety criteria.

Illustrative image related to motorbike helmet skull

In recent years, the trend has shifted towards stylish designs and personalization, reflecting changing consumer preferences. Modern skull caps now blend safety with aesthetics, catering to a diverse range of riders. This evolution highlights the importance of innovation in the sector, making it essential for B2B buyers to stay informed about new developments and emerging trends in helmet design and manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of motorbike helmet skull

-

How do I ensure the quality of motorbike helmet skulls from suppliers?

To ensure quality, start by vetting suppliers through their certifications, such as DOT or ECE approvals, which signify compliance with safety standards. Request samples to evaluate material durability and comfort. Additionally, inquire about their quality assurance processes, including inspections during production and before shipping. Consider conducting factory visits or audits if feasible, or use third-party inspection services to validate their claims. -

What is the best material for motorbike helmet skulls?

The best materials for motorbike helmet skulls typically include polycarbonate, fiberglass, and carbon fiber. Polycarbonate is lightweight and affordable, making it popular for budget-conscious buyers. Fiberglass offers a good balance of weight and strength, while carbon fiber provides the highest level of protection with minimal weight. The choice ultimately depends on your target market’s preferences for safety, aesthetics, and price. -

What customization options should I look for in motorbike helmet skulls?

When sourcing motorbike helmet skulls, inquire about customization options such as color, graphics, and branding. Many manufacturers offer services to print logos or unique designs, enhancing brand visibility. Additionally, consider options for sizing and fit to accommodate various head shapes. Ensure that any customizations still comply with safety regulations to maintain the helmets’ protective capabilities. -

What are typical minimum order quantities (MOQs) for motorbike helmet skulls?

Minimum order quantities for motorbike helmet skulls can vary significantly based on the supplier and the complexity of the order. Generally, MOQs range from 50 to several hundred units. It’s essential to discuss your needs with potential suppliers, as some may offer flexibility or lower MOQs for established buyers or first-time orders. Understanding MOQs helps in planning inventory and managing cash flow. -

What payment terms are standard for international B2B purchases of motorbike helmet skulls?

Standard payment terms for international B2B transactions often include a deposit of 30-50% upfront, with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or payment through escrow services for added security. It’s crucial to clarify payment terms upfront to avoid misunderstandings, and consider negotiating terms that align with your cash flow and risk tolerance. -

How can I manage logistics for importing motorbike helmet skulls?

Effective logistics management involves selecting reliable shipping partners and understanding international trade regulations. Determine the best shipping method—air freight for speed or sea freight for cost-effectiveness. Ensure all paperwork, including customs documentation, is accurate to avoid delays. It’s also wise to factor in insurance for your shipments to mitigate risks associated with loss or damage during transit. -

What safety standards should motorbike helmet skulls meet?

Motorbike helmet skulls should meet recognized safety standards such as DOT (Department of Transportation), ECE (Economic Commission for Europe), or Snell certifications. These standards ensure that helmets have undergone rigorous testing for impact resistance, retention, and penetration. When sourcing helmets, always verify the certification claims and request documentation from suppliers to ensure compliance with the safety regulations in your target markets. -

How do I handle returns or defects in motorbike helmet skulls?

Establish a clear returns policy with your suppliers before placing orders. This policy should outline procedures for handling defective products, including timelines for reporting issues and the process for returns or exchanges. Understand the warranty period offered by the supplier and any associated costs for returns. It’s beneficial to have a system in place for managing defective items to maintain customer satisfaction and protect your business reputation.

Top 6 Motorbike Helmet Skull Manufacturers & Suppliers List

1. Daytona – Skull Cap Half Shell Motorcycle Helmet

Domain: daytonahelmets.com

Registered: 1998 (27 years)

Introduction: This company, Daytona – Skull Cap Half Shell Motorcycle Helmet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Pinterest – Skull Motorcycle Helmets

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Skull Motorcycle Helmet, Custom Skull Helmet Design, Punisher Motorcycle Helmet, Ghost Rider Motorcycle Helmet, Sci Fi Skull Half Shell Motorcycle Helmets, Airbrush Motorcycle Helmet, Black Skull Motorcycle Helmet, Monster Motorcycle Helmet, Skull Racing Helmet, Futuristic Skull Mask, Skull-themed Welding Helmet, Modular Motorcycle Helmets, Custom Motorcycle Helmets, Unique Helmet Designs for Bike…

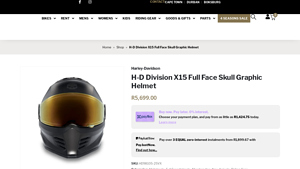

3. Harley-Davidson – H-D Division X15 Full Face Skull Graphic Helmet

Domain: leatherandchrome.com

Registered: 2020 (5 years)

Introduction: H-D Division X15 Full Face Skull Graphic Helmet

– Price: R 5,699.00

– SKU: HD98105-25VX

– Weight: 2 lbs. 15 ¾ oz. (1,350 grams)

– Dimensions: 40 × 40 × 40 cm

– Gender: Unisex

– Color: Black & Black Olive

– Brand: Harley-Davidson

– Size Options: 2XL, 3XL, L, M, S, XL, XS

– Construction: Pre-pregnated fiberglass shell, stainless double D-ring chin strap

– Features: Adjustable vents, removable and wa…

4. American Legend Rider – Skull Helmets

Domain: americanlegendrider.com

Registered: 2017 (8 years)

Introduction: Skull helmets are stylish yet authoritative helmets, popular amongst bikers for the respect and strength they command. They are the one kind of helmet that really comes to mind when you think about cool helmets, and they are somewhat of an acquired taste. Since they look like actual skulls, they are a tad bit reminiscent of the flaming demon-like fictional entity.

5. Harley-Davidson – H-D Division X15 Full Face Skull Graphic Helmet

Domain: harley-davidson.com

Registered: 1994 (31 years)

Introduction: {“name”: “H-D Division X15 Full Face Skull Graphic Helmet”, “price”: “$285.00”, “part_number”: “98105-25VX”, “average_weight”: “2 lbs. 15 ¾ oz. or 1,350 grams”, “helmet_construction”: “Pre-pregnated fiberglass shell”, “chin_strap”: “Stainless double D-ring chin strap”, “features”: {“stay_cool”: “Adjustable vents at chin, top of helmet, and spoiler on the back of the helmet”, “interior_linings”: “R…

6. Skull Helmets – Various Sizes & Types

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Skull Helmets available in various sizes (XS, S, M, L, XL, XXL, 3XL, 4XL) and types (Full Face, Half Helmet, Open Face, Modular, Off-Road, Dual Sport, Vintage, Convertible). Popular brands include Harley-Davidson, SHOEI, Bell, HJC, LS2, Arai, AGV, Icon, Scorpion, Fly Racing, Shark, Fox Racing, Nolan, Daytona Helmets, VIRTUE, GMAX, and TORC. Price range varies from under $115 to over $190. Shipping…

Strategic Sourcing Conclusion and Outlook for motorbike helmet skull

As the demand for motorbike helmet skulls continues to rise globally, strategic sourcing becomes paramount for B2B buyers seeking to capitalize on this opportunity. Understanding the diverse market preferences and regulatory requirements across regions—particularly in Africa, South America, the Middle East, and Europe—will enable buyers to tailor their offerings effectively. Key takeaways include the importance of sourcing helmets that meet international safety standards, such as DOT certifications, while also considering aesthetic preferences and price competitiveness.

Investing in quality suppliers who offer a range of styles—from plain designs to graphics and advanced materials—ensures that your product line remains appealing and compliant. Additionally, leveraging insights into regional consumer behavior can help in making informed purchasing decisions that enhance your competitive edge.

Illustrative image related to motorbike helmet skull

Looking ahead, the motorbike helmet skull market is poised for growth, driven by increased motorcycle usage and a heightened focus on safety. Now is the time for international B2B buyers to engage with reliable manufacturers and distributors. Take action today to secure your position in this dynamic market, ensuring that your offerings not only meet the current demand but also set the stage for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.