Led Light Board: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for led light board

In the ever-evolving landscape of global commerce, sourcing high-quality LED light boards presents a unique challenge for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia. As businesses seek to enhance their branding and operational efficiency through innovative lighting solutions, understanding the nuances of LED light boards—ranging from their types and applications to supplier vetting and cost considerations—becomes imperative.

This comprehensive guide aims to equip international B2B buyers with the insights necessary to make informed purchasing decisions. We delve into various types of LED light boards, including modular sheets and dynamic display options, and explore their applications across different industries, such as retail, events, and advertising. Additionally, we provide practical strategies for evaluating suppliers, ensuring compliance with regional regulations, and optimizing cost-effectiveness without compromising quality.

By navigating this guide, businesses can not only streamline their procurement processes but also leverage the full potential of LED technology to captivate audiences and enhance their operational environments. With the right knowledge and resources, B2B buyers can confidently invest in LED light boards that align with their strategic goals and market demands.

Understanding led light board Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LED Light Sheets | Thin, flexible, adhesive backing for easy mounting | Backlighting, light boxes, signage | Pros: Versatile, easy installation; Cons: Limited brightness compared to larger boards. |

| Modular LED Light Boards | Customizable size, high brightness, and resolution | Retail signage, event displays | Pros: High impact visuals; Cons: Higher initial investment. |

| Digital LED Displays | Capable of dynamic content, video playback | Advertising, entertainment venues | Pros: Engaging, versatile content; Cons: Requires regular updates and maintenance. |

| LED Message Boards | Fixed messages, often programmable | Informational displays, public announcements | Pros: Cost-effective for static messages; Cons: Limited content flexibility. |

| Tunable White LED Panels | Adjustable color temperature, energy-efficient | Architectural lighting, mood setting | Pros: Customizable ambiance; Cons: More complex installation and setup. |

What Are LED Light Sheets and Their Applications?

LED light sheets are thin and flexible, making them suitable for a variety of applications, such as backlighting for signage and light boxes. Their adhesive backing allows for hassle-free installation, while they can also be screw-mounted for more permanent setups. B2B buyers should consider the specific lighting needs of their projects, as these sheets provide even illumination but may not match the brightness of larger LED boards.

How Do Modular LED Light Boards Stand Out?

Modular LED light boards offer customizable sizes and high brightness levels, making them ideal for retail signage and event displays. They can be assembled into larger configurations, providing flexibility for various applications. Buyers should evaluate their visual impact needs, as these boards can deliver striking displays but often come with a higher initial cost compared to simpler options.

What Benefits Do Digital LED Displays Provide?

Digital LED displays can showcase dynamic content, including videos and animations, making them perfect for advertising and entertainment venues. Their ability to engage audiences with vivid, high-contrast imagery is a significant advantage. However, businesses must be prepared for the ongoing costs of content updates and maintenance, as these displays require regular attention to keep the content fresh and relevant.

Why Choose LED Message Boards for Static Information?

LED message boards are designed for displaying fixed messages and are often programmable, making them effective for informational displays and public announcements. They are typically more cost-effective than dynamic displays, offering a straightforward solution for businesses that need to communicate essential information. However, their content flexibility is limited, which may not suit companies looking for more dynamic advertising solutions.

How Do Tunable White LED Panels Enhance Ambiance?

Tunable white LED panels allow users to adjust the color temperature, making them suitable for architectural lighting and creating specific moods in various environments. These panels are energy-efficient and can significantly enhance the ambiance of a space. However, buyers should consider the complexity of installation and setup, as these systems may require more technical expertise compared to standard LED options.

Key Industrial Applications of led light board

| Industry/Sector | Specific Application of LED Light Board | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | In-store signage and displays | Enhances customer engagement and brand visibility | Consider size, brightness, customization options, and power consumption. |

| Events & Entertainment | Stage backdrops and live event displays | Creates immersive experiences and attracts audiences | Ensure high-resolution displays and weather resistance for outdoor use. |

| Transportation | Information displays in airports and train stations | Improves passenger information delivery and safety | Look for durability, energy efficiency, and ease of installation. |

| Hospitality | Menu boards and digital signage in restaurants | Streamlines operations and attracts customers | Assess brightness, clarity, and adaptability to different lighting conditions. |

| Education | Interactive learning boards and classroom displays | Enhances learning experiences and engagement | Evaluate interactivity features, size, and ease of content updates. |

How is LED Light Board Used in Retail and What Problems Does It Solve?

In the retail sector, LED light boards are utilized for in-store signage and displays, effectively drawing customer attention to promotions and new products. They solve the problem of static displays by offering dynamic content that can be easily updated, thereby keeping the messaging fresh and relevant. For international B2B buyers, it’s crucial to consider the size and brightness of the boards to ensure they are suitable for various retail environments, from bustling markets in Africa to high-end stores in Europe.

What Role Do LED Light Boards Play in Events and Entertainment?

In the events and entertainment industry, LED light boards serve as stage backdrops and live event displays, providing vibrant visuals that enhance the audience’s experience. These boards can display live feeds, graphics, and animations, solving the challenge of engaging large crowds. Buyers should prioritize high-resolution displays and consider weather-resistant options for outdoor events, particularly in regions like the Middle East where conditions can be harsh.

How Can LED Light Boards Improve Transportation Information Systems?

Transportation hubs such as airports and train stations benefit from LED light boards used for information displays. These boards provide real-time updates and critical information, significantly improving passenger communication and safety. For B2B buyers in this sector, durability and energy efficiency are paramount, as these boards must withstand heavy usage and varying environmental conditions.

What Advantages Do LED Light Boards Offer in the Hospitality Sector?

In the hospitality industry, LED light boards are commonly used for menu displays and digital signage, streamlining operations while attracting customers with visually appealing content. They address the challenge of quickly updating menus and promotions, allowing for flexibility in offerings. Buyers should evaluate the boards for their brightness and clarity, ensuring they remain effective in different lighting conditions, especially in outdoor dining settings prevalent in regions like South America.

How Are LED Light Boards Transforming Education?

In educational institutions, LED light boards are increasingly used as interactive learning tools and classroom displays. They enhance student engagement by allowing for dynamic presentations and interactive content. B2B buyers in this sector should focus on features such as interactivity, ease of content updates, and appropriate sizing to meet the needs of various classroom settings, from urban schools in Europe to remote learning environments in Africa.

3 Common User Pain Points for ‘led light board’ & Their Solutions

Scenario 1: Inconsistent Brightness Levels Across Displays

The Problem: A common issue for B2B buyers of LED light boards is the inconsistency in brightness levels across multiple displays. This inconsistency can lead to uneven illumination, which is particularly problematic in applications such as retail signage or exhibitions where visual impact is crucial. When displays do not match in brightness, it can diminish the overall aesthetic and effectiveness of the marketing message, causing frustration and potential loss of sales.

The Solution: To ensure uniform brightness across all LED light boards, buyers should prioritize sourcing products from reputable manufacturers that provide detailed specifications on brightness levels and color temperature. It is advisable to opt for LED boards with a high Color Rendering Index (CRI), as this will enhance the visual accuracy of the colors displayed. Additionally, consider investing in a tunable white LED option that allows adjustment of brightness and color temperature to match specific lighting conditions. Regularly calibrating the boards and using a centralized control system can also help maintain consistent performance across all units, ensuring that every display contributes effectively to the brand message.

Scenario 2: Complicated Installation and Setup Processes

The Problem: Many B2B buyers encounter difficulties during the installation and setup of LED light boards. Complicated procedures can lead to increased labor costs and downtime, which is particularly detrimental for businesses with tight schedules or event timelines. For instance, companies planning a large event may struggle with setting up multiple LED boards quickly and efficiently, leading to stress and potential delays.

The Solution: To mitigate installation challenges, businesses should seek LED light boards that come with comprehensive installation guides and support. Working with suppliers who offer pre-assembled solutions or modular designs can significantly reduce setup complexity. Furthermore, investing in training for staff on installation procedures can empower teams to handle setup independently. For larger projects, consider hiring professional installation services that specialize in LED technology; these experts can ensure proper alignment and functionality while minimizing setup time.

Scenario 3: High Energy Costs Associated with LED Displays

The Problem: While LED light boards are generally considered energy-efficient, some businesses find that their operational costs remain high due to improper usage or suboptimal product choices. For example, using LED boards that are not designed for the specific application can result in higher energy consumption, which is a significant concern for budget-conscious B2B buyers, particularly in regions with rising energy prices.

The Solution: Buyers should conduct a thorough energy audit to understand the power requirements of their chosen LED light boards. Opting for models with built-in energy-saving features, such as dimming capabilities or motion sensors, can significantly reduce energy consumption. Furthermore, selecting LED boards that are specifically designed for the intended application—whether for constant display or intermittent use—can enhance energy efficiency. Collaborating with suppliers who can provide energy usage estimates and recommendations based on application needs will enable buyers to make informed decisions that align with their operational budgets.

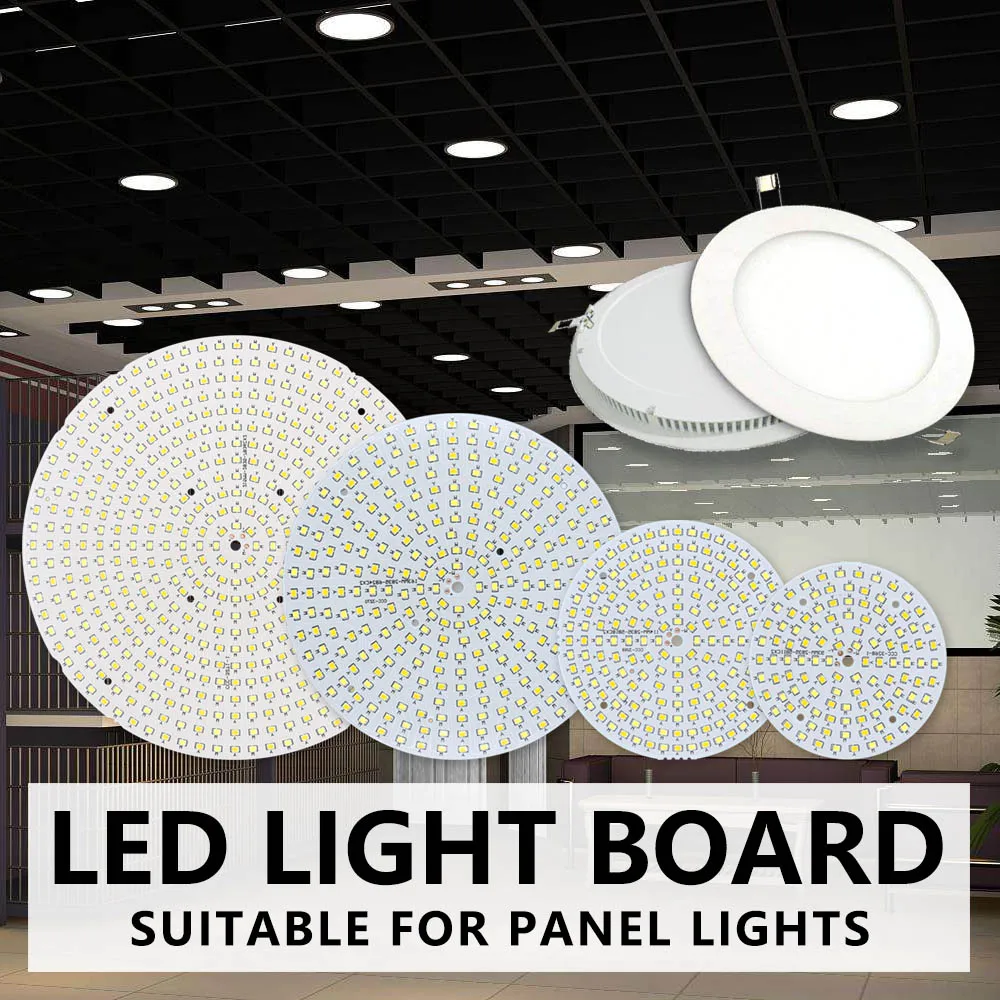

Illustrative image related to led light board

By addressing these pain points through targeted strategies, B2B buyers can enhance their LED light board experience, ensuring that they derive maximum value from their investment.

Strategic Material Selection Guide for led light board

When selecting materials for LED light boards, it is essential to consider properties that influence performance, durability, and overall application suitability. Below is an analysis of four common materials used in the manufacturing of LED light boards, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Polycarbonate for LED Light Boards?

Polycarbonate is a popular choice for LED light boards due to its excellent impact resistance and transparency. It typically withstands temperatures ranging from -40°C to 120°C, making it suitable for various environments. Polycarbonate is also resistant to UV radiation, which helps prevent yellowing over time.

Pros: Polycarbonate is lightweight and offers high durability, making it easy to handle and install. Its optical clarity ensures that light diffusion is even, enhancing the overall effectiveness of the LED display.

Illustrative image related to led light board

Cons: While polycarbonate is durable, it is susceptible to scratching and may require protective coatings, increasing manufacturing complexity. It is also more expensive than some other materials.

Impact on Application: Polycarbonate is compatible with various media, including digital printing, which allows for customized graphics on the LED boards.

International Considerations: Buyers from regions like Africa and the Middle East should ensure that the polycarbonate used meets local compliance standards, such as ASTM or DIN, to guarantee quality and safety.

How Does Aluminum Perform as a Material for LED Light Boards?

Aluminum is another widely used material for LED light boards, known for its lightweight properties and excellent thermal conductivity. It can withstand high temperatures and is resistant to corrosion, making it suitable for outdoor applications.

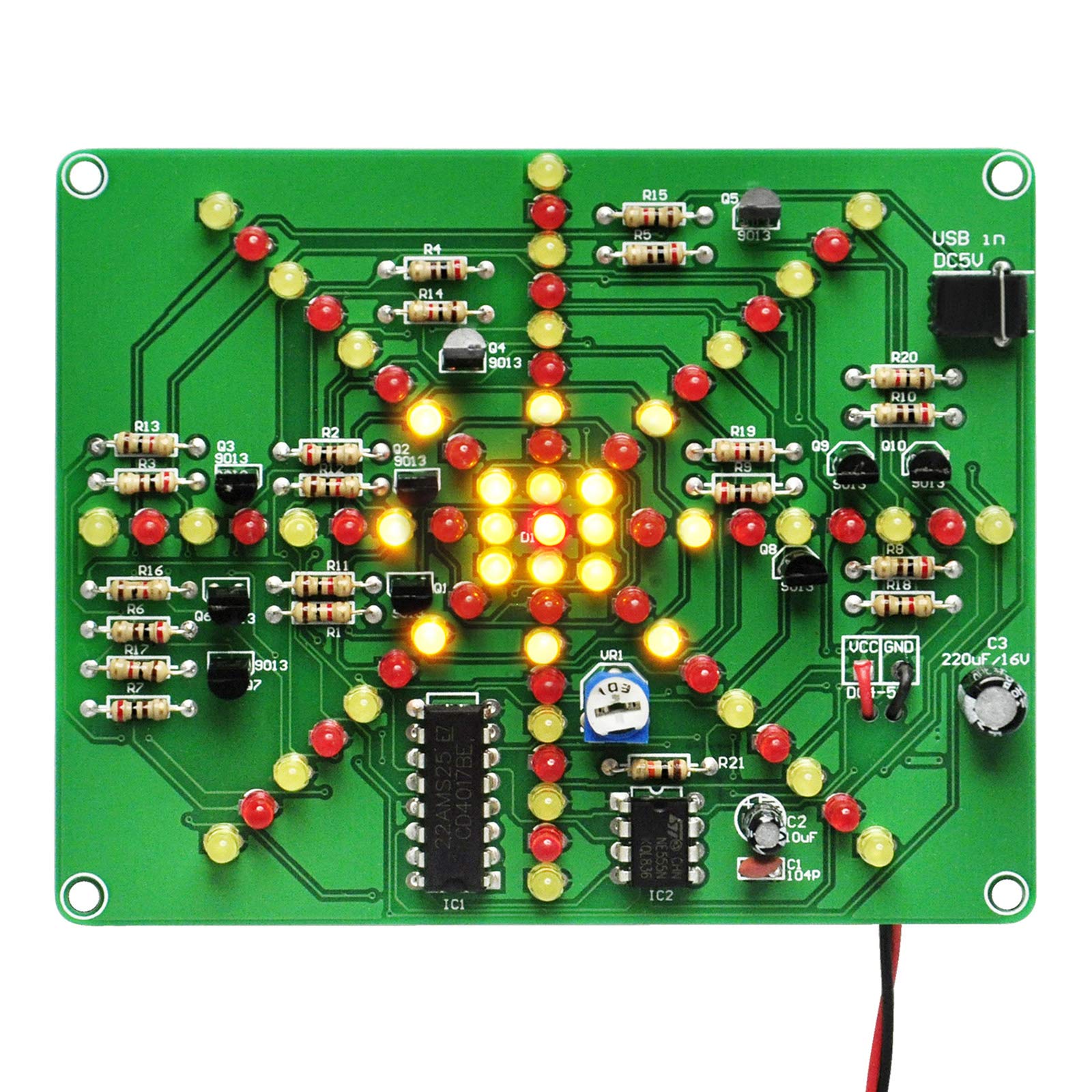

Illustrative image related to led light board

Pros: Aluminum is highly durable and can be easily fabricated into various shapes, allowing for flexibility in design. Its thermal properties help dissipate heat generated by LEDs, prolonging their lifespan.

Cons: The primary drawback of aluminum is its cost, which can be higher than plastic alternatives. Additionally, while it is corrosion-resistant, it may require anodizing or painting for enhanced protection in harsh environments.

Impact on Application: Aluminum frames are often used to house LED light boards, providing structural support while also enhancing aesthetics.

International Considerations: Compliance with international standards is crucial, especially for buyers in Europe, where specific regulations govern the use of metals in electronic applications.

What are the Benefits of Using Glass in LED Light Board Manufacturing?

Glass is sometimes utilized in LED light boards, particularly in high-end applications where aesthetics are paramount. It offers excellent light transmission and can be treated for additional durability.

Pros: Glass is highly resistant to scratching and provides a premium look. It can also be treated to enhance thermal resistance and minimize glare.

Cons: The fragility of glass makes it less suitable for environments where impact resistance is critical. It is also heavier than other materials, which can complicate installation.

Impact on Application: Glass can be used effectively in illuminated signage and displays where clarity and visual appeal are essential.

International Considerations: Buyers should be aware of safety regulations regarding glass, especially in public spaces, to ensure compliance with local laws.

How Does Acrylic Compare as a Material for LED Light Boards?

Acrylic, or polymethyl methacrylate (PMMA), is a lightweight alternative to glass that offers good optical clarity and weather resistance. It typically performs well in temperatures ranging from -30°C to 80°C.

Illustrative image related to led light board

Pros: Acrylic is shatter-resistant and lighter than glass, making it easier to transport and install. It can be easily molded into various shapes, allowing for creative designs.

Cons: Acrylic is more prone to scratching than glass and may yellow over time if not treated properly. Additionally, it has lower thermal resistance compared to polycarbonate and aluminum.

Impact on Application: Acrylic is commonly used in indoor LED displays and signage where weight and ease of installation are significant factors.

International Considerations: Buyers should consider the UV resistance of acrylic, especially in regions with high sunlight exposure, to ensure long-term performance.

Summary Table of Material Selection for LED Light Boards

| Material | Typical Use Case for LED Light Board | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Indoor and outdoor LED displays | High impact resistance | Susceptible to scratching | Medium |

| Aluminum | Structural frames for LED boards | Excellent thermal conductivity | Higher cost than plastics | High |

| Glass | High-end illuminated signage | Premium aesthetic and clarity | Fragile and heavy | High |

| Acrylic | Indoor signage and displays | Lightweight and shatter-resistant | Prone to scratching and yellowing | Medium |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for LED light boards, ensuring informed decisions that align with their specific applications and regional requirements.

Illustrative image related to led light board

In-depth Look: Manufacturing Processes and Quality Assurance for led light board

What Are the Main Stages in the Manufacturing Process of LED Light Boards?

The manufacturing process of LED light boards involves several critical stages that ensure the final product meets the required specifications for performance, durability, and aesthetic appeal. Understanding these stages can help B2B buyers identify potential suppliers and assess their capabilities.

Material Preparation: What Materials Are Used in LED Light Board Manufacturing?

The initial step in manufacturing LED light boards is material preparation. High-quality materials are essential for producing reliable LED products. Common materials include:

- LED Chips: These are the heart of the light board, typically made from gallium nitride (GaN) or other semiconductor materials.

- Substrates: Aluminum or fiberglass is often used as substrates due to their excellent thermal conductivity, which is crucial for heat dissipation.

- Resins and Adhesives: These are used to encapsulate the LED chips and secure various components together.

Suppliers should ensure that their materials meet international standards, which can affect performance and longevity.

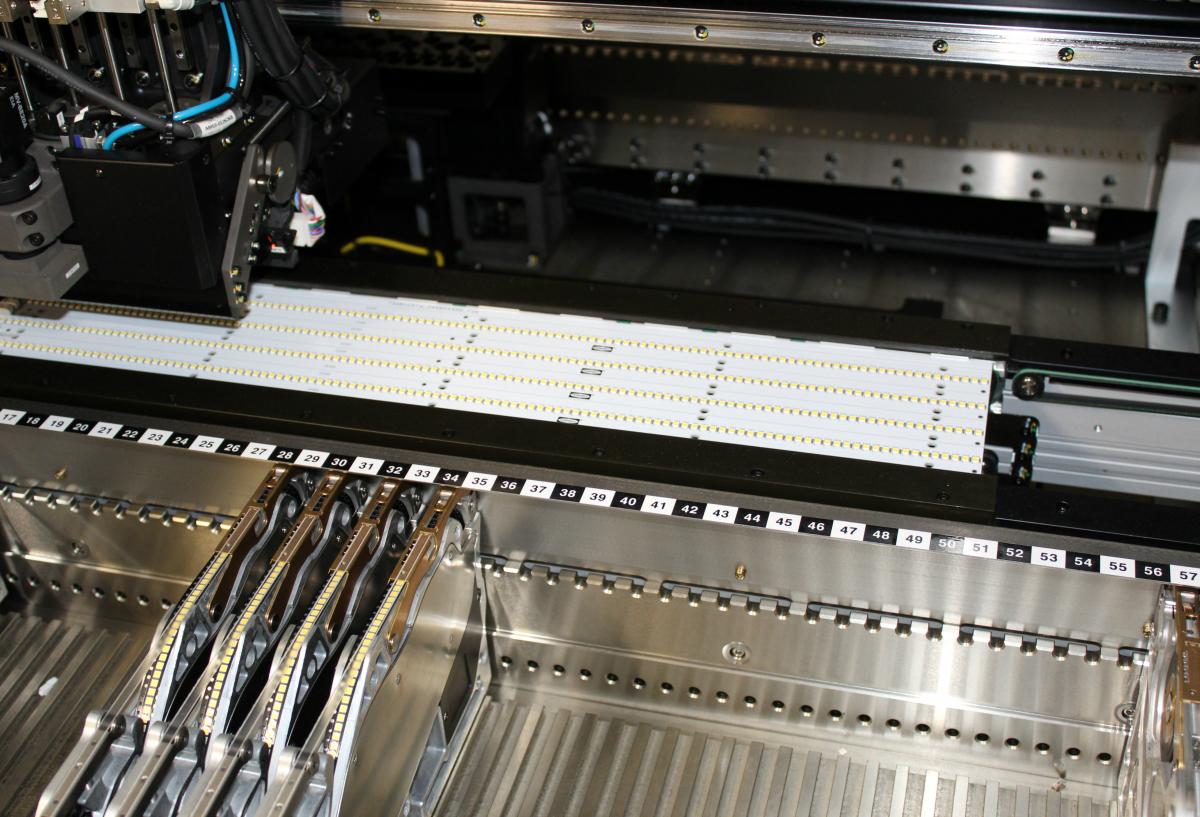

How Are LED Light Boards Formed and Assembled?

The forming and assembly stages involve several techniques to create the final product. Key processes include:

- Die Bonding: This involves attaching the LED chips to the substrate using thermally conductive adhesives.

- Wire Bonding: Fine wires are used to connect the LED chips to the circuit board, ensuring electrical continuity.

- Encapsulation: A protective layer, often made from silicone or epoxy, is applied over the LED chips to protect them from moisture and physical damage.

Automated assembly lines may be used to enhance efficiency and precision, reducing the risk of human error.

What Finishing Processes Are Involved in LED Light Board Production?

Finishing processes are crucial for enhancing the aesthetic and functional aspects of LED light boards. These may include:

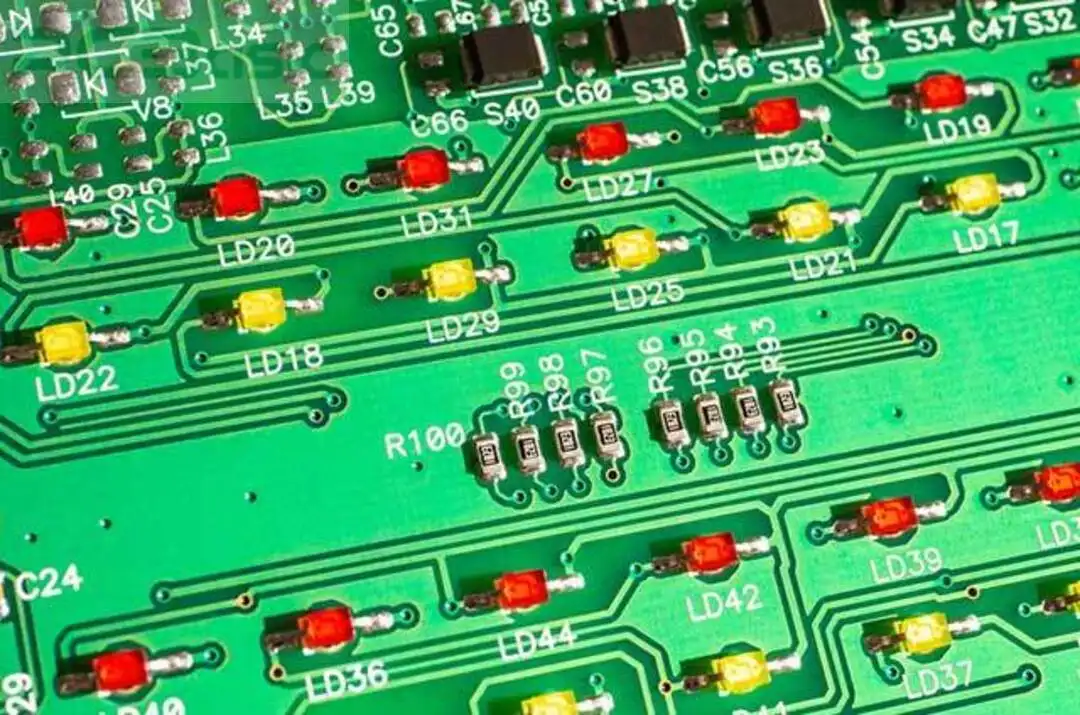

- Surface Mount Technology (SMT): This technique is used to attach surface-mounted components onto the circuit board, improving the board’s functionality.

- Coating: A protective coating can be applied to resist environmental factors like dust and moisture.

- Testing and Quality Control: Before packaging, the boards undergo rigorous testing to ensure they meet performance standards.

What Are the Key Quality Assurance Measures for LED Light Boards?

Quality assurance (QA) is vital to ensure that LED light boards meet the required safety and performance standards. Various international and industry-specific standards guide these practices.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a widely recognized standard for quality management systems. Suppliers adhering to this standard demonstrate their commitment to consistent quality and customer satisfaction. Other relevant certifications may include:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- RoHS Compliance: Ensures that products are free from hazardous substances.

For buyers in Africa, South America, the Middle East, and Europe, understanding these certifications can help in evaluating potential suppliers.

What Are the Common Quality Control Checkpoints in LED Manufacturing?

Quality control checkpoints ensure that each stage of manufacturing meets specific standards. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards.

- Final Quality Control (FQC): The final product undergoes comprehensive testing to confirm it meets performance and safety requirements.

These checkpoints are crucial in maintaining the quality and reliability of LED light boards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

Illustrative image related to led light board

- Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality control measures.

- Quality Control Reports: Requesting detailed reports from suppliers can help assess their quality assurance practices.

- Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased evaluations of product quality and compliance with standards.

These methods can help mitigate risks associated with sourcing LED light boards from international suppliers.

What Common Testing Methods Are Used for LED Light Boards?

Various testing methods are employed to ensure LED light boards perform as expected. Common tests include:

- Lumen Output Testing: Measures the brightness of the LED light boards to ensure they meet specifications.

- Thermal Testing: Evaluates the heat dissipation properties to prevent overheating and ensure longevity.

- Electrical Testing: Assesses the board’s electrical parameters, including voltage and current, to ensure safe operation.

These tests are crucial for verifying that the products will perform reliably in their intended applications.

Illustrative image related to led light board

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers must be aware of specific nuances related to quality control when sourcing LED light boards. These include:

- Regulatory Compliance: Different regions have varying regulations regarding electrical and safety standards. Understanding these regulations can prevent costly compliance issues.

- Cultural and Language Barriers: Effective communication is vital in ensuring that quality expectations are understood. Buyers may need to invest in translation services or local representatives.

- Supply Chain Considerations: Buyers should consider potential delays in shipping and customs clearance, which may affect the quality of products upon arrival.

Navigating these challenges requires diligence and a proactive approach to supplier management.

By understanding the manufacturing processes and quality assurance measures involved in LED light board production, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs. This knowledge not only enhances product quality but also strengthens partnerships within the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘led light board’

In the competitive landscape of LED light boards, making informed procurement decisions is critical for B2B buyers. This guide serves as a practical checklist to help you navigate the sourcing process effectively. By following these steps, you can ensure that you acquire high-quality products that meet your needs while minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the foundation of a successful procurement process. Clearly outline the technical specifications of the LED light board, including size, color temperature (CCT), brightness, and intended application. This clarity not only aids in communicating with suppliers but also ensures you select products that align with your project requirements.

- Key specifications to consider:

- Size and shape: Determine the dimensions that suit your installation.

- Brightness levels: Consider the lumens required for your application, whether for indoor or outdoor use.

Step 2: Research Potential Suppliers

Identifying reliable suppliers is essential for securing quality products. Conduct thorough research to compile a list of potential vendors specializing in LED light boards. Look for suppliers with experience in your industry and positive reviews from previous clients.

- What to look for:

- Industry reputation: Check online reviews and testimonials.

- Product range: Ensure they offer various types of LED light boards to suit different applications.

Step 3: Evaluate Supplier Certifications

Before engaging with a supplier, verify their certifications and compliance with international quality standards. This step is crucial to ensure that the products meet safety and performance benchmarks, which is particularly important in regions with stringent regulations.

- Important certifications to consider:

- ISO 9001: Indicates a commitment to quality management.

- CE and RoHS compliance: Ensures safety and environmental standards are met.

Step 4: Request Samples and Prototypes

Obtaining samples or prototypes is a vital step in assessing the product’s quality and suitability for your application. This allows you to evaluate the LED light board’s performance, color accuracy, and build quality before making a bulk purchase.

- Sample evaluation criteria:

- Light quality: Check for color consistency and brightness.

- Durability: Assess the materials used and overall build quality.

Step 5: Review Pricing and Terms

Comparing pricing structures is essential to ensure you receive a competitive deal without compromising quality. Request detailed quotes from multiple suppliers and carefully review the terms of sale, including payment options, lead times, and return policies.

- Key pricing considerations:

- Bulk discounts: Inquire about pricing for larger orders.

- Warranty and support: Understand the warranty terms and after-sales support offered.

Step 6: Check Logistics and Shipping Options

Logistics can significantly impact your project timeline. Discuss shipping options with your supplier, ensuring they can meet your delivery deadlines and offer reliable transport methods.

- Logistics factors to evaluate:

- Shipping times: Confirm lead times for your location.

- Import duties and taxes: Understand any additional costs associated with international shipping.

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan to manage expectations and timelines effectively. Regular updates on production and shipping can help mitigate potential issues.

- Communication strategies:

- Regular check-ins: Schedule updates to discuss progress.

- Point of contact: Designate a representative from both sides for streamlined communication.

By following this checklist, B2B buyers can enhance their sourcing strategy for LED light boards, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for led light board Sourcing

What Are the Key Cost Components in LED Light Board Manufacturing?

When sourcing LED light boards, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts costs. High-quality LEDs, circuit boards, and housing materials will increase initial expenses but can lead to lower failure rates and longer lifespans, ultimately reducing Total Cost of Ownership (TCO).

-

Labor: Labor costs vary based on the manufacturing location. Countries with lower labor costs may offer cheaper options, but this can also affect quality. Skilled labor is essential for assembly and quality assurance, particularly for custom specifications.

-

Manufacturing Overhead: This includes costs related to factory operations, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize overhead, which is particularly important for bulk orders.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider whether the supplier has existing molds or if new tooling is necessary, which could affect the overall cost.

-

Quality Control: Investing in robust QC processes can prevent costly defects. It’s important to ensure that the supplier adheres to relevant quality certifications, which can also influence pricing.

-

Logistics: Shipping and handling costs can vary greatly depending on the size of the order and distance to the destination. Understanding Incoterms can help buyers anticipate and manage these costs effectively.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. This margin can vary based on the supplier’s pricing strategy and market conditions.

How Do Price Influencers Impact LED Light Board Sourcing?

Several factors can influence the pricing of LED light boards, impacting how buyers approach sourcing.

Illustrative image related to led light board

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to lower per-unit costs. Buyers should inquire about MOQs and consider consolidating orders to achieve better pricing.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should balance the need for specific features with budget constraints. Standard products may offer better pricing.

-

Material Quality and Certifications: Premium materials and certifications (such as CE or RoHS) can raise prices. However, investing in higher quality can lead to improved performance and longevity.

-

Supplier Factors: The reliability and reputation of the supplier play a significant role in pricing. Established suppliers may offer better service and quality assurance but at a premium.

-

Incoterms: Understanding the shipping terms can help manage costs. Buyers should negotiate Incoterms that minimize risk and unexpected expenses.

What Are the Best Negotiation Tips for International B2B Buyers?

Navigating the nuances of international sourcing can be challenging, especially for buyers from Africa, South America, the Middle East, and Europe.

-

Understand Total Cost of Ownership: Beyond the purchase price, consider shipping, duties, and potential maintenance costs. A lower upfront price may lead to higher long-term costs.

-

Leverage Volume Discounts: If possible, commit to larger orders to negotiate better pricing. Suppliers are often willing to offer discounts for larger commitments.

-

Request Detailed Quotations: Ensure that suppliers provide comprehensive quotes, including breakdowns of all cost components. This transparency can facilitate better negotiation.

-

Build Relationships: Establishing a rapport with suppliers can lead to more favorable terms and better support. Long-term relationships often yield better pricing and service.

-

Stay Informed About Market Trends: Understanding market conditions and pricing trends can enhance negotiation leverage. This knowledge can help identify when to secure a deal or wait for better pricing.

In conclusion, while the sourcing of LED light boards involves various cost components and price influencers, strategic planning and informed negotiation can lead to significant savings and value for B2B buyers. Always remember that prices can vary widely based on specific requirements and market conditions, so thorough research and careful consideration are essential.

Alternatives Analysis: Comparing led light board With Other Solutions

Exploring Alternatives to LED Light Boards

In the rapidly evolving landscape of lighting solutions, LED light boards have emerged as a popular choice for businesses seeking efficient and dynamic display options. However, various alternatives are available that may better suit specific applications or budgetary constraints. This analysis compares LED light boards against two notable alternatives: LCD screens and traditional fluorescent lighting, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Led Light Board | LCD Screens | Fluorescent Lighting |

|---|---|---|---|

| Performance | High brightness, vibrant colors, customizable sizes | Excellent image quality, good for video and static images | Moderate brightness, less vibrant colors |

| Cost | Moderate initial cost, energy-efficient long-term | Higher upfront costs, requires additional components | Low initial cost, higher energy consumption |

| Ease of Implementation | Flexible installation with adhesive backing | Requires proper mounting and wiring | Simple installation, often a direct replacement |

| Maintenance | Low maintenance, long lifespan | Moderate maintenance, potential for screen damage | High maintenance due to frequent bulb replacements |

| Best Use Case | Retail displays, exhibitions, backlighting | Corporate presentations, advertising, event displays | General illumination, large area lighting |

Analyzing the Alternatives: LCD Screens

LCD screens offer a robust alternative to LED light boards, particularly in settings where high-quality video and static images are essential. They provide excellent image clarity and can display a wide range of content, making them ideal for corporate presentations and advertising. However, they generally come with a higher initial cost and may require additional components, such as controllers and mounts, which can complicate installation. Additionally, LCD screens can be susceptible to damage and may require more maintenance compared to LED solutions. Despite these drawbacks, their superior image quality makes them a compelling choice for high-impact visual applications.

Evaluating Traditional Fluorescent Lighting

Fluorescent lighting has been a staple in commercial lighting for decades. It boasts a low initial cost and is widely available, making it an accessible choice for businesses. However, its performance pales in comparison to LED light boards and LCD screens, offering less vibrant colors and lower energy efficiency. While installation is straightforward, fluorescent lights necessitate frequent bulb replacements, leading to higher long-term maintenance costs. They are best suited for general illumination rather than dynamic displays, making them less favorable for branding or advertising purposes.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate lighting solution for your business, consider the specific application and desired outcomes. LED light boards excel in providing customizable, vibrant displays suitable for retail and exhibitions, while LCD screens offer superior image quality for presentations and advertising. On the other hand, traditional fluorescent lighting may serve well for general illumination but falls short in dynamic visual applications. Assessing your budget, installation capabilities, and maintenance preferences will help you make an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for led light board

What Are the Key Technical Properties of LED Light Boards?

When sourcing LED light boards, understanding their technical specifications is essential for making informed purchasing decisions. Here are several critical properties to consider:

1. Material Grade

The material grade of an LED light board typically refers to the quality of the components used, such as the circuit board (PCB) material and the encapsulation. Common materials include FR-4 (a flame-retardant epoxy resin) and aluminum for better heat dissipation. In B2B applications, higher material grades ensure durability and reliability, reducing the need for frequent replacements and maintenance.

2. Lumen Output

Lumen output measures the total amount of visible light emitted by the LED light board. This specification is crucial for applications requiring specific brightness levels, such as advertising or indoor lighting. Understanding lumen output helps businesses select products that meet their illumination needs, ensuring effective visual communication and energy efficiency.

3. Color Temperature (CCT)

Color temperature is expressed in Kelvin (K) and indicates the hue of the light emitted by the LEDs, ranging from warm (2700K) to cool (6500K). This property is essential for B2B buyers as it affects the ambiance and functionality of the space. For instance, warmer temperatures are often preferred in hospitality settings, while cooler temperatures are ideal for workspaces.

Illustrative image related to led light board

4. Power Consumption

Power consumption, measured in watts, indicates how much energy the LED light board will use. Lower power consumption translates to reduced operational costs, making it a key consideration for businesses looking to enhance sustainability and energy efficiency. Understanding power consumption helps in calculating return on investment (ROI) for lighting projects.

5. Lifetime Rating

The lifetime rating, usually expressed in hours, indicates how long the LED light board is expected to function before its brightness diminishes significantly. A longer lifetime reduces the frequency of replacements and associated labor costs, making it an important factor for B2B buyers focused on long-term investments.

6. Ingress Protection (IP) Rating

The IP rating indicates the level of protection the LED light board has against dust and moisture. For outdoor applications, a higher IP rating (e.g., IP65 or above) is essential to ensure longevity and performance in various environmental conditions. Selecting the right IP rating can prevent costly repairs and replacements.

What Are Common Trade Terms Related to LED Light Boards?

Familiarizing yourself with industry jargon can enhance communication and streamline purchasing processes. Here are some common terms:

Illustrative image related to led light board

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the LED industry, buyers often collaborate with OEMs to customize light boards according to specific requirements, ensuring a tailored solution for their needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can impact inventory management and cash flow. Negotiating MOQs can lead to cost savings, especially for larger orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting pricing for specific products or services. This process is vital in B2B transactions, allowing buyers to compare costs and make informed purchasing decisions based on detailed quotations.

Illustrative image related to led light board

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping costs, risk management, and delivery obligations, which is essential for international trade.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are delivered. In the LED light board industry, understanding lead times can help businesses plan their projects effectively and avoid delays.

6. Dimming Capability

Dimming capability refers to the ability of an LED light board to adjust brightness levels. This feature is important for creating flexible lighting solutions tailored to various applications, allowing businesses to enhance ambiance and energy savings.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and budget constraints, ultimately leading to successful LED light board projects.

Navigating Market Dynamics and Sourcing Trends in the led light board Sector

What Are the Key Trends Shaping the LED Light Board Market?

The LED light board market is experiencing transformative growth, driven by technological advancements, increased energy efficiency, and evolving consumer preferences. Global drivers such as the push for sustainable energy solutions and the rise of smart technologies are propelling demand. In regions like Africa and South America, economic development and urbanization are enhancing the need for effective lighting solutions in commercial and residential sectors. Meanwhile, the Middle East and Europe are witnessing a surge in the adoption of LED light boards for advertising and events, spurred by their vibrant color output and adaptability.

Emerging trends indicate a growing preference for customizable LED solutions that cater to specific application needs, such as tunable white and RGB color variations. Furthermore, the integration of IoT technologies is enabling smart lighting systems that can be controlled remotely, providing enhanced functionality for businesses. As international B2B buyers from regions like Vietnam and Saudi Arabia seek innovative solutions, suppliers who offer flexible design options and comprehensive support will have a competitive edge.

How Is Sustainability and Ethical Sourcing Affecting the LED Light Board Market?

Sustainability is becoming a central pillar in the LED light board sector, influencing both sourcing and operational practices. The environmental impact of manufacturing processes and the materials used in LED products are critical considerations for B2B buyers. The shift towards eco-friendly materials and energy-efficient production methods is essential, as businesses aim to reduce their carbon footprint while complying with increasingly stringent regulations.

Ethical sourcing is equally important, particularly for international buyers who prioritize transparency in their supply chains. Certifications like Energy Star and RoHS (Restriction of Hazardous Substances) are vital indicators of a product’s sustainability credentials, offering assurance that the materials used are environmentally friendly. Additionally, suppliers who can demonstrate a commitment to fair labor practices and responsible sourcing will appeal to businesses looking to align their values with their purchasing decisions. By prioritizing sustainable and ethical options, companies can not only enhance their brand reputation but also contribute to global sustainability goals.

What Is the Historical Context of LED Light Boards in B2B Applications?

The evolution of LED light boards can be traced back to the early 2000s when LED technology began to gain traction due to its energy efficiency and longevity. Initially, these boards were used primarily for signage, but advancements in technology have expanded their applications significantly. As the capabilities of LED boards grew, so did their appeal for various industries, from retail to entertainment.

Over the years, the introduction of features such as programmable content and color variations has transformed LED boards into dynamic marketing tools. This evolution has paved the way for innovative applications, including backlighting for displays and interactive installations. As B2B buyers increasingly recognize the versatility and impact of LED light boards, their adoption is expected to continue growing, driven by both technological advancements and the need for effective communication strategies in a competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of led light board

-

How do I ensure the quality of LED light boards from international suppliers?

To ensure quality, conduct thorough research on potential suppliers by reviewing their certifications, customer reviews, and product samples. Request documentation for quality assurance processes, such as ISO certifications. Consider ordering a small batch for testing before committing to larger orders. It’s also beneficial to establish clear communication regarding quality expectations and to utilize third-party inspection services to verify product quality before shipping. -

What are the most important specifications to consider when sourcing LED light boards?

When sourcing LED light boards, focus on specifications such as brightness (measured in lumens), color temperature (CCT), energy efficiency (wattage), and lifespan (measured in hours). Additionally, consider the board’s flexibility for installation, the quality of materials used, and the warranty offered. These factors will influence the performance and longevity of the product in your specific application. -

What is the typical minimum order quantity (MOQ) for LED light boards?

Minimum order quantities (MOQ) can vary significantly by supplier and product type, typically ranging from 50 to 500 units for LED light boards. Smaller suppliers may offer lower MOQs, while larger manufacturers may have higher thresholds. It’s advisable to negotiate MOQs based on your project needs, and inquire if the supplier can accommodate smaller test orders or pilot runs. -

What payment terms should I expect when sourcing LED light boards internationally?

Payment terms can vary widely, but common practices include a 30% upfront deposit with the balance due before shipment or upon delivery. Some suppliers may offer more flexible terms, such as letters of credit or payment through escrow services to ensure security for both parties. Always clarify payment conditions in the contract and consider using secure payment methods to protect your financial interests. -

How do I customize LED light boards for my specific application?

Customization options for LED light boards often include variations in size, shape, color, and brightness. Many suppliers offer design services to create boards tailored to your branding or functional needs. When discussing customization, provide detailed specifications and examples of what you envision. Be sure to confirm lead times and any additional costs associated with custom orders. -

What logistics considerations should I keep in mind when importing LED light boards?

When importing LED light boards, consider shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder familiar with electronic imports to navigate duties and taxes efficiently. Ensure that the supplier provides all necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Additionally, factor in the cost of shipping and insurance when calculating total expenses. -

How can I evaluate potential suppliers of LED light boards?

To evaluate potential suppliers, check their industry experience, reputation, and customer service record. Request references or case studies from previous clients to assess their reliability and quality of service. Additionally, assess their production capabilities, lead times, and after-sales support. Attending trade shows or industry events can also provide insights into the supplier’s standing in the market. -

What are common applications for LED light boards in various industries?

LED light boards are versatile and can be used in numerous applications, including advertising displays, backlighting for signs, architectural lighting, and event staging. In retail, they enhance product visibility; in hospitality, they create engaging environments. Additionally, they are used in exhibitions and trade shows to capture attention. Understanding your target industry’s specific needs will help in selecting the right type of LED light board for maximum impact.

Top 6 Led Light Board Manufacturers & Suppliers List

1. Environmentallights – LED Light Sheets

Domain: environmentallights.com

Registered: 2006 (19 years)

Introduction: LED Light Sheets are thin, flexible sheets of LEDs designed for backlighting in light boxes and other applications. Each light sheet features an adhesive backing for easy mounting and can also be screw-mounted or linked together for larger setups. They provide even illumination and are available in various configurations, including:

1. 5-in-1 LED Light Sheets:

– RGBTW – 12 x 6 LEDs (Product Nu…

2. Revolution Light Boards – Turnkey Illuminated Glass Solutions

Domain: revolutionlightboards.com

Registered: 2017 (8 years)

Introduction: Turnkey lightboards available in a wide range of sizes. All lightboards include integrated edge lighting for internal illumination of ultra-clear glass. Professionally polished glass for optimal clarity. Robust perimeter frame with channels for mounting additional gear. Included presenter lighting systems to minimize or eliminate additional studio lighting. Studio packages available.

Products:

-…

3. Instructables – DIY Lightboard for Engaging Online Teaching

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: DIY lightboard for online teaching; requires LED strip, 24×36″ acrylic sheet, tape, one-handed clamps, neon-colored whiteboard markers, tripod, and phone/camera; easy to assemble and store; suitable for creating engaging video tutorials.

4. FASTSIGNS – LED Displays

Domain: fastsigns.com

Registered: 1996 (29 years)

Introduction: LED Displays are made up of many smaller light-emitting diodes used to create and project images. They can feature messages with vivid, high contrast content, including images and video. Large LED Displays can be rented for events, ensuring high impact and visibility, keeping crowds engaged.

5. Standoff Systems – Color Changing LED Light Board

Domain: standoffsystems.com

Registered: 1998 (27 years)

Introduction: Color Changing LED Light Board allows conversion of single-color LED standoffs into multi-color options. Compatible with existing standoff barrels, caps, and power supplies. Features include: remote control and receiver sold separately, showcases entire color spectrum, cycles through 10 display modes, custom color selection, and three white temperature options. Specifications: SKU SO-LED-RGB, requ…

6. Pinterest – Illuminated Signage

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Led sign board, 317 Pins, Art Print Lobby/Reception Signs, Signs & More, Marietta, Cartersville, Atlanta, Related interests include Medical Clinic Signage, Dental Clinic Signage, Corporate Signs, Wayfinding Design, Backlit Signage, 3D Signage, Colorful Illuminated Signage, and more.

Strategic Sourcing Conclusion and Outlook for led light board

As the demand for LED light boards continues to rise, strategic sourcing emerges as a critical factor for international B2B buyers. By understanding the diverse applications and benefits of LED technology—from energy efficiency to high visibility—companies can make informed decisions that enhance their brand presence and operational effectiveness.

Investing in quality LED products, such as modular light sheets and customizable displays, not only ensures superior performance but also fosters long-term partnerships with reliable suppliers. This approach allows businesses to leverage the latest innovations while optimizing costs, ensuring that they stay competitive in rapidly evolving markets.

Looking ahead, buyers from regions like Africa, South America, the Middle East, and Europe should actively seek partnerships that align with their unique needs and growth objectives. By prioritizing strategic sourcing and engaging with trusted suppliers, you can unlock new opportunities and elevate your business’s visibility. Now is the time to explore the vast potential of LED light boards—connect with industry experts and start your journey towards impactful lighting solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.