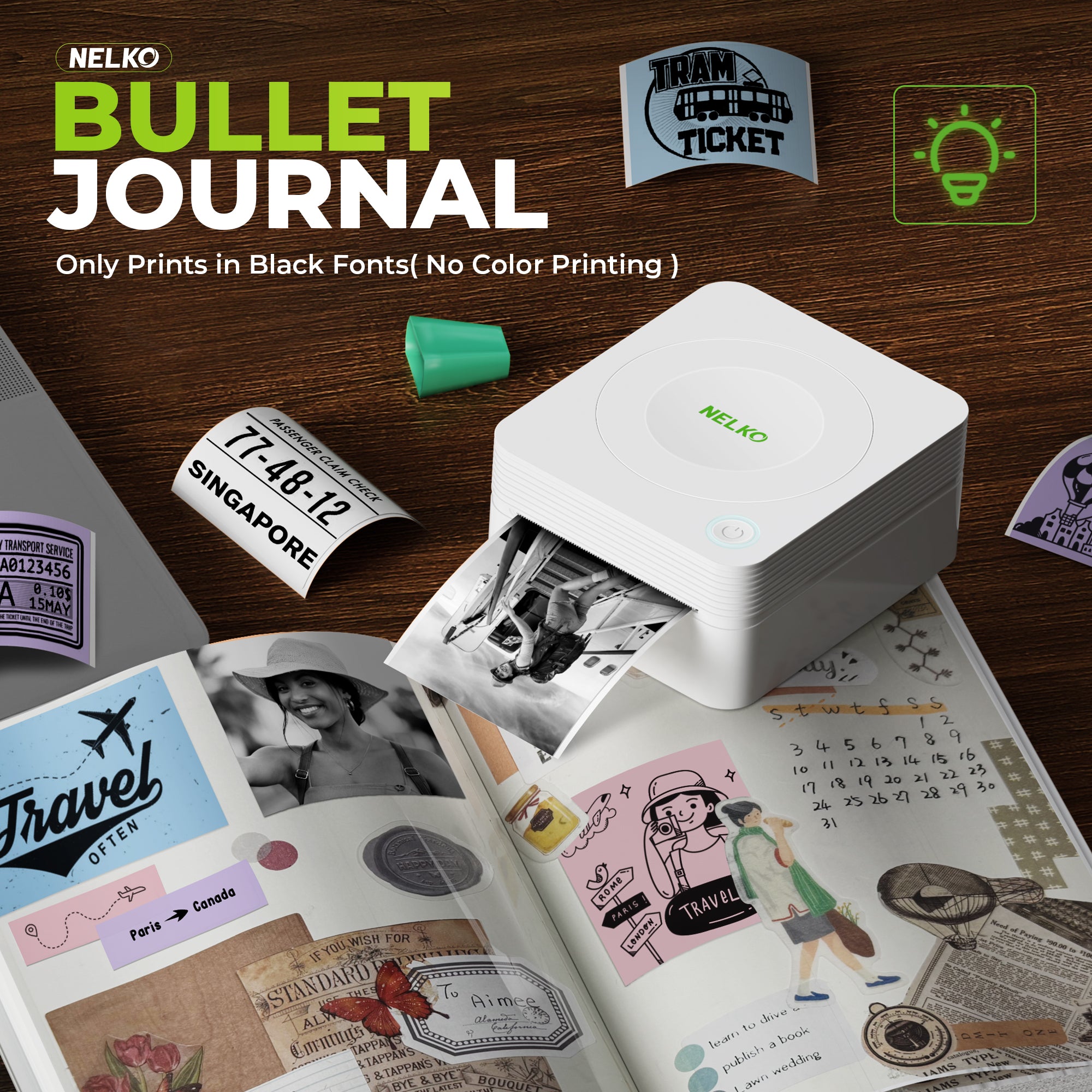

Mini Sticker Printer: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for mini sticker printer

In today’s fast-paced business environment, sourcing reliable mini sticker printers can be a daunting task for international B2B buyers. With a multitude of options available, companies must navigate varying technologies, quality standards, and supply chain complexities. This guide is designed to equip you with the essential insights needed to make informed purchasing decisions in the global market for mini sticker printers.

Throughout this comprehensive resource, we will explore different types of mini sticker printers, their diverse applications across various industries, and the intricacies of supplier vetting. We will also provide a thorough analysis of cost considerations, helping you understand the financial implications of your choices. By addressing these key areas, our guide empowers you to identify the best solutions tailored to your specific needs, whether you’re operating in Africa, South America, the Middle East, or Europe.

As the demand for portable and versatile printing solutions continues to rise, understanding the landscape of mini sticker printers will not only enhance your operational efficiency but also elevate your brand’s presence in a competitive marketplace. Armed with the right knowledge, you can confidently select a supplier that aligns with your business objectives and fosters long-term success.

Understanding mini sticker printer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mini Thermal Sticker Printer | Utilizes thermal printing technology; compact and portable | Retail, event branding, product labeling | Pros: No ink needed, easy to use. Cons: Limited color options. |

| Bluetooth Mini Photo Printer | Connects via Bluetooth; prints photos and stickers from smartphones | Marketing materials, personalized gifts | Pros: Wireless convenience, versatile. Cons: Battery life may vary. |

| Compact Label Printer | Designed for label creation; often supports larger paper widths | Shipping, inventory management | Pros: High-quality labels, efficient for bulk printing. Cons: May be pricier. |

| Multi-Function Mini Printer | Combines sticker and label printing; often features scanning options | Office management, creative projects | Pros: Versatile functionality, saves space. Cons: Complexity may deter some users. |

| Portable Inkless Printer | Uses inkless technology; ideal for on-the-go printing | Travel, journaling, DIY projects | Pros: Lightweight, eco-friendly. Cons: Limited to monochrome prints. |

What Are the Characteristics of Mini Thermal Sticker Printers?

Mini thermal sticker printers leverage thermal printing technology, which eliminates the need for ink, making them cost-effective and user-friendly. These printers are compact, fitting easily into small workspaces or even bags, making them ideal for businesses that require on-the-go printing solutions. They are particularly suited for retail environments where quick label creation is essential. When purchasing, businesses should consider the printer’s speed, compatibility with various thermal paper sizes, and overall print quality.

How Do Bluetooth Mini Photo Printers Enhance B2B Applications?

Bluetooth mini photo printers stand out for their wireless connectivity, allowing users to print directly from smartphones or tablets. This feature is particularly beneficial for marketing teams looking to create personalized promotional materials quickly. These printers are versatile, suitable for creating stickers, labels, and even small photos. B2B buyers should assess the printer’s compatibility with mobile devices, print resolution, and the variety of paper types supported to ensure it meets their specific needs.

Illustrative image related to mini sticker printer

What Makes Compact Label Printers Ideal for Business Use?

Compact label printers are designed specifically for creating high-quality labels, often accommodating larger paper widths for various applications. These printers are essential in logistics, inventory management, and shipping, where clear, durable labels are critical. When selecting a compact label printer, businesses should evaluate print speed, resolution, and whether it supports integration with existing systems for efficient workflow management.

Why Choose a Multi-Function Mini Printer for Diverse Needs?

Multi-function mini printers offer the flexibility of printing stickers, labels, and sometimes even scanning capabilities. This versatility makes them an attractive option for businesses that require different printing functions without needing multiple devices. They are especially useful in office settings or for creative projects. Buyers should consider the range of functionalities offered, ease of use, and the printer’s footprint to ensure it fits within their operational requirements.

What Are the Advantages of Portable Inkless Printers for Creative Projects?

Portable inkless printers are designed for those who prioritize convenience and eco-friendliness. They are lightweight and use thermal printing technology, making them ideal for creative projects, travel, or journaling. These printers typically produce monochrome prints, which can be a limitation for some businesses. When considering a portable inkless printer, buyers should look into battery life, ease of connectivity, and the quality of prints to ensure they align with their creative needs.

Key Industrial Applications of mini sticker printer

| Industry/Sector | Specific Application of mini sticker printer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & E-commerce | Printing product labels and promotional stickers | Streamlines inventory management and enhances brand visibility | Compatibility with various label sizes; reliable thermal printing technology; ease of integration with existing systems |

| Education & Training | Creating study aids, flashcards, and customized labels | Improves learning efficiency and organization for students | Lightweight and portable design; battery life; ease of use for students and teachers |

| Event Management | Producing event badges, labels, and promotional materials | Facilitates quick customization and enhances attendee experience | Durability of prints; speed of printing; ability to print on waterproof materials |

| Food & Beverage | Labeling food packaging and creating menu stickers | Ensures compliance with regulations and boosts product appeal | Food-safe materials; high-resolution printing; ability to print on various surfaces |

| Arts & Crafts | Generating personalized stickers for DIY projects | Enhances creativity and allows for unique product offerings | Variety of sticker paper options; color quality; user-friendly interface |

How Are Mini Sticker Printers Transforming the Retail and E-commerce Sector?

In the retail and e-commerce industry, mini sticker printers are invaluable for printing product labels and promotional stickers. They help businesses streamline inventory management by allowing for on-demand label printing, reducing the need for pre-printed stock. Furthermore, these printers enhance brand visibility through customized promotional materials. Buyers should consider sourcing printers that support various label sizes and integrate seamlessly with existing inventory systems, ensuring reliability and efficiency in high-demand environments.

What Benefits Do Mini Sticker Printers Offer in Education and Training?

In educational settings, mini sticker printers serve as essential tools for creating study aids, flashcards, and customized labels. They improve learning efficiency by enabling students to produce tailored materials that cater to their unique study needs. The lightweight and portable design of these printers makes them ideal for use in classrooms or study groups. B2B buyers in this sector should prioritize battery life and ease of use, ensuring that both students and educators can leverage the technology without extensive training.

How Can Event Management Professionals Leverage Mini Sticker Printers?

Event management professionals utilize mini sticker printers to produce event badges, labels, and promotional materials quickly. The ability to customize these items on-site enhances the attendee experience and allows for immediate adjustments based on event needs. Key considerations for sourcing include the durability of prints, speed of printing, and the capability to print on waterproof materials, ensuring that materials remain intact in various conditions.

Why Are Mini Sticker Printers Essential for the Food and Beverage Industry?

In the food and beverage sector, mini sticker printers are crucial for labeling food packaging and creating menu stickers. They help ensure compliance with labeling regulations while boosting product appeal through attractive designs. When sourcing these printers, businesses should focus on food-safe materials, high-resolution printing capabilities, and the ability to print on various surfaces, which are essential for maintaining quality and safety standards.

How Do Mini Sticker Printers Enhance Creativity in Arts and Crafts?

Mini sticker printers empower artists and crafters by enabling the generation of personalized stickers for DIY projects. This flexibility enhances creativity and allows businesses to offer unique product offerings that cater to niche markets. Buyers should consider the variety of sticker paper options available, color quality, and user-friendly interfaces to ensure that the printers meet the diverse needs of artists and hobbyists alike.

Illustrative image related to mini sticker printer

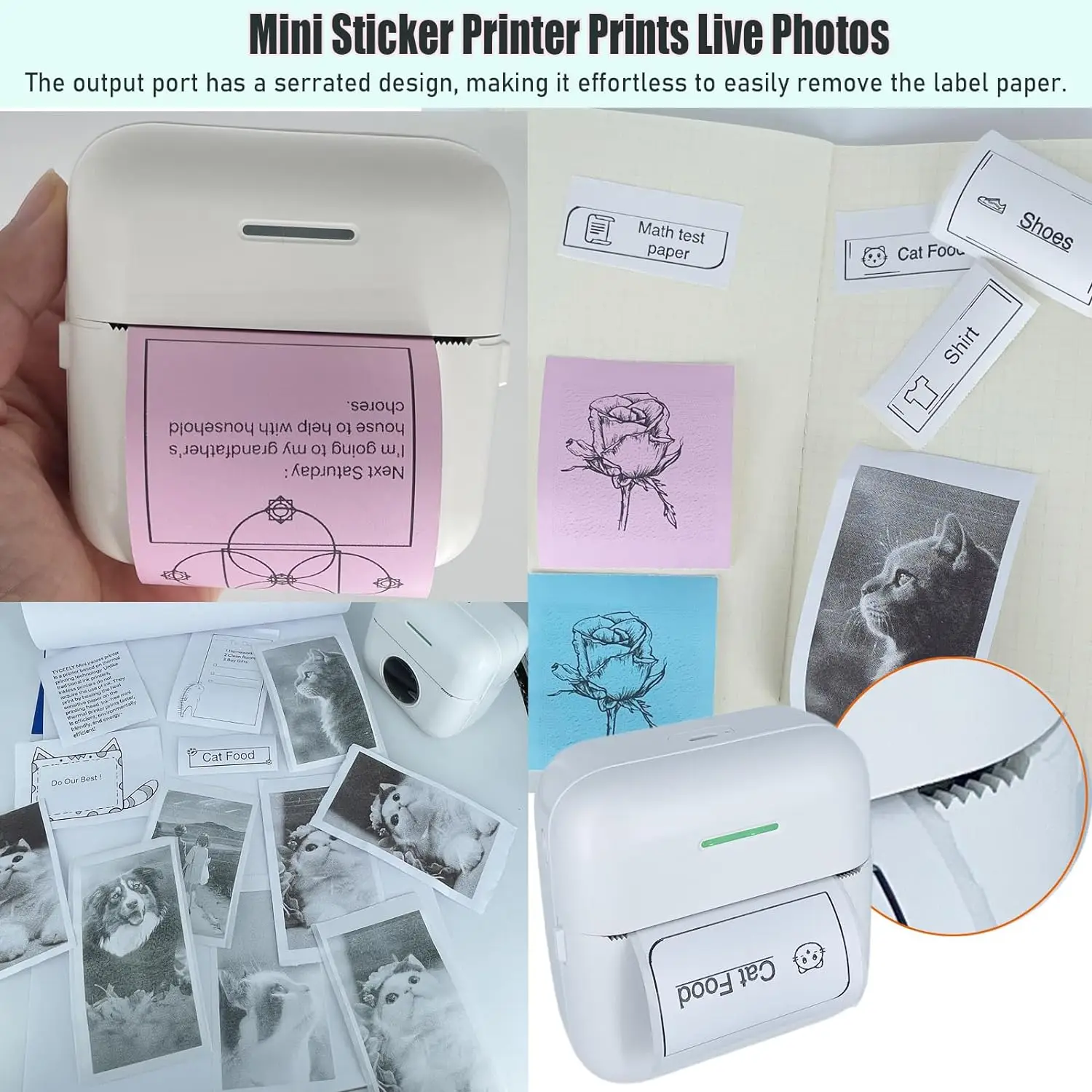

3 Common User Pain Points for ‘mini sticker printer’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Thermal Paper for Mini Sticker Printers

The Problem: Many B2B buyers encounter challenges when it comes to sourcing the right type of thermal paper for their mini sticker printers. The lack of standardized specifications across different manufacturers can lead to compatibility issues, resulting in wasted time and resources. For instance, a printing business in South America may invest in a mini sticker printer only to find that the thermal paper they purchased does not yield the desired print quality or fails to fit the printer entirely.

The Solution: To mitigate these sourcing challenges, buyers should conduct thorough research before making a purchase. This involves checking the specifications of the mini sticker printer, such as the required paper width and type (e.g., standard thermal paper versus sticker paper). Buyers should also establish relationships with multiple suppliers and request samples to ensure compatibility. Additionally, leveraging online platforms that specialize in printing supplies can provide access to a wider range of products, ensuring that the correct thermal paper is readily available. It’s advisable to maintain an inventory of various compatible thermal papers to avoid production delays.

Scenario 2: Managing Print Quality Issues with Mini Sticker Printers

The Problem: B2B buyers often face print quality issues when using mini sticker printers, which can be detrimental to their branding and customer satisfaction. For example, a marketing agency in Europe may rely on these printers to produce high-quality stickers for promotional events, but inconsistent print quality could lead to unsatisfactory results, damaging their reputation and client relationships.

The Solution: To address print quality issues, businesses should prioritize investing in mini sticker printers known for their reliability and high-resolution output. It is essential to regularly maintain and calibrate the printers, including cleaning print heads and ensuring that the thermal paper is stored correctly to prevent moisture damage. Training staff on proper usage and maintenance can further enhance print quality. Additionally, conducting test prints before large runs can help identify any issues early on, allowing for adjustments to be made without significant loss. Finally, seeking feedback from customers regarding print quality can provide actionable insights to improve the printing process.

Illustrative image related to mini sticker printer

Scenario 3: Integrating Mini Sticker Printers into Existing Workflows

The Problem: Integrating mini sticker printers into established workflows can be a significant hurdle for many businesses, especially those that have relied on traditional printing methods. For instance, a small retail business in Africa may struggle to incorporate a new mini sticker printer into their inventory management system, leading to inefficiencies and delays in order processing.

The Solution: To facilitate a smooth integration of mini sticker printers into existing workflows, businesses should first evaluate their current processes and identify where the new printer can add value. Establishing clear objectives for what the mini sticker printer should achieve—such as improving label efficiency or enhancing product presentation—can guide the integration process. Training sessions for staff on how to use the new printer effectively, as well as how to incorporate it into existing software systems, can ease the transition. Furthermore, seeking out mini sticker printers with robust connectivity options (such as Bluetooth or Wi-Fi) and compatibility with popular inventory management software can streamline operations. Finally, consider using pilot programs to test the integration on a smaller scale before rolling it out company-wide, allowing for adjustments based on real-world performance.

Strategic Material Selection Guide for mini sticker printer

What Are the Key Materials for Mini Sticker Printers?

When selecting materials for mini sticker printers, it’s essential to consider various properties that affect performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in the manufacturing of mini sticker printers, with a focus on their properties, pros and cons, and implications for international B2B buyers.

Illustrative image related to mini sticker printer

1. Thermal Paper

Key Properties:

Thermal paper is heat-sensitive and reacts to thermal printing technology. It typically has a temperature rating of up to 70°C and is designed to withstand moderate pressure during printing.

Pros & Cons:

The primary advantage of thermal paper is its cost-effectiveness and ease of use, as it requires no ink or toner. However, it is susceptible to fading when exposed to heat, sunlight, or moisture, which limits its durability for long-term applications.

Impact on Application:

Thermal paper is ideal for creating stickers that are used for short-term applications, such as promotional materials or temporary labels. However, it may not be suitable for products that require longevity or exposure to harsh environments.

Illustrative image related to mini sticker printer

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with local regulations regarding the use of thermal paper, particularly concerning chemical safety and environmental standards.

2. Vinyl

Key Properties:

Vinyl is a synthetic plastic material known for its flexibility and durability. It typically has a temperature resistance of up to 80°C and is resistant to water and UV light.

Pros & Cons:

Vinyl offers excellent durability and is suitable for both indoor and outdoor applications, making it a preferred choice for long-lasting stickers. However, it can be more expensive than thermal paper and may require specialized printing equipment.

Impact on Application:

Vinyl is commonly used for high-quality, weather-resistant stickers that need to withstand environmental factors. Its compatibility with various printing technologies enhances its application versatility.

Considerations for International Buyers:

B2B buyers in Africa and South America should consider local availability and cost implications of vinyl materials, as well as compliance with international standards for plastic products.

3. Adhesive Backing

Key Properties:

Adhesive backing materials vary widely but generally provide a strong bond and can withstand temperatures ranging from -10°C to 60°C. They are designed for easy application and removal.

Pros & Cons:

The main advantage of adhesive backing is its versatility in application, allowing for easy sticking on various surfaces. However, the adhesive quality can degrade over time, especially in humid conditions, which may affect the longevity of the sticker.

Impact on Application:

Adhesive backing is crucial for ensuring that stickers adhere properly to surfaces. This material is particularly important for products intended for retail or promotional use.

Considerations for International Buyers:

Buyers should evaluate the adhesive properties based on regional climate conditions, particularly in humid regions like parts of Africa and South America, to ensure product performance.

4. Eco-Friendly Materials

Key Properties:

Eco-friendly materials, such as biodegradable or recycled paper, are designed to minimize environmental impact. They often have lower temperature ratings and may not be as durable as synthetic materials.

Pros & Cons:

The key advantage of eco-friendly materials is their sustainability, appealing to environmentally conscious consumers. However, they may have limitations in durability and resistance to elements compared to traditional materials.

Impact on Application:

These materials are suitable for businesses aiming to promote sustainability. However, their application may be limited to indoor environments or short-term use.

Considerations for International Buyers:

B2B buyers in Europe may prioritize eco-friendly options due to stringent regulations and consumer preferences for sustainable products. Compliance with standards such as DIN EN 13432 for biodegradable materials is essential.

Summary Table

| Material | Typical Use Case for mini sticker printer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermal Paper | Short-term stickers and labels | Cost-effective and easy to use | Susceptible to fading and moisture | Low |

| Vinyl | Long-lasting outdoor stickers | Durable and weather-resistant | Higher cost and requires special equipment | High |

| Adhesive Backing | Retail and promotional stickers | Strong bond on various surfaces | Adhesive quality can degrade over time | Medium |

| Eco-Friendly Materials | Sustainable product labels | Environmentally friendly | Limited durability | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in mini sticker printers, enabling informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for mini sticker printer

What Are the Key Stages in the Manufacturing Process of Mini Sticker Printers?

The manufacturing process of mini sticker printers typically involves several critical stages that ensure the final product meets quality standards and performance expectations. These stages include material preparation, forming, assembly, and finishing.

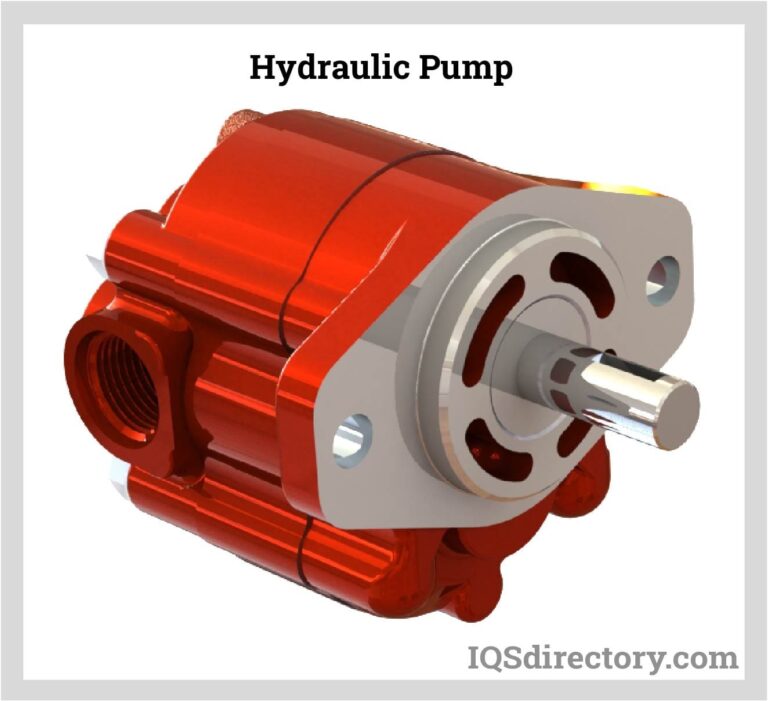

Illustrative image related to mini sticker printer

1. Material Preparation

The first stage in the manufacturing process involves sourcing and preparing high-quality materials. Manufacturers often utilize durable plastics, metals for structural components, and specialized thermal printing paper. The selection of materials is crucial, as they directly impact the printer’s durability, print quality, and overall performance. Suppliers should provide certifications for materials to ensure they meet industry standards.

2. Forming Techniques

Once materials are prepared, the next step is forming. This can involve various techniques such as injection molding for plastic components and stamping for metal parts. Advanced manufacturers may use CNC machining for precision components, ensuring tight tolerances that are critical for the printer’s functionality. The choice of forming technique can affect production speed and cost, making it an important consideration for B2B buyers.

3. Assembly

After forming, the individual components are assembled. This stage can be automated or manual, depending on the complexity of the printer design. Automated assembly lines can increase efficiency and reduce labor costs, while manual assembly may allow for more detailed quality checks. During assembly, components such as the thermal print head, control circuitry, and battery systems are integrated. Each assembly line should be designed to minimize errors and facilitate easy troubleshooting.

4. Finishing Processes

The finishing stage includes quality checks, surface treatments, and final product assembly. This may involve applying protective coatings, printing branding elements, or packaging the printer for shipment. Attention to detail during the finishing processes is essential, as this stage often determines the aesthetic quality of the final product, which can impact customer satisfaction.

How Do Quality Assurance Standards Impact Mini Sticker Printer Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process for mini sticker printers. Adhering to international standards not only enhances product reliability but also builds trust among B2B buyers.

Relevant International Standards

ISO 9001 is one of the most recognized quality management standards applicable to manufacturing processes. This standard focuses on meeting customer requirements and ensuring continuous improvement. Additionally, specific industry standards like CE marking for safety and environmental compliance in the EU, and certifications for electronic products (like FCC in the US) are vital for market acceptance.

Quality Control Checkpoints

Quality control is integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This checkpoint ensures that all incoming materials meet specified quality standards. Inspections may involve checking material certifications, conducting sample tests, and reviewing supplier documentation.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring the assembly and forming processes. This may include periodic checks of dimensions, weights, and functional tests to catch defects early in the production cycle.

-

Final Quality Control (FQC): After assembly, FQC verifies the completed printer against established specifications. Tests may include performance assessments, durability tests, and user experience evaluations.

What Testing Methods Are Commonly Used for Mini Sticker Printers?

Effective testing methods are essential to validate the performance and quality of mini sticker printers. Common methods include:

-

Functional Testing: Ensures that the printer operates correctly, including print quality, connectivity, and battery life. This testing simulates real-world usage to identify any potential issues.

-

Environmental Testing: Assesses the printer’s performance under various conditions such as temperature, humidity, and exposure to dust or liquids. This is particularly important for products intended for diverse markets.

-

Durability Testing: Evaluates how well the printer withstands physical stresses like drops or impacts. This is vital for portable devices that may be used in rugged environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers adhere to stringent quality control practices. Here are several strategies to verify these practices:

1. Supplier Audits

Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes and quality control measures firsthand. Audits can include reviewing documentation, inspecting facilities, and observing production practices.

2. Quality Control Reports

Requesting regular quality control reports from suppliers can provide insights into their manufacturing performance. Reports should detail inspection results, defect rates, and corrective actions taken to address any quality issues.

Illustrative image related to mini sticker printer

3. Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of production and offer peace of mind regarding the quality of the final product.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality. Understanding these nuances is crucial for effective sourcing.

1. Compliance with Local Regulations

Buyers must be aware of local regulations governing product safety and environmental standards. Compliance with these regulations is essential for successful market entry and avoiding potential legal issues.

2. Cultural and Communication Barriers

Cultural differences can impact communication and expectations regarding quality. Buyers should establish clear communication channels with suppliers and ensure that all quality expectations are documented and understood.

3. Variability in Quality Standards

Different regions may have varying quality standards and practices. Buyers should conduct thorough research on suppliers in different countries to understand their quality assurance processes and how they align with international standards.

Illustrative image related to mini sticker printer

Conclusion

In summary, the manufacturing processes and quality assurance measures for mini sticker printers are critical for ensuring product reliability and customer satisfaction. B2B buyers should focus on understanding these processes, verifying supplier practices, and navigating the complexities of international quality standards. By doing so, they can make informed purchasing decisions that enhance their business operations and market competitiveness.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini sticker printer’

Introduction

This sourcing guide is designed for B2B buyers looking to procure mini sticker printers. With the increasing demand for portable printing solutions, it’s essential to have a clear checklist that ensures you choose the right printer for your business needs. This guide will help streamline your purchasing process, ensuring you consider all relevant factors.

1. Define Your Technical Specifications

Before initiating your search, clarify the technical specifications that your business requires. Consider factors such as print size, resolution, and connectivity options.

– Print Size: Determine the dimensions of the stickers you’ll be printing. Some printers may only accommodate smaller formats, which might not fit your needs.

– Resolution: Look for printers with a minimum of 300 DPI for high-quality prints.

2. Research Market Trends and Needs

Understanding market trends can significantly influence your purchasing decisions. Evaluate what types of stickers are popular in your target market.

– Customization: Assess the demand for personalized stickers. Printers that support various customization options can cater to diverse customer preferences.

– Durability: Investigate the need for waterproof or UV-resistant stickers, as these features can enhance product appeal.

Illustrative image related to mini sticker printer

3. Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, case studies, and references from similar industries or regions.

– Reputation: Look for suppliers with a solid track record and positive reviews from previous clients.

– Certifications: Verify any industry certifications or standards that the supplier adheres to, ensuring compliance with quality benchmarks.

4. Request Samples for Testing

Before making a bulk purchase, always request samples. This step allows you to evaluate the printer’s performance firsthand.

– Print Quality: Assess the clarity and color accuracy of the prints. Ensure they meet your expectations before proceeding.

– Functionality: Test the printer’s connectivity options and user interface. A seamless operation can significantly enhance productivity.

5. Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, engage in negotiations to secure the best pricing and terms.

– Bulk Discounts: Inquire about discounts for larger orders or long-term contracts. This can lead to significant cost savings.

– Warranty and Support: Ensure that the supplier provides a warranty and reliable customer support. This is crucial for resolving any potential issues post-purchase.

6. Understand Shipping and Delivery Logistics

Consider the shipping options and delivery timelines when finalizing your order. Efficient logistics can affect your business operations.

– Lead Times: Confirm the estimated delivery times and whether they align with your project timelines.

– Shipping Costs: Evaluate the shipping costs and consider suppliers that offer competitive rates or free shipping for larger orders.

7. Plan for After-Sales Support and Maintenance

Finally, assess the after-sales support options available from your chosen supplier. Ongoing support can enhance the longevity and performance of your investment.

– Technical Assistance: Ensure that the supplier offers technical support for troubleshooting and maintenance.

– Replacement Parts: Check the availability of replacement parts and consumables, as this can impact your operational efficiency over time.

Illustrative image related to mini sticker printer

By following this step-by-step checklist, B2B buyers can make informed decisions when sourcing mini sticker printers, ensuring they meet both operational and market demands.

Comprehensive Cost and Pricing Analysis for mini sticker printer Sourcing

What Are the Key Cost Components in Mini Sticker Printer Sourcing?

When sourcing mini sticker printers, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality of materials used, such as thermal printing paper and electronic components, significantly influences the overall cost. Higher quality materials often result in better print quality and durability, impacting the price.

-

Labor: Labor costs vary by region and production scale. In regions with lower labor costs, such as parts of Asia, manufacturing can be cheaper, while European and North American manufacturers may incur higher labor expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, maintenance, and utilities. Efficient production processes can reduce these overhead costs, which should be considered when evaluating suppliers.

-

Tooling: Initial setup costs for manufacturing, including molds and machinery, are essential to account for, especially for customized models. These costs can be amortized over larger production runs.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability but adds to the overall cost. Buyers should assess the supplier’s QC measures, as this can affect long-term satisfaction and reduce warranty claims.

-

Logistics: Shipping costs can vary widely depending on the destination, mode of transport, and Incoterms used. International shipping may incur additional tariffs and customs fees, which need to be factored into the total cost.

-

Margin: Suppliers typically apply a margin to cover their risks and ensure profitability. Understanding the margin expectations of suppliers can help in negotiations.

What Influences Pricing for Mini Sticker Printers?

Several factors can influence the pricing of mini sticker printers, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate for favorable terms when ordering in bulk.

-

Specifications and Customization: Unique specifications or custom features can increase production costs. Discussing these requirements early can help manage expectations around pricing.

-

Materials and Quality Certifications: Printers that use premium materials or have specific certifications (e.g., CE, RoHS) may be priced higher. Buyers should evaluate whether these features justify the increased cost.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their quality assurance and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is critical, as they dictate who bears the shipping costs and risks. Choosing favorable Incoterms can lead to cost savings.

How Can Buyers Negotiate Cost-Effective Deals for Mini Sticker Printers?

To achieve cost-efficiency when sourcing mini sticker printers, consider the following tips:

-

Leverage Relationships: Build strong relationships with suppliers, which can lead to better pricing and terms. Long-term partnerships often yield more favorable negotiations.

-

Understand Total Cost of Ownership (TCO): Analyze not just the purchase price but also ongoing costs such as maintenance, supplies, and potential repairs. This holistic view can guide better purchasing decisions.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide leverage in negotiations. It also allows buyers to compare not just prices but also service levels and quality.

-

Negotiate Payment Terms: Favorable payment terms can improve cash flow. Discussing options such as delayed payments or installment plans can provide financial flexibility.

-

Consider Local Suppliers: For buyers in regions such as Africa and South America, sourcing from local suppliers can reduce shipping costs and lead times, making it a cost-effective option.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It is essential to note that prices for mini sticker printers can fluctuate based on market conditions, raw material availability, and currency exchange rates. Buyers should approach indicative prices with caution and seek formal quotes to ensure budget accuracy. Regularly revisiting pricing agreements can also help in adapting to changing market dynamics.

Alternatives Analysis: Comparing mini sticker printer With Other Solutions

Understanding Alternatives to Mini Sticker Printers

When evaluating printing solutions for stickers, labels, and photos, mini sticker printers are a popular choice due to their portability and ease of use. However, it’s essential to consider alternative technologies that may offer similar benefits while catering to specific business needs. This analysis compares mini sticker printers with label printers and digital printing services, helping B2B buyers make informed decisions.

Illustrative image related to mini sticker printer

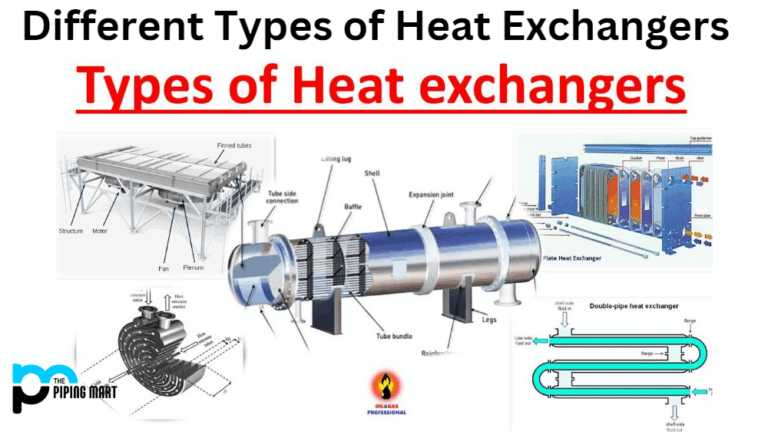

Comparison Table

| Comparison Aspect | Mini Sticker Printer | Label Printer | Digital Printing Service |

|---|---|---|---|

| Performance | High-quality, monochrome prints | High-quality, color prints | High-quality, full-color prints |

| Cost | Moderate upfront cost | Generally lower cost per label | Higher initial setup and per print cost |

| Ease of Implementation | Simple Bluetooth connection | Easy setup, often USB connected | Requires design software and setup |

| Maintenance | Minimal, mainly paper replacement | Low, occasional maintenance | Moderate, depending on equipment |

| Best Use Case | Personalization and DIY projects | Bulk label printing for products | Large-scale marketing materials |

Detailed Breakdown of Alternatives

Label Printer

Label printers are designed specifically for producing labels in bulk, making them ideal for businesses that require extensive labeling solutions. These printers often use thermal transfer technology, which provides a cost-effective way to produce high-quality labels. The main advantage is their efficiency in producing large quantities at a lower cost per unit compared to mini sticker printers. However, they may lack the personalization features that mini sticker printers offer, making them less suitable for creative projects.

Digital Printing Service

Digital printing services allow businesses to produce high-quality, full-color prints on demand. This method is particularly beneficial for companies needing larger runs of stickers or labels with intricate designs. The primary advantage of digital printing is its ability to handle complex graphics and color variations, which are often beyond the capabilities of mini sticker printers. However, digital printing typically involves higher upfront costs and may require longer turnaround times, making it less convenient for urgent, small-scale projects.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between a mini sticker printer, label printer, or digital printing service, B2B buyers should consider their specific needs. For businesses focused on personalization, creative projects, or small batches, mini sticker printers provide a unique advantage. Conversely, if bulk production of labels is the goal, label printers are more cost-effective. For high-quality, complex designs requiring full-color prints, digital printing services might be the best choice despite higher costs. By assessing performance, cost, implementation ease, maintenance, and use cases, buyers can select the most suitable printing solution for their operational demands.

Essential Technical Properties and Trade Terminology for mini sticker printer

What Are the Essential Technical Properties of a Mini Sticker Printer?

When evaluating mini sticker printers, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several key properties that international B2B buyers should consider:

-

Printing Technology

Mini sticker printers typically utilize thermal printing technology, which operates without ink. This method uses heat to create images on specially coated thermal paper. The significance of this technology lies in its cost-effectiveness and ease of use, making it ideal for businesses looking to minimize operational costs while maintaining print quality. -

Print Resolution

Measured in dots per inch (DPI), print resolution indicates the clarity and detail of printed images. A higher DPI (such as 300 DPI) results in sharper and more vibrant prints. For B2B buyers, especially in creative industries or retail, high print resolution is essential for producing professional-quality stickers that can enhance branding and customer engagement. -

Connectivity Options

Many mini sticker printers offer Bluetooth and USB connectivity, allowing for seamless integration with smartphones, tablets, and computers. This flexibility is vital for businesses that require mobility and convenience in printing. Ensuring compatibility with various devices can significantly enhance operational efficiency and user experience. -

Paper Compatibility

The type and width of paper that a mini sticker printer can handle are important considerations. Common sizes include 53mm, 80mm, and 110mm. Understanding paper compatibility is crucial for businesses that need specific formats for labels or stickers, as it can affect production workflows and inventory management. -

Battery Life

For portable mini sticker printers, battery life is a critical factor, as it determines how long the device can operate without needing a recharge. A longer battery life allows for greater flexibility in usage, especially in field operations or during events. Buyers should look for printers that can last at least one week on a full charge for optimal performance. -

Durability and Build Quality

The materials used in the construction of a mini sticker printer can impact its longevity and reliability. Look for devices made from high-grade plastics or metals that can withstand frequent use and potential drops. Durability is especially important for businesses in industries like logistics or retail, where equipment may be subject to rough handling.

What Are Common Trade Terms Related to Mini Sticker Printers?

Understanding industry jargon is essential for navigating B2B transactions effectively. Here are some common terms relevant to the purchase and supply of mini sticker printers:

Illustrative image related to mini sticker printer

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that are then sold under another brand name. In the context of mini sticker printers, understanding OEM relationships can help buyers assess product quality and warranty options. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for businesses to manage inventory and cash flow. Suppliers often set MOQs to ensure that production and shipping costs are covered. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and other relevant information for specific products. For B2B buyers, issuing an RFQ can help compare multiple suppliers and negotiate better terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for clarifying shipping costs, risks, and insurance responsibilities, which can significantly impact the total cost of purchasing mini sticker printers. -

Lead Time

This refers to the time it takes from placing an order to receiving the products. For businesses that rely on timely delivery, understanding lead times is critical for effective inventory management and planning. -

Warranty Period

This is the duration during which a product is guaranteed to be free from defects. Knowing the warranty period is important for B2B buyers to ensure they are protected against potential product failures, which can disrupt operations and incur additional costs.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing mini sticker printers, ultimately enhancing their operational efficiency and product offerings.

Navigating Market Dynamics and Sourcing Trends in the mini sticker printer Sector

What Are the Current Trends Driving the Mini Sticker Printer Market?

The mini sticker printer market is experiencing significant growth, driven by the increasing demand for personalized and customizable products across various sectors. B2B buyers are particularly interested in the compact nature of these printers, which facilitate on-the-go printing for businesses in creative industries, education, and e-commerce. Key trends include the adoption of thermal printing technology, which eliminates the need for ink, reducing operational costs and enhancing portability. Furthermore, the integration of Bluetooth and mobile app connectivity allows users to print directly from their smartphones, streamlining workflows and catering to the growing trend of remote work.

Emerging markets in Africa, South America, the Middle East, and Europe are witnessing a rise in small businesses and startups that leverage mini sticker printers for branding and promotional purposes. Countries like Vietnam and Germany are leading this shift, with businesses seeking affordable and efficient printing solutions. The focus on DIY projects and creative expression among younger consumers is also driving demand, as these printers enable users to create personalized stickers for planners, scrapbooking, and gifts. As the market evolves, B2B buyers must stay attuned to technological advancements and consumer preferences to capitalize on emerging opportunities.

How Are Sustainability and Ethical Sourcing Impacting the Mini Sticker Printer Industry?

Sustainability is becoming a critical consideration for businesses sourcing mini sticker printers. As consumers increasingly prioritize eco-friendly products, B2B buyers must evaluate the environmental impact of their supply chains. The mini sticker printer sector is responding by adopting sustainable practices, such as utilizing thermal printing technology, which is inherently more environmentally friendly due to its lack of ink and reduced waste.

Ethical sourcing is also gaining traction, with an emphasis on transparent supply chains and responsible manufacturing processes. Buyers should look for manufacturers that use recycled materials and offer products certified by recognized environmental organizations. Certifications such as Forest Stewardship Council (FSC) and Global Recycled Standard (GRS) can serve as indicators of a supplier’s commitment to sustainability. Additionally, focusing on suppliers who demonstrate a commitment to reducing their carbon footprint can enhance brand reputation and meet consumer expectations for corporate responsibility.

Illustrative image related to mini sticker printer

What is the Historical Context of Mini Sticker Printers in the B2B Market?

The evolution of mini sticker printers has been closely tied to advancements in printing technology and changing consumer behaviors. Initially, sticker printing was dominated by large, industrial-scale printers, which limited access for small businesses and individual creators. The introduction of compact, user-friendly devices in the late 2000s marked a turning point, making sticker printing more accessible.

As digital technology progressed, mini sticker printers transitioned from basic functionality to sophisticated devices capable of high-quality prints. The incorporation of thermal printing technology, which allows for inkless printing, significantly enhanced the usability and cost-effectiveness of these devices. Today, mini sticker printers are not just tools for printing; they have become integral to branding, marketing, and personal expression, particularly in the B2B sector where customization and efficiency are paramount. This historical context highlights the ongoing transformation of the mini sticker printer market, providing valuable insights for international buyers seeking to understand its trajectory.

Frequently Asked Questions (FAQs) for B2B Buyers of mini sticker printer

-

How do I choose the right mini sticker printer for my business needs?

Choosing the right mini sticker printer involves assessing your specific requirements such as print quality, speed, connectivity options, and paper size compatibility. For businesses that require high-quality stickers, look for printers that utilize thermal printing technology for crisp outputs. Additionally, consider the volume of printing—some models handle larger rolls and higher quantities better than others. Evaluate your workflow and whether you need mobile printing capabilities, as Bluetooth connectivity can enhance convenience for on-the-go tasks. -

What is the best mini sticker printer for small to medium-sized businesses?

For small to medium-sized businesses, the Phomemo M02 Pro stands out due to its balance of performance and affordability. It supports various paper sizes and is compact enough for easy transport. This model features fast printing speeds and high-definition outputs, making it suitable for producing custom stickers and labels efficiently. Additionally, its Bluetooth connectivity allows seamless integration with smartphones, enabling quick printing from anywhere, which is ideal for dynamic business environments. -

What are the typical payment terms when sourcing mini sticker printers internationally?

Payment terms can vary by supplier, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer net 30 or net 60 payment terms depending on your relationship and order volume. Always clarify payment methods accepted, such as wire transfers or letters of credit. It’s advisable to negotiate terms that protect your cash flow while ensuring the supplier has confidence in the transaction. -

What minimum order quantities (MOQ) should I expect when purchasing mini sticker printers?

MOQs for mini sticker printers typically range from 10 to 50 units, depending on the supplier and the specific model. Some manufacturers may have lower MOQs for certain products, while others may require higher quantities for custom orders. It’s essential to discuss your needs with potential suppliers and see if they can accommodate smaller orders, especially if you’re testing the market or starting a new product line. -

How can I ensure the quality of mini sticker printers when sourcing from overseas suppliers?

To ensure quality, conduct thorough supplier vetting by checking certifications, production capabilities, and customer reviews. Request samples before placing larger orders to assess print quality and durability. Additionally, consider third-party quality assurance services to inspect products before shipment. Clear communication about your quality expectations and standards is crucial in avoiding misunderstandings and ensuring that the final products meet your specifications. -

What logistics considerations should I keep in mind when importing mini sticker printers?

When importing mini sticker printers, consider shipping methods, lead times, and customs regulations in your country. Sea freight is cost-effective for larger orders but takes longer, while air freight is faster but more expensive. Ensure that you understand the import duties and taxes applicable to your product category, as these can significantly affect overall costs. Collaborating with a logistics partner experienced in international trade can streamline the process and mitigate risks. -

Can mini sticker printers be customized for branding purposes?

Yes, many suppliers offer customization options for mini sticker printers, including branding with your company logo or custom colors. Discuss your specific needs with potential suppliers, as some may require minimum order quantities for customized products. This can enhance your brand visibility and provide a unique touch for your products, making them more appealing to your customers. -

What are the best practices for maintaining mini sticker printers?

To maintain your mini sticker printer, regularly clean the print head and ensure the use of appropriate thermal paper. Avoid exposing the printer to extreme temperatures or humidity, which can affect performance. Follow the manufacturer’s guidelines for troubleshooting common issues and perform routine checks on connectivity and battery life if applicable. Keeping your printer in optimal condition will help extend its lifespan and ensure consistent print quality.

Top 7 Mini Sticker Printer Manufacturers & Suppliers List

1. Phomemo – Thermal Mini Printer

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Mini printers mentioned include Phomemo, HP Sprocket, Canon Ivy, and KODAK Step. Phomemo printer is favored for its thermal adhesive paper, offering various sizes and colors, but prints only in black or blue. Users report that the print lasts up to 20 years, but some find the images grainy or dark. The Canon Ivy is noted for its thickness, which can affect journal bulkiness, while the HP Sprocket …

2. Phomemo – Mini Thermal Printer

Domain: phomemo.com

Registered: 2018 (7 years)

Introduction: Mini Thermal Printer | Portable Photo Printer & Pocket Sticker Printer – Phomemo. Features: Portable design, inkless thermal technology, connects via Bluetooth, prints photos, notes, labels, and journal stickers. Compact size, delivers crisp prints, suitable for everyday life.

3. Phomemo – M02 Mini Photo Printer

Domain: misspettigrewreview.com

Registered: 2016 (9 years)

Introduction: Product Name: Phomemo M02 Mini Photo Printer

Type: Mini Sticker Printer

Color: Pink

Connectivity: Wireless, Bluetooth compatible

Charging: USB cable

Print Capability: Can continuously print 8.5 meters of thermal paper when fully charged

Printing Technology: Thermal printing (no ink needed)

Included Accessories: One roll of thermal paper, user manual, USB cable

App: Phomemo APP (free, includes stic…

4. Mini Pocket Thermal Printer – Wireless Bluetooth

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Mini Pocket Thermal Printer, Wireless Bluetooth, Photo Sticker Paper, Inkless Print, Brand New, Price Range: $6.99 to $26.92, Free delivery, Locations: Rowland Heights, CA; Hackettstown, NJ; Glen Allen, VA; Chino, CA; Las Vegas, NV; Ontario, CA, Includes options for open box and used conditions, Various models available with features like Bluetooth connectivity and multiple rolls of paper.

5. Marismix – Mini Inkless Thermal Portable Bluetooth Sticker Printer

Domain: marismix.com

Registered: 2024 (1 years)

Introduction: {“product_name”: “Mini Inkless Thermal Portable Bluetooth Sticker Printer”, “price”: “€47,96 EUR”, “original_price”: “€72,35 EUR”, “colors_available”: [“Pink”, “White”, “Blue”], “shipping_info”: “Free shipping with orders over 50€”, “features”: {“print_technology”: “Thermal (no ink needed)”, “compatible_devices”: [“iPhone”, “iPad”, “Android smartphones”, “tablets”], “control_method”: “Via mobile a…

6. HelloLeBT – Mini Printer Sticker Printer

Domain: hellolebt.com

Registered: 2024 (1 years)

Introduction: Mini Printer: Compact, versatile, and inkless mini printers designed for simplicity in printing. Ideal for organizing work plans, crafting bullet journals, and meeting diverse creative needs. Available products include:

1. Mini Printer Sticker Printer Print Pod with 6 Rolls Sticker Paper, Seven Color Lighting Modes for DIY Scrapbook, Travel, Notes, Label, Memo. Regular price: $50.00 USD (Sale pric…

7. Signs101 – Compact Sticker Printer & Cutter

Domain: signs101.com

Registered: 2003 (22 years)

Introduction: Looking for a small sticker machine that can print and cut small label stickers, capable of handling multiple designs. Preference for a machine that also laminates, though not essential. The user is a small business and does not require high volume production. Current method involves using a 54″ printer, which is time-consuming for larger projects.

Strategic Sourcing Conclusion and Outlook for mini sticker printer

What Are the Key Takeaways for B2B Buyers of Mini Sticker Printers?

The mini sticker printer market presents a wealth of opportunities for international B2B buyers, particularly in emerging markets such as Africa and South America. Key takeaways highlight the growing demand for portable, versatile printing solutions that cater to various applications—from creative projects to efficient labeling. By strategically sourcing mini sticker printers, businesses can capitalize on trends in personalization and DIY creativity, addressing the needs of diverse customer segments.

Illustrative image related to mini sticker printer

How Does Strategic Sourcing Enhance Business Operations?

Investing in the right mini sticker printers not only boosts operational efficiency but also enhances product offerings. The inkless thermal printing technology is both cost-effective and environmentally friendly, aligning with sustainability goals. Furthermore, the ability to integrate these devices with e-commerce platforms like Shopify streamlines the printing process, ensuring timely fulfillment and customer satisfaction.

What’s Next for International B2B Buyers?

As the market continues to evolve, international buyers should stay informed about technological advancements and supplier innovations. Engaging with manufacturers and distributors that prioritize quality and customer support will be crucial. Now is the time to explore partnerships that can drive growth, improve product offerings, and meet the rising demand for customized solutions. Embrace this opportunity to enhance your business’s competitive edge in the dynamic landscape of mini sticker printers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to mini sticker printer