Mesh Metal Bag: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for mesh metal bag

In today’s competitive landscape, sourcing high-quality mesh metal bags can present a significant challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe, such as Nigeria and Brazil. With a multitude of options available, from metallic mesh to specialized animal-proof designs, navigating this market requires a strategic approach. This comprehensive guide aims to demystify the complexities of the mesh metal bag sector by examining various types, their applications, and effective supplier vetting processes.

In this guide, you will gain insights into the different styles and functionalities of mesh metal bags, including their use in food storage, outdoor activities, and fashion accessories. Additionally, we delve into the critical aspects of cost considerations and quality assessment to ensure you make informed purchasing decisions. With a focus on actionable strategies, this resource empowers B2B buyers to identify reliable suppliers and negotiate favorable terms, ultimately enhancing their procurement processes.

By understanding the nuances of the mesh metal bag market, you can better align your sourcing strategies with your business needs, ensuring you meet customer demands while optimizing your supply chain. Whether you are looking to expand your product offerings or streamline your inventory, this guide serves as a valuable tool in your journey toward successful procurement in the global marketplace.

Understanding mesh metal bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metallic Mesh Bags | Made from interlocking metal rings; durable and stylish. | Fashion accessories, promotional items | Pros: High durability, aesthetic appeal; Cons: Can be heavier than alternatives. |

| Outsak® Spectrum Bags | Stainless steel wire mesh; animal-proof with Velcro closure. | Outdoor gear storage, camping supplies | Pros: Highly protective, flexible design; Cons: Limited color choices, higher cost. |

| Nylon Mesh Bags | Lightweight, often waterproof; available in various colors. | Sports equipment, laundry, and travel. | Pros: Lightweight, easy to carry; Cons: Less durable than metal options. |

| Gusset Cases | Expandable sides for increased storage capacity; often zippered. | Retail packaging, travel accessories | Pros: Versatile storage, easy access; Cons: Can be bulkier when expanded. |

| Zipper Cases | Secured with zippers; available in various sizes and colors. | Cosmetic cases, electronics storage | Pros: Secure closure, organized storage; Cons: Zipper may wear out over time. |

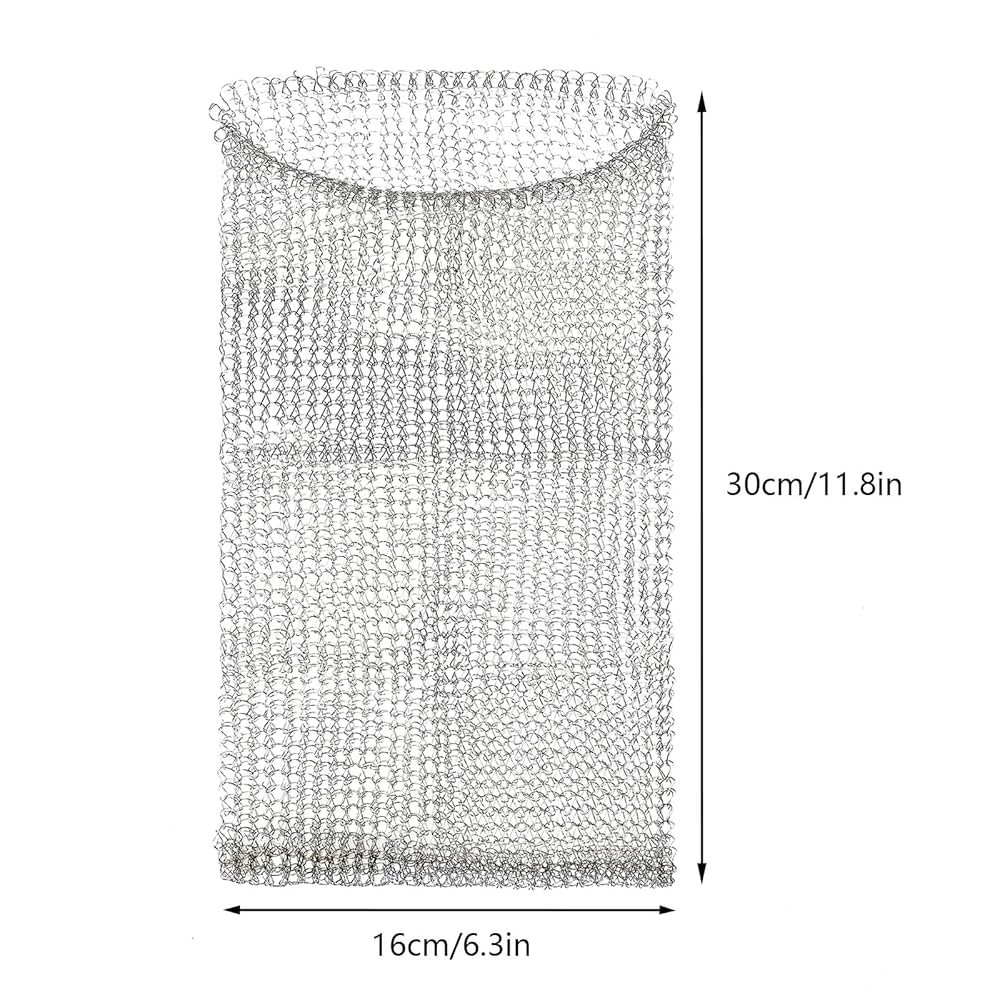

What are the Characteristics of Metallic Mesh Bags?

Metallic mesh bags are crafted from interlocking metal rings, providing a unique blend of durability and aesthetic appeal. Often used in fashion accessories, these bags can serve as promotional items due to their eye-catching designs. When considering a purchase, B2B buyers should assess the balance between style and functionality, as these bags can be heavier than alternatives, affecting shipping and handling.

How Do Outsak® Spectrum Bags Stand Out in the Market?

The Outsak® Spectrum bags are distinguished by their construction from stainless steel wire mesh, designed specifically to be animal-proof. This feature makes them ideal for outdoor gear storage, particularly in camping contexts where protection from wildlife is crucial. B2B buyers should consider the higher price point and limited color options against the bags’ superior protective qualities, especially for businesses that prioritize safety in outdoor activities.

Why Choose Nylon Mesh Bags for Lightweight Solutions?

Nylon mesh bags are lightweight and often waterproof, making them an excellent choice for various applications, including sports equipment and travel. Their availability in multiple colors adds to their appeal for branding and promotional purposes. However, B2B buyers should note that while they are convenient and portable, nylon bags may not offer the same level of durability as metal options, which could be a consideration for long-term use.

Illustrative image related to mesh metal bag

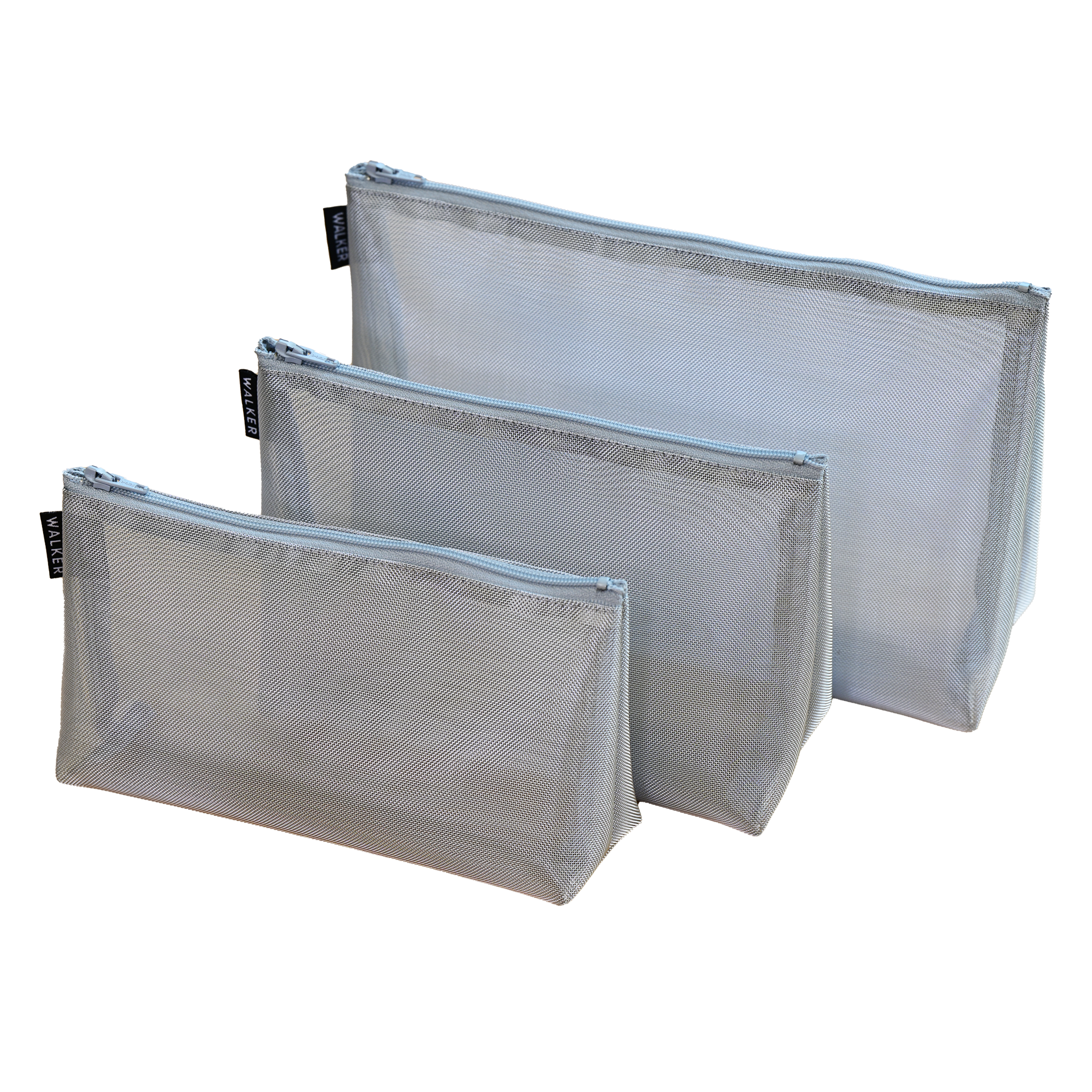

What Benefits Do Gusset Cases Offer for Storage Needs?

Gusset cases are designed with expandable sides that allow for increased storage capacity, often featuring a zipper for easy access. These bags are particularly useful in retail packaging and travel accessories, providing versatility for different storage needs. Buyers should weigh the convenience of expandable storage against the potential for bulkiness when expanded, which may affect transport logistics.

How Do Zipper Cases Enhance Organization for Various Industries?

Zipper cases are known for their secure closure and organized storage capabilities. They are commonly used for cosmetics and electronics, making them popular in the beauty and tech industries. B2B buyers should consider the practicality of these bags in terms of organization and security; however, it’s important to keep in mind that the zipper mechanism may wear out over time, which could impact long-term usability.

Key Industrial Applications of mesh metal bag

| Industry/Sector | Specific Application of mesh metal bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Storage of food items in outdoor environments | Protects against pests and contamination | Material durability, size options, and UV resistance |

| Outdoor Recreation | Backpacking and camping food storage | Lightweight and compact for easy transport | Flexibility, closure type, and weather resistance |

| Agriculture | Seed storage and transportation | Prevents moisture and pest damage | Breathability, size specifications, and mesh strength |

| Manufacturing & Logistics | Parts storage and organization | Enhances visibility and accessibility of items | Custom sizes, mesh type, and durability under stress |

| Waste Management | Sorting and transporting recyclables | Facilitates easy handling and sorting | Mesh size, tensile strength, and compliance with regulations |

How Are Mesh Metal Bags Used in the Food & Beverage Industry?

In the food and beverage sector, mesh metal bags are essential for storing and transporting food items, particularly in outdoor settings like camping or picnics. These bags are designed to protect food from pests, including rodents and insects, while allowing for ventilation, which helps prevent spoilage. International buyers, especially from regions like Africa and South America, should consider the durability of materials used, UV resistance to withstand harsh sunlight, and the size options available to accommodate various food storage needs.

Illustrative image related to mesh metal bag

What Role Do Mesh Metal Bags Play in Outdoor Recreation?

In outdoor recreation, mesh metal bags serve as ideal storage solutions for backpackers and campers, allowing them to pack food securely while keeping it lightweight and compact. These bags are often designed with strong closures to prevent wildlife access, ensuring that food remains safe during excursions. Buyers in the Middle East and Europe should prioritize flexibility in design, ease of use, and weather resistance when sourcing these bags, as conditions can vary significantly based on location.

How Are Mesh Metal Bags Beneficial in Agriculture?

In agriculture, mesh metal bags are utilized for seed storage and transportation. Their breathable design helps prevent moisture accumulation, which can lead to seed rot, while also protecting against pests. For B2B buyers in regions like Nigeria and Brazil, it is crucial to focus on the mesh strength and size specifications to ensure that the bags meet the specific requirements for different types of seeds and conditions during transport.

Why Are Mesh Metal Bags Important in Manufacturing & Logistics?

Manufacturing and logistics industries benefit from mesh metal bags for storing and organizing parts. These bags enhance visibility and accessibility, making it easier for workers to locate items without rummaging through opaque containers. Buyers should consider custom sizes and the type of mesh used to ensure that the bags can withstand the stresses of a manufacturing environment, particularly in high-traffic areas.

How Do Mesh Metal Bags Aid in Waste Management?

In waste management, mesh metal bags are effective for sorting and transporting recyclables. Their design allows for easy handling while ensuring that materials can be identified and sorted quickly. When sourcing these bags, businesses need to pay attention to the mesh size and tensile strength to ensure compliance with local regulations and to handle the weight of collected materials effectively.

Illustrative image related to mesh metal bag

3 Common User Pain Points for ‘mesh metal bag’ & Their Solutions

Scenario 1: Sourcing Quality Mesh Metal Bags for Diverse Applications

The Problem: Many B2B buyers face challenges in sourcing high-quality mesh metal bags that meet specific operational needs. Whether for food storage in outdoor settings or for packaging delicate items, the quality of the mesh and the construction of the bags can vary significantly across suppliers. Buyers often worry about the durability and effectiveness of the bags, especially when it comes to protecting contents from external factors like pests or moisture. This inconsistency can lead to product damage, increased costs, and dissatisfied end customers.

The Solution: To overcome these challenges, buyers should prioritize sourcing from reputable manufacturers with a proven track record in producing durable mesh metal bags. Request detailed product specifications, including the type of mesh used (e.g., stainless steel vs. nylon), closure mechanisms (like VELCRO®), and any certifications related to food safety or environmental compliance. It’s advisable to order samples before making bulk purchases to assess the quality firsthand. Additionally, consider establishing a direct line of communication with suppliers to discuss specific needs and obtain customized solutions, ensuring that the bags are tailored for the intended application.

Scenario 2: Ensuring Compliance with Local Regulations for Mesh Metal Bags

The Problem: Buyers in different regions may encounter regulatory hurdles when importing mesh metal bags. For instance, bags used for food storage must comply with health and safety regulations that vary by country. This can be especially challenging for international buyers from Africa, South America, the Middle East, and Europe, where the standards for materials and product safety can differ widely. Non-compliance can lead to costly fines, product recalls, or damage to brand reputation.

Illustrative image related to mesh metal bag

The Solution: To navigate these regulatory landscapes, B2B buyers should conduct thorough research on the specific regulations applicable in their target markets. This includes understanding the materials permitted for food contact, labeling requirements, and any certifications that may be necessary. Collaborating with a logistics partner experienced in international trade can help streamline the import process and ensure that all documentation is in order. Additionally, buyers should consider partnering with manufacturers who are knowledgeable about compliance standards in their regions and can provide documentation to verify that their products meet necessary requirements.

Scenario 3: Addressing Environmental Concerns with Mesh Metal Bags

The Problem: Increasingly, B2B buyers are faced with pressure to source environmentally friendly products, including mesh metal bags. Many consumers and businesses are becoming more eco-conscious and prefer products that are sustainable and recyclable. Buyers may struggle to find mesh bags that not only meet their functional requirements but also align with their corporate sustainability goals. Failing to address these concerns can result in lost business opportunities and damage to brand reputation.

The Solution: To address environmental concerns, B2B buyers should seek out suppliers that prioritize sustainability in their manufacturing processes. This includes using recyclable materials, such as stainless steel or biodegradable nylon, and adopting environmentally friendly production practices. When evaluating suppliers, inquire about their sustainability certifications and eco-friendly initiatives. Additionally, buyers can consider implementing a take-back program for used bags, encouraging recycling and reducing waste. By aligning product sourcing with sustainability goals, businesses can enhance their brand image and appeal to a growing segment of eco-conscious consumers.

Strategic Material Selection Guide for mesh metal bag

What Are the Key Materials Used in Mesh Metal Bags?

When selecting materials for mesh metal bags, it is essential to consider the properties, advantages, and limitations of various options. Here, we analyze four common materials used in the production of mesh metal bags: stainless steel, aluminum, nylon mesh, and galvanized steel. Each material offers unique characteristics that can significantly influence the performance and suitability of the bags for specific applications.

How Does Stainless Steel Perform in Mesh Metal Bags?

Stainless steel is a popular choice for mesh metal bags due to its excellent corrosion resistance and durability. This material can withstand high temperatures and pressures, making it suitable for various applications, including food storage and outdoor gear protection. The primary advantages of stainless steel include its strength and resistance to rust, which is critical for maintaining product integrity in humid or wet environments.

However, stainless steel can be more expensive than other materials, which may impact production costs. Additionally, its weight can be a drawback for applications requiring lightweight solutions. For international buyers, especially in regions like Africa and South America, ensuring compliance with local standards for food safety and corrosion resistance is crucial.

What Advantages Does Aluminum Offer for Mesh Metal Bags?

Aluminum mesh bags are lightweight and provide good resistance to corrosion, making them ideal for applications where weight is a concern. They are often used in camping and outdoor activities due to their portability. The manufacturing process for aluminum mesh is generally less complex than that of stainless steel, which can lead to lower production costs.

On the downside, aluminum is less durable than stainless steel and may not perform well under extreme conditions. It can be prone to dents and scratches, which may compromise the bag’s functionality over time. B2B buyers from regions like the Middle East should consider the specific environmental conditions their products will face, as aluminum may not be suitable for all climates.

How Does Nylon Mesh Compare in Terms of Versatility?

Nylon mesh is another option for mesh bags, particularly in applications requiring flexibility and lightweight properties. This material is often used in athletic gear and storage solutions due to its ability to allow airflow while providing a degree of protection against the elements. Nylon mesh is also relatively inexpensive and easy to manufacture.

However, nylon is less durable than metal options and may not withstand high temperatures or heavy loads. It is also susceptible to UV degradation, which can limit its lifespan when exposed to sunlight. For buyers in Europe, compliance with standards such as ASTM or DIN for textile safety is essential when considering nylon mesh for products intended for consumer use.

What Role Does Galvanized Steel Play in Mesh Metal Bags?

Galvanized steel offers a middle ground between stainless steel and aluminum, providing decent corrosion resistance at a lower cost than stainless steel. This material is often used in industrial applications where strength and durability are paramount. Galvanized steel mesh bags can withstand significant wear and tear, making them suitable for heavy-duty applications.

The primary limitation of galvanized steel is its susceptibility to rust if the protective coating is damaged. This can be a concern in humid environments, particularly in regions like Nigeria or Brazil, where moisture levels are high. Buyers should ensure that the galvanized steel used meets local standards for durability and corrosion resistance.

Summary of Material Selection for Mesh Metal Bags

| Material | Typical Use Case for mesh metal bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food storage, outdoor gear | Excellent corrosion resistance | Higher cost, heavier weight | High |

| Aluminum | Camping, lightweight storage | Lightweight, good corrosion resistance | Less durable, prone to dents | Medium |

| Nylon Mesh | Athletic gear, flexible storage | Inexpensive, allows airflow | Less durable, UV degradation | Low |

| Galvanized Steel | Industrial applications | Good strength at lower cost | Susceptible to rust | Medium |

This strategic material selection guide provides B2B buyers with critical insights into the various materials used in mesh metal bags, enabling informed decisions that align with their operational needs and market demands.

Illustrative image related to mesh metal bag

In-depth Look: Manufacturing Processes and Quality Assurance for mesh metal bag

What Are the Main Stages in the Manufacturing Process of Mesh Metal Bags?

The manufacturing process for mesh metal bags involves several key stages that ensure both functionality and aesthetic appeal.

Material Preparation

The process begins with the selection of high-quality materials. Stainless steel wire is commonly used due to its durability and resistance to corrosion, which is critical for outdoor and industrial applications. The wire is typically coated or treated to enhance its resistance to environmental factors. Suppliers often utilize materials that meet international standards for safety and performance, such as ASTM and ISO specifications.

Once the materials are selected, they undergo pre-processing to cut the wire into specific lengths. This stage may also involve surface treatments like polishing or galvanizing to enhance the material’s longevity and appearance.

Illustrative image related to mesh metal bag

What Techniques Are Used to Form Mesh Metal Bags?

The forming stage involves several techniques to create the mesh structure.

-

Weaving and Knitting: The primary technique for creating the mesh involves interweaving or knitting the wire strands to form a flexible fabric-like structure. Advanced machinery automates this process, ensuring uniformity in the mesh’s density and strength.

-

Punching and Cutting: After forming the mesh, additional processes like punching holes or cutting specific shapes may be required. This is particularly important for bags designed to have unique designs or features like ventilation.

-

Welding or Soldering: For structural integrity, parts of the mesh may be welded or soldered together, especially at seams and closures. This ensures that the bag can withstand the stresses of use without compromising its shape.

How Is the Assembly Process Conducted?

The assembly of mesh metal bags is a critical stage that involves combining various components into the final product.

-

Adding Closures and Handles: Depending on the design, closures such as zippers, Velcro, or hooks are integrated. Handles made from durable materials are also attached to enhance usability.

-

Quality Checks During Assembly: As each component is added, quality checks are performed to ensure that every piece fits correctly and functions as intended. This reduces the risk of defects in the final product.

What Finishing Touches Are Applied to Mesh Metal Bags?

Finishing processes enhance the bag’s aesthetic and functional properties. This can include:

-

Coating: A protective coating may be applied to improve resistance to wear and corrosion. This is especially important for bags intended for outdoor use.

-

Inspection and Cleaning: After assembly, bags undergo a thorough inspection to remove any residues from the manufacturing process. This step is essential for ensuring that the bags meet hygiene standards, particularly if they are used for food storage.

What Quality Assurance Processes Are Implemented?

Quality assurance is integral to the manufacturing of mesh metal bags, ensuring that the products meet both customer expectations and regulatory requirements.

Which International Standards Are Relevant for Mesh Metal Bags?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with these standards helps ensure consistent quality in production processes. Additionally, specific certifications like CE marking may be required for products sold in the European market, signifying compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are crucial throughout the manufacturing process. Common checkpoints include:

Illustrative image related to mesh metal bag

-

Incoming Quality Control (IQC): This is the first stage where raw materials are inspected upon arrival. Materials must meet pre-defined specifications to proceed in the production line.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks ensure that each stage meets quality standards. This includes verifying mesh density, closure functionality, and overall assembly.

-

Final Quality Control (FQC): The final inspection checks the completed bags against quality benchmarks, ensuring they are free from defects and ready for shipment.

What Common Testing Methods Are Used?

Manufacturers employ various testing methods to validate the quality of mesh metal bags:

-

Tensile Strength Testing: This assesses the strength of the mesh under tension, ensuring it can withstand the intended load.

-

Corrosion Resistance Testing: Particularly for outdoor applications, tests are conducted to evaluate how well the material resists environmental factors.

-

Durability Testing: This involves subjecting the bags to conditions that simulate real-world use to assess their lifespan and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is vital to ensure product reliability.

What Should Buyers Look for in Supplier Audits and Reports?

When assessing suppliers, buyers should request:

-

Quality Management System Documentation: This includes details on how the manufacturer complies with international standards like ISO 9001.

-

Audit Reports: Third-party audits can provide an unbiased view of the manufacturer’s quality processes and certifications.

-

Testing Certificates: Documentation proving that products have undergone necessary tests and meet specified standards.

How Do Quality Control Nuances Differ for International Buyers?

Different regions may have varying quality expectations and regulatory requirements. Buyers should be aware of:

-

Local Regulations: Import/export regulations can affect the type of certifications required for products entering specific markets.

-

Cultural Expectations: Preferences for product features or designs may vary by region, impacting quality standards.

-

Supply Chain Transparency: Buyers should ensure that suppliers can provide clear visibility into their manufacturing processes, as this can impact product quality and delivery timelines.

In conclusion, understanding the manufacturing processes and quality assurance measures for mesh metal bags is crucial for B2B buyers. By focusing on quality standards, testing methods, and supplier verification, businesses can ensure they receive reliable, high-quality products that meet their specific needs.

Illustrative image related to mesh metal bag

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mesh metal bag’

This guide serves as a practical checklist for B2B buyers looking to procure mesh metal bags, ensuring you make informed decisions that align with your business needs and standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of any successful procurement process. Consider the intended use of the mesh metal bags, including size, strength, and closure type. For instance, if the bags will be used for food storage, ensure they are made from materials that are safe and durable, such as stainless steel mesh or reinforced nylon.

Step 2: Research Market Trends and Applications

Understanding current market trends can help you identify the best suppliers and products. Investigate different applications for mesh metal bags across industries such as outdoor gear, fashion, or food storage. This knowledge allows you to source products that not only meet your specifications but also have a high demand in your target market.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record in producing high-quality mesh metal bags, as this will significantly reduce risks associated with product quality and reliability.

Illustrative image related to mesh metal bag

- Check Certifications: Ensure the suppliers meet international quality standards such as ISO certifications.

- Assess Production Capacity: Verify their ability to meet your order quantities and timelines.

Step 4: Request Samples for Quality Assessment

Always request samples before placing a bulk order. This step allows you to physically evaluate the product’s quality, durability, and functionality. Inspect the materials, stitching, and any closures to ensure they align with your specifications.

- Conduct Stress Tests: If applicable, perform stress tests to assess the strength and durability of the bags.

- Review Aesthetic Qualities: Ensure that the finish, color, and design meet your brand’s standards.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with potential suppliers to secure favorable terms. Discuss pricing, payment terms, and delivery schedules. Be clear about your expectations regarding quality assurance and return policies.

- Consider Volume Discounts: Leverage your order size to negotiate better pricing or additional services.

- Clarify Shipping Responsibilities: Ensure both parties understand who is responsible for shipping costs and risks.

Step 6: Finalize the Purchase Agreement

Once you have settled on a supplier, draft a comprehensive purchase agreement that outlines all terms discussed. This document should cover product specifications, pricing, delivery dates, and penalties for non-compliance. A well-defined agreement protects both parties and helps prevent disputes.

Step 7: Plan for Quality Control and Feedback

After receiving your order, implement a quality control process to verify that the products meet your specifications. Solicit feedback from your team on the performance of the mesh metal bags. This information is invaluable for future sourcing decisions and for maintaining strong supplier relationships.

By following these steps, B2B buyers can navigate the procurement process for mesh metal bags effectively, ensuring they obtain high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for mesh metal bag Sourcing

What Are the Key Cost Components in Sourcing Mesh Metal Bags?

When sourcing mesh metal bags, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to mesh metal bag

Materials: The type of mesh and metal used significantly impacts the cost. Stainless steel wire mesh, for example, is more durable and thus more expensive than alternatives like nylon mesh. Buyers should assess the material specifications to determine durability and suitability for their intended application.

Labor: Labor costs can vary by region and are influenced by the complexity of the manufacturing process. For instance, bags that require intricate designs or handwork will incur higher labor costs.

Manufacturing Overhead: This includes utilities, equipment depreciation, and facility expenses. Overhead can be a hidden cost, so it’s essential to understand how it is calculated by the supplier.

Tooling: Custom designs may necessitate specialized tooling, which can add to the initial investment. Buyers should inquire about any tooling fees, especially for unique sizes or designs.

Quality Control (QC): Ensuring the bags meet specific standards is vital, particularly for international trade. QC processes can add to costs but are essential for maintaining product quality and compliance with certifications.

Logistics: Shipping and handling expenses can vary widely based on distance, shipping method, and the Incoterms used. Proper logistics planning can help mitigate unexpected costs.

Margin: Finally, suppliers will add a profit margin, which can fluctuate based on market conditions and competition. Understanding the typical margins within the industry can aid in negotiation.

How Do Price Influencers Affect the Cost of Mesh Metal Bags?

Several factors can influence the pricing of mesh metal bags, making it essential for buyers to conduct thorough market research.

Volume/MOQ: Suppliers often have Minimum Order Quantities (MOQs). Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs against potential savings from higher volume purchases.

Specifications and Customization: Customization options can significantly impact pricing. Unique designs or materials will generally incur additional costs. Buyers should balance the need for customization with budget constraints.

Illustrative image related to mesh metal bag

Quality and Certifications: Higher quality materials and certifications can increase costs but may be necessary for certain markets or applications. International buyers should consider local regulations regarding materials and safety standards.

Supplier Factors: The reputation and location of the supplier can also influence pricing. Established suppliers with a good track record may charge more but can offer better reliability and quality assurance.

Incoterms: Understanding the shipping terms can help buyers anticipate costs. Terms such as CIF (Cost, Insurance, and Freight) include shipping in the overall price, while FOB (Free on Board) may require buyers to handle shipping logistics.

What Are Effective Buyer Tips for Negotiating Costs?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential.

Negotiate Wisely: Engage in open discussions with suppliers about pricing, especially if you have a substantial order. Don’t hesitate to ask for discounts or better payment terms.

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial costs, shipping, and potential maintenance expenses. This holistic view can often reveal more cost-effective solutions.

Understand Pricing Nuances: Be aware of regional pricing trends and fluctuations. Factors such as currency exchange rates, local tariffs, and import duties can all impact the final cost.

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service. Trust can lead to flexibility in negotiations and potential cost savings in future transactions.

Stay Informed: Keep abreast of market trends and pricing changes. Knowledge of the market landscape enables buyers to make timely and informed decisions.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always confirm with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing mesh metal bag With Other Solutions

Introduction: Understanding Alternatives for Mesh Metal Bags

When considering packaging and storage solutions, businesses often evaluate various options to find the most effective and economical choice. Mesh metal bags serve a specific purpose in industries such as food storage, outdoor gear protection, and more. However, several alternatives may fulfill similar roles, each with distinct advantages and drawbacks. This analysis compares mesh metal bags with two viable alternatives: nylon mesh bags and interlocking stainless steel containers.

Illustrative image related to mesh metal bag

Comparison Table

| Comparison Aspect | Mesh Metal Bag | Nylon Mesh Bag | Interlocking Stainless Steel Container |

|---|---|---|---|

| Performance | Durable, breathable, animal-resistant | Lightweight, less durable, breathable | Extremely durable, non-permeable, secure |

| Cost | Moderate ($19 – $54) | Low ($10 – $30) | High ($50 – $100) |

| Ease of Implementation | Easy to use | Easy to use | Requires more handling for assembly |

| Maintenance | Low maintenance, easy to clean | Low maintenance, but can wear over time | Requires regular cleaning, can be heavier |

| Best Use Case | Outdoor activities, food storage | General storage, lightweight items | Secure transport of sensitive materials |

Detailed Breakdown of Alternatives

Nylon Mesh Bags

Nylon mesh bags are a popular alternative due to their lightweight and cost-effective nature. These bags are typically easier to handle and transport, making them ideal for general storage needs. However, they may not offer the same durability as mesh metal bags, especially in environments prone to wear and tear or exposure to animals. Their breathability makes them suitable for items that require ventilation, but they are less effective at preventing animal access compared to metal options.

Interlocking Stainless Steel Containers

Interlocking stainless steel containers provide a robust and secure alternative for storage, especially in industries where contamination and spillage are critical concerns. These containers are highly durable and can withstand various environmental challenges. However, they come at a higher price point and may require more effort to handle and transport due to their weight. While they offer excellent protection, the need for regular cleaning and maintenance can be a drawback for some users, especially in high-volume settings.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right storage solution involves assessing specific requirements such as durability, cost, and intended use. For businesses focused on outdoor applications or needing a breathable solution, mesh metal bags may be the best choice. Conversely, those looking for lightweight and economical options might find nylon mesh bags suitable for their needs. If security and durability are paramount, interlocking stainless steel containers could be the ideal investment. Ultimately, understanding the unique characteristics of each option will enable B2B buyers to make informed decisions that align with their operational objectives.

Essential Technical Properties and Trade Terminology for mesh metal bag

What Are the Key Technical Properties of a Mesh Metal Bag?

When evaluating mesh metal bags for B2B procurement, understanding their technical specifications is crucial. Here are some essential properties to consider:

1. Material Grade

The material grade refers to the type and quality of the metal used in the mesh. Common materials include stainless steel, aluminum, or a combination of alloys. Higher-grade materials offer better resistance to corrosion, rust, and wear, which is vital for applications in harsh environments. For international buyers, especially in regions with varying climates, selecting the appropriate material grade can enhance durability and reduce replacement costs.

2. Mesh Size and Density

Mesh size is defined by the number of openings per inch, while density refers to the thickness of the wire used. A finer mesh size may provide better protection against small particles but could reduce airflow, which might be critical for certain applications. Understanding the balance between size and density helps businesses select bags that meet specific functional requirements, such as food storage or equipment protection.

3. Closure Type

The closure mechanism—such as Velcro, zippers, or drawstrings—affects the bag’s usability and security. For instance, a strong zipper closure can provide enhanced protection against external elements, making it suitable for outdoor or rugged use. Buyers should assess closure types based on their intended application to ensure ease of access and reliability.

Illustrative image related to mesh metal bag

4. Weight Capacity

Weight capacity indicates how much load the bag can carry without compromising structural integrity. This specification is particularly important for industries that require transporting heavy equipment or materials. Knowing the weight capacity helps buyers avoid overloading, which can lead to damage and increased liability.

5. UV Resistance

For bags intended for outdoor use, UV resistance is a critical property. This specification indicates the bag’s ability to withstand exposure to sunlight without degrading. For international buyers in sunny regions, selecting UV-resistant materials can prolong the lifespan of the bags and maintain their appearance.

6. Warranty and Compliance Standards

A manufacturer’s warranty provides assurance of product quality and durability, which is essential for B2B transactions. Compliance with international standards (e.g., ISO certifications) can also indicate that the product meets specific safety and quality benchmarks, giving buyers peace of mind regarding their purchases.

Illustrative image related to mesh metal bag

What Are Common Trade Terms Used in the Mesh Metal Bag Industry?

Familiarity with industry-specific jargon can streamline negotiations and purchasing processes. Here are key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. Understanding OEM relationships can help buyers source custom mesh metal bags tailored to specific applications or branding requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps businesses plan their purchases efficiently, ensuring they meet the supplier’s requirements while avoiding excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. Utilizing RFQs allows buyers to compare prices, specifications, and terms across multiple vendors, facilitating informed decision-making.

Illustrative image related to mesh metal bag

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps mitigate risks associated with shipping, insurance, and customs clearance, making it essential for global B2B transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management, especially for businesses that rely on timely deliveries to meet customer demands.

6. Customization

Customization involves modifying a product to meet specific client requirements, such as size, color, or branding. Buyers should explore customization options to enhance product appeal and functionality, particularly in competitive markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the mesh metal bag Sector

What Are the Current Market Dynamics and Key Trends in the Mesh Metal Bag Sector?

The mesh metal bag sector is experiencing robust growth driven by several global factors. The increasing demand for durable, versatile, and aesthetically appealing bags in various industries—from fashion to outdoor activities—has positioned mesh metal bags as a preferred choice among consumers. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that offer innovative designs and high-quality materials. Emerging trends include the integration of advanced manufacturing technologies such as automated weaving and metal finishing processes, enhancing production efficiency and product quality.

Moreover, the rise of e-commerce platforms has facilitated easier access to diverse suppliers, allowing buyers to compare offerings and negotiate better terms. The trend toward customization is also significant, as businesses look to differentiate their products in competitive markets. Custom sizes, colors, and branding options are becoming vital selling points for suppliers catering to the unique preferences of various regions, particularly in Nigeria and Brazil, where local styles and cultural influences are paramount.

How Is Sustainability and Ethical Sourcing Influencing B2B Purchases in This Sector?

Sustainability is a key consideration in the sourcing of mesh metal bags, as environmental concerns continue to shape purchasing decisions. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing practices. This includes the use of recycled or eco-friendly materials, which not only reduce environmental impact but also appeal to a growing segment of environmentally conscious consumers.

Certifications such as Global Recycled Standard (GRS) and OEKO-TEX® are gaining importance as they provide assurance of sustainability and ethical production methods. Suppliers that can showcase such certifications are likely to attract more interest from international buyers looking to align their products with sustainable values. Furthermore, the demand for transparency in supply chains is pushing businesses to adopt more responsible practices, ensuring that labor conditions are fair and materials are sourced ethically. This trend is particularly relevant in regions like Europe and the Middle East, where consumers are increasingly aware of the social and environmental implications of their purchases.

How Has the Mesh Metal Bag Sector Evolved Over Time?

The history of the mesh metal bag sector dates back to the late 19th century when it was pioneered by companies such as Whiting & Davis. The first mesh bags, created by hand, quickly gained popularity as fashionable accessories among affluent women. Over the decades, the industry has evolved significantly, with technological advancements enabling mass production and the introduction of innovative designs and materials.

By the 1920s, mesh bags became synonymous with glamour, often seen in the hands of Hollywood starlets. The shift towards automation in the 1910s allowed for greater production efficiency, leading to a broader range of styles and price points. Today, the sector is characterized by a blend of traditional craftsmanship and modern manufacturing techniques, catering to diverse markets and consumer preferences. This evolution has not only solidified the status of mesh metal bags as fashion staples but also as functional items in various sectors, including outdoor recreation and travel, enhancing their appeal to international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of mesh metal bag

-

How do I ensure quality when sourcing mesh metal bags from international suppliers?

To ensure quality when sourcing mesh metal bags, it’s crucial to vet potential suppliers thoroughly. Start by requesting samples to assess the material, craftsmanship, and overall durability. Additionally, check for certifications that demonstrate compliance with international quality standards. Consider visiting the manufacturing facility if feasible, or using third-party inspection services to evaluate production processes. Establishing a clear quality assurance agreement outlining your specifications and testing methods can further safeguard your interests. -

What is the best way to find reliable suppliers for mesh metal bags?

The best way to find reliable suppliers is to utilize reputable B2B platforms such as Alibaba, Global Sources, or ThomasNet. You can also attend industry trade shows, which provide opportunities to meet suppliers face-to-face. Conduct online research to read reviews and testimonials, and seek recommendations from industry contacts. Once you shortlist potential suppliers, initiate communication to gauge their responsiveness and professionalism, which can be indicative of their reliability. -

What are common customization options available for mesh metal bags?

Customization options for mesh metal bags typically include size, color, and branding features such as logos or specific designs. Many suppliers offer bespoke services where you can specify the dimensions, type of mesh, and closure mechanisms. You may also request additional features like reinforced stitching or specialized coatings for enhanced durability. Be sure to discuss your requirements upfront to ensure the supplier can accommodate your needs effectively. -

What is the minimum order quantity (MOQ) for mesh metal bags?

The minimum order quantity (MOQ) for mesh metal bags can vary significantly between suppliers and is often influenced by the type of customization requested. Generally, MOQs can range from 100 to 1,000 units. It’s advisable to negotiate with suppliers, especially if you are a new buyer. Some may offer lower MOQs for standard designs while requiring higher quantities for custom orders. Always clarify MOQs before proceeding to avoid unexpected costs. -

What payment terms should I expect when purchasing mesh metal bags?

Payment terms for purchasing mesh metal bags can vary, but common practices include a deposit (usually 30%) upfront with the balance due before shipping. Some suppliers may offer net 30 or 60 days terms for established relationships. It’s vital to discuss and agree on payment terms before finalizing the contract. Consider using secure payment methods like letters of credit or escrow services to protect your investment, particularly for large orders. -

What logistics considerations should I keep in mind when importing mesh metal bags?

When importing mesh metal bags, consider shipping options, customs regulations, and potential tariffs. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your timeline and budget. Ensure that all required documentation, such as invoices, packing lists, and certificates of origin, are in order to facilitate smooth customs clearance. Additionally, research your destination country’s import regulations to avoid unexpected delays or costs. -

How can I assess the reliability of a supplier for mesh metal bags?

Assessing the reliability of a supplier involves several steps. Start by checking their business licenses and certifications to ensure legitimacy. Request references from previous clients and verify their experiences. Conduct a factory audit if possible, or use third-party inspection services to evaluate production capabilities. Additionally, pay attention to communication responsiveness and transparency during negotiations, as these traits often reflect a supplier’s reliability. -

What are the best practices for quality assurance when sourcing mesh metal bags?

Best practices for quality assurance include developing a comprehensive quality control plan that outlines specific standards and testing procedures. Establish clear communication with suppliers regarding your quality expectations and any relevant compliance standards. Conduct pre-production meetings to align on specifications and perform random inspections during production. Upon receipt, carry out thorough quality checks to ensure the products meet your requirements before distribution.

Top 7 Mesh Metal Bag Manufacturers & Suppliers List

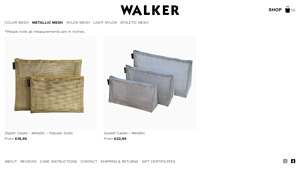

1. Metallic Mesh Shop – Zipper Cases

Domain: walkerbags.com

Registered: 1998 (27 years)

Introduction: {“shop_name”:”Metallic Mesh Shop”,”product_types”:[{“type”:”Zipper Cases”,”price”:”From $19.00″},{“type”:”Gusset Cases”,”price”:”From $26.00″}],”color_options”:[“Mesh”,”Metallic Mesh”,”Nylon Mesh”,”Light Nylon”,”Athletic Mesh”],”measurements”:”All measurements are in inches.”}

2. Antique Mesh Bags – Vintage Evening Styles

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Antique mesh bags, including various styles such as silver metal chainmail bags, vintage silver mesh evening bags, antique gold mesh bags, and more. Related interests include luxury silver chainmail bags, Victorian purses, and vintage evening bags. Notable items include rectangular chainmail evening bags, silver embellished evening bags, and antique silver purses. Additional mentions of vintage co…

3. Whiting & Davis – Vintage Mesh Purses

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Vintage Mesh Purses available for sale on eBay. Brands include Whiting & Davis and Unbranded. Color options include Antique Gold, Gold, Silver, Multi-Color, Ivory, and Beige. Related items include 1990s Vintage Luggage, Art Deco Mesh Purses, Vintage Bags, Handbags & Cases, Mesh Vintage Wallets & Coin Purses, and various vintage shoes and belts.

4. Outsak – Spectrum Series Storage Bag

Domain: simpleoutdoorstore.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “Outsak Spectrum Series”, “description”: “Rodent and Animal-Proof Steel Mesh Food and Gear Storage Bag”, “features”: [“Protects food and gear from animal teeth and claws”, “Available in 8 colors”, “Quality construction with strong and thick flexible wire mesh”, “2 inch polyester seatbelt webbing with UV inhibitor”, “Genuine VELCRO® closure guaranteed not to mold, mildew, or rot”, …

5. Whiting & Davis – Metal Mesh Handbags

Domain: whitinganddaviscollection.com

Registered: 2010 (15 years)

Introduction: This company, Whiting & Davis – Metal Mesh Handbags, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

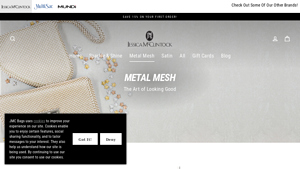

6. Jessica McClintock – Metal Mesh Evening Bags

Domain: jmcbags.com

Registered: 2015 (10 years)

Introduction: Jessica McClintock Metal Mesh Collection – Metal Mesh evening bags. Products include: Gena ($48.00), Gwen Ball Mesh Ring Wristlet Pouch ($42.00), Hailey Bow Clutch ($48.00), Logan Ball Mesh Pouch ($33.00), Metal Mesh Roll Evening Clutch ($42.00), Sarah Ring Wristlet Hobo ($32.00), Staci Mesh Wristlet Pouch (Regular price $52.00, Sale price $40.00), Trina Metal Mesh Clutch ($48.00).

7. Objects of Beauty – SG Liquid Metal Mesh Bags

Domain: objectsofbeauty.com

Registered: 2007 (18 years)

Introduction: SG Liquid Metal Mesh Bags are designed by Sergio Gutierrez, featuring a unique look and feel reminiscent of chain mail. The collection includes various styles such as the Arielle Metal Mesh Purse ($377.99), Brienne Liquid Metal Leather Cell Phone Bag ($274.99), Cassiopeia SG Liquid Metal Mesh Bag ($258.99), Guinevere Fringe Mesh Bag ($224.99), Gwendolyn Mesh Bag ($184.99), Indira Liquid Metal Leat…

Strategic Sourcing Conclusion and Outlook for mesh metal bag

In the evolving landscape of international trade, the mesh metal bag market presents significant opportunities for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Strategic sourcing is vital for navigating this market, as it allows businesses to tap into diverse suppliers offering high-quality products at competitive prices. By prioritizing relationships with manufacturers known for innovation and reliability, companies can ensure they meet the growing demand for durable and versatile mesh metal bags.

The versatility of mesh metal bags—ranging from food protection to stylish accessories—highlights their broad market appeal. As buyers explore options, they should consider not only the functional attributes but also the aesthetic potential that these products can bring to their offerings.

Looking ahead, the mesh metal bag market is poised for growth, driven by increasing consumer preferences for sustainable and multifunctional products. International B2B buyers should seize this moment to engage with suppliers, explore customization options, and align their product offerings with market trends. By doing so, they can capitalize on emerging opportunities and strengthen their competitive edge in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.