Mini Engine Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for mini engine

The global market for mini engines presents a wealth of opportunities, yet navigating this landscape can be daunting for international B2B buyers. Sourcing reliable mini engines that meet specific performance and application needs is often complicated by varying supplier standards, quality assurance challenges, and fluctuating prices. This guide is designed to illuminate the complexities of the mini engine market, offering a comprehensive analysis of types, applications, and best practices for supplier vetting.

From innovative model kits that cater to hobbyists to robust engines used in industrial applications, the mini engine sector is diverse and rapidly evolving. Buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Vietnam and Germany—must understand these nuances to make informed purchasing decisions.

This guide empowers B2B buyers by providing actionable insights into cost structures, supplier evaluations, and market trends, ensuring that they can identify high-quality products that align with their operational needs. By synthesizing expert knowledge and practical strategies, this resource serves as a valuable tool for navigating the complexities of sourcing mini engines in a competitive global market.

Understanding mini engine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| V8 Engine Model Kit | Realistic assembly, internal combustion design | Educational kits, hobbyist markets | Pros: Engaging for STEM education; Cons: Complexity may deter beginners. |

| Inline 4 Cylinder Engine Kit | Compact design, efficient power-to-weight ratio | Automotive models, racing simulations | Pros: Space-saving; Cons: Limited power compared to larger engines. |

| Stirling Engine Kit | External combustion, operates on temperature differences | Educational tools, renewable energy demos | Pros: Eco-friendly; Cons: Less power output for practical applications. |

| Radial Engine Model Kit | Unique design, often used in aviation | Aviation models, educational purposes | Pros: Intriguing engineering design; Cons: Niche market demand. |

| Diesel Engine Model Kit | High torque, fuel efficiency, durability | Industrial applications, model making | Pros: Cost-effective operation; Cons: Heavier than gasoline engines. |

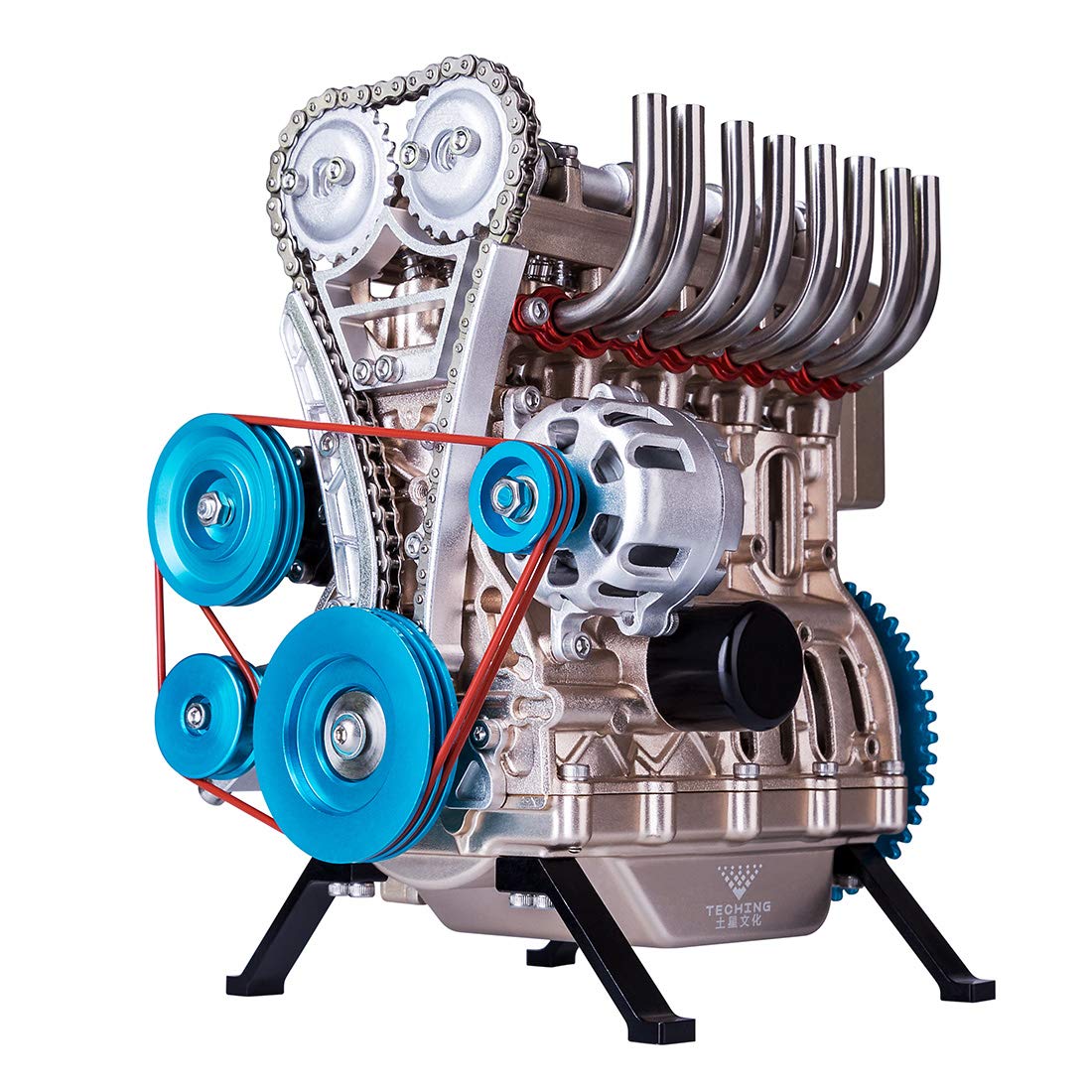

What are the Key Characteristics of V8 Engine Model Kits?

V8 engine model kits are designed to simulate real internal combustion engines, providing a detailed assembly experience. These kits often feature moving parts and realistic designs, making them ideal for educational purposes in STEM programs. B2B buyers in the educational sector or hobbyist markets will find value in these kits for their engaging and interactive nature. However, the complexity of assembly may pose challenges for beginners, requiring additional support or resources.

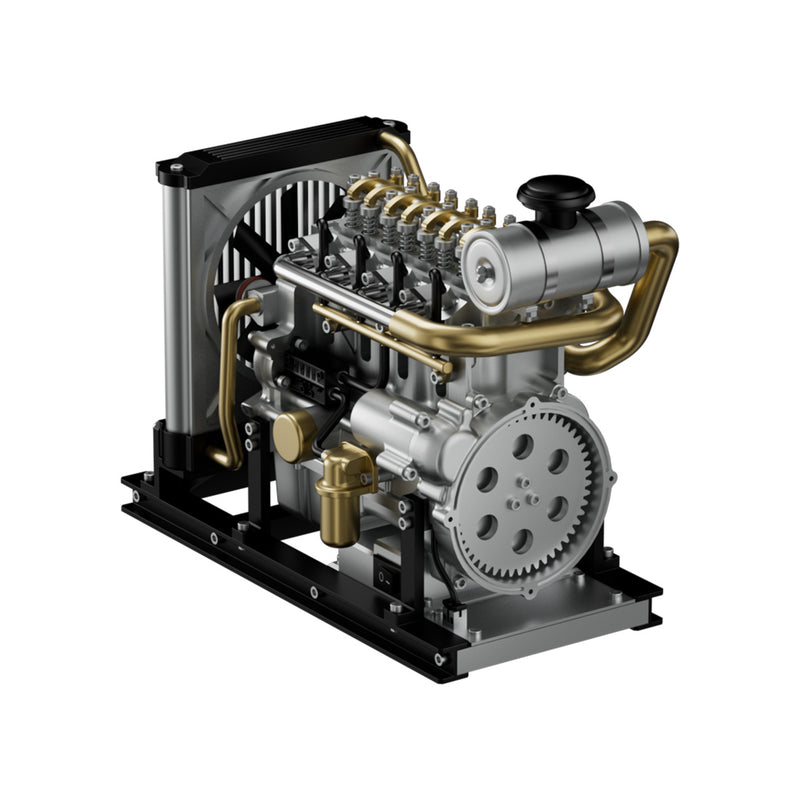

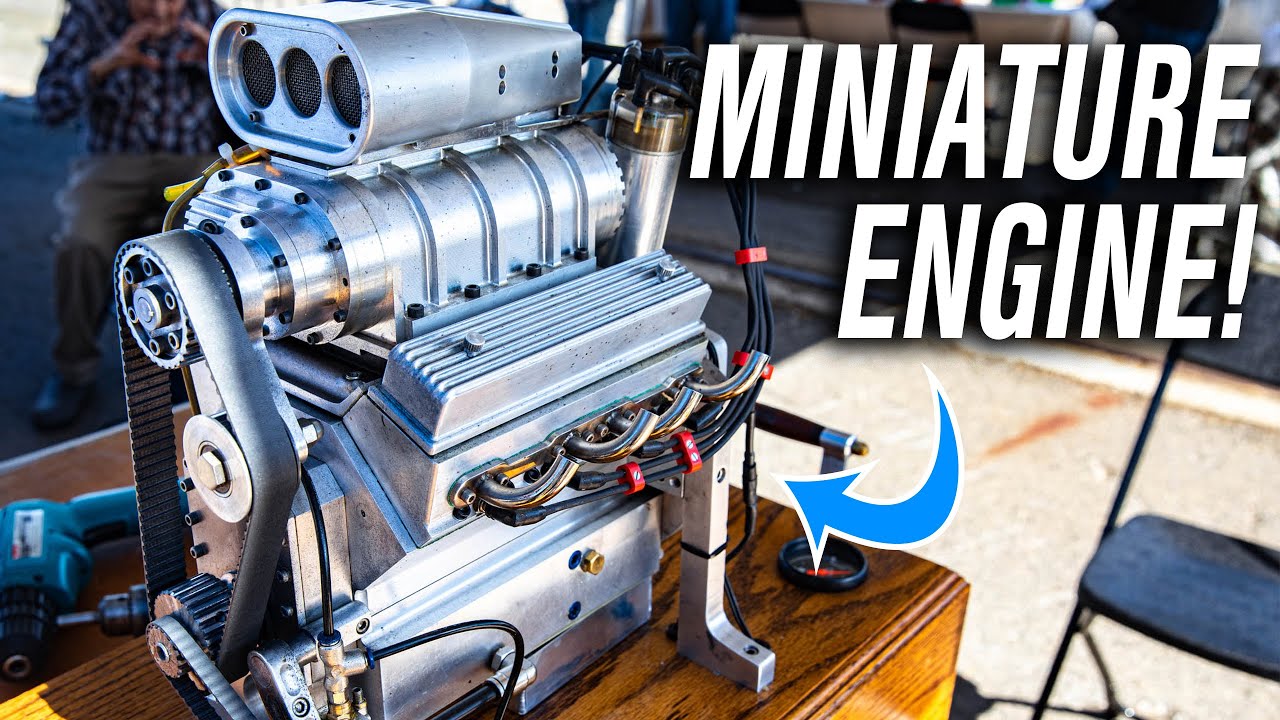

Illustrative image related to mini engine

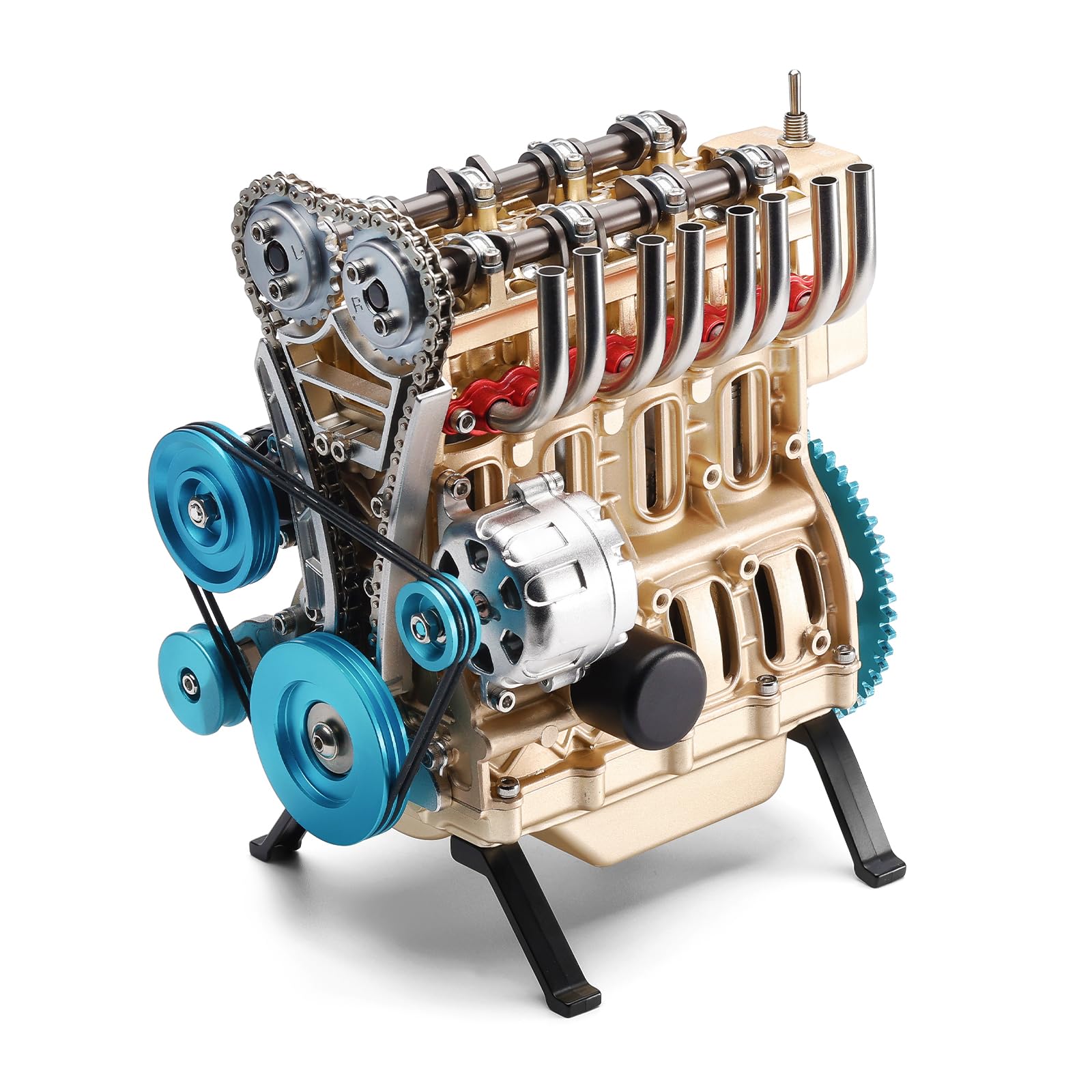

How Do Inline 4 Cylinder Engine Kits Stand Out?

Inline 4 cylinder engine kits are compact and efficient, making them popular among automotive enthusiasts and model makers. Their design allows for a balance between performance and space, ideal for smaller models or applications where weight is a concern. B2B buyers should consider the specific power requirements of their projects, as these engines may not deliver the same output as larger alternatives. Their simplicity can be advantageous for educational environments, promoting ease of understanding.

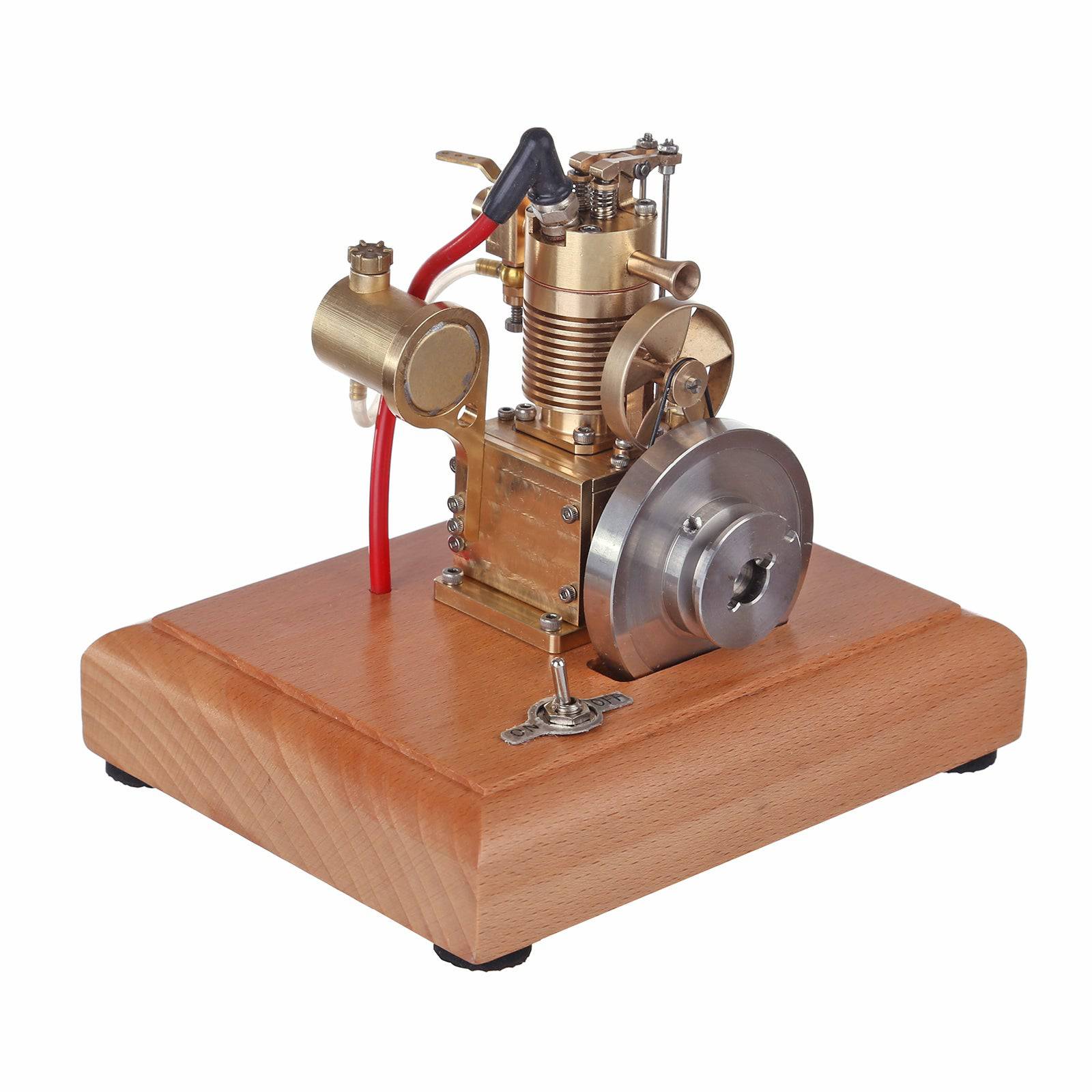

What Makes Stirling Engine Kits Unique?

Stirling engine kits operate on the principle of external combustion, using temperature differences to generate power. This eco-friendly approach makes them suitable for educational demonstrations in renewable energy. Businesses focusing on sustainability and innovation can leverage these kits to enhance their offerings. However, the lower power output may limit their practical applications, so buyers should assess their intended use carefully.

Why Choose Radial Engine Model Kits?

Radial engine model kits are characterized by their unique design and historical significance in aviation. These kits provide insights into the mechanics of radial engines, making them a valuable resource for educational institutions and aviation enthusiasts. While their niche appeal can be a drawback for mass-market applications, B2B buyers in specialized fields will appreciate the engineering challenges and learning opportunities they present.

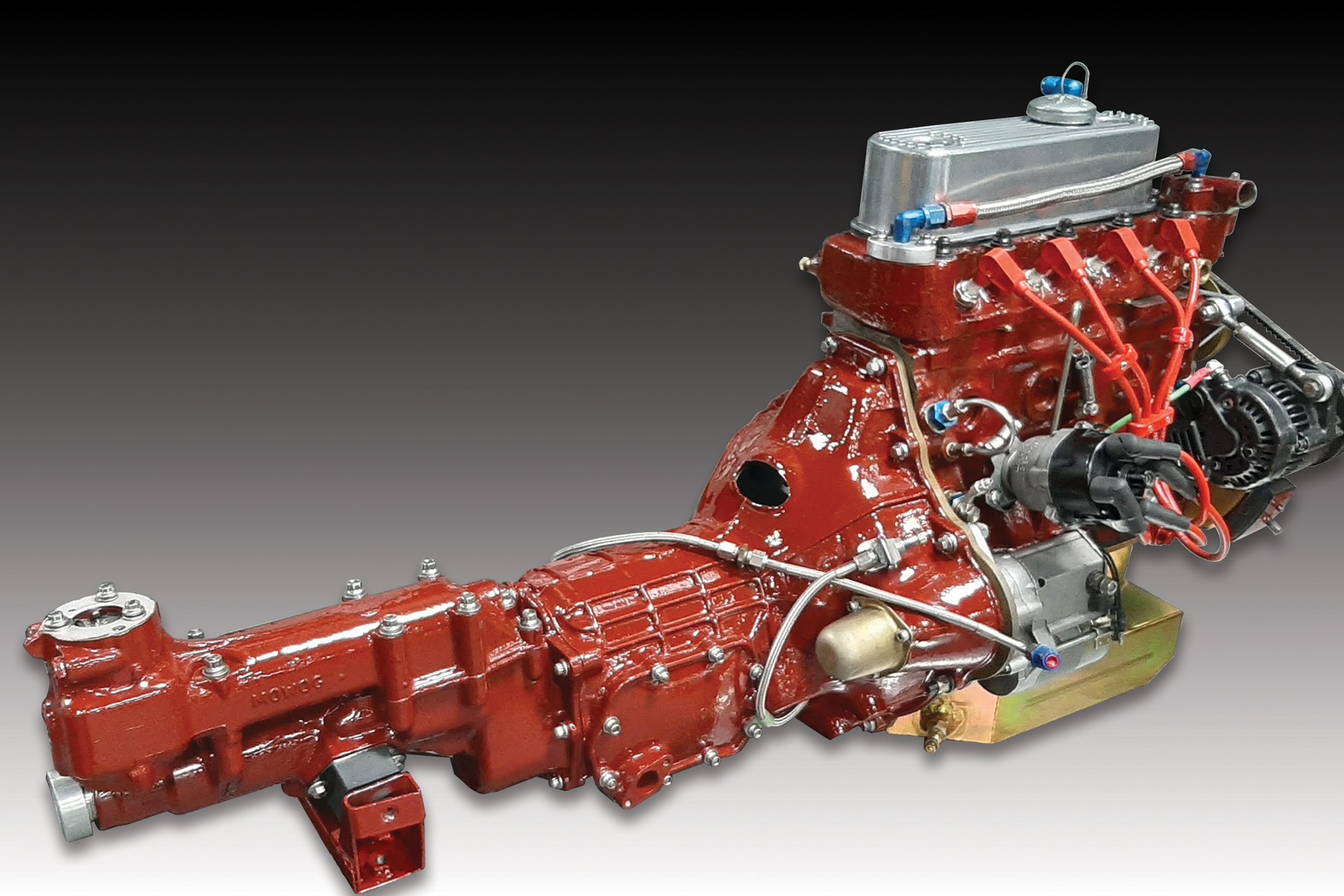

Illustrative image related to mini engine

What are the Advantages of Diesel Engine Model Kits?

Diesel engine model kits are known for their durability and fuel efficiency, making them suitable for industrial applications and model making. They offer high torque, which is advantageous for simulations requiring realistic power delivery. B2B buyers should consider the operational costs and weight implications of diesel engines, as they may be heavier than gasoline counterparts. However, their long-term cost-effectiveness makes them an attractive option for businesses focused on performance and reliability.

Key Industrial Applications of mini engine

| Industry/Sector | Specific Application of mini engine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Miniature engines for model car manufacturing | Enhances product offerings and engages hobbyist markets | Quality, precision in manufacturing, and cost-effectiveness |

| Education & Training | Educational kits for STEM learning | Fosters hands-on learning and technical skills development | Compliance with educational standards and safety regulations |

| Aerospace | Mini engines for aircraft model kits | Provides a realistic simulation for training and hobbyists | Authenticity in design, reliability, and ease of assembly |

| Agriculture | Mini engines in small farming equipment | Increases efficiency in small-scale farming operations | Durability, fuel efficiency, and adaptability to local conditions |

| Entertainment & Leisure | Mini engines in hobbyist model kits | Attracts enthusiasts and collectors, boosting sales | Availability of parts, customer support, and after-sales service |

How are Mini Engines Used in the Automotive Sector?

In the automotive industry, miniature engines are primarily utilized for model car manufacturing. These engines allow manufacturers to create realistic, functional models that appeal to hobbyists and collectors. By integrating mini engines into their products, companies can enhance their offerings and tap into a niche market that values precision and detail. For international buyers, it is crucial to consider sourcing high-quality components that ensure durability and performance while maintaining cost-effectiveness.

What Role Do Mini Engines Play in Education and Training?

Mini engines serve a significant role in educational settings, particularly for STEM (Science, Technology, Engineering, and Mathematics) programs. Educational kits featuring mini engines provide students with hands-on learning experiences, fostering technical skills and problem-solving abilities. When sourcing these kits, international buyers must ensure compliance with local educational standards and safety regulations, as well as the availability of instructional materials to facilitate effective learning.

How are Mini Engines Applied in the Aerospace Industry?

In the aerospace sector, miniature engines are commonly found in aircraft model kits. These engines offer enthusiasts a realistic simulation experience, making them ideal for training and educational purposes. For businesses in this sector, sourcing authentic and reliable mini engines is essential to meet the expectations of model builders. International buyers should prioritize suppliers who can guarantee authenticity in design, reliability, and ease of assembly to enhance customer satisfaction.

What Benefits Do Mini Engines Provide in Agriculture?

Mini engines find applications in small farming equipment, enhancing operational efficiency in small-scale agricultural settings. These engines power tools and machinery that are crucial for tasks such as irrigation and soil cultivation, particularly in regions where larger machinery may be impractical. When sourcing mini engines for agricultural applications, buyers must consider factors such as durability, fuel efficiency, and adaptability to local environmental conditions to ensure optimal performance.

How Do Mini Engines Enhance the Entertainment and Leisure Industry?

In the entertainment and leisure sector, mini engines are integral to various hobbyist model kits, including cars, boats, and airplanes. These kits attract enthusiasts and collectors, providing businesses with opportunities to boost sales through innovative product offerings. For international buyers, key sourcing considerations include the availability of replacement parts, customer support, and after-sales service, which are essential for maintaining customer loyalty and satisfaction in this competitive market.

3 Common User Pain Points for ‘mini engine’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Suppliers for Mini Engines

The Problem: B2B buyers often struggle to locate trustworthy suppliers for mini engines, particularly in emerging markets like Africa and South America. The challenge lies in ensuring that the supplier meets quality standards, delivers on time, and provides support for any technical issues that may arise. This uncertainty can lead to production delays, increased costs, and ultimately affect the buyer’s ability to serve their customers effectively.

The Solution: To overcome this challenge, buyers should conduct thorough research on potential suppliers. Start by leveraging platforms like Alibaba or industry-specific trade shows to identify manufacturers with positive reviews and certifications. Engage in direct communication with potential suppliers to assess their responsiveness and willingness to provide technical documentation. Establishing a small initial order can serve as a trial run to evaluate product quality and service before committing to larger purchases. Additionally, consider sourcing from suppliers who offer comprehensive after-sales support, including technical assistance and warranty services, to ensure that any issues can be resolved quickly.

Scenario 2: Complex Assembly and Maintenance Requirements

The Problem: Many mini engine models come with intricate designs that require specialized knowledge for assembly and maintenance. Buyers often face the frustration of navigating complex manuals or lacking the technical expertise necessary to put together these engines effectively. This pain point is particularly acute in regions where skilled labor is scarce or where training resources are limited, leading to wasted time and resources.

The Solution: To address this, buyers should prioritize sourcing mini engines that come with clear, detailed assembly instructions and video tutorials. Manufacturers who invest in creating comprehensive support materials can significantly ease the assembly process. Furthermore, consider partnering with local training organizations or technical schools to offer workshops on mini engine assembly and maintenance. This investment in human capital not only equips your team with the necessary skills but also fosters a culture of safety and efficiency within your operations. For ongoing maintenance, choose engines that are designed for easy access to parts, allowing for quicker repairs and reducing downtime.

Scenario 3: Navigating Regulatory Compliance and Standards

The Problem: B2B buyers often encounter regulatory hurdles when importing mini engines, especially in diverse markets like Europe and the Middle East. Compliance with safety and environmental regulations can be confusing and varies significantly by region. Failure to adhere to these regulations can result in fines, shipment delays, and reputational damage.

The Solution: To mitigate this risk, buyers should familiarize themselves with the specific regulations governing mini engines in their target markets. This can include emissions standards, safety certifications, and import tariffs. Engaging with a local compliance expert or legal advisor can provide valuable insights into the necessary documentation and procedures. Additionally, choosing to work with suppliers who are already compliant with international standards can streamline the process. Request certifications and compliance documentation upfront to ensure that the products meet the required regulations. Establishing a proactive approach to compliance not only protects the business from potential legal issues but also enhances your credibility in the market, fostering trust with customers and partners.

Strategic Material Selection Guide for mini engine

What are the Key Materials Used in Mini Engine Manufacturing?

When selecting materials for mini engines, several factors come into play, including performance, cost, and compliance with international standards. Here, we analyze four common materials used in mini engine construction: aluminum, steel, plastic composites, and brass. Understanding the properties, advantages, and limitations of these materials can guide international B2B buyers in making informed decisions.

Aluminum: A Lightweight Powerhouse

Aluminum is a popular choice for mini engines due to its lightweight and excellent thermal conductivity. It typically withstands temperatures up to 400°F (204°C) and exhibits good corrosion resistance, making it suitable for various applications. The manufacturing process for aluminum can be complex, often requiring precision machining and surface treatments.

Pros:

– Lightweight, enhancing engine efficiency.

– Good thermal conductivity aids in heat dissipation.

– Corrosion-resistant, extending the lifespan of the engine.

Illustrative image related to mini engine

Cons:

– More expensive than some alternatives like steel.

– Lower tensile strength compared to steel, which may limit application in high-stress environments.

– Requires careful handling during manufacturing to avoid deformation.

For international buyers, especially in regions like Africa and South America, understanding local aluminum sourcing and compliance with standards such as ASTM B221 is crucial.

Steel: The Strength Champion

Steel, particularly carbon and stainless varieties, is another common material for mini engines. It offers high strength and durability, with temperature ratings often exceeding 1,000°F (538°C). Steel’s resistance to wear and fatigue makes it suitable for high-performance applications.

Illustrative image related to mini engine

Pros:

– Exceptional tensile strength and durability.

– Cost-effective in large volumes, making it a preferred choice for manufacturers.

– Versatile, with various grades available for different applications.

Cons:

– Heavier than aluminum, potentially impacting engine efficiency.

– Prone to corrosion unless treated or alloyed.

– Manufacturing can be complex, requiring advanced techniques like forging or welding.

For B2B buyers in Europe, compliance with DIN standards is essential, while those in the Middle East may need to consider local regulations regarding material sourcing and environmental impact.

Plastic Composites: The Versatile Alternative

Plastic composites are increasingly used in mini engines, particularly in non-structural components. They can withstand moderate temperatures (up to 250°F or 121°C) and offer excellent chemical resistance.

Illustrative image related to mini engine

Pros:

– Lightweight and often less expensive than metals.

– Excellent resistance to corrosion and chemicals.

– Can be molded into complex shapes, allowing for design flexibility.

Cons:

– Lower strength compared to metals, limiting their use in high-stress applications.

– Temperature limitations can restrict their use in high-performance engines.

– Potential environmental concerns regarding disposal and recycling.

International buyers should consider local regulations on plastics, especially in regions like Europe where compliance with REACH and other environmental standards is mandatory.

Brass: The Corrosion-Resistant Choice

Brass, an alloy of copper and zinc, is often used in components like fittings and valves in mini engines. It exhibits excellent corrosion resistance and can handle temperatures up to 400°F (204°C).

Pros:

– High corrosion resistance, making it ideal for applications exposed to moisture.

– Good machinability allows for precise manufacturing.

– Aesthetic appeal for visible components.

Cons:

– More expensive than steel and aluminum.

– Weaker than steel, limiting its use in high-stress areas.

– Copper content may lead to environmental regulations regarding sourcing and recycling.

B2B buyers in regions like South America should be aware of the copper sourcing regulations and potential tariffs that may affect costs.

Summary Table of Material Selection for Mini Engines

| Material | Typical Use Case for mini engine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine blocks, housings | Lightweight and corrosion-resistant | Higher cost and lower tensile strength | High |

| Steel | Structural components, crankshafts | Exceptional strength and durability | Heavier and prone to corrosion | Medium |

| Plastic Composites | Non-structural parts, housings | Lightweight and design flexibility | Lower strength and temperature limitations | Low |

| Brass | Fittings, valves | High corrosion resistance | More expensive and weaker than steel | Medium |

This analysis provides a comprehensive overview of the materials commonly used in mini engine manufacturing, helping B2B buyers make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for mini engine

The manufacturing and quality assurance processes for mini engines are critical to ensuring product reliability, performance, and customer satisfaction. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these processes can help in making informed purchasing decisions. Below is an in-depth look at the typical stages of manufacturing and the associated quality control measures.

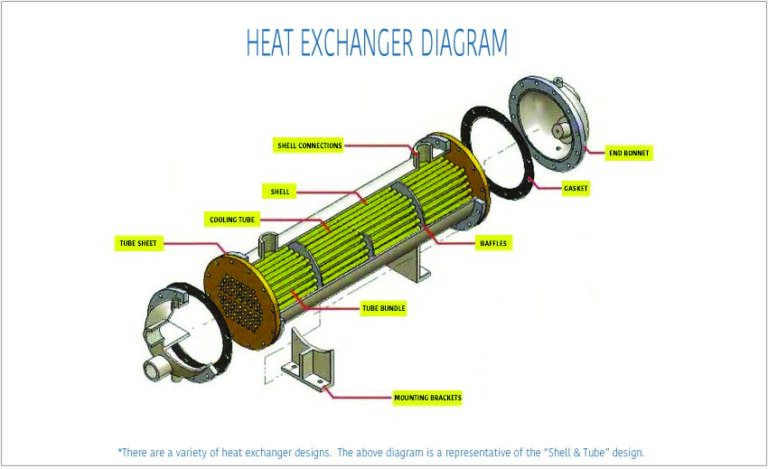

Illustrative image related to mini engine

What Are the Main Stages of Mini Engine Manufacturing?

How is Material Prepared for Mini Engine Production?

The manufacturing process begins with material preparation. The selection of high-quality materials is crucial, often involving metals such as aluminum, steel, and various alloys. These materials are typically sourced from reputable suppliers who adhere to international standards.

Once selected, the materials undergo various processes such as cutting, machining, and heat treatment to achieve the desired specifications. This stage may also include surface treatments to enhance corrosion resistance and durability.

What Forming Techniques Are Commonly Used in Mini Engine Manufacturing?

Forming techniques are essential for shaping the components of mini engines. Common methods include:

-

Casting: This involves pouring molten metal into molds to create engine blocks and other complex shapes. Precision casting ensures that the components have tight tolerances and high structural integrity.

-

Machining: After forming, components often undergo machining processes like milling and turning to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machines are widely used for their accuracy and efficiency.

-

Stamping and Forging: These techniques are employed for producing parts such as pistons and connecting rods, where high strength and durability are required.

How Does the Assembly of Mini Engines Take Place?

The assembly stage is where individual components come together to form the complete engine. This process typically follows a systematic approach:

-

Subassembly: Smaller groups of components are assembled first, such as the cylinder head, crankshaft, and camshaft assemblies.

-

Main Assembly: The subassemblies are then integrated into the engine block, often using automated assembly lines to enhance efficiency and precision.

-

Final Assembly: This includes the installation of ancillary components like fuel systems, ignition systems, and electrical wiring.

Proper torque specifications and assembly procedures are crucial to ensure the engine operates efficiently and reliably.

Illustrative image related to mini engine

What Finishing Processes Are Applied to Mini Engines?

After assembly, finishing processes enhance the engine’s performance and aesthetic appeal. These may include:

-

Surface Treatment: Processes such as anodizing, painting, or powder coating protect against wear and corrosion while improving appearance.

-

Balancing and Testing: Engines undergo dynamic balancing to minimize vibrations during operation. This is crucial for performance and longevity.

-

Final Inspection: Each engine is subjected to a thorough inspection to ensure it meets design specifications and quality standards before packaging.

What Quality Assurance Measures Are Essential for Mini Engine Production?

Which International Standards Are Relevant for Mini Engine Quality Control?

Quality assurance is paramount in mini engine production, and adherence to international standards is essential. The most relevant standards include:

-

ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent quality in products and services.

-

CE Marking: For engines sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

-

API Standards: For engines used in specific applications like oil and gas, adherence to American Petroleum Institute (API) standards is necessary for performance and safety.

What Are the Key Quality Control Checkpoints During Production?

Quality control checkpoints are integrated throughout the manufacturing process to ensure compliance and performance. Key checkpoints include:

Illustrative image related to mini engine

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, random samples are tested for dimensional accuracy, material properties, and other critical factors.

-

Final Quality Control (FQC): Before shipment, finished engines undergo a comprehensive inspection and testing process to validate performance and reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Effective strategies include:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities to assess their adherence to quality standards and manufacturing processes.

-

Requesting Quality Reports: Buyers can ask for detailed quality assurance reports, including IQC, IPQC, and FQC results, to gauge the supplier’s commitment to quality.

-

Third-party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of a supplier’s quality control processes and product reliability.

What Are the Quality Control Nuances for International Buyers?

International buyers face unique challenges regarding quality control, especially when sourcing from different regions. It is vital to consider:

-

Regulatory Compliance: Ensure that the supplier complies with local regulations in the target market, as non-compliance can lead to import issues.

-

Cultural and Operational Differences: Understanding cultural differences in manufacturing practices can help mitigate risks associated with quality assurance.

-

Communication: Establishing clear communication channels with suppliers can facilitate better understanding and adherence to quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance measures for mini engines is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside stringent quality control practices, buyers can make informed decisions that enhance their supply chain reliability and product performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini engine’

In the competitive landscape of mini engine procurement, having a structured approach is essential for B2B buyers. This guide provides a step-by-step checklist to streamline your sourcing process, ensuring that you select the right mini engine suppliers and products to meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes engine type (e.g., nitro, electric, or steam), size, power output, and intended application. A well-defined specification helps eliminate unsuitable options early and ensures that suppliers understand your precise needs.

- Consider compatibility with existing systems or machinery.

- Document performance expectations such as RPM and torque.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in mini engines. Look for manufacturers with a proven track record, especially those that cater to your specific industry or geographic region.

- Utilize B2B platforms such as Alibaba, ThomasNet, or industry-specific directories.

- Examine customer reviews and testimonials to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify the certifications and compliance of potential suppliers. Certifications like ISO 9001 or CE mark indicate adherence to quality and safety standards.

- Request documentation that confirms their compliance with international standards.

- Inquire about their quality control processes to ensure product consistency.

Step 4: Request Samples and Prototypes

Obtaining samples or prototypes is crucial for assessing the quality and performance of mini engines. This step allows you to evaluate the product firsthand before placing a larger order.

- Test for functionality and performance metrics outlined in your specifications.

- Assess the build quality and materials used to ensure durability.

Step 5: Negotiate Terms and Pricing

Once you have narrowed down your options, engage in negotiations regarding pricing, payment terms, and delivery schedules. Understanding the total cost of ownership, including shipping and potential tariffs, is vital for budgeting.

- Discuss volume discounts if you’re planning a bulk order.

- Clarify warranty and after-sales support to ensure long-term satisfaction.

Step 6: Finalize the Contract

Before placing an order, ensure all terms are documented in a formal contract. This should include delivery timelines, payment schedules, and return policies.

- Include clear terms regarding quality assurance and penalties for non-compliance.

- Consult legal experts if necessary to protect your interests.

Step 7: Establish a Relationship for Future Procurement

Building a strong relationship with your chosen supplier can lead to better pricing, faster response times, and improved service in the future. Maintain open lines of communication and provide feedback on the products and services received.

- Schedule regular check-ins to discuss performance and address any issues.

- Explore partnership opportunities for future projects or products.

By following this checklist, B2B buyers can approach mini engine procurement with confidence, ensuring that they select the best suppliers and products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for mini engine Sourcing

What Are the Key Cost Components in Mini Engine Manufacturing?

When sourcing mini engines, understanding the cost structure is critical for B2B buyers. The primary cost components include:

Illustrative image related to mini engine

-

Materials: The choice of materials significantly impacts costs. High-quality metals and plastics are commonly used, but sourcing from local suppliers can reduce expenses, especially for international buyers.

-

Labor: Labor costs vary greatly by region. Countries with lower wage standards may offer cost advantages, but this must be balanced against potential quality concerns. Skilled labor is essential for ensuring precise assembly, particularly for complex engine designs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient operations can minimize these costs, benefiting buyers in the long run.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider whether the supplier can absorb these costs or if they will be passed on.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specifications. While this adds to production costs, it is vital for maintaining the reliability of mini engines, which can affect end-user satisfaction.

-

Logistics: Shipping and handling costs are critical, particularly for international transactions. Factors such as distance, shipping method, and customs duties can all influence total logistics costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit margin. Understanding the markup can help buyers negotiate better pricing.

How Do Price Influencers Affect Mini Engine Costs?

Several factors influence the pricing of mini engines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it essential for buyers to assess their needs and negotiate accordingly.

-

Specifications and Customization: Customized engines with specific features or enhanced performance typically incur higher costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Engines made from premium materials or those that meet specific industry certifications (like ISO) may command higher prices. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial. These terms define responsibilities for shipping, insurance, and tariffs, affecting total costs significantly.

What Negotiation Tips Can Help Secure Better Pricing for Mini Engines?

Effective negotiation is key to achieving favorable pricing in B2B transactions. Here are some strategies:

-

Research and Benchmarking: Understand market prices and competitors’ offerings to strengthen your negotiation position.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better deals and more favorable terms.

-

Discuss Long-Term Partnerships: Offering to commit to ongoing orders can incentivize suppliers to provide better pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with the mini engine, including maintenance and operational costs, rather than just the upfront price.

-

Be Aware of Pricing Nuances for International Purchases: International buyers should account for currency fluctuations, import tariffs, and shipping costs, which can vary widely based on the supplier’s location.

Conclusion: How Should B2B Buyers Approach Mini Engine Sourcing?

While indicative prices for mini engines can range from $29.99 for simple kits to over $999.99 for complex models, the actual cost will depend on multiple factors discussed above. Buyers should conduct thorough due diligence, considering both direct and indirect costs, to make informed purchasing decisions. Understanding the cost structure and price influencers can lead to more successful negotiations and ultimately better value in sourcing mini engines.

Alternatives Analysis: Comparing mini engine With Other Solutions

Understanding Alternatives for Mini Engine Solutions

When considering the implementation of mini engines, it’s essential for B2B buyers to explore alternative technologies or methods that can achieve similar objectives. This analysis will compare mini engines with two viable alternatives: electric motors and Stirling engines. Each solution has unique attributes that cater to specific needs, so understanding their differences can facilitate informed decision-making.

Comparison Table

| Comparison Aspect | Mini Engine | Electric Motor | Stirling Engine |

|---|---|---|---|

| Performance | High torque, realistic simulations | Consistent power output | Efficient under stable conditions |

| Cost | $59.99 – $999.99 | $30 – $500 | $50 – $200 |

| Ease of Implementation | Moderate complexity | Easy to integrate | Requires precise assembly |

| Maintenance | Moderate, fuel-dependent | Low, minimal upkeep | Low, requires periodic checks |

| Best Use Case | Educational models, hobbyists | Industrial applications, automation | Eco-friendly applications, low-power uses |

Detailed Breakdown of Alternatives

Electric Motors

Electric motors are widely used in numerous applications ranging from household appliances to industrial machinery. They offer a consistent power output and are relatively easy to integrate into various systems. The cost of electric motors varies but generally ranges from $30 to $500, making them accessible for different budget levels. Their maintenance is minimal, often requiring just occasional checks. However, electric motors may not provide the same level of realism as mini engines in educational models or hobbyist projects, where the mechanical intricacies and visual appeal of traditional engines are valued.

Stirling Engines

Stirling engines present a unique alternative, utilizing external combustion to generate power. They are known for their efficiency and low environmental impact, making them suitable for eco-friendly applications. Costs for Stirling engines typically range from $50 to $200, positioning them as a cost-effective option for specific uses. While they require less maintenance than traditional internal combustion engines, they can be more complex to assemble and operate effectively. Stirling engines are best suited for applications where steady power output is required, but they may struggle in dynamic or variable conditions.

Conclusion: Choosing the Right Solution for Your Needs

In selecting the appropriate engine solution, B2B buyers should consider the specific requirements of their applications. Mini engines excel in providing a realistic and engaging experience for educational and hobbyist environments, while electric motors offer reliability and ease of integration for industrial needs. Stirling engines, on the other hand, provide an eco-friendly option with efficient power generation for stable applications. By evaluating the performance, cost, ease of implementation, maintenance requirements, and best use cases of each alternative, buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for mini engine

What Are the Key Technical Properties of Mini Engines?

When evaluating mini engines for purchase, understanding their technical specifications is crucial for making informed decisions. Here are some essential properties to consider:

-

Material Grade:

The materials used in mini engines significantly impact their durability and performance. Common materials include aluminum alloys, which provide a balance of lightweight and strength, and high-grade steel for critical components. Selecting engines made from high-quality materials ensures better resistance to wear and tear, which is vital for long-term operational efficiency. -

Tolerance:

Tolerance refers to the permissible limit of variation in a physical dimension. In mini engines, tight tolerances are critical for parts such as pistons and cylinders to ensure proper fit and function. Higher precision reduces friction and enhances engine efficiency, making it an important consideration for buyers looking to optimize performance in applications ranging from hobbyist projects to professional use. -

Displacement:

Engine displacement, usually measured in cubic centimeters (cc), indicates the total volume of all the cylinders in the engine. A higher displacement typically means more power output. For B2B buyers, understanding displacement helps in selecting engines that meet specific power requirements for applications, from remote-controlled vehicles to small machinery. -

Power Output:

Power output is a measure of the engine’s performance, usually expressed in horsepower (HP) or kilowatts (kW). This specification is critical for businesses that need to match engine capabilities with operational demands. When sourcing mini engines, it’s essential to ensure that the power output aligns with the intended application to avoid underperformance. -

Fuel Type:

Mini engines can run on various fuels, including gasoline, diesel, or electric power. Understanding fuel type is vital for operational planning and cost management. For instance, electric engines may require different infrastructure compared to traditional combustion engines. Buyers should consider fuel availability and compatibility with existing systems.

What Are Common Trade Terms Related to Mini Engines?

Familiarity with industry jargon can streamline communication and negotiations in the B2B space. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of mini engines, understanding OEM relationships can help buyers ensure they source quality parts that meet original specifications. -

MOQ (Minimum Order Quantity):

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses, knowing the MOQ is essential for budgeting and inventory management, particularly if they are entering new markets or scaling operations. -

RFQ (Request for Quotation):

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for specific products or services. Understanding how to craft and respond to RFQs can facilitate better purchasing decisions and foster competitive pricing in the mini engine market. -

Incoterms (International Commercial Terms):

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers navigate shipping and delivery responsibilities effectively. -

Lead Time:

Lead time refers to the amount of time from placing an order to receiving it. This metric is critical for businesses that rely on timely delivery for project timelines. Understanding lead times helps in planning and can also affect pricing and inventory strategies.

By grasping these technical properties and trade terms, B2B buyers can better navigate the complexities of sourcing mini engines, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the mini engine Sector

Understanding Market Dynamics and Sourcing Trends in the Mini Engine Sector

What Are the Global Drivers and Key Trends Affecting the Mini Engine Market?

The mini engine sector is witnessing significant growth, fueled by advancements in technology, increasing demand for compact power solutions, and the rise of hobbyist communities globally. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly seeking mini engines for applications ranging from educational purposes to model building and industrial applications. Key trends include the integration of digital technologies in sourcing processes and the use of additive manufacturing (3D printing) to create customized engine components, which allow for rapid prototyping and reduced lead times.

Furthermore, the globalization of supply chains is enabling buyers to tap into diverse sourcing networks. This trend is particularly relevant for international B2B buyers who are looking to establish reliable partnerships with manufacturers in emerging markets. Countries like Vietnam and Germany are becoming pivotal players in mini engine production, offering both cost-effective solutions and high-quality products. As manufacturers adapt to the evolving market dynamics, there is a noticeable shift towards modular designs that enhance versatility and ease of assembly, catering to the unique needs of various industries.

How Are Sustainability and Ethical Sourcing Impacting the Mini Engine Sector?

Sustainability and ethical sourcing have become paramount in the mini engine market, driven by increasing consumer awareness and regulatory pressures. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt greener practices. This includes utilizing sustainable materials and reducing waste during production. For B2B buyers, sourcing mini engines from manufacturers that adhere to environmental standards and possess certifications, such as ISO 14001, can enhance their brand image and appeal to eco-conscious consumers.

Moreover, ethical supply chains are essential in ensuring fair labor practices and transparency throughout the sourcing process. Buyers are encouraged to evaluate potential suppliers based on their commitment to ethical standards and sustainability initiatives. By prioritizing suppliers who demonstrate a clear dedication to environmental stewardship and social responsibility, businesses can mitigate risks associated with reputational damage and regulatory compliance.

What Is the Historical Context of the Mini Engine Market?

The mini engine sector has evolved significantly over the decades, transitioning from simple mechanical designs to sophisticated systems that incorporate advanced technologies. Initially, mini engines were primarily used for educational purposes and hobbyist projects. However, as technology progressed, the applications expanded into various industries, including automotive, aerospace, and renewable energy.

The introduction of digital manufacturing techniques and the rise of hobbyist communities in the late 20th century catalyzed innovation within the sector. Today, mini engines are not just toys or educational tools; they have become integral components in various applications, reflecting a broader trend towards customization and efficiency in manufacturing. This evolution underscores the importance of staying updated with market trends and technological advancements for B2B buyers navigating this dynamic landscape.

Illustrative image related to mini engine

In conclusion, the mini engine market is characterized by rapid advancements and evolving buyer expectations. By understanding these market dynamics, prioritizing sustainability, and considering historical context, international B2B buyers can make informed sourcing decisions that align with their strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of mini engine

-

How do I solve issues related to sourcing mini engines internationally?

To effectively solve sourcing issues for mini engines, start by identifying reliable suppliers in regions known for manufacturing, such as Asia and Europe. Conduct thorough research to check supplier credentials, including certifications and production capabilities. Utilize trade platforms and attend international trade fairs to connect with potential suppliers. Additionally, establish clear communication regarding quality standards, lead times, and compliance with local regulations to avoid misunderstandings that could impact delivery. -

What is the best mini engine type for small-scale projects?

The best mini engine for small-scale projects depends on the intended application. For educational purposes, a simple model like a Stirling engine kit is ideal due to its straightforward assembly and demonstration of basic principles. For hobbyists or collectors, a V8 engine model kit offers a more complex assembly experience and aesthetic appeal. Evaluate the project requirements, budget, and user experience level before making a decision to ensure the selected engine meets your needs. -

What are the typical minimum order quantities (MOQ) for mini engines?

Minimum order quantities (MOQ) for mini engines can vary significantly based on the supplier and the engine type. Generally, MOQs can range from 10 to 100 units for standard models, while custom-engineered products may require higher quantities. It’s crucial to negotiate MOQs with suppliers, especially if you are a smaller buyer or just starting. Some suppliers may offer flexible terms or sample orders to build trust before committing to larger purchases. -

What payment terms should I expect when sourcing mini engines?

Payment terms for sourcing mini engines typically vary by supplier and transaction size. Common arrangements include a 30% upfront deposit with the balance due before shipment or a letter of credit for larger orders. Always clarify payment options early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods to protect your investment and establish trust with your supplier, especially when dealing with international transactions. -

How can I ensure the quality of mini engines before purchase?

To ensure the quality of mini engines, request samples for testing before placing bulk orders. Verify the supplier’s quality control processes and certifications, such as ISO 9001, which indicate adherence to quality management standards. Additionally, consider third-party inspections or audits to assess production capabilities and quality assurance practices. Establishing clear quality standards in your purchase agreement can also help protect your interests. -

What logistics considerations should I keep in mind when importing mini engines?

Logistics is critical when importing mini engines. Be aware of shipping methods, costs, and transit times, as these can significantly impact your supply chain. Choose reliable freight forwarders experienced in handling international shipments. Understand customs regulations and duties in your destination country to avoid delays and unexpected costs. Additionally, consider warehousing options if you plan to import in bulk, ensuring you have adequate space for inventory management. -

How do I find trustworthy suppliers of mini engines?

To find trustworthy suppliers of mini engines, leverage online trade platforms like Alibaba or Global Sources, which feature supplier ratings and reviews. Attend industry trade shows to meet suppliers in person and evaluate their offerings. Utilize business networks and referrals from industry peers to identify reputable manufacturers. Conduct due diligence, including background checks and requesting references, to ensure the supplier has a solid track record of reliability and quality. -

Can I customize mini engines to meet specific requirements?

Yes, many manufacturers offer customization options for mini engines to meet specific requirements. Customizations may include size, materials, and engine specifications tailored to your project needs. When discussing customization, provide detailed specifications and design requirements to ensure the manufacturer understands your vision. Be prepared for potential lead time extensions and cost implications associated with custom orders, and ensure clear communication throughout the design and production phases.

Top 2 Mini Engine Manufacturers & Suppliers List

1. TECHING – Mini Engine Kit

Domain: enginediy.com

Registered: 2018 (7 years)

Introduction: Mini Engine Kit – Build Small/Miniature Model Engine Kit that runs. Brands include TECHING, CISON, RETROL, TOYAN, SKYMECH, ENJOMOR, SEMTO, MUSA, KACIO, HOWIN, RUIFEIYA. Various types of engines available: V8, V2, V12, Steam Engine, Jet Engine, IC Engine, E-Motors, Antique Engine, Diesel Engine, Motorcycle Engine, Car Engine Kits, 4 Stroke Engine, Stirling Engine, RC Models, and more. Products incl…

2. Stirling Kit – Engine Model Kits

Domain: stirlingkit.com

Registered: 2018 (7 years)

Introduction: Key product details include various engine model kits such as V8 Engine Kits, Inline 4 Engine Model Kits, Turbofan Engine Kits, Sterling Engine Kits, Steam Engine Kits, V Twin Engine Kits, and 3D Metal Model Kits. Brands featured are Toyan, Teching, Cison, Enjomor, Howin, Retrol, Musa, Skymechman, and Semto. Products include different types of engines like V2 Engine, 4 Stroke Engine, 4 Cylinder En…

Strategic Sourcing Conclusion and Outlook for mini engine

How Can Strategic Sourcing Enhance Your Mini Engine Procurement?

In the evolving landscape of mini engines, strategic sourcing emerges as a pivotal approach for international B2B buyers. By leveraging data-driven insights and supplier relationships, companies can optimize their procurement processes, reducing costs while ensuring quality and innovation. Understanding regional market dynamics—particularly in Africa, South America, the Middle East, and Europe—enables buyers to identify reliable suppliers who can meet their unique needs.

Investing in strategic sourcing not only mitigates risks associated with supply chain disruptions but also fosters collaboration with manufacturers that prioritize sustainability and technological advancement. As the demand for mini engines rises across various sectors, from automotive to educational kits, aligning procurement strategies with long-term business goals becomes essential.

Looking ahead, international buyers are encouraged to take proactive steps in their sourcing strategies. Embrace the opportunities presented by emerging markets and innovative suppliers to stay competitive. By focusing on strategic partnerships and leveraging the latest industry trends, you can ensure your business remains at the forefront of the mini engine market. Now is the time to explore these avenues and strengthen your supply chain for future success.

Illustrative image related to mini engine

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.