Metallic Eyelets Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for metallic eyelets

Navigating the global market for metallic eyelets presents a unique challenge for international B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. With varying standards of quality, application needs, and sourcing practices, identifying reliable suppliers can feel daunting. This comprehensive guide aims to demystify the complexities of sourcing metallic eyelets by exploring the different types available, their various applications across industries, and essential criteria for supplier vetting.

From the durability of stainless steel to the versatility of brass, understanding the material properties of metallic eyelets is crucial for making informed purchasing decisions. Buyers will also find valuable insights into pricing structures, shipping considerations, and the implications of regional regulations that may affect their sourcing strategy. By equipping B2B buyers with the tools and knowledge necessary to navigate this market, this guide empowers them to forge partnerships with reputable suppliers, ensuring their projects are met with the highest standards of quality and reliability.

Whether you are looking to enhance manufacturing processes, improve product designs, or ensure compliance with local standards, this guide is designed to streamline your sourcing journey and enhance your competitive edge in the global marketplace. With actionable insights and expert advice, you can confidently make decisions that align with your business objectives and operational needs.

Understanding metallic eyelets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Eyelets | High corrosion resistance, durable, polished finish | Marine applications, medical devices | Pros: Long-lasting, aesthetic appeal. Cons: Higher cost. |

| Brass Eyelets | Strong, durable, and corrosion-resistant | Heavy-duty tarps, banners, outdoor use | Pros: Excellent strength, versatile. Cons: Heavier than alternatives. |

| Iron Eyelets | Economical, suitable for short-term use | Indoor signs, campaign materials | Pros: Cost-effective, easy to install. Cons: Prone to rust. |

| Plastic-Coated Metal Eyelets | Coating for additional protection against corrosion | Outdoor signage, promotional materials | Pros: Enhanced durability, lightweight. Cons: Limited high-temperature resistance. |

| Aluminum Eyelets | Lightweight, good corrosion resistance | Apparel, crafts, and light-duty applications | Pros: Easy to handle, good for various projects. Cons: Less robust than steel. |

What Are the Key Characteristics of Stainless Steel Eyelets?

Stainless steel eyelets are renowned for their exceptional corrosion resistance and durability, making them ideal for demanding environments like marine applications and medical devices. Their polished finish not only adds aesthetic value but also enhances their resistance to wear and tear. When considering B2B purchases, companies should weigh the higher upfront costs against the long-term savings on replacements and maintenance, especially in high-humidity or corrosive settings.

How Do Brass Eyelets Stand Out in Various Applications?

Brass eyelets are strong and durable, often favored for heavy-duty applications such as tarps, banners, and outdoor installations. Their ability to withstand harsh weather conditions makes them a go-to choice for businesses requiring reliable fastening solutions. When purchasing brass eyelets, buyers should consider their weight and the potential need for additional support in applications where they are subjected to heavy loads.

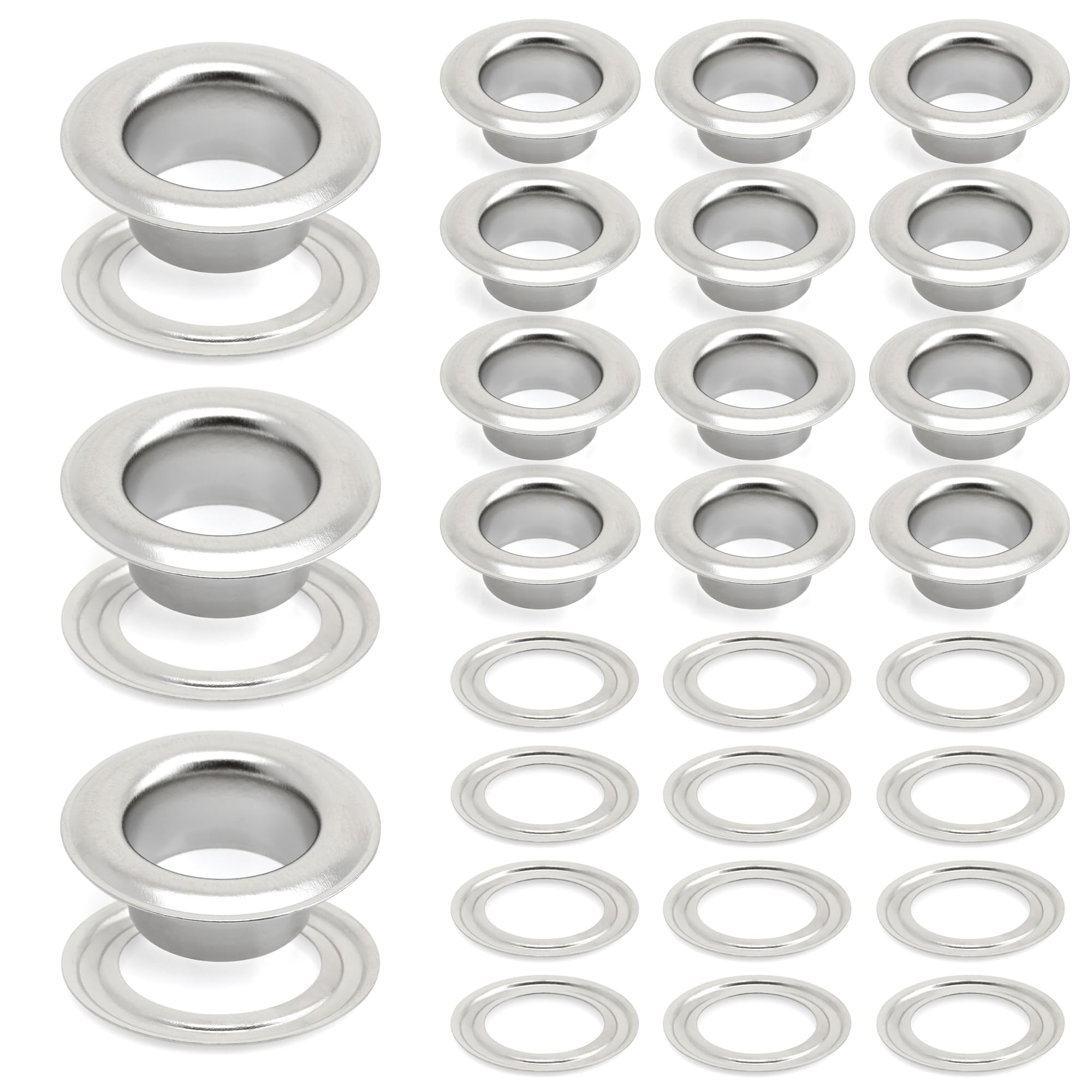

Illustrative image related to metallic eyelets

Why Choose Iron Eyelets for Short-Term Projects?

Iron eyelets are the most economical choice for projects requiring temporary solutions, such as indoor signs and campaign materials. While they offer a cost-effective option, their susceptibility to rust makes them unsuitable for long-term outdoor use. B2B buyers should evaluate the project’s duration and environmental conditions before opting for iron eyelets, ensuring they meet their specific needs without incurring unnecessary costs.

What Are the Benefits of Using Plastic-Coated Metal Eyelets?

Plastic-coated metal eyelets provide an additional layer of protection against corrosion, making them suitable for outdoor signage and promotional materials. Their lightweight nature facilitates easy installation, but businesses should be cautious about their limitations in high-temperature environments. When considering these eyelets, buyers should assess the conditions of use to determine if the benefits outweigh the potential drawbacks.

How Do Aluminum Eyelets Compare to Other Types?

Aluminum eyelets are lightweight and offer good corrosion resistance, making them ideal for applications in apparel, crafts, and light-duty projects. They are easy to handle and install, appealing to businesses looking for efficiency. However, buyers should note that while aluminum eyelets are versatile, they may not provide the same level of strength as their stainless steel or brass counterparts, which could be a critical factor depending on the application.

Key Industrial Applications of metallic eyelets

| Industry/Sector | Specific Application of metallic eyelets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile & Apparel | Reinforcement in garments and accessories | Enhances durability and extends product lifespan | Material compatibility, corrosion resistance, bulk pricing |

| Marine & Outdoor Equipment | Attachment points in tarps and covers | Provides reliable fastening for harsh environments | Weather resistance, size specifications, delivery timelines |

| Medical Devices | Custom fittings in orthotic devices | Improves patient comfort and device functionality | Regulatory compliance, material safety, custom designs |

| Signage & Display | Eyelets for banners and signage | Increases visibility and durability in outdoor use | Aesthetic finish, size and shape requirements, order volume |

| Paper & Packaging | Reinforcement in tags and labels | Enhances product presentation and usability | Material thickness, adhesive properties, environmental considerations |

How Are Metallic Eyelets Used in the Textile & Apparel Industry?

Metallic eyelets serve as reinforcement points in garments, bags, and accessories, allowing for laces, cords, or straps to pass through without tearing the fabric. This application is particularly beneficial for high-stress areas, enhancing durability and extending the lifespan of the products. For international buyers, especially those in Africa and South America, sourcing eyelets that are compatible with various fabric types and resistant to rust is crucial to ensure quality and longevity in their offerings.

Illustrative image related to metallic eyelets

What Role Do Metallic Eyelets Play in Marine & Outdoor Equipment?

In marine and outdoor applications, metallic eyelets are employed as attachment points for tarps, covers, and sails. Their robust design ensures that they can withstand harsh weather conditions, providing reliable fastening solutions. Buyers in the Middle East and Europe should focus on sourcing materials that are corrosion-resistant and suitable for prolonged exposure to water and UV rays to ensure product reliability in outdoor settings.

How Are Metallic Eyelets Utilized in Medical Devices?

Metallic eyelets are integral to the design of orthotic devices, providing custom fittings that enhance patient comfort and device functionality. They allow for adjustable straps and supports that can be tailored to individual needs. For international buyers, particularly in the medical sector, compliance with regulatory standards and the use of biocompatible materials are critical factors when sourcing these components.

Why Are Metallic Eyelets Important for Signage & Display?

In the signage and display industry, metallic eyelets are used to reinforce banners and signs, allowing for easy hanging and increased durability in outdoor environments. This application enhances visibility and ensures that signage remains intact despite weather conditions. Buyers should consider the aesthetic finish and size requirements of eyelets to match their specific branding and display needs, particularly in competitive markets like Europe and South America.

How Do Metallic Eyelets Benefit Paper & Packaging Applications?

In the paper and packaging sector, metallic eyelets are used to reinforce tags and labels, improving their usability and presentation. This application is particularly useful for businesses looking to enhance product packaging and branding. When sourcing, international buyers should pay attention to the thickness of the materials and the environmental impact of the eyelets, ensuring they meet sustainability goals while maintaining product integrity.

Illustrative image related to metallic eyelets

3 Common User Pain Points for ‘metallic eyelets’ & Their Solutions

Scenario 1: Quality Assurance in Manufacturing Processes

The Problem: A B2B buyer responsible for sourcing metallic eyelets for a manufacturing operation often faces challenges related to quality control. Inconsistent quality in eyelet production can lead to product failures, increased return rates, and ultimately damage to brand reputation. Buyers may encounter issues such as variations in size, material defects, or inadequate corrosion resistance, especially when sourcing from multiple suppliers across different regions. This inconsistency not only complicates the production process but also strains relationships with end-users who rely on the durability of these components.

The Solution: To mitigate quality assurance challenges, buyers should establish stringent specifications that outline the required material properties, dimensions, and performance criteria for the metallic eyelets. Implementing a robust supplier evaluation process is crucial; this could include requesting samples for testing before placing bulk orders. Building long-term relationships with reputable manufacturers known for their quality control measures can also help ensure consistency. Utilizing technology for tracking and monitoring production processes can further enhance quality assurance. Regular audits and inspections at the manufacturing site will allow buyers to verify compliance with specifications, fostering trust and reliability in the supply chain.

Scenario 2: Difficulty in Matching Eyelet Specifications with Applications

The Problem: B2B buyers often struggle with selecting the appropriate metallic eyelet type for specific applications, leading to compatibility issues. For instance, using a standard eyelet in a high-stress environment may result in premature failure, impacting product integrity and safety. This scenario is particularly pertinent for industries like marine, medical, or heavy-duty manufacturing, where eyelet specifications such as size, material (stainless steel vs. brass), and design features (like self-piercing capabilities) play a critical role in performance.

The Solution: To address this issue, buyers should conduct a thorough analysis of the application requirements before sourcing metallic eyelets. This includes evaluating factors such as load-bearing capacity, environmental conditions (e.g., exposure to moisture or chemicals), and expected wear and tear. Collaborating with engineers or technical experts can provide insights into the best eyelet types for specific applications. Additionally, creating a detailed matrix that lists the application requirements alongside eyelet specifications can streamline the selection process. Engaging suppliers who offer technical support and guidance can further enhance decision-making, ensuring that the right eyelet is sourced for each unique application.

Illustrative image related to metallic eyelets

Scenario 3: Supply Chain Disruptions Affecting Timely Deliveries

The Problem: International B2B buyers often face significant challenges related to supply chain disruptions, particularly in regions like Africa and South America. Delays in the delivery of metallic eyelets can halt production lines and disrupt project timelines, resulting in financial losses and strained client relationships. Factors such as geopolitical issues, transportation bottlenecks, and varying lead times from suppliers can complicate sourcing efforts, making it essential for buyers to have contingency plans in place.

The Solution: To counteract supply chain disruptions, buyers should diversify their supplier base across multiple regions. This strategy not only provides backup options in case of delays but also allows for competitive pricing. Implementing just-in-time inventory practices can help maintain sufficient stock levels while minimizing excess inventory costs. Additionally, buyers can establish clear communication channels with suppliers to receive real-time updates on order status and potential delays. Investing in supply chain management software can also facilitate better tracking of shipments and inventory levels, enabling proactive decision-making. Finally, maintaining a buffer stock of critical components can provide an additional safeguard against unexpected disruptions, ensuring that production remains uninterrupted.

Strategic Material Selection Guide for metallic eyelets

What Are the Key Properties of Common Materials for Metallic Eyelets?

When selecting metallic eyelets for various applications, understanding the properties of different materials is crucial for ensuring optimal performance. Here, we analyze four common materials used for metallic eyelets: stainless steel, brass, iron, and aluminum.

Illustrative image related to metallic eyelets

Stainless Steel: A Durable Choice for Corrosion Resistance

Stainless steel, particularly grades 304 and 316, is renowned for its exceptional corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for demanding environments, such as marine and medical applications. The primary advantages of stainless steel eyelets include their durability and aesthetic appeal, as they maintain their appearance over time without significant degradation.

However, stainless steel can be more expensive than other materials, which may affect budget considerations for large-scale orders. Additionally, the manufacturing process can be complex, requiring specialized equipment. For international buyers, compliance with standards such as ASTM and DIN is essential, especially in regions like Europe where stringent regulations apply.

Brass: The Versatile Option for Heavy-Duty Applications

Brass eyelets are favored for their strength and resistance to corrosion, particularly in outdoor applications. They are often used in heavy-duty tarps, banners, and sign-making due to their durability and ability to withstand harsh weather conditions. The manufacturing process for brass is relatively straightforward, which can lead to lower costs compared to stainless steel.

On the downside, brass may not perform as well in highly corrosive environments, such as saltwater, and can tarnish over time. For buyers in regions like South America and Africa, understanding local environmental conditions is crucial when choosing brass eyelets for outdoor applications.

Illustrative image related to metallic eyelets

Iron: An Economical Option for Short-Term Use

Iron eyelets are often the most economical choice, making them suitable for temporary applications such as campaign signs or indoor displays. They are easy to manufacture and can be produced at a low cost, which appeals to budget-conscious buyers. However, iron has limited corrosion resistance and is generally recommended for indoor use or short-term outdoor applications.

For international buyers, particularly in the Middle East, it is essential to consider the local climate and potential for rust when opting for iron eyelets. Compliance with local standards may also vary, so it’s advisable to check specific regulations.

Aluminum: A Lightweight Alternative for Diverse Applications

Aluminum eyelets are lightweight and resistant to corrosion, making them an excellent choice for applications requiring both strength and minimal weight. They are commonly used in the textile industry and for lightweight tarps and banners. The manufacturing process for aluminum is generally less complex, resulting in competitive pricing.

However, aluminum may not provide the same level of strength as stainless steel or brass, which can limit its use in heavy-duty applications. For buyers in Europe and Africa, understanding the specific load requirements of their applications is vital when choosing aluminum eyelets.

Summary of Material Selection for Metallic Eyelets

| Material | Typical Use Case for metallic eyelets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine and medical applications | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

| Brass | Heavy-duty tarps and outdoor signage | Strong and durable | Can tarnish and less corrosion-resistant | Medium |

| Iron | Campaign signs and indoor displays | Economical and easy to manufacture | Limited corrosion resistance | Low |

| Aluminum | Lightweight textiles and banners | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on application needs, environmental conditions, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for metallic eyelets

What Are the Main Stages in the Manufacturing Process of Metallic Eyelets?

The manufacturing process of metallic eyelets involves several critical stages that ensure high-quality products suitable for various applications. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used for Metallic Eyelets?

The first step in manufacturing metallic eyelets is material preparation. Common materials include stainless steel, brass, and aluminum, each chosen for its unique properties such as corrosion resistance, strength, and weight. For instance, stainless steel is favored for marine applications due to its durability, while brass is often used for decorative purposes.

Illustrative image related to metallic eyelets

Before production, raw materials undergo thorough inspection to ensure they meet specifications. Suppliers often provide certificates of compliance to confirm material quality, allowing buyers to verify that the materials are suitable for their intended use.

How Are Metallic Eyelets Formed?

The forming stage involves shaping the prepared materials into eyelet forms. This is typically done using techniques such as stamping, extrusion, or die casting.

-

Stamping: This method involves pressing flat metal sheets into molds, creating the desired eyelet shape. It’s efficient for large production runs.

-

Extrusion: In this process, metal is forced through a die to create long shapes, which can then be cut into eyelet lengths. This method is useful for creating complex designs.

-

Die Casting: For more intricate designs or specific material requirements, die casting can be employed. This involves pouring molten metal into a mold, allowing for high precision and detailed features.

Each technique has its advantages and is selected based on factors like cost, design complexity, and production volume.

Illustrative image related to metallic eyelets

What Happens During the Assembly Stage?

Once the eyelets are formed, they may require assembly with other components, such as washers or grommets, depending on their application. Automated assembly lines are often used to enhance efficiency and consistency.

During this stage, it is crucial to ensure that all components fit together correctly to maintain the integrity and functionality of the final product. Automated systems can significantly reduce the risk of human error, contributing to higher quality outcomes.

What Finishing Techniques Are Commonly Used?

The finishing stage involves surface treatments that enhance the eyelet’s durability and aesthetic appeal. Common techniques include:

-

Electroplating: This process adds a thin layer of metal (such as nickel or chrome) to improve corrosion resistance and appearance.

-

Powder Coating: A dry finishing process that provides a durable, colorful surface, often used for decorative eyelets.

-

Anodizing: Particularly for aluminum eyelets, anodizing increases corrosion resistance and allows for dyeing in various colors.

These finishing processes not only improve the eyelet’s performance but also its suitability for different environments, such as outdoor or industrial settings.

Illustrative image related to metallic eyelets

What Quality Assurance Measures Are Important for Metallic Eyelets?

Quality assurance is vital for ensuring that metallic eyelets meet international standards and customer expectations. B2B buyers should familiarize themselves with the key quality assurance processes and standards.

Which International Standards Should B2B Buyers Be Aware Of?

International standards, such as ISO 9001, play a significant role in quality management systems across manufacturing sectors. Compliance with these standards ensures that suppliers maintain consistent quality throughout their processes.

In addition to ISO standards, other industry-specific certifications may be relevant, such as CE marking for products sold in Europe or API standards for products used in the petroleum and natural gas industries. Understanding these certifications can help buyers assess the reliability of their suppliers.

Illustrative image related to metallic eyelets

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process and typically includes several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection checks raw materials for compliance with specifications before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that processes remain within defined parameters. This stage often involves monitoring equipment settings and product dimensions.

-

Final Quality Control (FQC): Once production is complete, the final product undergoes a comprehensive inspection. This may include dimensional checks, visual inspections, and functional tests to ensure that the eyelets meet all specified requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. Here are several strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting access to supplier audits and quality control reports can provide insights into their manufacturing practices. This includes documentation of compliance with international standards and records of past quality issues.

Regular audits, whether conducted internally or by third-party organizations, can help ensure that suppliers maintain their quality assurance commitments over time.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct thorough inspections at various stages of the manufacturing process, from raw material checks to final product evaluations. This not only provides peace of mind but also helps build trust between buyers and suppliers.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. Different regions may have specific regulations or standards that affect product acceptance.

For instance, buyers in Europe must ensure that products comply with CE marking requirements, while Middle Eastern markets may have specific certifications tied to local regulations. Understanding these regional differences can help buyers avoid compliance issues and ensure a smooth procurement process.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for metallic eyelets is crucial for B2B buyers. By focusing on the stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions that align with their operational needs and quality expectations.

Illustrative image related to metallic eyelets

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metallic eyelets’

This sourcing guide is designed to assist international B2B buyers in effectively procuring metallic eyelets. By following these steps, you can ensure that your purchasing decisions are informed and strategic, ultimately leading to high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for metallic eyelets. Consider factors such as size, material (e.g., stainless steel, brass), and intended application. This step is crucial as it helps you communicate effectively with suppliers and ensures you receive products that fit your project requirements.

- Material Considerations: Different materials offer varying levels of durability and corrosion resistance. For example, stainless steel is ideal for marine applications, while brass is suitable for heavy-duty use.

- Size and Dimensions: Ensure you specify the exact measurements needed for your application to avoid compatibility issues.

Step 2: Conduct Market Research

Thoroughly investigate the market to identify potential suppliers. Utilize online platforms, industry directories, and trade shows to gather information about various manufacturers and distributors. Understanding the landscape helps you compare options and identify reputable suppliers.

Illustrative image related to metallic eyelets

- Supplier Reviews and Ratings: Look for customer testimonials and ratings to gauge supplier reliability.

- Industry Specialization: Focus on suppliers that specialize in metallic eyelets relevant to your industry for more tailored solutions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This information will provide insights into their reliability and product quality.

- Quality Assurance: Inquire about their quality control processes to ensure they meet your standards.

- Certifications: Check for industry certifications that validate their manufacturing processes, such as ISO certification.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality and suitability of the metallic eyelets for your application. Testing samples can save you from costly mistakes and ensure product compliance with your specifications.

- Test for Durability: Evaluate the samples for strength and resistance to corrosion, especially if they will be used in demanding environments.

- Fit and Functionality: Ensure the samples fit your intended use, such as embedding in thermoplastics or serving as fastening points.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms that align with your budget and timelines.

- Volume Discounts: Inquire about discounts for bulk orders, which can significantly reduce costs.

- Payment Flexibility: Discuss payment terms that work for both parties, such as net 30 or net 60 days.

Step 6: Confirm Shipping and Delivery Details

Clarify shipping methods, costs, and expected delivery times before finalizing your order. This step is essential to ensure that your supply chain remains uninterrupted and that you receive your products on time.

Illustrative image related to metallic eyelets

- Shipping Options: Evaluate available shipping methods and choose one that balances cost and speed.

- Tracking and Insurance: Ensure that your shipment includes tracking options and consider insurance for high-value orders.

Step 7: Establish a Relationship for Future Orders

After completing your purchase, maintain communication with your supplier to build a long-term relationship. A strong partnership can lead to better service, priority access to new products, and more favorable terms in future transactions.

- Feedback Loop: Provide feedback on product performance and service to help the supplier improve.

- Regular Check-Ins: Schedule periodic reviews to discuss upcoming needs and innovations in their offerings.

By following this checklist, you will be well-equipped to navigate the complexities of sourcing metallic eyelets, ensuring that your procurement process is efficient and effective.

Comprehensive Cost and Pricing Analysis for metallic eyelets Sourcing

What Are the Key Cost Components in Sourcing Metallic Eyelets?

When sourcing metallic eyelets, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The type of metal used (e.g., stainless steel, brass, or iron) significantly affects the price. Stainless steel eyelets, known for their durability and corrosion resistance, typically cost more than those made from iron, which is more economical but less durable.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Regions with higher labor costs may increase the overall pricing of the eyelets.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturers often have lower overhead costs, translating to better pricing for buyers.

-

Tooling: Custom tooling for specific designs can add to the initial costs. However, these costs can be amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Ensuring that eyelets meet international quality standards can incur additional costs. Certifications and testing for compliance with industry standards can influence the final price.

-

Logistics: Shipping costs, including freight and handling, play a significant role, especially for international transactions. Factors like distance, mode of transport, and Incoterms (International Commercial Terms) can impact logistics costs.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the competitive landscape can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of Metallic Eyelets?

Several factors influence the pricing of metallic eyelets, including order volume, specifications, materials, quality, supplier factors, and shipping terms.

Illustrative image related to metallic eyelets

-

Volume/MOQ: Minimum Order Quantities (MOQ) often dictate pricing. Larger orders generally benefit from bulk pricing, reducing the cost per unit.

-

Specifications and Customization: Customized eyelets tailored to specific applications or designs may incur higher costs due to additional tooling and manufacturing processes.

-

Materials: The choice of material directly affects pricing. For instance, marine-grade stainless steel is more expensive than standard iron due to its enhanced properties.

-

Quality and Certifications: Eyelets that comply with specific industry standards or possess certifications will typically command higher prices. Buyers should assess the necessity of these certifications based on their application.

-

Supplier Factors: The supplier’s reputation, reliability, and service quality can also impact pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the implications of Incoterms is essential. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears the shipping costs and risks, affecting the total cost of ownership.

What Are the Best Buyer Tips for Sourcing Metallic Eyelets Internationally?

International B2B buyers should adopt strategic approaches to maximize cost-efficiency and negotiate favorable terms.

-

Negotiation: Leverage volume discounts and establish long-term relationships with suppliers. Negotiating payment terms and delivery schedules can also yield cost savings.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like maintenance, durability, and replacement frequency when assessing the value of eyelets.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that may affect final costs. Engage with suppliers familiar with your region to navigate these complexities.

-

Supplier Evaluation: Conduct thorough due diligence on potential suppliers. Consider their production capacity, quality assurance processes, and past performance.

-

Market Research: Stay informed about market trends and pricing benchmarks in different regions. This knowledge can empower you during negotiations and help you identify competitive suppliers.

By understanding the cost structure and pricing influencers, B2B buyers can make informed decisions when sourcing metallic eyelets, ensuring they receive quality products at competitive prices.

Alternatives Analysis: Comparing metallic eyelets With Other Solutions

Introduction: Exploring Alternatives to Metallic Eyelets

In the fast-paced B2B landscape, businesses often seek effective fastening solutions to enhance product durability and functionality. Metallic eyelets are widely recognized for their strength and versatility, but various alternatives may better suit specific applications or budgetary constraints. This analysis compares metallic eyelets with two viable alternatives: plastic grommets and self-piercing grommets, providing insights for informed decision-making.

Comparison Table

| Comparison Aspect | Metallic Eyelets | Plastic Grommets | Self-Piercing Grommets |

|---|---|---|---|

| Performance | High durability and load-bearing capacity | Adequate for lightweight applications | Strong and quick installation |

| Cost | Moderate to high cost | Low cost | Moderate cost |

| Ease of Implementation | Requires specialized tools for installation | Easy to install with basic tools | Minimal tools needed, user-friendly |

| Maintenance | Low maintenance, corrosion-resistant | May degrade over time in UV light | Low maintenance, corrosion-resistant |

| Best Use Case | Heavy-duty applications, textiles, and banners | Lightweight banners, crafts, and tags | Quick assembly in various materials |

Detailed Breakdown of Alternatives

Plastic Grommets

Plastic grommets are a cost-effective alternative to metallic eyelets, particularly for lightweight applications. They are often used in crafting, clothing, and signage. The primary advantage of plastic grommets is their affordability and ease of use; they can be installed with basic tools and are available in various colors. However, they may not offer the same load-bearing capacity and durability as metallic options, making them unsuitable for heavy-duty applications. Additionally, prolonged exposure to UV light can lead to degradation, limiting their lifespan in outdoor settings.

Self-Piercing Grommets

Self-piercing grommets provide a robust fastening solution that combines ease of installation with substantial strength. They are designed to pierce through materials during installation, eliminating the need for pre-drilled holes. This feature makes them ideal for quick assembly in a variety of materials, including heavy fabrics and tarps. While self-piercing grommets are moderately priced, they offer excellent corrosion resistance and low maintenance requirements. However, they may not be the best choice for applications where precise hole placement is critical, as the installation method can sometimes lead to misalignment.

Conclusion: Choosing the Right Fastening Solution

When selecting a fastening solution, B2B buyers should consider the specific requirements of their application, including material type, load-bearing needs, and environmental conditions. Metallic eyelets excel in heavy-duty scenarios where durability is paramount, while plastic grommets serve as a budget-friendly option for lighter applications. Self-piercing grommets strike a balance between strength and ease of use, making them suitable for various settings. By carefully evaluating these alternatives, businesses can make informed decisions that align with their operational goals and project requirements.

Essential Technical Properties and Trade Terminology for metallic eyelets

What Are the Key Technical Properties of Metallic Eyelets?

Metallic eyelets are essential components in various industrial applications, and understanding their technical specifications is critical for making informed purchasing decisions. Here are some of the key properties to consider:

Illustrative image related to metallic eyelets

-

Material Grade

The most common materials for metallic eyelets include stainless steel, brass, and iron. Stainless steel (especially marine-grade) is preferred for its corrosion resistance and durability, making it ideal for outdoor and marine applications. Brass offers a balance of strength and aesthetic appeal, while iron is generally more economical for short-term indoor use. Selecting the right material is vital for ensuring the longevity and performance of the eyelets in their intended applications. -

Size and Diameter

Eyelets come in various sizes, typically defined by their inner and outer diameters. The size affects the compatibility with the material they will be embedded in, as well as the load they can bear. In B2B contexts, specifying the correct size is crucial to prevent operational failures and ensure the integrity of the final product. -

Tolerance

Tolerance refers to the permissible limits of variation in the dimensions of the eyelet. Tight tolerances are essential in applications where precision is critical, such as in medical devices or high-performance equipment. Understanding the tolerance levels helps buyers ensure that the eyelets will fit properly and function effectively within their specific applications. -

Finish

The finish of metallic eyelets can vary from polished to matte, with some eyelets undergoing additional treatments for enhanced corrosion resistance or aesthetic qualities. The finish not only impacts the eyelet’s appearance but also its performance in different environments. For instance, a high-polish finish may be desirable in decorative applications, while a matte finish might be preferred for industrial uses. -

Load Capacity

Load capacity indicates the maximum weight an eyelet can support before failure. This property is particularly important in applications like tarps, banners, or safety equipment where the eyelet will bear significant stress. Buyers must assess the load requirements of their projects to select eyelets that will perform reliably under anticipated conditions.

What Are Common Trade Terms Related to Metallic Eyelets?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of metallic eyelets, understanding OEM relationships can help buyers navigate supply chains and identify reliable sources for custom or standard products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for buyers to understand, as it impacts inventory levels and overall purchasing costs. Knowing the MOQ can help in planning purchases and managing budgets effectively. -

RFQ (Request for Quotation)

An RFQ is a formal document that buyers use to solicit price quotes from suppliers for specific products. For metallic eyelets, issuing an RFQ can help buyers compare prices, terms, and lead times, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is essential for managing shipping logistics and costs effectively, ensuring clarity on who bears the risk at various stages of the delivery process. -

Lead Time

Lead time is the time taken from placing an order to receiving the product. For buyers of metallic eyelets, understanding lead times is critical for project planning and ensuring timely delivery of materials to avoid production delays.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, streamline their procurement processes, and foster better relationships with suppliers in the metallic eyelet industry.

Navigating Market Dynamics and Sourcing Trends in the metallic eyelets Sector

What Are the Current Market Dynamics and Key Trends for Metallic Eyelets?

The global metallic eyelets market is experiencing significant growth driven by various factors, including the rising demand for durable fastening solutions across multiple industries such as textiles, automotive, and construction. Key trends include the increasing adoption of automation in manufacturing processes, which enhances efficiency and reduces production costs. Additionally, the shift towards customization is becoming prominent, as manufacturers offer tailored solutions to meet specific client requirements, especially for B2B buyers in diverse regions like Africa, South America, the Middle East, and Europe.

Emerging technologies, such as 3D printing and advanced machining techniques, are revolutionizing how metallic eyelets are produced, enabling rapid prototyping and reducing lead times. B2B buyers are increasingly leveraging digital sourcing platforms that facilitate real-time price comparisons and supplier evaluations, enhancing their decision-making process. Furthermore, the rise of e-commerce has made it easier for international buyers to access a broader range of suppliers, allowing them to find cost-effective solutions while ensuring quality.

How Is Sustainability Impacting the Sourcing of Metallic Eyelets?

Sustainability is becoming a critical consideration for B2B buyers sourcing metallic eyelets. The environmental impact of production processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly seeking suppliers who adopt sustainable practices, such as using recycled materials and minimizing emissions during manufacturing. The demand for ‘green’ certifications, such as ISO 14001, is also on the rise, as businesses aim to enhance their corporate social responsibility profiles.

Ethical sourcing is equally important, with buyers prioritizing suppliers that ensure fair labor practices and ethical treatment of workers in their supply chains. This trend is particularly relevant for international buyers who are keen on aligning their procurement strategies with global sustainability goals. By selecting suppliers who prioritize environmental stewardship and ethical practices, businesses can not only reduce their carbon footprint but also enhance their brand reputation in competitive markets.

What Is the Historical Context of Metallic Eyelets in B2B Markets?

The use of metallic eyelets can be traced back to the early industrial era when manufacturers sought robust solutions for fastening materials in textiles and apparel. Initially crafted from basic metals, advancements in metallurgy and production techniques have led to the development of a diverse range of materials, including stainless steel and brass, which offer superior durability and corrosion resistance. Over the decades, metallic eyelets have evolved to meet the needs of various sectors, including fashion, construction, and medical applications. This historical progression reflects the ongoing innovation within the sector, enabling B2B buyers to access a vast array of high-quality products tailored to their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of metallic eyelets

-

How do I choose the right metallic eyelets for my application?

When selecting metallic eyelets, consider the material compatibility, size, and intended use. For instance, stainless steel eyelets are ideal for marine applications due to their corrosion resistance, while brass eyelets offer durability for outdoor uses. Additionally, assess the thickness of the material where the eyelet will be installed to ensure a proper fit. Consulting with suppliers about your specific application can also help in making the best choice. -

What are the typical applications for metallic eyelets?

Metallic eyelets are versatile and used in various industries, including textiles, packaging, marine, and construction. They serve to reinforce holes in materials like fabric, paper, and plastics, providing a durable point for fastening or lacing. Specific applications include banners, tarpaulins, and outdoor gear, where strength and weather resistance are crucial. Understanding your industry’s requirements will guide you to the most suitable eyelet type. -

What is the minimum order quantity (MOQ) for metallic eyelets?

Minimum order quantities for metallic eyelets can vary significantly based on the supplier and the specific product. Some suppliers may offer MOQs as low as 100 units, while others may require orders of 1,000 units or more for custom products. It’s essential to discuss your needs with potential suppliers to find a balance between your requirements and their capabilities, especially if you are looking for unique specifications. -

How can I verify the credibility of a metallic eyelet supplier?

To verify a supplier’s credibility, consider checking their business licenses, certifications, and customer reviews. Requesting references from other clients can also provide insights into their reliability and quality of service. Additionally, visiting their manufacturing facility, if feasible, can give you a firsthand look at their operations and quality control processes. Utilizing platforms like Alibaba or ThomasNet can also help in assessing supplier ratings and feedback. -

What customization options are available for metallic eyelets?

Many suppliers offer customization options for metallic eyelets, including size, color, material, and packaging. You can often request specific finishes, such as nickel plating for added corrosion resistance, or different eyelet styles to suit your application. Discussing your requirements with suppliers early in the procurement process ensures that they can meet your specifications and help you achieve the desired look and functionality. -

What payment terms should I expect when sourcing metallic eyelets internationally?

Payment terms can vary widely among suppliers. Common practices include upfront payments, net 30 or net 60 terms, and letters of credit for larger orders. It’s crucial to clarify payment expectations early in negotiations and ensure that they align with your financial processes. Consider discussing options for secure payment methods to protect both parties in the transaction, especially when dealing with international shipments. -

How do I ensure quality assurance for metallic eyelets?

To ensure quality assurance, request samples before placing large orders. This allows you to assess the eyelets for durability, finish, and fit. Additionally, inquire about the supplier’s quality control processes, including any certifications such as ISO 9001. Establishing clear quality standards and inspection protocols in your purchase agreement can help mitigate risks associated with defective products. -

What logistics considerations should I keep in mind when importing metallic eyelets?

When importing metallic eyelets, consider shipping methods, lead times, and customs regulations. Select a shipping option that balances cost and speed, and confirm with your supplier about their shipping capabilities. Familiarize yourself with import duties and taxes in your country to avoid unexpected costs. Working with a freight forwarder can streamline the logistics process and ensure compliance with international trade regulations.

Top 6 Metallic Eyelets Manufacturers & Suppliers List

1. NC Medical – Metal Eyelets (100)

Domain: ncmedical.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Metal Eyelets (100)”, “item_number”: “NC22558”, “price”: “$6.95”, “availability”: “In Stock”, “features”: [“Easy to embed in warm thermoplastics”, “Used to guide outrigger line or elastic traction”], “shipping_info”: {“standard_shipping”: “Orders placed by 5:00 PM EST will ship the same day”, “expedited_shipping”: “Orders placed by 11:00 AM EST will ship the same day”}, “special_…

2. Eyelets Metal – Key Product Details

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for Eyelets Metal on eBay include: 1. Categories: Art & Craft Supplies, Leathercraft Accessories, Sewing Eyelets, Decorative Brads, etc. 2. Colors available: Silver, Gold, Black, Gray, Multicolor, Blue, White, Green, Pink, Red, etc. 3. Condition: New, Used, Not Specified. 4. Buying Formats: Auction, Buy It Now, Accepts Offers. 5. Price Range: Under $15.00, $15.00 to $35.00, Ove…

3. Raleigh Beer Garden – Metal Grommet Eyelet Rivets

Domain: theraleighbeergarden.com

Registered: 2013 (12 years)

Introduction: This company, Raleigh Beer Garden – Metal Grommet Eyelet Rivets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. RC Fastener – Custom Metal Eyelets & Grommets

Domain: rcfastener.com

Registered: 2015 (10 years)

Introduction: This company, RC Fastener – Custom Metal Eyelets & Grommets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Sailrite – Grommets & Eyelets

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Grommets & Eyelets: Metal, Brass, Stainless Steel. Types include spur grommets, washer grommets, curtain grommets, decorative eyelets for leatherworking, and vent grommets for airflow in projects like vinyl upholstery and slipcovers.

6. Kaos Softwear – Metallic Skin Eyelets

Domain: kaossoftwear.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Metallic Skin Eyelets”, “price”: “$10.99”, “dimensions”: {“width”: “0.10 in”, “height”: “0.10 in”, “depth”: “0.10 in”}, “shipping”: “Calculated at Checkout”, “color_options”: [“Rose Gold”, “Gold”, “Silver”, “Copper”], “size_options”: [“6g”, “4g”, “2g”, “0g”, “00g”, “7/16\””, “1/2\””, “9/16\””, “5/8\””, “3/4\””, “7/8\””, “1\””] , “note”: “All Items Are Sold Individually. Order 2 F…

Strategic Sourcing Conclusion and Outlook for metallic eyelets

How Can Strategic Sourcing Enhance Your Metallic Eyelet Procurement?

In today’s competitive market, the strategic sourcing of metallic eyelets is essential for international B2B buyers seeking quality and reliability. By fostering strong relationships with suppliers, businesses can ensure consistent product availability and optimize pricing structures. Understanding the diverse applications of metallic eyelets—from medical devices to outdoor canopies—enables buyers to tailor their sourcing strategies effectively.

Moreover, leveraging local suppliers in regions such as Africa and South America can enhance supply chain efficiency, reduce lead times, and mitigate risks associated with international shipping. As manufacturers continue to innovate, staying informed about advancements in materials and production techniques will further empower buyers to make educated decisions that align with their operational needs.

Illustrative image related to metallic eyelets

Looking ahead, the demand for durable and aesthetically pleasing metallic eyelets is poised to grow, particularly in sectors like marine, medical, and textile industries. International B2B buyers are encouraged to actively engage with suppliers, explore new markets, and adopt a proactive approach to sourcing. By doing so, they can unlock greater value and enhance their competitive edge in an evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to metallic eyelets

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.