Material Used To Make Gears That Can Tolerate High Loads: The Ultimate B2B Sourcing…

Introduction: Navigating the Global Market for material used to make gears that can tolerate high loads

In an increasingly competitive global market, sourcing the right materials for manufacturing gears that can tolerate high loads poses a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe ramp up production capabilities, the demand for durable and reliable gear materials—such as steel and bronze—has never been higher. This comprehensive guide aims to equip procurement professionals with the knowledge needed to navigate this complex landscape, addressing critical factors such as material types, applications, supplier vetting processes, and cost considerations.

Understanding the nuances of gear materials is essential for making informed purchasing decisions that impact operational efficiency and product longevity. This guide will delve into various gear types, including spur, helical, and bevel gears, each suited for different operational demands. Additionally, it will provide insights into the performance characteristics of materials like steel, known for its strength, and bronze, favored for its high load tolerance.

By empowering buyers with actionable insights and strategic approaches, this guide facilitates smarter sourcing decisions, enabling businesses to optimize their supply chains and enhance their competitive edge. Whether you’re a manufacturer in Nigeria looking for high-performance materials or a European distributor seeking reliable suppliers, the information contained herein is designed to streamline your procurement process and elevate your operational success.

Understanding material used to make gears that can tolerate high loads Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel | High strength, ductility, and wear resistance. | Automotive, aerospace, heavy machinery. | Pros: Excellent load-bearing capacity, long lifespan. Cons: Can be prone to corrosion if not treated. |

| Bronze | Good tensile strength, corrosion resistance, and self-lubricating properties. | Marine applications, pumps, and high-load gear systems. | Pros: Excellent for high-load applications, resistant to wear. Cons: Higher initial cost compared to steel. |

| Cast Iron | High compressive strength and excellent wear resistance. | Gearboxes, industrial machinery, and automotive applications. | Pros: Cost-effective, good vibration damping. Cons: Brittle, may not handle tensile loads well. |

| Plastic | Lightweight, corrosion-resistant, and can be molded into complex shapes. | Consumer products, low-load applications, and prototyping. | Pros: Low cost, lightweight. Cons: Limited load tolerance and thermal resistance. |

| Composite | Combines materials for enhanced properties, such as strength-to-weight ratio. | Aerospace, automotive, and specialized machinery. | Pros: Tailored properties for specific applications. Cons: Can be expensive and complex to manufacture. |

What Are the Key Characteristics of Steel as a Gear Material?

Steel is renowned for its high strength and ductility, making it a preferred choice for high-load gears in various industries. It exhibits excellent wear resistance, which translates to longevity in applications like automotive and aerospace. When purchasing steel gears, buyers should consider the type of steel (e.g., carbon steel, alloy steel) based on specific load requirements and potential corrosion risks, as untreated steel can be susceptible to rust.

Why is Bronze Considered a Superior Material for High Load Gears?

Bronze is another significant material used for gears that can tolerate high loads due to its impressive tensile strength and corrosion resistance. Its self-lubricating properties reduce friction, making it ideal for marine applications and high-load gear systems. B2B buyers should weigh the initial cost against the long-term benefits of reduced maintenance and increased durability, particularly in harsh environments.

How Does Cast Iron Compare to Other Gear Materials?

Cast iron is characterized by its high compressive strength and excellent wear resistance, making it suitable for gearboxes and heavy industrial machinery. While it offers a cost-effective solution for many applications, buyers should be cautious of its brittleness, which can lead to failure under tensile loads. Understanding the specific application requirements will help buyers determine if cast iron is the right choice for their needs.

In What Situations Should Plastic Gears Be Used?

Plastic gears are lightweight and corrosion-resistant, making them ideal for low-load applications and consumer products. They can be molded into complex shapes, allowing for innovative designs. However, B2B buyers must consider the limitations of plastic in terms of load tolerance and thermal resistance, ensuring they are suitable for the intended application without compromising performance.

What Advantages Do Composite Gears Offer Over Traditional Materials?

Composite gears leverage the strengths of multiple materials to achieve enhanced properties, such as a superior strength-to-weight ratio. These gears are particularly beneficial in aerospace and specialized machinery applications where weight savings are critical. However, buyers should be aware of the potential for higher costs and complexity in manufacturing, necessitating a thorough evaluation of performance requirements and budget constraints.

Key Industrial Applications of material used to make gears that can tolerate high loads

| Industry/Sector | Specific Application of material used to make gears that can tolerate high loads | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmission systems utilizing high-strength steel gears | Enhanced performance and durability under heavy loads | Supplier reliability, compliance with automotive standards |

| Mining | Gear systems in heavy machinery like excavators and drills | Improved operational efficiency and reduced downtime | Material quality certification, local sourcing options |

| Renewable Energy | Gears in wind turbines made from bronze for high load tolerance | Increased energy output and reliability | Resistance to corrosion, availability of specialized alloys |

| Manufacturing | Precision gears in CNC machines made from high-strength materials | Consistent product quality and precision | Tolerance specifications, availability of custom sizes |

| Construction | Gear systems in cranes and hoisting equipment | Safety and reliability in lifting heavy loads | Compliance with safety regulations, local market conditions |

How is High-Load Gear Material Used in the Automotive Sector?

In the automotive industry, high-strength steel gears are integral to transmission systems, where they manage significant torque and stress. These gears ensure smooth power transfer from the engine to the wheels, enhancing vehicle performance and reliability. For international buyers, especially in regions like Africa and South America, sourcing from suppliers who meet stringent automotive standards is crucial. This ensures that the gears can withstand the rigors of diverse driving conditions while maintaining safety and efficiency.

What Role Does High-Load Gear Material Play in Mining Applications?

In mining, heavy machinery such as excavators and drills relies on robust gear systems made from high-load tolerant materials. These gears are designed to endure extreme conditions and heavy loads, significantly improving operational efficiency and minimizing equipment downtime. Buyers in the mining sector must prioritize suppliers who can provide certified materials that meet industry specifications, especially considering the often harsh and demanding environments of mining operations.

Illustrative image related to material used to make gears that can tolerate high loads

Why are High-Load Gears Essential in Renewable Energy?

Wind turbines utilize gears made from bronze, known for their high load tolerance and resistance to environmental stresses. These gears are crucial for converting wind energy into electrical power, directly impacting the efficiency and reliability of energy production. For B2B buyers in the renewable energy sector, sourcing materials that offer corrosion resistance and longevity is vital, particularly in coastal regions where salt exposure can accelerate wear and tear.

How Do High-Load Gears Improve Manufacturing Processes?

In manufacturing, high-strength gears are essential components of CNC machines, where precision and durability are paramount. These gears help maintain consistent product quality and precision, which is critical in competitive markets. International buyers should focus on suppliers who can provide gears that meet specific tolerance requirements, ensuring compatibility with existing machinery and processes while also considering lead times and customization options.

What are the Benefits of High-Load Gears in Construction Equipment?

Construction equipment, particularly cranes and hoisting systems, depend on high-load gear systems for safe and reliable operation. These gears must handle substantial weights and dynamic loads, making material strength and design critical. Buyers in the construction sector should ensure that their suppliers comply with safety regulations and can deliver materials that meet the rigorous demands of construction activities, especially in regions with varying regulatory environments.

3 Common User Pain Points for ‘material used to make gears that can tolerate high loads’ & Their Solutions

Scenario 1: Inconsistent Gear Performance Under Load

The Problem: B2B buyers often encounter performance inconsistencies in gears made from traditional materials when subjected to high loads. This can lead to premature gear wear, increased noise, and even catastrophic failure in machinery. For manufacturers in industries such as automotive or heavy machinery, the stakes are high. A gear failure can halt production, lead to costly downtime, and damage the reputation of a business. Buyers need a reliable material that can withstand high stress without compromising performance.

The Solution: To address this issue, buyers should consider sourcing gears made from high-strength steel or bronze, specifically designed for high-load applications. When specifying materials, look for those with high tensile strength and fatigue resistance. Request detailed material specifications from suppliers, including load ratings and stress test results. Additionally, implementing a rigorous quality control process during manufacturing can help ensure that the gears meet necessary performance standards. Consider utilizing advanced manufacturing techniques, such as heat treatment or surface hardening, to enhance the material properties and extend the lifespan of the gears.

Scenario 2: Increased Operational Costs Due to Gear Failures

The Problem: Frequent gear failures can lead to significant operational costs, not only from repairs but also from the loss of productivity. B2B buyers in industries such as mining or construction may find that their existing gear materials cannot handle the extreme conditions, leading to unexpected breakdowns and maintenance delays. This cycle of failure contributes to increased operational costs and impacts the bottom line.

The Solution: To mitigate these costs, buyers should invest in high-performance gear materials that are engineered for durability under high-load conditions. For instance, selecting bronze gears can be beneficial due to their excellent wear resistance and ability to handle high loads without deformation. Furthermore, it is crucial to collaborate with material suppliers who can provide comprehensive testing data to ensure the selected materials are suitable for the specific operational environment. Establishing a preventive maintenance schedule can also help in identifying wear and tear before it leads to failure, thus reducing long-term operational costs.

Scenario 3: Difficulty in Sourcing Reliable Gear Materials

The Problem: Many B2B buyers struggle with the inconsistent availability of quality materials for high-load gears, which can lead to project delays and frustration. This issue is particularly pronounced in regions like Africa and South America, where supply chain challenges may limit access to high-performance materials. Buyers may find themselves compromising on material quality due to limited options, ultimately affecting their machinery’s reliability and performance.

The Solution: To overcome sourcing challenges, buyers should build relationships with multiple suppliers and seek those who specialize in high-load gear materials. This approach not only provides a backup source but also enables buyers to negotiate better terms and pricing. Additionally, exploring local manufacturers or regional suppliers can minimize lead times and shipping costs. Engage in industry networks or trade associations to gain insights into reliable suppliers and emerging materials that are tailored for high-load applications. Finally, consider investing in custom solutions from manufacturers who can produce materials that meet specific operational requirements, ensuring that buyers are not limited by standard offerings.

Strategic Material Selection Guide for material used to make gears that can tolerate high loads

When selecting materials for gears designed to tolerate high loads, it is crucial to consider their mechanical properties, manufacturing complexities, and suitability for specific applications. Below is an analysis of four common materials used in high-load gear applications, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel for High-Load Gears?

Steel is one of the most widely used materials in gear manufacturing due to its high strength and durability. It has excellent tensile strength, which allows it to withstand significant loads without deformation. Steel gears can also be heat-treated to enhance hardness and wear resistance, making them suitable for high-pressure applications. However, steel is prone to corrosion, which necessitates protective coatings or treatments in certain environments.

Pros & Cons: The primary advantage of steel is its strength and ability to handle high loads, making it ideal for heavy machinery and automotive applications. However, the cost of high-quality steel can be significant, and its weight may be a disadvantage in applications requiring lightweight materials.

Impact on Application: Steel gears are often used in automotive transmissions, industrial machinery, and heavy equipment. Their compatibility with high-torque applications makes them a preferred choice in sectors requiring reliability.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM or DIN for steel grades. Understanding local availability and cost fluctuations is also vital for procurement.

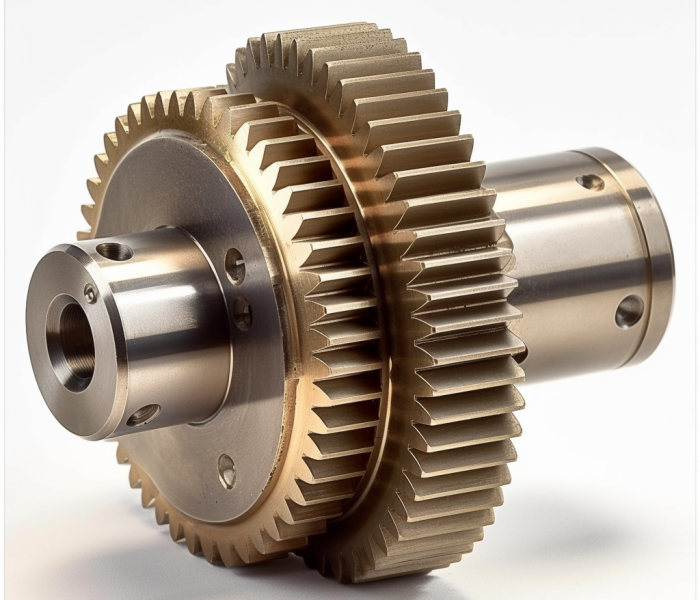

How Does Bronze Compare for High-Load Gear Applications?

Bronze is another material that excels in high-load applications, particularly in environments where corrosion resistance is essential. It possesses good wear resistance and can operate effectively under high friction conditions. Its ability to withstand stress without cracking makes it suitable for gears that experience continuous loading.

Pros & Cons: The main advantage of bronze is its excellent anti-friction properties, making it ideal for applications involving sliding contact. However, bronze is generally more expensive than steel and may not be as readily available in certain markets.

Illustrative image related to material used to make gears that can tolerate high loads

Impact on Application: Bronze gears are commonly found in marine applications, where corrosion resistance is critical, and in gearboxes that require low friction. They are also used in applications involving high temperatures.

Considerations for International Buyers: Buyers should check for compliance with material standards and certifications, especially in industries like marine or aerospace, where specifications are stringent.

What Role Does Plastic Play in High-Load Gear Manufacturing?

While plastic gears are not typically associated with high-load applications, advancements in engineering plastics have led to their increased use in specific scenarios. Materials like polyamide (Nylon) and polyoxymethylene (POM) can offer good load-bearing capabilities and are lightweight, making them suitable for certain applications.

Pros & Cons: The primary advantage of plastic gears is their lightweight nature, which can reduce the overall weight of machinery. They also exhibit good resistance to chemicals and moisture. However, their load-bearing capacity is limited compared to metals, and they may deform under excessive stress.

Impact on Application: Plastic gears are often used in consumer electronics, small machinery, and automotive applications where weight savings are crucial. They are suitable for low to moderate load applications.

Considerations for International Buyers: Buyers should be aware of the specific grades of plastics that meet industry standards, as well as the environmental conditions they will be exposed to, especially in regions with extreme temperatures.

Why Is Aluminum Considered for High-Load Gears?

Aluminum is increasingly being utilized in gear manufacturing due to its favorable strength-to-weight ratio. It is lightweight and can be treated to enhance its hardness, making it suitable for moderate load applications. Aluminum gears are also resistant to corrosion, which is beneficial in various environments.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which can improve fuel efficiency in automotive applications. However, its strength is lower than that of steel and bronze, which limits its use in high-load situations.

Impact on Application: Aluminum gears are often used in applications where weight reduction is critical, such as in aerospace and automotive industries. They are suitable for applications with moderate load requirements.

Considerations for International Buyers: Buyers should ensure that aluminum gears meet relevant standards and specifications, particularly in industries where safety and performance are paramount.

Summary Table of Material Selection for High-Load Gears

| Material | Typical Use Case for material used to make gears that can tolerate high loads | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive transmissions, industrial machinery | High strength and durability | Prone to corrosion | High |

| Bronze | Marine applications, gearboxes with high friction | Excellent wear resistance | Higher cost than steel | High |

| Plastic | Consumer electronics, small machinery | Lightweight and corrosion-resistant | Limited load-bearing capacity | Medium |

| Aluminum | Aerospace components, automotive applications | Lightweight and corrosion-resistant | Lower strength than steel/bronze | Medium |

This comprehensive analysis provides B2B buyers with critical insights into material selection for gears that can tolerate high loads, ensuring informed purchasing decisions aligned with industry standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for material used to make gears that can tolerate high loads

What Are the Key Stages in the Manufacturing Process for Gears Made from High Load Tolerant Materials?

Manufacturing gears that can withstand high loads involves a series of intricate processes, each crucial for ensuring the final product meets industry specifications. The typical stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The journey begins with selecting the right raw materials. Steel and bronze are popular choices for high-load gears due to their exceptional strength and durability. During this stage, materials undergo processes such as melting, casting, or forging. For example, steel is often forged to improve its microstructure, enhancing its load-bearing capabilities. Quality checks at this stage ensure that the materials meet predefined standards for chemical composition and mechanical properties. -

Forming Techniques

The forming process involves shaping the raw materials into gear forms. Common techniques include:

– CNC Machining: This precision method allows for the creation of complex gear geometries with tight tolerances. CNC machines can produce spur, helical, and bevel gears, ensuring consistency across batches.

– Hobbing and Shaping: These processes are specifically used for cutting gear teeth. Hobbing is ideal for producing gears with straight teeth, while shaping is suitable for helical gears. Both techniques require skilled operators to monitor the machining process closely.

– Casting: For bronze gears, casting is often employed, allowing for intricate designs that would be difficult to achieve through machining alone. -

Assembly

Once the components are formed, they are assembled. This may involve fitting multiple gears together or integrating them into larger mechanical systems. During assembly, precision is paramount; even minor misalignments can lead to operational inefficiencies or failures under load. -

Finishing Processes

The finishing stage enhances the surface properties of the gears, improving wear resistance and reducing friction. Techniques such as heat treatment, grinding, and surface hardening are commonly used. Heat treatment can significantly increase the hardness of steel gears, making them more capable of handling high loads. Surface finishing techniques also reduce surface roughness, which is vital for reducing noise and enhancing the operational lifespan of the gears.

How Is Quality Assurance Managed in Gear Manufacturing?

Quality assurance (QA) is critical throughout the manufacturing process to ensure that the gears meet international and industry-specific standards. Here are the key components of a robust QA system:

-

International and Industry-Specific Standards

– ISO 9001: This widely recognized standard sets the framework for a quality management system. Compliance ensures that manufacturers maintain consistent quality and continuously improve their processes.

– CE Marking: For gears sold within the European Union, CE marking indicates compliance with health, safety, and environmental protection standards.

– API Standards: In industries such as oil and gas, API standards ensure that gears can withstand the specific conditions encountered in these environments. -

Quality Control Checkpoints

Effective quality control involves multiple checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, random sampling and inspections are conducted to catch any deviations early. This includes monitoring the machining processes and measuring the dimensions of the gears.

– Final Quality Control (FQC): Once manufacturing is complete, the final products undergo rigorous testing for performance, dimensional accuracy, and surface finish. This stage is crucial for validating that the gears can tolerate high loads as intended. -

Common Testing Methods

Various testing methods are employed to ensure quality:

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection can identify internal flaws without damaging the gears.

– Load Testing: Gears are subjected to simulated operational conditions to ensure they can handle specified loads without failure.

– Dimensional Inspection: Using tools like coordinate measuring machines (CMM), manufacturers can verify that the gears conform to precise specifications.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential for making informed purchasing decisions. Here are strategies for ensuring supplier reliability:

-

Supplier Audits

Conducting audits of potential suppliers can provide deep insights into their manufacturing processes and quality control systems. During an audit, buyers can assess compliance with ISO 9001 and other relevant standards, as well as evaluate the effectiveness of their quality assurance practices. -

Requesting Quality Reports

Buyers should request detailed quality reports that include information on material certifications, test results, and compliance with relevant standards. These documents can provide reassurance about the quality of the gears being purchased. -

Third-Party Inspections

Engaging third-party inspection services can add an extra layer of confidence. Independent inspectors can verify that the manufacturing processes align with specified standards and that the final products meet quality expectations. -

Understanding QC Nuances for International Trade

Buyers should be aware of the specific quality assurance requirements that may vary by region. For instance, while CE marking is essential for products sold in Europe, different certifications may be required in other markets. Understanding these nuances can prevent regulatory issues and ensure a smoother import process.

Conclusion

The manufacturing processes and quality assurance systems for gears that can tolerate high loads are critical for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers. Implementing thorough verification methods, including audits, quality reports, and third-party inspections, will further enhance confidence in the products being sourced, ultimately leading to more successful partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘material used to make gears that can tolerate high loads’

To successfully procure materials for gears that can withstand high loads, it is essential to follow a structured approach. This guide provides a step-by-step checklist to help B2B buyers ensure they are making informed decisions when sourcing these critical materials.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the materials needed in your gear production. Consider factors such as load tolerance, environmental conditions, and mechanical properties.

– Material Types: Identify whether you need high-strength steel or durable bronze, as these materials are renowned for their load-bearing capabilities.

– Load Ratings: Specify the maximum load the gears must handle to ensure the materials meet your operational demands.

Step 2: Research Material Options

Conduct thorough research to understand the materials available for high-load gear manufacturing. Different materials offer distinct advantages and disadvantages.

– Steel vs. Bronze: While steel is known for its strength, bronze is favored for its resistance to wear and corrosion. Assess which material aligns best with your application.

– Performance Characteristics: Investigate the fatigue resistance, tensile strength, and thermal properties of the materials to determine their suitability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is crucial to vet suppliers thoroughly. This step ensures you partner with reliable manufacturers who can deliver quality materials consistently.

– Company Profiles: Request detailed company profiles, including their production capabilities and experience in the industry.

– References: Seek testimonials or case studies from other buyers in similar sectors to validate the supplier’s reliability and product quality.

Step 4: Request Samples and Conduct Testing

Once you have shortlisted potential suppliers, request material samples for evaluation. Testing these samples is vital to ensure they meet your specifications.

– Mechanical Testing: Perform tests for tensile strength, hardness, and load tolerance to confirm the material’s performance under expected conditions.

– Quality Assurance: Ensure that the materials comply with relevant international standards and certifications.

Illustrative image related to material used to make gears that can tolerate high loads

Step 5: Negotiate Pricing and Terms

After evaluating the materials and suppliers, proceed to negotiate pricing and contractual terms. This step is crucial for securing a favorable deal while ensuring quality.

– Bulk Pricing Discounts: Inquire about discounts for large orders to optimize your procurement costs.

– Payment Terms: Establish clear payment terms and conditions to avoid any misunderstandings later in the transaction process.

Step 6: Finalize Logistics and Delivery Schedules

Plan the logistics of your order to ensure timely delivery of the materials. This includes discussing shipping methods, timelines, and any import/export regulations applicable to your region.

– Transportation Methods: Decide on the most efficient shipping options based on your location and urgency.

– Customs Clearance: Ensure all necessary documentation is prepared for smooth customs clearance, especially when dealing with international suppliers.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the materials upon arrival. This helps maintain consistent quality and performance throughout your production.

– Inspection Protocols: Develop inspection protocols to assess the received materials against your specifications.

– Feedback Loop: Create a feedback mechanism to communicate any issues with the supplier, fostering a collaborative relationship for future orders.

By following this checklist, B2B buyers can effectively navigate the procurement process for materials used in high-load gear manufacturing, ensuring they make informed decisions that support their operational needs.

Comprehensive Cost and Pricing Analysis for material used to make gears that can tolerate high loads Sourcing

What Are the Key Cost Components for Sourcing Materials Used in High Load Gears?

When sourcing materials for gears designed to tolerate high loads, understanding the cost structure is essential. The primary components of the cost include:

Illustrative image related to material used to make gears that can tolerate high loads

-

Materials: The choice of material significantly affects the overall cost. High-strength materials such as steel and bronze are commonly used for manufacturing gears that can withstand heavy loads. Steel, while generally more affordable, offers excellent strength and durability. Bronze, on the other hand, is more expensive but provides superior wear resistance and load tolerance.

-

Labor: Labor costs encompass the expenses associated with skilled workers who manufacture and assemble the gears. The complexity of the gear design can influence labor costs, as intricate designs may require more time and specialized skills.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, equipment maintenance, and other operational expenses. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: The initial setup for gear production requires specialized tools and molds, which represent a significant upfront investment. The cost of tooling can be amortized over large production runs, making it more cost-effective for high-volume orders.

-

Quality Control (QC): Ensuring that gears meet industry standards and specifications is critical, particularly for high-load applications. QC costs involve testing, inspections, and certifications, which can add to the overall expenditure.

-

Logistics: Shipping and handling costs must be factored in, especially for international transactions. These costs can vary based on the mode of transport, distance, and any tariffs or duties that may apply.

-

Margin: Finally, suppliers will include a profit margin in their pricing, which can vary based on market conditions and the competitiveness of the supplier.

How Do Price Influencers Impact the Cost of High Load Gear Materials?

Several factors influence pricing in the market for materials used in high load gear manufacturing:

-

Volume/MOQ: Minimum order quantities (MOQ) can lead to lower per-unit costs. Suppliers often provide discounts for bulk orders, making it essential for buyers to consider long-term needs when negotiating prices.

-

Specifications and Customization: Tailored specifications can lead to increased costs. Custom gear designs or materials can incur additional fees, so it’s crucial to balance the need for customization with cost efficiency.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO or industry-specific standards) can elevate costs. Buyers should assess the necessity of these certifications based on their application requirements.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a history of quality may command higher prices but can offer better assurance of material performance.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly impact overall costs. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to make informed decisions.

What Tips Should Buyers Consider for Cost-Efficiency in Gear Material Sourcing?

To maximize cost-efficiency when sourcing materials for high-load gears, consider the following tips:

-

Negotiate Effectively: Engage in discussions with suppliers about pricing structures and potential discounts for larger orders. Building a strong relationship with suppliers can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, evaluate the TCO, which includes maintenance, durability, and operational costs. This approach ensures long-term value.

-

Understand Pricing Nuances for International Transactions: For buyers from Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import tariffs, and regional supply chain challenges that can affect pricing.

-

Request Multiple Quotes: Obtaining quotes from various suppliers helps benchmark prices and provides leverage during negotiations.

-

Plan for Future Needs: Consider future demand when placing orders. Anticipating needs can help secure better pricing and reduce the risk of supply chain disruptions.

Final Note on Pricing Indications

While the insights provided can guide buyers in their sourcing endeavors, prices can vary widely based on market conditions, supplier relationships, and specific project requirements. Therefore, it is advisable to conduct thorough market research and engage with multiple suppliers to obtain a comprehensive understanding of the pricing landscape.

Alternatives Analysis: Comparing material used to make gears that can tolerate high loads With Other Solutions

Exploring Alternatives to Materials Used in High Load Gears: A Comprehensive Comparison

In the realm of industrial machinery and equipment, selecting the right materials for gear manufacturing is pivotal, especially when high load tolerance is essential. While materials such as bronze and steel are frequently used for their strength and durability, exploring alternative solutions can provide additional options for businesses looking to optimize performance, cost, and maintenance. This analysis compares the traditional materials with two viable alternatives: composite materials and advanced ceramics.

| Comparison Aspect | Material Used To Make Gears That Can Tolerate High Loads | Composite Materials | Advanced Ceramics |

|---|---|---|---|

| Performance | High strength, excellent wear resistance | Good strength, lightweight, but may wear faster under extreme loads | Excellent wear resistance, high temperature tolerance |

| Cost | Moderate to high, depending on processing | Generally lower than metals, but varies by type | Higher initial cost, but can reduce long-term maintenance costs |

| Ease of Implementation | Standard manufacturing processes available | Requires specialized techniques for molding and curing | Complex manufacturing processes, may require specialized equipment |

| Maintenance | Regular lubrication needed to ensure longevity | Lower maintenance but can be sensitive to environmental factors | Minimal maintenance required, very durable |

| Best Use Case | Heavy machinery, automotive applications | Aerospace, automotive lightweight applications | High-temperature environments, precision instruments |

What Are the Advantages and Disadvantages of Composite Materials in Gear Manufacturing?

Composite materials, often made from a blend of polymers and reinforcing fibers, offer several advantages for gear applications. They are typically lighter than metals, which can enhance energy efficiency in moving parts. Additionally, composites can be engineered to provide specific mechanical properties, making them suitable for various applications. However, they may not withstand extreme loads as effectively as metals, leading to potential wear issues over time. The manufacturing process for composites can also be more complex, requiring specialized techniques that could increase production time and costs.

How Do Advanced Ceramics Compare in Gear Applications?

Advanced ceramics are renowned for their exceptional hardness and resistance to wear, making them an attractive option for high-load applications. They perform well under high temperatures and harsh environments, which can be beneficial in industries such as aerospace and automotive. However, the initial cost of advanced ceramics can be significantly higher than traditional metals, and their brittleness may pose challenges during manufacturing and installation. Despite these drawbacks, the long-term durability and lower maintenance requirements of ceramics can justify the investment for certain applications.

Illustrative image related to material used to make gears that can tolerate high loads

Conclusion: How Should B2B Buyers Choose the Right Gear Material?

When selecting materials for high-load gears, B2B buyers should consider their specific operational needs, including performance requirements, budget constraints, and maintenance capabilities. Traditional materials like steel and bronze offer proven reliability, while alternatives like composites and advanced ceramics can provide unique advantages in specific contexts. By assessing the trade-offs between these options and aligning them with their operational demands, businesses can make informed decisions that enhance productivity and reduce costs in the long run.

Essential Technical Properties and Trade Terminology for material used to make gears that can tolerate high loads

What Are the Key Technical Properties of Materials Used for High Load Gears?

When selecting materials for gears that must withstand high loads, several critical specifications should be considered. Understanding these properties can significantly affect the durability, performance, and cost-effectiveness of gear assemblies.

-

Material Grade

The material grade denotes the quality and strength of the material used for gear manufacturing. Common grades for high-load applications include high-strength steel (e.g., AISI 4140 or 8620) and bronze (e.g., C93200). The right grade ensures that gears can handle the expected stress and load conditions, which is essential for maintaining operational efficiency and longevity. -

Tensile Strength

This property measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. For gears subjected to high loads, tensile strength is a critical factor. For instance, high-strength steel typically boasts tensile strengths ranging from 600 to 800 MPa, making it suitable for heavy-duty applications. Understanding tensile strength helps buyers ensure that the selected material can endure operational demands without deforming or breaking. -

Hardness

Hardness refers to a material’s resistance to deformation, abrasion, and wear. Hardness is particularly important in gear applications where contact stress is prevalent. Materials like hardened steel or bronze are often used because they offer superior hardness levels, which translates to better wear resistance and longer service life. Buyers should assess hardness values using standards like Rockwell or Brinell to ensure compatibility with their specific applications. -

Fatigue Strength

Fatigue strength is the maximum stress a material can endure for an extended period without failing. In high-load environments, gears are subjected to cyclic loading, making fatigue strength a vital property. Materials with high fatigue strength can reduce the risk of catastrophic failure in applications such as machinery and automotive systems. Buyers should look for materials that provide a good balance between tensile and fatigue strength. -

Impact Toughness

Impact toughness measures a material’s ability to absorb energy during sudden impacts or shocks. This property is essential for gears that operate in dynamic environments where unexpected loads may occur. Materials with high impact toughness can prevent fractures and extend the life of gears. Buyers should evaluate impact toughness alongside other mechanical properties to ensure optimal performance.

What Common Trade Terms Should B2B Buyers Know in the Gear Manufacturing Industry?

Navigating the gear manufacturing industry requires familiarity with specific jargon and trade terms that can influence purchasing decisions.

Illustrative image related to material used to make gears that can tolerate high loads

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the gear industry, understanding OEM relationships is crucial for ensuring compatibility and quality. Buyers should verify that the gear manufacturer is an established OEM to ensure they receive reliable products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is essential for B2B buyers, as it can impact inventory management and cost-effectiveness. Understanding the MOQ helps companies plan their purchases and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a formal request from a buyer to suppliers to provide pricing and terms for specific products. In the gear industry, submitting an RFQ is a standard practice to gather multiple quotes and select the best supplier based on price, quality, and delivery terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including delivery, risk, and costs. Familiarity with Incoterms is vital for B2B buyers engaged in international procurement of gear materials, as they dictate shipping terms and responsibilities, reducing the risk of misunderstandings. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. In the gear manufacturing sector, understanding lead times is crucial for project planning and ensuring timely delivery of components to avoid production delays.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance the performance and reliability of their gear systems while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the material used to make gears that can tolerate high loads Sector

What Are the Current Market Dynamics Affecting the Material Used to Make Gears That Can Tolerate High Loads?

The global market for materials used in high-load gear manufacturing is influenced by several factors, including technological advancements, the increasing demand for robust machinery, and the push towards automation across industries. Key drivers include the need for durability and efficiency in sectors such as automotive, aerospace, and industrial machinery. Countries in Africa, South America, the Middle East, and Europe are increasingly looking for materials like steel and bronze, which are renowned for their high strength and load-bearing capabilities.

Emerging trends in B2B sourcing revolve around digital transformation and the adoption of Industry 4.0 principles. Businesses are leveraging advanced analytics and AI to optimize their supply chains, ensuring they can respond swiftly to market fluctuations. Moreover, as manufacturers seek to enhance operational efficiency, there is a growing preference for suppliers who can provide not only high-quality materials but also innovative solutions, such as composite materials that offer enhanced performance characteristics while reducing weight.

International buyers must also navigate the complexities of global trade dynamics, including tariffs and trade agreements that can affect sourcing costs. For instance, the fluctuating prices of raw materials, driven by geopolitical tensions and environmental regulations, can significantly impact procurement strategies. Therefore, establishing strong relationships with reliable suppliers who can offer consistent quality at competitive prices becomes paramount.

How Is Sustainability Shaping the Sourcing of Materials for High-Load Gears?

Sustainability has become a critical consideration in the sourcing of materials for gears that can withstand high loads. The environmental impact of traditional manufacturing processes is prompting companies to prioritize ethical sourcing and the use of sustainable materials. Buyers are increasingly aware of the need to minimize their carbon footprints and are actively seeking suppliers that adhere to environmentally responsible practices.

The importance of ethical supply chains cannot be overstated. Businesses are scrutinizing their suppliers to ensure compliance with labor laws and environmental regulations, particularly in regions where regulations may be less stringent. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers aiming to demonstrate their commitment to sustainable practices.

Additionally, the use of ‘green’ materials, such as recycled metals and bio-based composites, is gaining traction. These materials not only reduce environmental impact but also appeal to a growing segment of eco-conscious consumers. As companies strive to meet sustainability goals, they are encouraged to collaborate with suppliers who can provide transparent sourcing practices and demonstrate a commitment to reducing waste and energy consumption throughout the supply chain.

What Historical Developments Have Influenced Material Choices for Gears?

The evolution of materials used for high-load gears has been significantly shaped by advancements in metallurgy and manufacturing technologies. Initially, gears were predominantly made from wood or simple metals, which limited their load-bearing capacities and longevity. The introduction of steel in the late 19th century revolutionized gear manufacturing, offering superior strength and durability.

Illustrative image related to material used to make gears that can tolerate high loads

The 20th century witnessed further innovations, such as the development of alloys and composite materials, which enhanced the performance characteristics of gears. These advancements allowed for the production of lighter yet stronger gears, capable of withstanding greater loads in increasingly demanding applications.

As industries continue to evolve, the focus is now shifting towards integrating smart technologies and sustainable practices in gear production, reflecting a broader trend towards innovation and responsibility in manufacturing. This historical context is crucial for B2B buyers as it highlights the ongoing importance of material selection in meeting both performance requirements and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of material used to make gears that can tolerate high loads

-

How do I determine the right material for high-load gears?

Choosing the right material for high-load gears involves evaluating factors such as load capacity, environmental conditions, and operational lifespan. Common materials include steel for its high strength and durability, and bronze for its excellent load tolerance and resistance to wear. Consider the specific application and operating conditions, including temperature and moisture exposure, to ensure optimal performance. Consulting with suppliers about material properties and testing can also guide your selection. -

What is the best gear type for applications requiring high load tolerance?

For applications demanding high load tolerance, helical gears and bevel gears are often recommended. Helical gears provide smoother and quieter operation due to their angled teeth that distribute loads evenly, while bevel gears are ideal for changing the direction of power transmission at right angles. Additionally, bronze gears are well-suited for high-load applications due to their toughness. The choice may also depend on the specific requirements of your machinery or system. -

What are the key factors to consider when vetting suppliers for gear materials?

When vetting suppliers for gear materials, consider their industry reputation, experience, and certifications (such as ISO standards). Evaluate their manufacturing capabilities, quality assurance processes, and customer service responsiveness. Request samples and check for compliance with international standards to ensure the materials meet your specifications. Additionally, review their logistics and delivery capabilities, especially if you are sourcing from different regions like Africa or South America. -

How can I ensure the quality of high-load gear materials?

To ensure the quality of high-load gear materials, request detailed specifications and certifications from suppliers. Conduct material testing, such as tensile strength and hardness tests, to verify compliance with your requirements. Implement a quality assurance process that includes regular inspections and audits of supplier facilities. Building a strong relationship with your suppliers can also facilitate better communication regarding quality expectations and any necessary adjustments. -

What are the typical minimum order quantities (MOQs) for gear materials?

Minimum order quantities (MOQs) for gear materials can vary significantly based on the supplier and material type. Generally, MOQs can range from a few hundred kilograms for bulk materials to thousands for specialized gear components. It’s advisable to discuss your project needs with potential suppliers to negotiate MOQs that align with your production schedules and budget constraints. Some suppliers may offer flexibility for first-time orders or prototype runs. -

What payment terms should I expect when sourcing gear materials internationally?

Payment terms when sourcing gear materials internationally can vary widely, but common practices include partial payment upfront (e.g., 30% deposit) and the remainder upon delivery or upon receipt of shipping documents. Some suppliers may also offer letters of credit or escrow services for larger orders. Always clarify payment terms before finalizing agreements to avoid misunderstandings. Consider the currency exchange rates and potential transaction fees in your financial planning. -

How do logistics and shipping impact the sourcing of gear materials?

Logistics and shipping play a crucial role in the timely delivery of gear materials. Factors such as shipping methods, lead times, customs regulations, and potential delays can significantly impact your supply chain. Choose suppliers with reliable logistics partners and track record in international shipping. Additionally, understanding the local import regulations and duties in your region (e.g., in Africa or South America) can help avoid unexpected costs and delays. -

Can I customize gear materials for specific applications?

Yes, many suppliers offer customization options for gear materials to meet specific application requirements. This can include variations in dimensions, material composition, or surface treatments to enhance performance characteristics. When discussing customization, provide detailed specifications and any testing data that support your needs. Engaging with the supplier early in the design process can facilitate better outcomes and ensure that the final product aligns with your operational demands.

Top 3 Material Used To Make Gears That Can Tolerate High Loads Manufacturers & Suppliers List

1. BD Gears – Gear Material Selection Guide

Domain: bdgears.com

Registered: 2023 (2 years)

Introduction: Gear Material Selection Guide: Key factors for selecting gear materials include load capacity and torque requirements, speed and rotational forces, operating environment and conditions, desired gear lifespan and durability, compatibility with other gear components, and budget considerations. Best materials for various gear types: Spur gears – carbon steel, alloy steel, stainless steel; Helical gea…

2. Gear Solutions – Gear Construction Materials

Domain: gearsolutions.com

Registered: 2008 (17 years)

Introduction: The article discusses various materials used in gear construction, categorized into copper alloys, iron alloys, aluminum alloys, and tool steel alloys. 1. Copper Alloys: – Brass: Alloy of copper and zinc, used for spur gears and gear racks in low-load environments. – Phosphor Bronze: Combines copper with tin and phosphorus, suitable for high-friction drive components like worm wheels. – Aluminum B…

3. Brainly – Gears and Materials

Domain: brainly.com

Registered: 2004 (21 years)

Introduction: High strength material commonly used to make gears: Steel; Material used to make gears that can tolerate high loads: Bronze; Straight-cut teeth and make noise when operating: Spur gears; Teeth of this gear are cut so they resemble screw threads: Worm gears; Teeth cut on an angle to evenly distribute the load across the gear tooth, making it quieter: Helical gears; Teeth of this gear are mounted at…

Strategic Sourcing Conclusion and Outlook for material used to make gears that can tolerate high loads

In the evolving landscape of gear manufacturing, the importance of selecting the right materials cannot be overstated. High-load tolerant gears are predominantly made from steel and bronze, each offering unique benefits that cater to different operational demands. Steel stands out for its remarkable strength, while bronze excels in environments where resilience against wear and corrosion is paramount.

Strategic sourcing plays a critical role in optimizing your supply chain, ensuring that you not only secure high-quality materials but also enhance cost efficiency and reliability. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe consider their sourcing strategies, it is essential to evaluate suppliers based on their ability to provide materials that meet specific load-bearing requirements.

Illustrative image related to material used to make gears that can tolerate high loads

Looking ahead, the demand for advanced gear solutions will continue to grow, propelled by technological advancements and increasing industrial applications. Now is the time to strengthen partnerships with reliable suppliers who can deliver the high-performance materials necessary for your gear production. Invest in strategic sourcing today to stay ahead in the competitive market and ensure that your gear systems can withstand the demands of the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to material used to make gears that can tolerate high loads