Leather Eyelets Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for leather eyelets

In today’s competitive landscape, sourcing high-quality leather eyelets presents a significant challenge for international B2B buyers. With the demand for durable, aesthetically pleasing, and functional components rising across various industries—from fashion to automotive—buyers must navigate a complex global market filled with diverse suppliers and products. This guide is designed to illuminate the intricate world of leather eyelets, offering insights into different types, applications, and the critical factors to consider when sourcing these essential components.

Throughout this comprehensive guide, we will explore the myriad types of leather eyelets available, including their specific applications across different sectors. We will also delve into effective strategies for vetting suppliers, understanding cost structures, and assessing quality standards. This resource aims to empower B2B buyers, particularly those from Africa, South America, the Middle East, and Europe (including regions like Vietnam and Saudi Arabia), by providing actionable insights that facilitate informed purchasing decisions.

By equipping buyers with the knowledge needed to select the right products and partners, this guide serves as a valuable tool in overcoming sourcing challenges. Ultimately, it aims to enhance supply chain efficiency and drive competitive advantage in your respective markets.

Understanding leather eyelets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Eyelet | Small, hollow post, typically available in various diameters. | Footwear, bags, and soft leather goods. | Pros: Affordable, easy installation. Cons: Limited strength for heavy-duty applications. |

| Grommet | Features a washer, providing additional support and strength. | Tarps, awnings, and outdoor gear. | Pros: High durability, weather-resistant options. Cons: Requires specific installation tools. |

| Decorative Eyelet | Often comes in various colors and finishes for aesthetic appeal. | Fashion accessories, custom leather goods. | Pros: Enhances visual appeal. Cons: May not be suitable for heavy-duty use. |

| Metal Eyelet | Made from steel or brass, often plated for corrosion resistance. | Industrial applications, heavy-duty items. | Pros: Strong, rust-resistant options available. Cons: Heavier than alternatives, may require special tools. |

| Plastic Eyelet | Lightweight and often used in non-load bearing applications. | Crafts, lightweight bags, and apparel. | Pros: Cost-effective, lightweight. Cons: Less durable than metal options. |

What Are the Characteristics and Suitability of Standard Eyelets?

Standard eyelets are small, hollow posts designed to reinforce holes in softer materials like leather. They are available in various diameters, making them suitable for a range of applications such as footwear and bags. When considering purchasing standard eyelets, B2B buyers should evaluate the specific diameter needed for their projects and ensure they have the appropriate tools for installation. While they offer an economical solution, their strength is limited compared to other options, making them less ideal for heavy-duty applications.

How Do Grommets Enhance Durability in Leather Products?

Grommets are distinguished by their additional washer, which provides enhanced support and strength, making them ideal for applications exposed to harsh conditions, such as tarps and awnings. Their robust construction often includes materials like solid brass, which is resistant to rust. When purchasing grommets, B2B buyers should consider the environmental conditions their products will face, ensuring they select the right material for longevity. While grommets require specific installation tools, their durability justifies the investment for outdoor and heavy-duty applications.

Illustrative image related to leather eyelets

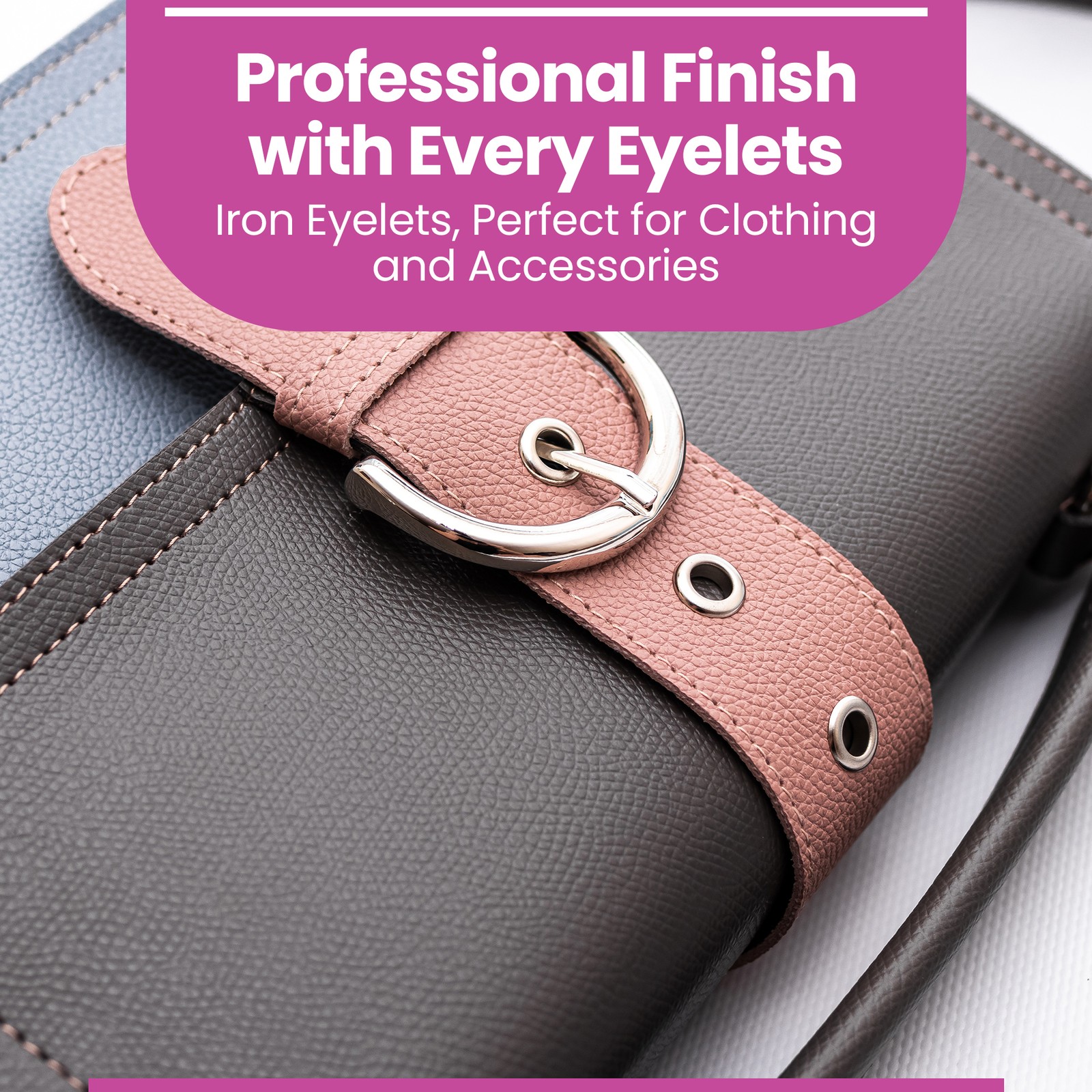

What Are the Benefits of Using Decorative Eyelets in Fashion?

Decorative eyelets serve both functional and aesthetic purposes, available in various colors and finishes that can elevate the design of fashion accessories and custom leather goods. B2B buyers focusing on the fashion industry should consider the visual appeal these eyelets bring to their products, allowing for creative customization. However, it’s essential to assess the strength requirements of the end product, as decorative eyelets may not be suitable for heavy-duty applications.

Why Choose Metal Eyelets for Industrial Applications?

Metal eyelets, typically made from steel or brass, are favored for their strength and corrosion resistance, making them suitable for industrial applications and heavy-duty items. B2B buyers should prioritize metal eyelets when durability is a primary concern, especially in environments where exposure to moisture is common. The heavier weight of metal eyelets may necessitate special installation tools, but the long-term benefits of their robustness often outweigh these considerations.

When to Use Plastic Eyelets in Lightweight Applications?

Plastic eyelets are lightweight and often used in applications where load-bearing capacity is not critical, such as crafts and lightweight bags. Their cost-effectiveness makes them an attractive option for businesses looking to minimize expenses. However, B2B buyers should be cautious about their durability compared to metal alternatives, particularly in applications that may face wear and tear. Understanding the specific needs of the project will help buyers determine if plastic eyelets are the right choice.

Key Industrial Applications of leather eyelets

| Industry/Sector | Specific Application of leather eyelets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Reinforcing shoe laces in various types of footwear | Enhances durability and aesthetic appeal of footwear | Size variety, corrosion resistance, and bulk purchasing options |

| Textile and Apparel | Used in garments for adjustable features | Improves product functionality and customer satisfaction | Material compatibility, color options, and ease of installation |

| Outdoor Gear | Securing components on tents and backpacks | Increases product longevity and performance in harsh conditions | Weather resistance, size specifications, and installation tools |

| Leather Goods Production | Strengthening bags, wallets, and belts | Provides structural integrity and design flexibility | Aesthetic finishes, custom sizes, and bulk pricing |

| Home Décor and Upholstery | Decorative elements in curtains and upholstery | Adds visual interest while providing functional benefits | Style variety, material quality, and sourcing from local suppliers |

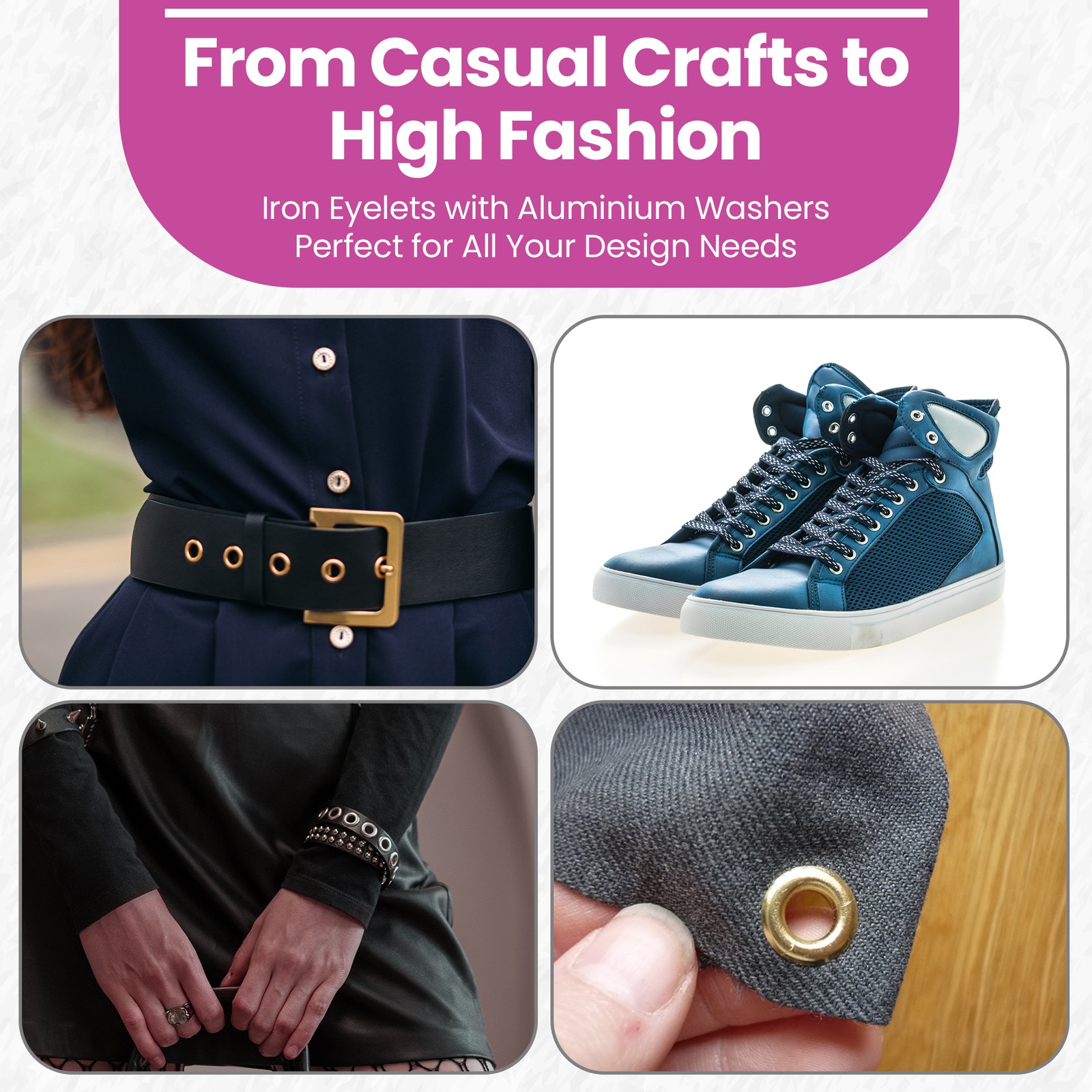

How are leather eyelets used in footwear manufacturing?

In the footwear industry, leather eyelets are essential for reinforcing lace holes, ensuring that laces remain securely fastened. This application enhances both the durability and visual appeal of shoes, catering to consumer preferences for both style and functionality. Buyers in this sector should consider the eyelet’s size, material (such as rust-resistant brass), and the ability to purchase in bulk to optimize production efficiency and cost-effectiveness.

What role do leather eyelets play in textile and apparel?

Leather eyelets are commonly used in garments to create adjustable features, such as laces and drawstrings. They provide a robust solution for reinforcing holes in softer fabrics, ensuring longevity and user satisfaction. International buyers should focus on compatibility with various textile materials and consider color options to match garment designs, as well as ensuring that the eyelets can be easily installed in mass production settings.

How do leather eyelets benefit outdoor gear manufacturers?

In outdoor gear, leather eyelets are critical for securing components on tents, backpacks, and other equipment. Their ability to withstand harsh weather conditions while providing structural integrity makes them invaluable in this sector. Buyers should prioritize sourcing eyelets that are weather-resistant and available in various sizes to accommodate different product specifications, ensuring that they meet performance standards necessary for outdoor applications.

Illustrative image related to leather eyelets

Why are leather eyelets important in leather goods production?

In leather goods production, eyelets are used to strengthen bags, wallets, and belts, enhancing both functionality and design. They allow for the incorporation of laces and straps while maintaining the aesthetic appeal of the product. Buyers in this industry should consider the finishes available, the custom sizes that can be ordered, and the pricing structures for bulk purchases to maximize their production capabilities.

How do leather eyelets enhance home décor and upholstery?

In home décor, leather eyelets serve as decorative elements in curtains and upholstery, adding both style and functional benefits. They allow for easy installation of drapery and can enhance the overall design of a space. Buyers should look for a variety of styles and materials to ensure that the eyelets match the aesthetic of their products, as well as consider sourcing from local suppliers to reduce shipping costs and lead times.

3 Common User Pain Points for ‘leather eyelets’ & Their Solutions

Scenario 1: Selecting the Right Size and Type of Leather Eyelet

The Problem: B2B buyers often encounter challenges when trying to choose the appropriate size and type of leather eyelet for their specific applications. With a vast array of options available, including various diameters and materials, the risk of selecting an eyelet that does not fit properly can lead to delays in production and increased costs. For instance, using an eyelet that is too large may compromise the integrity of the leather, while one that is too small could easily pull through, rendering it useless. This decision-making process can be overwhelming, especially when buyers are under pressure to meet tight deadlines.

The Solution: To effectively source the right eyelets, buyers should begin by conducting a thorough assessment of their project requirements. This includes evaluating the thickness of the leather, the intended use (e.g., for bags, shoes, or apparel), and any environmental factors (such as exposure to moisture) that might affect material choice. After gathering this information, it’s crucial to refer to the manufacturer’s sizing charts and guidelines. Many suppliers provide detailed specifications that outline which eyelet sizes are compatible with different leather thicknesses. Additionally, investing in a sample pack of various eyelet types can facilitate testing before making a bulk purchase, ensuring that the selected eyelet meets the project’s needs without causing production delays.

Illustrative image related to leather eyelets

Scenario 2: Difficulty with Installation of Leather Eyelets

The Problem: A common frustration for B2B buyers is the difficulty in properly installing leather eyelets. If the installation process is not executed correctly, it can lead to improper fitting, damage to the leather, or even eyelets that fall out after a short period of use. This not only affects the quality of the final product but can also lead to costly returns and dissatisfaction among clients. Buyers often face challenges in ensuring that their teams have the right tools and techniques for installation, particularly when working with different eyelet sizes or materials.

The Solution: To address installation challenges, companies should prioritize training for their staff on proper eyelet installation techniques. This includes familiarizing them with the use of specific tools such as grommet setters and hole punches that match the size of the eyelets. A detailed instructional guide or video can be invaluable in ensuring consistency across installations. Furthermore, buyers should consider sourcing eyelet kits that come with comprehensive instructions and all necessary tools included. This will not only streamline the installation process but also enhance the quality and durability of the finished product, ultimately reducing the risk of returns.

Scenario 3: Managing Supply Chain and Quality Control for Eyelets

The Problem: For international B2B buyers, maintaining a consistent supply of high-quality leather eyelets can be a significant pain point. Fluctuations in supply chain reliability, particularly when sourcing from different regions, can lead to inconsistent quality, which in turn affects the overall quality of finished products. Additionally, buyers may struggle with ensuring that the specifications of the eyelets match their requirements, leading to potential production delays and increased costs due to reordering.

Illustrative image related to leather eyelets

The Solution: To mitigate supply chain issues, buyers should establish strong relationships with reputable suppliers who can provide consistent quality and timely deliveries. Conducting regular quality audits and requesting samples before committing to larger orders can help ensure that the eyelets meet the required standards. Moreover, diversifying the supplier base can provide a safety net against disruptions. Buyers should also implement a robust inventory management system to keep track of stock levels and reorder points, ensuring that they maintain adequate supplies without overstocking. This proactive approach not only enhances quality control but also enables businesses to respond quickly to changes in demand, thus maintaining a competitive edge in the market.

Strategic Material Selection Guide for leather eyelets

What Are the Key Properties of Common Materials Used for Leather Eyelets?

When selecting materials for leather eyelets, it is crucial to consider their properties, performance, and suitability for specific applications. The most commonly used materials include solid brass, steel, aluminum, and plastic. Each material has distinct characteristics that can influence the final product’s durability, cost, and performance.

Solid Brass: A Durable and Corrosion-Resistant Option

Solid brass is a popular choice for leather eyelets due to its excellent corrosion resistance and aesthetic appeal. It can withstand a wide range of temperatures and pressures, making it suitable for both indoor and outdoor applications. The key advantage of brass is its durability; it does not rust and maintains its appearance over time. However, brass can be more expensive than other materials, which may be a consideration for budget-conscious buyers. Additionally, while it is suitable for various applications, it may not be the best choice for environments with extreme chemical exposure.

For international buyers, particularly in regions like the Middle East and Africa, compliance with local standards such as ASTM or DIN is essential. Brass eyelets are often favored in high-quality leather goods, and their aesthetic quality aligns well with market preferences in Europe and South America.

Steel: Strength with Cost-Effectiveness

Steel eyelets are another common option, known for their strength and cost-effectiveness. They are often nickel or brass plated to enhance corrosion resistance. While steel offers high tensile strength, it can rust if exposed to moisture without protective coatings. This makes it less suitable for outdoor applications unless adequately treated.

Illustrative image related to leather eyelets

From a B2B perspective, steel eyelets can provide significant savings, especially for large-scale manufacturing. However, buyers should consider the potential for rust and ensure that the end product will not be exposed to harsh environmental conditions. Compliance with regional standards is also important, as some markets may have specific requirements for metal products.

Aluminum: Lightweight and Versatile

Aluminum eyelets are lightweight and offer good corrosion resistance, making them suitable for various applications, including fashion and accessories. They are often used in products that require a lighter weight without sacrificing strength. However, aluminum may not be as durable as brass or steel, particularly in high-stress applications.

For international buyers, aluminum eyelets can be an attractive option due to their versatility and compliance with various industry standards. However, their lower durability may limit their use in more demanding applications, which is an important consideration for manufacturers in sectors like automotive or industrial.

Plastic: Cost-Effective and Lightweight

Plastic eyelets are a cost-effective alternative, especially for applications where weight is a concern. They are resistant to corrosion and can be produced in various colors, making them visually appealing for fashion applications. However, plastic may not offer the same level of strength and durability as metal options, which can limit its use in high-stress environments.

Illustrative image related to leather eyelets

For B2B buyers, plastic eyelets can provide significant cost savings and flexibility in design. However, it is essential to ensure that the plastic used meets relevant compliance standards, particularly in regions like Europe, where environmental regulations may dictate the types of materials that can be used.

Summary Table of Material Selection for Leather Eyelets

| Material | Typical Use Case for leather eyelets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Solid Brass | High-quality leather goods, outdoor applications | Excellent corrosion resistance | Higher cost compared to others | High |

| Steel | Industrial applications, budget-friendly options | Strong and cost-effective | Prone to rust if uncoated | Medium |

| Aluminum | Fashion accessories, lightweight products | Lightweight and versatile | Lower durability under stress | Medium |

| Plastic | Fashion items, low-stress applications | Cost-effective and colorful | Limited strength and durability | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of various materials used in leather eyelets. Understanding these factors can help in making informed purchasing decisions that align with product requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leather eyelets

What Are the Key Stages in the Manufacturing Process of Leather Eyelets?

The manufacturing of leather eyelets involves several critical stages, each designed to ensure the final product meets both functional and aesthetic standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The first step in the manufacturing process is selecting the appropriate materials. Leather eyelets are commonly made from materials such as brass, steel, or aluminum, each offering different properties in terms of strength, corrosion resistance, and aesthetic appeal. The materials are then cut to size, ensuring that they meet the specific dimensions required for the eyelets being produced. This stage may also involve surface treatment, such as plating, to enhance durability and appearance. -

Forming:

During the forming stage, the prepared materials are shaped into eyelets. This is typically done through processes such as stamping or extrusion. For instance, brass eyelets are often stamped from sheets of metal using a die, which allows for precise shaping and consistent dimensions. The forming process must be closely monitored to prevent defects such as warping or incomplete shapes, which could compromise the eyelet’s functionality. -

Assembly:

After forming, the components are assembled. In the case of eyelets, this may involve the addition of washers, which provide additional support when the eyelet is installed in a material. The assembly process is crucial for ensuring that all components fit together correctly and that the finished product can withstand the stresses of use. Automated assembly lines are often employed to increase efficiency and consistency in this stage. -

Finishing:

The finishing stage involves applying coatings or treatments to the eyelets to enhance their performance and aesthetic appeal. This may include electroplating, anodizing, or painting, depending on the material and desired finish. The eyelets are then inspected for quality and consistency before being packaged for shipment.

What Quality Control Measures Are Essential for Leather Eyelets?

Quality control (QC) is a vital aspect of the manufacturing process for leather eyelets, ensuring that products meet international standards and customer expectations. Key QC measures include adherence to international standards, implementation of checkpoints throughout the manufacturing process, and various testing methods.

Illustrative image related to leather eyelets

-

International Standards:

Compliance with international standards such as ISO 9001 is essential for manufacturers aiming to operate in the global market. ISO 9001 outlines requirements for a quality management system (QMS) that helps organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking for products sold in Europe and API specifications for specific applications may also apply. -

Quality Control Checkpoints:

Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials upon receipt to ensure they meet specified criteria before production begins.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to identify defects or deviations from standards, allowing for corrective actions to be taken immediately.

– Final Quality Control (FQC): Once the eyelets are finished, a final inspection is performed to ensure that the products meet all quality standards and specifications before they are packaged and shipped. -

Common Testing Methods:

Various testing methods are employed to evaluate the performance and durability of leather eyelets. These may include tensile strength tests, corrosion resistance tests, and dimensional inspections. Manufacturers may also conduct functional tests to ensure that the eyelets perform effectively when installed in leather or other materials.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring that products meet required standards. Here are several strategies for buyers to consider:

-

Supplier Audits:

Conducting on-site audits of potential suppliers is one of the most effective ways to assess their quality control processes. During an audit, buyers can evaluate the manufacturing environment, review quality control procedures, and ensure compliance with international standards. This direct interaction allows buyers to gauge the supplier’s commitment to quality. -

Requesting Quality Reports:

Buyers should request detailed quality reports from suppliers, including data on inspection results, defect rates, and compliance with relevant standards. This documentation can provide insight into the supplier’s quality management practices and highlight any areas of concern. -

Engaging Third-Party Inspectors:

Utilizing third-party inspection services can offer an additional layer of assurance. These independent inspectors can assess product quality at various stages of production, from raw material inspection to final product evaluation. This impartial assessment helps mitigate risks associated with sourcing from international suppliers. -

Understanding QC Nuances for International Transactions:

Buyers should be aware of specific quality control nuances that may vary by region. For example, certain markets may have stricter regulations regarding materials used in manufacturing or specific certification requirements. Understanding these regional differences can help buyers make informed decisions and select suppliers who can meet their specific needs.

Conclusion: Ensuring Quality in Leather Eyelet Manufacturing

The manufacturing processes and quality assurance measures for leather eyelets are integral to producing high-quality products that meet the demands of diverse markets. By understanding the key stages of production and the importance of rigorous quality control, B2B buyers can make informed decisions when sourcing leather eyelets from international suppliers. Engaging in thorough verification practices not only ensures compliance with international standards but also fosters long-term relationships built on trust and quality assurance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather eyelets’

In the competitive landscape of B2B sourcing, selecting the right leather eyelets is essential for ensuring product quality and meeting customer demands. This practical guide will help you navigate the procurement process efficiently, providing a structured checklist to streamline your purchasing decisions.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your leather eyelets is crucial. Consider the size, material, and finish that will best suit your application. For instance, solid brass eyelets offer durability and rust resistance, ideal for outdoor products, while nickel-plated options provide a different aesthetic.

- Size: Determine the diameter and length based on the thickness of the leather or fabric you are using.

- Material: Decide between brass, steel, or other materials based on exposure conditions and required strength.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in leather eyelets. Look for companies with a proven track record in the industry, especially those with experience supplying to your specific market region.

Illustrative image related to leather eyelets

- Company Background: Evaluate their history, market presence, and customer reviews.

- Product Range: Ensure they offer a diverse selection of eyelet types, sizes, and materials to meet your needs.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This is vital for ensuring product quality and safety.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance standards.

- Environmental Compliance: Inquire about their adherence to environmental regulations, especially if your products will be marketed in eco-sensitive regions.

Step 4: Request Samples for Testing

Always request samples before making a bulk purchase. This allows you to assess the quality and suitability of the eyelets for your specific applications.

- Fit and Finish: Test the eyelets in your production environment to confirm they fit well and meet your aesthetic requirements.

- Durability Testing: Check for rust resistance and overall strength by subjecting samples to stress tests.

Step 5: Negotiate Pricing and Terms

Once you have evaluated potential suppliers and tested samples, engage in price negotiations. It’s important to secure competitive pricing while also considering the total cost of ownership.

- Bulk Discounts: Inquire about pricing tiers based on order volume.

- Payment Terms: Discuss payment options that align with your cash flow and procurement processes.

Step 6: Finalize the Order and Confirm Delivery

After agreeing on terms, finalize your order with clear specifications. Confirm the delivery timeline to ensure it aligns with your production schedule.

- Order Confirmation: Ensure all details are documented, including quantities, sizes, and materials.

- Logistics Planning: Discuss shipping methods and timelines to avoid disruptions in your supply chain.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your supplier can lead to better service, pricing, and product innovations. Regular communication and feedback can enhance collaboration and ensure your sourcing needs are consistently met.

Illustrative image related to leather eyelets

- Performance Reviews: Schedule periodic evaluations to discuss performance and address any issues.

- Future Collaboration: Explore opportunities for joint development of new products or materials.

By following this structured checklist, B2B buyers can effectively source leather eyelets that meet their quality standards while optimizing costs and supplier relationships.

Comprehensive Cost and Pricing Analysis for leather eyelets Sourcing

What Are the Key Cost Components in Sourcing Leather Eyelets?

When sourcing leather eyelets, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly affects costs. Brass and steel are common materials for eyelets, with brass typically being more expensive but offering better resistance to corrosion. The cost can vary based on the quality and source of the materials.

-

Labor: Labor costs will vary by region. In countries with lower labor costs, such as Vietnam, manufacturing expenses may be lower, impacting the final pricing of the eyelets.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with the production facility. Efficient manufacturing processes can reduce overhead costs and, consequently, the price of the eyelets.

-

Tooling: Custom tooling for specific eyelet designs adds to the upfront costs. However, once established, the per-unit cost decreases significantly with higher production volumes.

-

Quality Control: Investing in quality control is essential, particularly for international buyers who may face higher costs due to returns or defects. The implementation of strict QC measures can increase initial costs but reduce long-term expenses related to product failure.

-

Logistics: Shipping and handling costs can vary significantly based on the distance and mode of transport. International buyers must also consider customs duties and tariffs, which can impact the overall cost.

-

Margin: Suppliers typically include a profit margin that can range from 10% to 30%, depending on market conditions and competition.

How Do Price Influencers Impact the Cost of Leather Eyelets?

Several factors influence the pricing of leather eyelets, particularly for international B2B transactions.

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for bulk purchases. Understanding the MOQ is vital, as larger orders can lead to significant savings.

-

Specifications and Customization: Customized eyelets tailored to specific applications can incur additional costs. Standard sizes and specifications generally have lower prices, while unique designs will require more investment.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO standards) can increase costs but are often necessary for compliance and longevity, especially in markets with stringent regulations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can significantly affect the total cost. Understanding these terms is essential for managing logistics expenses effectively.

What Are the Best Practices for B2B Buyers in Negotiating Leather Eyelet Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield favorable pricing.

-

Leverage Total Cost of Ownership (TCO): When negotiating, consider the TCO rather than just the unit price. This includes maintenance, quality assurance, and potential defects. A slightly higher upfront cost may lead to savings in the long run.

-

Establish Long-Term Relationships: Building a strong relationship with suppliers can lead to better pricing and priority in production schedules. Consistent orders often result in loyalty discounts.

-

Be Transparent About Needs: Clearly communicating your requirements can help suppliers tailor their offerings, potentially leading to better pricing and service.

-

Stay Informed About Market Trends: Keeping abreast of material costs, labor trends, and international trade agreements can empower buyers to negotiate more effectively.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall cost efficiency.

Conclusion

Understanding the comprehensive cost and pricing structure for leather eyelets is vital for B2B buyers. By analyzing cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can optimize their sourcing decisions. It is essential to approach the market with a clear understanding of the total cost implications, enabling informed purchasing decisions that align with business objectives. Prices can vary widely; thus, buyers are encouraged to seek multiple quotes and remain vigilant about market conditions.

Alternatives Analysis: Comparing leather eyelets With Other Solutions

Understanding Alternatives to Leather Eyelets: A Comparative Analysis

In the realm of leather goods manufacturing and repair, leather eyelets are a popular choice for reinforcing holes. However, there are alternative solutions available that may provide unique advantages depending on the specific requirements of a project. This analysis explores leather eyelets in comparison with grommets and metal snaps, two viable alternatives that serve similar functions.

Comparison Table

| Comparison Aspect | Leather Eyelets | Grommets | Metal Snaps |

|---|---|---|---|

| Performance | Good for lightweight materials; offers decent reinforcement | Superior strength; ideal for heavy-duty applications | Quick fastening; easy to use |

| Cost | Generally low-cost, bulk options available | Moderate cost; varies by size and material | Moderate to high; depends on design |

| Ease of Implementation | Requires specific tools; straightforward process | Similar installation process; requires matching tools | Simple installation; minimal tools needed |

| Maintenance | Low maintenance; durable with proper use | Low maintenance; resistant to rust | Low maintenance; durable |

| Best Use Case | Ideal for light leather goods, crafts, and garments | Best for heavy-duty items like tarps, bags, and outdoor gear | Great for clothing, bags, and accessories requiring quick access |

Detailed Breakdown of Alternatives

Grommets: A Stronger Reinforcement Option

Grommets are often favored for their superior strength compared to leather eyelets. They consist of a metal ring with a washer that provides additional support, making them suitable for heavy-duty applications such as tarps, bags, and outdoor gear. The installation process is similar to eyelets but requires a snug hole for the grommet to fit securely. Grommets are typically made from rust-resistant materials like solid brass, making them ideal for outdoor use. However, they may be more expensive than leather eyelets and require specialized tools for different sizes, which can add to the overall cost.

Metal Snaps: Quick and Convenient Fastening

Metal snaps are a practical alternative for applications that require quick fastening and unfastening, such as in clothing and bags. They are easy to install, often requiring minimal tools, which can streamline production processes. Snaps can be found in various designs and finishes, making them versatile for different styles. However, they may not provide the same level of reinforcement as eyelets or grommets, particularly in high-stress situations. While the cost can vary based on design, metal snaps generally fall into a moderate to high price range compared to eyelets.

Illustrative image related to leather eyelets

Making the Right Choice for Your Needs

When selecting between leather eyelets, grommets, and metal snaps, B2B buyers should assess their specific needs based on the intended application. If the project involves lightweight materials and cost-efficiency is a priority, leather eyelets may be the best choice. Conversely, for projects demanding durability and resistance to wear and tear, grommets would be more suitable. Metal snaps serve a unique function when convenience and quick access are paramount. Understanding the distinct advantages and limitations of each option will empower buyers to make informed decisions tailored to their manufacturing or design requirements.

Essential Technical Properties and Trade Terminology for leather eyelets

What Are the Key Technical Properties of Leather Eyelets?

When sourcing leather eyelets, understanding their technical properties is essential for ensuring that the products meet your specific application needs. Here are some critical specifications to consider:

-

Material Grade

Eyelets can be made from various materials, including solid brass, steel, and aluminum. Solid brass is highly preferred for outdoor applications due to its rust-resistant properties, making it suitable for products exposed to moisture. Steel eyelets, while more cost-effective, are prone to rust if not properly coated. Choosing the right material is vital for ensuring durability and longevity in your products. -

Size and Diameter

Eyelets come in various sizes and diameters, typically ranging from 1/8 inch to 3/4 inch. The size you choose will depend on the thickness of the leather and the specific application. A snug fit is crucial to prevent the eyelet from pulling through the material. Understanding size specifications helps in making informed decisions, especially when manufacturing products that require consistent quality. -

Post Length

The post length of an eyelet is another critical factor. It must be long enough to extend above the thickness of the leather to ensure proper crimping and secure installation. If the post is too short, the eyelet may not set correctly, leading to potential failures in use. This specification directly impacts the performance and reliability of the finished product. -

Finish Type

The finish on eyelets can include nickel plating, brass plating, or even powder coating. These finishes not only enhance aesthetics but also provide additional protection against corrosion and wear. For B2B buyers, selecting the appropriate finish is essential to match the desired look and functional requirements of the end product. -

Tolerance Levels

Tolerances refer to the permissible limits of variation in the eyelet’s dimensions. High tolerance levels ensure that eyelets fit perfectly in their designated holes, minimizing the risk of defects during production. Understanding tolerance specifications is essential for maintaining quality control in manufacturing processes.

What Are Common Trade Terms Related to Leather Eyelets?

Navigating the world of leather eyelets also involves familiarizing oneself with industry terminology. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing eyelets, understanding OEM relationships can help ensure that you are getting quality products that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory planning, especially for businesses that may not need large quantities of eyelets regularly. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price offers from suppliers for specific products. It is a critical step in the procurement process, allowing buyers to compare pricing and terms from multiple vendors. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B transactions, as they clarify shipping costs, risks, and delivery obligations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time for eyelet orders can help businesses plan their production schedules and manage customer expectations effectively. -

Bulk Pricing

This term refers to discounted rates offered for purchasing large quantities of products. For businesses looking to reduce costs, understanding bulk pricing structures can lead to significant savings when sourcing leather eyelets.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing leather eyelets for your business needs, ensuring the products meet your quality and performance standards.

Navigating Market Dynamics and Sourcing Trends in the leather eyelets Sector

What Are the Key Trends Shaping the Leather Eyelets Market Today?

The leather eyelets market is currently experiencing dynamic shifts driven by a combination of global demand, technological advancements, and evolving consumer preferences. The growth in the fashion and accessories sectors, particularly in regions like Africa, South America, the Middle East, and Europe, has led to an increased need for durable and aesthetically pleasing eyelets. Notably, the rise of e-commerce has facilitated easier access to a broader range of products, enabling international B2B buyers to source leather eyelets from diverse suppliers more efficiently.

Illustrative image related to leather eyelets

Emerging technologies such as automation in manufacturing and digital supply chain management are reshaping sourcing processes. Automated production techniques are enhancing the quality and consistency of eyelets, while digital platforms allow for streamlined ordering and inventory management. Additionally, there is a notable trend towards customization, where buyers seek specific sizes, colors, and materials to cater to niche markets.

International buyers are also focusing on competitive pricing, often requiring suppliers to provide bulk options and flexible payment terms. As markets evolve, staying abreast of these trends is essential for B2B buyers to maintain a competitive edge.

How Is Sustainability Influencing the Sourcing of Leather Eyelets?

Sustainability has become a cornerstone in the sourcing of leather eyelets, with increasing awareness of environmental impact among B2B buyers. The leather industry is scrutinized for its ecological footprint, prompting buyers to prioritize ethical sourcing practices. Suppliers are now expected to provide transparency regarding their supply chains, focusing on responsible sourcing of materials and minimizing waste during production.

The demand for ‘green’ certifications is on the rise, with buyers looking for suppliers who adhere to environmentally friendly practices. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) are becoming essential for suppliers aiming to attract conscientious buyers. Additionally, there is a growing interest in alternative materials such as synthetic leather and recycled metals for eyelets, which can significantly reduce environmental impact.

By aligning with sustainable practices, B2B buyers not only fulfill their corporate social responsibility but also appeal to an increasingly eco-conscious consumer base, enhancing their brand reputation and marketability.

What Is the Historical Context Behind the Evolution of Leather Eyelets?

The use of eyelets dates back centuries, with early applications found in various cultures for reinforcing fabric and leather. Originally crafted from wood or bone, eyelets evolved with advancements in metallurgy, leading to the use of brass, steel, and other metals for enhanced durability.

The industrial revolution marked a significant turning point, as mass production techniques allowed for the widespread availability of eyelets, transforming them from a niche artisanal product to an essential component in fashion and manufacturing. Today, leather eyelets are not only functional but also serve as decorative elements in various products, reflecting the ongoing evolution of design and material technology.

Understanding this historical context helps B2B buyers appreciate the craftsmanship and innovation that continues to shape the leather eyelets market, informing their sourcing decisions and product development strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of leather eyelets

-

How do I choose the right eyelets for my leather project?

Selecting the appropriate eyelets involves considering the thickness and type of leather you are using. For thinner leathers, smaller eyelets are usually sufficient, while thicker materials may require larger grommets for added strength. Ensure the eyelet diameter matches your hole size, which should be snug enough to prevent pull-through. Additionally, consider the eyelet material; solid brass and nickel-plated options are durable and rust-resistant, making them suitable for various applications. -

What is the difference between eyelets and grommets?

Eyelets and grommets serve similar purposes in reinforcing holes in materials. However, eyelets are typically smaller and lack a washer, making them suitable for lighter applications like shoe laces. Grommets, on the other hand, include a washer that provides additional support and are available in larger diameters, making them ideal for more robust applications such as tarps and awnings. When deciding between the two, assess the load-bearing requirements of your project. -

What are the minimum order quantities (MOQ) for leather eyelets?

Minimum order quantities can vary widely by supplier and region. Many manufacturers may have an MOQ ranging from a few hundred to several thousand pieces, especially for custom orders. It’s essential to communicate your specific needs with suppliers to negotiate MOQs that align with your production requirements. Bulk purchasing can often lead to cost savings, so consider your long-term needs when placing orders. -

How can I ensure the quality of the eyelets I am purchasing?

To ensure quality, request samples from suppliers before placing a bulk order. Look for eyelets made from solid materials like brass or stainless steel, as these are more durable and resistant to corrosion. Additionally, inquire about the supplier’s quality assurance processes, including testing and certifications. Checking customer reviews and testimonials can also provide insights into the reliability of the supplier’s products. -

What customization options are available for leather eyelets?

Many suppliers offer customization options for eyelets, including size, color, and material. Some may also provide branding options, allowing you to engrave your logo or design on the eyelets. When seeking customization, discuss your requirements upfront and ask for a prototype to ensure the final product meets your specifications. Keep in mind that custom orders may come with higher MOQs and longer lead times. -

What payment terms are typically available when sourcing eyelets internationally?

Payment terms can vary significantly depending on the supplier and the nature of your relationship. Common options include advance payments, letters of credit, and net payment terms (e.g., net 30 or net 60 days). It’s advisable to negotiate payment terms that protect your interests while also accommodating the supplier’s policies. Always ensure that payment methods are secure and traceable, especially for large orders. -

How do I manage logistics for importing eyelets from international suppliers?

Managing logistics involves selecting reliable shipping partners who understand customs regulations and can efficiently handle your order’s transport. Determine shipping methods based on urgency and budget—air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure your supplier provides all necessary documentation for customs clearance. Consider working with freight forwarders to streamline the process and mitigate potential delays. -

What are the common challenges faced when sourcing eyelets internationally?

Challenges may include language barriers, cultural differences, and varying quality standards. To mitigate these, conduct thorough research on potential suppliers, engage in clear communication, and establish a comprehensive contract outlining all terms. Additionally, be prepared for potential delays in shipping and customs clearance. Building a strong relationship with suppliers can also help address these challenges and ensure smoother transactions in the future.

Top 2 Leather Eyelets Manufacturers & Suppliers List

1. Leathersmith Designs – Eyelets and Grommets

Domain: leathersmithdesigns.com

Registered: 2000 (25 years)

Introduction: Eyelets and grommets are used to strengthen holes in thinner and softer leathers for laces, strings, ropes, or hooks. Grommets have a washer underneath, providing more strength than eyelets. Eyelets are typically smaller in diameter, often called shoe eyelets, while grommets come in a larger range of diameters. The grommets are made of solid brass, preventing rust, suitable for outdoor application…

2. Tandy Leather – Eyelets 100 Pack

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: Eyelets 100 Pack from Tandy Leather, Inc. – Ideal for leather crafting and projects. Includes 100 eyelets for versatile use. Suitable for various applications in leatherwork.

Strategic Sourcing Conclusion and Outlook for leather eyelets

How Can Strategic Sourcing Enhance Your Procurement of Leather Eyelets?

In conclusion, strategic sourcing is paramount for international B2B buyers seeking leather eyelets. By leveraging bulk purchasing options, businesses can not only reduce costs but also ensure consistent quality across their products. The diverse range of materials—such as solid brass and nickel-plated options—offers flexibility to meet varying project specifications, while understanding the differences between eyelets and grommets can significantly impact product durability and application.

Moreover, sourcing from reliable suppliers ensures timely delivery and mitigates supply chain risks, which is crucial for maintaining production schedules. As the demand for high-quality leather products continues to rise in regions like Africa, South America, the Middle East, and Europe, aligning with trusted manufacturers can position your business for success.

Looking ahead, it is essential to stay informed about emerging trends and innovations in the leather industry. Engaging with suppliers who prioritize sustainability and technological advancements will not only enhance product offerings but also align with the growing consumer preference for eco-friendly solutions. Take action now by evaluating your sourcing strategies and exploring new partnerships to elevate your business in the competitive leather market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.