Mini Donut Machine Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for mini donut machine

In the competitive landscape of the food industry, sourcing a reliable mini donut machine can pose significant challenges for international B2B buyers. Whether you are looking to enhance your coffee shop’s menu in Saudi Arabia, launch a concession stand in Nigeria, or diversify offerings in a European bakery, understanding the intricacies of mini donut machines is crucial. This guide delves into the diverse types of machines available, their various applications, and essential factors to consider when vetting suppliers.

From automatic models that can produce up to 300 donuts per hour to portable options ideal for events and festivals, the choices are extensive and tailored to meet different business needs. Additionally, we will explore cost considerations, maintenance requirements, and the importance of reliable after-sales support to ensure your investment pays off.

By equipping yourself with the insights provided in this comprehensive guide, you will be empowered to make informed purchasing decisions that align with your operational goals. This resource aims to bridge the gap between buyers and suppliers, fostering a clearer understanding of the mini donut machine market across Africa, South America, the Middle East, and Europe. Whether you are a seasoned entrepreneur or venturing into the donut business for the first time, this guide will serve as your roadmap to success in the sweet world of mini donuts.

Understanding mini donut machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Mini Donut Maker | Fully automated operation, adjustable temperature, high output (300 donuts/hour) | Bakeries, coffee shops, concession stands | Pros: High efficiency, easy operation. Cons: Higher initial investment. |

| Electric Mini Donut Machine | Compact design, electric-powered, suitable for indoor use | Food courts, mall kiosks, events | Pros: Easy to use, no gas required. Cons: Limited to indoor environments. |

| Gas-Fired Mini Donut Machine | Operates on gas, portable, suitable for outdoor events | Festivals, fairs, outdoor catering | Pros: Greater mobility, can operate in various locations. Cons: Requires gas supply. |

| Countertop Mini Donut Maker | Smaller footprint, manual operation, lower output | Home-based businesses, small cafes | Pros: Cost-effective, space-saving. Cons: Limited production capacity. |

| Conveyor Mini Donut Machine | Continuous production line, integrates heating and feeding | High-volume bakeries, industrial applications | Pros: High output, consistent quality. Cons: Complex installation and maintenance. |

What are the Characteristics of Automatic Mini Donut Makers?

Automatic mini donut makers are designed for high efficiency, capable of producing up to 300 donuts per hour. They feature adjustable temperature settings and interchangeable nozzles for varying donut sizes. These machines are ideal for bakeries and coffee shops that require a steady supply of fresh donuts without extensive manual labor. When purchasing, consider the machine’s capacity, energy requirements, and the level of automation that aligns with your production needs.

How Do Electric Mini Donut Machines Differ from Other Types?

Electric mini donut machines are compact and designed for indoor use, making them perfect for food courts and mall kiosks. They typically require a standard electrical outlet, eliminating the need for gas. This type of machine is user-friendly and ideal for businesses looking to serve fresh donuts in a confined space. Buyers should assess the machine’s power consumption and output capacity to ensure it meets their operational demands.

What Advantages Do Gas-Fired Mini Donut Machines Offer?

Gas-fired mini donut machines are favored for their portability and ability to operate in outdoor environments, such as festivals and fairs. They provide a unique advantage by allowing vendors to set up in diverse locations without reliance on electrical outlets. However, these machines require a consistent gas supply. Businesses should evaluate the availability of gas sources in their target operating areas when considering this option.

Illustrative image related to mini donut machine

Why Choose Countertop Mini Donut Makers for Small Operations?

Countertop mini donut makers are designed for smaller-scale operations, making them suitable for home-based businesses or small cafes. They occupy minimal space and are generally more affordable than larger machines. While their output is limited, they offer a cost-effective solution for entrepreneurs starting in the donut business. Buyers should consider their space constraints and expected volume when selecting this type of machine.

What Makes Conveyor Mini Donut Machines Ideal for High-Volume Production?

Conveyor mini donut machines are engineered for continuous production, integrating heating and automatic feeding mechanisms. They are well-suited for high-volume bakeries and industrial applications where consistency and efficiency are paramount. While they offer significant output, the complexity of installation and maintenance can be a drawback. Businesses should ensure they have the technical expertise to manage these machines effectively.

Key Industrial Applications of mini donut machine

| Industry/Sector | Specific Application of mini donut machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Coffee Shops and Cafés | Increases menu offerings and customer footfall | Consider machine capacity, energy efficiency, and local service support. |

| Event Catering | Festivals and Fairs | Provides a popular, high-margin snack option | Evaluate portability, ease of operation, and local ingredient sourcing. |

| Retail and Concessions | Mall Kiosks and Food Courts | Enhances customer experience with fresh snacks | Look for compact designs and reliable performance under high demand. |

| Hospitality | Hotels and Resorts | Adds unique dining experiences for guests | Assess warranty, maintenance services, and customization options. |

| Education | School Fundraising Events | Engages community and raises funds effectively | Ensure compliance with local health regulations and ease of use for students. |

How Is a Mini Donut Machine Used in Coffee Shops and Cafés?

In coffee shops and cafés, mini donut machines are utilized to enhance the menu with freshly made donuts, appealing to customers seeking quick snacks alongside their beverages. This not only drives sales but also increases customer dwell time. Buyers in this sector should consider machines that offer high production rates and energy efficiency to ensure consistent quality during peak hours, along with local service support for maintenance.

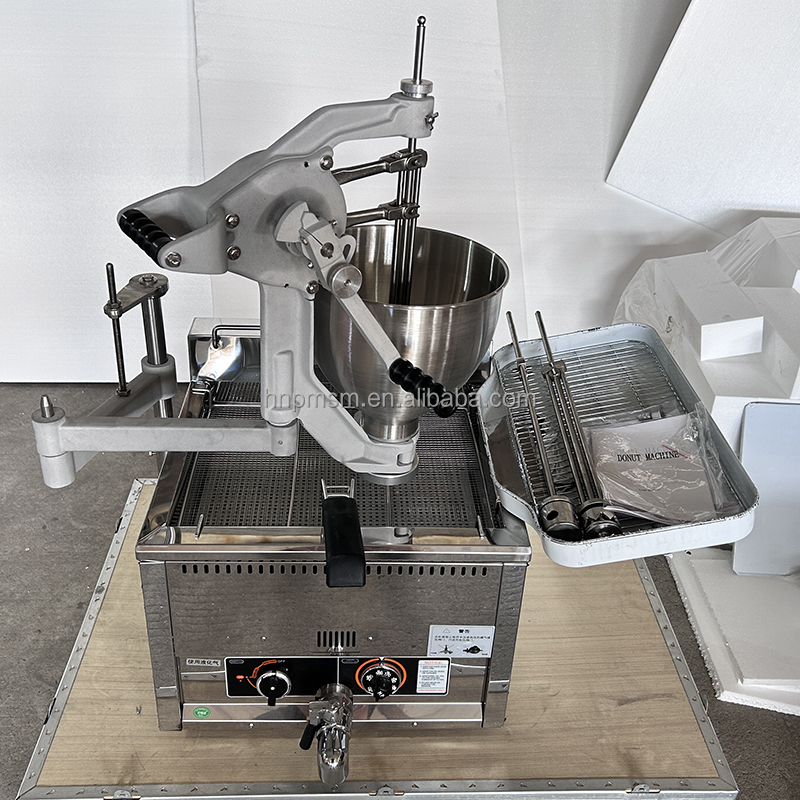

Illustrative image related to mini donut machine

What Role Does a Mini Donut Machine Play in Event Catering?

At festivals and fairs, mini donut machines serve as a vital component in catering operations, providing a beloved snack that draws crowds. They address the need for high-margin, quick-service food options that can be produced in volume. International buyers should prioritize portability and ease of use, ensuring that machines can operate effectively in various settings and that they can source ingredients locally to minimize costs.

How Can Mall Kiosks Benefit from Mini Donut Machines?

In mall kiosks and food courts, mini donut machines enhance the customer experience by offering fresh, hot donuts that attract shoppers. These machines can operate in limited spaces while meeting high demand, making them ideal for retail environments. When sourcing, businesses should look for compact designs that maintain performance reliability, ensuring they can meet customer expectations during busy periods.

Why Are Mini Donut Machines Important for Hotels and Resorts?

Hotels and resorts can leverage mini donut machines to create unique dining experiences that delight guests, especially during breakfast or brunch services. This adds value to their food offerings and can serve as a marketing tool to attract visitors. Buyers should consider the warranty and maintenance services available, as well as customization options for branding the donuts to enhance their guest experience.

How Do Mini Donut Machines Support School Fundraising Events?

In educational settings, mini donut machines are used for fundraising events, engaging students and the community while generating revenue. They solve the problem of providing attractive, affordable snacks that appeal to a wide audience. Buyers must ensure compliance with local health regulations and seek machines that are easy to operate, allowing students to participate in the fundraising efforts effectively.

Illustrative image related to mini donut machine

3 Common User Pain Points for ‘mini donut machine’ & Their Solutions

Scenario 1: High Production Demand during Peak Times

The Problem: Many B2B buyers in the food service industry experience significant pressure during peak business hours, such as festivals or sporting events. A common challenge they face is the inability of their mini donut machines to keep up with high production demands. This can lead to long wait times for customers and potential loss of sales. For example, a concession stand at a busy fair may find that their machine only produces a limited number of donuts per hour, causing frustration for both staff and customers.

The Solution: To effectively address this issue, buyers should consider investing in a high-capacity mini donut machine that can produce a larger volume of donuts per hour. For instance, machines that offer adjustable settings for donut thickness and temperature can help optimize production efficiency. Additionally, proper training of staff on the machine’s operation and maintenance can ensure smooth workflow during busy times. It’s also beneficial to have a backup unit on-site to avoid downtime, allowing for continuous production even if one machine requires maintenance or has a malfunction.

Scenario 2: Consistency in Quality and Taste

The Problem: Another pain point for B2B buyers is achieving consistency in the quality and taste of mini donuts. Variations in ingredients, machine settings, and operator techniques can lead to inconsistencies that disappoint customers. This is particularly critical for businesses that rely on repeat customers, such as coffee shops or food trucks, where brand reputation hinges on product quality.

The Solution: To ensure consistent quality, buyers should opt for machines that come with precise temperature controls and programmable settings. Utilizing pre-mixed dough or specific ingredient blends designed for mini donuts can also help maintain flavor consistency. Establishing standard operating procedures (SOPs) for staff on how to measure and mix ingredients, as well as how to operate the machine, will further enhance product uniformity. Regular quality control checks and customer feedback sessions can provide insights into any necessary adjustments, allowing businesses to fine-tune their offerings.

Scenario 3: Maintenance and Downtime Issues

The Problem: Frequent machine breakdowns or maintenance issues can be a significant pain point for B2B buyers. Not only does this lead to unexpected downtime, which affects service delivery and revenue, but it can also create additional operational stress for the staff. For example, a mini donut machine that requires frequent repairs may disrupt operations during a critical sales window, leading to customer dissatisfaction.

Illustrative image related to mini donut machine

The Solution: To mitigate maintenance issues, buyers should invest in high-quality machines that are known for their durability and reliability. It’s advisable to thoroughly research manufacturers and select those who offer comprehensive warranties and reliable customer support. Establishing a routine maintenance schedule can help identify potential issues before they escalate into major problems. Additionally, sourcing replacement parts from the original manufacturer ensures compatibility and reliability. Training staff on basic troubleshooting can empower them to handle minor issues quickly, reducing the likelihood of significant downtime.

By addressing these common pain points with proactive solutions, B2B buyers can enhance their mini donut machine operations, leading to improved customer satisfaction and increased profitability.

Strategic Material Selection Guide for mini donut machine

What are the Key Materials Used in Mini Donut Machines?

When selecting materials for mini donut machines, it is essential to consider their properties, advantages, disadvantages, and their impact on performance. This analysis focuses on four common materials used in the manufacturing of mini donut machines: stainless steel, aluminum, food-grade plastics, and cast iron.

How Does Stainless Steel Perform in Mini Donut Machines?

Stainless steel is a popular choice for mini donut machines due to its excellent corrosion resistance and durability. It can withstand high temperatures, making it suitable for cooking applications. Key properties include a high-temperature rating (up to 1,500°F) and resistance to oxidation and staining.

Pros: Stainless steel is robust, easy to clean, and maintains its appearance over time. It is also compliant with food safety regulations, making it a preferred choice for food processing equipment.

Illustrative image related to mini donut machine

Cons: The primary drawback is its higher cost compared to other materials. Additionally, while it is durable, it can be prone to denting if mishandled during installation or transport.

Impact on Application: Stainless steel is compatible with various cooking media, including oils and fats, ensuring consistent performance.

Considerations for International Buyers: Buyers should ensure compliance with local food safety standards, such as those outlined by the European Union (EU) or the Food and Drug Administration (FDA) in the U.S. It is also essential to verify that the stainless steel meets ASTM standards for food-grade applications.

Illustrative image related to mini donut machine

What Role Does Aluminum Play in Mini Donut Machine Manufacturing?

Aluminum is another common material used in mini donut machines, particularly for components that require lightweight and good thermal conductivity. It typically has a temperature rating of around 1,200°F.

Pros: Aluminum is lightweight, which simplifies transportation and installation. It also heats up quickly, allowing for efficient cooking.

Cons: However, aluminum is less durable than stainless steel and can be prone to warping at high temperatures. It also requires a protective coating to prevent corrosion.

Impact on Application: Aluminum’s thermal conductivity enhances cooking efficiency, but it may not be suitable for high-fat cooking media without proper treatment.

Illustrative image related to mini donut machine

Considerations for International Buyers: Buyers should be aware of the specific alloy used, as not all aluminum types are food safe. Compliance with international standards such as JIS (Japanese Industrial Standards) is crucial.

How Do Food-Grade Plastics Fit into Mini Donut Machine Design?

Food-grade plastics are often used for components that do not come into direct contact with high heat, such as handles and control panels. These materials can withstand moderate temperatures and are resistant to moisture.

Pros: They are lightweight and cost-effective, making them suitable for various applications in donut machines.

Illustrative image related to mini donut machine

Cons: Food-grade plastics may not be as durable as metals and can degrade over time, especially under high heat or exposure to oils.

Impact on Application: Their compatibility with food products makes them suitable for non-cooking components, but care must be taken to ensure they do not come into contact with hot surfaces.

Considerations for International Buyers: Buyers should verify that the plastics used meet local food safety regulations and standards, such as those set by the FDA or EU.

What Advantages Does Cast Iron Offer for Mini Donut Machines?

Cast iron is sometimes used in mini donut machines, particularly for frying components due to its excellent heat retention and distribution properties. It can handle high temperatures, typically exceeding 1,500°F.

Illustrative image related to mini donut machine

Pros: Cast iron provides superior heat retention, ensuring even cooking and reducing energy consumption. It is also incredibly durable when properly maintained.

Cons: The main drawback is its weight, which can complicate installation and transport. Additionally, cast iron requires regular seasoning to maintain its non-stick properties and prevent rust.

Impact on Application: Cast iron is ideal for frying applications, providing consistent results. However, it may not be suitable for all cooking media due to its porosity.

Considerations for International Buyers: Buyers should check for compliance with local health and safety regulations regarding cast iron cookware. It is also important to consider shipping logistics due to its weight.

Summary Table of Material Selection for Mini Donut Machines

| Material | Typical Use Case for mini donut machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Cooking surfaces, frames | Corrosion resistant and durable | Higher cost, prone to denting | High |

| Aluminum | Lightweight components | Lightweight and good thermal conductivity | Less durable, requires coating | Medium |

| Food-Grade Plastics | Handles, control panels | Cost-effective and lightweight | Less durable, can degrade over time | Low |

| Cast Iron | Frying components | Excellent heat retention | Heavy, requires maintenance | Medium |

Selecting the appropriate materials for mini donut machines is crucial for ensuring product performance and compliance with international standards. Understanding the properties and implications of each material can help B2B buyers make informed decisions that align with their operational needs and market demands.

Illustrative image related to mini donut machine

In-depth Look: Manufacturing Processes and Quality Assurance for mini donut machine

What Are the Key Stages in the Manufacturing Process of Mini Donut Machines?

The manufacturing process of mini donut machines involves several critical stages that ensure the production of high-quality equipment. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves sourcing high-quality materials, primarily stainless steel, which is preferred for its durability and resistance to corrosion. Stainless steel components are cut, shaped, and prepared according to the machine specifications. This stage may also involve the preparation of electrical components and heating elements, which are essential for the machine’s operation. Suppliers often conduct thorough inspections of raw materials to ensure they meet required standards.

Forming and Fabrication Techniques

In the forming stage, the prepared materials undergo various fabrication processes. Techniques such as CNC machining, laser cutting, and bending are employed to create the machine’s body and essential components. For instance, CNC machining allows for precise shaping of the stainless steel parts, ensuring they fit together seamlessly. Additionally, forming techniques may include welding and assembly of heating elements, which are crucial for efficient donut production.

Assembly of Components

Once the components are fabricated, they proceed to the assembly stage. This involves integrating the heating elements, temperature controls, and automatic flipping mechanisms into the donut machine’s body. Skilled technicians perform this assembly, ensuring that all parts are correctly fitted and securely fastened. During this phase, the focus is on the functionality and safety features of the machine, such as ensuring that the oil drainage systems work effectively to maintain hygiene.

Illustrative image related to mini donut machine

Finishing Processes

The final stage in the manufacturing process is finishing, which may include polishing the stainless steel surface for aesthetic appeal and applying protective coatings. This not only enhances the machine’s appearance but also extends its lifespan. Quality checks are performed during this stage to ensure that the machine meets design specifications and is free from defects.

How Is Quality Assurance Implemented in Mini Donut Machine Manufacturing?

Quality assurance (QA) is a vital component in the manufacturing of mini donut machines, ensuring that the final product meets industry standards and customer expectations. Various international standards, such as ISO 9001, and industry-specific certifications like CE and API, guide manufacturers in their QA processes.

What International Standards Apply to Mini Donut Machines?

ISO 9001 is a globally recognized standard for quality management systems. It emphasizes customer satisfaction and continuous improvement, requiring manufacturers to establish documented procedures and policies that ensure quality in their processes. CE marking indicates compliance with European health, safety, and environmental protection standards, which is crucial for machines marketed in Europe.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these certifications can provide confidence in the quality and safety of the equipment being procured.

Illustrative image related to mini donut machine

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure product integrity. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage checks the quality of raw materials upon receipt. Suppliers should provide documentation that confirms compliance with specified standards.

-

In-Process Quality Control (IPQC): During assembly and fabrication, ongoing inspections are performed to detect any defects early in the process. This may involve functional tests of components before they are assembled into the final product.

-

Final Quality Control (FQC): Once the mini donut machine is fully assembled, it undergoes a final inspection. This includes operational testing to confirm that the machine performs as expected, including checking the temperature control, oil drainage, and automatic flipping mechanisms.

What Common Testing Methods Are Used in Quality Assurance?

To ensure that mini donut machines meet quality standards, various testing methods are employed:

-

Functional Testing: This assesses the performance of the machine under normal operating conditions, verifying that it can produce the expected quantity of donuts without malfunction.

-

Safety Testing: This involves checking for electrical safety, including insulation resistance tests and verification of safety features to prevent overheating or electrical hazards.

-

Durability Testing: The machine is subjected to stress tests that simulate long-term use, ensuring that components can withstand the rigors of a commercial kitchen environment.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying the quality control measures of suppliers is crucial. Here are several ways to ensure that your supplier maintains high standards:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the quality management systems in place. This can be done by the buyer or through a third-party service.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation detailing their QA processes, including results from IQC, IPQC, and FQC stages. These reports can help assess the reliability of the manufacturing process.

-

Engage Third-Party Inspection Services: Hiring third-party inspection agencies to perform quality checks can provide an unbiased assessment of the machine’s quality before shipment.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers, particularly those in diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding QC and certification:

-

Local Regulations: Different countries may have varying regulatory requirements for food processing equipment. It is essential to understand the local certifications needed to ensure compliance with health and safety standards.

-

Cultural Considerations: Understanding the expectations of local markets regarding equipment quality and safety can help buyers make more informed decisions when selecting suppliers.

-

Logistics and Warranty Considerations: International shipping can complicate the return and warranty processes. Buyers should ensure that suppliers have clear policies for international returns and warranty claims, especially for large machinery.

In conclusion, understanding the manufacturing processes and quality assurance measures for mini donut machines is vital for B2B buyers aiming to invest in reliable and high-quality equipment. By recognizing key manufacturing stages, relevant quality standards, and effective verification methods, buyers can make informed purchasing decisions that align with their operational needs.

Illustrative image related to mini donut machine

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mini donut machine’

To assist B2B buyers in sourcing mini donut machines effectively, this guide provides a structured checklist that outlines essential steps to consider. Whether you are looking to equip a bakery, concession stand, or a coffee shop, following these steps will help ensure you make an informed purchasing decision.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the mini donut machine meets your operational needs. Consider factors such as production capacity, size, and power requirements. For instance, if you anticipate high demand, look for machines that can produce a substantial number of donuts per hour, such as those capable of producing 300 donuts hourly.

Step 2: Identify Your Target Market

Understanding your target market will help you choose the right machine and features. Are you catering to local events, festivals, or a permanent retail space? Each scenario may require different machine capabilities, such as portability for events or larger capacity for storefronts. Tailoring your selection to your market’s preferences can enhance customer satisfaction and boost sales.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it is essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record in the donut machine market, as this can provide insights into their reliability and product quality.

- Check for certifications: Ensure that the supplier adheres to international safety and quality standards.

- Assess customer service: Good after-sales support can make a significant difference in your operational success.

Step 4: Review Warranty and Return Policies

An understanding of warranty and return policies is vital to protect your investment. Look for suppliers that offer comprehensive warranty coverage on their machines, which can safeguard against manufacturing defects. Additionally, a clear return policy can provide peace of mind, especially for large equipment purchases.

- Consider return conditions: Ensure the policy covers issues like faulty machines or unsatisfactory performance.

- Understand shipping and handling: Know who bears the cost in case of returns, especially if you are located internationally.

Step 5: Request Product Demonstrations

Whenever possible, request demonstrations of the mini donut machines you are considering. Observing the machine in action can provide insights into its ease of use, efficiency, and overall performance. A hands-on experience can also help you evaluate the quality of donuts produced.

- Ask about training: Inquire if the supplier offers training for your staff on operating the machine effectively.

- Test different models: If feasible, compare several models to determine which best fits your business needs.

Step 6: Calculate Total Cost of Ownership

Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, energy consumption, and potential repairs. A more expensive machine with higher efficiency may save costs in the long run. Evaluate your budget against these factors to ensure a sustainable investment.

- Assess maintenance needs: Understand how often the machine requires servicing and what parts may need replacement over time.

- Factor in energy costs: Choose machines that are energy-efficient to reduce operational expenses.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier and machine, carefully review the purchase agreement. Ensure that all terms, including delivery timelines, payment terms, and any additional services, are clearly outlined. A well-structured agreement can help prevent misunderstandings and ensure a smooth transaction.

Illustrative image related to mini donut machine

By following this step-by-step checklist, B2B buyers can confidently navigate the sourcing process for mini donut machines, leading to informed decisions that support their business goals.

Comprehensive Cost and Pricing Analysis for mini donut machine Sourcing

What Are the Key Cost Components of Sourcing Mini Donut Machines?

Understanding the cost structure of mini donut machines is crucial for international B2B buyers. Key components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary materials for mini donut machines often include stainless steel for durability and ease of cleaning, electrical components for automation, and various internal mechanisms for operation. The quality and sourcing of these materials can significantly impact the overall cost.

-

Labor: Labor costs vary by region and can influence manufacturing prices. Countries with lower labor costs may offer more competitive pricing, but quality control and craftsmanship should not be overlooked.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, rent, and equipment depreciation. Buyers should consider suppliers’ overhead structures to gauge their pricing strategies.

-

Tooling: Tooling costs involve the creation and maintenance of molds and machinery used in production. Customization or specialized features may necessitate higher tooling investments.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet safety and performance standards. Suppliers with stringent QC measures may charge a premium, but this often results in higher reliability and lower maintenance costs.

-

Logistics: Transportation costs can vary based on distance, method (air vs. sea), and the Incoterms agreed upon. International shipping regulations, tariffs, and local taxes can further complicate logistics expenses.

-

Margin: Supplier margins can vary widely depending on brand reputation, market demand, and production capabilities. Understanding the supplier’s margin can provide insight into the pricing strategy.

How Do Price Influencers Affect Mini Donut Machine Costs?

Several factors can influence the pricing of mini donut machines, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes often lead to reduced per-unit costs. Negotiating lower MOQs can also result in better pricing for smaller operations.

-

Specifications and Customization: Customized machines tailored to specific business needs or regional preferences may incur additional costs. It’s essential to weigh the benefits of customization against the price increase.

-

Materials and Quality Certifications: Machines made from high-quality materials or those that meet certain certifications (e.g., CE, ISO) often come at a premium but can enhance longevity and reliability.

-

Supplier Factors: Established suppliers may charge higher prices due to brand reputation and perceived quality. However, newer entrants might offer competitive prices to gain market share.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can significantly affect the total landed cost. Buyers should be aware of their responsibilities regarding shipping and customs clearance.

What Buyer Tips Can Help Optimize Costs for Mini Donut Machines?

To ensure cost-effectiveness in sourcing mini donut machines, consider the following tips:

-

Negotiate: Always engage in negotiations to obtain the best possible price. Suppliers may be willing to offer discounts based on volume or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operation, and potential downtime costs. A slightly higher upfront cost may lead to lower TCO if the machine is more durable and efficient.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and import tariffs that may affect pricing.

-

Request Quotes from Multiple Suppliers: Getting multiple quotes allows for comparative analysis and may highlight pricing discrepancies that can be leveraged during negotiations.

-

Conduct Supplier Visits: If possible, visit suppliers to assess their operations and quality control measures firsthand. This helps build relationships and may lead to better pricing agreements.

In summary, sourcing mini donut machines involves a comprehensive understanding of cost components and price influencers. By utilizing strategic negotiation tactics and evaluating total costs, international B2B buyers can make informed purchasing decisions that align with their business needs.

Alternatives Analysis: Comparing mini donut machine With Other Solutions

Exploring Alternatives to Mini Donut Machines for Efficient Production

In the competitive world of food service, finding the right equipment is crucial for maximizing efficiency and profitability. While mini donut machines are designed to automate and enhance donut production, businesses may also consider alternative solutions that can achieve similar results. This analysis provides a comparison of mini donut machines against two viable alternatives: traditional deep frying methods and automated conveyor donut systems.

Comparison Table

| Comparison Aspect | Mini Donut Machine | Traditional Deep Frying Method | Automated Conveyor Donut System |

|---|---|---|---|

| Performance | Produces up to 300 donuts/hour | Varies; typically slower and labor-intensive | High output; can produce thousands/hour |

| Cost | Moderate initial investment; low operating costs | Low initial cost but high labor costs | High initial investment; efficient long-term |

| Ease of Implementation | Simple setup; user-friendly | Requires skilled labor and supervision | Complex installation; requires training |

| Maintenance | Low maintenance; durable stainless steel | Moderate; requires regular cleaning and monitoring | High; intricate systems may need specialist repairs |

| Best Use Case | Small to medium businesses; events and fairs | Home use; small-scale operations | Large-scale operations; bakeries, factories |

Detailed Breakdown of Alternatives

1. Traditional Deep Frying Method

Traditional deep frying involves manually frying donuts in hot oil. This method is well-known and can be cost-effective for small businesses or home bakers who do not require high volumes of production. However, the performance can vary significantly based on the skill of the operator, and it typically involves longer cooking times. Additionally, labor costs can be higher since the process requires constant supervision and manual handling. While this method can produce delicious results, it may not be suitable for businesses aiming for efficiency and high output.

2. Automated Conveyor Donut System

Automated conveyor donut systems are designed for high-volume production, capable of creating thousands of donuts per hour. These systems integrate multiple processes, including frying, glazing, and cooling, into one streamlined operation. While they can significantly boost output and efficiency, they come with a high initial investment and complex installation requirements. Maintenance can also be a challenge due to the intricacies of the machinery, often necessitating specialized technicians for repairs. This solution is ideal for large bakeries or factories that need to meet high demand consistently.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate equipment for donut production, B2B buyers must consider their specific operational needs, budget constraints, and production goals. Mini donut machines offer a balanced approach for small to medium enterprises seeking efficiency and ease of use, while traditional deep frying might be suitable for lower-volume operations. On the other hand, automated conveyor systems cater to larger businesses focused on maximizing output. By evaluating these alternatives against their unique requirements, buyers can make informed decisions that enhance their production capabilities and profitability.

Essential Technical Properties and Trade Terminology for mini donut machine

What Are the Key Technical Properties of a Mini Donut Machine?

When investing in a mini donut machine, understanding its technical specifications is crucial for ensuring it meets your business needs. Here are some essential properties to consider:

-

Material Grade

The most common material used in mini donut machines is stainless steel. This material is preferred for its durability, resistance to rust and corrosion, and ease of cleaning. For B2B buyers, a high-grade stainless steel construction signifies a long-lasting investment that can withstand the rigors of commercial use. -

Production Capacity

Production capacity is typically measured in donuts produced per hour. For instance, a machine that can produce 300 donuts per hour is ideal for high-demand environments such as events and food festivals. Understanding production capacity helps businesses gauge whether the machine can meet their customer demand, thus impacting profitability. -

Temperature Range

The ability to adjust temperature is vital for achieving the perfect donut consistency. Machines with a temperature range of 122°F to 392°F allow operators to create a variety of donut styles, from cake-like to fluffy. This flexibility is essential for businesses aiming to offer diverse product lines and cater to different tastes. -

Power Requirements

Most mini donut machines operate on either 110V or 220V electricity. Knowing the power requirements is essential for ensuring compatibility with local electrical standards. This information helps prevent operational delays and ensures that the machine can be used in the intended location without additional costs for electrical modifications. -

Size and Footprint

The dimensions of the machine affect its placement and mobility. Buyers should consider the available space in their establishment and whether they will need a more portable model. A compact design can be beneficial for businesses with limited kitchen space or those that require mobility for events. -

Automation Features

Features such as automatic donut flipping and adjustable nozzles for varying donut sizes enhance operational efficiency. Automation reduces labor costs and allows for consistent product quality, making it an attractive option for businesses looking to streamline operations.

What Common Trade Terms Should B2B Buyers of Mini Donut Machines Know?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some key terms to be familiar with:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that may be marketed by another company. For buyers, knowing whether a supplier is an OEM can help ensure that they are purchasing quality equipment directly from the manufacturer, which often results in better pricing and support. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding the MOQ is essential for budgeting and inventory management. For businesses just starting out, negotiating lower MOQs can help minimize upfront costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. When considering a mini donut machine, issuing an RFQ can help buyers compare pricing and features across different suppliers, leading to more informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized shipping terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help businesses understand shipping costs, risks, and responsibilities, ensuring smoother logistics for imported equipment. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the machine and the terms of repair or replacement in case of defects. Understanding warranty terms is crucial for B2B buyers, as it affects long-term operational costs and peace of mind. -

Filtration System

This refers to the technology used to filter oil in donut machines. A good filtration system can significantly improve the quality of donuts and extend the lifespan of the equipment. Buyers should inquire about the filtration options available to ensure they are investing in a machine that delivers high-quality products.

By understanding these essential properties and trade terms, B2B buyers can make informed decisions when selecting a mini donut machine, ultimately leading to improved operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the mini donut machine Sector

What Are the Key Market Dynamics and Trends Influencing the Mini Donut Machine Sector?

The mini donut machine sector is experiencing notable growth driven by increasing demand for convenient, ready-to-eat snacks globally. As consumer preferences shift towards unique food experiences, mini donuts have gained popularity in various venues, from food trucks to high-end cafes. This trend is particularly prominent in regions such as Africa, South America, the Middle East, and Europe, where local flavors and innovative toppings are being introduced to attract diverse customer bases.

Technological advancements are shaping the market, with automatic machines allowing for higher production rates and efficiency. For instance, machines that can produce up to 300 donuts per hour with adjustable temperature settings are becoming standard. These advancements not only streamline operations but also reduce labor costs, making it appealing for small businesses and startups. Additionally, the rise of e-commerce platforms has made sourcing these machines easier for international buyers, allowing them to compare options and prices seamlessly.

Illustrative image related to mini donut machine

Emerging markets are increasingly recognizing the potential of mini donut machines as a lucrative investment. Countries like Nigeria and Saudi Arabia are witnessing a burgeoning interest in snack food offerings, driven by urbanization and a growing middle class. Consequently, B2B buyers in these regions should focus on sourcing machines that offer durability and ease of maintenance, considering local environmental factors.

How Can Sustainability and Ethical Sourcing Impact the Mini Donut Machine Supply Chain?

The environmental impact of food production equipment is becoming a critical concern for B2B buyers in the mini donut machine sector. Sustainability practices are now essential, as consumers increasingly prefer brands that demonstrate a commitment to ethical sourcing and environmentally friendly operations. This trend is prompting manufacturers to adopt green certifications and utilize sustainable materials in their machines.

For instance, sourcing mini donut machines made from stainless steel not only enhances durability but also reduces waste in the long term. Additionally, companies are increasingly seeking suppliers who use energy-efficient technologies to minimize carbon footprints, which can also lead to lower operational costs. As consumers become more eco-conscious, B2B buyers should prioritize suppliers that offer transparent sourcing practices and environmentally friendly options.

Furthermore, ethical supply chains are gaining traction, with buyers keen on understanding the origins of their equipment and materials. This includes ensuring that labor practices meet international standards and that suppliers are committed to fair trade principles. Investing in machines from manufacturers who prioritize ethical practices can enhance brand reputation and foster customer loyalty, positioning businesses favorably in competitive markets.

Illustrative image related to mini donut machine

What Is the Historical Context of Mini Donut Machines and Their Impact on the Current Market?

The concept of mini donut machines dates back to the 1970s when the first portable models were introduced to cater to snack vendors and small businesses. This innovation revolutionized the way donuts were produced, allowing for on-the-spot preparation and sale at fairs, festivals, and concession stands. As consumer interest in fresh and unique snack offerings grew, these machines became essential tools for entrepreneurs looking to capitalize on this trend.

Over the decades, advancements in technology have led to the development of more efficient and user-friendly machines, making it easier for businesses to produce high-quality mini donuts at scale. The evolution from manual to automatic machines has significantly enhanced productivity, allowing operators to focus on customer engagement rather than labor-intensive processes. Today, mini donut machines are not only popular in traditional settings but also find applications in cafes, restaurants, and even home kitchens, reflecting their adaptability and enduring appeal in the snack food market.

Understanding this evolution provides B2B buyers with valuable insights into the reliability and performance of different models, guiding them toward informed purchasing decisions that align with current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of mini donut machine

-

How do I choose the right mini donut machine for my business?

Choosing the right mini donut machine involves evaluating several factors including production capacity, type (electric or gas), and ease of use. Consider your business model and volume; for instance, a machine producing 300 donuts per hour may be ideal for high-traffic venues like fairs or festivals. Additionally, check for features such as adjustable temperature settings and interchangeable nozzles, which can enhance versatility. Always request a demo or video of the machine in operation to assess its performance and reliability. -

What are the key features to look for in a mini donut machine?

Key features to consider include production capacity, ease of operation, and material quality. Look for machines made from durable materials like stainless steel for longevity. Automatic operations can save time and labor, while adjustable temperature and thickness settings allow for customization. Also, ensure the machine has a reliable draining system for oil, as this can affect the quality of the donuts and ease of cleanup. -

What is the typical lead time for international orders of mini donut machines?

Lead times for international orders can vary significantly based on the supplier and shipping method. Generally, expect a timeframe of 4 to 12 weeks from order confirmation to delivery. Factors influencing this include production schedules, customs clearance, and shipping routes. It’s advisable to discuss timelines directly with suppliers and factor in potential delays due to local regulations or logistics challenges in your country. -

What are the minimum order quantities (MOQ) for mini donut machines?

Minimum order quantities for mini donut machines can range from one unit for smaller suppliers to several units for larger manufacturers. MOQs may also depend on the specific machine model and customization options. When sourcing, confirm the MOQ with the supplier and evaluate whether it aligns with your business needs. Some suppliers may offer flexibility, especially for first-time buyers or those looking to establish a long-term partnership. -

How do I vet suppliers for mini donut machines?

Vetting suppliers involves checking their reputation, customer reviews, and business certifications. Look for suppliers with a proven track record in the industry and positive feedback from previous clients. Request references or case studies to understand their service quality. Additionally, consider visiting their manufacturing facility if possible or conducting virtual meetings to gauge their professionalism and reliability. -

What payment terms should I expect when purchasing a mini donut machine?

Payment terms can vary widely among suppliers, but common practices include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer financing options or credit terms for established businesses. Always clarify payment methods accepted (bank transfer, letter of credit, etc.) and ensure that the terms are documented in your purchase agreement to avoid misunderstandings. -

What kind of warranty and after-sales support can I expect?

Most reputable suppliers offer warranties ranging from one to three years, covering manufacturing defects and parts. It’s essential to inquire about the specifics of the warranty, including what it covers and the process for claims. Additionally, assess the level of after-sales support, such as access to spare parts, maintenance services, and customer service responsiveness. Reliable support can significantly enhance your operational efficiency in the long run. -

How do I handle logistics for importing mini donut machines?

Handling logistics for importing involves coordinating with freight forwarders for shipping arrangements, understanding customs regulations, and preparing necessary documentation. Familiarize yourself with import duties, taxes, and any specific requirements in your country. It’s also wise to establish a clear communication channel with your supplier regarding shipping updates and to consider insurance for your shipment to safeguard against potential losses or damages during transit.

Top 5 Mini Donut Machine Manufacturers & Suppliers List

1. State Fair – Mini Donut Oven

Domain: statefairminidonuts.com

Registered: 2004 (21 years)

Introduction: State Fair Mini Donut Oven – Regular price: $1,449.00 USD – Output: Up to 1200 mini donuts per hour – Safe and easy operation (no hot oil required) – Compact size: 14.25″ x 20″ (13 1/2″ H) – Portable: 120V, plugs in anywhere – Includes: Sugar Bottle, Funnel, Marketing Materials (Point of Sale), Attractive State Fair® Oven Clings, Easy operating & cleaning instructions – 1 year warranty – Warranty …

2. Lil Orbits – Donut Making Equipment and Mixes

Domain: lilorbits.com

Registered: 1996 (29 years)

Introduction: Lil Orbits offers a range of American-made donut and mini donut making equipment and mixes. Key products include electric and gas-fired donut machines (models 800, SS1200, SS2400, SS1200GII, SS2400GII), high-quality donut mixes that require only water to prepare, and home donut kits. The machines are designed for various settings such as concession trailers, coffee shops, bakeries, and events. The…

3. ALDKitchen – Mini Donut Maker

Domain: ald.kitchen

Introduction: ALDKitchen Mini Donut Maker Commercial | Automatic Doughnut Machine | 3 Nozzles Set | Stainless Steel

4. Belshaw – Donut Robot Machines

Domain: belshaw.com

Registered: 1995 (30 years)

Introduction: Donut Robot Machines are designed for high-volume production of donuts. They feature automatic frying, precise temperature control, and a variety of models to suit different production needs. The machines are easy to operate and maintain, ensuring consistent quality and efficiency. Ideal for bakeries, cafes, and food service operations.

5. Kolice – Automatic Donuts Machine

Domain: kolice.cc

Registered: 2014 (11 years)

Introduction: Kolice offers a variety of donut machines with different specifications and prices. Key products include: 1. Kolice Automatic Donuts Machine: Produces 450-800 pcs/hour, includes 3 molds, timer control, priced at $1,270.00 (discounted to $1,210.00). 2. Kolice Donut Maker 4 Rows: Auto doughnut making machine with digital display, 1800 pcs/hour capacity, 5.5L hopper, intelligent control panel, priced…

Strategic Sourcing Conclusion and Outlook for mini donut machine

In conclusion, the strategic sourcing of mini donut machines presents a significant opportunity for B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing quality, efficiency, and supplier reliability, businesses can not only enhance their product offerings but also drive customer satisfaction and loyalty. Key considerations include understanding local market preferences, ensuring compliance with international standards, and evaluating the total cost of ownership, which encompasses maintenance, operational efficiency, and potential for scalability.

Illustrative image related to mini donut machine

The mini donut machine market is poised for growth, driven by the rising popularity of mini donuts as a versatile snack option at events and retail locations. Investing in advanced, automated machines can lead to increased production capacity and reduced labor costs, ultimately maximizing profit margins.

As you explore your sourcing options, consider the unique needs of your target market and the potential for differentiation through quality and innovation. Now is the time to capitalize on this trend by forging partnerships with reputable suppliers and leveraging the right technology to position your business for success in the ever-evolving foodservice landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.