Machine Shop Directory Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for machine shop directory

In today’s competitive landscape, sourcing reliable machining suppliers can be a daunting task for international B2B buyers. The challenge is not just finding a machine shop; it’s about identifying a partner that aligns with your specific needs, whether in precision machining, custom fabrication, or specialized services. A comprehensive machine shop directory serves as a vital resource, enabling businesses across Africa, South America, the Middle East, and Europe—such as Nigeria and Saudi Arabia—to navigate this complex market effectively.

This guide offers an in-depth exploration of various types of machine shops, including those with critical certifications like ISO and AS9100, ensuring that you can find suppliers who meet your quality and regulatory requirements. Additionally, we delve into the applications of different machining services, the vetting process for suppliers, and factors influencing costs. By leveraging the insights presented in this guide, B2B buyers can make informed purchasing decisions, streamline their sourcing processes, and ultimately enhance their operational efficiency.

Understanding the global market for machine shops is not just about finding a vendor; it’s about building strategic partnerships that can drive innovation and success. With a wealth of information at your fingertips, you are equipped to select the right machining supplier tailored to your business needs, paving the way for growth and competitiveness in your industry.

Understanding machine shop directory Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Geographic Directories | Organized by location; easy to find local suppliers | Local sourcing, regional partnerships | Pros: Quick access to nearby options; Cons: Limited to specific regions. |

| Specialty Directories | Categorized by machining services (e.g., CNC, milling) | Targeted service procurement | Pros: Focused search for specific needs; Cons: May miss broader options. |

| Certification-Based Directories | Lists shops by quality certifications (ISO, AS9100) | Compliance-driven sourcing | Pros: Assurance of quality and standards; Cons: Can be restrictive based on certifications. |

| Industry-Specific Directories | Tailored to specific industries (automotive, aerospace) | Niche market engagements | Pros: Direct access to industry experts; Cons: Limited to specific sectors. |

| Comprehensive Directories | Extensive listings covering multiple types and regions | General procurement, diverse sourcing | Pros: Wide range of options; Cons: Can be overwhelming without filters. |

What Are the Characteristics of Geographic Directories?

Geographic directories are organized by location, allowing B2B buyers to quickly identify machine shops within a specific area. This is particularly beneficial for companies seeking local suppliers to minimize shipping costs and lead times. Buyers should consider their geographic proximity to ensure timely delivery and ease of communication. However, while these directories provide convenience, they can limit options if the buyer is not open to sourcing from a broader area.

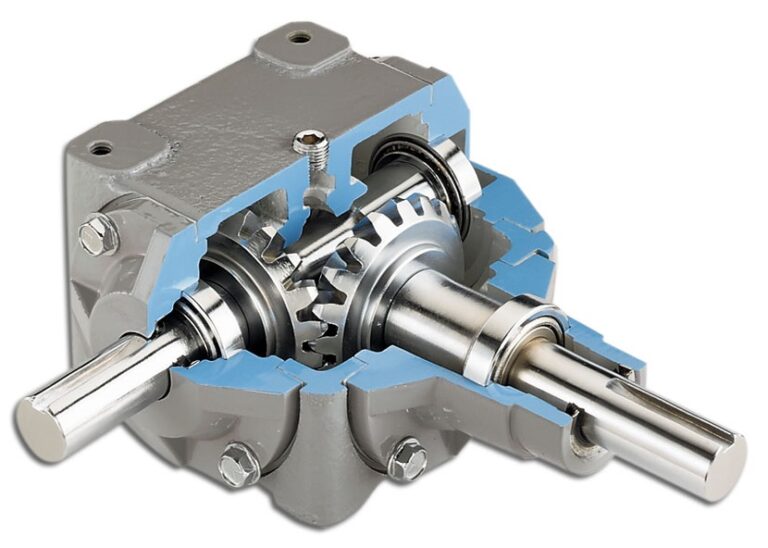

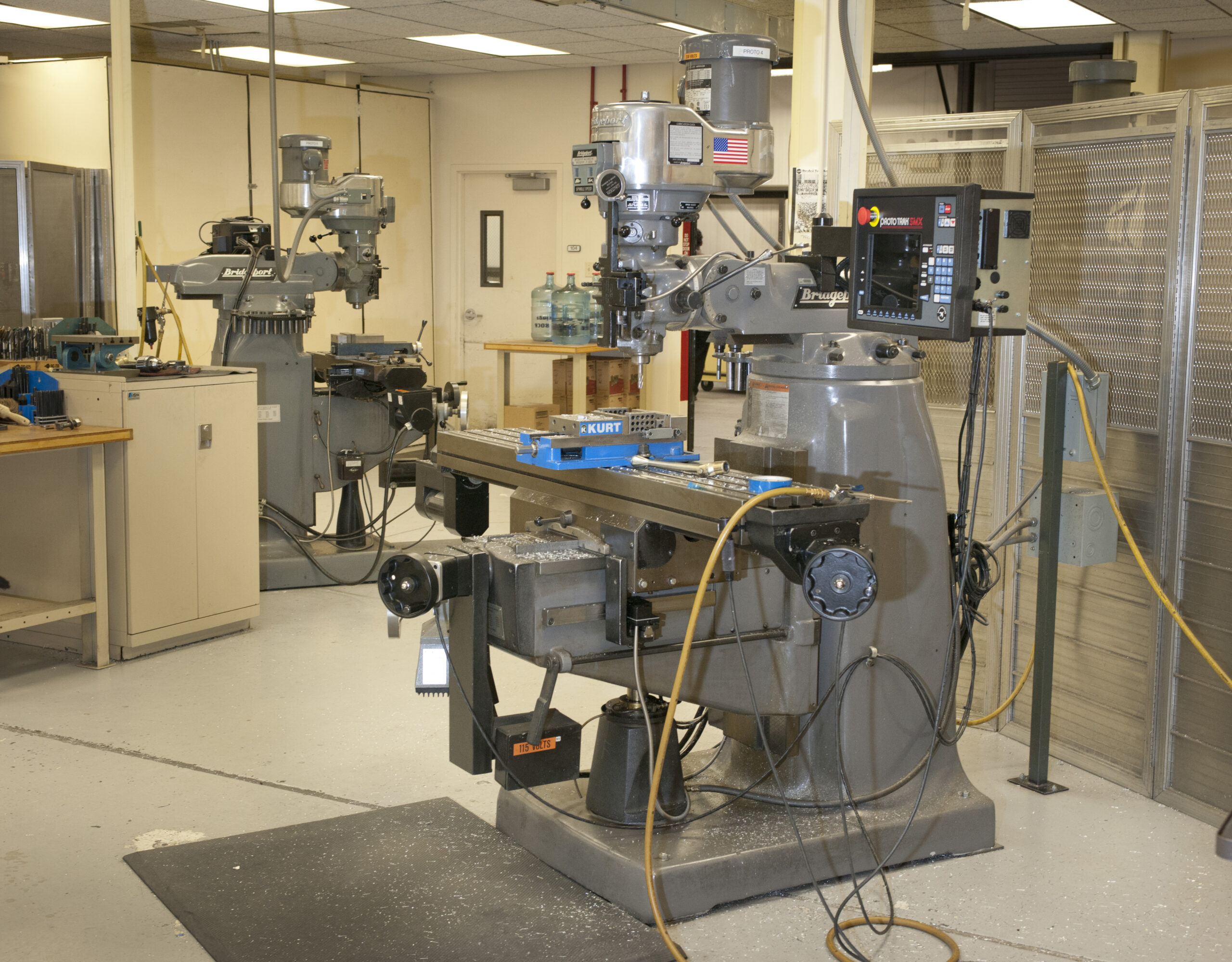

Illustrative image related to machine shop directory

How Do Specialty Directories Cater to Specific Needs?

Specialty directories categorize machine shops based on the specific machining services they offer, such as CNC machining, milling, or turning. This targeted approach helps buyers find suppliers with the exact capabilities needed for their projects. For B2B buyers, this means a more efficient procurement process as they can quickly access shops that specialize in their required services. However, relying solely on specialty directories may restrict buyers from exploring shops that could offer innovative solutions outside their primary focus.

Why Are Certification-Based Directories Important for Compliance?

Certification-based directories list machine shops according to their quality certifications, such as ISO 9001 or AS9100. These directories are essential for B2B buyers in regulated industries, as they ensure that suppliers meet specific quality standards and compliance requirements. Buyers should prioritize these directories if their projects require strict adherence to quality protocols. While these directories provide peace of mind regarding quality, they may limit options if many local shops do not hold the necessary certifications.

What Are the Benefits of Industry-Specific Directories?

Industry-specific directories focus on machine shops that cater to particular sectors, such as aerospace or automotive manufacturing. This specialization allows buyers to connect with experts who understand the unique challenges and requirements of their industry. B2B buyers should leverage these directories for tailored solutions and industry insights. However, the drawback is that these directories may not provide options outside the targeted industry, potentially missing out on innovative solutions from other sectors.

How Do Comprehensive Directories Offer Diverse Sourcing Options?

Comprehensive directories provide extensive listings of machine shops across various categories and regions. This broad approach allows B2B buyers to explore a wide range of suppliers, facilitating diverse sourcing strategies. Buyers can benefit from comparing multiple options to find the best fit for their needs. However, the sheer volume of listings can be overwhelming, making it crucial for buyers to utilize filtering tools to streamline their search effectively.

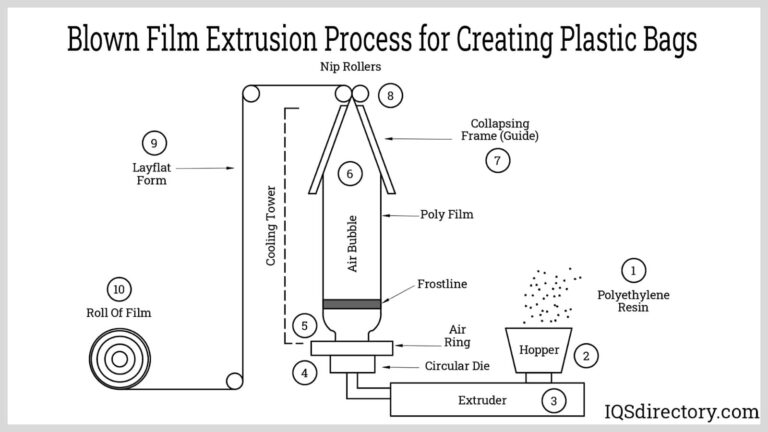

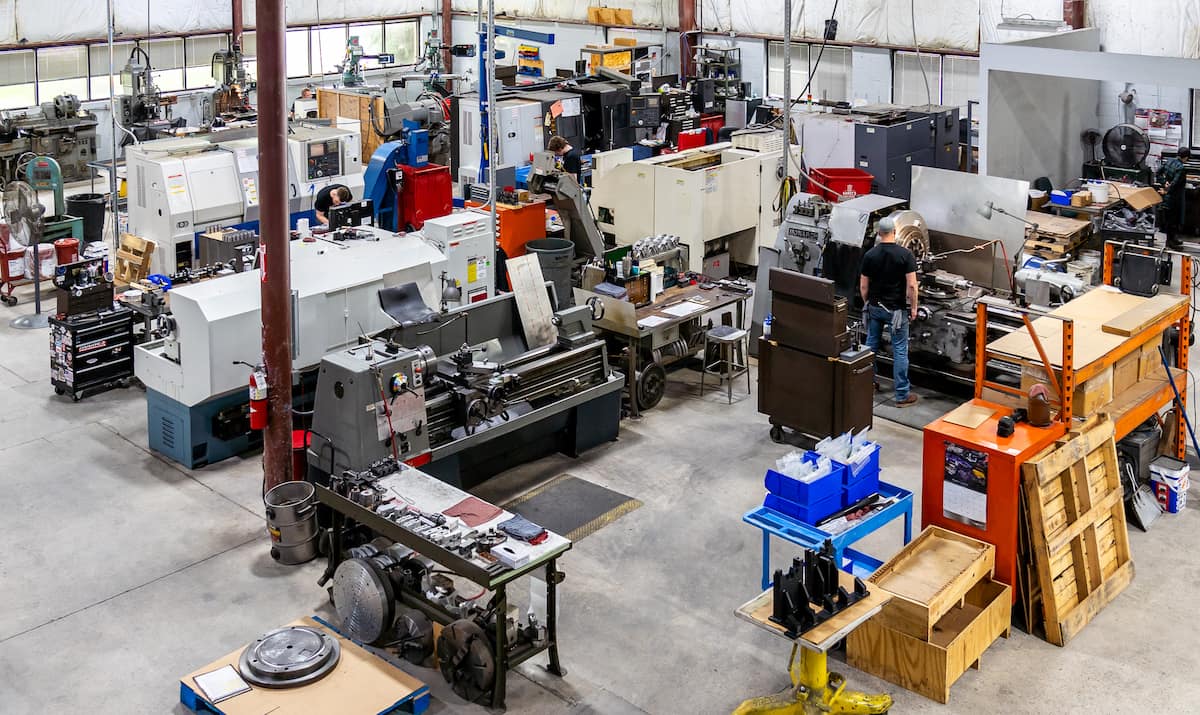

Illustrative image related to machine shop directory

Key Industrial Applications of machine shop directory

| Industry/Sector | Specific Application of machine shop directory | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Finding ISO-certified machine shops for aircraft components | Ensures compliance with stringent safety and quality standards | Certification levels, geographic proximity, and specialization |

| Automotive | Sourcing suppliers for precision engine parts | Reduces lead time and enhances supply chain efficiency | Production capabilities, certifications, and delivery timelines |

| Medical Devices | Identifying suppliers for surgical instruments | Guarantees high-quality production with regulatory compliance | ISO certifications, material specifications, and reliability |

| Oil & Gas | Locating machine shops for specialized drilling equipment | Supports operational efficiency and equipment reliability | Customization capabilities, industry experience, and location |

| Electronics Manufacturing | Sourcing for components in electronic devices | Streamlines production and ensures component compatibility | Technology compatibility, lead times, and cost-effectiveness |

How Can the Aerospace Industry Benefit from a Machine Shop Directory?

In the aerospace sector, a machine shop directory is crucial for identifying ISO-certified suppliers capable of manufacturing aircraft components. Given the industry’s rigorous safety and quality standards, international buyers, particularly from regions like the Middle East and Europe, must ensure that their suppliers meet specific certifications. This directory aids in sourcing shops that specialize in aerospace components, ensuring compliance with regulations while also enhancing supply chain reliability.

What Advantages Does the Automotive Industry Gain from Using a Machine Shop Directory?

Automotive manufacturers rely heavily on precision-engineered parts. A machine shop directory allows them to quickly locate suppliers who specialize in engine components and other critical parts. By streamlining sourcing, businesses can reduce lead times and improve overall supply chain efficiency. For international buyers from regions like Africa and South America, it is essential to evaluate the production capabilities and certifications of potential suppliers to ensure they can meet the demands of modern automotive manufacturing.

Why Is a Machine Shop Directory Essential for Medical Device Manufacturing?

In the medical device industry, sourcing suppliers for surgical instruments is a critical application of a machine shop directory. It enables manufacturers to find vendors that not only produce high-quality products but also comply with necessary regulatory standards. Buyers, especially from regions like Nigeria and Saudi Arabia, must focus on suppliers with relevant ISO certifications to guarantee the reliability and safety of medical instruments. This directory helps mitigate risks associated with regulatory non-compliance.

How Does the Oil & Gas Sector Utilize a Machine Shop Directory?

The oil and gas industry requires specialized machinery, such as drilling equipment, which demands precise engineering. A machine shop directory helps businesses locate suppliers with expertise in producing such specialized equipment. For international buyers, particularly in regions with emerging markets, understanding customization capabilities and the experience of suppliers in the oil and gas sector is crucial for ensuring operational efficiency and equipment reliability.

What Role Does a Machine Shop Directory Play in Electronics Manufacturing?

In the rapidly evolving electronics manufacturing sector, sourcing components that meet specific technological requirements is vital. A machine shop directory enables manufacturers to find suppliers who can provide compatible parts for electronic devices. Buyers should consider factors like technology compatibility, lead times, and cost-effectiveness when sourcing internationally. This directory not only streamlines the procurement process but also enhances the ability to maintain production schedules and product quality.

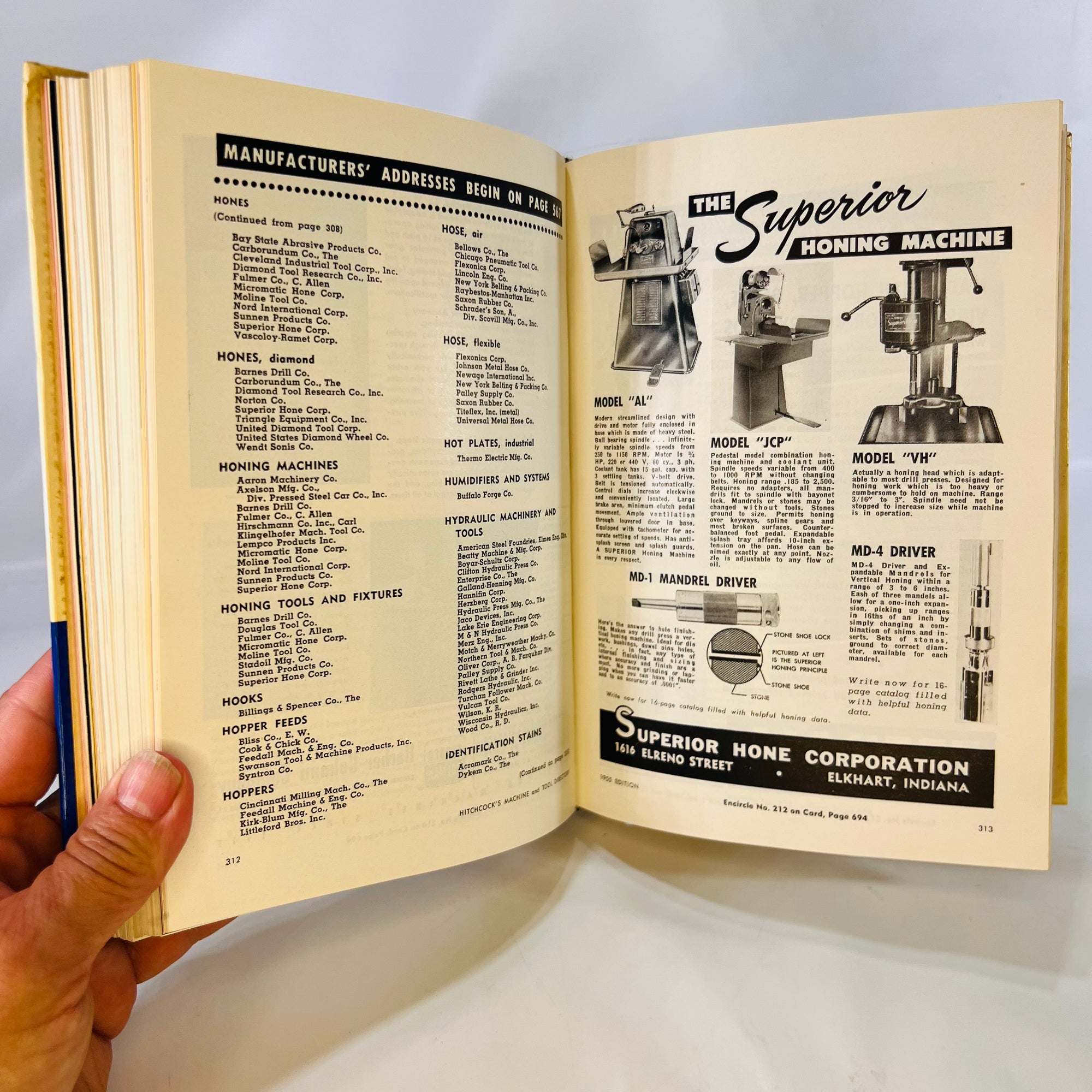

Illustrative image related to machine shop directory

3 Common User Pain Points for ‘machine shop directory’ & Their Solutions

Scenario 1: Difficulty in Finding Specialized Machine Shops

The Problem:

International B2B buyers often struggle to find machine shops that specialize in niche services or specific industries, such as aerospace or medical device manufacturing. With the vast number of listings in machine shop directories, it can be overwhelming to sift through general listings. This is particularly challenging for buyers in regions like Africa or South America, where access to reliable suppliers is limited. Consequently, buyers may waste valuable time and resources contacting unsuitable vendors, leading to frustration and potential project delays.

The Solution:

To effectively navigate a machine shop directory, buyers should leverage advanced search filters that focus on specific capabilities, certifications, and industries. For example, utilize directories that categorize shops by specialization, such as “ISO 13485 Certified Machine Shops” for medical products or “AS9100 Certified Shops” for aerospace needs. Additionally, always check for customer reviews and case studies that highlight the shop’s expertise in similar projects. When making initial inquiries, provide detailed specifications of your project to help suppliers assess their suitability. This proactive approach will streamline the selection process and connect buyers with the right machine shops more efficiently.

Scenario 2: Concerns About Supplier Reliability and Quality

The Problem:

Buyers from regions like the Middle East and Europe often face concerns regarding the reliability and quality of machine shops listed in directories. With varying standards of practice and certification levels across countries, it can be challenging to determine which suppliers can meet specific quality requirements. The fear of receiving subpar products or missing delivery deadlines can lead to hesitation in committing to a supplier, ultimately impacting project timelines and budgets.

The Solution:

To mitigate these concerns, buyers should prioritize directories that provide detailed supplier profiles, including certifications, quality management systems, and past project examples. Look for machine shops that are ISO certified or hold industry-specific certifications, as these often indicate a commitment to quality. Additionally, engage in direct communication with potential suppliers to discuss their quality control processes and request references from previous clients. This due diligence will not only build confidence in the supplier’s capabilities but also establish a foundation for a strong working relationship.

Scenario 3: Language Barriers and Communication Challenges

The Problem:

For B2B buyers in Africa or South America, language barriers can create significant challenges when sourcing machine shops from different regions. Misunderstandings can arise during negotiations, leading to errors in project specifications and expectations. This lack of clear communication can result in costly mistakes, delays, and ultimately strained relationships between buyers and suppliers.

The Solution:

To overcome language barriers, buyers should seek out machine shop directories that offer multilingual support or translation features. Look for directories that provide listings with English descriptions and contact details, as many global suppliers will have English-speaking representatives. Additionally, consider using clear and concise communication tools such as visual aids or technical drawings to convey project requirements more effectively. Establishing a single point of contact within the supplier’s organization can also help streamline communication and ensure that all parties are on the same page. Utilizing these strategies will enhance mutual understanding and facilitate smoother transactions.

Strategic Material Selection Guide for machine shop directory

What Are the Key Properties of Common Materials Used in Machine Shops?

In the realm of machine shops, the selection of materials is pivotal for ensuring product performance and suitability for various applications. Below, we analyze four common materials—aluminum, steel, stainless steel, and plastics—highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to machine shop directory

How Does Aluminum Perform in Machine Shop Applications?

Aluminum is renowned for its lightweight and excellent corrosion resistance. It has a relatively high strength-to-weight ratio, making it suitable for applications where weight savings are crucial, such as in aerospace and automotive sectors. Its melting point is around 660°C, which allows for effective machining and fabrication.

Pros: Aluminum is easy to machine, offers good thermal and electrical conductivity, and is cost-effective. It is also recyclable, which appeals to environmentally conscious buyers.

Cons: However, aluminum can be less durable than other metals, particularly under high-stress conditions. It is also susceptible to wear and tear if not treated properly.

Impact on Application: Aluminum is compatible with various media, including air and water, but may not be suitable for high-pressure applications without additional treatment.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local standards for aluminum products, such as ASTM and ISO certifications, to ensure compliance with international quality benchmarks.

What Are the Strengths and Weaknesses of Steel in Machining?

Steel, particularly carbon steel, is one of the most widely used materials in machining due to its strength and versatility. It offers excellent tensile strength and can withstand high temperatures, making it ideal for heavy-duty applications.

Pros: Steel is durable and can be heat-treated to enhance its properties. It is also relatively inexpensive compared to many other materials.

Illustrative image related to machine shop directory

Cons: The downside is that steel can be prone to corrosion if not properly coated or treated. Additionally, its weight can be a disadvantage in applications where weight savings are critical.

Impact on Application: Steel is highly compatible with various media, including oils and fuels, making it suitable for automotive and industrial applications.

Considerations for International Buyers: Buyers should ensure that the steel grades they select comply with local and international standards like DIN and JIS, particularly when sourcing from different regions.

How Does Stainless Steel Compare in Terms of Performance?

Stainless steel is an alloy known for its exceptional corrosion resistance and aesthetic appeal. It is commonly used in food processing, medical devices, and chemical industries due to its non-reactive nature.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, making it ideal for harsh environments. It also maintains its strength at high temperatures.

Cons: However, stainless steel is generally more expensive than carbon steel and can be more challenging to machine due to its toughness.

Impact on Application: Stainless steel is compatible with a wide range of media, including acids and alkalis, making it suitable for chemical processing applications.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider compliance with standards like ASTM A240 for stainless steel to ensure quality and compatibility with local regulations.

What Role Do Plastics Play in Machine Shop Operations?

Plastics, such as polycarbonate and nylon, are increasingly used in machining due to their lightweight and versatile properties. They can be molded into complex shapes, making them suitable for a variety of applications.

Illustrative image related to machine shop directory

Pros: Plastics are resistant to corrosion and can be produced at a lower cost compared to metals. They also offer good insulation properties.

Cons: However, plastics may not be suitable for high-temperature applications and can be less durable than metals.

Impact on Application: Plastics are compatible with a variety of media, but their suitability for specific applications should be assessed based on temperature and chemical exposure.

Considerations for International Buyers: Buyers should be aware of international standards for plastics, such as ISO 9001, to ensure quality and performance in their applications.

Summary Table of Material Selection for Machine Shops

| Material | Typical Use Case for machine shop directory | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Steel | Industrial machinery, automotive frames | High strength and cost-effective | Prone to corrosion | Low |

| Stainless Steel | Food processing, medical devices | Excellent corrosion resistance | Higher cost and machining difficulty | High |

| Plastics | Electrical enclosures, consumer products | Lightweight and versatile | Not suitable for high temperatures | Low |

This guide aims to provide B2B buyers with actionable insights into material selection, ensuring they make informed decisions that align with their operational requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for machine shop directory

What Are the Main Stages of Manufacturing Processes in a Machine Shop?

Manufacturing processes in a machine shop encompass several critical stages, each essential for producing high-quality components. The typical stages include:

Material Preparation

The first step involves selecting the appropriate raw materials based on the specifications of the final product. Common materials include metals, plastics, and composites. Material preparation may also involve cutting, shearing, or machining to achieve the desired dimensions and shapes before moving to forming.

How Is Forming Performed in Machine Shops?

Forming processes such as machining, welding, and casting transform raw materials into usable parts. Machining, which includes turning, milling, and drilling, is a prevalent technique in machine shops. CNC (Computer Numerical Control) machines are often employed for precision and efficiency, allowing for intricate designs and tight tolerances.

What Role Does Assembly Play in Manufacturing?

After forming, the next stage is assembly, where individual components are joined to create a complete product. This stage may involve mechanical fastening, welding, or adhesive bonding, depending on the materials used and the product requirements. Efficient assembly lines are crucial for maintaining production schedules and minimizing costs.

How Is Finishing Achieved in Machine Shops?

Finishing processes enhance the surface quality and functionality of the manufactured parts. Techniques such as polishing, coating, and anodizing improve aesthetics and protect against corrosion. The choice of finishing process is often dictated by the intended use of the product and customer specifications.

What Quality Assurance Standards Are Important for Machine Shops?

Quality assurance (QA) is vital in ensuring that manufactured products meet specified requirements and standards. For B2B buyers, understanding the relevant international and industry-specific standards is essential.

Which International Standards Should B2B Buyers Look For?

ISO 9001 is a widely recognized quality management standard that outlines the criteria for an effective quality management system (QMS). It emphasizes customer satisfaction and continuous improvement, making it crucial for machine shops aiming to serve international markets. Other relevant standards include:

Illustrative image related to machine shop directory

- ISO 13485: Important for medical device manufacturing.

- AS9100: A requirement for aerospace industry suppliers.

- ITAR Registration: Necessary for companies working with defense-related products.

What Are the Common QC Checkpoints in Machine Shops?

Quality control is typically divided into three checkpoints:

- Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified criteria before they enter the production process.

- In-Process Quality Control (IPQC): Conducted during manufacturing, this stage involves regular inspections and testing to ensure that components are being produced correctly and within tolerances.

- Final Quality Control (FQC): The final inspection checks the completed products against customer specifications and relevant standards. This stage may involve functional testing and dimensional checks.

What Testing Methods Are Commonly Used in Machine Shops?

Quality assurance relies on various testing methods to verify the integrity and performance of manufactured components. Common testing methods include:

- Visual Inspections: Basic checks for surface defects or inconsistencies.

- Dimensional Measurements: Using tools like calipers and micrometers to ensure components meet specified dimensions.

- Destructive Testing: Assessing the material properties by subjecting samples to stress until failure, providing insights into the material’s strength and durability.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspection allow for internal flaws to be detected without damaging the components.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are several ways to ensure compliance and quality:

What Are the Steps for Conducting Supplier Audits?

Conducting supplier audits involves visiting the manufacturing facility to assess their quality management systems, processes, and adherence to standards. During the audit, buyers should focus on:

- Documentation: Review quality manuals, process flows, and records of previous inspections.

- Process Observations: Observe manufacturing and quality control processes in action.

- Interviews: Speak with staff about their roles and understanding of quality procedures.

How Can Buyers Request Quality Reports?

Buyers should request quality assurance reports that provide insights into the supplier’s performance metrics, including defect rates and corrective actions taken. Regular reports can help maintain transparency and foster trust between the buyer and supplier.

Why Is Third-Party Inspection Important?

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These organizations often have the expertise to conduct thorough inspections and can help ensure compliance with international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is particularly important for international buyers who may face different regulatory environments and standards. Here are key considerations:

- Regional Standards: Different regions may have specific certifications that are more relevant. For instance, CE marking is essential for products sold in the European Union, while API certification is crucial for oil and gas components.

- Cultural Expectations: Quality standards may vary based on cultural expectations and norms. Buyers should be aware of these differences to avoid misunderstandings and ensure that their quality expectations align with the supplier’s capabilities.

- Supply Chain Transparency: Establishing a clear line of communication and transparency in the supply chain is vital. Buyers should engage with suppliers to understand their quality control processes and how they ensure compliance with relevant standards.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and establish reliable partnerships within the machine shop industry. Understanding the intricacies of manufacturing and quality control will empower buyers to source high-quality components that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machine shop directory’

To effectively navigate the procurement of services from a machine shop directory, this checklist provides an actionable step-by-step guide tailored for B2B buyers, particularly in international markets. By following these steps, you can ensure a comprehensive evaluation of suppliers, ultimately leading to successful partnerships.

Illustrative image related to machine shop directory

Step 1: Identify Your Project Requirements

Before diving into a machine shop directory, clearly outline your specific project needs. Determine the materials, tolerances, and any specialized processes required for your project. This foundational knowledge will help you filter suppliers who can meet your exact specifications.

- Key Considerations:

- Define the type of machining services needed (e.g., CNC machining, turning, milling).

- Specify any industry standards or certifications required for your project.

Step 2: Research Available Directories

Not all machine shop directories are created equal. Spend time researching various platforms to find one that aligns with your geographic and technical needs. Look for directories that offer user-friendly interfaces and robust filtering options.

- What to Look For:

- Directory coverage in your target regions (e.g., Africa, South America).

- Availability of specialized categories based on industry or machining processes.

Step 3: Verify Supplier Certifications

When evaluating potential suppliers, ensure they hold relevant certifications such as ISO 9001, AS9100, or ITAR registration. These certifications demonstrate a commitment to quality management and compliance with industry standards, which is essential for reducing risks in your supply chain.

Illustrative image related to machine shop directory

- Important Actions:

- Request documentation of certifications.

- Confirm that the certifications are up-to-date and relevant to your needs.

Step 4: Evaluate Supplier Experience and Capabilities

Assess the experience level of suppliers listed in the directory. Look for companies that have successfully completed projects similar to yours. This not only indicates their capability but also their understanding of industry-specific challenges.

- Evaluation Methods:

- Review case studies or project portfolios.

- Ask for references from previous clients in your industry.

Step 5: Request Quotes and Compare Pricing

Once you’ve narrowed down your list of potential suppliers, request detailed quotes. This will allow you to compare pricing structures, lead times, and any additional services offered. Ensure that each quote includes a breakdown of costs to facilitate an accurate comparison.

- Comparison Tips:

- Look for hidden costs that may not be included in the initial quote.

- Consider the value of services offered, not just the price.

Step 6: Conduct On-site Visits or Virtual Meetings

If feasible, arrange to visit the machine shop or conduct virtual meetings to gauge their operations and capabilities firsthand. This step can provide invaluable insights into their work environment, machinery, and overall professionalism.

- What to Observe:

- Cleanliness and organization of the facility.

- Engagement level of staff and management.

Step 7: Establish Clear Communication Channels

Before finalizing your partnership, ensure that clear communication protocols are established. Effective communication will facilitate smoother project execution and help resolve any issues that may arise during the production process.

- Recommended Practices:

- Define points of contact and preferred communication methods.

- Set expectations for regular updates throughout the project lifecycle.

By following this checklist, you can navigate the machine shop directory landscape with confidence, ensuring that you select suppliers who can meet your manufacturing needs effectively and efficiently.

Illustrative image related to machine shop directory

Comprehensive Cost and Pricing Analysis for machine shop directory Sourcing

What Are the Key Cost Components in Machine Shop Directory Sourcing?

When engaging with machine shops through directories, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts pricing. High-quality materials may incur higher upfront costs but can lead to better durability and performance, ultimately reducing long-term expenses.

-

Labor: Labor costs vary by region and skill level. Regions with lower labor costs, such as parts of Africa or South America, may offer competitive pricing, but this can also affect quality and turnaround times.

-

Manufacturing Overhead: This includes utilities, rent, and maintenance costs. Shops with advanced technology may have higher overhead but can offer faster and more precise services.

-

Tooling: Specialized tooling can be a substantial investment for machine shops. Buyers should inquire whether these costs are included in the quoted prices or charged separately.

-

Quality Control (QC): Effective QC measures can enhance product reliability but may increase the overall cost. Certifications like ISO or AS9100 add credibility but also reflect in the pricing.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transport, and customs duties. Understanding these logistics is vital for accurate total cost assessments.

-

Margin: The supplier’s profit margin will influence final prices. It’s essential to recognize that higher margins may be justified by superior service or quality.

How Do Price Influencers Affect Machine Shop Directory Sourcing?

Several factors can influence pricing when sourcing from machine shop directories:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower unit costs due to economies of scale. Buyers should negotiate MOQs that suit their needs while minimizing costs.

-

Specifications and Customization: Customized parts often incur additional costs. Clearly defining specifications upfront can help avoid unexpected price hikes later in the process.

-

Materials Used: As previously mentioned, the choice of materials can significantly affect costs. Buyers should consider both initial costs and long-term performance when selecting materials.

-

Quality and Certifications: Machine shops that maintain industry certifications may charge a premium, but this often correlates with higher quality and reliability.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may command higher prices due to their track record, while newer entrants might offer lower prices to build market share.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they dictate the responsibilities of buyers and sellers in shipping and logistics. This can significantly affect the total landed cost.

What Are Essential Tips for Buyers Negotiating Costs?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are key:

-

Negotiate Wisely: Always negotiate terms and pricing. Establishing a rapport can lead to better terms, especially for recurring orders.

-

Focus on Cost-Efficiency: Evaluate suppliers based on total cost rather than just unit price. Consider shipping, tariffs, and potential delays in your cost analysis.

-

Understand Total Cost of Ownership (TCO): TCO includes all costs associated with acquiring and using a product over its lifespan. This perspective helps in identifying the most cost-effective suppliers.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures. For instance, suppliers in Nigeria may operate under different economic conditions than those in Europe. Familiarize yourself with local market dynamics to negotiate effectively.

-

Request Detailed Quotes: Ensure that quotes from suppliers detail all components of pricing, including shipping and potential additional fees. This transparency aids in making informed decisions.

Disclaimer on Indicative Prices

Please note that prices in machine shop directory sourcing can vary widely based on numerous factors, including market demand, material costs, and supplier capabilities. Always request updated quotes tailored to your specific needs to obtain the most accurate pricing information.

Alternatives Analysis: Comparing machine shop directory With Other Solutions

Exploring Alternative Solutions to Machine Shop Directories

In today’s competitive manufacturing landscape, B2B buyers are often faced with various methods to identify and connect with machine shops that meet their specific needs. While machine shop directories offer a comprehensive solution, there are alternative approaches worth considering. This analysis examines how machine shop directories compare with other viable solutions such as direct sourcing through trade shows and utilizing online marketplaces.

| Comparison Aspect | Machine Shop Directory | Trade Shows | Online Marketplaces |

|---|---|---|---|

| Performance | High – comprehensive listings | Moderate – depends on attendance | Variable – quality varies by platform |

| Cost | Typically low – often free listings | High – travel and participation costs | Moderate – listing fees and transaction costs |

| Ease of Implementation | Easy – quick registration and access | Challenging – requires planning and logistics | Moderate – requires account setup |

| Maintenance | Low – updated by directory operators | High – requires ongoing management | Moderate – platform updates needed |

| Best Use Case | Broad industry search, specific certifications | Networking and relationship building | Quick access to diverse suppliers |

How Do Trade Shows Compare to Machine Shop Directories?

Trade shows provide a dynamic environment for B2B buyers to engage directly with machine shop representatives. They allow for real-time discussions, product demonstrations, and the opportunity to forge relationships. However, the costs associated with travel, accommodation, and participation can be significant. Furthermore, the effectiveness of trade shows can vary based on attendance and the specific focus of the event. For buyers seeking immediate and personal interactions, trade shows can be invaluable, but they require more effort and investment compared to the straightforward nature of machine shop directories.

What Advantages Do Online Marketplaces Offer Over Directories?

Online marketplaces represent a modern alternative to machine shop directories, offering a platform where buyers can browse listings and communicate with suppliers directly. They often feature user reviews and ratings, providing insights into supplier reliability. However, the quality of listings can be inconsistent, as not all platforms maintain rigorous vetting processes. While they offer quick access to a wide range of suppliers, the transaction costs and potential for lower-quality leads can detract from their appeal. For buyers looking for speed and variety, online marketplaces are a good option, but they may lack the specialized focus of a dedicated machine shop directory.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the best solution for connecting with machine shops, B2B buyers should consider their specific requirements, such as the urgency of their needs, budget constraints, and the importance of personal relationships. Machine shop directories are ideal for those seeking comprehensive listings and cost-effective solutions. In contrast, trade shows are best suited for buyers prioritizing face-to-face interactions, while online marketplaces can serve those looking for a broader array of options. By assessing these factors, buyers can make informed decisions that align with their operational goals and procurement strategies.

Essential Technical Properties and Trade Terminology for machine shop directory

What Are the Key Technical Properties Important for Machine Shop Directories?

When navigating the complexities of a machine shop directory, understanding key technical properties can significantly enhance decision-making for international B2B buyers. Here are several critical specifications to consider:

-

Material Grade

Material grade refers to the classification of materials based on their properties, such as tensile strength, hardness, and corrosion resistance. In the context of machining, knowing the material grade is essential for ensuring that the right material is selected for specific applications, which directly impacts the performance and durability of the final product. For buyers, this means assessing whether a supplier can meet their specific material requirements, particularly for industries like aerospace and automotive, where compliance with stringent standards is critical. -

Tolerance

Tolerance defines the permissible limit of variation in a physical dimension, which is crucial in machining processes. It ensures that parts fit together correctly and function as intended. Buyers must understand the tolerance levels a machine shop can achieve, as tighter tolerances typically indicate higher precision and quality. This can be particularly important for industries requiring exact specifications, such as medical device manufacturing. -

Surface Finish

Surface finish pertains to the texture of a machined surface, which can affect both the aesthetic and functional aspects of a part. Different surface finishes can enhance corrosion resistance, reduce friction, and improve adhesion for coatings. For B2B buyers, specifying surface finish requirements can help ensure that the final products meet both operational and visual standards. -

Heat Treatment

Heat treatment involves processes like annealing, hardening, and tempering that alter the physical and sometimes chemical properties of a material. Understanding the heat treatment capabilities of a machine shop is vital for buyers looking for components that require enhanced strength or durability. This is particularly relevant in sectors such as automotive and aerospace, where material properties are critical for safety and performance. -

Production Capacity

Production capacity refers to the maximum output a machine shop can achieve within a given timeframe. For B2B buyers, understanding a supplier’s production capacity helps in planning and ensuring that orders can be fulfilled within desired timelines. This is especially important for companies operating on tight schedules or high-volume production runs. -

Certification Standards

Certifications such as ISO 9001, AS9100, or ITAR signify compliance with international quality management standards and regulatory requirements. For international buyers, ensuring that a machine shop holds relevant certifications can provide confidence in the shop’s ability to deliver quality and reliable products, which is essential for maintaining compliance in regulated industries.

What Are Common Trade Terms Used in Machine Shop Directories?

Familiarizing oneself with industry jargon can streamline communication and enhance negotiations. Here are several common terms that buyers should know:

Illustrative image related to machine shop directory

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the relationship with OEMs is crucial for buyers, as it often dictates the quality and compatibility of parts supplied. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory management, especially for small businesses or new projects that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. It helps buyers gather information on pricing and terms, facilitating a more informed decision-making process. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is crucial for international transactions, as they dictate who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order from the time it is placed until it is delivered. For buyers, knowing the lead time helps in planning production schedules and inventory management. -

Prototype

A prototype is an early sample or model of a product used to test a concept or process. For B2B buyers, requesting prototypes can be an effective way to evaluate a machine shop’s capabilities and the quality of their work before committing to larger orders.

Understanding these technical properties and trade terms can empower B2B buyers to make more informed decisions when sourcing machining services and products from machine shops worldwide.

Navigating Market Dynamics and Sourcing Trends in the machine shop directory Sector

What Are the Current Market Dynamics and Key Trends in the Machine Shop Directory Sector?

The machine shop directory sector is experiencing significant evolution driven by globalization, technological advancements, and the need for efficiency in sourcing. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly utilizing online directories to access a diverse range of machining suppliers. Key trends include the adoption of digital platforms that facilitate real-time communication, enhanced search functionalities, and tailored listings based on specific machining capabilities such as CNC machining, milling, or turning.

Emerging technologies like artificial intelligence and machine learning are transforming how directories operate, enabling smarter matching between buyers and suppliers. Additionally, there is a growing emphasis on data analytics to provide insights into supplier performance, pricing trends, and market demands. As international trade barriers reduce, buyers are seeking suppliers with certifications that meet their quality and regulatory standards, such as ISO and AS9100. This trend underscores the importance of compliance for machine shops to remain competitive in the global marketplace.

How Is Sustainability and Ethical Sourcing Influencing B2B in the Machine Shop Directory Sector?

Sustainability and ethical sourcing are becoming paramount in the B2B landscape, particularly in the machine shop directory sector. Environmental concerns are pushing businesses to prioritize suppliers that demonstrate responsible practices. This includes using eco-friendly materials, implementing waste reduction strategies, and pursuing certifications like ISO 14001, which focuses on effective environmental management systems.

The demand for ‘green’ certifications is rising among buyers who are increasingly aware of the environmental impact of their supply chains. Suppliers listed in machine shop directories that can showcase their commitment to sustainability are likely to gain a competitive edge. Moreover, ethical sourcing practices enhance brand reputation and customer loyalty, making it crucial for machine shops to adopt transparent supply chain practices that ensure fair labor and sourcing conditions.

How Has the Machine Shop Directory Sector Evolved Over Time?

The evolution of the machine shop directory sector reflects the broader changes in manufacturing and globalization. Traditionally, buyers relied on print directories and word-of-mouth referrals to find machining suppliers. However, the advent of the internet revolutionized this landscape, allowing for the creation of comprehensive online directories that provide detailed listings by location, specialty, and certification.

In recent years, the focus has shifted towards creating user-friendly platforms that facilitate seamless interactions between buyers and suppliers. Enhanced functionalities such as online quoting systems and integrated communication tools have further streamlined the sourcing process. This evolution not only improves accessibility for international buyers but also empowers machine shops to reach a broader audience, ultimately driving competitiveness and innovation in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of machine shop directory

-

How do I find reliable machine shops in the directory?

To find reliable machine shops, start by utilizing online directories that categorize shops by specialty, location, and certifications. Look for shops with relevant industry certifications like ISO 9001 or AS9100, as these indicate a commitment to quality standards. Additionally, read reviews and testimonials from other buyers to gauge their experiences. Don’t hesitate to reach out to multiple shops for quotes and additional information, which can provide insights into their responsiveness and customer service. -

What factors should I consider when selecting a machine shop?

When selecting a machine shop, consider their experience in your specific industry, the range of services they offer, and their technological capabilities. Evaluate their certifications and compliance with international standards, especially if you require precision work. Additionally, assess their communication efficiency, lead times, and pricing structures. Understanding their minimum order quantities (MOQ) and payment terms is also crucial to ensure alignment with your project requirements and budget. -

What are the minimum order quantities (MOQ) typically required by machine shops?

Minimum order quantities (MOQ) can vary significantly among machine shops depending on their capabilities and the type of services offered. Some shops may have no MOQ for prototype services, while others might require a minimum order for bulk production to justify setup costs. It’s advisable to inquire directly with potential suppliers about their MOQ policies, as negotiating these terms can be beneficial for both small and large-scale projects. -

How can I ensure the quality of the products from a machine shop?

To ensure product quality, request samples or prototypes before committing to larger orders. Verify the shop’s quality assurance processes, including inspections and testing protocols. Look for certifications like ISO 9001, which indicate adherence to quality management standards. Regular communication during the production process can help address any quality concerns early on, ensuring the final product meets your specifications. -

What payment terms are standard when dealing with international machine shops?

Payment terms can vary widely based on the shop’s policies and the buyer’s location. Common terms include upfront deposits, payment upon delivery, or net 30/60 days after invoice. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. It’s essential to clarify payment terms before finalizing contracts to avoid misunderstandings and ensure smooth transactions. -

How do logistics work when sourcing from international machine shops?

Logistics involve several steps, including shipping, customs clearance, and delivery. When sourcing internationally, confirm the shop’s ability to handle logistics or partner with a freight forwarder. Understand the shipping options available, such as air or sea freight, and factor in lead times and costs. Additionally, ensure that the shop provides necessary documentation for customs clearance to prevent delays in receiving your order. -

What customization options are available when working with machine shops?

Many machine shops offer customization options tailored to your specific requirements, including material selection, design modifications, and finishing processes. When discussing your project, clearly communicate your needs and any technical specifications. Some shops may also provide design assistance or engineering support to help refine your ideas. It’s beneficial to work closely with the shop during the design phase to ensure the final product aligns with your expectations. -

How can I vet potential machine shop suppliers effectively?

To effectively vet machine shop suppliers, conduct thorough research that includes reviewing their online presence, certifications, and customer feedback. Request references from previous clients and check their track record for reliability and quality. A site visit can also provide valuable insights into their operations and capabilities. Finally, engaging in open communication about your needs and expectations can help establish a trustworthy relationship with potential suppliers.

Top 5 Machine Shop Directory Manufacturers & Suppliers List

1. Machine Shop Web – Global Directory for Machining Suppliers

Domain: machineshopweb.com

Registered: 2000 (25 years)

Introduction: Machine Shops Directory, Machining Suppliers, Free Listings, U.S. and Global Directory, Organized by Location, Specialty, Certification, ISO Certified Machine Shops, AS9100 Certified, ISO 13485 Certified, ITAR Registered, Contract Manufacturing, Small Machine Shops, Lead Generation Opportunities, OEMs, Cutting Tools, Tooling Inserts, Machining Centers, 2,3,4,5 Axis Machines, Cutting and Grinding T…

2. IQS Directory – Precision CNC Machining Services

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: CNC machining services, CNC machining capabilities, precision CNC machining, CNC machining centers, intricate and accurate parts, tight tolerances, small and large production runs, prototyping, full-scale production, high precision commercial grade parts, Swiss Screw Machining, 5 Axis CNC Lathe Machining, Vertical Milling, Horizontal Milling, 4 Axis CNC Machining, CNC Lathe and Swiss Screw Machine…

3. CGTech – VERICUT CNC Programming Software

Domain: machineshoplist.com

Registered: 2012 (13 years)

Introduction: [{‘name’: ‘CGTech’, ‘address’: ‘9000 Research Dr. Irvine, CA 92618’, ‘phone’: ‘949-753-1050’, ‘services’: ‘CNC Programming Software Simulation, Verification and Optimization’, ‘description’: ‘Since 1988, VERICUT software has become the industry standard for simulating CNC machining to detect errors, potential collisions, or areas of inefficiency.’}, {‘name’: ‘Strategic Aerospace Materials’, ‘addre…

4. Traceamatic – Precision CNC Engineering Solutions

Domain: traceamatic.com

Registered: 1998 (27 years)

Introduction: CNC Engineering, 5-Axis Machining, Horizontal Milling, Vertical Milling, CNC Turning, Horizontal Turning, Vertical Turning, CNC Fabrication, Special Processes, Inspection Services, Precision Machining, Metal Machining, Aerospace Components, Aerospace Fabrication, Aerospace Machined Parts, CNC Medical Machining, CNC Military Machining, CNC Pharmaceutical Machining, Large Machined Parts, Marine Fabr…

5. 413 Machining – Precision CNC Machined Products

Domain: veteranownedbusiness.com

Registered: 2005 (20 years)

Introduction: 413 Machining provides precision CNC machined products for various commercial and government applications.

Strategic Sourcing Conclusion and Outlook for machine shop directory

In the dynamic landscape of global manufacturing, strategic sourcing stands as a pivotal element for B2B buyers looking to enhance operational efficiency and reduce costs. By leveraging a comprehensive machine shop directory, international buyers can easily identify qualified suppliers that meet specific industry needs, whether in aerospace, automotive, or medical sectors. The ability to filter suppliers by location, specialization, and certifications—such as ISO and AS9100—ensures that buyers can make informed decisions that align with quality standards and compliance requirements.

Illustrative image related to machine shop directory

Moreover, the directory serves as a vital resource for fostering relationships with small and medium-sized enterprises (SMEs) that often provide innovative solutions and competitive pricing. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable machining services will only grow.

Now is the time for buyers to tap into this extensive network of machine shops. By actively engaging with suppliers listed in the directory, businesses can position themselves for success in an increasingly competitive environment. Explore the directory today to discover the right partners that can help propel your manufacturing capabilities into the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.