Mini Forklift: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for mini forklift

Navigating the complex landscape of sourcing mini forklifts can present significant challenges for international B2B buyers, particularly those operating in dense urban environments or confined spaces. As businesses strive to optimize their material handling operations, the need for compact, efficient, and versatile equipment becomes paramount. This guide delves into the world of mini forklifts, highlighting various models and their specific applications, from warehouse operations to retail environments.

Buyers will find valuable insights on how to effectively vet suppliers, assess costs, and understand the technological advancements that enhance performance and safety. With a focus on markets across Africa, South America, the Middle East, and Europe—including key countries like Germany and Brazil—this guide empowers decision-makers to make informed choices tailored to their unique operational needs.

By exploring different types of mini forklifts, their ergonomic features, and energy-efficient technologies, you will be equipped to select the right equipment that not only meets your logistical requirements but also supports sustainability goals. Whether you are looking to maximize space utilization or enhance workplace safety, this comprehensive resource serves as your essential tool for navigating the global mini forklift market.

Understanding mini forklift Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compact Electric Forklifts | Extremely narrow (as small as 33.4”), electric-powered, low maintenance | Warehousing, retail, small manufacturing | Pros: Excellent maneuverability, low operational costs. Cons: Limited load capacity (up to 1,100 lbs). |

| Standing Electric Forklifts | Operator stands while operating, compact design, various lifting heights | Small warehouses, retail, logistics | Pros: Space-efficient, easy to operate in tight spaces. Cons: Less ergonomic for extended use. |

| Pallet Jacks | Manual or electric, designed specifically for pallet handling | Warehousing, distribution centers | Pros: Cost-effective, simple operation. Cons: Limited lifting height and capacity compared to forklifts. |

| Rough Terrain Mini Forklifts | Designed for uneven surfaces, higher ground clearance, durable tires | Construction, outdoor applications | Pros: Versatile in challenging environments. Cons: Heavier and less compact than standard mini forklifts. |

| Multi-Purpose Mini Forklifts | Adaptable with various attachments (e.g., clamps, forks) | Agriculture, construction, manufacturing | Pros: Versatility for different tasks. Cons: May require additional investment in attachments. |

What are the Characteristics of Compact Electric Forklifts?

Compact electric forklifts are specifically engineered for tight spaces, with widths as narrow as 33.4 inches, allowing them to maneuver through standard doorways and confined areas. These forklifts typically have a lifting capacity of up to 1,100 lbs, making them ideal for light to moderate material handling tasks in warehousing and retail settings. When considering a purchase, buyers should evaluate the operational efficiency, battery life, and maintenance needs, as these factors directly influence total cost of ownership.

How Do Standing Electric Forklifts Benefit Operations?

Standing electric forklifts are characterized by their ergonomic design, allowing operators to stand while handling materials. This design is particularly advantageous in small warehouses and retail environments where space is at a premium. They offer a variety of lifting heights, making them suitable for stocking shelves or handling pallets. Buyers should consider the comfort of their operators and the frequency of use, as prolonged standing can lead to fatigue.

Why Choose Pallet Jacks for Material Handling?

Pallet jacks, either manual or electric, are a fundamental tool in material handling, primarily used for moving pallets within warehouses and distribution centers. They are cost-effective and straightforward to operate, making them a common choice for small businesses. However, their limited lifting capabilities and height make them less suitable for tasks requiring significant elevation. When purchasing, businesses should assess their specific handling needs and the volume of pallet movement.

What Makes Rough Terrain Mini Forklifts Unique?

Rough terrain mini forklifts are designed to operate effectively on uneven surfaces, featuring higher ground clearance and durable tires. They are particularly useful in construction sites and outdoor applications where traditional forklifts may struggle. While they offer versatility in challenging environments, they tend to be heavier and less compact than standard mini forklifts. Buyers should evaluate the terrain they will be working on and the weight capacity needed for their operations.

How Do Multi-Purpose Mini Forklifts Enhance Flexibility?

Multi-purpose mini forklifts come equipped with various attachments, such as clamps and forks, allowing them to perform a range of tasks across different industries, including agriculture and construction. This adaptability can lead to increased efficiency and reduced need for multiple machines. However, prospective buyers should consider the additional costs of attachments and ensure compatibility with their operational requirements.

Illustrative image related to mini forklift

Key Industrial Applications of mini forklift

| Industry/Sector | Specific Application of mini forklift | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Warehousing & Logistics | Narrow aisle operations in warehouses | Maximizes storage space efficiency and improves inventory management | Capacity requirements, aisle width, battery life, and maintenance support |

| Retail | Stock replenishment in retail environments | Enhances customer experience by ensuring product availability and accessibility | Compact size, maneuverability, and operator safety features |

| Manufacturing | Transporting materials in assembly lines | Increases operational efficiency and reduces labor costs | Load capacity, lifting height, and compatibility with existing equipment |

| Food & Beverage | Handling goods in cold storage or freezer areas | Ensures compliance with safety standards and maintains product integrity | Temperature resistance, battery performance in cold environments, and hygiene standards |

| Construction | Moving materials in tight job site conditions | Facilitates quick and efficient material handling, reducing downtime | Durability, terrain adaptability, and safety features for operators |

How Are Mini Forklifts Utilized in Warehousing and Logistics?

In the warehousing and logistics sector, mini forklifts are invaluable for navigating narrow aisles and tight spaces. Their compact design allows for efficient stacking and retrieval of goods, maximizing storage capacity without sacrificing accessibility. This is particularly beneficial for businesses looking to optimize their inventory management systems. Buyers should consider the lift capacity and aisle width compatibility to ensure seamless integration into existing warehouse layouts.

What Role Do Mini Forklifts Play in Retail Environments?

In retail settings, mini forklifts are used for stock replenishment, enabling staff to quickly and efficiently restock shelves. This not only enhances product availability but also improves customer satisfaction by ensuring that popular items are always accessible. Retailers should focus on the maneuverability and operator safety features of mini forklifts to ensure a smooth operation in crowded store environments.

How Do Mini Forklifts Improve Manufacturing Processes?

Within manufacturing, mini forklifts are utilized to transport materials along assembly lines, streamlining production processes. Their ability to handle loads in confined spaces minimizes the risk of workplace accidents and boosts operational efficiency. When sourcing mini forklifts for manufacturing, businesses should evaluate load capacity, lifting height, and compatibility with existing machinery to optimize their workflows.

Why Are Mini Forklifts Essential in the Food & Beverage Industry?

In the food and beverage sector, mini forklifts are essential for handling goods in cold storage and freezer areas. They ensure compliance with health and safety regulations while maintaining the integrity of temperature-sensitive products. Buyers in this industry should prioritize features such as battery performance in low temperatures and hygiene standards to meet regulatory requirements.

How Do Mini Forklifts Enhance Construction Site Operations?

On construction sites, mini forklifts facilitate the movement of materials in tight job site conditions. Their compact size allows for efficient material handling, reducing downtime and improving overall project timelines. When sourcing mini forklifts for construction, buyers should consider durability, terrain adaptability, and safety features to ensure they can withstand the rigors of job site environments.

3 Common User Pain Points for ‘mini forklift’ & Their Solutions

Scenario 1: Limited Maneuverability in Tight Spaces

The Problem: Many warehouses and manufacturing facilities, especially in urban settings, are designed with limited space. B2B buyers often struggle with traditional forklifts that are too large to navigate narrow aisles or doorways. This can result in inefficiencies, increased labor costs, and even potential damage to goods or infrastructure. The inability to move materials efficiently can hinder productivity and lead to delays in operations.

The Solution: Mini forklifts are specifically designed to address this challenge. Their compact size allows them to operate in tight spaces, including narrow aisles and through standard office doorways. When sourcing a mini forklift, buyers should look for models with a small turning radius and adjustable wheelbases, as these features enhance maneuverability. Additionally, incorporating training for operators on how to efficiently navigate these machines can maximize their potential in confined environments. By investing in a mini forklift, businesses can improve their logistical efficiency and ensure a seamless flow of operations, even in space-restricted settings.

Scenario 2: High Maintenance Costs and Downtime

The Problem: A common pain point for B2B buyers is the high maintenance costs associated with traditional forklifts. Frequent repairs, downtime, and the need for specialized service can quickly add up, impacting the bottom line. Companies operating in competitive markets cannot afford delays or unexpected expenses, making reliable equipment a necessity.

The Solution: Mini forklifts, particularly those featuring AC technology, offer a solution to this issue. These forklifts are designed with fewer mechanical components, leading to lower maintenance requirements and costs. Buyers should prioritize mini forklifts with features such as power steering and energy-efficient systems that reduce wear and tear on the equipment. Additionally, selecting models with easily accessible components for routine checks can help minimize downtime. By investing in a mini forklift with robust engineering and lower maintenance needs, companies can enhance operational efficiency and reduce unexpected expenses.

Scenario 3: Operator Comfort and Safety Concerns

The Problem: In environments where mini forklifts are used extensively, operator comfort and safety are paramount. Poor ergonomics can lead to operator fatigue, reducing productivity and increasing the risk of accidents. B2B buyers often face challenges in selecting equipment that not only meets operational needs but also prioritizes the health and safety of their workforce.

The Solution: When sourcing mini forklifts, buyers should look for models that emphasize ergonomic design. Features such as adjustable steering columns, comfortable seating, and well-placed controls can significantly enhance operator comfort. Additionally, safety features like LED lights, stable wheelbases, and advanced braking systems should not be overlooked. Providing thorough training on safe operation and encouraging feedback from operators can help identify any further ergonomic improvements. By choosing a mini forklift designed with operator comfort and safety in mind, businesses can foster a more productive work environment while minimizing the risk of workplace injuries.

Strategic Material Selection Guide for mini forklift

What Are the Key Materials Used in Mini Forklift Construction?

When selecting materials for mini forklifts, several factors come into play, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of mini forklifts: steel, aluminum, plastic composites, and rubber.

How Does Steel Influence Mini Forklift Performance?

Key Properties: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for various operational environments. Steel also offers excellent corrosion resistance when treated with protective coatings.

Pros & Cons: The primary advantage of steel is its strength, which contributes to the overall durability of the forklift. However, steel is heavier than other materials, which can affect the forklift’s maneuverability in tight spaces. Manufacturing complexity is moderate, as steel can be easily welded and formed into various shapes.

Impact on Application: Steel is ideal for heavy-duty applications where high load capacities are essential. However, it may not be suitable for environments with high humidity unless adequately treated to prevent rust.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the steel used complies with local standards such as ASTM or ISO. In Europe, compliance with DIN standards is crucial, particularly for safety and performance.

What Role Does Aluminum Play in Mini Forklift Design?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It performs well in various temperatures and is non-magnetic, which can be advantageous in certain operational settings.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which enhances the forklift’s efficiency and reduces energy consumption. However, aluminum is generally more expensive than steel and can be more challenging to weld, increasing manufacturing complexity.

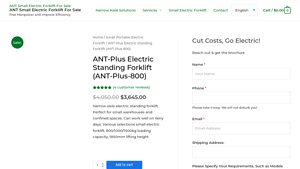

Illustrative image related to mini forklift

Impact on Application: Aluminum is particularly beneficial for mini forklifts operating in confined spaces, as its reduced weight allows for better maneuverability. It is also suitable for environments prone to corrosion, such as food processing or chemical handling.

Considerations for International Buyers: Buyers should verify that aluminum components meet international standards such as JIS in Japan or EN in Europe. Additionally, the higher cost may be a consideration for budget-conscious buyers in developing regions.

How Do Plastic Composites Enhance Mini Forklift Functionality?

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They also offer excellent insulation properties.

Pros & Cons: The main advantage of plastic composites is their resistance to chemicals and moisture, making them ideal for specific applications. However, they typically lack the strength of metals, which can limit their use in load-bearing components.

Impact on Application: These materials are well-suited for non-structural components like covers and panels, where weight savings and corrosion resistance are prioritized.

Considerations for International Buyers: Buyers should ensure that plastic composites meet relevant safety and performance standards, particularly in regions with strict regulations.

What Is the Importance of Rubber in Mini Forklift Applications?

Key Properties: Rubber offers excellent elasticity, shock absorption, and grip. It performs well under various temperatures and is resistant to wear and tear.

Pros & Cons: The primary advantage of rubber is its ability to provide traction and absorb shock, enhancing operator comfort. However, rubber can degrade over time when exposed to certain chemicals or extreme temperatures, which may necessitate more frequent replacements.

Impact on Application: Rubber is essential for tires and grips, providing stability and safety during operation. Its shock-absorbing properties also contribute to reducing operator fatigue.

Considerations for International Buyers: Buyers should consider the local climate and operational conditions when selecting rubber components. Compliance with international quality standards is also vital to ensure safety and performance.

Summary Table of Material Selection for Mini Forklifts

| Material | Typical Use Case for mini forklift | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and durability | Heavier, affects maneuverability | Medium |

| Aluminum | Frame and non-structural parts | Lightweight, corrosion-resistant | Higher cost, manufacturing complexity | High |

| Plastic Composites | Covers and panels | Corrosion-resistant, moldable | Limited strength for load-bearing | Medium |

| Rubber | Tires and grips | Excellent traction and shock absorption | Degrades over time with chemicals | Low |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for mini forklifts, ensuring they make informed decisions tailored to their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mini forklift

What Are the Main Stages of Mini Forklift Manufacturing?

The manufacturing process for mini forklifts involves several key stages, each critical to ensuring the final product meets performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to mini forklift

Material Preparation: Sourcing and Quality

The first step in the manufacturing process is material preparation. High-quality raw materials, such as steel and aluminum, are sourced from reputable suppliers. This stage often includes rigorous testing of materials to ensure they meet specific strength and durability requirements. Suppliers typically provide certifications that verify compliance with international standards, which is essential for B2B buyers looking for reliable products.

How Is Mini Forklift Formed?

Once materials are prepared, the next phase is forming. This involves cutting, bending, and shaping the raw materials into the components needed for the mini forklift. Advanced techniques such as laser cutting and CNC machining are commonly employed to achieve precision. For instance, the mast and chassis are formed to exact specifications to ensure stability and performance under load.

What Does the Assembly Process Involve?

The assembly process is where all individual components come together to form the complete forklift. This stage involves meticulous work, as each part must be aligned and secured correctly. Key components, such as the drive system, battery, and hydraulic systems, are integrated during this stage. Quality control checks are often performed at various assembly points to identify and rectify any issues early in the process.

What Finishing Techniques Are Used in Mini Forklift Production?

Finishing is the final stage of manufacturing, where the mini forklift is painted, assembled with safety features, and prepared for delivery. The paint used is typically durable and resistant to chipping and scratching, which is crucial for operational longevity. Additionally, features such as LED safety lights and ergonomic controls are installed, enhancing both operator comfort and safety.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) in mini forklift manufacturing is critical for ensuring safety and reliability. International standards like ISO 9001 are commonly adopted, which focus on maintaining quality management systems throughout the manufacturing process. This certification helps buyers verify that the manufacturer adheres to stringent quality controls.

Which Industry-Specific Certifications Are Important?

In addition to ISO 9001, mini forklifts may need to meet industry-specific certifications such as CE marking in Europe or API standards in certain applications. These certifications indicate that the product complies with health, safety, and environmental protection standards. For B2B buyers from regions like Africa or South America, ensuring compliance with local regulations is also essential, as these may vary significantly from international standards.

What Are the Key Quality Control Checkpoints?

Quality control is integrated into various stages of the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they are used in production. Ensuring that materials meet specified standards is vital for the quality of the final product.

-

In-Process Quality Control (IPQC): This phase includes monitoring the manufacturing process itself. Regular checks during assembly help catch defects early, minimizing waste and rework.

-

Final Quality Control (FQC): Before the mini forklifts are shipped, they undergo comprehensive testing to ensure they meet operational specifications. This may include load testing, battery performance checks, and functional tests of safety features.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for mini forklifts can vary based on the manufacturer but typically include:

- Load Testing: Ensures the forklift can handle its rated capacity safely.

- Durability Testing: Simulates long-term use to identify potential weaknesses in design or materials.

- Safety Feature Verification: Confirms that all safety systems, such as emergency brakes and stability controls, function correctly.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in international markets, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

-

Conduct Audits: Regular audits of potential suppliers can reveal their adherence to quality standards and manufacturing practices. Buyers should request audit reports to assess compliance with relevant certifications.

-

Request Documentation: Buyers can ask for quality assurance documentation, including ISO certifications, test reports, and compliance certificates. This documentation should be readily available from the manufacturer.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of the manufacturing process and the final product. This is particularly beneficial for buyers unfamiliar with local suppliers.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers must be aware of specific quality control nuances that can affect their procurement process. For instance, regulatory compliance may differ between regions, requiring buyers to understand local standards thoroughly. Additionally, language barriers can complicate communication about quality specifications and requirements, making it essential to establish clear channels of communication with suppliers.

How Do Cultural Differences Impact Quality Assurance?

Cultural differences can also play a role in quality assurance practices. Buyers from Europe may expect stricter adherence to safety standards compared to those from less regulated markets. Therefore, understanding the supplier’s cultural context can help buyers set realistic expectations and negotiate terms effectively.

Conclusion

The manufacturing and quality assurance processes for mini forklifts are intricate and essential for delivering reliable and safe products. B2B buyers must consider various factors, including manufacturing stages, quality certifications, testing methods, and verification processes, to ensure they are partnering with reputable suppliers. By staying informed and proactive, buyers can navigate the complexities of international procurement and secure high-quality mini forklifts tailored to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini forklift’

Introduction

This guide serves as a comprehensive checklist for B2B buyers aiming to source mini forklifts effectively. Mini forklifts are increasingly vital in various industries, especially for operations in confined spaces. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your specific operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your mini forklift. Consider factors such as lifting capacity, dimensions, battery type, and operational environment.

– Capacity Needs: Determine the maximum weight your forklift will need to lift. Models typically range from 750 lbs to 1,100 lbs.

– Space Constraints: Measure the width of aisles and doorways to ensure compatibility with the selected model. Many mini forklifts are designed to navigate tight spaces, with some as narrow as 33.4 inches.

Illustrative image related to mini forklift

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in mini forklifts. Look for companies with a proven track record in your target markets, such as Africa, South America, Europe, and the Middle East.

– Industry Experience: Prioritize suppliers with experience in your specific industry to ensure they understand your unique challenges.

– Customer Reviews: Check online reviews and testimonials to gauge the reliability and service quality of potential suppliers.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers comply with international safety and quality standards. This step is crucial to ensure that you are sourcing safe and reliable equipment.

– Certification Checks: Look for ISO certifications or local equivalents that indicate adherence to quality management systems.

– Safety Standards: Ensure that the mini forklifts meet relevant safety standards, such as those set by OSHA or ANSI, especially if operating in a high-risk environment.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, delivery times, and terms of service. This will allow you to compare offers effectively.

– Cost Breakdown: Ensure the quotation includes a breakdown of costs, including shipping and any additional fees.

– Warranty and Service Plans: Inquire about warranty periods and after-sales service options to understand the long-term value of your investment.

Illustrative image related to mini forklift

Step 5: Conduct Product Demonstrations

If possible, arrange for product demonstrations to assess the performance and ease of use of the mini forklifts you are considering. This step is essential for evaluating ergonomics and operational efficiency.

– Operator Comfort: Pay attention to features such as adjustable seating and control placement, which can significantly impact operator productivity.

– Maneuverability Tests: Test the forklift in conditions similar to your operational environment to assess its maneuverability and functionality.

Step 6: Assess Financing Options

Consider the financing options available for your mini forklift purchase. Understanding your financing choices can help you manage your budget effectively.

– Leasing vs. Buying: Evaluate whether leasing or purchasing is more advantageous based on your financial situation and operational needs.

– Government Incentives: Investigate any local or regional grants or incentives for purchasing energy-efficient or eco-friendly equipment.

Step 7: Finalize the Purchase Agreement

Once you have made a decision, finalize the purchase agreement with your chosen supplier. Ensure that all terms are clearly defined to avoid any misunderstandings.

– Contract Review: Have your legal team review the agreement to ensure all aspects are covered, including delivery timelines and warranty conditions.

– Payment Terms: Clarify payment terms, including any deposit requirements and payment schedules, to ensure smooth transaction processing.

Following these steps will help you navigate the complexities of sourcing mini forklifts effectively and ensure you select the right equipment for your operational needs.

Comprehensive Cost and Pricing Analysis for mini forklift Sourcing

What Are the Key Cost Components for Sourcing Mini Forklifts?

When evaluating the cost structure for mini forklift sourcing, several critical components contribute to the overall pricing. These include:

-

Materials: The type and quality of materials used significantly impact the cost. For mini forklifts, high-strength steel for the frame and durable plastic for components can elevate costs but enhance longevity and safety.

-

Labor: Skilled labor is essential in the assembly of mini forklifts, particularly for precision tasks like wiring and hydraulic system installation. Labor costs can vary widely based on geographical location and labor market conditions.

-

Manufacturing Overhead: This encompasses utilities, rent, and other fixed costs associated with the manufacturing facility. Efficient production lines can reduce overhead, positively influencing the final price.

-

Tooling: The initial investment in tooling for mini forklift production can be substantial, especially for custom designs or specialized features. This cost is often amortized over the production volume.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure the forklifts meet safety standards and operational efficiency. Enhanced QC can lead to higher costs but ultimately results in reduced warranty claims and improved customer satisfaction.

-

Logistics: Transportation costs, including shipping and handling, can add significant expenses, especially for international buyers. Factors like distance, mode of transport, and freight charges play crucial roles.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the industry standard margin can help buyers gauge fair pricing.

What Influences Pricing for Mini Forklifts?

Several factors can affect the pricing of mini forklifts, especially in the international B2B market:

-

Volume/MOQ: Bulk purchasing often leads to lower unit prices. Suppliers may offer discounts based on minimum order quantities (MOQs), making it advantageous for larger buyers.

-

Specifications and Customization: Custom features, such as specialized attachments or enhanced safety features, can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Quality and Certifications: Forklifts that meet international safety and quality standards (e.g., ISO certification) may command higher prices. However, these certifications can lead to lower total costs through increased reliability and reduced downtime.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers with a track record of delivering quality products may charge premium prices.

-

Incoterms: Understanding the terms of trade is crucial. Costs can vary significantly depending on whether the price includes shipping, insurance, and tariffs, which can add complexity to pricing negotiations.

How Can Buyers Optimize Costs and Negotiate Effectively?

To maximize value when sourcing mini forklifts, buyers should consider the following strategies:

-

Conduct Thorough Research: Understanding market trends and pricing benchmarks can empower buyers during negotiations. Compare quotes from multiple suppliers to identify competitive pricing.

-

Leverage Total Cost of Ownership (TCO): Evaluate the long-term costs associated with ownership, including maintenance, energy consumption, and potential downtime. This approach helps in assessing the true value of a forklift beyond the initial purchase price.

-

Negotiate Wisely: Engage in discussions about payment terms, discounts for larger orders, and delivery schedules. Don’t hesitate to ask for better terms, especially if you can offer a larger order volume or quicker payment.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times, improving overall efficiency and cost-effectiveness.

-

Be Mindful of Currency Fluctuations: For international transactions, currency exchange rates can significantly impact pricing. Locking in rates or negotiating in a stable currency can mitigate this risk.

Conclusion

Understanding the cost structure and pricing influencers for mini forklifts is vital for international B2B buyers. By leveraging strategic negotiation techniques and focusing on the total cost of ownership, businesses can make informed purchasing decisions that enhance operational efficiency and reduce long-term expenses. Prices may vary, and it’s essential to approach each sourcing opportunity with a comprehensive analysis of costs and value.

Alternatives Analysis: Comparing mini forklift With Other Solutions

Exploring Alternative Solutions to Mini Forklifts for Material Handling

In the quest for efficient material handling solutions, businesses often consider various equipment types to optimize their operations. Mini forklifts have gained popularity due to their compact size and maneuverability, especially in tight spaces. However, several alternatives may also serve similar purposes, offering distinct advantages depending on the specific needs of a business. Below, we compare mini forklifts with two viable alternatives: electric pallet jacks and standing forklifts.

| Comparison Aspect | Mini Forklift | Electric Pallet Jack | Standing Forklift |

|---|---|---|---|

| Performance | Lift capacity: 750-1,100 lbs; compact design for tight spaces | Lift capacity: up to 5,500 lbs; ideal for flat surfaces | Lift capacity: up to 3,000 lbs; efficient for limited spaces |

| Cost | Higher initial investment; cost-effective in the long run due to low maintenance | Lower initial cost; generally less durable | Moderate to high initial investment; long-term value with high efficiency |

| Ease of Implementation | Requires training; easy to integrate into existing operations | Simple to operate; minimal training needed | Requires operator training; some space needed for maneuvering |

| Maintenance | Low maintenance due to AC technology; regular inspections needed | Minimal maintenance; battery charging required | Moderate maintenance; more complex systems may require specialized service |

| Best Use Case | Ideal for warehouses with narrow aisles and office environments | Best for flat, open spaces and light lifting | Suitable for small to medium warehouses requiring flexibility in tight spaces |

What Are the Pros and Cons of Electric Pallet Jacks?

Electric pallet jacks are an efficient alternative for businesses focused on moving goods over flat surfaces. They are generally less expensive upfront and easier to operate, making them an attractive option for businesses with limited budgets or those new to material handling equipment. However, their performance is limited to lighter loads and flat terrains, and they may not be suitable for environments requiring maneuverability in tight spaces. Additionally, while they offer lower maintenance needs, they still require regular battery charging and basic upkeep.

How Do Standing Forklifts Compare to Mini Forklifts?

Standing forklifts offer a middle ground between mini forklifts and larger models. They are designed for small to medium warehouses and provide good maneuverability in tight spaces while allowing operators to stand. This design can enhance visibility and reduce fatigue during operation. However, standing forklifts typically have a lower lifting capacity compared to mini forklifts and may require more operator training. They can also be more complex to maintain due to their mechanical systems, potentially leading to higher long-term costs.

How Can B2B Buyers Choose the Right Material Handling Solution?

When evaluating options, B2B buyers should consider their specific operational needs, including the types of loads they handle, the layout of their workspace, and their budget constraints. Mini forklifts excel in compact environments where space is a premium, while electric pallet jacks are ideal for straightforward material movement across flat areas. Standing forklifts provide flexibility and visibility, making them suitable for varied tasks. Ultimately, the decision should align with the business’s workflow, safety requirements, and long-term operational goals to ensure maximum efficiency and productivity.

Illustrative image related to mini forklift

Essential Technical Properties and Trade Terminology for mini forklift

What Are the Key Technical Properties of Mini Forklifts?

Understanding the essential technical properties of mini forklifts is crucial for B2B buyers, especially when evaluating their suitability for specific operational environments. Here are several critical specifications that impact performance, safety, and efficiency.

-

Load Capacity

– The load capacity of a mini forklift indicates the maximum weight it can safely lift and transport. Typical capacities range from 750 lbs to 1,100 lbs for compact models. This specification is vital as it determines the types of loads that can be handled, ensuring operations remain within safe limits to prevent accidents and equipment damage. -

Mast Height and Lifting Range

– The mast height refers to how high the forklift can elevate loads, typically measured in inches. Mini forklifts can have lifting heights up to 169 inches. Understanding this property is essential for B2B buyers who need to operate in environments with limited vertical space, such as warehouses with low ceilings or retail spaces. -

Turning Radius

– The turning radius measures the space needed for the forklift to make a complete turn. Mini forklifts are designed to maneuver in tight spaces, often requiring a radius as small as 33.4 inches. This property is particularly beneficial for operations in confined areas, such as narrow aisles in warehouses, enhancing operational efficiency. -

Drive System

– The drive system, often rear-wheel drive for mini forklifts, affects how the vehicle handles and navigates. A rear-wheel drive system provides better stability and maneuverability, especially in tight spaces. Buyers should consider the drive system’s implications for operator comfort and ease of use in specific environments. -

Power Source and Battery Specifications

– Mini forklifts commonly utilize a 24V battery system, which impacts their operating time and efficiency. Battery specifications, including capacity (e.g., 375Ah), are crucial for determining how long the forklift can operate before needing a recharge. This information helps businesses plan shifts and reduce downtime. -

Safety Features

– Safety features such as ergonomic controls, adjustable seating, and LED safety lights are critical for operator comfort and accident prevention. Understanding these features can help B2B buyers select models that prioritize worker safety, thereby reducing liability and improving workplace morale.

What Are Common Trade Terms in the Mini Forklift Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are several common terms that buyers should know.

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of mini forklifts, knowing the OEM helps buyers understand the quality and reliability of components, which can influence purchasing decisions. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers who need to manage inventory levels effectively and negotiate terms with suppliers, especially when planning for bulk purchases. -

RFQ (Request for Quotation)

– An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. Crafting a clear RFQ helps streamline the procurement process, allowing buyers to compare offers from various suppliers efficiently. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms is essential for B2B transactions, especially in cross-border trade, as they clarify who is responsible for costs and risks during transport. -

Payload

– Payload refers to the total weight of the load that a forklift can safely carry, including the weight of the fork attachments. Understanding payload is essential for ensuring compliance with safety regulations and optimizing load management. -

Battery Cycle Life

– This term describes the number of charge and discharge cycles a forklift battery can undergo before its capacity significantly diminishes. Knowing the battery cycle life helps buyers assess long-term operational costs and battery replacement schedules.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting mini forklifts that best fit their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the mini forklift Sector

What Are the Key Drivers and Trends in the Mini Forklift Market?

The global mini forklift market is witnessing significant growth driven by several factors. One major driver is the increasing demand for efficient material handling solutions in confined spaces, particularly in urban environments where warehouse sizes are shrinking. In regions like Africa and South America, rapid industrialization and urbanization are pushing businesses to adopt compact forklifts that can maneuver in tight spaces. Furthermore, advancements in battery technology, particularly the adoption of 24V AC systems, are enhancing the efficiency and performance of mini forklifts, leading to reduced maintenance costs and improved operator comfort.

Emerging technologies such as IoT integration and automation are also reshaping the mini forklift landscape. Smart forklifts equipped with sensors can provide real-time data on operational efficiency, maintenance needs, and safety compliance, which is highly appealing to B2B buyers looking to optimize their logistics. Additionally, the growing trend of e-commerce in Europe, particularly in countries like Germany, is driving demand for mini forklifts capable of rapid and efficient order fulfillment in small warehouses.

Lastly, the shift toward sustainable practices is prompting manufacturers to innovate. Buyers are increasingly looking for forklifts that not only meet their operational needs but also align with their sustainability goals, influencing sourcing decisions.

How Is Sustainability Shaping the Mini Forklift Supply Chain?

Sustainability is becoming a critical consideration for B2B buyers in the mini forklift sector. The environmental impact of traditional material handling equipment has prompted companies to seek greener alternatives. Mini forklifts, particularly electric models, offer a lower carbon footprint compared to their gas-powered counterparts. As a result, many manufacturers are focusing on developing energy-efficient models that utilize sustainable materials and innovative production processes.

Ethical sourcing is also gaining traction, with businesses increasingly prioritizing suppliers that adhere to responsible labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential for suppliers seeking to establish credibility in the market. B2B buyers are advised to consider suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly and ethically.

Moreover, the importance of recyclability and the use of non-toxic materials in the production of mini forklifts is rising. Buyers should look for products that are designed with the end-of-life in mind, promoting a circular economy where materials can be reused or recycled, thus reducing waste.

How Has the Mini Forklift Evolved Over Time?

The evolution of mini forklifts can be traced back to the growing need for efficient material handling solutions in increasingly compact spaces. Initially, forklifts were large, cumbersome machines primarily designed for extensive warehouse operations. However, as urbanization intensified and warehouse spaces became more confined, the demand for smaller, more maneuverable forklifts grew.

The introduction of electric models marked a significant turning point, as they offered a quieter, more environmentally friendly alternative to traditional gas-powered forklifts. Innovations such as advanced battery technologies and ergonomic designs have further enhanced their appeal, making them a preferred choice for businesses operating in tight spaces. Today, mini forklifts represent a blend of efficiency, safety, and sustainability, adapting to the diverse needs of modern B2B operations across the globe.

Illustrative image related to mini forklift

In conclusion, the mini forklift sector is poised for significant growth, driven by market dynamics that prioritize efficiency, sustainability, and technological advancement. B2B buyers should stay informed about these trends to make strategic sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of mini forklift

-

How do I determine the right mini forklift for my business needs?

To choose the right mini forklift, assess your operational requirements, including load capacity, lift height, and workspace dimensions. Consider the specific environment in which the forklift will operate, such as narrow aisles or confined spaces. Additionally, think about the frequency of use and potential future expansion. Engaging with suppliers for demonstrations and reviewing technical specifications can provide insights into which model best aligns with your needs. -

What are the key features to look for in a mini forklift?

When selecting a mini forklift, prioritize features such as compact size, maneuverability, and lifting capacity. Look for advanced technologies like AC motors for efficiency and lower maintenance costs. Ergonomic design elements, such as adjustable steering columns and comfortable seating, enhance operator safety and productivity. Safety features like LED lights, integrated side shifts, and robust braking systems should also be considered to ensure safe operations in tight environments. -

What are the average costs associated with purchasing a mini forklift?

The cost of a mini forklift can vary significantly based on brand, specifications, and included features. Generally, prices can range from $3,000 to $10,000 or more. Additional costs may include shipping, customs duties, and after-sale services such as maintenance and training. It is advisable to obtain quotes from multiple suppliers to ensure you receive competitive pricing and to factor in long-term operational costs when making your decision. -

How can I ensure the reliability of my mini forklift supplier?

To vet a mini forklift supplier, conduct thorough research by checking their industry reputation, customer reviews, and length of operation. Request references from previous clients and analyze case studies relevant to your industry. Additionally, assess their customer service responsiveness and support options. Engaging in direct conversations about warranties, service agreements, and parts availability can also provide valuable insights into their reliability. -

What customization options are available for mini forklifts?

Many manufacturers offer customization options to meet specific operational needs. Common customizations include varying lift heights, battery types, and specialized attachments such as clamps or forks. Additionally, you can often choose colors or branding to align with your company’s identity. Discuss your requirements with potential suppliers to understand the extent of customization available and any associated costs. -

What are the typical minimum order quantities (MOQ) for mini forklifts?

Minimum order quantities can vary by supplier and region. Some manufacturers may allow single-unit purchases, while others may require bulk orders of 5-10 units to secure lower pricing. Understanding your operational needs and future growth plans can help determine if a bulk order is feasible. Always clarify MOQs with suppliers before proceeding with negotiations to avoid unexpected commitments. -

What payment terms should I expect when purchasing a mini forklift?

Payment terms for mini forklifts typically vary by supplier and may include options such as upfront payment, installment plans, or financing. Common practices involve a deposit at the time of order, followed by the remaining balance upon delivery. International buyers should also be aware of currency fluctuations and potential additional fees related to cross-border transactions. Always negotiate clear terms and confirm them in writing before finalizing the purchase. -

How is logistics handled for international shipments of mini forklifts?

Logistics for international shipments of mini forklifts involves coordinating with freight forwarders and understanding import/export regulations in your country. Suppliers usually provide shipping options, which can include sea or air freight depending on urgency and budget. Ensure that you discuss packaging, insurance, and customs clearance processes with your supplier. Additionally, familiarize yourself with local import duties and taxes to avoid unexpected costs upon arrival.

Top 3 Mini Forklift Manufacturers & Suppliers List

1. Mariotti – Mini Series

Domain: mariottiusa.com

Registered: 2002 (23 years)

Introduction: {“series_name”: “Mini Series”, “description”: “The Mini Series contains models considered the ‘Most Compact Riders in the World’ with lift trucks as narrow as 43 inches, suitable for small spaces and able to drive through standard office doorways.”, “models”: [{“model_name”: “Mini 4”, “capacity”: “750 lbs”, “drive_system”: “Rear Wheel Drive”}, {“model_name”: “Mini 6”, “capacity”: “1,100 lbs”, “dri…

2. ANT-Plus – Electric Standing Forklift

Domain: smallelectricforklift.com

Registered: 2022 (3 years)

Introduction: ANT-Plus Electric Standing Forklift (ANT-Plus-800) – Narrow aisle electric standing forklift for small warehouses and confined spaces. Current price: $3,645.00 (original price: $4,050.00). Loading capacity: 800/1000/1500 kg. Lifting height: 1850 mm. Weight: 950 kg. Dimensions: 300 × 95 × 130 cm. Fully electric, zero emissions, easy maintenance. Models available: ANT-Plus-1000 (1300 kg), ANT-Plus-1…

3. VAT19 – R/C Mini Toy Forklift

Domain: vat19.com

Registered: 2002 (23 years)

Introduction: R/C Mini Toy Forklift with Rack, Pallets, Crates, and Boxes

– Price: $49.99

– Scale: 1:14

– Dimensions (Forklift): 11″ x 6.5″ x 3.25″

– Forklift raises to a height of 13.5″

– Lift capacity: 11 ounces

– Batteries required: 3 x AA, 1 x 9V (not included)

– Recommended age: 5+

– Accessories included: shelf, five pallets, four drums, two cargo loads, hinged crate, cardboard box

– Remote control feature…

Strategic Sourcing Conclusion and Outlook for mini forklift

What Are the Key Benefits of Strategic Sourcing for Mini Forklifts?

In conclusion, the strategic sourcing of mini forklifts presents significant advantages for international B2B buyers. These compact machines are not only designed for narrow spaces but also offer impressive lifting capacities, making them ideal for diverse operational environments across Africa, South America, the Middle East, and Europe. The integration of advanced technologies, such as AC motors and ergonomic designs, enhances productivity while minimizing maintenance costs.

The value of strategic sourcing lies in aligning your procurement processes with suppliers who can deliver quality, efficiency, and tailored solutions. Leveraging partnerships with manufacturers like Mariotti or ANT-Plus can ensure access to reliable equipment that meets specific industry needs, ultimately driving operational success.

How Can International Buyers Prepare for Future Trends in Mini Forklift Sourcing?

As the market continues to evolve, it’s essential for international buyers to stay informed about emerging trends in mini forklift technology and application. Investing in equipment that offers versatility and energy efficiency will be crucial. Engage with suppliers who are committed to innovation and sustainability, as these factors will play a pivotal role in enhancing your operational capabilities.

Illustrative image related to mini forklift

Take action today by evaluating your current equipment needs and exploring the latest mini forklift options. By doing so, you position your business for growth and efficiency in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.