Laser Welding Machine Price Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for laser welding machine price

Navigating the intricate landscape of laser welding machine pricing can be a daunting challenge for B2B buyers, particularly when aiming to make a well-informed investment. With prices varying significantly based on machine type, capability, and features, understanding the costs associated with laser welding technology is essential. This guide offers a comprehensive exploration of the different types of laser welding machines, their applications, and the factors that influence pricing—from power output to brand reputation.

In this resource, international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—will find actionable insights tailored to their unique needs. We delve into the nuances of sourcing laser welding equipment, providing a detailed breakdown of price ranges for handheld welders, CNC machines, and industrial robots, along with expert tips for optimizing your investment. Additionally, this guide addresses the total cost of ownership, helping buyers assess not just the initial outlay but also ongoing operational expenses, maintenance, and training costs.

By equipping B2B buyers with essential knowledge and strategic considerations, this guide empowers organizations to navigate the global market for laser welding machines effectively. Whether you are a small workshop or a large manufacturing facility, understanding these elements will enable you to make confident purchasing decisions that align with your business goals.

Understanding laser welding machine price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Handheld Laser Welders | Portable, versatile, and easy to operate | Small workshops, on-site repairs, jewelry manufacturing | Pros: Low cost, high portability. Cons: Limited power and automation. |

| CNC Laser Welding Machines | Automated, high precision with programmable controls | Large-scale manufacturing, automotive parts production | Pros: Consistent quality, high efficiency. Cons: Higher initial investment. |

| Industrial Laser Welding Robots | Fully automated systems with advanced integration capabilities | Automotive assembly, aerospace applications | Pros: Maximum efficiency, 3D welding capabilities. Cons: High cost, complex setup. |

| Combination Laser Cutter and Welder | Multi-functionality for cutting and welding | Job shops, prototyping, versatile manufacturing | Pros: Cost-effective for dual applications. Cons: May require more space. |

| Fiber Laser Welding Machines | High energy efficiency, excellent beam quality | Heavy industry, precision parts manufacturing | Pros: Lower operational costs, superior weld quality. Cons: Higher upfront cost. |

What Are the Key Characteristics of Handheld Laser Welders?

Handheld laser welders are designed for portability and ease of use, making them suitable for small workshops and on-site applications. They typically range from 1000W to 2000W, allowing for flexibility in welding various materials. Businesses often choose these machines for their lower initial investment and the ability to perform quick repairs or intricate designs, such as in jewelry making. However, buyers should consider the limitations in power and automation, which may affect production efficiency in larger operations.

How Do CNC Laser Welding Machines Benefit Medium to Large Enterprises?

CNC laser welding machines stand out for their automation and high precision, making them ideal for medium to large manufacturing enterprises. These machines are programmable, allowing for consistent weld quality and efficiency in mass production environments, such as automotive parts manufacturing. The investment in a CNC system is higher, but the return on investment can be significant due to increased production rates and reduced labor costs. Buyers should evaluate their needs for precision and automation against the upfront costs to ensure a suitable fit.

Why Are Industrial Laser Welding Robots Essential for High-Volume Production?

Industrial laser welding robots are at the forefront of automation technology, designed for large-scale production in sectors like automotive and aerospace. They offer the highest level of efficiency and can handle complex welding tasks with precision. While the initial investment can be substantial, the automation capabilities lead to significant labor savings and improved production speeds. Businesses must assess their production volume and complexity to justify the investment in such advanced systems.

What Advantages Do Combination Laser Cutter and Welder Systems Offer?

Combination laser cutter and welder systems provide versatility, allowing businesses to perform both cutting and welding operations within a single machine. This dual functionality is particularly beneficial for job shops and prototyping facilities, where space and cost efficiency are critical. While these systems can save on equipment costs, businesses should consider the space requirements and ensure they can effectively utilize both functions to maximize their investment.

How Do Fiber Laser Welding Machines Stand Out in Terms of Efficiency?

Fiber laser welding machines are recognized for their high energy efficiency and exceptional beam quality, making them suitable for heavy industries and precision parts manufacturing. They typically come with a higher upfront cost but offer lower operational expenses due to reduced energy consumption and longer laser life. Buyers should weigh the initial investment against the potential long-term savings and improved weld quality to determine if this technology aligns with their operational goals.

Key Industrial Applications of laser welding machine price

| Industry/Sector | Specific Application of Laser Welding Machine Price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Welding of automotive body parts and frames | Enhances structural integrity and reduces weight | Power capacity needed for specific materials, automation features for high-volume production |

| Aerospace | Joining of lightweight components in aircraft | Improves fuel efficiency and performance | Precision requirements, certification standards, compatibility with advanced materials |

| Electronics | Assembly of electronic components and circuit boards | Increases production speed and reduces rework | Fine beam quality for intricate designs, after-sales support for maintenance |

| Medical Device Manufacturing | Fabrication of surgical instruments and implants | Ensures high precision and biocompatibility | Compliance with medical regulations, specialized welding heads for different materials |

| Energy Sector (Renewables) | Welding of solar panel frames and wind turbine components | Reduces manufacturing costs and enhances durability | Material compatibility, energy efficiency of the machine, supplier reliability |

How is Laser Welding Used in Automotive Manufacturing?

In the automotive sector, laser welding machines are pivotal for fabricating body parts and frames, promoting structural integrity while minimizing weight. This technology allows for precise welding of complex geometries, which is crucial for modern vehicle designs focused on safety and efficiency. Buyers in this sector should consider the machine’s power capacity to handle various materials, along with automation features that facilitate high-volume production and ensure consistent weld quality.

What Role Does Laser Welding Play in Aerospace Applications?

Aerospace manufacturers utilize laser welding for joining lightweight components, such as those found in aircraft structures. The precision offered by laser technology is essential for meeting stringent safety and performance standards. Buyers must focus on the machine’s ability to handle advanced materials and comply with industry certification standards, ensuring that the welding process meets the rigorous demands of aerospace applications.

How is Laser Welding Beneficial in Electronics Manufacturing?

In the electronics industry, laser welding is employed to assemble delicate components and circuit boards. The high speed and accuracy of laser welding significantly reduce production times and minimize the risk of defects, which can lead to costly rework. For international buyers, it is crucial to assess the beam quality for intricate designs and ensure robust after-sales support for ongoing maintenance, particularly in regions with evolving technology needs.

Why is Laser Welding Important for Medical Device Manufacturing?

The medical device sector relies on laser welding to fabricate surgical instruments and implants with high precision and biocompatibility. This process not only ensures the integrity of the devices but also meets the stringent regulatory requirements of the industry. Buyers should prioritize machines that comply with medical standards and consider specialized welding heads tailored to different materials, ensuring the highest quality in their manufacturing processes.

How Does Laser Welding Impact the Energy Sector, Especially in Renewables?

In the energy sector, particularly within renewable energy, laser welding is crucial for manufacturing solar panel frames and components of wind turbines. This technology enhances durability and reduces overall manufacturing costs, making renewable energy solutions more viable. Buyers should evaluate the compatibility of the welding machine with various materials used in energy applications and consider energy efficiency features to optimize operational costs, especially in developing markets.

3 Common User Pain Points for ‘laser welding machine price’ & Their Solutions

Scenario 1: Budget Constraints for Small Manufacturers

The Problem: Small manufacturers often face significant financial constraints when considering the purchase of a laser welding machine. With prices ranging from $4,700 for entry-level handheld models to over $500,000 for industrial systems, the initial investment can be daunting. Many small businesses struggle to justify these costs, especially when cash flow is tight. The fear of making a poor investment decision looms large, as they may not have the resources to absorb any potential losses.

The Solution: To address budget constraints, small manufacturers should explore multiple financing options. Leasing can provide immediate access to advanced technology without the hefty upfront costs, typically allowing businesses to pay around 2% to 3% of the total machine cost monthly. Additionally, considering used or refurbished machines can yield savings of 30% to 50% off the original price. It’s essential to conduct thorough due diligence on the machine’s condition, including checking maintenance records and remaining laser life. Furthermore, businesses should investigate grants or tax incentives available in their region that can subsidize equipment costs, helping to alleviate financial pressure while investing in essential technology.

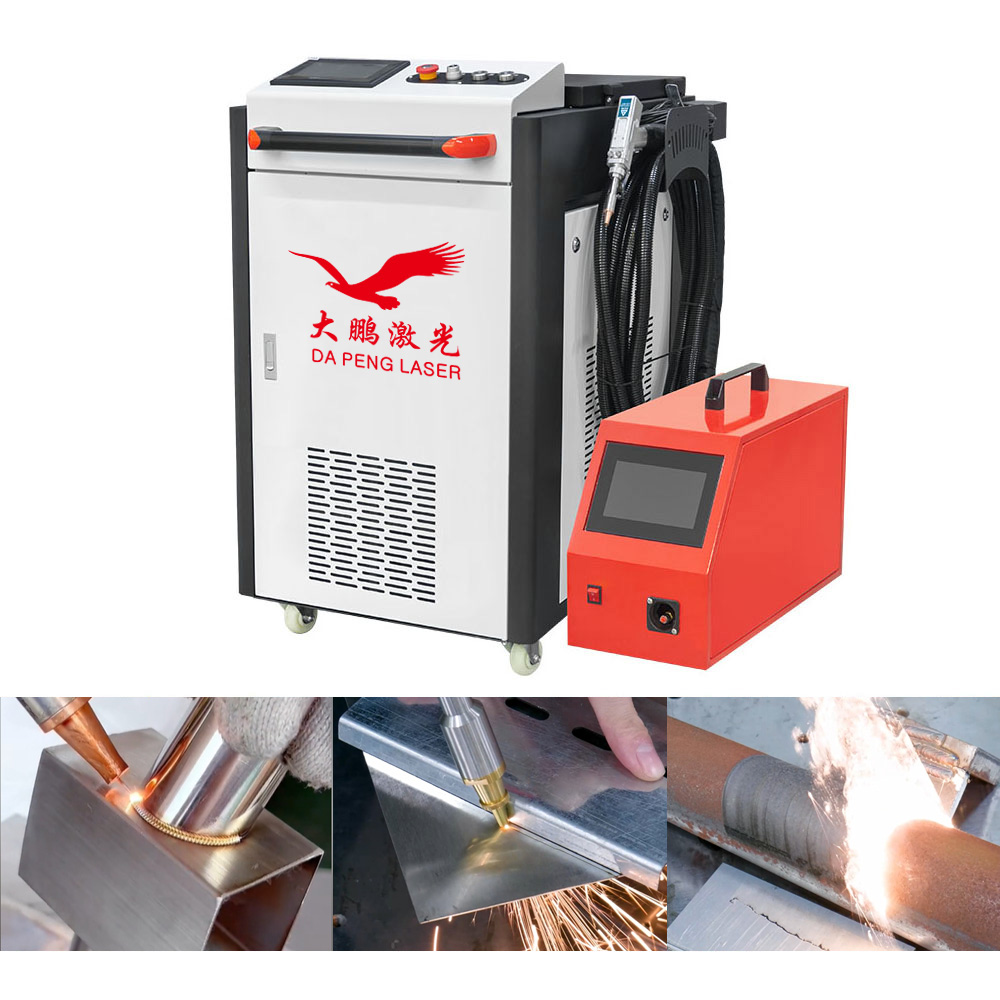

Illustrative image related to laser welding machine price

Scenario 2: Misalignment of Machine Specifications and Application Needs

The Problem: Many buyers are overwhelmed by the technical specifications of laser welding machines and may choose a model that doesn’t align with their specific application needs. For instance, a company may invest in a high-power CNC laser welding machine for thin materials, leading to inefficiencies and wasted resources. This misalignment can result in higher operational costs and decreased productivity, causing frustration and financial strain.

The Solution: To avoid mismatched specifications, businesses should conduct a thorough needs assessment before making a purchase. This involves evaluating the types of materials to be welded, the thickness of those materials, and the desired weld quality. Engaging with industry experts or suppliers to discuss specific applications can provide valuable insights. Additionally, investing in a machine with adjustable settings can offer flexibility for future projects, accommodating various materials without the need for constant upgrades. Creating a detailed comparison chart of different models based on their specifications and intended use can also guide the decision-making process.

Scenario 3: Hidden Costs and Total Cost of Ownership

The Problem: Buyers often focus solely on the purchase price of a laser welding machine, neglecting the total cost of ownership, which includes operational costs, maintenance, and consumables. This oversight can lead to unexpected expenses that strain budgets, particularly for companies that are already managing tight margins. For example, a machine that appears economical upfront may incur high energy costs or require expensive consumables, leading to a false sense of affordability.

The Solution: To mitigate the risk of hidden costs, it is crucial for buyers to conduct a comprehensive total cost of ownership analysis. This should include evaluating energy consumption, which can average $1.50 to $3.00 per hour for a 1000W machine, alongside anticipated maintenance costs that could range from 2% to 5% of the machine’s value annually. Buyers should also inquire about the cost of consumables, such as shielding gases and replacement parts, which can add significantly to overall expenses. By creating a detailed budget that encompasses these factors, businesses can make more informed purchasing decisions and select a machine that not only meets their immediate needs but also proves cost-effective in the long run.

Strategic Material Selection Guide for laser welding machine price

What Are the Key Materials for Laser Welding Machines?

When selecting a laser welding machine, the choice of materials is crucial for ensuring optimal performance and cost-effectiveness. Different materials exhibit unique properties that can significantly influence the machine’s efficiency, durability, and suitability for specific applications. Below, we analyze four common materials used in laser welding, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to laser welding machine price

How Do Carbon Steel Properties Affect Laser Welding?

Key Properties: Carbon steel is known for its high strength and versatility. It can withstand high temperatures and pressures, making it suitable for various applications. Additionally, it offers good machinability and weldability.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness, which makes it an ideal choice for many manufacturing processes. However, it is prone to corrosion, which can limit its lifespan unless adequately treated or coated. The manufacturing complexity is moderate, as it requires proper welding techniques to avoid warping or distortion during the process.

Impact on Application: Carbon steel is commonly used in construction, automotive, and machinery manufacturing. Its compatibility with various welding techniques allows for flexibility in production.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards (such as ASTM or DIN) for carbon steel products. Additionally, understanding the availability of treated carbon steel can influence procurement decisions.

What Advantages Does Stainless Steel Offer in Laser Welding?

Key Properties: Stainless steel is characterized by its excellent corrosion resistance, high strength, and ability to withstand high temperatures. Its alloy composition often includes chromium, which enhances its durability.

Illustrative image related to laser welding machine price

Pros & Cons: The key advantage of stainless steel is its longevity and resistance to rust and stains, making it suitable for industries like food processing and pharmaceuticals. However, it is generally more expensive than carbon steel and can be more challenging to weld due to its thermal properties, which may require specialized techniques.

Impact on Application: Stainless steel is ideal for applications requiring hygiene and durability, such as medical equipment and kitchen appliances. Its compatibility with laser welding enhances precision and reduces the risk of contamination.

Considerations for International Buyers: Buyers in Europe, particularly Germany, often prefer stainless steel due to stringent quality standards. Understanding the specific grades (e.g., 304, 316) and their applications can aid in making informed purchasing decisions.

How Does Aluminum Perform in Laser Welding Applications?

Key Properties: Aluminum is lightweight and has excellent corrosion resistance. Its thermal conductivity allows for quick heat dissipation, which is beneficial during the welding process.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which is essential for applications in aerospace and automotive industries. However, it is more expensive than carbon steel and can be challenging to weld due to its thermal properties, requiring precise control during the welding process to avoid defects.

Impact on Application: Aluminum is widely used in industries where weight savings are critical, such as aerospace and automotive. Its compatibility with laser welding allows for thin materials to be joined effectively.

Considerations for International Buyers: In regions like the Middle East, where aluminum is prevalent in construction, buyers should consider local sourcing options and compliance with international standards to ensure quality.

Illustrative image related to laser welding machine price

What Role Does Copper Play in Laser Welding?

Key Properties: Copper is known for its excellent thermal and electrical conductivity. It is highly ductile and can be easily shaped, making it suitable for various applications.

Pros & Cons: The key advantage of copper is its superior conductivity, which is essential for electrical applications. However, it is more expensive than other metals and can be difficult to weld due to its high thermal conductivity, which may require specialized equipment and techniques.

Impact on Application: Copper is widely used in electrical components and plumbing. Its compatibility with laser welding allows for precise joints, essential for high-performance applications.

Considerations for International Buyers: Buyers in South America should be aware of the availability of high-quality copper and the specific welding requirements to ensure successful applications.

Summary Table of Material Selection for Laser Welding Machines

| Material | Typical Use Case for laser welding machine price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, automotive parts | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Medical equipment, food processing | Excellent corrosion resistance | Higher cost and welding complexity | High |

| Aluminum | Aerospace, automotive components | Lightweight and corrosion-resistant | Expensive and difficult to weld | Medium |

| Copper | Electrical components, plumbing | Superior conductivity | High cost and welding challenges | High |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them navigate the complexities of laser welding machine pricing and material suitability. Understanding these factors will enable companies to make informed decisions that align with their operational needs and market demands.

Illustrative image related to laser welding machine price

In-depth Look: Manufacturing Processes and Quality Assurance for laser welding machine price

What Are the Main Stages in Manufacturing Laser Welding Machines?

The manufacturing of laser welding machines involves a series of critical stages that ensure the final product meets industry standards for performance, reliability, and safety. Understanding these stages can help B2B buyers assess the quality of the equipment they are considering.

Material Preparation: What Materials Are Used in Laser Welding Machines?

The first step in the manufacturing process is the selection and preparation of materials. High-quality metals, such as carbon steel, stainless steel, and aluminum alloys, are commonly used for various components. These materials undergo rigorous testing to ensure they can withstand the high temperatures and pressures involved in laser welding.

After selection, materials are cut and shaped into specific dimensions using CNC machining and laser cutting techniques. This precision ensures that all parts fit together seamlessly during assembly, which is crucial for maintaining the integrity of the machine.

Forming: How Are Components Shaped and Assembled?

Once materials are prepared, they move into the forming stage. This stage often employs advanced techniques such as stamping, bending, and welding to create machine components. For instance, the laser source housing must be precisely formed to protect the sensitive laser equipment inside.

Automated assembly lines are increasingly common in manufacturing laser welding machines. Robots are used to assemble parts quickly and accurately, minimizing human error and enhancing productivity. This automation is particularly beneficial for large-scale production, ensuring consistency across multiple units.

Illustrative image related to laser welding machine price

Assembly: What Are the Key Processes in Assembly?

The assembly process is where individual components come together to create a fully functional laser welding machine. This stage typically involves several key processes:

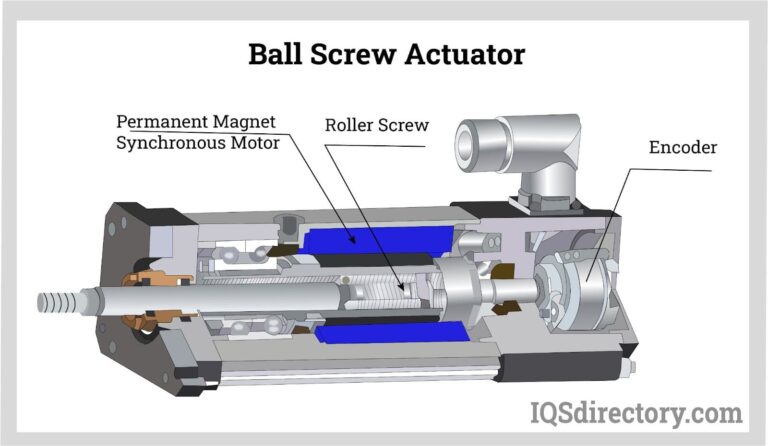

-

Integration of Laser Sources: The laser source, which can be fiber or CO2, is installed and calibrated for optimal performance. This is a critical step as the type and power of the laser directly impact welding capabilities.

-

Electrical and Control Systems Setup: Wiring and control systems are integrated, allowing for precise operation of the machine. This includes the installation of user interfaces and safety mechanisms.

-

Cooling Systems Installation: Effective cooling systems, such as industrial chillers or air-cooled setups, are crucial to maintain optimal operating temperatures. This is essential for preventing overheating during prolonged use.

Finishing: How Is Quality Enhanced in the Final Stages?

The finishing stage involves several processes to enhance the durability and aesthetics of the machine. This includes surface treatment methods such as anodizing or powder coating, which provide protection against corrosion and wear.

Final inspections are conducted at this stage to ensure that the machine meets all specifications and quality standards before it is shipped to customers. This may include functional tests to verify that all systems operate correctly and safely.

What Quality Assurance Practices Are Essential in Laser Welding Machine Manufacturing?

Quality assurance (QA) is vital in the manufacturing process of laser welding machines. It ensures that every unit produced meets both company standards and international regulations, which is particularly important for B2B buyers operating across various global markets.

Illustrative image related to laser welding machine price

Which International Standards Should Buyers Be Aware Of?

International standards play a significant role in ensuring the quality and safety of laser welding machines. Some of the most relevant include:

-

ISO 9001: This quality management standard outlines the criteria for a quality management system. Manufacturers adhering to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

-

CE Marking: For machines sold in Europe, CE marking signifies compliance with European health, safety, and environmental protection standards. This is crucial for B2B buyers in Europe, as it guarantees that the equipment meets essential safety requirements.

-

API Standards: For buyers in industries such as oil and gas, compliance with American Petroleum Institute (API) standards may be necessary, particularly for machines used in the fabrication of components for these sectors.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established to catch potential issues early. These checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): During manufacturing, processes are monitored to ensure that parts are produced to the correct specifications. This may include measurements of component dimensions and performance tests.

-

Final Quality Control (FQC): Before shipment, finished machines undergo thorough testing to verify their performance, safety, and compliance with all regulatory standards. This may include operational tests, safety checks, and aesthetic evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is crucial in making informed purchasing decisions. Here are some strategies to ensure that suppliers adhere to high standards:

What Types of Audits Can Buyers Conduct?

Buyers can request audits of potential suppliers to assess their manufacturing and quality control processes. This may include:

-

Factory Audits: Visiting the manufacturing facility allows buyers to observe processes firsthand, review quality management systems, and assess the overall working environment.

-

Quality Management System Audits: Reviewing documentation related to ISO certifications and internal quality control processes can provide insights into the supplier’s commitment to quality.

How Can Reports and Third-Party Inspections Help?

Requesting detailed reports from suppliers on their quality control processes can also be beneficial. These reports should outline testing methods, inspection results, and compliance with international standards.

Additionally, hiring third-party inspection services can provide an unbiased assessment of the supplier’s capabilities. These inspections can be conducted at various stages of the manufacturing process, offering an extra layer of assurance regarding product quality.

What Are the Specific QC Considerations for Buyers in Different Regions?

Understanding regional nuances in quality control is essential for B2B buyers, especially those from Africa, South America, the Middle East, and Europe.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and regulations that affect the quality assurance processes of laser welding machines. For example:

Illustrative image related to laser welding machine price

-

Africa: Buyers should consider local regulations and standards, which may differ significantly from international norms. Establishing relationships with local distributors familiar with regional requirements can help navigate these complexities.

-

South America: Compliance with local certifications and standards is critical for market entry. Buyers should verify that suppliers have obtained necessary certifications that meet both local and international requirements.

-

Middle East: The demand for high-quality machinery is rising, particularly in industries such as construction and oil and gas. Buyers should ensure that suppliers can meet the specific standards required in these sectors.

-

Europe: European buyers must prioritize suppliers who can provide CE marking and comply with EU regulations. This ensures that machines are safe and reliable for use in various applications.

Conclusion: Why Understanding Manufacturing Processes and QC Is Key to Laser Welding Machine Purchases

For B2B buyers, understanding the manufacturing processes and quality assurance practices of laser welding machines is crucial. By focusing on the stages of production and the standards that govern them, buyers can make more informed decisions. This not only helps ensure a high-quality investment but also enhances operational efficiency and safety in their own manufacturing processes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘laser welding machine price’

The procurement of laser welding machines can be a complex process, especially for international B2B buyers. This guide serves as a practical checklist to help you navigate the key considerations and steps necessary to make an informed purchasing decision regarding laser welding machines.

Step 1: Define Your Technical Specifications

Understanding your specific needs is crucial before you start sourcing. Consider the materials you will be welding, the required power output, and the types of projects you will undertake. This will help you determine the appropriate machine type—be it handheld, CNC, or robotic welding systems—ensuring that the equipment aligns with your operational demands.

Step 2: Research Price Ranges for Different Models

Laser welding machines come in various types, each with distinct price ranges. Handheld models may start around $5,000, while industrial systems can exceed $500,000. Familiarize yourself with these ranges based on power and functionality to set a realistic budget and avoid overpaying.

Illustrative image related to laser welding machine price

- Handheld Laser Welders: Typically priced between $4,700 and $26,300.

- CNC Laser Welding Machines: Ranging from $30,000 to over $150,000.

- Industrial Robots: Starting at $100,000 and can go up to $500,000.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their experience and reputation in the market, as well as their after-sales support and warranty offerings.

- Check Certifications: Ensure that the suppliers comply with international quality standards.

- Seek Reviews: Look for testimonials or reviews from previous clients to gauge reliability.

Step 4: Consider Total Cost of Ownership

Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, energy consumption, and consumables. A machine that appears cheaper upfront may lead to higher long-term costs due to poor energy efficiency or expensive upkeep.

- Operational Costs: Estimate annual energy and maintenance expenses to compare different models effectively.

- Training Costs: Factor in any costs for operator training to ensure your team can use the equipment efficiently.

Step 5: Negotiate Terms and Financing Options

Once you have selected a potential supplier, discuss payment terms and financing options. Many suppliers offer leasing arrangements that can ease cash flow concerns. Ensure you understand any terms related to warranties and service agreements.

Illustrative image related to laser welding machine price

- Leasing vs. Buying: Weigh the benefits of leasing equipment against outright purchase, considering your financial situation.

- Incentives: Inquire about any grants or rebates available for energy-efficient equipment.

Step 6: Request Demonstrations and Trials

Before finalizing your purchase, request a demonstration or trial of the laser welding machine. This allows you to evaluate the machine’s performance firsthand and assess its suitability for your specific applications.

- Test Compatibility: Ensure the machine can handle the materials and thicknesses you plan to work with.

- Evaluate User-Friendliness: Consider how easy it is for your operators to use the machine effectively.

Step 7: Plan for Installation and Training

Finally, ensure that you have a plan for installation and training once the equipment arrives. Proper installation can prevent future operational issues, while adequate training will maximize productivity.

- Installation Support: Confirm whether the supplier provides installation services or if you need to engage a third party.

- Ongoing Training: Consider scheduling periodic training sessions for your staff to keep their skills updated.

By following this checklist, you can make well-informed decisions that will enhance your operational efficiency and return on investment when procuring a laser welding machine.

Comprehensive Cost and Pricing Analysis for laser welding machine price Sourcing

Analyzing the cost structure and pricing for laser welding machines is crucial for international B2B buyers, especially those from diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the various cost components and price influencers can help buyers make informed purchasing decisions that align with their operational needs and budget constraints.

What Are the Key Cost Components in Laser Welding Machines?

-

Materials: The primary cost driver includes the raw materials used in the manufacturing of laser welding machines. This encompasses high-quality metals for structural components and specialized materials for the laser source. The choice of materials can significantly impact the machine’s durability and performance.

-

Labor: Skilled labor is necessary for both the manufacturing and assembly of laser welding machines. Labor costs may vary by region, with higher wages in developed markets like Germany compared to emerging markets. Understanding local labor rates can influence total costs.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses associated with production. Buyers should consider these overhead costs as they can vary widely based on the manufacturer’s location and operational efficiency.

-

Tooling: The cost of specialized tooling required for the production of laser welding machines can add to the overall expense. Custom tooling for unique designs or specifications may lead to higher costs but can improve the quality and precision of the final product.

-

Quality Control (QC): Implementing stringent QC processes ensures that the machines meet industry standards. This involves testing and validation, which can incur additional costs. Buyers should inquire about the QC measures in place as they are crucial for long-term operational reliability.

-

Logistics: Shipping costs, including freight and insurance, can vary based on the machine’s size and weight, as well as the distance from the supplier. For international buyers, understanding Incoterms (International Commercial Terms) is essential for calculating total landed costs.

-

Margin: Manufacturers typically build a profit margin into the pricing structure, which can vary based on market conditions and competition. Premium brands may command higher margins due to their reputation and after-sales support.

What Influences Laser Welding Machine Pricing?

-

Volume and Minimum Order Quantity (MOQ): Pricing can be significantly affected by order size. Larger orders often qualify for bulk discounts, making it advantageous for buyers with high-volume needs.

-

Specifications and Customization: Custom features such as increased laser power, automation capabilities, and specialized tooling can influence the price. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Machines built with superior materials or those that meet specific industry certifications may come at a premium. Buyers must weigh the benefits of higher initial costs against potential long-term savings in reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may offer better after-sales support, which can justify higher upfront costs.

-

Incoterms: Understanding the implications of different Incoterms is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total cost of ownership.

What Are the Best Practices for Buyers to Ensure Cost-Efficiency?

-

Negotiate Terms: Buyers should not hesitate to negotiate pricing and terms with suppliers. Discussing payment terms, warranties, and support can lead to better deals.

-

Calculate Total Cost of Ownership: Beyond the initial purchase price, consider ongoing operational costs such as energy consumption, maintenance, and training. This holistic view will provide a clearer picture of long-term investments.

-

Consider Used or Refurbished Options: For budget-conscious buyers, exploring used or refurbished machines can yield significant savings. Ensure thorough inspections and check maintenance histories before purchasing.

-

Leverage Grants and Incentives: Some regions may offer financial incentives or grants for purchasing advanced manufacturing equipment. Researching these opportunities can help offset initial costs.

Disclaimer on Indicative Prices

Prices for laser welding machines can vary widely based on the factors mentioned above. The figures presented in this analysis serve as a general guideline and should be verified with suppliers for accurate quotes tailored to specific needs and configurations.

Alternatives Analysis: Comparing laser welding machine price With Other Solutions

Introduction: Exploring Alternatives to Laser Welding Machines

As businesses seek efficient and cost-effective solutions for their welding needs, it’s essential to consider various alternatives to laser welding machines. While laser welding offers precision and speed, other technologies may provide unique advantages depending on specific operational requirements and budget constraints. This section delves into a comparative analysis of laser welding machine pricing against two viable alternatives: MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding.

Comparison Table

| Comparison Aspect | Laser Welding Machine Price | MIG Welding | TIG Welding |

|---|---|---|---|

| Performance | High precision; minimal heat-affected zone | Good for thicker materials; less precision | Excellent for thin materials; high precision |

| Cost | $30,000 – $500,000+ | $2,000 – $50,000 | $1,500 – $30,000 |

| Ease of Implementation | Moderate; requires training and setup | Easy; often user-friendly | Moderate; skilled operators needed |

| Maintenance | High; specialized parts and training required | Low; simple components | Moderate; regular upkeep necessary |

| Best Use Case | High-precision applications; automation | General fabrication; thicker metals | Thin materials; art and intricate work |

Detailed Breakdown of Alternatives

MIG Welding: Cost-Effective for General Applications

MIG welding is a popular choice for many manufacturing sectors due to its affordability and ease of use. With initial setup costs ranging from $2,000 to $50,000, MIG welding machines provide a significant cost advantage over laser welding systems. This method excels in welding thicker materials and is often favored in automotive and construction industries. However, it lacks the precision of laser welding, which can lead to a higher heat-affected zone, potentially compromising material integrity. Maintenance for MIG systems is generally low, making them an attractive option for businesses looking to minimize operational costs.

TIG Welding: Precision for Specialized Tasks

TIG welding stands out for its exceptional precision and control, making it ideal for applications involving thin metals, such as stainless steel and aluminum. The cost of TIG welding equipment typically ranges from $1,500 to $30,000, providing a more accessible entry point for small businesses or specialized shops. While TIG welding requires skilled operators and can be more time-consuming than MIG or laser welding, the quality of the welds is often superior, with minimal defects. Maintenance is moderate, but operators must be trained adequately to achieve the desired results, which can add to operational costs.

Conclusion: Choosing the Right Welding Solution for Your Business Needs

When considering a welding solution, B2B buyers must evaluate their specific operational needs, budget constraints, and desired outcomes. Laser welding machines are ideal for high-precision tasks and automation, albeit at a higher investment. In contrast, MIG welding offers a cost-effective solution for general fabrication needs, while TIG welding provides unmatched precision for specialized applications. By analyzing these alternatives, businesses can make informed decisions that align with their production goals, ultimately enhancing their manufacturing efficiency and product quality.

Essential Technical Properties and Trade Terminology for laser welding machine price

What Are the Key Technical Properties of Laser Welding Machines?

Understanding the essential technical specifications of laser welding machines is crucial for B2B buyers, as these properties significantly influence both performance and cost. Here are some of the most critical specifications:

-

Laser Power (Wattage)

The power of a laser welding machine, measured in watts (W), directly impacts its capability to weld different materials and thicknesses. Common power ranges include 1000W to 6000W. Higher wattage allows for faster welding speeds and the ability to work with thicker materials. For businesses in sectors like automotive and aerospace, where precision and speed are vital, selecting the appropriate laser power is essential for operational efficiency and cost-effectiveness. -

Beam Quality

Beam quality is a measure of the laser beam’s focus and intensity, usually represented by parameters such as the M² value and Beam Parameter Product (BPP). A lower M² value indicates better beam quality, which allows for finer welds and reduced heat-affected zones. For manufacturers aiming for high precision in applications like jewelry or medical device production, investing in machines with superior beam quality can lead to less rework and higher customer satisfaction. -

Welding Speed

Measured in millimeters per second (mm/s), welding speed is a critical factor that affects productivity. Faster welding speeds can lead to increased throughput, making it essential for businesses that require high-volume production. Buyers should assess their operational needs and select a machine that balances speed with the quality of the weld. -

Material Compatibility

Different laser welding machines are designed to work with various materials, including carbon steel, stainless steel, aluminum alloys, and copper. Understanding the material compatibility is vital for B2B buyers who need to ensure that the machine they choose can handle the specific materials relevant to their operations. This flexibility can reduce the need for multiple machines, thereby lowering overall capital expenditure. -

Cooling System

The efficiency of the cooling system, whether air-cooled or water-cooled, can impact the machine’s performance and longevity. A robust cooling system prevents overheating, which can lead to machine failures and downtime. Buyers should evaluate the cooling requirements of their operational environment to ensure optimal performance and reliability. -

Automation Features

Advanced automation features, such as automatic tool changing and integrated vision systems, enhance the machine’s functionality and ease of use. While these features may increase initial costs, they can lead to significant savings in labor and operational efficiency. For larger enterprises, investing in automation can yield substantial long-term ROI.

What Are Common Trade Terms Related to Laser Welding Machine Pricing?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B space. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess the quality and reliability of the machines they are considering, as well as the availability of spare parts. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses plan their budgets and inventory management strategies. Some manufacturers may have higher MOQs for specialized machines, affecting cash flow and procurement strategies. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing information on specific products or services. It is a critical step in the purchasing process, allowing buyers to compare prices and terms from multiple vendors. A well-prepared RFQ can streamline the procurement process and ensure better pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transit. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with acquiring and operating a laser welding machine over its lifespan, including purchase price, maintenance, operational costs, and potential resale value. Evaluating TCO helps businesses make informed decisions that go beyond initial purchase price, ensuring a comprehensive understanding of long-term investment. -

Lead Time

Lead time refers to the time it takes from placing an order until the machine is delivered and operational. This metric is particularly important for businesses that require quick turnaround times for production. Understanding lead times allows buyers to plan their operations more effectively and manage customer expectations.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of laser welding machine pricing and make informed purchasing decisions that align with their operational needs and financial goals.

Navigating Market Dynamics and Sourcing Trends in the laser welding machine price Sector

What Are the Current Market Dynamics Affecting Laser Welding Machine Prices?

The laser welding machine market is experiencing robust growth, driven by increasing demand for high-precision manufacturing across diverse sectors such as automotive, aerospace, and electronics. International B2B buyers from regions like Africa, South America, the Middle East, and Europe (notably Germany and Brazil) are particularly influenced by advancements in technology that enhance production efficiency and reduce operational costs. The trend towards automation and Industry 4.0 practices has further accelerated the adoption of laser welding machines, as businesses seek to improve throughput and quality.

Illustrative image related to laser welding machine price

One of the notable trends is the rise of handheld and portable laser welders, which are becoming increasingly popular for small workshops and on-site repairs. These machines offer affordability and ease of use, with prices ranging from $4,700 to $26,300, making them accessible for a broader range of businesses. In contrast, industrial-grade machines, particularly CNC laser welders and robotic systems, command higher prices—ranging from $30,000 to over $500,000—due to their advanced capabilities and automation features.

Another significant factor influencing pricing is the growing competition among manufacturers, particularly from emerging markets, which is expected to drive prices down. However, established brands may still maintain a premium due to their reputation and the quality of after-sales support. Buyers must also consider the total cost of ownership, which includes ongoing operational expenses, maintenance, and potential training costs, to make informed purchasing decisions.

How Can Sustainability and Ethical Sourcing Influence Laser Welding Machine Pricing?

Sustainability is becoming a critical consideration for B2B buyers in the laser welding machine sector. The environmental impact of manufacturing processes and the sourcing of materials have gained heightened awareness, leading companies to prioritize sustainable practices. This shift is reflected in the increasing demand for laser welding machines that utilize energy-efficient technologies and materials sourced from ethical suppliers.

Illustrative image related to laser welding machine price

Buyers should look for suppliers that offer ‘green’ certifications or utilize eco-friendly materials in their manufacturing processes. These certifications not only reflect a commitment to reducing environmental impact but can also enhance a company’s brand reputation in a market that increasingly values corporate responsibility. Furthermore, machines that are designed to minimize waste and energy consumption can lead to significant cost savings over time, making them a more attractive investment.

In terms of pricing, while sustainable machines may initially have a higher upfront cost, the long-term savings and benefits associated with reduced operational costs and improved efficiency often justify the investment. Buyers are encouraged to engage with suppliers about their sustainability practices and inquire about potential certifications, which can help ensure that their purchases align with their corporate social responsibility goals.

What Has Been the Evolution of Laser Welding Machines?

The evolution of laser welding technology has significantly transformed manufacturing processes since its inception. Initially developed in the 1960s, laser welding began as a niche technology, primarily used in aerospace and defense industries. Over the decades, advancements in laser sources and beam quality have enabled wider applications, including automotive manufacturing and electronics.

As technology progressed, the introduction of fiber lasers in the 2000s revolutionized the market, offering increased efficiency and lower operational costs compared to traditional laser systems. This innovation allowed for greater penetration depth and improved weld quality, making laser welding more accessible to various industries. Today, the market continues to evolve, with emerging trends such as AI-assisted welding and the integration of smart technologies that promise to further enhance productivity and precision.

Understanding this evolution is essential for B2B buyers as they navigate the landscape of laser welding machine prices. By recognizing the historical context and technological advancements, buyers can make more informed decisions and anticipate future trends that may impact pricing and availability.

Frequently Asked Questions (FAQs) for B2B Buyers of laser welding machine price

-

How do I determine the right type of laser welding machine for my business?

To choose the best laser welding machine, assess your specific needs based on the materials you work with, the scale of your operations, and the types of projects you undertake. Handheld welders are ideal for small workshops and on-site repairs, while CNC machines are suited for medium to large manufacturers needing precision and automation. Consider factors such as power requirements, welding speed, and the complexity of the welds to ensure the machine aligns with your production capabilities. -

What factors influence the price of laser welding machines?

The price of laser welding machines is influenced by several factors, including the type of machine (handheld, CNC, or robotic), power output, precision, automation features, and brand reputation. Higher power levels generally lead to increased costs, as do advanced features like automated tool changing and vision systems. Additionally, market conditions, technological advancements, and the inclusion of after-sales support can also affect pricing, making it essential to evaluate all aspects before purchasing. -

What are the typical payment terms for purchasing laser welding machines in international trade?

Payment terms for laser welding machines can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation, followed by the remaining balance before shipment. Some suppliers may offer payment in full prior to production or flexible financing options. It’s crucial to clarify payment methods accepted (e.g., wire transfer, letters of credit) and to negotiate terms that protect your interests while ensuring a smooth transaction process. -

How can I ensure quality assurance when sourcing laser welding machines?

To ensure quality assurance, thoroughly vet potential suppliers by reviewing their certifications, customer testimonials, and case studies. Request samples or demonstrations of their machines to assess performance firsthand. Additionally, inquire about warranty terms, after-sales support, and maintenance services, as these factors contribute significantly to the overall quality and reliability of the equipment you will be investing in. -

What are the minimum order quantities (MOQs) for laser welding machines?

Minimum order quantities (MOQs) for laser welding machines can vary by manufacturer. Many suppliers may set an MOQ for bulk orders, especially for customized machines. For standard models, you may be able to purchase single units. Always confirm MOQs during your initial discussions with suppliers and assess whether they align with your budget and operational needs to avoid excess inventory or unnecessary costs. -

How do I assess the total cost of ownership for a laser welding machine?

To evaluate the total cost of ownership, consider not only the initial purchase price but also ongoing operational expenses such as energy consumption, maintenance, and consumables. Factor in training costs for operators and technicians, as well as potential depreciation and resale value over time. This comprehensive analysis will help you understand the long-term financial implications of your investment, enabling better budgeting and financial planning. -

What logistical considerations should I keep in mind when importing laser welding machines?

When importing laser welding machines, consider shipping costs, customs duties, and import regulations specific to your country. Ensure that the supplier provides accurate documentation and complies with international shipping standards. It’s also advisable to work with logistics providers experienced in handling industrial equipment to mitigate risks associated with damage during transit and to ensure timely delivery. -

What are the benefits of customizing a laser welding machine for my specific applications?

Customizing a laser welding machine can significantly enhance its efficiency and suitability for your specific applications. Tailored features, such as specialized welding heads, automation options, and software for weld pattern design, can improve precision and reduce waste. While customization may increase initial costs, the long-term benefits often include greater operational efficiency, reduced downtime, and improved product quality, making it a worthwhile investment for many businesses.

Top 5 Laser Welding Machine Price Manufacturers & Suppliers List

1. LightObject – GWH 3-in-1 Handheld Fiber Laser Welding Machine

Domain: lightobject.com

Registered: 2004 (21 years)

Introduction: GWH 3-in-1 Handheld Water-cooled Fiber Laser Welding Machine

– SKU: LSR-GW1500H

– Price: $7,950.00

– Functions: Welder, Cutter, Cleaner

– Max Laser Power: 1500W

– Max Welding Thickness: 5mm (dual sides welding)

– Operating Voltage: Single phase AC 208V+/-10%, 60Hz (input ~35Amps)

– Air Assist Required: N2 (nitrogen) or Argon

– Supported Metals: Carbon steel, stainless steel, aluminum, Zinc (galvan…

2. Laser Welding Machines – Handheld, Fiber, and Multi-Functional

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Laser Welding Machines available on eBay include various types such as handheld laser welders, fiber laser welding machines, and multi-functional machines for welding, cleaning, and cutting. Key brands include Unbranded, Hypertherm, CINCINNATI, JINSLU, and TRUMPF. Price ranges from under $460 to over $700, with many items listed as new (10,624) and some used (40). Popular models include a 1200W ai…

3. Kirin Laser – Handheld Laser Welding Machines

Domain: kirinlaser.com

Registered: 2021 (4 years)

Introduction: Handheld laser welding machines cost between $2,500 and $15,000, with Kirin Laser models priced from under $2,000 to $6,200. Key specifications include: 1200W ($1,860 – $2,745) for thin stainless, 1500W ($2,285 – $2,935) for light to medium metal fabrication, 2000W ($2,715 – $4,720) for high-speed production, and 3000W ($4,145 – $6,200) for industrial-grade applications. Power requirements range f…

4. Xlaserlab – Key Products

Domain: xlaserlab.com

Registered: 2024 (1 years)

Introduction: Xlaserlab® offers the following key products:

1. Xlaserlab X1 Pro Laser Welder, Cleaner & Cutter – Price: $3,731.00 (originally $3,999.00)

2. X1 Laser Welding Machine – Price: $3,499.00

3. Accessories:

– Welding Apron – Price: $29.95

– X1 Pro Laser Nozzles Accessories Box – Price: $89.00 (originally $178.00)

– Laser Safety Goggles – Price: $49.00 (originally $98.00)

– X1 Pro Pro…

5. Reddit – Inexpensive Laser Welder

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Inexpensive laser welder that plugs into a 110v outlet and costs $43. Advertised to clean rust and weld various metals. Concerns raised about its effectiveness, safety, and potential misrepresentation as a soldering gun rather than a true laser welder.

Strategic Sourcing Conclusion and Outlook for laser welding machine price

How Can Strategic Sourcing Optimize Your Laser Welding Machine Investment?

In conclusion, understanding the pricing landscape of laser welding machines is pivotal for international B2B buyers aiming to enhance their manufacturing capabilities. Key takeaways include recognizing the diverse price ranges based on machine type and power, which can significantly impact operational efficiency and overall cost-effectiveness. By strategically sourcing equipment that aligns with specific production needs, businesses can not only reduce initial investments but also optimize total cost of ownership through careful consideration of ongoing operational expenses.

Moreover, factors such as automation features, brand reputation, and after-sales support should influence purchasing decisions. For buyers from Africa, South America, the Middle East, and Europe, leveraging local suppliers and exploring financing options can further enhance value while minimizing risks associated with international procurement.

Looking ahead, staying informed about technological advancements and market trends will be essential in navigating future pricing fluctuations. As the laser welding landscape continues to evolve, proactive engagement with suppliers and continuous evaluation of equipment performance will ensure your investment remains competitive. Embrace the opportunities that strategic sourcing presents to drive efficiency and growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to laser welding machine price

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.