Mechanical Conveyor System Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for mechanical conveyor system

In the rapidly evolving landscape of global supply chains, sourcing an effective mechanical conveyor system has emerged as a pivotal challenge for businesses aiming to enhance operational efficiency. These systems are essential for automating the transportation of materials, ultimately reducing labor costs and minimizing human error. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, you face unique hurdles in identifying the right systems that align with your operational demands and budget constraints.

This comprehensive guide delves into the multifaceted world of mechanical conveyor systems, exploring various types such as belt, roller, and overhead conveyors, along with their specific applications across industries. We will also provide insights into supplier vetting processes, ensuring you choose reliable partners who can meet your unique requirements. Understanding cost factors, including initial investments and long-term maintenance, is crucial for making informed financial decisions that will impact your bottom line.

By equipping you with the knowledge to navigate this complex market, this guide empowers you to make strategic purchasing decisions that enhance productivity and maintain a competitive edge. Whether you are operating in Nigeria, Saudi Arabia, or any other region, our insights will help you streamline your operations and optimize your supply chain logistics effectively.

Understanding mechanical conveyor system Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Belt Conveyor | Continuous loop of material, flexible in design | Warehousing, manufacturing, mining | Pros: Efficient for bulk materials; customizable. Cons: Limited incline ability; potential belt wear. |

| Roller Conveyor | Uses rollers for movement; gravity or powered | Distribution centers, packaging lines | Pros: Low maintenance; versatile for various loads. Cons: Not suitable for small items without additional support. |

| Slat Conveyor | Made from slats or plates; robust construction | Heavy manufacturing, automotive | Pros: Handles heavy items; durable. Cons: Higher initial cost; less flexible in layout. |

| Overhead Conveyor | Suspended design; space-saving | Assembly lines, warehouses | Pros: Maximizes floor space; efficient in tight areas. Cons: Complex installation; may require specialized maintenance. |

| Bucket Elevator | Vertical lifting mechanism with buckets | Food processing, grain handling | Pros: Efficient for vertical transport; minimizes spillage. Cons: Limited to specific materials; more complex design. |

What Are the Key Characteristics of Belt Conveyors?

Belt conveyors are characterized by a continuous loop of material that transports goods along a defined path. They are adaptable to various shapes and sizes, making them suitable for numerous industries, including warehousing, manufacturing, and mining. When considering a belt conveyor for purchase, B2B buyers should evaluate factors such as load weight, speed requirements, and potential incline angles. The flexibility of design allows for customization, but potential belt wear and limitations in incline capacity should be taken into account.

How Do Roller Conveyors Differ in Functionality?

Roller conveyors utilize a series of rollers to facilitate the movement of products. They can be powered or gravity-driven, making them ideal for distribution centers and packaging lines. The primary advantage lies in their low maintenance and versatility, allowing for the transportation of various load types. Buyers should consider the weight and size of the items to be transported, as roller conveyors may not support smaller items without additional support systems. Their efficiency in handling medium to heavy loads makes them a popular choice in logistics.

What Makes Slat Conveyors Suitable for Heavy Items?

Slat conveyors are designed with slats or plates, offering robust construction ideal for moving heavy materials in environments such as automotive and heavy manufacturing. Their strength allows for the transport of bulky items that traditional belt systems may not handle effectively. B2B buyers should assess the initial investment against the long-term durability and efficiency of slat conveyors. While they provide excellent support for heavy loads, the higher upfront cost and limited layout flexibility may be drawbacks for some operations.

What Are the Advantages of Using Overhead Conveyors?

Overhead conveyors are suspended systems that save floor space while efficiently transporting items in environments like assembly lines and warehouses. Their design allows for maximum utilization of vertical space, making them suitable for facilities with limited ground area. Buyers should consider the complexity of installation and the need for specialized maintenance, which can add to operational costs. However, the efficiency gained from utilizing overhead space often outweighs these considerations, particularly in high-density environments.

Why Choose Bucket Elevators for Vertical Transport?

Bucket elevators are specialized for vertical transport, utilizing buckets attached to a belt or chain to lift materials. They are particularly effective in industries like food processing and grain handling, where minimizing spillage and maintaining product integrity are crucial. When purchasing a bucket elevator, B2B buyers should evaluate the types of materials being handled, as these systems are typically limited to specific products. While their ability to efficiently transport materials vertically is a significant advantage, the complexity of their design can be a consideration for potential buyers.

Key Industrial Applications of mechanical conveyor system

| Industry/Sector | Specific Application of mechanical conveyor system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Automation | Increases production efficiency and reduces labor costs | Adaptability to product types and automation needs |

| Food and Beverage | Bulk Material Handling | Ensures consistent flow and minimizes contamination risks | Compliance with hygiene standards and durability |

| Logistics and Warehousing | Order Fulfillment Systems | Enhances speed and accuracy in order processing | Space optimization and scalability |

| Mining and Minerals | Transporting Ore and Materials | Reduces manual handling and enhances safety | Robustness to withstand harsh environments |

| Pharmaceuticals | Automated Packaging Lines | Streamlines production and ensures regulatory compliance | Precision in handling sensitive materials |

How is a Mechanical Conveyor System Used in Manufacturing?

In the manufacturing sector, mechanical conveyor systems are vital for assembly line automation. They facilitate the seamless movement of components between different production stages, significantly boosting efficiency and minimizing labor costs. Buyers from regions like Africa and South America should prioritize systems adaptable to various product types and automation needs, ensuring they can accommodate fluctuating production demands while maintaining operational safety.

What Role Do Mechanical Conveyor Systems Play in Food and Beverage Industries?

In the food and beverage sector, mechanical conveyor systems are employed for bulk material handling, ensuring a consistent flow of ingredients while minimizing contamination risks. These systems are designed to meet stringent hygiene standards, making them essential for food safety. Buyers in the Middle East and Europe should focus on sourcing conveyors that are not only durable but also compliant with local food safety regulations to enhance operational reliability.

How Do Mechanical Conveyor Systems Enhance Logistics and Warehousing?

Mechanical conveyor systems are integral to logistics and warehousing, particularly in order fulfillment systems. They improve speed and accuracy in processing orders, allowing businesses to efficiently manage high volumes of products. For international buyers, especially in regions like Nigeria and Saudi Arabia, it’s crucial to consider solutions that optimize space and are scalable to adapt to business growth, ensuring that the logistics operations remain efficient.

Illustrative image related to mechanical conveyor system

Why Are Mechanical Conveyor Systems Important in Mining and Minerals?

In the mining and minerals industry, mechanical conveyor systems are essential for transporting ore and materials from extraction sites to processing facilities. These systems reduce manual handling, which enhances safety and operational efficiency. Buyers should look for robust conveyor solutions that can withstand harsh environments, ensuring reliability and longevity in challenging conditions typical of mining operations.

How Do Mechanical Conveyor Systems Benefit Pharmaceuticals?

In the pharmaceutical industry, mechanical conveyor systems are used in automated packaging lines, streamlining production processes and ensuring compliance with regulatory standards. These systems are designed for precision, handling sensitive materials with care to prevent contamination. Buyers in this sector need to prioritize sourcing conveyors that offer accuracy and reliability, as well as compliance with stringent industry regulations to maintain product integrity.

3 Common User Pain Points for ‘mechanical conveyor system’ & Their Solutions

Scenario 1: Inefficient Material Handling Leading to Downtime

The Problem: B2B buyers often face the challenge of inefficient material handling due to inadequate conveyor system design. This inefficiency can lead to significant downtime, particularly during peak operational hours. Buyers may find themselves dealing with bottlenecks where products fail to move efficiently from one area to another, causing delays in order fulfillment and increased labor costs as workers are forced to manually intervene.

Illustrative image related to mechanical conveyor system

The Solution: To address this issue, it’s crucial for buyers to conduct a thorough needs assessment before selecting a conveyor system. This involves analyzing the specific materials being transported, their dimensions, weights, and the required flow rates. By engaging with conveyor system manufacturers early in the design phase, buyers can ensure that the system is tailored to their operational needs. It is also beneficial to consider modular conveyor systems that can be easily reconfigured to adapt to changing requirements. Investing in advanced conveyor technology with built-in sensors can also provide real-time monitoring of system performance, allowing for proactive adjustments to minimize downtime.

Scenario 2: High Maintenance Costs and Frequent Breakdowns

The Problem: Many B2B buyers experience the frustration of high maintenance costs and frequent breakdowns of their mechanical conveyor systems. These issues often stem from choosing the wrong type of conveyor for their specific application or failing to perform regular maintenance. As a result, companies face unexpected repair expenses, loss of productivity, and ultimately, a negative impact on customer satisfaction.

The Solution: Buyers should prioritize selecting a conveyor system that is not only suitable for their specific operational requirements but also designed for durability. This includes considering the material composition of the conveyor components, such as belts, pulleys, and frames, which can greatly influence longevity and performance. Additionally, implementing a scheduled maintenance program that includes routine inspections and timely replacement of worn-out parts can significantly reduce the likelihood of unexpected failures. Partnering with a reliable service provider for ongoing support can also ensure that maintenance is performed correctly and on time, ultimately reducing long-term costs.

Scenario 3: Difficulty in Integrating New Technology with Existing Systems

The Problem: As technology continues to advance, B2B buyers often struggle with integrating new conveyor systems with their existing machinery and workflows. This integration challenge can lead to operational inefficiencies and complicate the training process for staff, ultimately hindering productivity and affecting the bottom line.

Illustrative image related to mechanical conveyor system

The Solution: To overcome integration difficulties, buyers should adopt a phased implementation strategy. This involves gradually introducing new conveyor systems while ensuring compatibility with existing equipment. Conducting a thorough compatibility assessment prior to purchase can help identify potential issues. Collaborating with suppliers who offer comprehensive integration support, including software for automation and data analytics, can also streamline the transition process. Providing adequate training for staff on the new system will facilitate smoother adoption and minimize disruptions in day-to-day operations. Moreover, leveraging a flexible conveyor design that accommodates future upgrades can ensure that the system remains relevant as technological advancements continue.

By addressing these common pain points with actionable solutions, B2B buyers can make informed decisions that enhance operational efficiency and drive long-term success in their material handling processes.

Strategic Material Selection Guide for mechanical conveyor system

When selecting materials for mechanical conveyor systems, it is essential to consider the specific operational requirements, environmental conditions, and regulatory standards that may apply in different regions. Below is an analysis of four common materials used in conveyor systems, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Steel in Conveyor Systems?

Steel is one of the most commonly used materials in conveyor systems due to its strength and durability. It typically has a high temperature and pressure rating, making it suitable for heavy-duty applications. Steel is also resistant to wear and tear, which contributes to its longevity in demanding environments.

Pros: Steel’s durability ensures a long lifespan, reducing the frequency of replacements. It can handle heavy loads and is often used in industrial settings where strength is paramount.

Illustrative image related to mechanical conveyor system

Cons: The primary drawback of steel is its susceptibility to corrosion, especially in humid or wet environments. This can lead to increased maintenance costs and potential failures if not properly coated or treated.

Impact on Application: Steel is ideal for heavy materials and environments where high strength is required. However, its weight can be a disadvantage in applications where lighter materials are preferred.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN for steel quality. Corrosion-resistant coatings may be necessary in humid climates.

How Does Aluminum Compare as a Material Choice?

Aluminum is another popular choice for conveyor systems, particularly in applications requiring lightweight components. It has good corrosion resistance and can perform well in various temperatures.

Illustrative image related to mechanical conveyor system

Pros: The lightweight nature of aluminum allows for easier installation and less energy consumption during operation. Its corrosion resistance makes it suitable for diverse environments, including those with moisture.

Cons: While aluminum is strong, it is not as durable as steel, making it less suitable for very heavy loads. It can also be more expensive than steel, which may affect overall project budgets.

Impact on Application: Aluminum is often used in food processing and packaging industries, where hygiene and corrosion resistance are critical. Its lightweight nature can improve efficiency in automated systems.

Considerations for International Buyers: Buyers should verify that aluminum components meet international standards for food safety and corrosion resistance, particularly in regions with stringent regulations.

What are the Advantages of Using Plastic in Conveyor Systems?

Plastic materials, including high-density polyethylene (HDPE) and polyvinyl chloride (PVC), are increasingly used in conveyor systems, especially in industries like food processing and pharmaceuticals.

Pros: Plastic is lightweight, resistant to corrosion, and can be molded into various shapes, allowing for flexibility in design. It is also quieter in operation compared to metal conveyors.

Cons: The primary limitation of plastic is its lower strength compared to metal options, which may restrict its use in heavy-duty applications. Additionally, plastics can be more susceptible to wear and tear over time.

Impact on Application: Plastic conveyors are ideal for transporting lightweight items and are commonly used in environments where cleanliness is essential. However, they may not be suitable for high-temperature applications.

Considerations for International Buyers: Buyers should ensure that plastic materials comply with local health and safety regulations, especially in food-related industries. Understanding the specific grades of plastic that meet international standards is crucial.

Why is Stainless Steel a Preferred Material in Certain Applications?

Stainless steel is favored for its excellent corrosion resistance and strength, particularly in environments exposed to moisture or chemicals.

Illustrative image related to mechanical conveyor system

Pros: Its durability and resistance to rust make stainless steel ideal for food processing, pharmaceuticals, and other industries where hygiene is critical. It can withstand high temperatures and pressures.

Cons: The cost of stainless steel is generally higher than that of other materials, which can impact budget considerations. Additionally, it can be heavier, affecting the overall design and installation of the conveyor system.

Impact on Application: Stainless steel conveyors are essential in applications where sanitation is paramount, such as in food and beverage processing. Its robustness allows it to handle a variety of materials effectively.

Considerations for International Buyers: Buyers must ensure compliance with international food safety standards and certifications. In regions like Europe and the Middle East, adherence to specific quality standards is crucial for market acceptance.

Summary Table of Material Selection for Mechanical Conveyor Systems

| Material | Typical Use Case for mechanical conveyor system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Susceptible to corrosion | High |

| Aluminum | Lightweight and food processing applications | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Plastic | Lightweight items in food/pharmaceuticals | Lightweight and flexible design | Lower strength | Low |

| Stainless Steel | Food processing and pharmaceuticals | Excellent corrosion resistance | Higher cost | High |

This guide provides a comprehensive overview of material options for mechanical conveyor systems, enabling international B2B buyers to make informed decisions based on their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mechanical conveyor system

What Are the Main Stages in the Manufacturing Process of Mechanical Conveyor Systems?

The manufacturing of mechanical conveyor systems involves several critical stages, each contributing to the overall functionality, efficiency, and durability of the final product. Understanding these stages helps B2B buyers assess potential suppliers and ensure they meet the required standards.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in the manufacturing process is material preparation. Typically, high-quality materials such as steel, aluminum, and various plastics are selected based on the type of conveyor system being produced. Steel is often used for heavy-duty applications due to its strength, while aluminum offers lightweight and corrosion-resistant properties.

Once the materials are chosen, they undergo various processes such as cutting, milling, and bending to achieve the desired dimensions and shapes. Advanced CNC (Computer Numerical Control) machines are commonly used in this stage to ensure precision and minimize waste. For B2B buyers, knowing the type of materials and the preparation techniques can provide insights into the expected lifespan and durability of the conveyor systems.

Illustrative image related to mechanical conveyor system

What Techniques Are Used in Forming Conveyor Components?

After material preparation, the next step is forming the components that make up the conveyor system. This stage often includes techniques such as welding, stamping, and injection molding.

Welding is crucial for joining metal parts, especially in heavy-duty systems where strength is paramount. Stamping is frequently used for creating metal parts like brackets and supports, while injection molding is ideal for producing plastic components like rollers and guides. Understanding these forming techniques allows buyers to gauge the strength and integrity of the components, which directly impacts the conveyor’s performance.

How Is Assembly Conducted in the Manufacturing Process?

The assembly phase involves putting together the various components formed in the previous stages. This can be a complex process, especially for systems with multiple moving parts. Assembly lines may utilize both manual labor and automation, depending on the scale of production.

Key considerations during assembly include alignment, fastening, and integration of components like motors and controls. Quality control measures are often employed during this stage to ensure that each conveyor system meets design specifications. For B2B buyers, it’s essential to inquire about the assembly methods used, as they can affect the reliability and maintenance requirements of the conveyor systems.

What Finishing Processes Are Commonly Used?

The finishing stage is vital for enhancing the durability and aesthetic appeal of conveyor systems. Common finishing processes include painting, powder coating, and galvanizing. These processes not only provide a protective layer against corrosion but also improve the system’s overall appearance.

Finishing techniques can vary based on the intended environment of the conveyor system. For instance, conveyor systems used in food processing industries may require specific food-safe coatings. Buyers should consider the environmental conditions in which the conveyor will operate and ensure that the finishing processes align with their industry requirements.

What Are the Key Quality Assurance Practices in Conveyor System Manufacturing?

Quality assurance is a critical aspect of manufacturing conveyor systems, ensuring that they meet international and industry-specific standards. Understanding these practices can help B2B buyers select reliable suppliers.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are fundamental in manufacturing processes. ISO 9001 outlines the requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. Compliance with this standard indicates that a manufacturer is committed to delivering quality products consistently.

Illustrative image related to mechanical conveyor system

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are important for specific applications. CE certification is crucial for products sold in the European market, ensuring they meet health, safety, and environmental protection standards. B2B buyers should verify that their suppliers hold the relevant certifications for their target markets.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that every component meets the required specifications. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves regular inspections to monitor the production process and identify any deviations from quality standards.

- Final Quality Control (FQC): Before shipment, final inspections are performed to ensure the completed conveyor systems meet all design specifications and quality standards.

B2B buyers should ask suppliers about their QC processes and what specific checkpoints are in place to guarantee product quality.

Illustrative image related to mechanical conveyor system

What Common Testing Methods Are Used to Ensure Quality?

Testing methods play a crucial role in verifying the quality and performance of conveyor systems. Common methods include:

- Load Testing: Assessing the system’s ability to handle the specified load without failure.

- Operational Testing: Evaluating the conveyor’s functionality under real-world conditions to ensure smooth operation.

- Durability Testing: Subjecting components to wear and tear to assess their longevity and resistance to environmental factors.

Understanding these testing methods allows buyers to ensure that the conveyor systems they purchase will perform reliably over time.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers, particularly when sourcing from international markets. Here are several strategies to ensure quality:

- Conduct Audits: Regular audits of suppliers can help verify compliance with quality standards and identify areas for improvement.

- Request Reports: Buyers should request quality control reports and testing results to gain insights into the supplier’s performance.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality assurance practices.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must consider specific nuances related to quality control and certification. Different markets may have varying requirements for certifications, which can affect the acceptance of products.

Illustrative image related to mechanical conveyor system

For instance, products sold in the European market must comply with CE regulations, while those in the Middle East may require specific local certifications. Buyers should be aware of these regional differences and ensure that their suppliers are compliant with the necessary certifications to avoid potential legal and logistical challenges.

In conclusion, understanding the manufacturing processes and quality assurance practices for mechanical conveyor systems is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can make informed decisions, ensuring they select reliable suppliers that meet their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mechanical conveyor system’

Introduction

This sourcing guide provides a structured checklist for B2B buyers seeking to procure mechanical conveyor systems. By following these steps, businesses can ensure they select a system that meets their operational needs while maximizing efficiency and minimizing costs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s vital to clearly outline your technical requirements. This includes the type of products to be transported, their weights, dimensions, and any specific handling requirements. Having a detailed specification helps you communicate effectively with suppliers and ensures that the proposed solutions align with your operational needs.

- Product Characteristics: Identify the average and maximum weight, dimensions, and fragility of the items.

- Operational Environment: Consider factors such as temperature, humidity, and space constraints.

Step 2: Determine Your Budget and Total Cost of Ownership

Understanding your budget is crucial, not only for the initial purchase but also for ongoing operational costs. Total cost of ownership (TCO) includes installation, maintenance, and potential downtime costs. This comprehensive view will help you avoid unexpected financial burdens in the future.

Illustrative image related to mechanical conveyor system

- Initial Costs: Get quotes based on your specifications.

- Long-term Costs: Estimate maintenance and energy consumption over the system’s lifespan.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements and deliver quality products. Request documentation such as company profiles, case studies, and client references, particularly from businesses in your industry or region. This will provide insight into their reliability and expertise.

- Supplier History: Look for experience in your specific application.

- Client Testimonials: Seek feedback from previous customers regarding performance and support.

Step 4: Assess Customization Options

Not all conveyor systems are one-size-fits-all. Inquire about customization capabilities to ensure the system can be tailored to fit your unique operational processes. Custom solutions can enhance efficiency and address specific challenges that standard systems may not accommodate.

- Modular Designs: Check if the supplier offers modular components for flexibility.

- Integration Capabilities: Ensure compatibility with existing equipment and software systems.

Step 5: Verify Compliance and Certifications

Ensure that the conveyor systems meet local and international safety and quality standards. Compliance with regulations not only protects your employees but also mitigates risks associated with liability and operational disruptions.

- Safety Certifications: Look for ISO, CE, or other relevant certifications.

- Quality Assurance Processes: Inquire about the supplier’s quality control measures.

Step 6: Review After-Sales Support and Warranty Terms

Understanding the after-sales support structure is essential for long-term satisfaction with your conveyor system. A robust support plan can minimize downtime and ensure that any issues are resolved promptly. Review warranty terms to understand the coverage and duration.

- Support Availability: Confirm the hours of operation and response times.

- Warranty Coverage: Clarify what is included and the duration of the warranty.

Step 7: Conduct a Pilot Test

Before finalizing your purchase, consider conducting a pilot test of the conveyor system in your facility. This allows you to evaluate its performance in real-world conditions and confirm that it meets your operational requirements.

- Performance Evaluation: Assess speed, reliability, and adaptability to your processes.

- Feedback Collection: Gather input from staff who will operate the system to identify any concerns or adjustments needed.

By following this checklist, B2B buyers can navigate the complexities of sourcing mechanical conveyor systems and make informed decisions that enhance their operational efficiency.

Comprehensive Cost and Pricing Analysis for mechanical conveyor system Sourcing

When sourcing mechanical conveyor systems, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This section delves into the key cost components, price influencers, and practical tips for negotiating favorable terms, particularly for businesses operating in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components of Mechanical Conveyor Systems?

The total cost of acquiring a mechanical conveyor system encompasses several components:

-

Materials: The choice of materials significantly impacts costs. High-quality steel, for instance, is more expensive but offers durability and strength, while lighter materials may reduce initial costs but compromise longevity.

-

Labor: Labor costs vary by region and are influenced by the complexity of the conveyor system. In regions with higher wage standards, labor may account for a significant portion of the total expenditure.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and factory rent. Efficient manufacturing processes can help keep these costs down.

-

Tooling: Specialized tools for the manufacturing process can be a substantial upfront investment, especially for custom conveyor systems. These costs should be factored into the overall budget.

-

Quality Control (QC): Ensuring that the conveyor systems meet quality standards requires investment in QC processes, which can add to the overall cost but is essential for operational reliability.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the chosen Incoterms. International shipping often incurs additional fees, including tariffs and insurance.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on market conditions, competition, and the supplier’s perceived value of their product.

What Influences the Pricing of Mechanical Conveyor Systems?

Several factors can influence the pricing of conveyor systems, making it essential for buyers to understand these nuances:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, while smaller orders may incur higher per-unit costs due to lower economies of scale.

-

Specifications and Customization: Customized conveyor systems tailored to specific operational needs will generally cost more than standard models. Detailed specifications can lead to higher material and labor costs.

-

Materials and Quality Certifications: High-grade materials and certifications (e.g., ISO, CE) can enhance the system’s reliability but also increase costs. Buyers should weigh the benefits against the additional expense.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms dictate who bears responsibility for shipping costs and risks during transport. Understanding these terms is crucial for accurately assessing total costs.

What Tips Can Buyers Utilize for Cost-Efficient Sourcing?

To maximize value when sourcing mechanical conveyor systems, consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Volume purchases and long-term contracts can often yield better rates.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider installation, maintenance, and operational costs over the system’s lifespan to ensure a comprehensive understanding of expenses.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local regulations that may impact costs. Collaborating with local experts can provide insights into potential hidden costs.

-

Focus on Quality: While it may be tempting to choose lower-cost options, investing in higher-quality systems can lead to lower maintenance costs and improved operational efficiency in the long run.

In conclusion, a thorough understanding of the cost components and pricing influences, coupled with strategic negotiation and evaluation of long-term costs, can significantly enhance the sourcing experience for mechanical conveyor systems. For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, these insights are essential for making informed purchasing decisions. Always remember that pricing can vary widely, so obtaining multiple quotes is advisable to secure the best deal.

Alternatives Analysis: Comparing mechanical conveyor system With Other Solutions

Understanding the Importance of Alternative Solutions in Material Handling

In the realm of material handling, selecting the most effective system is crucial for optimizing operations. While mechanical conveyor systems are widely adopted for their efficiency and reliability, several alternative solutions can also fulfill similar functions. This section will compare mechanical conveyor systems with two notable alternatives: Automated Guided Vehicles (AGVs) and Robotic Arm Systems. Each solution presents unique advantages and considerations that can greatly influence a B2B buyer’s decision.

Illustrative image related to mechanical conveyor system

Comparison of Mechanical Conveyor System and Alternative Solutions

| Comparison Aspect | Mechanical Conveyor System | Automated Guided Vehicles (AGVs) | Robotic Arm Systems |

|---|---|---|---|

| Performance | High throughput; efficient for continuous transport | Flexible routing; good for varied layouts | Precise handling; ideal for assembly tasks |

| Cost | High initial investment; lower operating costs | Moderate to high initial cost; variable operating costs | High initial investment; potential for high ROI |

| Ease of Implementation | Requires infrastructure setup; longer installation time | Quick to deploy in existing layouts; minimal disruption | Integration complexity; needs programming |

| Maintenance | Regular maintenance needed; parts can be costly | Lower maintenance; fewer moving parts | High maintenance; requires skilled labor |

| Best Use Case | Bulk material transport in fixed layouts | Dynamic environments with changing needs | Tasks requiring precision and repetition |

Pros and Cons of Each Alternative

Automated Guided Vehicles (AGVs)

AGVs are mobile robots that transport materials within a facility. They excel in environments where flexibility is paramount, as they can navigate around obstacles and adapt to changes in layout. Their deployment is generally quicker than conveyor systems, as they do not require extensive infrastructure modifications. However, AGVs can have moderate to high initial costs and may incur variable operational costs depending on the technology used (e.g., battery life and charging infrastructure). They are most suitable for facilities with changing workflows or where space constraints exist.

Robotic Arm Systems

Robotic arm systems are designed for tasks requiring high precision, such as assembly and packaging. These systems can handle a wide range of products and are particularly effective in repetitive tasks, enhancing productivity. While they offer significant advantages in terms of accuracy and speed, the initial investment can be substantial, and integration into existing operations can be complex. Maintenance can also be more intensive, as skilled labor is often required for repairs and programming. Robotic arms are best suited for manufacturing environments where precision and consistency are critical.

Making the Right Choice for Your Business Needs

When evaluating the best material handling solution for your operations, it is essential to consider your specific requirements. Factors such as the nature of your products, the layout of your facility, and your budget will significantly influence your decision. Mechanical conveyor systems are ideal for high-volume, fixed operations, while AGVs provide flexibility for dynamic environments. On the other hand, robotic arms excel in precision tasks but may require more investment and maintenance. By carefully analyzing these aspects, B2B buyers can choose the right solution to enhance efficiency and support their operational goals.

Illustrative image related to mechanical conveyor system

Essential Technical Properties and Trade Terminology for mechanical conveyor system

Understanding the technical properties and trade terminology of mechanical conveyor systems is crucial for B2B buyers, particularly those operating in diverse international markets. This knowledge not only aids in selecting the right system but also enhances negotiation and procurement processes.

What are the Key Technical Specifications for Mechanical Conveyor Systems?

-

Material Grade

– The material grade of conveyor components, such as belts, pulleys, and frames, determines durability and suitability for specific applications. Common materials include stainless steel for food-grade conveyors and carbon steel for industrial use. Understanding material grades helps buyers select a system that meets operational requirements and regulatory standards, particularly in regions with stringent safety regulations. -

Load Capacity

– Load capacity refers to the maximum weight a conveyor system can handle without compromising performance or safety. This specification is essential for ensuring that the chosen conveyor can efficiently transport products without risk of failure. Buyers must assess the weight of the items being conveyed to prevent costly downtimes or damages. -

Belt Width and Length

– The dimensions of the conveyor belt, including its width and length, significantly impact its effectiveness in transporting goods. Wider belts can accommodate larger products, while the length determines the distance over which materials can be moved. Buyers should evaluate their operational layout and material sizes to ensure that the conveyor system fits seamlessly into their workflow. -

Speed and Drive Mechanism

– Conveyor speed, measured in feet per minute (FPM), indicates how quickly materials can be moved. The drive mechanism—whether electric, hydraulic, or manual—affects energy consumption and operational efficiency. Understanding these factors allows buyers to select a system that balances speed with energy efficiency, especially in high-demand environments. -

Tolerance Levels

– Tolerance levels define the acceptable variations in dimensions for conveyor components, influencing the system’s alignment and overall functionality. Higher tolerance levels ensure smoother operation and reduce wear and tear, which is critical in maintaining long-term efficiency. This specification is particularly relevant for industries requiring precise handling of materials, such as pharmaceuticals or electronics.

What Are Common Trade Terms in the Conveyor Industry?

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces components that are used in another company’s end product. In the context of conveyor systems, understanding OEM relationships is vital for buyers looking for high-quality parts and reliable support. It can also influence warranty and service agreements. -

MOQ (Minimum Order Quantity)

– MOQ refers to the minimum number of units a supplier is willing to sell. This term is significant for B2B buyers who need to assess their purchasing strategy and budget constraints. Knowing the MOQ helps in negotiating better terms and understanding inventory management needs. -

RFQ (Request for Quotation)

– An RFQ is a standard business process to invite suppliers to submit price proposals for specific products or services. For conveyor systems, submitting an RFQ allows buyers to compare different suppliers’ offerings, ensuring they receive competitive pricing and terms. -

Incoterms (International Commercial Terms)

– Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. Familiarity with these terms is crucial for international transactions, especially regarding shipping costs, risk management, and the delivery process. -

Lead Time

– Lead time is the duration between placing an order and receiving the product. Understanding lead times is essential for planning and inventory management, particularly in industries with tight production schedules or seasonal fluctuations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, optimize procurement processes, and enhance operational efficiency in their conveyor system investments.

Navigating Market Dynamics and Sourcing Trends in the mechanical conveyor system Sector

What Are the Current Market Dynamics and Key Trends Affecting the Mechanical Conveyor System Sector?

The mechanical conveyor system sector is witnessing transformative changes driven by globalization, technological advancements, and evolving market demands. Key market dynamics include the increasing automation of supply chains, which enhances operational efficiency and reduces labor costs. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to modernize their logistics and manufacturing processes, they are turning to advanced conveyor solutions that integrate smart technology and IoT capabilities. This trend enables real-time monitoring and predictive maintenance, ultimately leading to minimized downtime and maximized productivity.

Emerging trends such as the shift toward modular conveyor systems allow for flexibility and scalability in operations. This adaptability is particularly crucial for businesses in regions with fluctuating market demands, enabling them to quickly adjust their systems without significant capital investment. Additionally, the rise of e-commerce is compelling companies to optimize their logistics, thus driving the demand for high-speed, efficient conveyor systems capable of handling diverse product types. B2B buyers should also consider the impact of regional regulations and trade agreements that may influence sourcing strategies and supplier relationships.

How Is Sustainability and Ethical Sourcing Shaping the Mechanical Conveyor System Market?

Sustainability is becoming a cornerstone of procurement strategies in the mechanical conveyor system sector. The environmental impact of manufacturing processes and the materials used in conveyor systems is under increasing scrutiny. As such, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainability through ethical sourcing practices and environmentally friendly materials. This includes the use of recycled materials in conveyor components and the implementation of energy-efficient technologies.

Certifications such as ISO 14001 for environmental management systems and LEED certification for green buildings are gaining importance in supplier evaluations. Buyers are encouraged to seek out manufacturers who can provide transparency in their supply chains and demonstrate adherence to ethical labor practices. By aligning their sourcing strategies with sustainability goals, businesses can not only enhance their corporate social responsibility (CSR) profiles but also mitigate risks associated with regulatory compliance and potential reputational damage.

How Has the Mechanical Conveyor System Evolved Over Time?

The mechanical conveyor system has undergone significant evolution since its inception in the late 19th century. Originally designed for simple material transport, advancements in engineering have led to the development of specialized conveyor types, such as belt, roller, and slat systems, each tailored for specific applications. The introduction of automation and control systems in the late 20th century marked a pivotal shift, allowing for increased efficiency and reduced manual labor.

Today, the integration of smart technology, including IoT connectivity and machine learning, is setting new standards for conveyor systems. These innovations not only optimize performance but also provide data-driven insights that enable businesses to make informed operational decisions. As the industry continues to evolve, B2B buyers must stay informed about these advancements to ensure their systems remain competitive and capable of meeting future demands.

Illustrative image related to mechanical conveyor system

Frequently Asked Questions (FAQs) for B2B Buyers of mechanical conveyor system

-

How do I choose the right mechanical conveyor system for my business needs?

Choosing the right mechanical conveyor system involves assessing both product and process requirements. Start by evaluating the types of products you need to move, including their weight, dimensions, and fragility. Next, consider your operational environment—factors like distance, elevation changes, and transfer speed are critical. It’s also essential to analyze your facility’s flow rate and available space. Consulting with suppliers about your specific needs can help you identify the best system configuration to enhance efficiency and reduce costs. -

What are the key factors that affect the cost of a conveyor system?

The cost of a conveyor system can vary significantly based on several factors. Key considerations include the type of conveyor (e.g., belt, roller, overhead), overall length, required speed, and the complexity of the design, such as curves or transfers. Additionally, installation costs and potential restructuring of your warehouse space must be factored in. Maintenance and operational costs over the system’s lifetime can also impact the total cost of ownership, making it crucial to consider both upfront and ongoing expenses. -

What are the minimum order quantities (MOQ) when sourcing conveyor systems?

Minimum order quantities (MOQ) for conveyor systems can differ between suppliers and depend on the type of system you require. Generally, larger orders may qualify for better pricing, but many suppliers are willing to accommodate smaller orders, especially for customized solutions. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQ policies and explore options that fit your budget and operational requirements. -

How can I ensure quality assurance (QA) when purchasing conveyor systems internationally?

To ensure quality assurance when sourcing conveyor systems internationally, begin by vetting potential suppliers thoroughly. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request references and case studies from previous clients to assess reliability and performance. Additionally, consider arranging for an on-site inspection or third-party quality checks before finalizing the purchase. Establishing clear communication regarding your quality expectations will also help mitigate risks. -

What payment terms should I expect when sourcing conveyor systems from international suppliers?

Payment terms can vary widely among international suppliers, but common options include upfront payments, partial payments before shipment, and net payment terms (e.g., net 30 or net 60 days). It’s important to negotiate terms that align with your cash flow needs while ensuring the supplier feels secure in the transaction. Utilizing secure payment methods, such as letters of credit or escrow services, can also protect both parties during international transactions. -

How do I handle logistics and shipping for conveyor systems sourced internationally?

Managing logistics and shipping for international conveyor systems involves careful planning. Start by discussing shipping options with your supplier, including freight forwarders experienced in handling industrial equipment. Consider factors such as shipping times, customs clearance, and potential tariffs or duties. It’s also crucial to ensure proper packaging to prevent damage during transit. Collaborating with logistics experts can help streamline the process and mitigate potential delays. -

Can conveyor systems be customized to fit unique operational needs?

Yes, many conveyor systems can be customized to meet specific operational requirements. Customization options may include adjustments in size, material, speed, and configuration to accommodate unique product types and handling processes. When discussing your needs with suppliers, provide detailed information about your operational challenges and goals. This will enable them to propose tailored solutions that enhance productivity and efficiency in your facility. -

What are the benefits of investing in an automated conveyor system for my business?

Investing in an automated conveyor system can yield numerous benefits, including increased productivity, reduced labor costs, and improved safety. Automated systems minimize human error and enhance the speed of material handling, allowing for faster order fulfillment. They can also be designed to reduce workplace hazards by minimizing manual handling of heavy or bulky items. Overall, automation can lead to a more streamlined operation, improving your competitive edge in the market.

Top 4 Mechanical Conveyor System Manufacturers & Suppliers List

1. Exotec – Skypod System & Skypath Conveyors

Domain: exotec.com

Registered: 1996 (29 years)

Introduction: Exotec Skypod system and Skypath automated conveyors.

2. AMG – Mechanical Conveying Systems

Domain: blog.amg-eng.com

Registered: 1997 (28 years)

Introduction: Mechanical conveying systems are efficient for transferring large amounts of product over long distances, ideal for offloading vehicles like trucks and rail cars. They can handle various product shapes, sizes, and weights, offering design flexibility for horizontal, inclined, or vertical conveying. Key types include: 1. Screw Conveyors – good for small spaces and wet products, ideal for short dist…

3. AutoStore System – Conveyor Solutions

Domain: autostoresystem.com

Registered: 2011 (14 years)

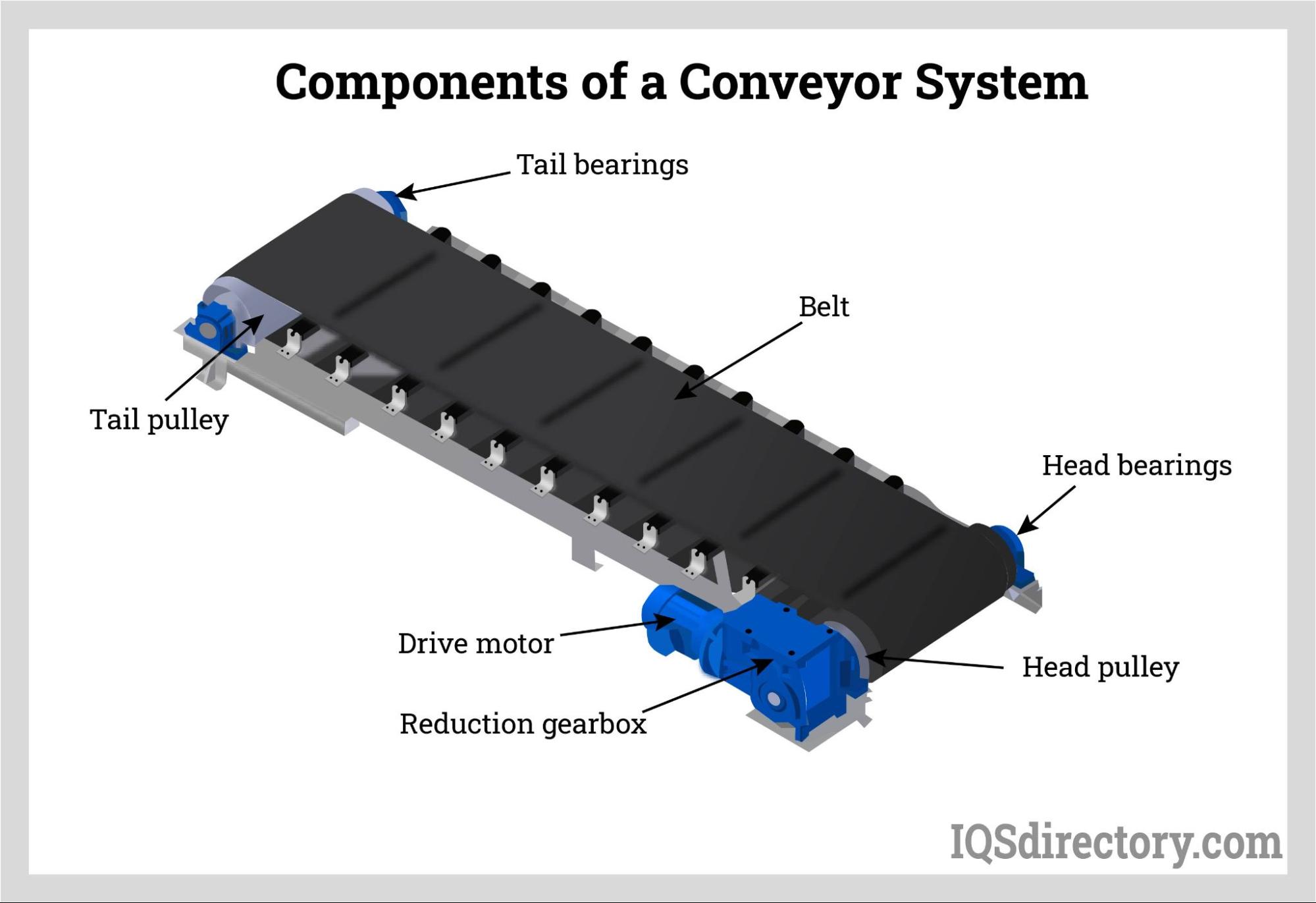

Introduction: Conveyor systems are mechanical devices used to move materials, products, or goods from one place to another in a continuous stream within warehouses or manufacturing facilities. They can be manual or automated, with automated systems integrating machines for tasks like sorting and packaging. Key components include:

– Conveyor Belt: The main component that moves materials, powered by rollers or pu…

4. FNS Heppard – Key Products

Domain: fnsheppard.com

Registered: 1996 (29 years)

Introduction: Key product details include: 1. Timing Belts: Anaconda Belts, Belt Coverings, Custom Belt Machining, Custom Fabricating, False Tooth Attachment Options, Flex Belt & Wound Endless, Food Grade Belting. 2. Conveyor Belts: Custom Fabricating, PTFE & Silicone Belts, Screen & Filter Belts, TPU Round, V, & Flat Belts, Vacuum & Perforated Belts. 3. Timing Hardware: Conveyor Rollers/Pulleys and Lagging, Ti…

Strategic Sourcing Conclusion and Outlook for mechanical conveyor system

In conclusion, understanding the strategic sourcing of mechanical conveyor systems is vital for organizations looking to enhance operational efficiency and reduce costs. Key takeaways include the importance of selecting the right conveyor type tailored to specific product and process requirements, ensuring optimal performance and longevity. Additionally, investing in modern conveyor technology can significantly minimize workplace risks and improve ergonomics, ultimately leading to higher productivity and customer satisfaction.

For international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe, it is crucial to recognize the long-term value of strategic sourcing. By carefully evaluating potential suppliers and understanding the total cost of ownership, businesses can make informed decisions that align with their growth objectives.

As we look ahead, the demand for efficient and adaptable conveyor systems will only increase. Now is the time to leverage strategic sourcing practices to secure the best solutions for your operational needs. Engage with trusted suppliers, explore innovative technologies, and ensure your organization remains competitive in an ever-evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.