Lasersnijden Machines: The Ultimate B2B Sourcing Guide for Global Buyer

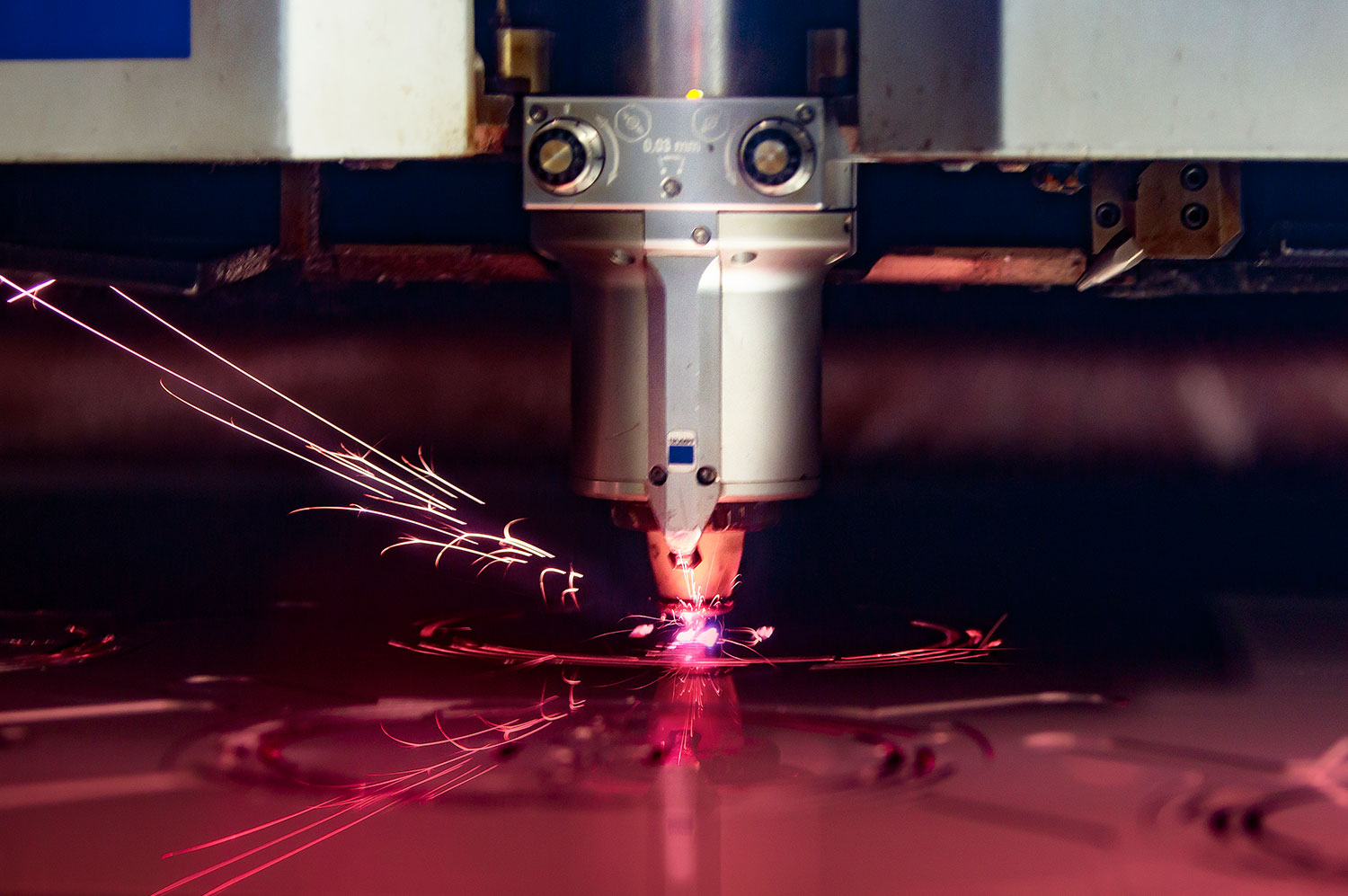

Introduction: Navigating the Global Market for lasersnijden machines

In today’s rapidly evolving manufacturing landscape, sourcing the right lasersnijden machines can be a daunting challenge for international B2B buyers. With various technologies available, including CO2 and fiber lasers, understanding which machine best meets your specific application is crucial. This guide aims to provide comprehensive insights into the global market for lasersnijden machines, covering essential topics such as machine types, their diverse applications, supplier vetting processes, and cost considerations.

For businesses operating in regions like Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—making informed purchasing decisions is imperative to enhance operational efficiency and maintain competitive advantage. This guide not only empowers buyers with the necessary knowledge to evaluate and select the right equipment but also highlights best practices in supplier selection to ensure reliability and safety.

By diving into the nuances of lasersnijden technology and its applications, this resource serves as a vital tool for B2B buyers seeking innovative, efficient, and safe solutions tailored to their unique needs. With expert insights and actionable advice, you can navigate the complexities of the global market with confidence, ensuring that your investment in lasersnijden machines yields maximum value and productivity.

Understanding lasersnijden machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Laser Cutting Machines | Ideal for non-metal materials, versatile in cutting and engraving | Sign-making, woodworking, textile industry | Pros: Cost-effective, versatile, good for a variety of materials. Cons: Slower cutting speed for thicker materials. |

| Fiber Laser Cutting Machines | High precision, fast cutting speed, suitable for metals | Automotive, aerospace, metal fabrication | Pros: Excellent for metal, high speed, low maintenance. Cons: Higher initial investment, less effective on non-metals. |

| Diode Laser Engravers | Compact, user-friendly, suitable for small-scale operations | Prototyping, crafts, educational purposes | Pros: Affordable, easy to use, ideal for beginners. Cons: Limited power and cutting capabilities compared to larger machines. |

| Specialty Laser Machines | Customized solutions for unique applications and materials | Research, development, specialized industries | Pros: Tailored solutions, flexibility in design. Cons: Longer lead times, potentially higher costs. |

| Hybrid Laser Systems | Combines multiple functions (cutting, engraving, 3D printing) | Prototyping, small batch production | Pros: Multifunctional, space-saving, versatile. Cons: Complexity in operation, may require more maintenance. |

What Are the Characteristics of CO2 Laser Cutting Machines?

CO2 laser cutting machines are primarily designed for non-metal materials such as wood, acrylic, and textiles. They utilize a gas laser, which is effective for engraving and cutting intricate designs. B2B buyers in industries like sign-making and woodworking benefit from their cost-effectiveness and versatility. When purchasing, consider the machine’s cutting speed and the thickness of materials it can handle, as these factors will significantly impact operational efficiency.

How Do Fiber Laser Cutting Machines Stand Out in the Market?

Fiber laser cutting machines are known for their high precision and speed, making them ideal for metal processing. They are widely used in sectors such as automotive and aerospace due to their ability to cut through various metals with minimal waste. B2B buyers should evaluate the machine’s power output and its compatibility with different metal types, as these will influence production capabilities and overall cost-effectiveness.

What Are the Advantages of Diode Laser Engravers?

Diode laser engravers are compact and user-friendly, making them suitable for small-scale operations and educational purposes. Their affordability and ease of use appeal to startups and hobbyists, allowing them to enter the laser processing market without significant investment. However, buyers should be aware of their limitations in terms of power and cutting capabilities, which may restrict their use in more demanding industrial applications.

Why Consider Specialty Laser Machines for Unique Applications?

Specialty laser machines offer customized solutions tailored to specific needs, making them invaluable in research and development or niche industries. These machines can handle unique materials and complex designs that standard machines cannot. Buyers should assess the customization options available and the associated lead times, as these factors can affect project timelines and costs.

What Are the Benefits of Hybrid Laser Systems?

Hybrid laser systems combine multiple functions, such as cutting, engraving, and even 3D printing, into a single machine. This multifunctionality can save space and increase productivity for businesses that require diverse processing capabilities. However, buyers must consider the complexity of operation and potential maintenance issues when investing in such systems, as these can impact overall efficiency and user training requirements.

Key Industrial Applications of lasersnijden machines

| Industry/Sector | Specific Application of lasersnijden machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Metal fabrication for automotive parts | High precision cutting reduces waste and improves efficiency | Ensure machine can handle specific metal types and thicknesses; consider local support for maintenance. |

| Aerospace | Component cutting for aircraft structures | Lightweight and precise parts enhance performance and safety | Look for machines with certifications for aerospace standards; check for advanced software integration. |

| Electronics | PCB etching and cutting | Increased accuracy in circuit design and reduced production time | Verify compatibility with various PCB materials; assess the availability of training for operators. |

| Signage and Branding | Custom signage production | Ability to create intricate designs quickly, improving customer satisfaction | Consider the versatility of the machine for different materials; inquire about customization options. |

| Education and Training | Prototyping and hands-on learning | Enhances student engagement and practical skills development | Evaluate training packages and support offered; ensure safety features meet educational requirements. |

How Are Lasersnijden Machines Used in Manufacturing?

In the manufacturing sector, lasersnijden machines are vital for metal fabrication, particularly in automotive part production. These machines offer high precision cutting capabilities, which not only reduce material waste but also enhance overall production efficiency. For B2B buyers, it is crucial to consider the types of metals the machine can handle, as well as the thickness of materials. Additionally, having local support for maintenance can significantly reduce downtime and operational costs, particularly in regions such as Africa and South America where logistical challenges may arise.

What Role Do Lasersnijden Machines Play in Aerospace?

In the aerospace industry, lasersnijden machines are employed for cutting components that are critical to aircraft structures. The lightweight and precise parts produced by these machines contribute to enhanced performance and safety. Buyers in this sector should prioritize sourcing machines that meet stringent aerospace certifications and standards. It is also beneficial to assess the integration of advanced software that can streamline the design and production process, ensuring compliance with industry regulations.

How Are Lasersnijden Machines Transforming Electronics?

Lasersnijden machines are increasingly utilized in the electronics industry for PCB etching and cutting. Their ability to deliver increased accuracy in circuit design not only reduces production time but also minimizes errors, which is crucial for maintaining product quality. International buyers should verify the compatibility of the machines with various PCB materials and consider the availability of operator training to ensure efficient use of the technology. This is especially important in regions where skilled labor may be limited.

In What Ways Are Lasersnijden Machines Beneficial for Signage and Branding?

In the signage and branding sector, lasersnijden machines facilitate the production of custom signage with intricate designs. The speed and precision of these machines enhance customer satisfaction by allowing businesses to meet specific branding requirements quickly. When sourcing such machines, it is essential to evaluate their versatility in handling various materials, such as acrylic and wood, and to inquire about customization options that can cater to diverse design needs. This adaptability is particularly advantageous in competitive markets across Europe and the Middle East.

How Can Lasersnijden Machines Enhance Education and Training?

Lasersnijden machines also play a significant role in educational settings by enabling prototyping and hands-on learning experiences. These machines help engage students and enhance their practical skills development in fields such as engineering and design. Buyers from educational institutions should evaluate the training packages and support offered by suppliers, ensuring that safety features align with educational requirements. In regions like Africa and South America, where educational resources may be limited, having comprehensive training and support is vital for successful implementation.

3 Common User Pain Points for ‘lasersnijden machines’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Laser Cutting Machine

The Problem: For many B2B buyers, particularly those in regions with diverse manufacturing needs such as Africa and South America, selecting the appropriate laser cutting machine can be daunting. Buyers often grapple with understanding the differences between CO2 and fiber lasers, which are designed for specific materials and applications. A common scenario involves a company looking to expand its production capabilities but struggling to determine which machine will best meet their needs for precision cutting and engraving across various materials, including metals, plastics, and wood. This indecision can lead to costly mistakes, including purchasing machines that are either over-capable or insufficient for the intended tasks.

The Solution: To effectively navigate this selection process, buyers should conduct a thorough needs assessment that includes evaluating their current and future production requirements. Consulting with experts from reputable suppliers can provide invaluable insights into the capabilities of different laser machines. It is crucial to consider factors such as material types, thickness, and desired precision levels. Additionally, buyers should request demonstrations of various machines to see firsthand how each performs with the materials they intend to use. This hands-on approach can demystify the technology and clarify which machine aligns best with their operational goals. Furthermore, seeking tailored solutions that allow for future upgrades or expansions can help ensure that investments remain viable as business needs evolve.

Scenario 2: Ensuring Safety and Compliance in Laser Operations

The Problem: Safety and compliance are paramount concerns for businesses that utilize laser cutting machines. Many organizations, especially in the Middle East and Europe, face challenges in ensuring that their operations meet strict regulatory standards. Issues can arise from insufficient safety features, improper training of operators, or failure to comply with local safety regulations regarding laser use. Without proper protocols, companies risk not only legal repercussions but also the safety of their employees, which can lead to accidents and operational downtime.

The Solution: To mitigate these risks, B2B buyers should prioritize purchasing laser machines that come equipped with comprehensive safety features and have been certified by recognized safety standards. Before finalizing any purchase, it is essential to review compliance documentation and certification reports from accredited bodies. Moreover, investing in thorough training programs for operators is crucial. Suppliers often provide training services that educate staff on the safe operation of laser machines, including emergency procedures and maintenance practices. Regular safety audits and updates to operational protocols can further enhance workplace safety and ensure compliance with evolving regulations. Establishing a culture of safety within the organization reinforces best practices and minimizes the risk of accidents, ultimately leading to a more efficient and responsible operation.

Scenario 3: Limited Technical Support and Maintenance Challenges

The Problem: After acquiring a laser cutting machine, many B2B buyers encounter issues related to technical support and maintenance. Companies, especially those in remote areas or emerging markets, may find it challenging to access timely support when machine malfunctions occur. This can lead to extended downtime, disrupting production schedules and incurring significant costs. Furthermore, a lack of readily available spare parts can exacerbate these problems, leaving businesses vulnerable to operational delays.

The Solution: To address these challenges, buyers should select suppliers that offer robust after-sales support, including technical assistance and maintenance services. It is advisable to inquire about the availability of local service teams or partnerships with regional technicians who can provide quick responses to maintenance requests. Establishing a service agreement that outlines the terms of support, including response times and costs, can provide peace of mind. Additionally, maintaining an inventory of critical spare parts on-site can significantly reduce downtime. Companies should also invest in preventive maintenance plans to ensure that machines operate efficiently and to preempt potential issues. By fostering a proactive maintenance culture, businesses can enhance the longevity of their equipment and ensure consistent production quality.

Strategic Material Selection Guide for lasersnijden machines

When selecting materials for lasersnijden machines, it is essential to consider various factors that can impact performance, durability, and cost-effectiveness. Below, we analyze four common materials used in laser cutting applications, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Acrylic in Laser Cutting Applications?

Acrylic, often referred to as PMMA (polymethyl methacrylate), is a popular choice for laser cutting due to its excellent optical clarity and ease of processing. It has a melting point of approximately 160°C and exhibits good weather resistance, making it suitable for both indoor and outdoor applications. Acrylic is lightweight and can be easily shaped into various forms.

Pros: Acrylic is relatively inexpensive and offers high durability against impact. It also provides a smooth finish, which is ideal for aesthetic applications.

Cons: While acrylic is durable, it can be prone to scratching and may not withstand high temperatures as well as other materials. Additionally, it can emit harmful fumes when cut, necessitating proper ventilation.

Impact on Application: Acrylic is commonly used for signage, displays, and protective barriers. Its ability to be easily colored and shaped makes it a versatile option for creative applications.

Considerations for International Buyers: Buyers should ensure compliance with local safety regulations regarding the handling of fumes. Standards such as ASTM D4802 for acrylic materials may apply.

How Does Stainless Steel Perform in Laser Cutting?

Stainless steel is renowned for its corrosion resistance and strength, with a melting point around 1400-1450°C depending on the alloy. It is available in various grades, each offering different properties suitable for specific applications.

Pros: Stainless steel is highly durable, resistant to rust and staining, and can withstand high temperatures. It is ideal for applications requiring structural integrity and hygiene, such as in the food and medical industries.

Cons: The cost of stainless steel can be high compared to other materials, and its hardness may require more powerful laser cutting systems, increasing operational costs.

Impact on Application: Commonly used in industrial applications, stainless steel is suitable for manufacturing parts, tools, and equipment that must endure harsh environments.

Considerations for International Buyers: Compliance with ASTM A240 or DIN EN 10088 standards is crucial for ensuring quality and performance. Buyers should also consider the availability of specific grades in their region.

What Are the Advantages of Using Wood for Laser Cutting?

Wood is a traditional material that is widely used in laser cutting due to its natural availability and aesthetic appeal. It has a variable density and melting point, typically around 200-300°C, depending on the type of wood.

Pros: Wood is relatively inexpensive and easy to work with. It can be cut and engraved to create intricate designs, making it popular for crafts and furniture.

Cons: Wood can warp or crack over time, especially if not properly treated. Additionally, different wood types may require different laser settings, complicating the cutting process.

Impact on Application: Wood is commonly used for decorative items, prototypes, and furniture. Its versatility allows for a wide range of applications.

Considerations for International Buyers: Buyers should be aware of local regulations regarding sustainable sourcing and the use of treated wood, as standards may vary by region.

How Does Fabric Perform in Laser Cutting Applications?

Fabrics, including natural and synthetic types, are increasingly popular for laser cutting due to their flexibility and variety. The melting point varies widely depending on the fabric type, with natural fibers like cotton melting at around 200-300°C and synthetic fibers like polyester at higher temperatures.

Pros: Fabrics can be cut quickly and efficiently, offering clean edges without fraying. They are lightweight and can be used in various applications, from fashion to industrial uses.

Cons: Fabrics may require specific laser settings to avoid burning or melting, which can complicate the cutting process. Additionally, certain synthetic fabrics can release harmful fumes when cut.

Impact on Application: Fabrics are widely used in the fashion industry, upholstery, and promotional materials. Their adaptability makes them suitable for both functional and decorative purposes.

Considerations for International Buyers: Compliance with safety standards for handling fumes and ensuring the quality of fabric materials is essential. Familiarity with standards such as ASTM D5034 for textile testing may be beneficial.

Summary Table of Material Selection for Lasersnijden Machines

| Material | Typical Use Case for lasersnijden machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Signage, displays, protective barriers | High durability and optical clarity | Prone to scratching and fume emission | Low |

| Stainless Steel | Industrial parts, tools, equipment | Corrosion resistance and strength | Higher cost and requires powerful lasers | High |

| Wood | Decorative items, furniture, prototypes | Inexpensive and easy to work with | Can warp or crack over time | Low |

| Fabric | Fashion, upholstery, promotional materials | Quick cutting with clean edges | Requires precise settings to avoid damage | Medium |

This guide provides a comprehensive overview of material selection for lasersnijden machines, enabling B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for lasersnijden machines

What Are the Main Stages in the Manufacturing Process of Lasersnijden Machines?

The manufacturing process of lasersnijden machines involves several critical stages that ensure the final product meets the high standards required for precision cutting and engraving. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in the manufacturing process is selecting high-quality materials, such as steel, aluminum, and specialized alloys, which are essential for the machine’s durability and performance. The materials undergo rigorous inspection to confirm they meet specified standards. This can include chemical composition tests and mechanical property evaluations. Suppliers often utilize advanced technologies like laser cutting and CNC machining to prepare the raw materials to precise dimensions. -

Forming

In this stage, the prepared materials are shaped into components using various techniques. Common methods include laser cutting, bending, and welding. Laser cutting is particularly advantageous as it allows for intricate designs and high precision, minimizing material waste. The forming process is critical; any discrepancies can lead to misalignments in the final assembly. -

Assembly

After forming, the next step is assembly, where various components are brought together. This stage often involves precise alignment and the use of jigs and fixtures to ensure accuracy. Automated systems may be employed to enhance consistency and speed. Quality assurance checkpoints are critical during this phase, as any errors in assembly can significantly affect the machine’s performance. -

Finishing

The final stage involves finishing processes, such as surface treatment, painting, and quality inspections. Surface treatments, like anodizing or powder coating, enhance the machine’s durability and aesthetic appeal. Each machine undergoes a series of tests to ensure it meets performance standards, including operational efficiency and safety features.

How Is Quality Assurance Implemented in the Manufacturing of Lasersnijden Machines?

Quality assurance (QA) in the manufacturing of lasersnijden machines is vital to ensure that products meet international standards and customer expectations. Key aspects of QA include adherence to international standards, implementation of quality checkpoints, and the use of common testing methods.

-

What Are the Relevant International Standards for Lasersnijden Machines?

Compliance with international standards such as ISO 9001 is crucial for manufacturers. ISO 9001 outlines the requirements for a quality management system (QMS) that helps organizations ensure they meet customer and regulatory requirements consistently. Additionally, CE marking is essential for machines sold in Europe, indicating conformity with health, safety, and environmental protection standards. For specific applications, standards from the American Petroleum Institute (API) may also apply, particularly in sectors like oil and gas. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints play a significant role throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Quality checks during the manufacturing process help identify defects early, preventing costly rework.

– Final Quality Control (FQC): A comprehensive inspection of the finished product ensures it meets all specifications before shipment. -

Which Testing Methods Are Commonly Used?

Various testing methods are employed to verify the quality of lasersnijden machines. These include:

– Functional Testing: Ensures the machine operates correctly under normal working conditions.

– Performance Testing: Assesses cutting speed, precision, and the ability to handle various materials.

– Safety Testing: Evaluates electrical safety, laser safety, and mechanical safety to comply with regulatory standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of suppliers. This can include conducting audits, reviewing quality reports, and utilizing third-party inspections.

-

What Role Do Audits Play in Supplier Verification?

Regular audits are essential for ensuring that suppliers adhere to quality management systems and comply with international standards. Buyers should request documentation of past audits and any corrective actions taken by the supplier. This transparency can provide insights into the supplier’s commitment to quality. -

How Can Buyers Access Quality Reports?

Buyers should request quality assurance reports, including IQC, IPQC, and FQC results. These reports should detail inspection findings, testing results, and any non-conformities found during the manufacturing process. This information can help buyers make informed decisions regarding supplier reliability. -

Why Consider Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control measures. This is particularly important for buyers from regions with different regulatory environments, as it ensures that products meet local and international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial for successful transactions and long-term partnerships. These nuances can vary based on regional regulations, standards, and market expectations.

-

How Do Regional Regulations Impact Quality Control?

Different regions may have unique regulatory requirements that affect product standards. For example, while CE marking is necessary in Europe, compliance with local safety and environmental regulations may be more stringent in some African or South American countries. Buyers should familiarize themselves with these regulations to ensure that the products they procure are compliant. -

What Should Buyers Know About Supplier Certifications?

Certifications from recognized bodies can enhance a supplier’s credibility. Buyers should look for suppliers with certifications like ISO 9001, which indicate a commitment to quality management practices. However, buyers should also verify the authenticity of these certifications through direct communication with certifying bodies. -

How Can Buyers Ensure Ongoing Quality Assurance?

Establishing strong communication channels with suppliers and conducting regular follow-ups can help ensure ongoing quality assurance. Buyers may consider setting up key performance indicators (KPIs) that suppliers must meet, along with regular reviews to monitor compliance and performance.

In conclusion, understanding the manufacturing processes and quality assurance measures for lasersnijden machines is critical for B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and safety.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lasersnijden machines’

To assist B2B buyers in the procurement of lasersnijden machines, this guide provides a structured checklist that outlines essential steps to ensure a successful acquisition. By following these steps, you can make informed decisions that align with your operational needs and ensure safety, efficiency, and reliability in your laser cutting operations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right lasersnijden machines for your needs. Consider factors such as the materials you will be working with (e.g., metal, wood, acrylic), the thickness of these materials, and the required precision level. This will help you narrow down options to machines that can handle your specific applications effectively.

Step 2: Research Different Types of Lasers

Familiarize yourself with various types of lasers available in the market, such as CO2 lasers and fiber lasers. Each type has distinct advantages; for instance, CO2 lasers are versatile for non-metal materials, while fiber lasers excel in cutting metals with high precision. Understanding these differences will guide you in selecting a machine that best suits your production requirements.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, it’s vital to conduct thorough evaluations. Request detailed company profiles, case studies, and references from businesses in similar industries or regions. This will provide insights into their reliability, customer service, and the quality of their machines. Consider visiting their facilities if possible to see the machines in action.

Step 4: Verify Supplier Certifications

Confirm that potential suppliers hold necessary certifications and compliance with safety standards. Look for CE marking and laser safety classifications, as these indicate adherence to European safety norms. Request copies of certification documents and inspection reports from accredited agencies to ensure that the machines meet safety and performance standards.

Step 5: Inquire About Customization Options

Assess whether the supplier offers customization options to meet your unique operational needs. Many suppliers provide tailored solutions that can enhance productivity and efficiency. Discuss your specific requirements, such as automation features or software compatibility, to ensure the machine can integrate seamlessly into your existing workflow.

Step 6: Consider Post-Purchase Support and Training

Evaluate the level of post-purchase support and training that suppliers provide. Adequate training is essential for your operators to maximize the machine’s capabilities safely. Inquire about maintenance services, availability of spare parts, and customer support options to ensure you have reliable assistance after purchase.

Step 7: Request a Demonstration

Before making a final decision, request a demonstration of the machines you are considering. This allows you to assess the machine’s performance firsthand and determine if it meets your expectations. Bring sample materials to test the machine’s capabilities in real-world conditions, ensuring it aligns with your production standards.

By following this structured checklist, B2B buyers can navigate the complexities of procuring lasersnijden machines effectively, ensuring they choose the right equipment that meets their operational needs while ensuring safety and compliance.

Comprehensive Cost and Pricing Analysis for lasersnijden machines Sourcing

What Are the Key Cost Components in Sourcing Lasersnijden Machines?

When sourcing lasersnijden machines, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in manufacturing laser machines significantly affects the cost. High-grade components, such as precision optics and durable casings, increase both the upfront cost and long-term reliability.

-

Labor: Labor costs vary by region and manufacturing processes. Skilled labor is essential for the assembly and calibration of lasers, impacting the overall price. In countries with higher wage standards, such as Germany, labor costs will be reflected in the final pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient production processes can help minimize overhead, but buyers should be aware that lower overhead costs might compromise quality.

-

Tooling: Custom tooling for specific applications may be necessary, especially for bespoke machines. This can add to initial costs but can be justified by the machine’s tailored performance.

-

Quality Control (QC): Rigorous quality control processes ensure that machines meet safety and performance standards. This is particularly important for lasersnijden machines, where precision is paramount. The costs associated with QC can be significant but are vital for reliability.

-

Logistics: Shipping and handling costs are influenced by the machine’s size, weight, and the shipping distance. Buyers should consider these logistics costs, especially when sourcing from international suppliers.

-

Margin: Supplier profit margins can vary significantly based on market conditions, competition, and the supplier’s reputation. It’s essential to compare different suppliers to ensure competitive pricing.

What Influences the Price of Lasersnijden Machines?

Several factors can influence the pricing of lasersnijden machines:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on their anticipated needs.

-

Specifications and Customization: Customized machines tailored to specific applications often come at a premium. While customization can enhance performance, it’s essential to balance features against costs.

-

Materials and Quality Certifications: Machines built with high-quality materials or that comply with international safety standards (e.g., CE certification) may have higher price points. Buyers should weigh the importance of certifications against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more due to perceived quality and service levels.

-

Incoterms: The agreed terms of shipment (e.g., FOB, CIF) can significantly affect the total landed cost. Understanding these terms is crucial for budget planning.

How Can Buyers Optimize Their Sourcing Strategy for Lasersnijden Machines?

-

Negotiation: Engage in discussions with multiple suppliers to explore pricing flexibility. Leveraging your position as a bulk buyer can lead to significant discounts.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as maintenance, energy consumption, and potential downtime.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa or South America should be mindful of currency fluctuations, import duties, and taxes that can impact final costs. Researching local regulations can prevent unexpected expenses.

-

Understand the Market: Stay informed about market trends and technological advancements in laser cutting. This knowledge can provide leverage in negotiations and help identify the best value options.

-

Seek Comprehensive Support: Opt for suppliers that provide extensive after-sales support, training, and maintenance services. This can enhance machine longevity and operational efficiency, ultimately lowering costs.

Disclaimer on Indicative Prices

Pricing for lasersnijden machines can vary widely based on the aforementioned factors. It is advisable to request quotes from multiple suppliers and to specify all requirements to ensure accurate comparisons. Always account for potential fluctuations in costs due to economic conditions and supplier changes.

Alternatives Analysis: Comparing lasersnijden machines With Other Solutions

Exploring Alternatives to Lasersnijden Machines

In the competitive landscape of manufacturing and fabrication, businesses often seek the most efficient and cost-effective solutions for cutting and engraving materials. While lasersnijden machines (laser cutting machines) are renowned for their precision and versatility, several alternative technologies can also achieve similar results. This analysis will compare lasersnijden machines with CNC machining and plasma cutting, helping B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Lasersnijden Machines | CNC Machining | Plasma Cutting |

|---|---|---|---|

| Performance | High precision, intricate designs | Excellent for complex shapes | Fast for thick materials, less precise |

| Cost | Higher initial investment, low operating costs | Moderate initial cost, varied operating costs | Lower initial cost, high consumables cost |

| Ease of Implementation | Requires training and setup | Moderate complexity, skilled operators needed | Simple setup, less training required |

| Maintenance | Regular maintenance, parts availability | Moderate maintenance, skilled service required | Low maintenance, consumables need frequent replacement |

| Best Use Case | Detailed engravings, thin materials | Prototyping, high precision parts | Heavy-duty cutting of metals |

What Are the Benefits and Drawbacks of CNC Machining?

CNC (Computer Numerical Control) machining is a versatile manufacturing process that uses pre-programmed software to control the movement of machinery. One of its key advantages is its ability to produce complex shapes with high precision, making it ideal for intricate parts and prototypes. However, CNC machines can have a moderate initial cost and require skilled operators, which may not be feasible for all businesses. Additionally, while CNC machining can handle a variety of materials, it may not be as efficient for very thin materials as lasersnijden machines.

How Does Plasma Cutting Compare to Lasersnijden Machines?

Plasma cutting is a process that utilizes a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials. Its primary advantage lies in speed; plasma cutters can quickly cut through thick metals, making them suitable for heavy-duty applications. However, plasma cutting is less precise than lasersnijden machines and may produce rougher edges, requiring additional finishing work. Furthermore, while the initial investment in plasma cutting equipment is generally lower, the ongoing costs for consumables can add up quickly.

Conclusion: How to Choose the Right Cutting Solution for Your Business

When selecting a cutting solution, B2B buyers should assess their specific operational needs, material types, and production volumes. Lasersnijden machines are ideal for businesses focused on high-precision work with intricate designs and thinner materials. CNC machining offers flexibility and precision for complex shapes but may require more skilled labor. Plasma cutting, while fast and cost-effective for thicker materials, may not meet the precision needs of all applications. By carefully evaluating these alternatives, businesses can optimize their production processes and align their investments with their strategic goals.

Essential Technical Properties and Trade Terminology for lasersnijden machines

What Are the Essential Technical Properties of Lasersnijden Machines?

When investing in lasersnijden machines, understanding key technical properties is crucial for making informed decisions. Here are several critical specifications that every B2B buyer should consider:

1. Laser Type

Lasersnijden machines typically utilize either CO2 or fiber laser technology. CO2 lasers are ideal for cutting non-metal materials such as wood, acrylic, and plastics, offering a good balance of speed and precision. Fiber lasers, on the other hand, are more suited for metal cutting and marking, providing higher efficiency and precision, especially for reflective materials like brass and aluminum. Choosing the right laser type directly impacts operational efficiency and material versatility.

2. Cutting Speed

Measured in millimeters per second (mm/s), cutting speed is an essential performance metric that influences productivity. Faster cutting speeds can significantly reduce production time, which is particularly beneficial in high-volume manufacturing environments. However, the optimal speed often depends on the material type and thickness, making it essential to balance speed with quality to avoid issues like burn marks or incomplete cuts.

3. Work Area Size

The size of the working area dictates the maximum dimensions of the materials that can be processed. Lasersnijden machines come in various sizes, and selecting one that accommodates your typical material dimensions is critical. A larger work area provides flexibility for diverse projects but may require a larger footprint in your facility.

4. Power Rating

The power rating, usually measured in watts, influences the machine’s ability to cut through different material thicknesses. Higher wattage allows for cutting thicker materials more efficiently. For instance, a 100W fiber laser can cut through metal sheets up to several millimeters thick, while a 40W CO2 laser may only handle thin acrylic or wood. Understanding the power requirements relative to your application ensures that the machine can meet your specific cutting needs.

5. Precision and Tolerance

Precision is vital in industries such as aerospace and automotive, where tight tolerances are necessary. Tolerance refers to the allowable deviation from a standard measurement. Lasersnijden machines typically offer high precision, with tolerances of around ±0.1 mm. High precision not only ensures product quality but also minimizes material wastage, which is critical for cost management.

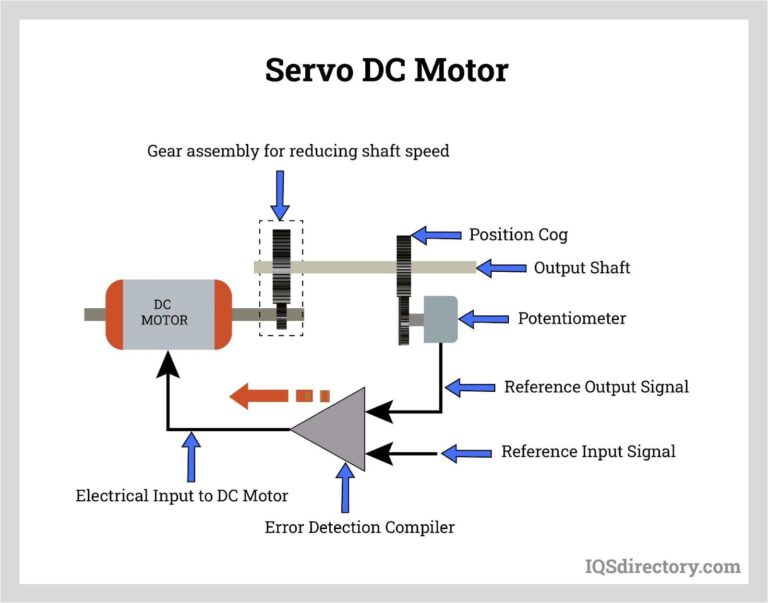

6. Cooling System

An efficient cooling system is necessary to maintain optimal operating temperatures, prolonging the life of the laser and ensuring consistent performance. Different machines may employ air-cooled or water-cooled systems, with water-cooled options typically offering better thermal management for high-powered lasers. Understanding the cooling requirements can help in planning the necessary infrastructure for machine installation.

What Are Common Trade Terms Related to Lasersnijden Machines?

Familiarity with industry terminology can facilitate smoother negotiations and procurement processes. Here are several key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that may be marketed by another company. In the context of lasersnijden machines, working with an OEM can ensure that you receive high-quality components tailored to your specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest order size a supplier is willing to accept. Understanding the MOQ is crucial for inventory planning and cost management, as it can affect your cash flow and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. When considering lasersnijden machines, issuing an RFQ can help you gather comparative pricing and specifications from multiple vendors, aiding in decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help clarify shipping, insurance, and delivery obligations, reducing the risk of disputes during the procurement process.

5. After-Sales Support

This term refers to the services provided by the manufacturer or supplier after the purchase is completed. Ensuring that after-sales support is available is critical for maintenance and troubleshooting, which can minimize downtime and enhance productivity.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when selecting lasersnijden machines, ensuring that they meet their operational needs efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the lasersnijden machines Sector

What Are the Current Market Dynamics and Key Trends in the Lasersnijden Machines Sector?

The global market for lasersnijden machines is experiencing robust growth driven by technological advancements and increasing demand across various industries, including manufacturing, automotive, and aerospace. Key trends influencing the sector include the integration of automation and artificial intelligence, which enhance precision and reduce operational costs. Additionally, the demand for customized solutions is on the rise, with manufacturers offering tailored machines that meet specific client requirements. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the impact of local market conditions, such as regulatory environments and economic stability, on sourcing decisions.

Emerging technologies, such as fiber laser systems, are gaining traction due to their efficiency and versatility in cutting various materials, including metals and plastics. Furthermore, there is a notable shift towards compact, user-friendly machines that accommodate smaller production spaces, making lasersnijden machines accessible to a broader range of businesses. As companies increasingly prioritize agility and responsiveness to market changes, sourcing partners that offer rapid prototyping and quick delivery will be crucial for success.

How Can Sustainability and Ethical Sourcing Impact the Lasersnijden Machines Industry?

Sustainability is becoming a pivotal concern for B2B buyers in the lasersnijden machines sector. The environmental impact of production processes is under scrutiny, prompting companies to seek out machines that minimize waste and energy consumption. Buyers should prioritize suppliers who adopt sustainable practices, such as utilizing eco-friendly materials and implementing efficient manufacturing processes. The certification of lasersnijden machines with recognized ‘green’ standards can also influence purchasing decisions, reflecting a commitment to environmental responsibility.

Moreover, ethical sourcing is gaining importance, as businesses increasingly recognize the value of transparent supply chains. Buyers should inquire about the sourcing practices of their suppliers, ensuring that materials are procured responsibly and that labor conditions meet ethical standards. Engaging with suppliers who prioritize sustainability not only enhances brand reputation but can also lead to long-term cost savings through efficiency improvements and reduced environmental liabilities.

What Is the Brief Evolution of Lasersnijden Machines and Its Significance for B2B Buyers?

The evolution of lasersnijden machines began in the late 1960s when the first industrial laser systems were developed for cutting and engraving applications. Over the decades, advancements in laser technology—such as the introduction of CO2 and fiber lasers—have significantly enhanced cutting speed, precision, and material versatility. The transition from bulky, complex machines to compact, user-friendly systems has made lasersnijden technology more accessible to small and medium enterprises (SMEs).

For B2B buyers, understanding this evolution is crucial. It highlights the importance of investing in modern, efficient equipment that not only meets current operational needs but also positions businesses to adapt to future technological advancements. By selecting suppliers with a strong track record of innovation and reliability, buyers can ensure their operations remain competitive in an ever-evolving market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of lasersnijden machines

-

How do I select the right lasersnijden machine for my business needs?

Choosing the right lasersnijden machine involves evaluating your specific applications, materials, and production volume. Start by identifying the materials you will be working with, such as metals, plastics, or wood, as different machines have varying capabilities. Assess the desired precision, cutting speed, and power requirements. Additionally, consider whether you need a standard machine or a customized solution tailored to your unique requirements. Consulting with suppliers for expert advice can also help you make an informed decision. -

What are the key features to look for in a lasersnijden machine?

Key features to consider include laser type (CO2 or fiber), power output, cutting speed, and precision. Look for machines with advanced cooling systems for prolonged use, and ensure they have safety certifications that comply with your region’s regulations. User-friendly interfaces and software compatibility are also crucial for seamless operation. Finally, consider the machine’s maintenance requirements and the availability of spare parts to minimize downtime. -

What is the typical lead time for ordering lasersnijden machines internationally?

Lead times can vary widely based on the supplier’s location, production capabilities, and shipping logistics. Generally, you should expect a lead time of 4 to 12 weeks from order placement to delivery. Custom machines may take longer due to design and manufacturing processes. It’s advisable to discuss timelines with your supplier upfront and factor in potential delays related to customs and import regulations in your country. -

How can I ensure the quality of lasersnijden machines from international suppliers?

To ensure quality, request certification documents and inspection reports from potential suppliers. Look for machines that comply with international safety and quality standards, such as CE marking in Europe. Conduct background checks on the supplier’s reputation and customer feedback. If possible, visit the manufacturing facility or request a product demonstration. Additionally, consider purchasing from suppliers who offer warranties and after-sales support to safeguard your investment. -

What are the payment terms typically offered by lasersnijden machine suppliers?

Payment terms can vary, but common practices include a deposit (often 30-50%) upon order confirmation, followed by the balance due before shipment. Some suppliers may offer financing options or extended payment terms based on your business relationship. Always clarify payment methods accepted (e.g., bank transfer, letter of credit) and ensure that terms are documented in the purchase agreement to avoid any misunderstandings. -

What is the minimum order quantity (MOQ) for lasersnijden machines?

MOQs can vary significantly based on the supplier and the type of machine. While some suppliers may allow single-unit orders, others may have MOQs that require you to order multiple machines to benefit from lower pricing. It’s essential to discuss your needs directly with the supplier, as they may be flexible, especially for first-time customers or long-term partnerships. -

How do I manage logistics and shipping for lasersnijden machines?

Managing logistics involves coordinating with your supplier and shipping company to determine the best shipping method based on cost and delivery speed. Consider factors such as customs clearance, insurance, and transportation regulations in your region. Working with a freight forwarder can help streamline the process and ensure that all necessary documentation is in order. Additionally, factor in potential delays due to customs inspections when planning your project timelines. -

What kind of support and training should I expect after purchasing a lasersnijden machine?

After purchasing, reputable suppliers typically offer comprehensive support, including installation, training, and ongoing maintenance. Training sessions should cover machine operation, safety protocols, and troubleshooting common issues. Ensure that your supplier provides access to technical support and spare parts, as well as resources like user manuals and online tutorials. Establishing a good relationship with your supplier can facilitate better support and training tailored to your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Lasersnijden Machines Manufacturers & Suppliers List

1. Bystronic – Advanced Laser Cutting Technology

Domain: bystronic.com

Registered: 1999 (26 years)

Introduction: Bystronic offers advanced laser cutting technology designed for high precision and efficiency. Their systems are suitable for various materials, including steel, stainless steel, aluminum, and non-ferrous metals. Key features include high cutting speeds, excellent edge quality, and the ability to handle complex geometries. Bystronic’s laser cutting solutions are equipped with automation options to…

2. MetaQuip – Laser Cutting and Engraving Machines

Domain: metaquip.nl

Registered: 2014 (11 years)

Introduction: MetaQuip offers a range of laser machines for cutting and engraving, including CO2 lasers for organic materials like wood, plastics, rubber, stone, paper, textiles, and more. They also provide fiber lasers for metal engraving and cutting, including aluminum and other metals. The product line includes CO2 laser machines (hobby, desktop, production, professional), fiber laser engravers (open, portab…

3. Creality 3D – Falcon A1 Laser Engraver

Domain: 123-3d.nl

Registered: 2014 (11 years)

Introduction: CNC machine | Snapmaker 3 in 1: laser, CNC, and 3D printing. Key product details: 1. Creality 3D Falcon A1 Laser Engraver – 10W laser, work area 381 x 305 mm, speed up to 600 mm/s, precision 0.01 mm, dimensions 567 x 468 x 196 mm, weight 15.55 kg, price €529.00 (incl. 21% VAT). 2. Creality 3D Falcon2 Pro 40W Laser Engraver – 40W laser, work area 400 x 400 mm, speed up to 417 mm/s, dimensions 664 x…

4. STYLECNC – Beste Lasersnijders 2025

Domain: nl.stylecnc.com

Registered: 2015 (10 years)

Introduction: Beste lasersnijders voor 2025 – STYLECNC. Lasersnijmachines zijn automatische snijgereedschappen die gebruikmaken van een DSP- of CNC-controller met CAM-software om CO2 of FIBER laserstralen te gebruiken voor het snijden van metalen, metalloïden en niet-metalen. Ze zijn geschikt voor het maken van precisie-onderdelen, borden, labels, decoraties, kunst, knutselspullen, cadeaus, sieraden, lampen en …

5. Trumpf – Laser Cutting Machine

Domain: trumpf.com

Registered: 1996 (29 years)

Introduction: The world’s largest laser cutting machine, built by Tecoi for M. den Oudsten Buigwerken, measures 4.5 meters wide and 66 meters long. It can cut giant sheets and plates up to 3 by 12 meters and 30 millimeters thick. The machine features a 66-meter cutting table at ground level for easy loading and unloading, operated by a single person using a ceiling crane. It has two cutting heads with 0.5 and 1…

6. Voortman – V353 Plaatlaser

Domain: voortman.net

Introduction: Voortman Steel Machinery biedt moderne CNC lasersnijmachines voor staal, waaronder de volgende modellen:

1. **V353 | Plaatlaser**

– Efficiënt en flexibel lasersnijden van XXL formaat platen

– Aangedreven door een 15kW laser

– Modulair snijbed tot 36m

– Lasklare eindproducten tot 40 mm

– Ononderbroken werking in de nacht

2. **V342 | Plaatlaser**

– Instapmodel lase…

7. Bystronic – Lasersnijmachine

Domain: machineseeker.nl

Registered: 2016 (9 years)

Introduction: Lasersnijden gebruikt te koop op Machineseeker NL. Fabrikanten: Bystronic (12), DURMA (6), TRUMPF (4), Mazak (2), Yawei (2), Adige (1), Amada (2), AMADA PROMECAM (2), Baykal (1), Bodor (3), Costa (1), Deckel Maho (1), Keller Lufttechnik (1), Kimla (1), Prima Power (1). Voorbeelden van machines: 1. Bystronic BY Sprint Fiber 3015, Bouwjaar: 2015, Toestand: gebruikt, X-AS slag: 3048 mm, Y-AS slag: 15…

Strategic Sourcing Conclusion and Outlook for lasersnijden machines

As the demand for precision and efficiency in manufacturing continues to rise, the strategic sourcing of lasersnijden machines presents a unique opportunity for international B2B buyers. Key takeaways emphasize the importance of selecting suppliers that not only provide high-quality, reliable machines but also offer comprehensive support, including training and maintenance services. This holistic approach ensures that businesses can maximize the value of their investment, minimize downtime, and enhance operational safety.

Moreover, understanding the specific needs of diverse markets—such as those in Africa, South America, the Middle East, and Europe—can guide buyers in making informed decisions that align with local industry requirements and standards. By engaging with suppliers who prioritize innovation and customization, companies can leverage advanced technologies tailored to their unique applications.

Looking ahead, the landscape for lasersnijden machines is poised for further growth, driven by advancements in technology and increasing global demand. We encourage B2B buyers to actively explore partnerships with reputable suppliers, ensuring they are equipped with the latest solutions to remain competitive in their respective markets. Embrace the potential of lasersnijden machines to transform your operations today.