Metallic Shirt: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for metallic shirt

In an increasingly competitive fashion landscape, sourcing high-quality metallic shirts presents a unique challenge for international B2B buyers. The allure of metallic fabrics—known for their striking aesthetic and versatility—can quickly become overshadowed by concerns about quality, cost, and supplier reliability. This guide aims to illuminate the complexities of the global market for metallic shirts, equipping decision-makers with the insights needed to navigate these challenges effectively.

We will explore various types of metallic shirts, their applications across different industries, and the essential criteria for vetting suppliers. Additionally, we will provide a detailed analysis of cost factors, helping you understand price variations based on material, design, and market demand. Whether your business operates in Africa, South America, the Middle East, or Europe, this comprehensive resource empowers you to make informed purchasing decisions.

By understanding the intricacies of the metallic shirt market, you can enhance your product offerings, meet customer expectations, and ultimately drive sales. This guide is your roadmap to confidently sourcing metallic shirts that not only meet your business’s aesthetic needs but also align with your operational goals.

Understanding metallic shirt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metallic T-Shirts | Casual fit, lightweight fabrics, often with a shiny finish | Promotional events, casual wear | Pros: Affordable, versatile; Cons: Less formal |

| Metallic Blouses | Tailored design, often embellished, suitable for office wear | Corporate events, formal gatherings | Pros: Professional appearance; Cons: Higher cost |

| Metallic Tank Tops | Sleeveless, breathable materials, great for layering | Summer collections, nightlife fashion | Pros: Comfortable, trendy; Cons: Limited warmth |

| Metallic Sweaters | Knitted, heavier fabric, often with metallic threads | Fall/winter collections, casual wear | Pros: Warmth, style; Cons: Can be bulkier |

| Metallic Tunics | Longer length, often with unique cuts or patterns | Casual outings, beachwear | Pros: Flattering fit, versatile; Cons: May require layering |

What Are the Characteristics of Metallic T-Shirts?

Metallic T-shirts are characterized by their casual fit and lightweight fabric, often featuring a shiny finish that catches the eye. These shirts are ideal for promotional events or casual wear, making them a popular choice for businesses looking to create a relaxed brand image. When purchasing, consider the fabric composition and durability, as these factors affect the shirt’s longevity and overall appearance after multiple washes.

How Do Metallic Blouses Differ in Design and Application?

Metallic blouses offer a more tailored design, often embellished with sequins or other decorative elements, making them suitable for office wear or corporate events. Their professional appearance allows businesses to present a polished image during formal gatherings. Buyers should focus on the quality of materials and craftsmanship, as these blouses can be a more significant investment compared to casual options.

Why Are Metallic Tank Tops Popular in Fashion?

Metallic tank tops are defined by their sleeveless design and breathable materials, making them perfect for layering or wearing alone in warmer weather. They are frequently included in summer collections and are a staple for nightlife fashion. When considering bulk purchases, businesses should evaluate the fit and comfort level, as these factors can significantly influence customer satisfaction.

What Benefits Do Metallic Sweaters Offer for Seasonal Collections?

Metallic sweaters are typically knitted and feature heavier fabric, often incorporating metallic threads for added flair. These sweaters are ideal for fall and winter collections, providing both warmth and style. Buyers should consider the sweater’s weight and texture, as these elements contribute to the garment’s overall comfort and appeal during colder months.

How Can Metallic Tunics Enhance Casual Outfits?

Metallic tunics are known for their longer length and unique cuts or patterns, providing a flattering fit for various body types. They are versatile enough for casual outings or beachwear, appealing to a wide range of consumers. When sourcing tunics, businesses should pay attention to the tunic’s drape and fabric quality, as these factors affect how well the garment fits and moves with the wearer.

Key Industrial Applications of metallic shirt

| Industry/Sector | Specific Application of metallic shirt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Seasonal Collections | Enhances brand appeal and attracts fashion-forward customers | Quality of fabric, trend alignment, regional preferences |

| Event Management | Uniforms for Promotional Events | Creates a cohesive brand image and enhances visibility | Durability, ease of maintenance, customization options |

| Hospitality | Staff Apparel for High-End Venues | Elevates customer experience through stylish presentation | Comfort, fit, and fabric quality for diverse climates |

| Entertainment & Media | Costumes for Performances | Adds visual impact and aligns with thematic elements | Fabric durability, design complexity, and quick turnaround |

| Corporate Branding | Branded Merchandise for Corporate Events | Strengthens brand identity and employee engagement | MOQ (Minimum Order Quantity), branding options, and lead times |

How is the Metallic Shirt Used in Fashion Retail, and What Problems Does It Solve?

In the fashion retail industry, metallic shirts are often featured in seasonal collections aimed at fashion-conscious consumers. These garments help brands stand out in a crowded market by offering unique styles that resonate with current trends. For international buyers, particularly from regions like Africa and Europe, sourcing high-quality metallic fabrics that align with local fashion preferences is crucial. Retailers must ensure that the garments are not only visually appealing but also comfortable and durable enough for frequent wear, addressing the challenge of balancing aesthetics with practicality.

What Role Do Metallic Shirts Play in Event Management?

Event management companies frequently use metallic shirts as uniforms for promotional events. These shirts enhance brand visibility and create a unified look among staff, which is essential for customer engagement. For B2B buyers in this sector, sourcing options should focus on the durability of the fabric, as uniforms must withstand long hours of wear. Additionally, ease of maintenance is vital; materials that are stain-resistant and easy to clean can significantly reduce operational costs, making them an attractive choice for event planners.

How Do Metallic Shirts Elevate Hospitality Experiences?

In the hospitality industry, metallic shirts are utilized as staff apparel in high-end venues, contributing to an upscale customer experience. These garments help create an elegant atmosphere, making a lasting impression on guests. Buyers in this sector should prioritize comfort and fit, as staff members need to perform their duties efficiently while looking polished. Furthermore, considering the diverse climates of regions like the Middle East and South America, selecting breathable fabrics that maintain a professional appearance is essential.

In What Ways Are Metallic Shirts Used in Entertainment & Media?

Metallic shirts serve as eye-catching costumes in the entertainment and media industries, adding visual flair to performances and productions. They are particularly effective in creating a thematic consistency that resonates with audiences. For B2B buyers in this field, sourcing requirements often include fabric durability to withstand stage lighting and movement, as well as the ability to accommodate intricate designs. Quick turnaround times are also crucial, especially for productions that operate on tight schedules.

Illustrative image related to metallic shirt

How Can Corporate Branding Benefit from Metallic Shirts?

In corporate branding, metallic shirts are increasingly used as branded merchandise for corporate events. These shirts not only promote brand identity but also foster employee engagement by providing staff with stylish apparel that reflects company values. When sourcing for corporate branding, buyers should consider minimum order quantities, customization options, and lead times to ensure timely delivery for events. Selecting fabrics that balance comfort and style will enhance the overall impact of the branding efforts.

3 Common User Pain Points for ‘metallic shirt’ & Their Solutions

Scenario 1: Sourcing High-Quality Metallic Shirts for Diverse Markets

The Problem: B2B buyers often struggle to source high-quality metallic shirts that meet the diverse needs of their target markets. Variability in quality, style, and material can lead to dissatisfaction among customers, especially in regions with distinct fashion preferences, such as Africa, South America, the Middle East, and Europe. Inconsistent quality can also damage a brand’s reputation, leading to lost sales and customer trust.

The Solution: To mitigate these risks, buyers should establish strong relationships with reputable manufacturers who specialize in metallic fabrics. Conduct thorough research to identify suppliers that prioritize quality control and have positive reviews from previous clients. Request samples before placing bulk orders to assess the quality firsthand. Additionally, consider regional preferences in your sourcing strategy; for instance, lightweight, breathable fabrics may be more suitable for warmer climates, while heavier materials could appeal in cooler areas. Utilizing trade shows and online marketplaces can also provide insights into trending styles and materials specific to your target markets, ensuring that your offerings resonate with local consumers.

Scenario 2: Managing Inventory for Seasonal Demand Fluctuations

The Problem: B2B buyers often face challenges in managing inventory levels for metallic shirts due to seasonal demand fluctuations. A lack of accurate forecasting can lead to overstock situations during low demand periods or stockouts during peak seasons, resulting in lost revenue and wasted resources.

The Solution: Implement a robust inventory management system that uses historical sales data to predict future demand patterns. Collaborate with suppliers to establish flexible ordering agreements that allow for quick replenishment of popular styles and sizes. Consider adopting a just-in-time inventory approach, which minimizes excess stock while ensuring that you can meet customer demands. Additionally, diversifying your product range can help mitigate risks associated with seasonal fluctuations. Offering a variety of metallic shirts, such as different styles, colors, and materials, can attract a broader customer base and stabilize sales throughout the year.

Scenario 3: Addressing Customer Concerns About Fabric Durability and Care

The Problem: Buyers often encounter customer hesitations regarding the durability and care requirements of metallic shirts. Concerns about how well these garments hold up after repeated wear and washing can deter potential buyers, especially in competitive markets where alternatives may seem more practical.

The Solution: Educate your customers about the specific care instructions for metallic fabrics to alleviate concerns regarding durability. Provide detailed care labels on your products and include information on how to properly wash and store metallic shirts to maintain their luster and shape. Consider creating informative content, such as care guides or instructional videos, that can be shared on your website and social media platforms. Additionally, sourcing materials known for their durability—such as blends that incorporate polyester or spandex—can enhance the longevity of the shirts and reassure customers of their investment. By addressing care concerns proactively, you can foster customer confidence and encourage repeat purchases.

Strategic Material Selection Guide for metallic shirt

What Are the Key Properties of Common Materials Used in Metallic Shirts?

When selecting materials for metallic shirts, international B2B buyers must consider various factors, including performance properties, manufacturing complexities, and compliance with regional standards. Here, we analyze four common materials used in metallic shirts: polyester, nylon, silk, and metallic blends.

How Does Polyester Perform in Metallic Shirt Applications?

Polyester is a synthetic material known for its durability and resistance to shrinking and stretching. It offers excellent moisture-wicking properties, making it suitable for various climates. Polyester can withstand moderate temperatures but may not perform well under high heat, which could affect its longevity.

Pros: Polyester is cost-effective and easy to manufacture, which reduces production costs. It is also lightweight and resistant to wrinkles, making it a popular choice for casual and formal wear.

Cons: While polyester is durable, it may not have the same luxurious feel as natural fibers like silk. Additionally, it can be less breathable, which may not be ideal for hotter climates.

Impact on Application: Polyester is compatible with a wide range of dyes and finishes, allowing for vibrant metallic effects. However, it may not be suitable for high-temperature applications or environments with extreme conditions.

Considerations for International Buyers: Buyers from Africa and South America should consider the local climate when selecting polyester. Compliance with standards such as ASTM D5034 for fabric strength is crucial in ensuring product quality.

Illustrative image related to metallic shirt

What Advantages Does Nylon Offer for Metallic Shirts?

Nylon is another synthetic fabric that boasts high strength and elasticity. It is resistant to abrasion and has a natural sheen, making it an attractive option for metallic shirts. Nylon can withstand higher temperatures than polyester but is still susceptible to melting at extreme heat levels.

Pros: Nylon is lightweight and offers excellent durability, making it suitable for active wear. Its moisture-wicking properties enhance comfort, especially in humid conditions.

Cons: The cost of nylon can be higher than polyester, which may affect pricing strategies for B2B buyers. Additionally, nylon may require special care in washing to maintain its appearance.

Impact on Application: Nylon’s compatibility with various finishes allows for effective metallic coatings. However, it may not be the best choice for applications requiring extensive exposure to heat or chemicals.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure compliance with EU regulations regarding textile safety and environmental impact, such as REACH.

Illustrative image related to metallic shirt

Why Consider Silk for Premium Metallic Shirts?

Silk is a luxurious natural fiber known for its softness and luster. It provides excellent breathability and comfort, making it ideal for high-end metallic shirts. However, silk is less durable than synthetic options and requires careful handling.

Pros: The aesthetic appeal of silk is unmatched, offering a premium feel that can elevate the brand image. It is also biodegradable, appealing to environmentally conscious consumers.

Cons: Silk is more expensive and requires more complex manufacturing processes, which can increase production costs. It is also more sensitive to moisture and can be damaged by prolonged exposure to sunlight.

Impact on Application: Silk can achieve stunning metallic finishes but may not be suitable for everyday wear due to its delicate nature.

Illustrative image related to metallic shirt

Considerations for International Buyers: Buyers should be aware of the specific care requirements for silk and ensure compliance with textile labeling regulations in their respective markets.

What Are the Benefits of Using Metallic Blends?

Metallic blends typically combine synthetic and natural fibers to create a unique texture and appearance. These blends can offer the best of both worlds, providing durability while maintaining a luxurious feel.

Pros: Blends can enhance the overall performance of the fabric, offering improved breathability and moisture management. They also allow for a wider range of design possibilities.

Cons: The manufacturing process for blends can be more complex, potentially leading to higher costs. Additionally, the performance characteristics can vary widely based on the specific blend.

Illustrative image related to metallic shirt

Impact on Application: Metallic blends can be tailored for specific applications, offering versatility in design and function. However, understanding the properties of each component is crucial for maintaining quality.

Considerations for International Buyers: Buyers should ensure that blends meet local standards for textile safety and performance, including ASTM and JIS certifications.

Summary Table of Material Properties

| Material | Typical Use Case for metallic shirt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Casual and formal wear | Cost-effective and durable | Less breathable than natural fibers | Low |

| Nylon | Active and performance wear | High strength and elasticity | Higher cost and care requirements | Med |

| Silk | Premium and luxury shirts | Luxurious feel and aesthetic appeal | Delicate and expensive | High |

| Metallic Blends | Versatile applications | Combines durability with luxury | Complex manufacturing process | Med |

This guide provides B2B buyers with a comprehensive overview of material options for metallic shirts, enabling informed decisions that align with market demands and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for metallic shirt

What Are the Key Stages in the Manufacturing Process of Metallic Shirts?

The manufacturing process of metallic shirts involves several critical stages, each requiring specialized techniques to ensure high-quality output. Here are the main stages involved:

Material Preparation: How Are Fabrics Selected and Treated?

The first step in the manufacturing of metallic shirts is material preparation. Manufacturers often choose fabrics that can hold metallic finishes effectively, such as polyester, nylon, or cotton blends. These fabrics undergo several treatments to enhance their properties, including:

Illustrative image related to metallic shirt

- Dyeing and Coating: Fabrics may be dyed with metallic inks or coated with metallic finishes to achieve the desired shine and aesthetic appeal. This process requires precision to ensure uniformity in color and texture.

- Testing for Durability: Before proceeding, materials are tested for durability, stretchability, and washability to meet the demands of the market.

How Are Metallic Shirts Formed Through Cutting and Sewing?

The next stage is forming, where the prepared fabrics are cut and sewn into the desired shirt designs. This stage typically involves:

- Cutting: Automated cutting machines are used to ensure accuracy and efficiency in fabric utilization. Pattern design is crucial here, as it affects the final appearance of the shirt.

- Sewing Techniques: Various sewing techniques are employed, including flatlock and overlock stitching, to create seams that are both strong and flexible. Attention to detail is vital to maintain the integrity of the metallic finish during this process.

What Does the Assembly Process Involve?

Once the individual components are sewn together, the assembly process begins. This includes:

- Adding Embellishments: Metallic shirts often feature additional embellishments like sequins, beads, or prints. These are applied at this stage to enhance the aesthetic appeal.

- Quality Checks: Before moving to the finishing stage, garments undergo preliminary quality checks to identify any defects in stitching or finishing.

What Finishing Techniques Are Used for Metallic Shirts?

The finishing stage is crucial for achieving the final look and feel of the metallic shirt. Key techniques include:

- Pressing and Heat Setting: To ensure that the metallic finish is set and the shirt maintains its shape, heat setting is performed. This step is crucial to prevent the fabric from wrinkling or losing its metallic sheen.

- Final Inspection and Packing: Each shirt undergoes a final inspection to ensure it meets quality standards before being packed for shipment. This includes checking for any defects in the fabric, stitching, and embellishments.

What Quality Assurance Measures Are Essential for Metallic Shirt Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, especially for metallic shirts, which must meet specific aesthetic and durability standards. Here are the key aspects of QA:

Illustrative image related to metallic shirt

Which International Standards Should B2B Buyers Look For?

B2B buyers should ensure that their suppliers adhere to international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems and ensures that the manufacturing processes are consistent and meet customer requirements.

- CE Marking: Particularly relevant for products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For specialized applications, such as protective clothing, API standards may apply, ensuring that the materials and manufacturing processes meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that the final product meets specified standards. The key QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet required specifications before they enter the manufacturing process.

- In-Process Quality Control (IPQC): Regular inspections are conducted during the manufacturing stages to identify and rectify any issues immediately.

- Final Quality Control (FQC): This final inspection assesses the completed garments for defects in fabric, stitching, and overall appearance before they are packaged and shipped.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to validate the quality of metallic shirts:

- Fabric Testing: This includes tests for colorfastness, tensile strength, and shrinkage to ensure the fabric meets durability standards.

- Visual Inspection: A thorough visual inspection is conducted to identify any defects in the finish or construction.

- Wear Testing: For some applications, wear tests may be performed to evaluate how the fabric holds up under regular use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is crucial for B2B buyers, especially when sourcing internationally. Here are some strategies:

What Audit Processes Should Buyers Implement?

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards. This includes reviewing their manufacturing processes, quality control measures, and documentation.

- Certifications Review: Buyers should request copies of relevant certifications, such as ISO 9001 and CE, to ensure compliance with international standards.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an additional layer of assurance. These independent inspectors can:

- Conduct Random Inspections: Performing random checks during various stages of production can help identify issues early in the process.

- Provide Detailed Reports: Third-party inspectors can offer detailed reports on compliance with quality standards, which can be valuable for buyers in making informed decisions.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances related to quality control when sourcing metallic shirts:

- Cultural Differences in Quality Expectations: Different markets may have varying standards for quality. Understanding these differences can help buyers set realistic expectations and avoid potential disputes.

- Regulatory Compliance: Buyers must ensure that the products comply with local regulations in their respective countries, which may involve additional certifications or testing.

By understanding the manufacturing processes and quality assurance measures associated with metallic shirts, B2B buyers can make informed decisions that align with their business needs and market expectations. This comprehensive approach ensures that they source high-quality products that meet international standards, ultimately enhancing their competitive advantage in the market.

Illustrative image related to metallic shirt

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metallic shirt’

In the competitive landscape of fashion retail, sourcing metallic shirts requires a strategic approach to ensure quality and market relevance. This guide serves as a practical checklist for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your sourcing process and secure the best products for your business.

1. Define Your Target Market Needs

Understanding your target demographic is crucial. Are you catering to high-end fashion consumers, or is your focus on budget-conscious buyers? Consider regional preferences, such as color trends and styles popular in specific markets like Europe or Africa. This insight will guide your selection process and ensure you meet customer expectations.

2. Identify Technical Specifications

Before searching for suppliers, outline the technical specifications of the metallic shirts you wish to procure. This includes fabric types (e.g., polyester, silk blends), weight, and finish (e.g., matte, shiny). Detailed specifications help in communicating your requirements clearly to potential suppliers, minimizing misunderstandings later in the process.

Illustrative image related to metallic shirt

3. Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers that specialize in metallic shirts. Look for manufacturers with experience in your target markets. Utilize industry directories, trade shows, and online platforms to compile a list of reputable suppliers. Pay attention to their product range, pricing, and customer reviews to gauge their reliability.

4. Evaluate Supplier Certifications and Compliance

It’s essential to verify that suppliers meet industry standards and regulations. Request relevant certifications such as ISO, Oeko-Tex, or any specific compliance documents that pertain to your market. This step not only ensures product quality but also builds trust and credibility in your business relationships.

5. Request Samples for Quality Assurance

Before making bulk orders, always request samples of the metallic shirts. This allows you to assess the quality, feel, and durability of the fabric. Check for color consistency, stitching quality, and overall craftsmanship. Having tangible samples also aids in making informed decisions about your final order.

6. Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, minimum order quantities, and delivery timelines. Ensure that you clarify payment terms and any potential discounts for bulk purchases. Establishing favorable terms can lead to long-term partnerships and better financial margins.

7. Plan for Logistics and Distribution

Finally, consider the logistics involved in transporting your products from suppliers to your business. Evaluate shipping options, customs regulations, and any tariffs that may apply. A clear logistics plan ensures timely delivery and can help you avoid unexpected delays that could impact your sales.

By following these steps, B2B buyers can effectively navigate the sourcing process for metallic shirts, ensuring they acquire high-quality products that resonate with their target markets.

Comprehensive Cost and Pricing Analysis for metallic shirt Sourcing

What Are the Key Cost Components in Sourcing Metallic Shirts?

When sourcing metallic shirts, understanding the cost structure is crucial for B2B buyers aiming to optimize their procurement strategies. The primary cost components include:

-

Materials: The choice of fabric significantly influences the total cost. Metallic shirts can be made from various materials like polyester, cotton blends, or specialty fabrics with metallic finishes. Higher-quality materials may incur additional costs but can enhance the garment’s durability and appeal.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs, such as Vietnam and Bangladesh, may offer more competitive pricing. However, quality craftsmanship can demand higher wages, which is essential for maintaining the integrity of metallic finishes.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory management. Efficient production processes can lower these costs, making it vital for buyers to assess suppliers’ operational efficiencies.

-

Tooling: Custom designs or unique metallic finishes may require specialized tooling, adding to the upfront costs. Understanding these expenses upfront can prevent unexpected financial burdens later in the production process.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the finished products meet specified standards. While this incurs additional costs, it can prevent costly returns and enhance buyer satisfaction.

-

Logistics: Shipping and handling costs depend on factors such as the origin of the goods, destination, and shipping method. International buyers should consider freight rates and potential tariffs, especially when importing from regions like Asia or Europe.

-

Margin: Suppliers typically include a markup in their pricing to cover their operational costs and profit margins. Understanding the average industry margins can help buyers negotiate better deals.

How Do Price Influencers Impact the Sourcing of Metallic Shirts?

Numerous factors influence pricing in the metallic shirt market, and being aware of these can help buyers make informed decisions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing, making it advantageous for buyers to consolidate their orders. However, buyers must also consider storage and inventory management.

-

Specifications and Customization: Custom designs, unique colors, or specialized finishes can significantly affect the price. Buyers should evaluate whether these customizations add enough value to justify the increased costs.

-

Material Quality and Certifications: Higher-quality materials or those certified for sustainability may come with a premium price. Buyers should assess whether the added costs align with their target market’s expectations.

-

Supplier Factors: The reliability, reputation, and location of suppliers can impact pricing. Buyers should conduct thorough due diligence to ensure they partner with reputable manufacturers.

-

Incoterms: The choice of Incoterms can influence total costs, including shipping responsibilities and risk management. Understanding these terms is vital for negotiating favorable contracts.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Metallic Shirts?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Illustrative image related to metallic shirt

-

Negotiation Skills: Effective negotiation can significantly reduce costs. Establishing a good relationship with suppliers can lead to better pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with quality, durability, and maintenance. Investing in higher-quality shirts can lead to lower replacement rates.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, tariffs, and shipping costs. Buyers should conduct market research to understand these nuances and leverage them in negotiations.

-

Leverage Technology: Use digital platforms to compare prices and suppliers effectively. This can help identify competitive pricing and streamline the sourcing process.

In summary, a comprehensive understanding of cost components, price influencers, and effective sourcing strategies can empower B2B buyers to make informed decisions when sourcing metallic shirts. Buyers should remain vigilant about market trends and supplier dynamics to ensure they achieve the best possible outcomes in their sourcing endeavors.

Alternatives Analysis: Comparing metallic shirt With Other Solutions

Introduction: Understanding Alternatives to Metallic Shirts

In the evolving landscape of fashion, particularly within B2B markets, the need for versatile clothing options has never been more crucial. Metallic shirts, known for their distinctive shine and stylish appeal, serve a specific niche but may not always be the best fit for every buyer’s needs. To help international B2B buyers make informed decisions, it is essential to explore viable alternatives that can offer similar aesthetic and functional benefits while considering various factors such as cost, maintenance, and performance.

Comparison Table of Metallic Shirt and Alternatives

| Comparison Aspect | Metallic Shirt | Alternative 1: Cotton Blouse | Alternative 2: Polyester Shirt |

|---|---|---|---|

| Performance | High visual appeal, lightweight | Breathable, comfortable | Durable, wrinkle-resistant |

| Cost | Moderate to high | Low to moderate | Low to moderate |

| Ease of Implementation | Easy to incorporate into wardrobes | Readily available | Readily available |

| Maintenance | Hand wash or dry clean recommended | Machine washable | Machine washable |

| Best Use Case | Evening events, fashion-forward | Everyday wear, casual settings | Business casual, travel |

Detailed Breakdown of Alternatives

Alternative 1: Cotton Blouse

Cotton blouses are a classic choice for B2B buyers seeking comfort without sacrificing style. They are breathable and soft against the skin, making them ideal for everyday wear. Their cost-effectiveness is a significant advantage, allowing businesses to purchase in bulk without overstretching budgets. However, cotton may not provide the same level of visual appeal or luxury as metallic shirts, which could be a downside for brands targeting high-fashion markets.

Alternative 2: Polyester Shirt

Polyester shirts are known for their durability and low maintenance requirements. They are wrinkle-resistant and can withstand frequent washing, making them a practical choice for businesses that require consistent wearability. Additionally, polyester can be produced at a lower cost, making it an attractive option for bulk orders. However, the fabric may not offer the same luxurious look as metallic options, which could impact brand perception in more upscale markets.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right shirt for your business needs, consider the specific use case and target audience. Metallic shirts are ideal for occasions that demand a touch of glamour, while cotton and polyester alternatives offer practicality and comfort for everyday settings. Evaluating factors such as performance, cost, and maintenance will guide B2B buyers in making informed decisions that align with their branding and operational requirements. By understanding the strengths and weaknesses of each option, businesses can strategically select apparel that enhances their market presence and meets customer expectations.

Essential Technical Properties and Trade Terminology for metallic shirt

What Are the Key Technical Properties of Metallic Shirts?

When sourcing metallic shirts for B2B applications, understanding their technical properties is essential for ensuring quality and meeting market demands. Here are some critical specifications to consider:

-

Material Composition

Metallic shirts are typically made from a blend of synthetic fibers such as polyester or nylon infused with metallic threads. The inclusion of materials like Lurex or metallic foil enhances the garment’s shine and durability. For B2B buyers, knowing the material composition helps assess the quality and longevity of the product, which can influence customer satisfaction and return rates. -

Weight and Fabric Thickness

The weight of the fabric is measured in grams per square meter (GSM). A higher GSM usually indicates a thicker, more durable fabric, while lower GSM can suggest a lighter, more breathable shirt. For B2B buyers, understanding fabric weight is crucial for selecting appropriate garments for specific climates or uses, such as seasonal collections or promotional events. -

Colorfastness and Shine Level

Colorfastness tests determine how well the fabric retains its color when exposed to washing, light, and sweat. Additionally, the shine level refers to the intensity of the metallic finish. Buyers need to ensure that the products they source maintain their appearance over time, as this can significantly affect brand reputation. -

Size Tolerance and Fit

Tolerance levels indicate acceptable variations in size during production. For example, a tolerance of ±0.5 inches in garment measurements allows for minor discrepancies in manufacturing. Understanding size tolerance is vital for B2B transactions, as it ensures that the products will fit the intended market, avoiding costly returns and exchanges. -

Care Instructions

Proper care instructions, including washing and drying methods, are vital for maintaining the quality of metallic shirts. Typically, these garments may require delicate handling to preserve their metallic finish. Buyers must communicate these care requirements clearly to their customers to enhance product longevity and satisfaction.

What Trade Terms Should B2B Buyers Know When Sourcing Metallic Shirts?

Navigating the B2B landscape requires familiarity with specific trade jargon. Here are some essential terms to understand:

Illustrative image related to metallic shirt

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products based on another company’s specifications. For buyers of metallic shirts, working with an OEM can allow for customized designs and branding, enabling differentiation in the marketplace. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to ensure that their orders align with their inventory needs and budget constraints. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing metallic shirts, issuing an RFQ can help buyers receive competitive offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and logistics. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and delivery timelines associated with their orders. -

Lead Time

Lead time is the duration between placing an order and receiving the goods. For B2B buyers, understanding lead times is crucial for inventory management and ensuring timely product availability in the market. -

Quality Assurance (QA)

QA refers to the systematic process of ensuring that products meet specified quality standards. Implementing QA measures in the sourcing of metallic shirts can reduce defects and enhance overall product quality, leading to greater customer satisfaction.

By understanding these key technical properties and trade terms, B2B buyers can make informed decisions when sourcing metallic shirts, ensuring quality products that meet their business needs.

Navigating Market Dynamics and Sourcing Trends in the metallic shirt Sector

What Are the Current Market Dynamics and Key Trends in the Metallic Shirt Sector?

The metallic shirt market is experiencing significant growth driven by changing fashion trends, increased demand for unique apparel, and the rise of online retail platforms. Global buyers are increasingly drawn to the aesthetic versatility of metallic fabrics, which can be styled for casual, formal, and party wear. As international fashion markets expand, particularly in regions like Africa, South America, and the Middle East, the metallic shirt’s appeal as a statement piece is becoming more pronounced. Additionally, B2B buyers are leveraging technology to enhance sourcing efficiency, using platforms that offer real-time inventory data and supplier ratings to streamline procurement processes.

Emerging trends indicate a shift toward customization and personalization in the metallic shirt sector. B2B buyers are increasingly interested in suppliers who can offer tailored solutions, whether in terms of fabric choice, color variations, or design alterations. Sustainability is another critical trend, with buyers prioritizing eco-friendly materials and ethical manufacturing processes, reflecting a broader global consciousness about environmental impacts. Additionally, the digital transformation in the fashion industry is facilitating better communication and collaboration between manufacturers and retailers, enabling quicker response times to market changes.

Illustrative image related to metallic shirt

How Important Is Sustainability and Ethical Sourcing in the Metallic Shirt Industry?

Sustainability and ethical sourcing are paramount in today’s metallic shirt market. The environmental impact of textile production, particularly the use of synthetic materials often found in metallic fabrics, has raised concerns among consumers and businesses alike. Buyers are increasingly demanding transparency in supply chains, seeking out suppliers who adhere to sustainable practices. This shift is not just a trend but a necessity, as consumers across Europe, Africa, and South America are more inclined to support brands that prioritize eco-friendly initiatives.

To meet these demands, suppliers are adopting ‘green’ certifications and sustainable materials such as organic cotton, recycled polyester, and other eco-conscious alternatives. Such certifications not only enhance brand reputation but also open up access to a broader range of markets, particularly in regions where consumers value ethical practices. B2B buyers should consider partnering with manufacturers that demonstrate a commitment to sustainability, as this can lead to long-term relationships and improved market positioning.

What Is the Brief Evolution and History of Metallic Shirts in the B2B Context?

Metallic shirts have evolved significantly since their inception in the fashion industry. Initially popularized in the disco era of the 1970s, these garments were often associated with flamboyant styles and nightlife. Over the decades, metallic fabrics have been reinterpreted and integrated into mainstream fashion, with designers experimenting with different textures, colors, and cuts to appeal to diverse consumer bases.

In the B2B context, the evolution of metallic shirts has been influenced by technological advancements in fabric production and dyeing processes, enabling manufacturers to create high-quality, durable metallic finishes. This evolution has allowed B2B buyers to source products that not only meet consumer demands for style but also maintain quality and affordability. As the market continues to grow, understanding the historical context of metallic shirts can provide valuable insights into current trends and future opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of metallic shirt

-

How do I choose the right supplier for metallic shirts?

Choosing the right supplier for metallic shirts involves several critical steps. Start by researching potential suppliers’ reputations through online reviews and industry references. Request samples to evaluate the quality of their products, ensuring they meet your specifications. Additionally, check for compliance with international trade regulations and ethical manufacturing practices. It’s also beneficial to ask for client testimonials and case studies to gauge their reliability and service quality. -

What are the common minimum order quantities (MOQs) for metallic shirts?

Minimum order quantities (MOQs) for metallic shirts can vary significantly depending on the supplier and the complexity of the designs. Typically, MOQs range from 100 to 500 units per style, but some manufacturers may accommodate lower quantities for specific orders or samples. Always clarify MOQs during negotiations, especially if you are entering a new market or testing a product line. This will help you assess your inventory needs effectively without overcommitting. -

What customization options are available for metallic shirts?

Customization options for metallic shirts can include fabric type, color, size range, and embellishments like sequins or embroidery. Many suppliers also offer private labeling and logo printing to enhance brand identity. When discussing customization, be clear about your design requirements and any specific technical specifications needed for production. It’s advisable to obtain prototypes before finalizing large orders to ensure the customization aligns with your expectations. -

What payment terms should I expect when sourcing metallic shirts internationally?

Payment terms for international orders of metallic shirts typically include options such as advance payment, letter of credit, or net 30/60 terms. Many suppliers may require a deposit upfront, especially for custom orders, with the balance due upon delivery or after shipping documents are provided. Always negotiate payment terms that work for your cash flow while ensuring supplier trustworthiness, and consider using escrow services for added security in transactions. -

How can I ensure quality assurance (QA) for metallic shirts?

To ensure quality assurance for metallic shirts, establish clear quality control standards and communicate them to your supplier. Consider implementing a third-party inspection service to evaluate the products before shipment. Additionally, conduct pre-production meetings to align on fabric quality, color accuracy, and finishing details. Regular communication throughout the production process can help address any issues early, ensuring that the final products meet your quality expectations. -

What are the typical shipping and logistics considerations for metallic shirts?

Shipping and logistics for metallic shirts involve selecting the right freight forwarder, understanding customs regulations, and determining shipping methods. Consider the destination country’s import duties and taxes, as these can impact overall costs. It’s also important to discuss lead times with your supplier and plan for potential delays, especially during peak shipping seasons. Utilizing reliable tracking systems will help you monitor your shipment and maintain communication with your supplier. -

What are the key market trends influencing metallic shirt demand?

Current market trends influencing the demand for metallic shirts include the growing popularity of sustainable fashion and the rise of athleisure and casual wear. Metallic fabrics are increasingly being integrated into everyday clothing as consumers seek unique, eye-catching styles. Additionally, social media trends and influencer marketing play a significant role in shaping consumer preferences. Keeping abreast of these trends can help you make informed purchasing decisions and align your inventory with market demands. -

How do I handle returns or exchanges for defective metallic shirts?

Handling returns or exchanges for defective metallic shirts involves establishing a clear return policy with your supplier. This policy should outline the process for reporting defects, the timeframe for returns, and any conditions for exchanges. Ensure you maintain documentation of all communications regarding defects to facilitate the return process. It’s also beneficial to discuss with your supplier how they handle shipping costs associated with returns, as this can affect your overall cost management.

Top 5 Metallic Shirt Manufacturers & Suppliers List

1. Lauren Ralph Lauren – Women’s Metallic Chiffon Shirt

Domain: macys.com

Registered: 1994 (31 years)

Introduction: This company, Lauren Ralph Lauren – Women’s Metallic Chiffon Shirt, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. LOFT – Metallic Shirts for Women

Domain: loft.com

Registered: 1997 (28 years)

Introduction: This company, LOFT – Metallic Shirts for Women, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. PrettyLittleThing – Metallic Tops Collection

Domain: prettylittlething.us

Registered: 2015 (10 years)

Introduction: Metallic Tops collection featuring various styles including:

– Grey Metallic Satin Cowl Long Top: $19.50 (originally $53.00)

– Silver Metallic Coated Denim Corset Top: $22.50 (originally $53.00)

– Silver Tinsel Knit Bandeau Top: $11.75 (originally $47.00)

– Pink Metallic Denim Stitch Detail Corset: $13.25 (originally $53.00)

– Dark Silver Metallic Open Back Cap Sleeve Longline Top: $8.00 (original…

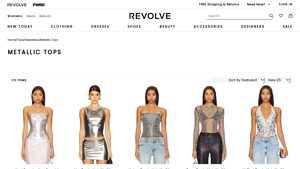

4. Lovers and Friends – Novi Fau

Domain: revolve.com

Registered: 1995 (30 years)

Introduction: Women’s Metallic Tops collection featuring silver, gold, and neutral hues. Brands include Lovers and Friends, House of Harlow 1960, Retrofete, and more. Available styles include strapless, cropped, sleeveless, long sleeve, and blouses. Prices range from $39 to $391. Key products include: 1) Novi Faux Leather Corset in Metallic Silver – $61; 2) Liza Top in Metallic Silver – $77; 3) Fame Top in Meta…

5. Pinterest – Metallic Blouse Outfit Ideas

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Metallic Shirt Outfit Ideas, Metallic Button-up Blouse For Fall, Chic Long Sleeve Metallic Blouse, Glamorous Metallic Long Sleeve Blouse, Metallic Shiny Long Sleeve Blouse, Fitted Long Sleeve Metallic Blouse, Satin Shirt Outfit, Button Front Drop Shoulder Metallic Blouse, Casual Birthday Party Outfit, Summer Metallic Shirt Outfit Ideas, Plus Size Metallic Top, Affordable Gold T-shirt For Streetwea…

Strategic Sourcing Conclusion and Outlook for metallic shirt

How Can Strategic Sourcing Enhance Your Metallic Shirt Offerings?

In the competitive landscape of fashion, particularly with metallic shirts, strategic sourcing has become a vital component for B2B buyers looking to capitalize on emerging trends. By aligning with reliable suppliers who offer a variety of styles—from sequined blouses to metallic tank tops—businesses can diversify their inventory and meet consumer demand effectively. The insights gathered from current market offerings highlight a growing preference for innovative designs and quality materials, underscoring the importance of partnering with manufacturers who can deliver both.

Moreover, the international market, particularly in regions like Africa, South America, the Middle East, and Europe, presents vast opportunities for growth. Buyers are encouraged to leverage data-driven sourcing strategies that not only enhance product quality but also optimize costs. This approach not only strengthens supply chains but also positions businesses to respond swiftly to changing consumer preferences.

Looking ahead, the metallic shirt segment is poised for continued growth. B2B buyers should actively seek partnerships that offer not just products, but collaborative opportunities to innovate and engage with the market. Embrace the potential of strategic sourcing and take decisive steps today to stay ahead in this dynamic industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.