Model Of Bench Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for model of bench

In today’s competitive landscape, sourcing the right model of bench can pose significant challenges for international B2B buyers. Whether you’re looking for durable outdoor benches for public spaces or stylish indoor seating solutions, understanding the nuances of the global market is essential. This guide addresses the complexities of sourcing benches by providing a comprehensive overview of various types, applications, and materials available. It also emphasizes the importance of supplier vetting, allowing you to make informed decisions that align with your quality standards and budget constraints.

As businesses expand their reach into markets across Africa, South America, the Middle East, and Europe, the demand for versatile and aesthetically pleasing bench models continues to rise. Buyers from countries like Brazil and Vietnam are increasingly seeking suppliers who can offer not only quality products but also innovative designs that reflect local tastes and preferences. This guide empowers you to navigate the global market effectively, presenting actionable insights on cost considerations, supplier reliability, and product customization options.

By the end of this guide, you will be equipped with the knowledge to streamline your purchasing process, ensuring that you select the best bench models that meet your operational needs and enhance your overall business offerings. The journey toward finding the ideal bench model begins here, setting the stage for successful procurement in an ever-evolving marketplace.

Understanding model of bench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Outdoor Park Bench | Durable materials, weather-resistant, often made of wood or metal | Parks, public spaces, outdoor restaurants | Pros: Aesthetic appeal, community engagement. Cons: Requires maintenance to prevent weathering. |

| Gym Bench | Adjustable features, heavy-duty construction, designed for fitness use | Gyms, fitness centers, personal training studios | Pros: Versatile for various exercises. Cons: Higher upfront cost, may require specific space planning. |

| Garden Bench | Decorative design, typically made from wood or metal, often includes cushions | Residential gardens, public parks, commercial landscapes | Pros: Enhances aesthetics, encourages relaxation. Cons: Limited durability in harsh weather without proper care. |

| Technogym Bench | Multi-functional, often includes integrated storage, designed for professional use | High-end gyms, rehabilitation centers | Pros: Space-efficient, tailored for diverse workouts. Cons: Premium price point may limit accessibility. |

| Vintage Street Bench | Classic design, often made of cast iron or reclaimed wood | Urban settings, historical sites, outdoor cafes | Pros: Adds character and charm. Cons: May require restoration or upkeep, not suitable for all modern environments. |

What Are the Characteristics of Outdoor Park Benches?

Outdoor park benches are primarily designed for durability and comfort in public spaces. Made from weather-resistant materials like treated wood or metal, they are built to withstand various environmental conditions. These benches encourage social interaction and provide resting spots for visitors. When considering a purchase, B2B buyers should evaluate factors like design, maintenance requirements, and the expected foot traffic in the intended area.

How Do Gym Benches Differ in Functionality?

Gym benches are specialized equipment designed for fitness applications. Their adjustable features cater to a variety of exercises, making them essential for gyms and personal training studios. The construction is robust, ensuring stability during workouts. Buyers should consider the space available for installation, as well as the specific functionalities required for their clientele, such as whether they need benches that support multiple exercise types.

What Makes Garden Benches Suitable for Landscaping?

Garden benches serve both functional and aesthetic purposes in landscaping. Typically crafted from wood or metal, they enhance the visual appeal of gardens while providing a place for relaxation. Their design can vary from simple to elaborate, often including cushions for added comfort. Buyers in this sector should focus on the materials used, ensuring they align with the intended environment, and consider maintenance needs to preserve their appearance over time.

Why Choose Technogym Benches for Professional Use?

Technogym benches are engineered for high-performance use in professional settings, such as gyms and rehabilitation centers. They often feature multi-functional capabilities and integrated storage solutions, maximizing space efficiency. This type of bench is ideal for facilities that require versatile workout options. When purchasing, B2B buyers should assess the cost versus the potential return on investment, especially in high-traffic environments.

What Are the Advantages of Vintage Street Benches?

Vintage street benches offer a nostalgic charm that enhances urban landscapes and historical sites. Often made from cast iron or reclaimed wood, these benches add character to outdoor cafes and community areas. However, they may require restoration and regular maintenance to preserve their appeal. Buyers should consider the aesthetic fit within their environment and the potential upkeep costs associated with maintaining vintage pieces.

Key Industrial Applications of model of bench

| Industry/Sector | Specific Application of model of bench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Urban Development | Public Parks and Recreation Areas | Enhances community spaces, attracting visitors and promoting social interaction. | Durability, weather resistance, and design aesthetics to fit local culture. |

| Education | School and University Campuses | Provides students with comfortable outdoor seating for study and socializing, improving campus life. | Safety standards, ergonomic design, and maintenance requirements. |

| Hospitality | Hotels and Resorts | Offers guests a comfortable space to relax, enhancing their overall experience and satisfaction. | Style compatibility with existing decor, ease of cleaning, and durability. |

| Retail | Shopping Malls and Outdoor Retail Spaces | Encourages foot traffic and provides resting spots, increasing dwell time and customer engagement. | Customization options, durability under high foot traffic, and aesthetic appeal. |

| Fitness and Recreation | Gyms and Outdoor Fitness Areas | Supports various workout routines, enhancing the functionality of fitness spaces. | Material quality, safety features, and adaptability for different exercises. |

How is the ‘model of bench’ utilized in Urban Development?

In urban development, the model of bench plays a critical role in enhancing public parks and recreational areas. These benches provide essential seating that encourages community interaction and engagement, making parks more inviting. For international buyers, particularly in regions like Africa and South America, sourcing benches that withstand diverse weather conditions and cultural aesthetics is vital. Durability and design must align with local preferences to ensure longevity and community acceptance.

What are the benefits of benches in Educational Institutions?

In educational settings, such as schools and universities, benches serve as essential furniture for outdoor spaces, allowing students to gather, study, and socialize. This contributes significantly to campus life and student satisfaction. Buyers from the Middle East and Europe should prioritize safety features and ergonomic designs when sourcing these benches, ensuring they meet local educational standards and provide comfort for prolonged use.

Why are benches important in the Hospitality Sector?

For hotels and resorts, the model of bench enhances guest experience by providing comfortable outdoor seating areas. These spaces allow guests to relax and enjoy the surroundings, thereby improving overall satisfaction and encouraging longer stays. When sourcing benches, hospitality businesses must consider style compatibility with existing decor and ease of maintenance, particularly in high-traffic areas where durability is crucial.

How do benches impact Retail Environments?

In retail environments, such as shopping malls and outdoor retail spaces, benches are strategically placed to encourage foot traffic and provide resting spots for shoppers. This increases customer dwell time and enhances the shopping experience. For B2B buyers in regions like Brazil and Vietnam, customization options are essential, as benches must reflect the brand’s identity while being robust enough to handle high foot traffic.

What role do benches play in Fitness and Recreation?

In gyms and outdoor fitness areas, benches support a variety of workout routines, making them integral to the functionality of these spaces. They must be constructed from high-quality materials that ensure safety during use. Buyers should focus on sourcing benches that are adaptable for different exercises and meet international safety standards, especially in regions with varying fitness trends and practices.

3 Common User Pain Points for ‘model of bench’ & Their Solutions

Scenario 1: Sourcing Quality Bench Models for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality 3D models of benches that meet specific design needs. Whether for architectural visualization, gaming, or product design, the available models may not align with the required aesthetics, dimensions, or functionalities. This challenge can lead to wasted time and resources, as businesses might need to purchase multiple models or even resort to creating custom designs from scratch.

The Solution: To effectively source the right bench models, buyers should leverage specialized online marketplaces like CGTrader or Sketchfab, where a variety of 3D models are available. Filtering options by parameters such as style, material, and intended use can help narrow down choices. Additionally, reaching out to the model creators for customization options or commissioning bespoke designs may ensure that the final product meets specific project requirements. Engaging with designers who understand the business’s vision can lead to more tailored solutions that enhance the overall project quality.

Scenario 2: Ensuring Compatibility Across Different Software Platforms

The Problem: Another common pain point for B2B buyers is the compatibility of bench models with various design and visualization software. A model that works seamlessly in one application may not function correctly in another, leading to integration issues and project delays. This incompatibility can be particularly frustrating for businesses operating in industries where time is of the essence, such as architecture and product development.

The Solution: To mitigate compatibility issues, buyers should prioritize obtaining models that come with detailed specifications on file formats and software compatibility. Many reputable 3D model vendors provide information about which software their models support, such as AutoCAD, Blender, or Unity. It is advisable to choose models that are available in multiple file formats to ensure flexibility across different platforms. Additionally, conducting thorough testing of models in the intended software environment before full-scale implementation can help identify potential issues early in the project lifecycle.

Scenario 3: Navigating Licensing and Usage Rights for Bench Models

The Problem: B2B buyers frequently encounter confusion regarding the licensing and usage rights associated with 3D bench models. Unclear licensing terms can lead to unintended legal issues, particularly if models are used in commercial projects without proper rights. This concern is heightened for businesses that operate internationally, as licensing laws can vary significantly between regions.

The Solution: To navigate licensing complexities effectively, buyers should focus on sourcing models from established platforms that provide clear and comprehensive licensing information. Understanding the difference between personal, commercial, and editorial use licenses is crucial. Buyers should also consider negotiating licensing terms directly with model creators if they have specific usage needs that are not covered by standard licenses. Keeping meticulous records of all licensing agreements and ensuring compliance with usage terms can safeguard against potential legal challenges, allowing businesses to use their models confidently in diverse markets.

Strategic Material Selection Guide for model of bench

What Are the Key Properties of Wood as a Material for Benches?

Wood is a traditional choice for bench construction, widely appreciated for its aesthetic appeal and natural warmth. Key properties include its strength-to-weight ratio, which makes it suitable for various designs. However, wood is sensitive to environmental factors; it can warp or crack under extreme temperatures and humidity. Additionally, untreated wood is susceptible to rot and insect damage, making it less durable in outdoor settings.

Pros and Cons of Using Wood for Benches

The primary advantages of wood include its natural beauty, ease of machining, and relatively low cost. It can be sourced sustainably, appealing to environmentally conscious buyers. However, wood’s disadvantages include a shorter lifespan compared to metals and composites, higher maintenance requirements, and vulnerability to weather conditions. For international buyers, compliance with local regulations regarding sustainable forestry practices is essential, especially in regions like Europe where such standards are stringent.

How Does Metal Perform as a Material for Benches?

Metal, particularly steel and aluminum, is increasingly popular for bench manufacturing due to its durability and strength. Steel offers high tensile strength and can withstand significant loads, while aluminum is lightweight and corrosion-resistant. Both materials can endure extreme temperatures and are less prone to damage from pests.

Pros and Cons of Using Metal for Benches

Metal benches are highly durable and require minimal maintenance, making them ideal for high-traffic areas. They also offer a modern aesthetic that appeals to urban planners and architects. However, metal can be more expensive than wood and may require additional treatments to prevent corrosion, especially in humid or coastal environments. International buyers should be aware of compliance with standards such as ASTM for corrosion resistance, particularly in regions like the Middle East where humidity can be high.

What Are the Advantages of Using Composite Materials for Benches?

Composite materials, which combine wood fibers with plastic, offer a unique blend of aesthetics and functionality. They are designed to mimic the appearance of wood while providing superior durability and resistance to weathering. Composites are non-porous, preventing rot and insect damage, and are available in various colors and finishes.

Pros and Cons of Using Composite Materials for Benches

The key advantages of composites include their low maintenance requirements and long lifespan. They are resistant to fading, splintering, and warping, making them suitable for outdoor applications. However, composites can be more expensive than traditional materials and may not have the same load-bearing capacity as metals. Buyers in regions like South America and Africa should consider local climate conditions and the availability of composite materials, as well as compliance with relevant standards.

What Should International Buyers Consider When Selecting Materials for Benches?

When selecting materials for benches, international buyers must consider various factors, including local environmental conditions, compliance with standards, and the intended use of the benches. For example, benches used in public spaces may require materials that meet specific safety and durability standards, such as those set by DIN in Europe or JIS in Japan. Understanding regional preferences and regulations can help buyers make informed decisions that align with their market needs.

| Material | Typical Use Case for model of bench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Residential gardens, parks | Aesthetic appeal and warmth | Susceptible to weathering and pests | Low |

| Metal | Urban parks, public spaces | High durability and low maintenance | Higher cost and corrosion risk | Med |

| Composite | Outdoor recreational areas | Low maintenance and weather resistance | Higher initial cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for model of bench

What Are the Key Stages in the Manufacturing Process of a Bench Model?

The manufacturing process of a bench model typically comprises four main stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring the final product meets both functional and aesthetic standards.

1. Material Preparation

Material preparation begins with the selection of appropriate materials, which can vary based on the intended use of the bench. Common materials include wood, metal, and composite materials. Once selected, the materials undergo processes like cutting and drying (for wood) or alloying (for metals) to ensure they meet specific strength and durability requirements. This stage is crucial for minimizing defects and ensuring the longevity of the bench.

2. Forming

The forming stage involves shaping the materials into the desired form. For wooden benches, this might include techniques such as milling, sanding, and carving. Metal benches often utilize processes like welding, bending, and machining. Advanced technologies such as CNC (Computer Numerical Control) machining are increasingly used to enhance precision and reduce waste.

3. Assembly

During assembly, the various components of the bench are put together. This can involve fastening parts using screws, bolts, or adhesives, depending on the design and material used. Automated assembly lines may be employed for mass production, while hand-assembly might be favored for custom or artisanal benches. The assembly stage is vital for ensuring that the bench is structurally sound and meets design specifications.

4. Finishing

The finishing stage is where the bench is given its final touches. This can include sanding, painting, varnishing, or applying protective coatings to enhance aesthetics and durability. Quality control measures are often implemented during this stage to ensure that the finish meets specified standards. This is particularly important for outdoor benches that require weather-resistant treatments.

How Is Quality Assurance Implemented in Bench Manufacturing?

Quality assurance (QA) is a critical aspect of bench manufacturing, ensuring that the products meet international standards and customer expectations. Various quality control (QC) checkpoints are established throughout the manufacturing process.

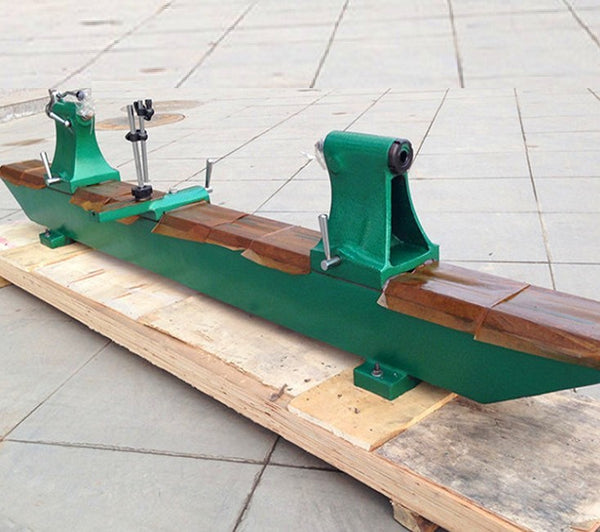

Illustrative image related to model of bench

International Standards for Quality Assurance

To ensure the quality of bench models, manufacturers often adhere to internationally recognized standards such as ISO 9001, which focuses on maintaining an effective quality management system. Additionally, industry-specific certifications like CE marking in Europe or API standards in the oil and gas sector may apply, depending on the bench’s application.

What Are the Key Quality Control Checkpoints?

Quality control in bench manufacturing typically involves several key checkpoints:

-

Incoming Quality Control (IQC): This is the first checkpoint where raw materials are inspected upon arrival. This ensures that only materials meeting the required specifications are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, various inspections and tests are conducted to monitor quality at different stages. This may include checking dimensions, material properties, and assembly integrity.

-

Final Quality Control (FQC): The final inspection occurs after assembly and finishing. Here, the overall quality of the bench is evaluated against design specifications, and any defects are addressed before shipment.

What Common Testing Methods Are Used in Bench Quality Assurance?

Common testing methods employed during the quality assurance process for bench models include:

-

Visual Inspections: This involves checking for aesthetic flaws, such as paint defects or misalignments.

-

Dimensional Testing: Using tools like calipers and gauges, manufacturers verify that the bench meets specified dimensions.

-

Load Testing: For benches designed to support significant weight, load testing ensures they can withstand the required load without failure.

-

Durability Testing: This may involve subjecting the bench to environmental conditions (e.g., moisture, UV exposure) to assess how well the materials hold up over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure reliability and performance.

Supplier Audits

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. An audit can provide insights into the manufacturing practices, quality management systems, and adherence to international standards.

Requesting Quality Reports

Buyers should request quality reports and certifications from suppliers. These documents should detail the QC processes and any relevant test results. Understanding the supplier’s history of compliance with quality standards can also inform purchasing decisions.

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of the manufacturing process, providing an additional layer of assurance.

What Are the Quality Control and Certification Nuances for International Buyers?

Navigating quality control and certification can be complex for international buyers, especially when dealing with suppliers from different regions. Here are some nuances to consider:

-

Regional Standards: Different regions may have unique quality standards and certifications. For instance, while ISO 9001 is globally recognized, specific countries may require additional certifications.

-

Documentation Requirements: Buyers should be aware of the necessary documentation for importing products, which may include certificates of origin, compliance documents, and safety data sheets.

-

Cultural Considerations: Understanding cultural differences in business practices can also be beneficial. Building strong relationships with suppliers can facilitate better communication and compliance with quality expectations.

By keeping these factors in mind, B2B buyers can make informed decisions when selecting suppliers for bench models, ensuring they receive high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘model of bench’

To assist international B2B buyers in effectively sourcing a ‘model of bench’, this practical guide outlines essential steps to streamline the procurement process. By following this checklist, buyers can ensure they make informed decisions that align with their business needs and market demands.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the bench models you require. This includes dimensions, materials (e.g., wood, metal, plastic), design style, and intended use (e.g., outdoor, indoor, commercial). Establishing these specifications will help you communicate your needs effectively to potential suppliers, ensuring that you receive relevant proposals.

Step 2: Conduct Market Research

Understanding the market landscape is crucial for identifying trends and pricing benchmarks. Research different types of bench models available in the market and compare features, durability, and aesthetic appeal. Utilize industry reports, trade publications, and online platforms to gather insights about popular designs and materials that resonate with your target audience.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they meet your quality and reliability standards. Request company profiles, product catalogs, and case studies. Look for testimonials and references from other B2B buyers within your industry or region, as this will provide insight into the supplier’s track record and customer service capabilities.

Illustrative image related to model of bench

- Tip: Check for suppliers who have experience with international shipping and compliance with regional regulations.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the bench models. This step allows you to assess the quality, craftsmanship, and material used in the production. Evaluating samples can also help you determine how well the benches align with your specifications and market expectations.

Step 5: Verify Certifications and Compliance

Ensure that suppliers adhere to industry standards and safety regulations by verifying their certifications. This may include ISO certifications, environmental compliance, and product safety standards. Compliance is particularly important if you are sourcing for markets that have stringent regulations, as it can affect your business’s credibility and legal standing.

Step 6: Negotiate Pricing and Terms

Once you have settled on a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget while also considering the total cost of ownership, including shipping and potential tariffs. Establishing favorable terms can lead to long-term relationships and better pricing in future orders.

Step 7: Finalize Contracts and Place Orders

After negotiations, draft a contract that outlines all agreed-upon terms, including specifications, delivery timelines, and payment conditions. Ensure that both parties sign the contract to avoid any misunderstandings. Once finalized, place your order and maintain open communication with the supplier throughout the production and shipping process.

By following these steps, B2B buyers can streamline their sourcing process for bench models, ensuring they select the right products that meet their operational needs and market demands.

Comprehensive Cost and Pricing Analysis for model of bench Sourcing

What Are the Key Cost Components in Sourcing Bench Models?

When evaluating the costs associated with sourcing bench models, several critical components contribute to the overall price structure. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. For instance, premium woods or metals will elevate the price compared to standard alternatives. Buyers should consider the durability and aesthetics of materials, especially for outdoor benches exposed to the elements.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs can offer more competitive pricing, while skilled craftsmanship, especially for custom or high-quality designs, may increase expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, leading to more competitive pricing for buyers.

-

Tooling: Initial investments in tooling for production can be substantial, particularly for custom designs. This cost is often amortized over large production runs, making it essential to consider minimum order quantities (MOQ).

-

Quality Control (QC): Ensuring product quality can incur additional costs. Implementing stringent QC processes is critical for maintaining standards, especially for international markets where regulations may differ.

-

Logistics: Transportation costs, including shipping and handling, are essential in the total cost structure. Factors such as distance, mode of transport, and the complexity of delivery can affect logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business sustainability. Understanding the supplier’s pricing strategy can help buyers negotiate better terms.

How Do Pricing Influencers Affect Bench Model Costs?

Several factors influence the pricing of bench models, which can be pivotal for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to lower per-unit costs. Buyers should assess their needs and consider bulk purchasing to maximize cost efficiency.

-

Specifications and Customization: Custom designs or specific features can increase the cost. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (such as eco-friendliness or safety standards) often come at a premium. Buyers should evaluate whether these certifications align with their market needs.

-

Supplier Factors: The reliability, reputation, and location of the supplier can impact pricing. Established suppliers may offer better quality assurance but at a higher cost.

-

Incoterms: Understanding shipping terms is crucial for budgeting. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the products.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Bench Models?

B2B buyers should consider the following strategies to enhance cost-efficiency when sourcing bench models:

-

Negotiate Pricing: Engage in open discussions with suppliers about pricing structures and potential discounts for larger orders or long-term contracts. Leverage competitive quotes to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, durability, and potential replacement costs over the product’s lifecycle to understand the true value.

-

Understand Pricing Nuances for International Markets: Currency fluctuations, tariffs, and local regulations can significantly impact costs. Buyers from regions such as Africa, South America, the Middle East, and Europe should stay informed about these factors to budget accurately.

-

Research Supplier Options: Conduct thorough research on potential suppliers, including reviews and ratings. A reliable supplier can save money in the long run through consistent quality and timely delivery.

-

Consider Local Sourcing: Where feasible, sourcing from local manufacturers can reduce logistics costs and lead times, providing a competitive edge in pricing and delivery.

Disclaimer on Indicative Prices

Prices for bench models can vary widely based on the factors outlined above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are receiving fair pricing reflective of their specific requirements.

Illustrative image related to model of bench

Alternatives Analysis: Comparing model of bench With Other Solutions

Exploring Alternatives to the Model of Bench

When evaluating the ‘model of bench’, it’s essential to consider various alternatives that can fulfill similar functions or offer comparable benefits. The selection of the right solution depends on several factors, including performance, cost, ease of implementation, maintenance requirements, and specific use cases. Below, we provide a detailed comparison of the ‘model of bench’ against two viable alternatives.

| Comparison Aspect | Model of Bench | Alternative 1: Modular Seating Systems | Alternative 2: Fixed Seating Solutions |

|---|---|---|---|

| Performance | High durability and comfort for outdoor use | Versatile configurations for different spaces | Fixed structures with long-term durability |

| Cost | Moderate initial investment | Higher upfront costs, but customizable | Generally lower cost, but limited customization |

| Ease of Implementation | Straightforward installation | Requires professional setup for optimal use | Simple installation, often pre-assembled |

| Maintenance | Requires periodic cleaning and weatherproofing | Low maintenance; materials are durable | Minimal upkeep; often resistant to wear and tear |

| Best Use Case | Parks, public spaces, and commercial areas | Events, flexible spaces, and collaborative environments | Schools, auditoriums, and transport hubs |

What Are Modular Seating Systems and Their Advantages?

Modular seating systems provide flexible configurations that can adapt to various environments. They are designed to be rearranged easily, which makes them ideal for spaces that require frequent reconfiguration, such as conference rooms or outdoor events. The primary advantage of modular systems lies in their versatility; they can be tailored to fit specific spatial needs. However, they often come with higher upfront costs and may require professional installation, which could be a barrier for some organizations.

How Do Fixed Seating Solutions Compare?

Fixed seating solutions, such as benches installed in schools or transport hubs, offer a reliable and cost-effective alternative. These solutions are typically lower in initial investment and provide long-lasting durability. They require minimal maintenance and are often constructed from materials resistant to wear and tear. However, their lack of flexibility can be a disadvantage in dynamic environments that benefit from customizable layouts. Fixed seating is best suited for locations where space configuration does not change frequently.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the ideal seating solution, B2B buyers must assess their specific needs and operational context. For environments that prioritize flexibility and adaptability, modular seating systems may be the best fit despite their higher costs. Conversely, if budget constraints and durability are primary concerns, fixed seating solutions provide a practical choice. The ‘model of bench’ remains a strong contender for outdoor and public settings, delivering a balance of comfort and performance. Ultimately, the decision should align with the intended use case, budget, and long-term maintenance capabilities to ensure the best return on investment.

Essential Technical Properties and Trade Terminology for model of bench

What Are the Key Technical Properties of a Bench Model?

When considering the procurement of bench models, understanding their technical specifications is crucial for ensuring they meet your operational requirements. Below are some critical properties to consider:

-

Material Grade

The material used in bench construction significantly affects durability and maintenance. Common materials include wood, metal, and composite materials. High-grade materials, such as stainless steel or treated hardwood, are recommended for outdoor benches to resist weathering and corrosion. Selecting the right material ensures longevity, which is vital for reducing replacement costs and enhancing customer satisfaction. -

Weight Capacity

This specification indicates the maximum load a bench can safely support. It is essential for ensuring user safety and compliance with local regulations. For public spaces, benches often need to accommodate higher weight capacities, which can influence the overall design and material choice. Understanding weight limits is critical for B2B buyers in sectors like hospitality, parks, and recreation. -

Dimensions and Tolerance

Bench dimensions (length, width, height) must align with the intended use, whether for public parks, commercial spaces, or private installations. Tolerance refers to acceptable variations in these measurements, which is important for ensuring that benches fit seamlessly into designated spaces. Accurate dimensions and tolerances are vital for avoiding costly modifications post-purchase. -

Finish and Texture

The finish of the bench (e.g., painted, varnished, or powder-coated) not only affects aesthetics but also impacts maintenance and weather resistance. A textured finish can provide better grip and reduce slippage, which is particularly important in outdoor environments. Buyers should consider the required finish based on the intended use and environmental conditions. -

Assembly Requirements

Knowing whether a bench comes pre-assembled or requires assembly is important for logistics and installation. Some models may need specialized tools or skills for assembly, which can affect installation timelines and costs. Clarity on assembly requirements helps streamline the procurement process and ensures readiness for use.

What Trade Terminology Should B2B Buyers Understand When Purchasing Benches?

Navigating the procurement landscape involves familiarizing yourself with key trade terms that can affect your purchasing decisions:

Illustrative image related to model of bench

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of benches, understanding whether you’re dealing with OEM products can influence pricing and quality assurance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of an item that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management. Buyers should negotiate to meet their needs without overcommitting to excess stock. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods. This process is essential for comparing offers and ensuring you secure the best deal. Clarity in your RFQ can lead to more accurate quotes and better supplier relationships. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping costs, risk, and delivery timelines, especially when importing benches from different regions. -

Lead Time

This term refers to the time taken from placing an order until it is fulfilled. Knowing the lead time is critical for planning and inventory management, especially in projects that require timely delivery of benches for public spaces or events.

By familiarizing yourself with these technical properties and trade terminologies, you can make informed decisions that align with your business needs and operational goals in the bench procurement process.

Navigating Market Dynamics and Sourcing Trends in the model of bench Sector

What Are the Key Market Dynamics and Trends Impacting the Bench Model Sector?

The global market for bench models has seen significant growth, driven by several factors including urbanization, the rise in outdoor spaces, and an increasing demand for recreational areas. Particularly in regions like Africa, South America, the Middle East, and Europe, urban development projects are fostering a need for aesthetically pleasing and functional bench designs. Countries such as Brazil and Vietnam are witnessing a surge in public infrastructure projects aimed at enhancing community spaces, which in turn drives the demand for various types of benches, from park and street furniture to specialized seating solutions for commercial environments.

Emerging B2B tech trends are also reshaping the sourcing landscape. The integration of 3D modeling and virtual reality is allowing buyers to visualize products before making purchasing decisions, streamlining the procurement process. Platforms like Sketchfab and CGTrader are gaining traction among B2B buyers as they offer a diverse range of 3D bench models that can be customized according to specific project requirements. Moreover, the rise of online marketplaces facilitates easier access to suppliers, enabling buyers to compare products and prices efficiently.

How Are Sustainability and Ethical Sourcing Shaping the Bench Model Industry?

Sustainability has become a cornerstone of modern sourcing strategies in the bench model sector. Environmental concerns over the production and disposal of furniture are prompting buyers to prioritize eco-friendly materials and practices. The use of recycled materials, sustainably sourced wood, and low-impact manufacturing processes are becoming essential criteria for B2B buyers. Certifications such as FSC (Forest Stewardship Council) and GREENGUARD are increasingly sought after, as they assure buyers of the environmental integrity of the products they are sourcing.

Ethical sourcing extends beyond materials; it encompasses labor practices and community impact. B2B buyers are now more inclined to partner with suppliers that demonstrate a commitment to fair labor practices and community engagement. This shift not only enhances brand reputation but also resonates with consumers who prioritize sustainability and ethical considerations in their purchasing decisions. For international buyers, particularly from regions like Africa and South America, aligning with suppliers that uphold these values can foster stronger business relationships and open up new market opportunities.

What Is the Evolution of Bench Models in the B2B Market?

The evolution of bench models has been marked by significant technological advancements and shifting consumer preferences. Initially, benches were primarily functional, designed for durability and utility. However, over the years, the focus has expanded to include aesthetics, comfort, and environmental considerations. The introduction of innovative materials and design techniques has enabled manufacturers to create benches that are not only practical but also serve as focal points in public and private spaces.

As urban areas continue to evolve, so too does the demand for multifunctional and adaptable bench designs. The rise of smart cities has further influenced this evolution, with benches being integrated into urban infrastructure to accommodate technological advancements, such as solar-powered charging stations. This trajectory reflects a broader trend in the B2B market towards versatility and sustainability, positioning the bench model sector as a dynamic and integral part of urban development strategies worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of model of bench

-

How do I ensure the quality of benches sourced from international suppliers?

To guarantee the quality of benches, it’s crucial to implement a thorough vetting process for suppliers. Request samples to assess material quality and craftsmanship. Additionally, consider utilizing third-party inspection services that can conduct quality checks before shipment. Establishing clear quality standards and specifications in your purchase agreement can also help mitigate risks. It’s beneficial to ask for references or case studies from previous clients to understand the supplier’s reliability and adherence to quality. -

What customization options are available for bench models?

Many manufacturers offer a variety of customization options to suit specific needs. You can request alterations in size, materials, colors, and design features to align with your branding or project requirements. It’s advisable to communicate your customization needs early in the negotiation process. Some suppliers may provide 3D renderings or prototypes to visualize the final product. Always confirm if there are additional costs associated with customization and the lead times required for production. -

What are the typical minimum order quantities (MOQs) for benches?

Minimum order quantities for benches can vary widely depending on the supplier and the complexity of the design. Generally, MOQs can range from a few dozen to several hundred units. It’s essential to discuss MOQs upfront to ensure they align with your purchasing capabilities. If you require fewer units, inquire about the possibility of negotiating lower MOQs or consider sourcing from suppliers that cater to smaller orders, often found in local markets or through online platforms. -

What payment terms should I expect when sourcing benches internationally?

Payment terms can differ significantly between suppliers. Common practices include payment in advance, letters of credit, or partial payments upon order confirmation and before shipment. It’s important to negotiate terms that are mutually beneficial while ensuring your financial security. Some suppliers might offer discounts for early payments or bulk orders. Always clarify the payment methods accepted and any associated fees, especially for international transactions, to avoid unexpected costs. -

How can I effectively manage logistics for importing benches?

Effective logistics management involves selecting a reliable freight forwarder familiar with the destination country’s regulations and customs processes. Collaborate with your supplier to determine the best shipping methods, whether by air or sea, based on cost and urgency. Ensure all documentation is accurate to avoid delays at customs. Additionally, consider using insurance to protect your investment during transit. Familiarize yourself with local import duties and taxes to budget accordingly. -

What certifications or standards should I look for in bench suppliers?

When sourcing benches, it’s crucial to verify that suppliers comply with relevant international standards and certifications, such as ISO 9001 for quality management or environmental certifications like FSC for sustainably sourced wood. Depending on your market, look for compliance with local regulations regarding safety and materials. Request documentation to ensure that the products meet these standards, as this can enhance your credibility and reduce liability risks. -

How do I handle disputes with international bench suppliers?

Dispute resolution can be challenging in international trade. It’s essential to include a clear dispute resolution clause in your contracts, specifying mediation or arbitration procedures. Maintain open communication with suppliers to address issues promptly. If disputes arise, gather all relevant documentation and evidence to support your position. Consulting with legal professionals experienced in international trade can provide guidance on the best course of action to resolve conflicts effectively. -

What are the trends in bench designs that I should be aware of?

Staying updated on bench design trends can help you make informed purchasing decisions. Current trends include sustainable materials, modular designs, and multifunctional uses that cater to urban environments. The rise of outdoor spaces has led to an increase in demand for weather-resistant benches. Additionally, consider the cultural preferences of your target market, as styles may vary significantly across regions. Engaging with design professionals or attending trade shows can provide valuable insights into emerging trends.

Top 1 Model Of Bench Manufacturers & Suppliers List

1. Instagram – Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

Strategic Sourcing Conclusion and Outlook for model of bench

In today’s competitive landscape, strategic sourcing for bench models presents significant opportunities for international B2B buyers. By leveraging a diverse range of suppliers and materials, businesses can optimize costs while ensuring quality and durability in their offerings. The importance of sourcing from regions that align with your market’s aesthetic and functional needs cannot be overstated, particularly for buyers in Africa, South America, the Middle East, and Europe.

Understanding the trends in 3D modeling and the growing demand for customizable solutions allows businesses to stay ahead of the curve. Collaborating with suppliers that provide innovative designs, such as those highlighted in platforms like Sketchfab and CGTrader, can enhance product offerings and differentiate your brand in the market.

Looking ahead, it is essential for B2B buyers to remain agile and responsive to emerging trends and consumer preferences. Investing in strategic sourcing initiatives not only improves supply chain resilience but also drives long-term growth. We encourage you to explore partnerships with leading suppliers and embrace the potential of new technologies to elevate your business. The future of bench models is bright—seize the opportunity to innovate and lead in your market today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to model of bench